Five-rod fluid feeding machine double-pony ladle mechanical arm

A five-link, soup-feeding machine technology, which is applied to the equipment for feeding molten metal into molds, metal processing equipment, casting equipment, etc., can solve the problems that it can only be used in large-scale production, the distance is fixed, and the price is high. , to save production space, reduce production costs, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

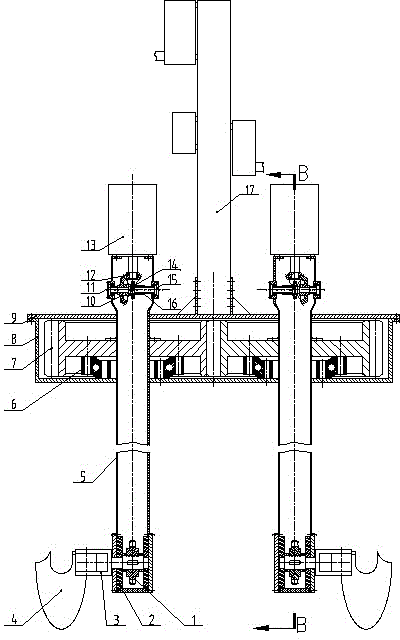

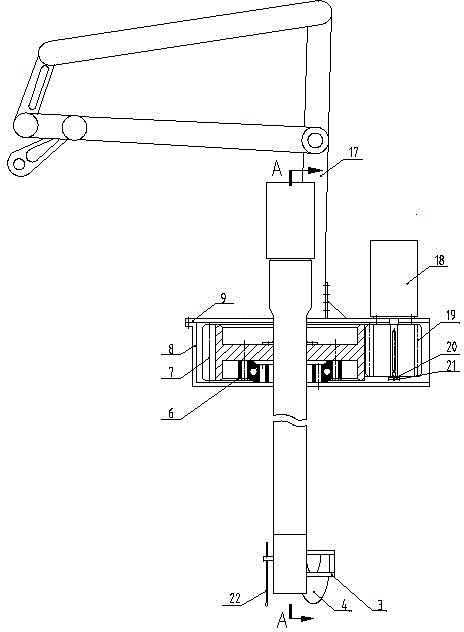

[0020] like Figure 1 to Figure 2 As shown in the figure, a five-linkage soup machine double ladle mechanical arm includes: a five-linkage working arm 17, an arm drive mechanism, and two ladle drive mechanisms.

[0021] The arm driving mechanism includes a servo motor 18, an upper fixed plate 9, a pinion 19, a large gear 7, and a pouring arm 5; the above-mentioned servo motor 18 is fixedly connected to the upper fixed plate 9 by bolts, and the motor shaft of the servo motor 18 is connected by a key The lower pinion 19, the pinion 19 is meshed with the large gear 7, and the large gear 7 is fixedly welded to the pouring arm 5; the large gear 7 is two on the lower part of the upper fixing plate 9, and forms a large gear group, through which the large gear group Intermeshing rotation makes the pouring arm 5 relatively rotate; in addition, the above-mentioned pinion gear 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com