Dry-method coating machine

A coating machine and dry method technology, which is applied in the field of equipment for coating solid preparations with dry powder, can solve the problems of environmental pollution, high manufacturing cost, and low production efficiency, and achieve environmental friendliness, low manufacturing cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

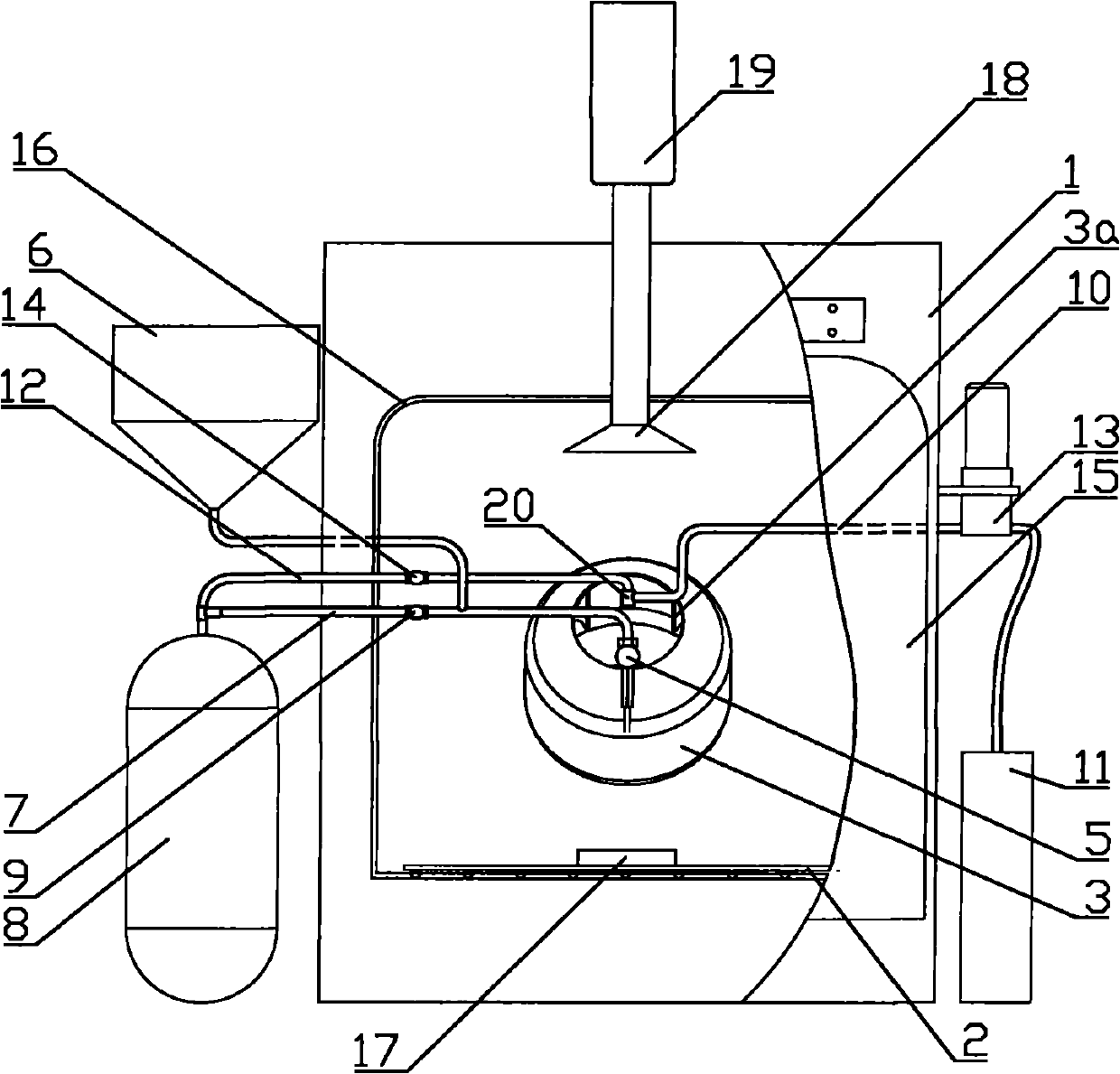

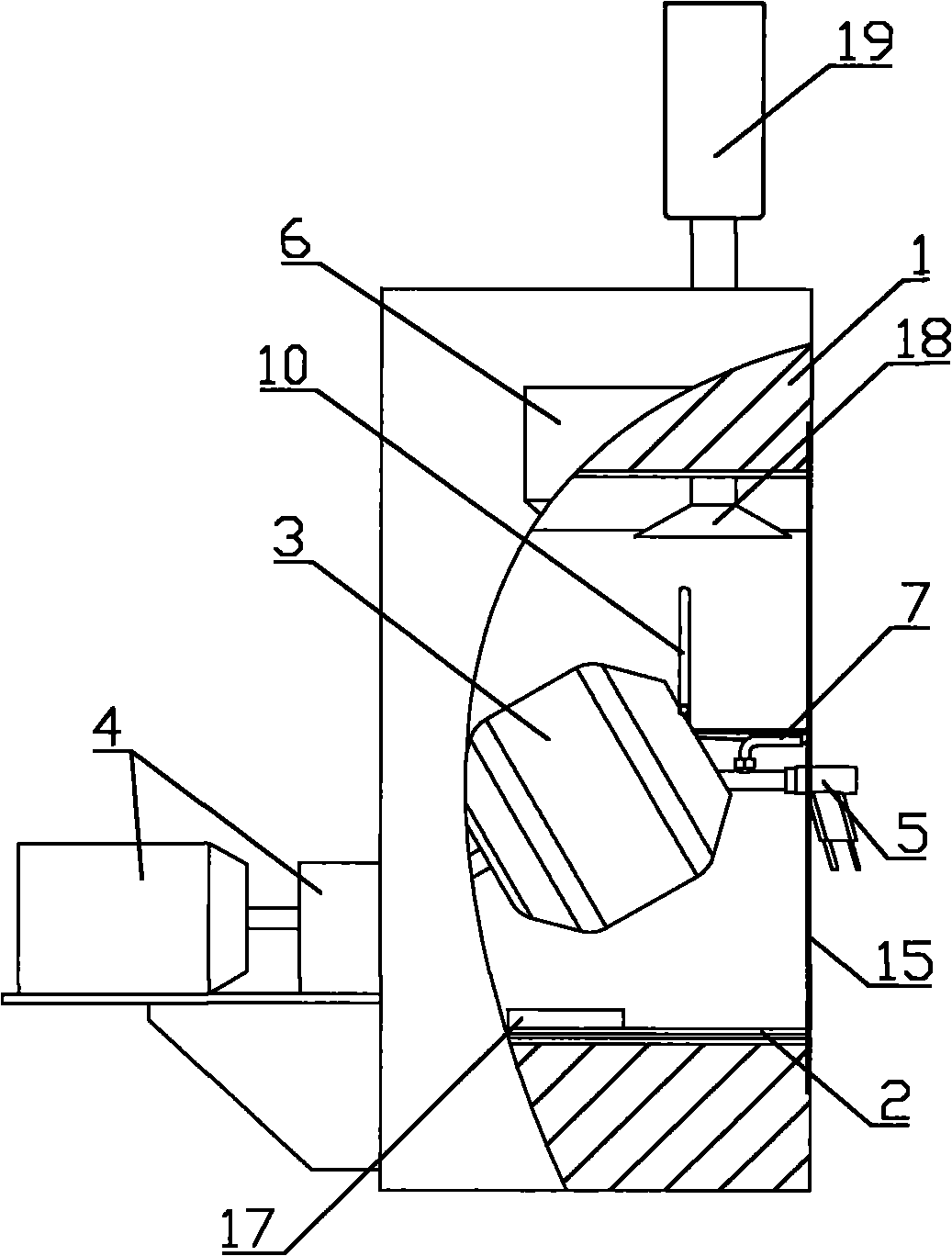

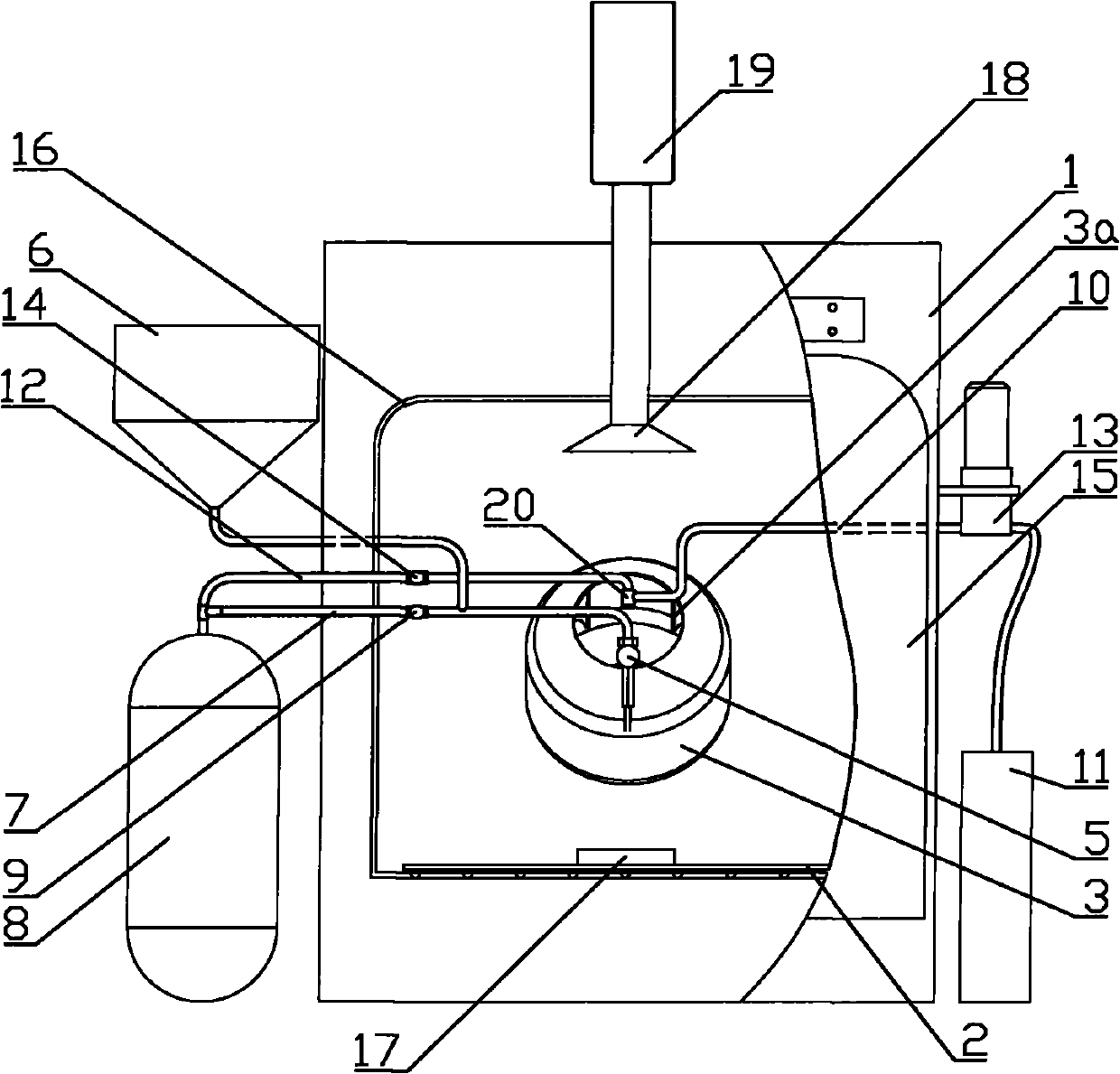

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 As shown in the figure: the dry coating machine of this embodiment includes a box body, a coating device, a dry powder directional supply device and an auxiliary material supply device, and a heat source 2 is arranged at the inner bottom of the box body 1; The coating device includes a cylindrical coating pan 3 with an open end and a coating pan driving assembly 4. The coating pan 3 is arranged in the casing 1 in a manner that can rotate around its own axis, and the coating pan driving assembly 4 drives to cooperate with the coating. Pot 3; The dry powder directional supply device includes an electrostatic spray gun 5, a dry powder feed box 6, a dry powder conveying air pipe 7 and a high-pressure gas source 8, and the electrostatic spray gun of the present embodiment adopts a corona spray gun. A charged spray gun can also achieve the purpose of the present invention. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com