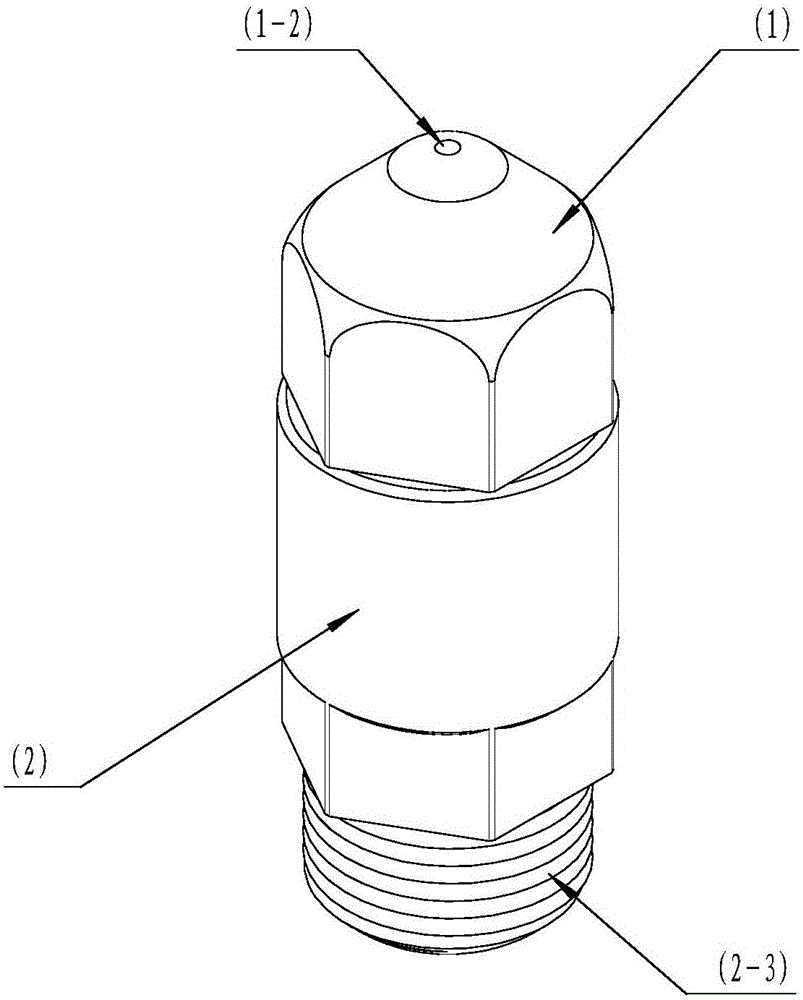

Self-recovery type anti-overflow spray nozzle

An anti-splash and self-recovering technology, applied in the field of injection molding machine parts, can solve problems such as mold production inconvenience, mold damage, product scrapping, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

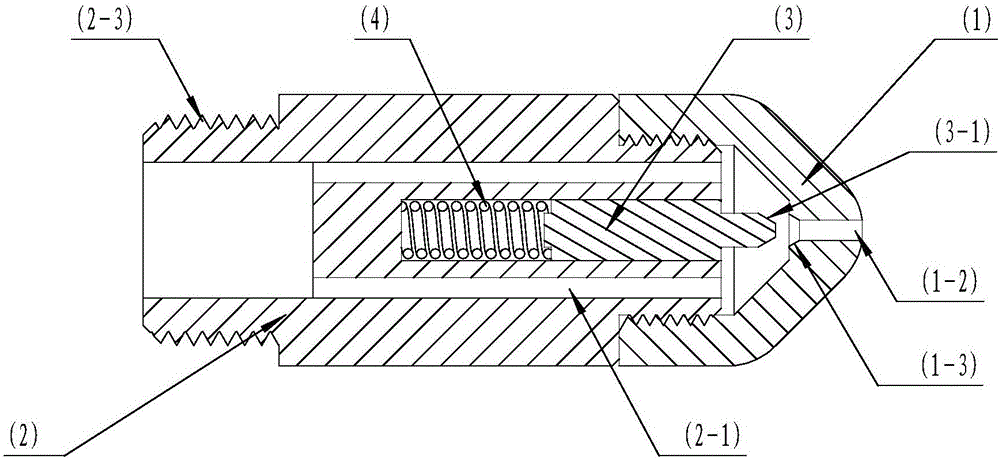

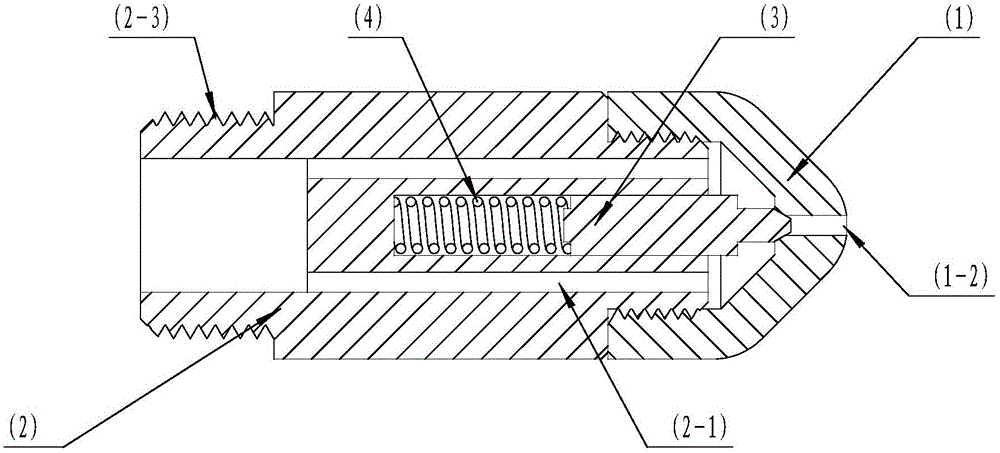

[0014] Specific implementation: The self-returning anti-overflow nozzle includes a nozzle cap (1), a nozzle body (2), a valve core (3) and a spring (4) as main components. Its characteristics: during injection molding, the hydraulic device pushes the screw forward, forming a high-pressure plastic melting zone in the previously closed nozzle cap (1), and the high-pressure melting glue acts on the force surface (3-2) of the valve core (3) , generating thrust to compress the spring (4) to move the spool (3) towards the direction of the spring (4), at this time, the blocking slope (3-1) of the spool (3) is blocked from the inner side of the nozzle cap (1). Exit from the overflow slope (1-3), such as figure 2 At this time, the melt is injected into the cavity of the mold through the injection channel (2-1) and the injection channel (1-2) of the nozzle body (2), until the injection action is completed, the hydraulic device drives the screw back, and the injection The high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com