Metering control device for pre-molding type electric injection molding machine

A technology of control device and injection molding machine, applied in the field of metering control device, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

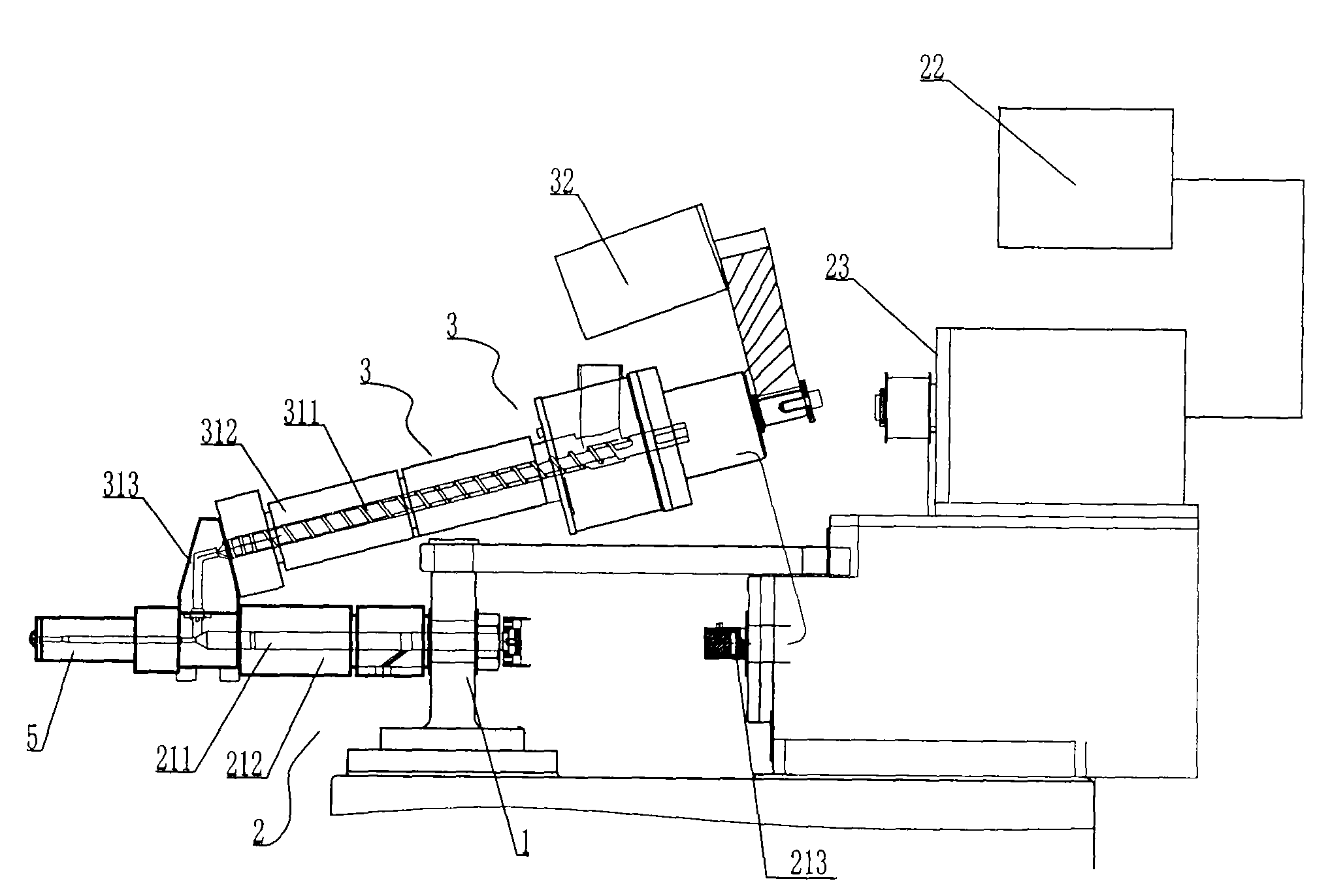

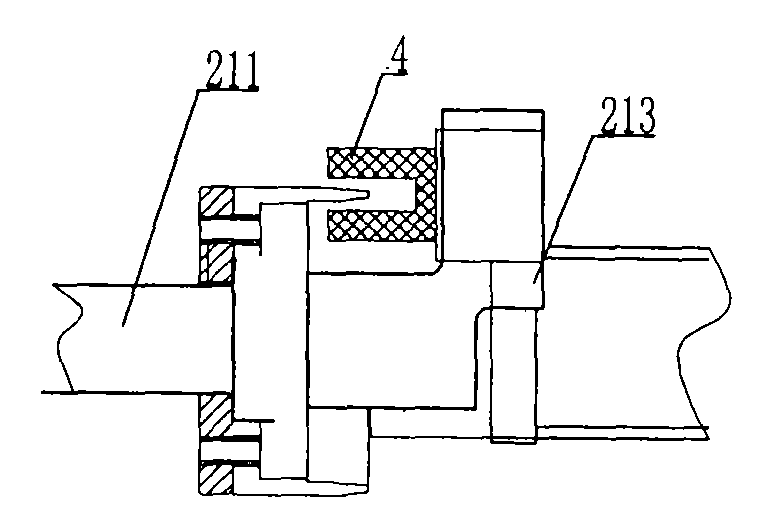

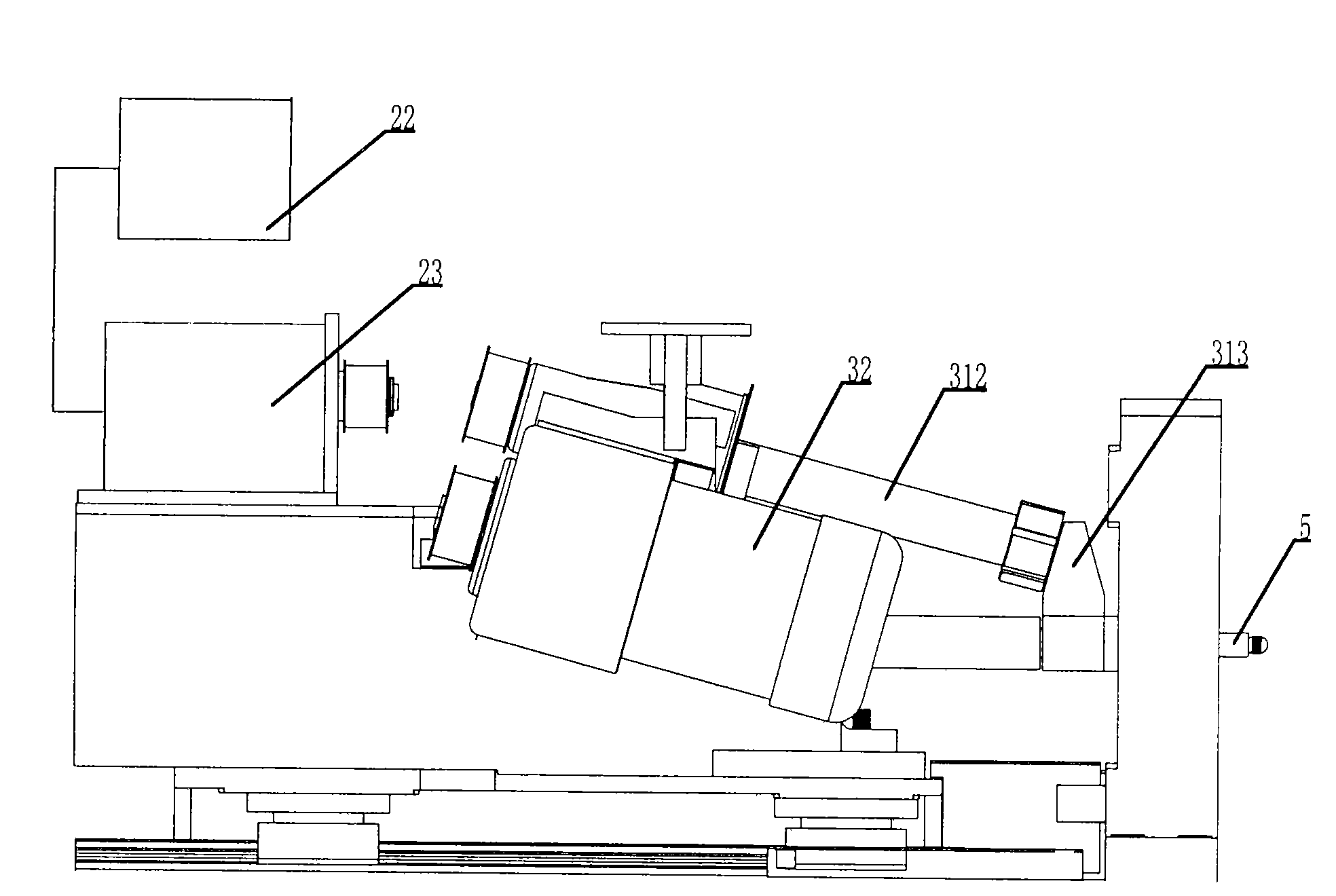

[0021] One of the embodiments of the present invention is that the pre-molding motor adopts a common three-phase motor, and its structure is composed of a frame 1, an injection mechanism 2 and a pre-molding mechanism 3. The injection mechanism 2 and the pre-molding mechanism 3 form a triangular structure. The injection mechanism 2 is composed of a syringe 21, a precision controller 22 and an injection motor 23. The syringe 21 is composed of a plunger rod 211, an injection cylinder 212 and a ball screw 213. The pre-molding mechanism 3 is composed of a pre-molding device 31 and a pre-molding motor 32, and the pre-molding device 31 is composed of a screw 311, a pre-molding cylinder 312 and an intermediate body 313. The precision controller 22 is a servo controller or a frequency converter. The injection cylinder 212 is fixedly installed on the frame 1, and its front end communicates with the discharge port of the intermediate body 313; the rear end of the plunger rod 211 in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com