Patents

Literature

43results about How to "Achieve pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

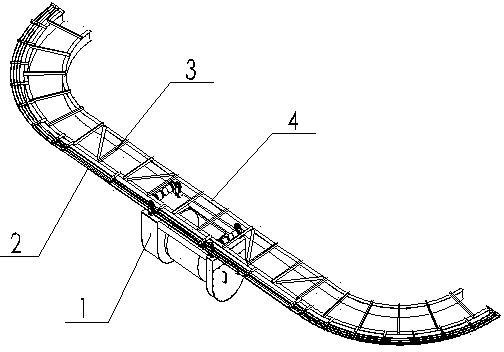

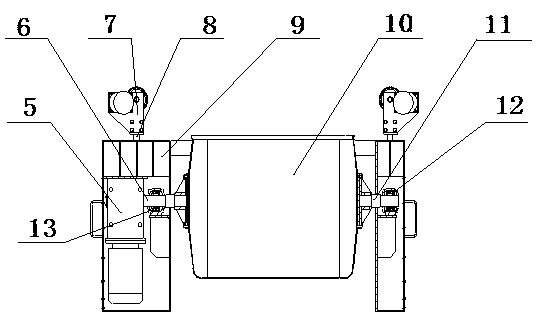

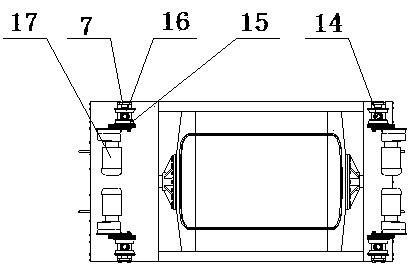

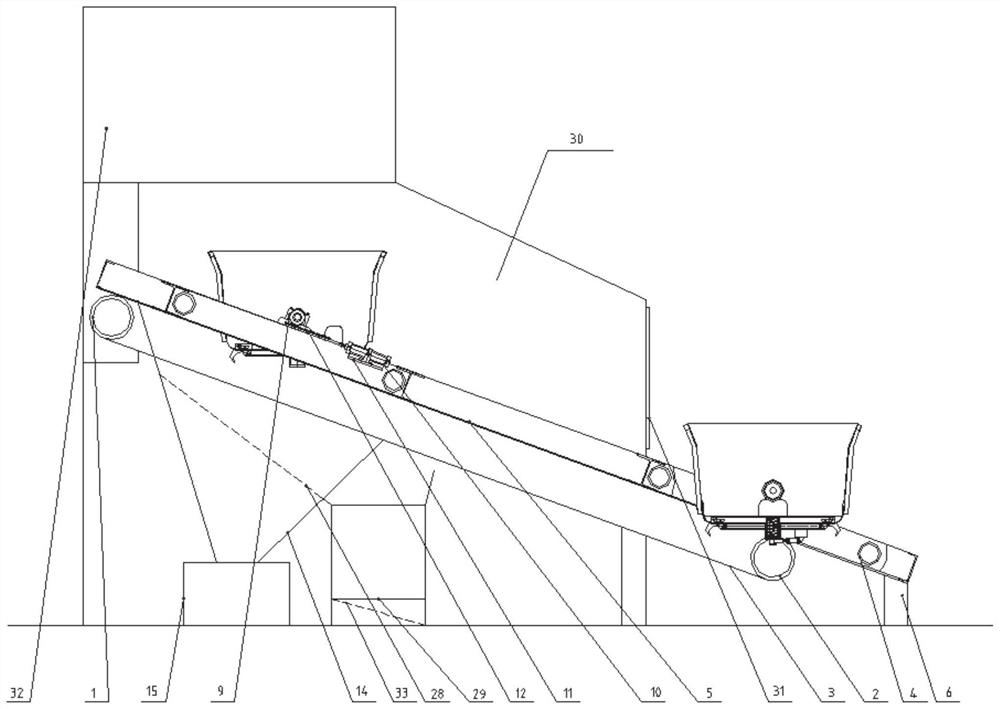

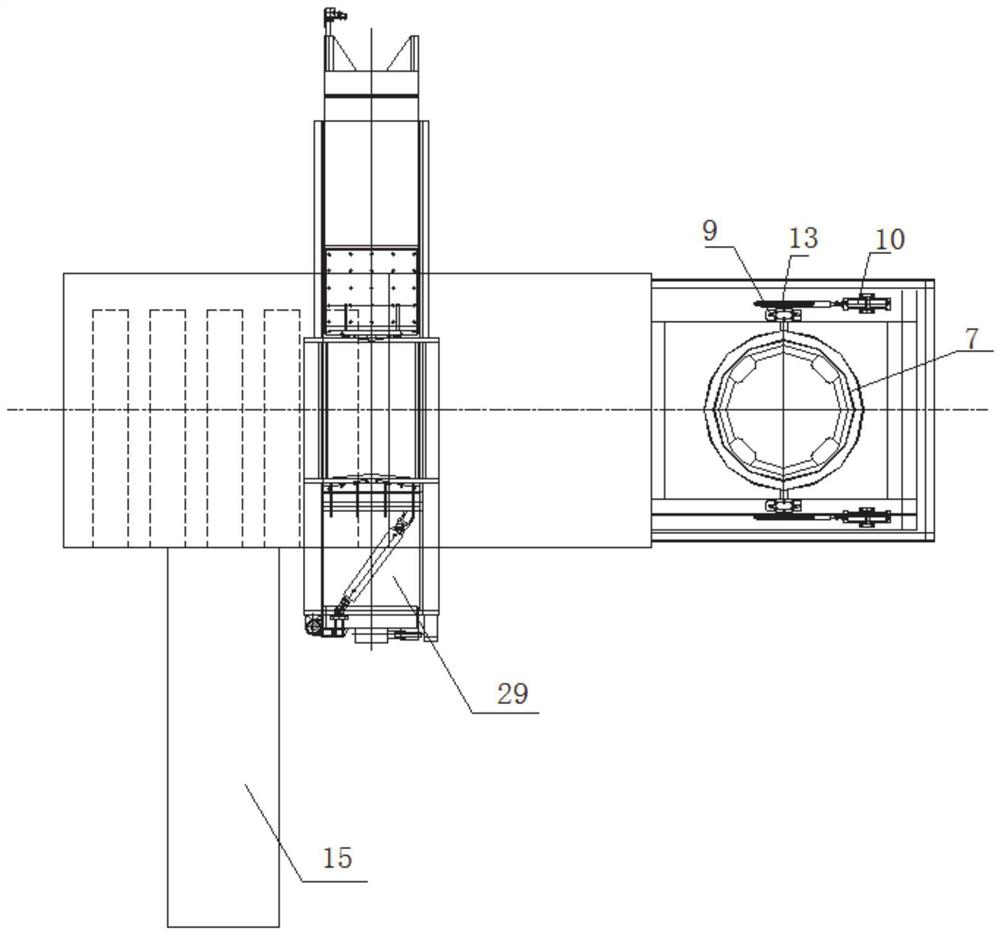

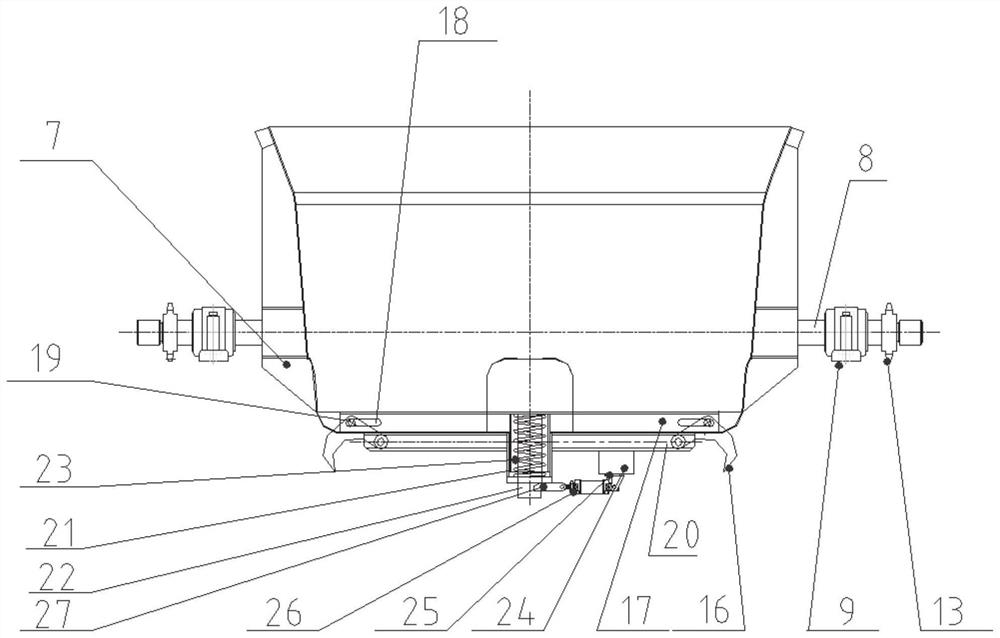

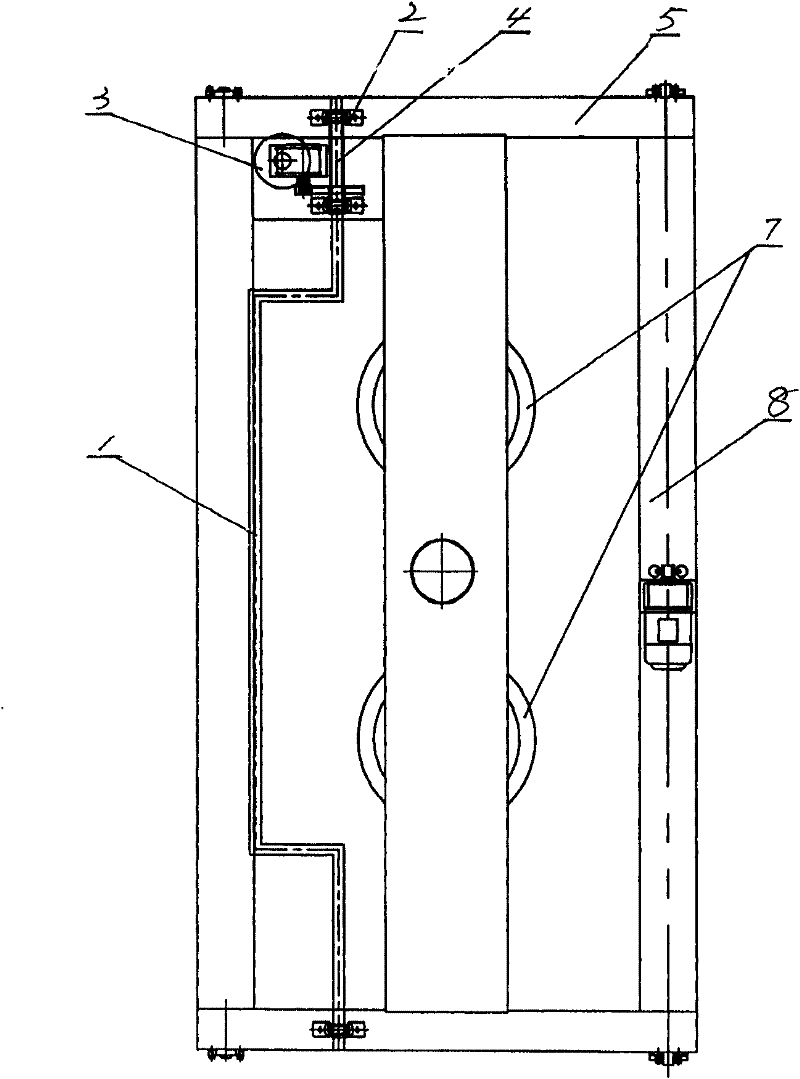

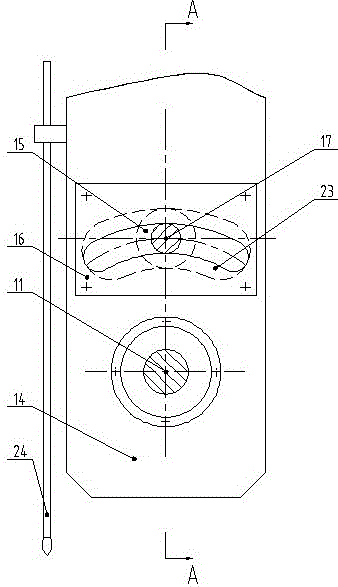

Novel turnover type material conveying cart

ActiveCN103407779AAchieve pouringSimple structureConveyor partsMechanical conveyorsEngineeringMotor speed

Provided is a novel turnover type material conveying cart. A cylindrical tank body or a cylindrical-like tank body is used as a container for containing concrete, a discharging port is formed in the face of the container, a long half shaft and a short half shaft are connected and fixed on the outer portions of the two ends of the container respectively, the long half shaft and the short half shaft are connected with a long half shaft bearing seat and a short half shaft bearing seat respectively, the long half shaft bearing seat and the short half shaft bearing seat are arranged in a hanging frame, a motor speed reducer is arranged on the long half shaft, the four corners of the hanging frame are connected with hanging rod bearing seats through hanging rods, the hanging rod bearing seats are connected with driving wheels and driven wheels through hanging plates, the driving wheels and the driven wheels are hung on two steel rails parallel to each other, the driving wheels are provided with large gears, and mono overhead crane walking driving devices drive the driving wheels to rotate and drive the driven wheels to rotate together. The novel turnover type material conveying cart is simple in structure, reliable in running and capable of meeting the operation requirement that one material conveying cart supplies materials for multiple sets of material distribution machines, the materials will not leak, and environment-protection performance and technical performance are good.

Owner:YUANDA RESIDENTIAL IND HANGZHOU CO LTD

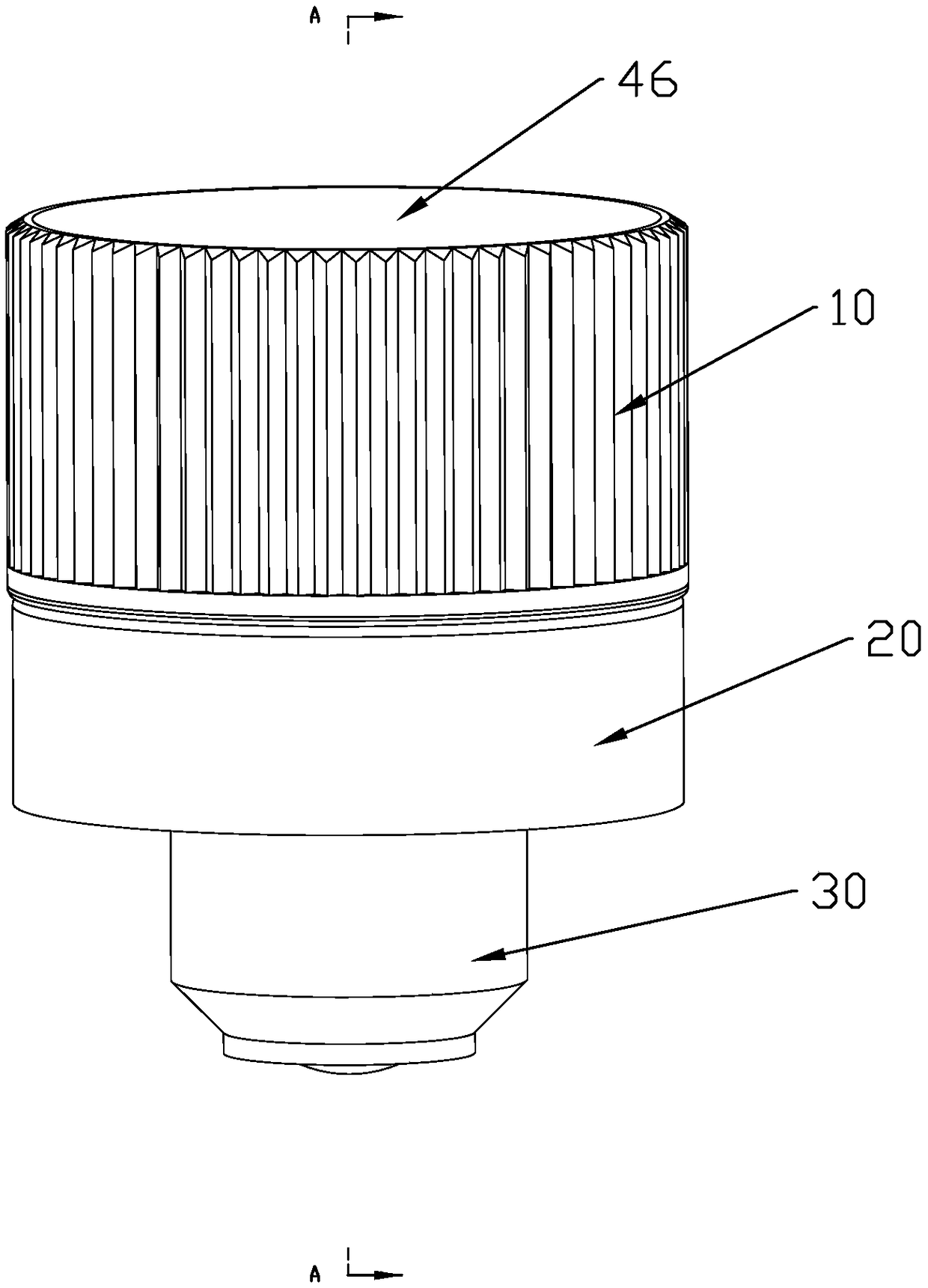

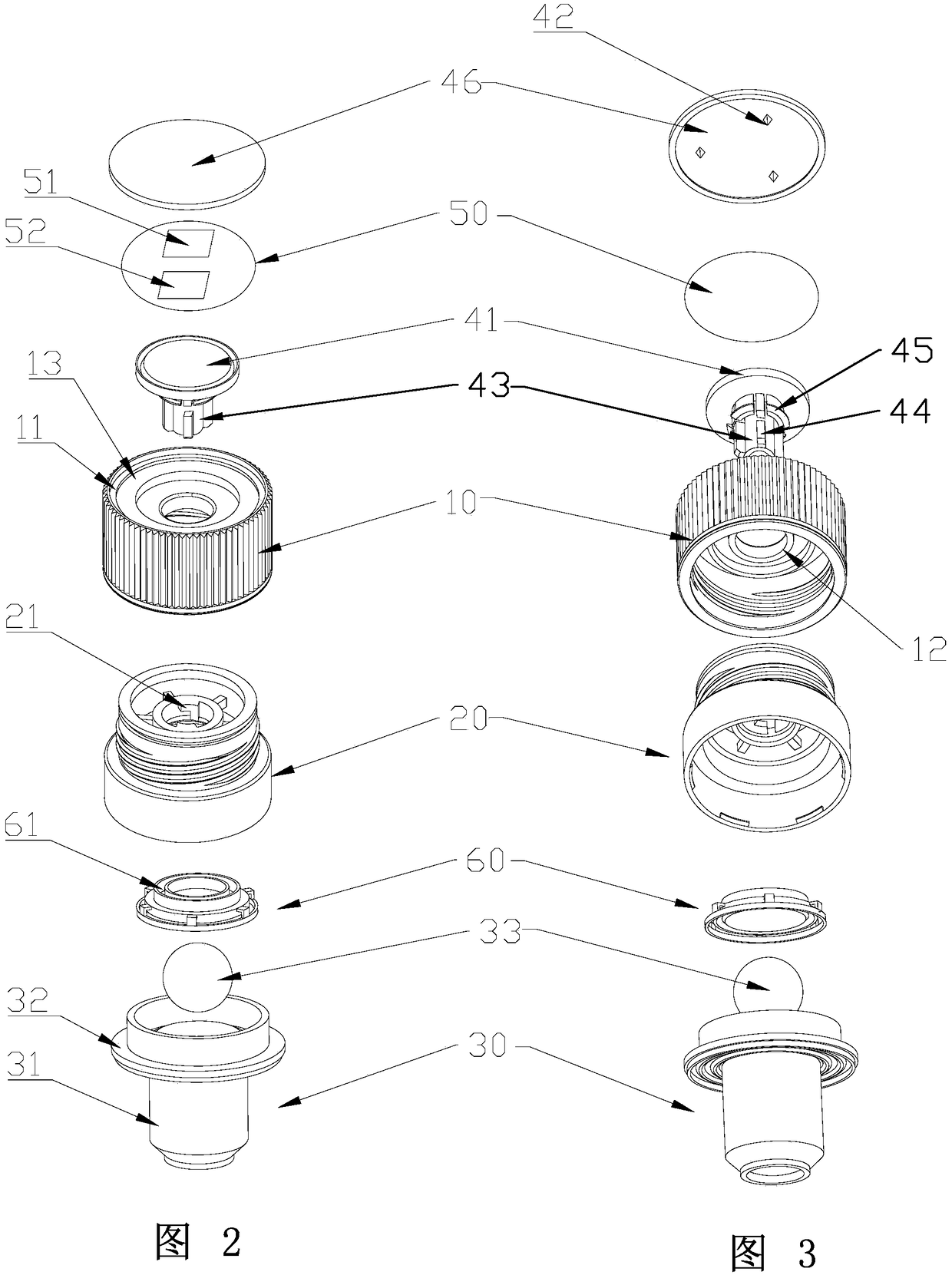

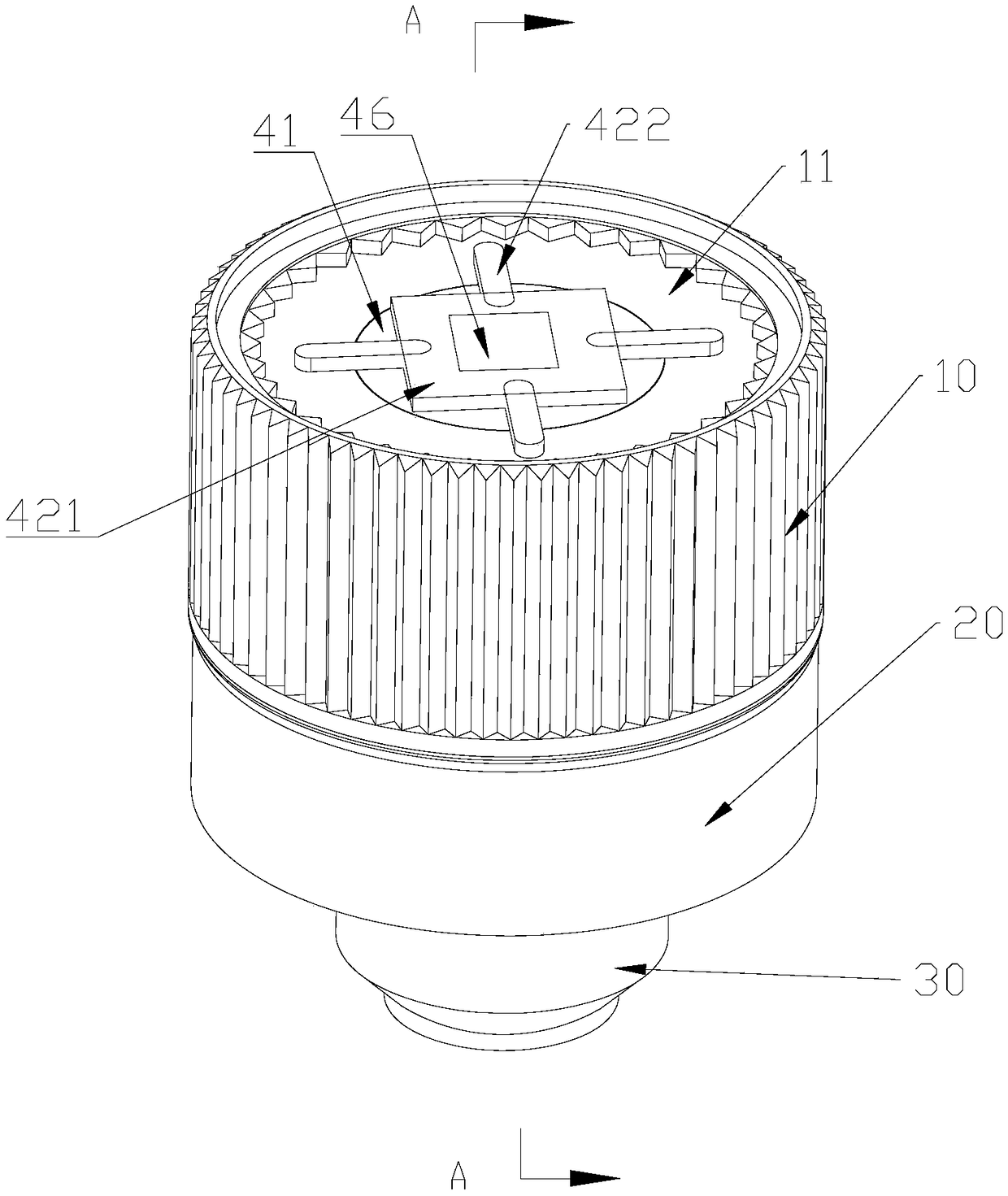

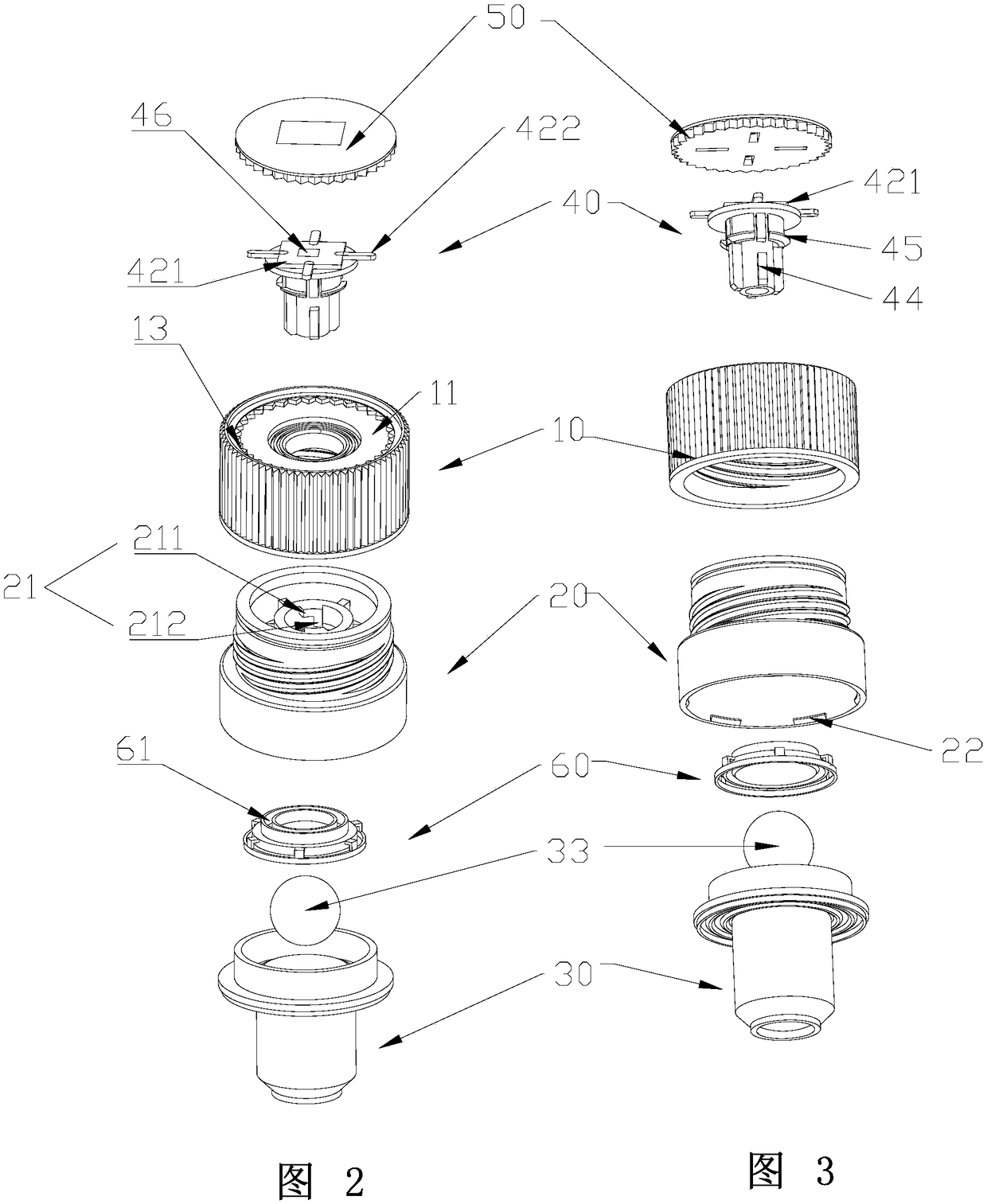

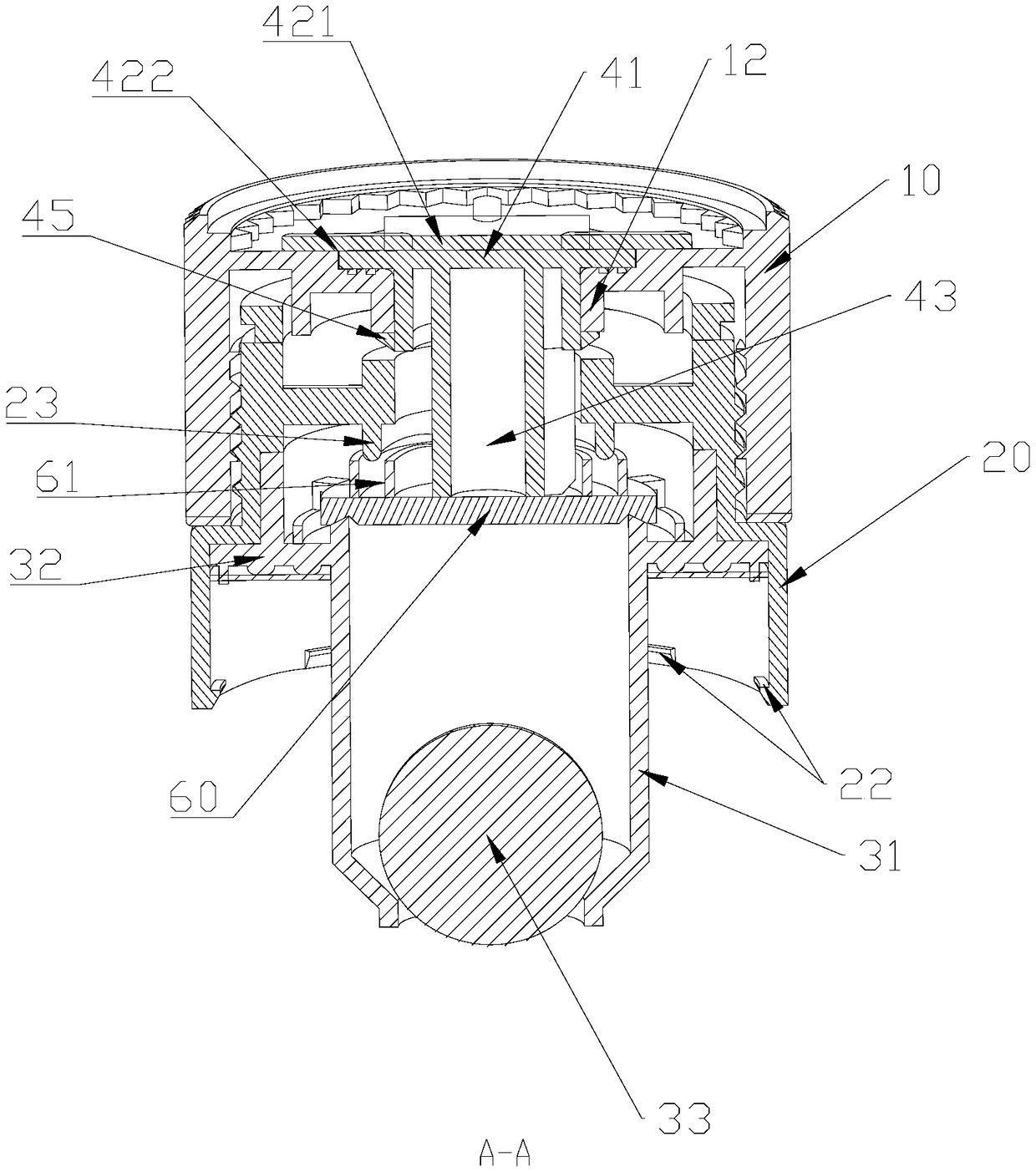

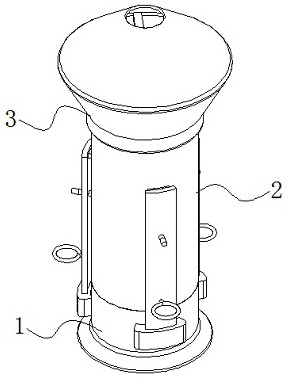

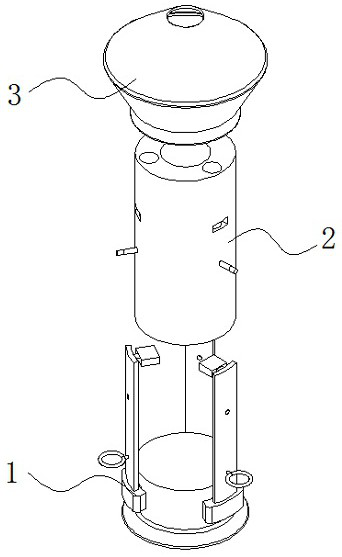

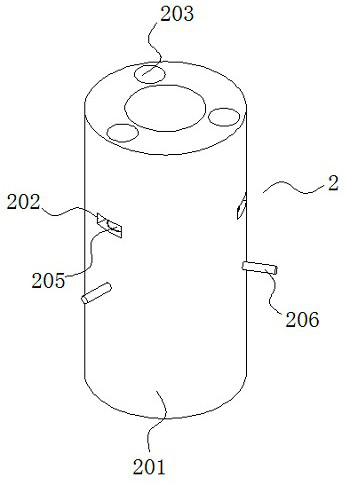

Opening self-destruction type anti-fake bottle cap

ActiveCN109502176AEasy to useSolving Recycling ProblemsPackage recyclingContainer decorationsEngineeringBottle cap

The invention discloses an opening self-destruction type anti-fake bottle cap, and belongs to the technical field of bottle caps. The bottle cap comprises an upper cap body, a lower cap body, a self-destruction device and an anti-fake label; a cavity penetrating through the top wall of the upper cap body is formed inside the upper cap body; a cavity penetrating through the top wall of the lower cap body is formed inside the lower cap body; the self-destruction device is arranged inside the cavities and comprises a fixing part matched with the upper cap body and the lower cap body and a self-destruction part matched with the anti-fake label; the fixing part comprises an upper fixing plate and a fixing column; the upper fixing plate is arranged at the top of the upper cap body; the fixing column is arranged inside the cavities and is movably connected with the inner wall of the lower cap body; the anti-fake label is arranged at the top of the upper fixing plate and the top of the upper cap body; the upper cap body comprises a cover plate made of a transparent material and located above the anti-fake label; the self-destruction part comprises a puncturing part; the puncturing part isarranged on the lower surface of the cover plate; and the head of the puncturing part abuts against the anti-fake label. According to the bottle cap, the anti-fake label is damaged by the aid of the bottle cap through self-destruction during first-time cap opening, so that the bottle cap cannot be reused and has the dismounting-preventing effect; and the bottle cap is stable in structure, convenient to use and high in practicability.

Owner:HANGZHOU WOPUWULIAN SCI & TECH

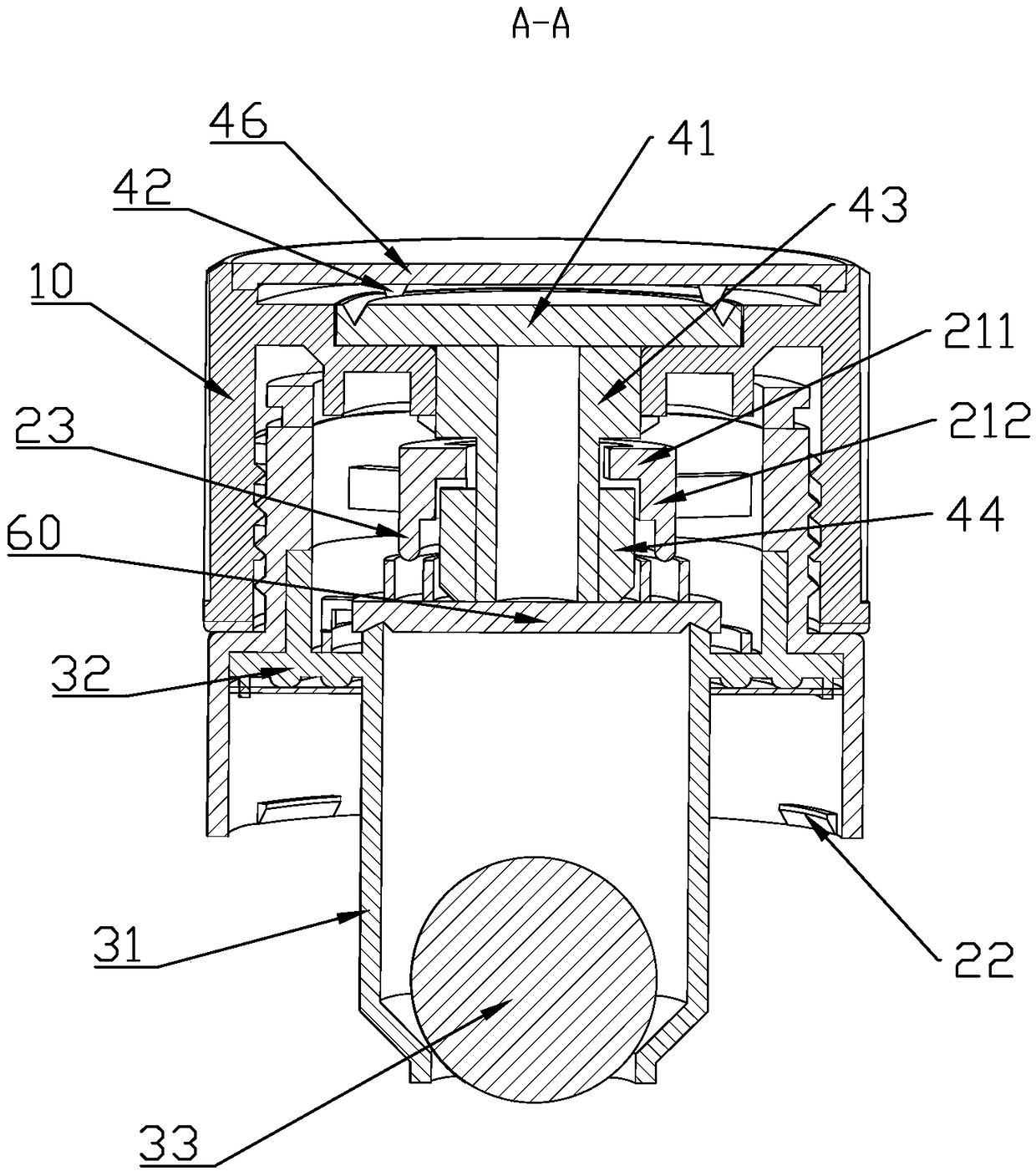

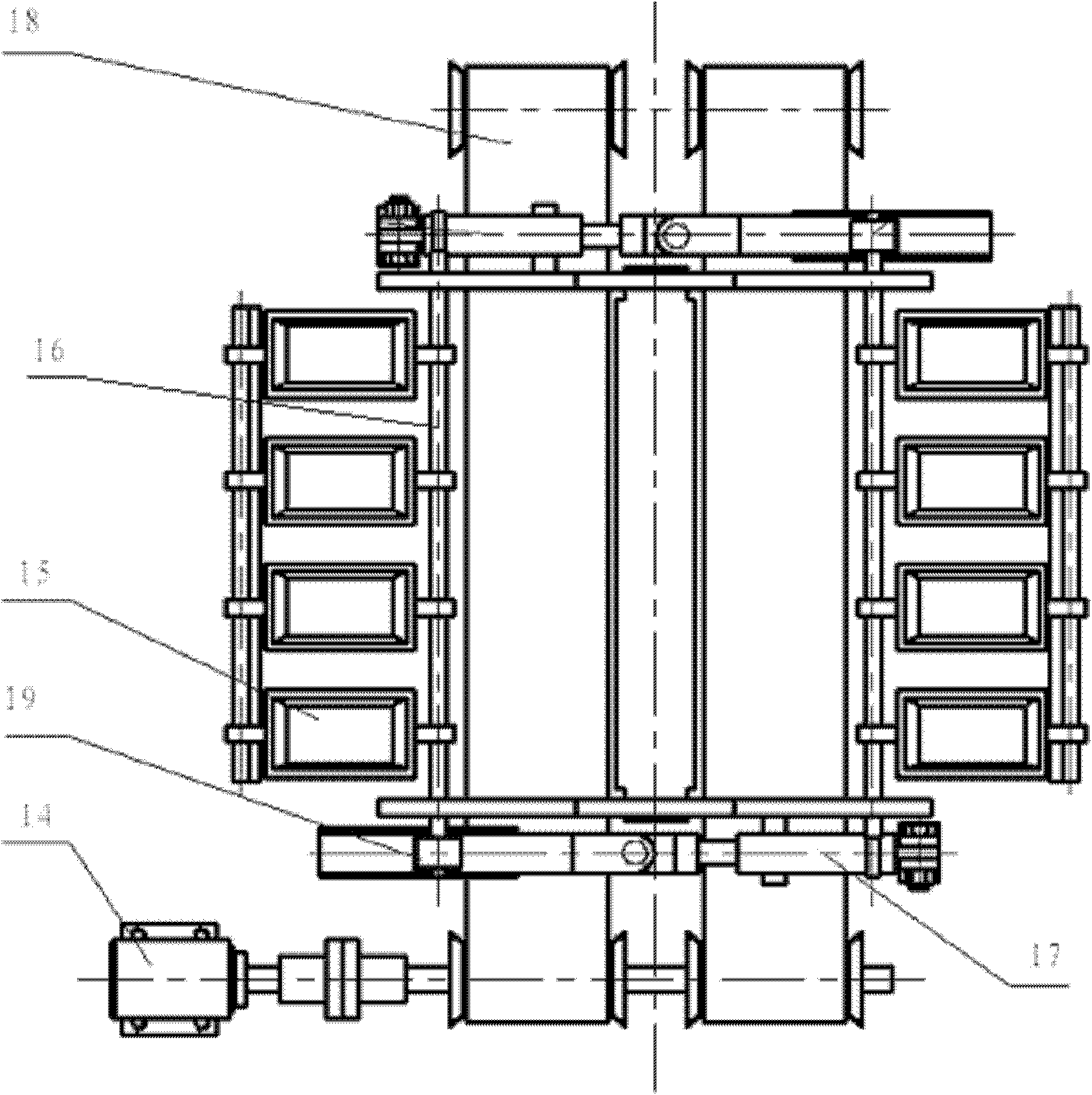

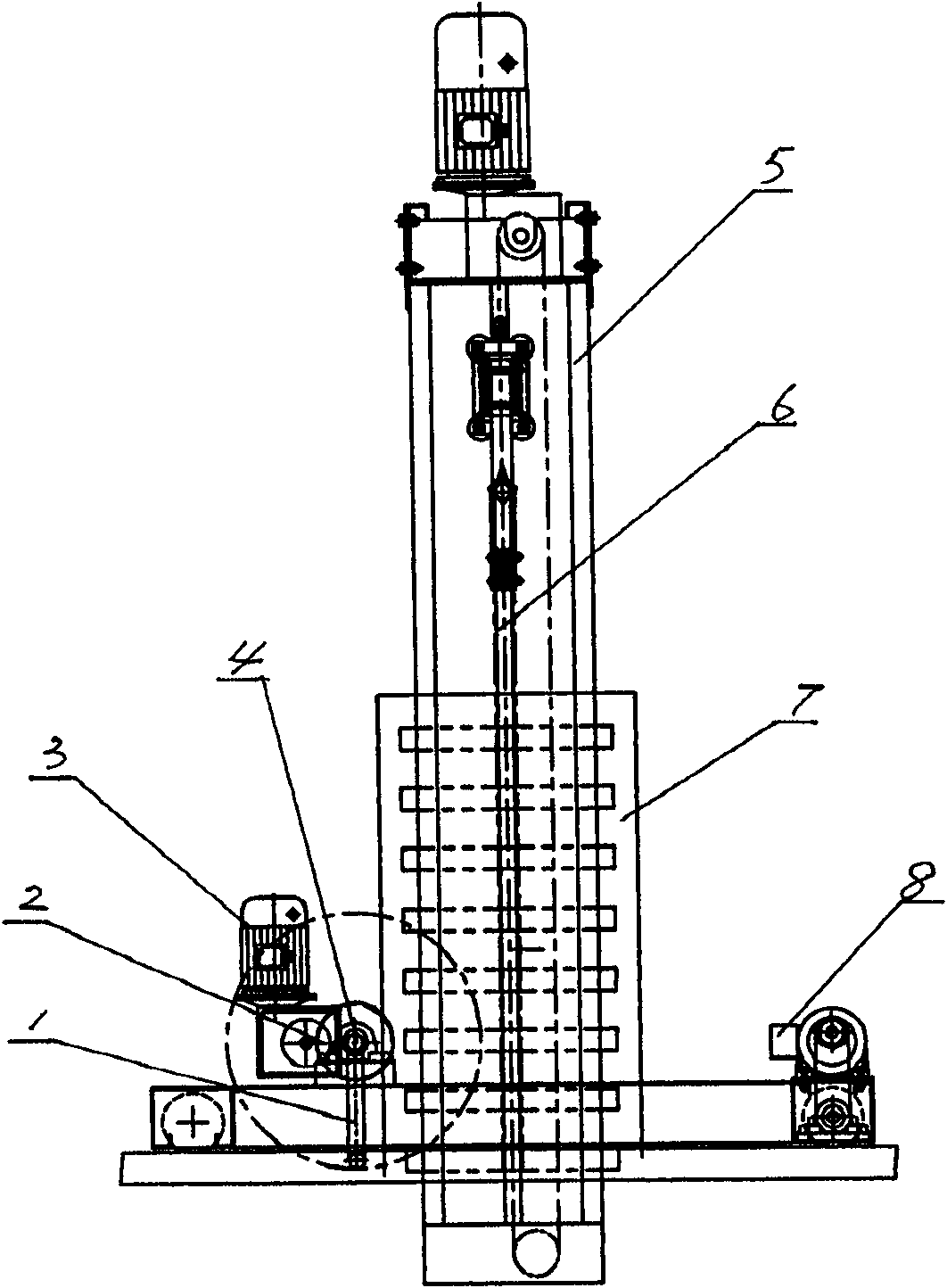

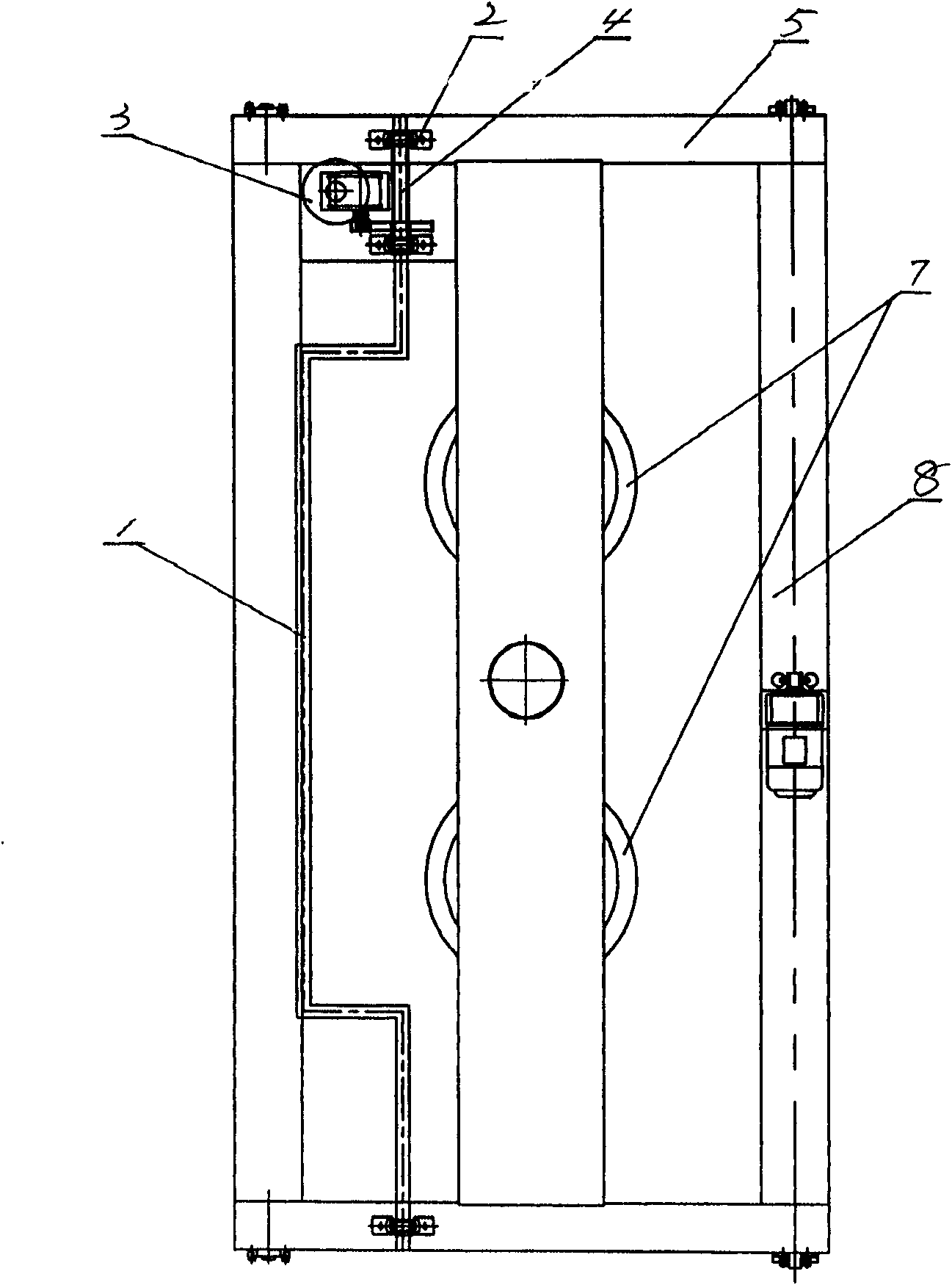

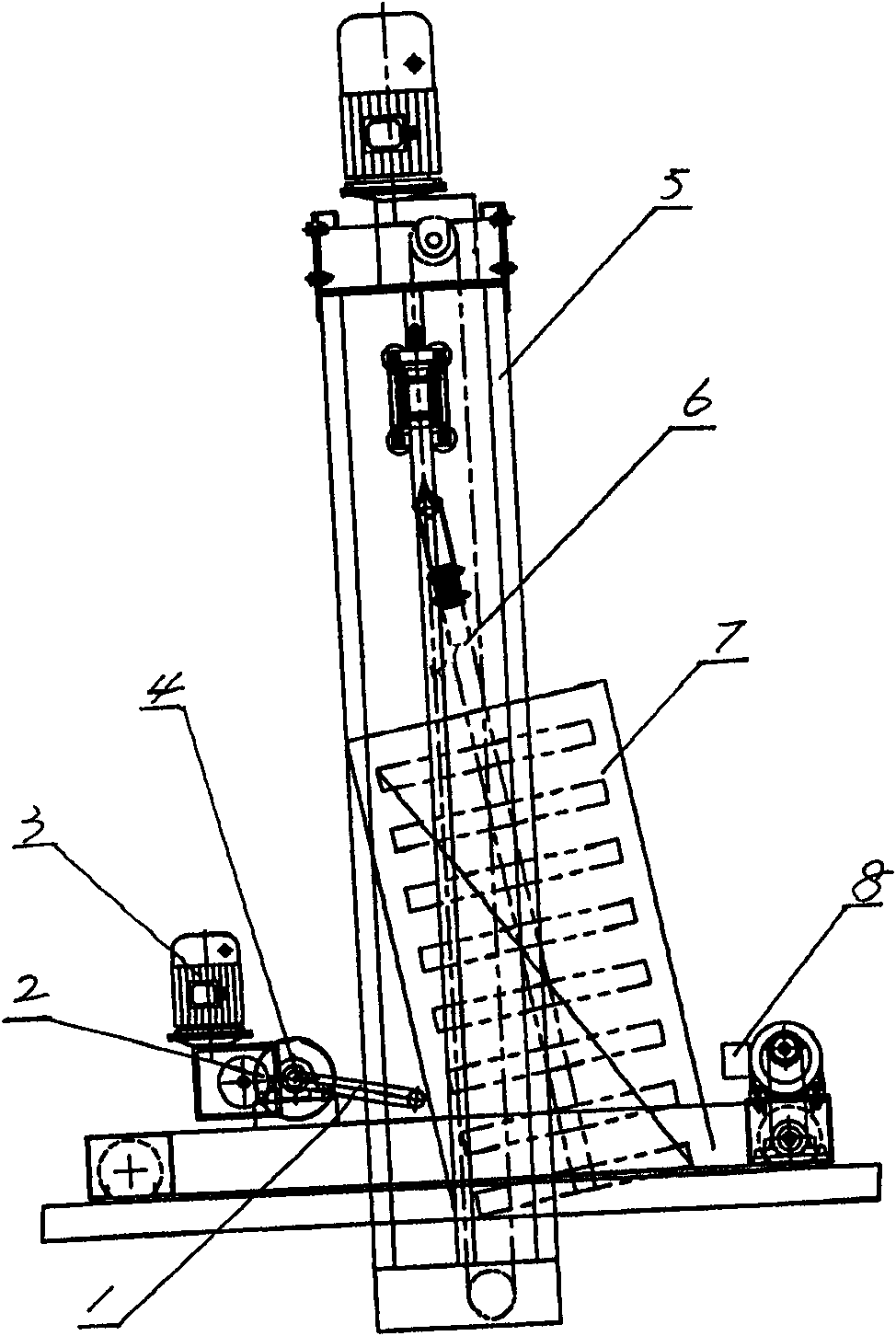

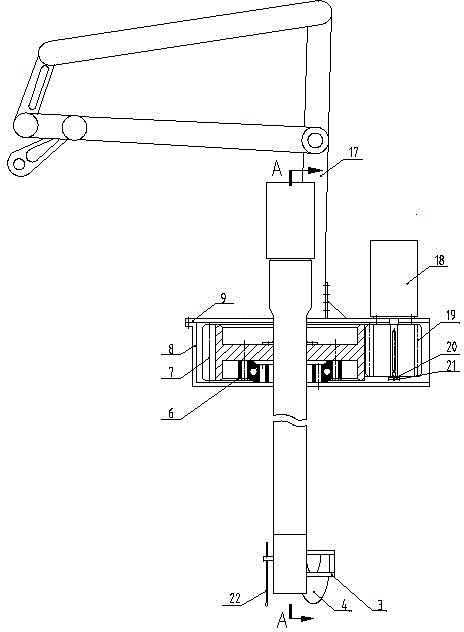

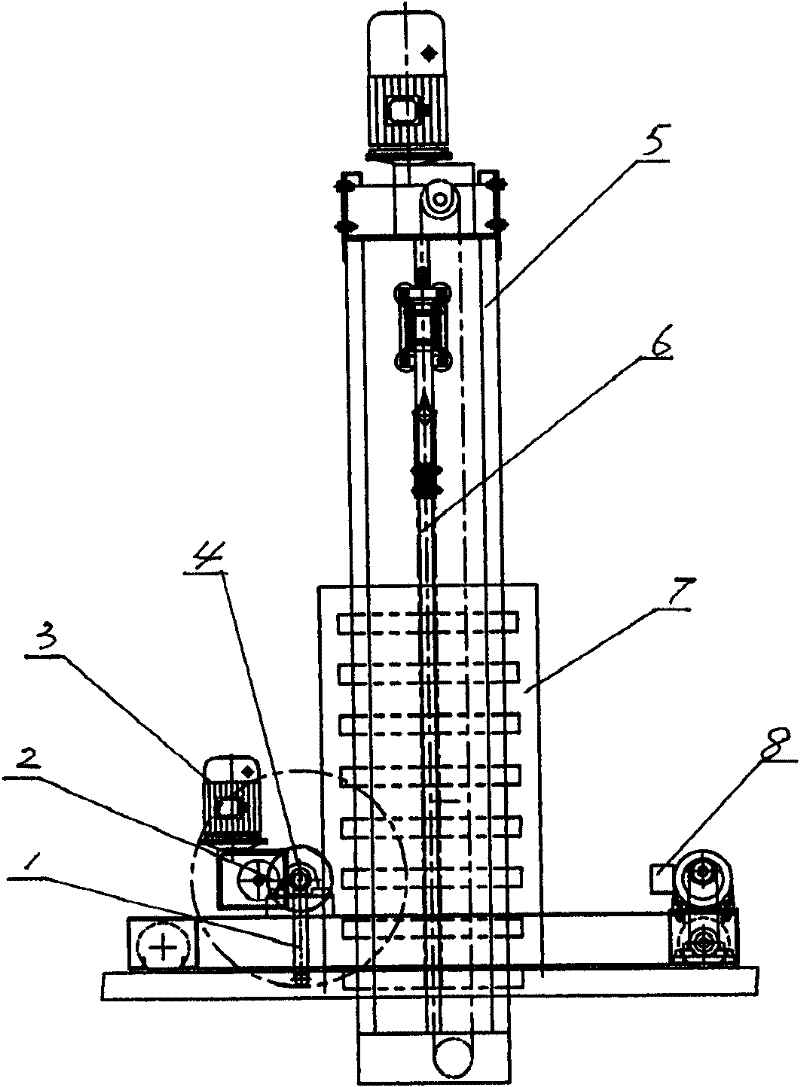

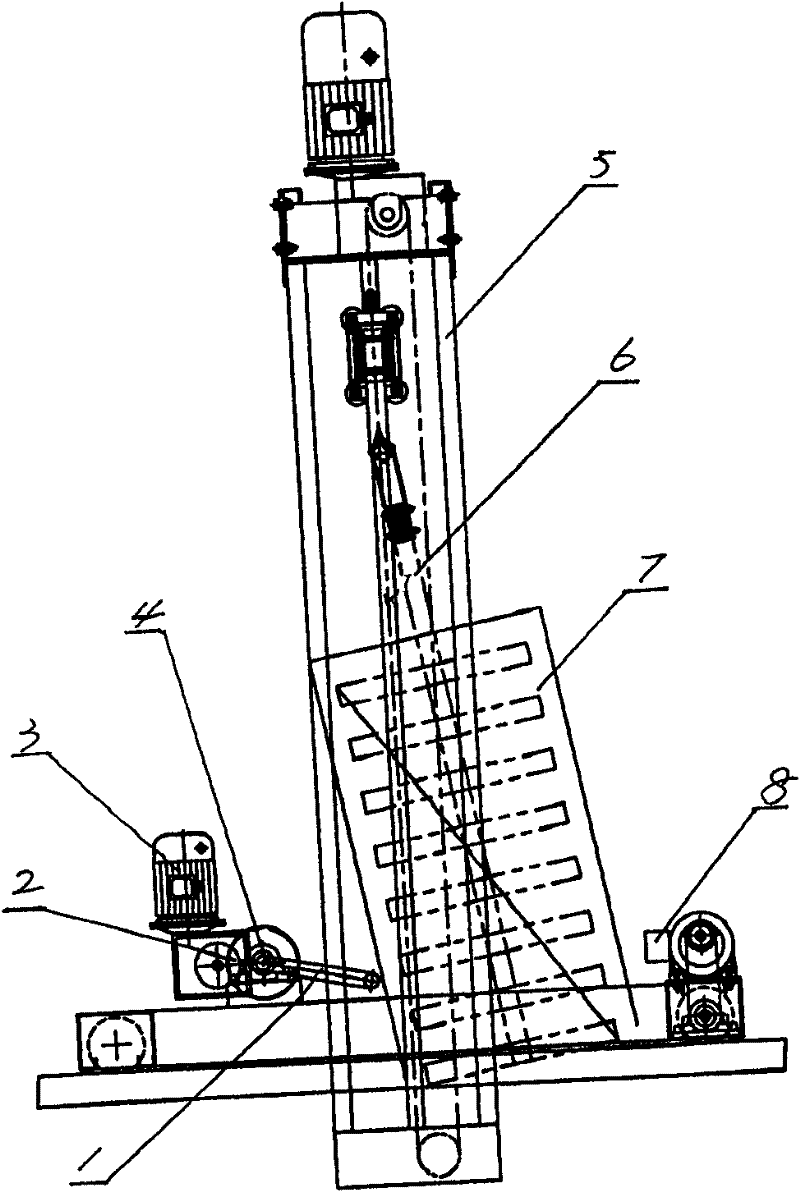

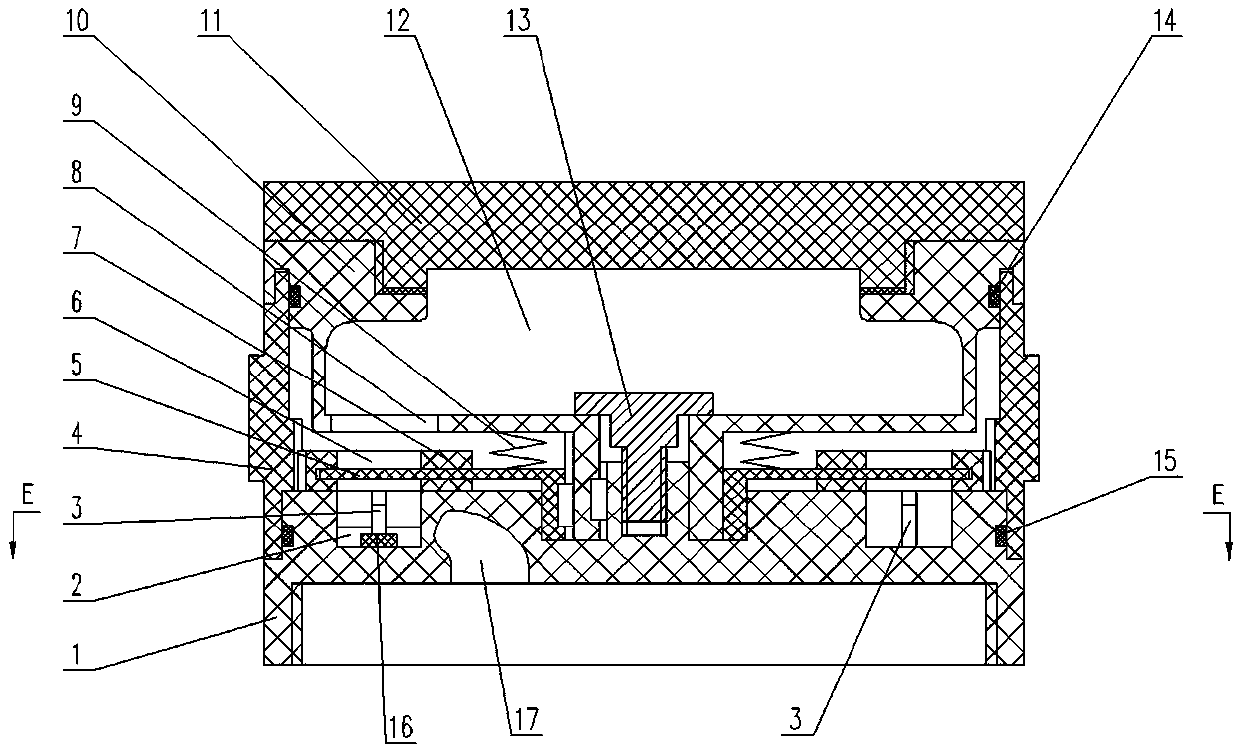

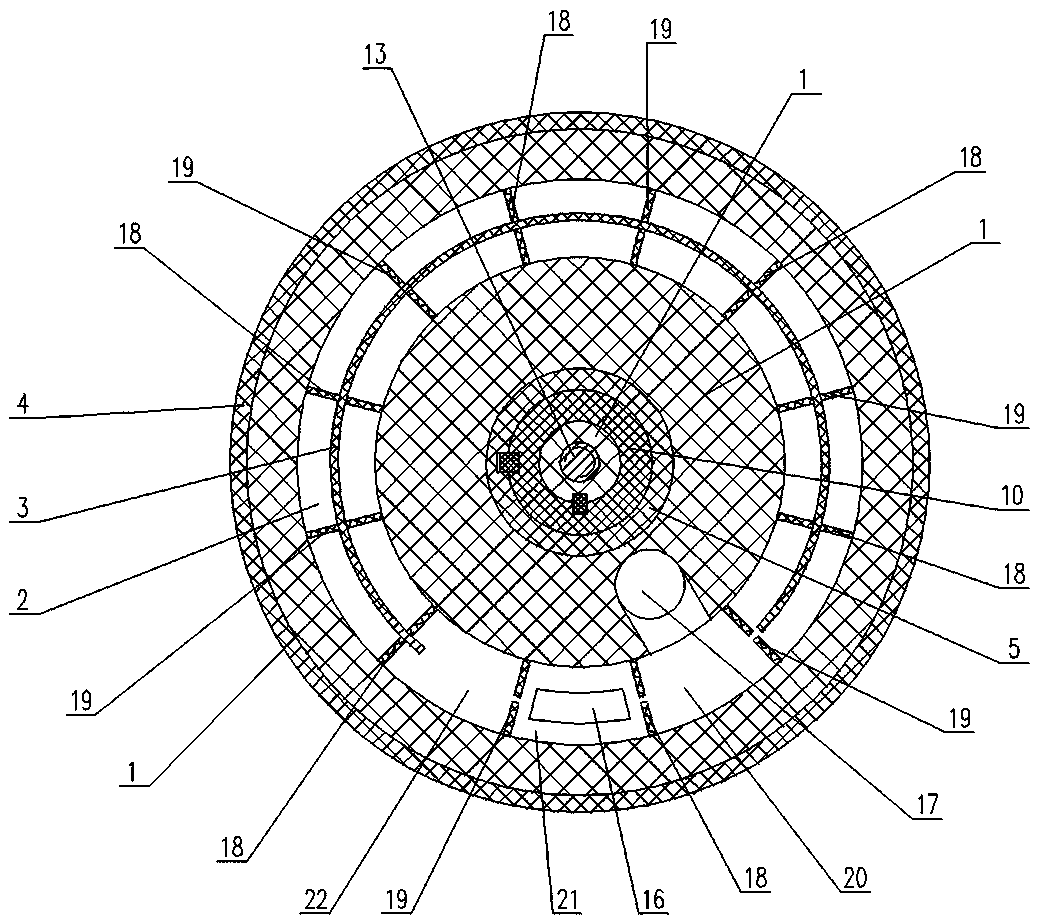

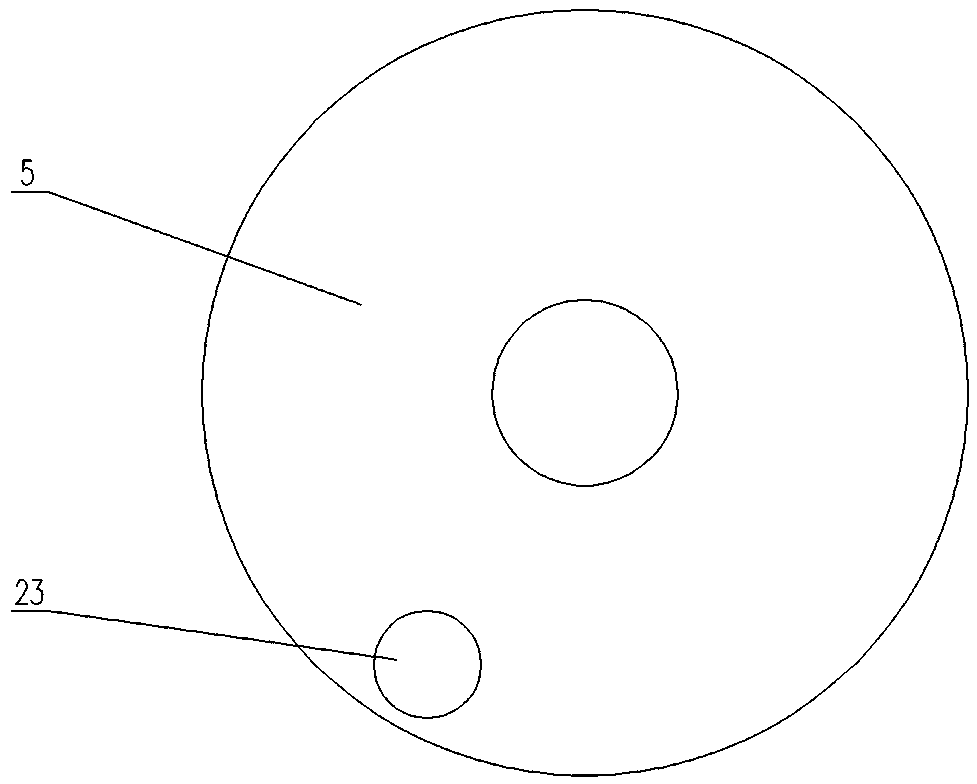

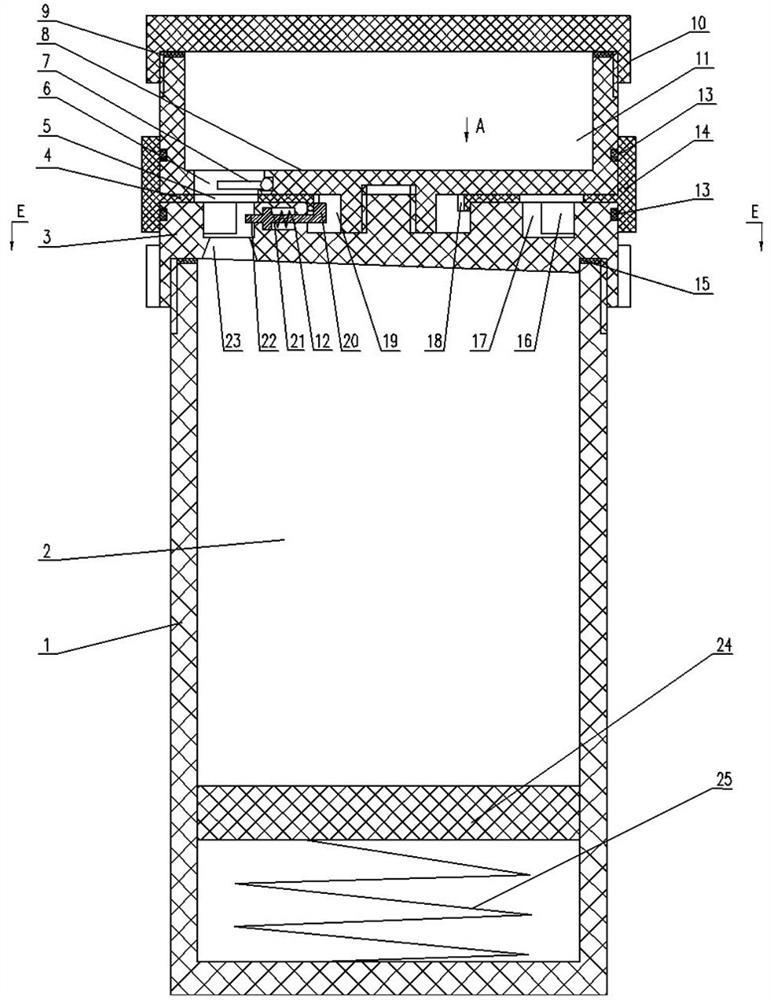

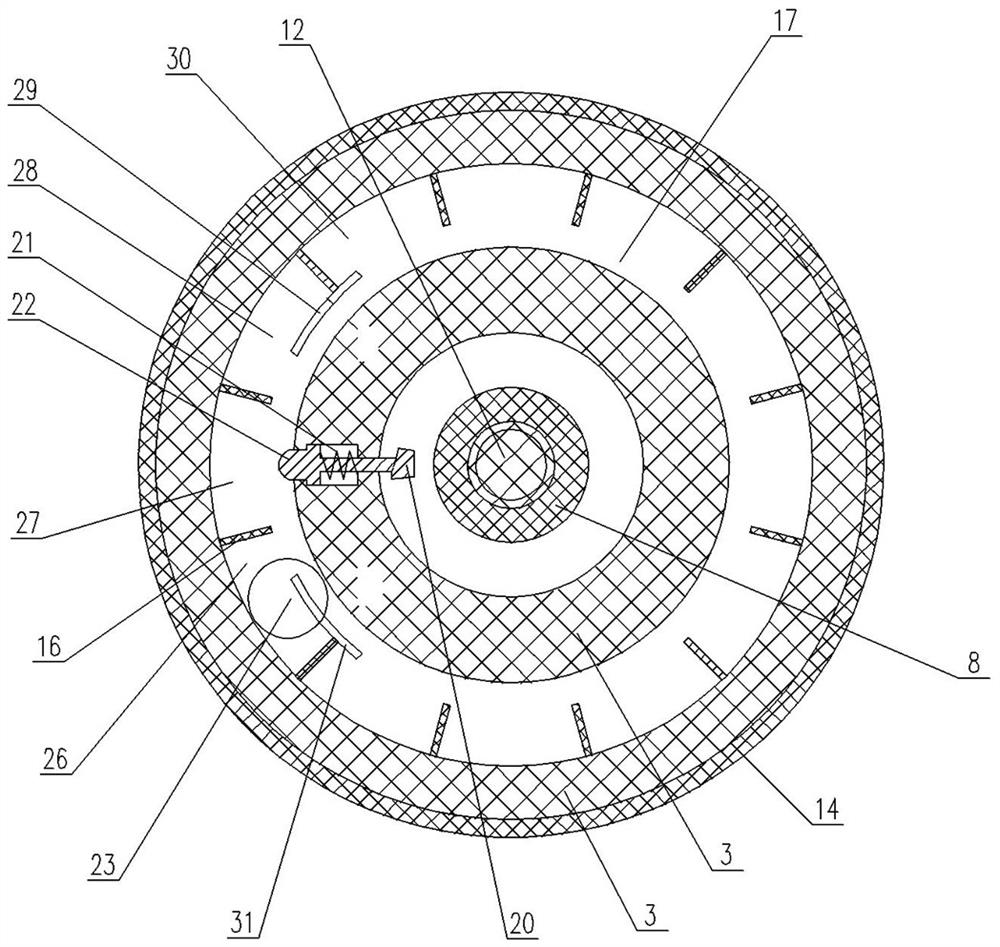

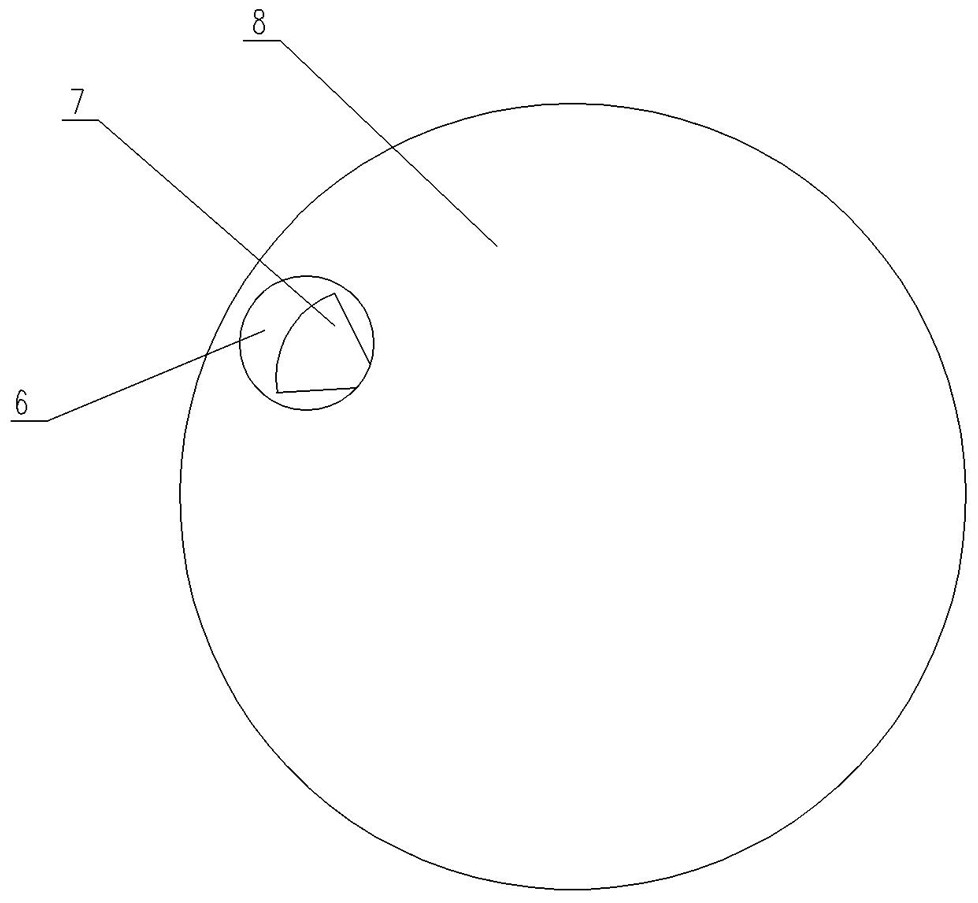

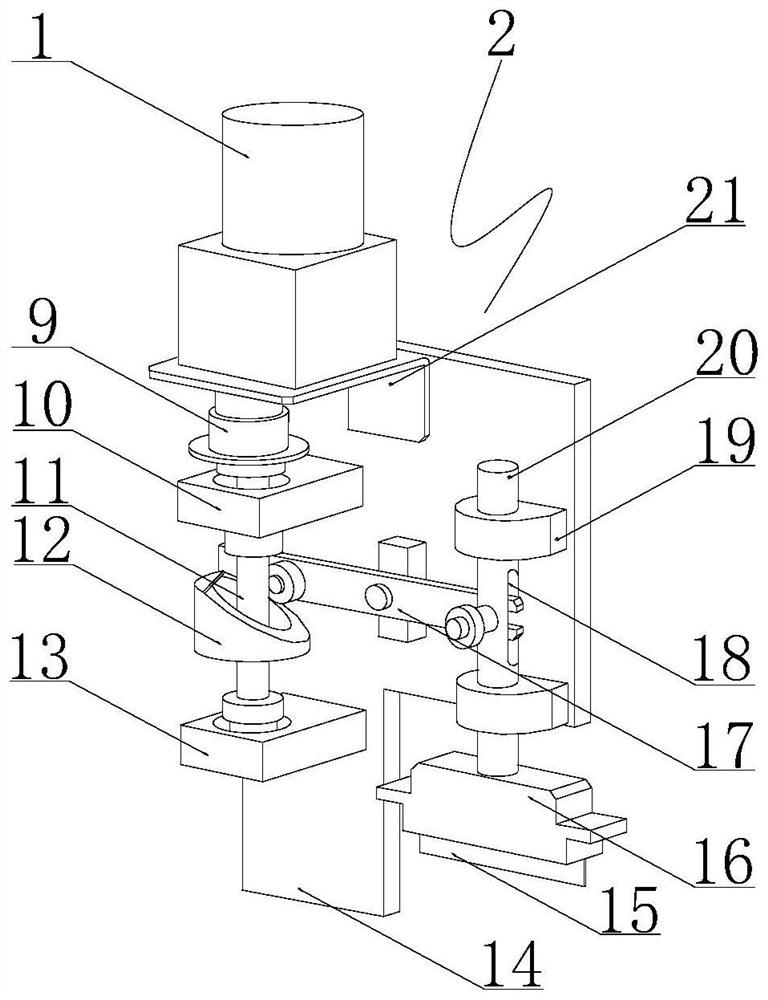

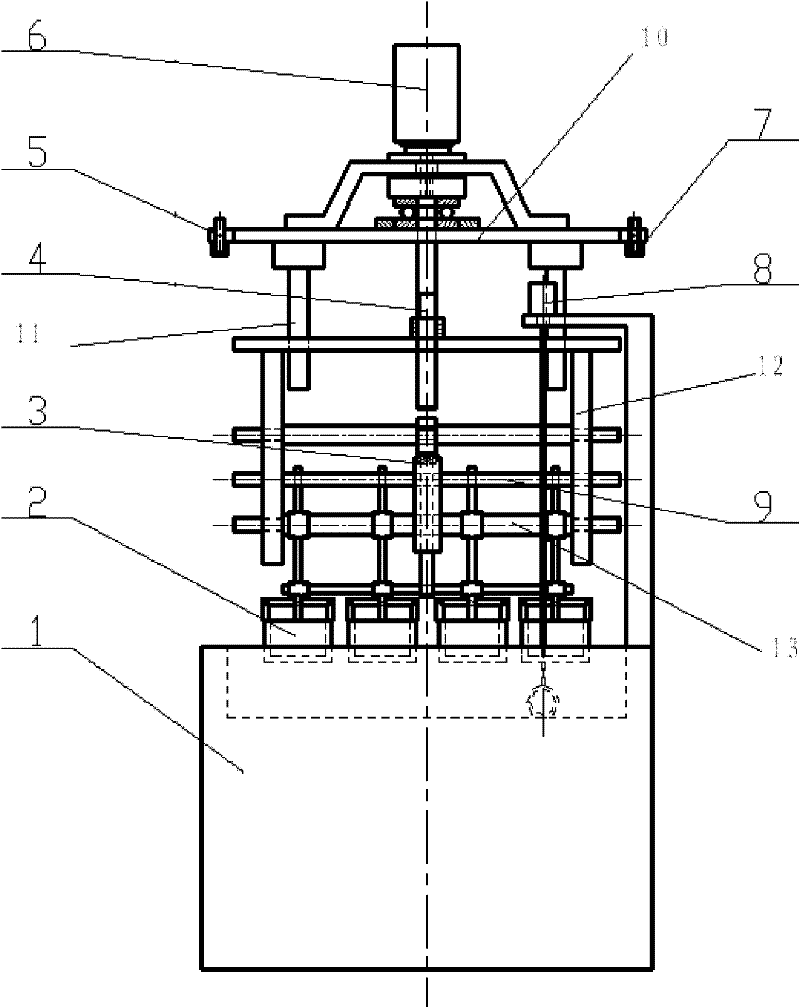

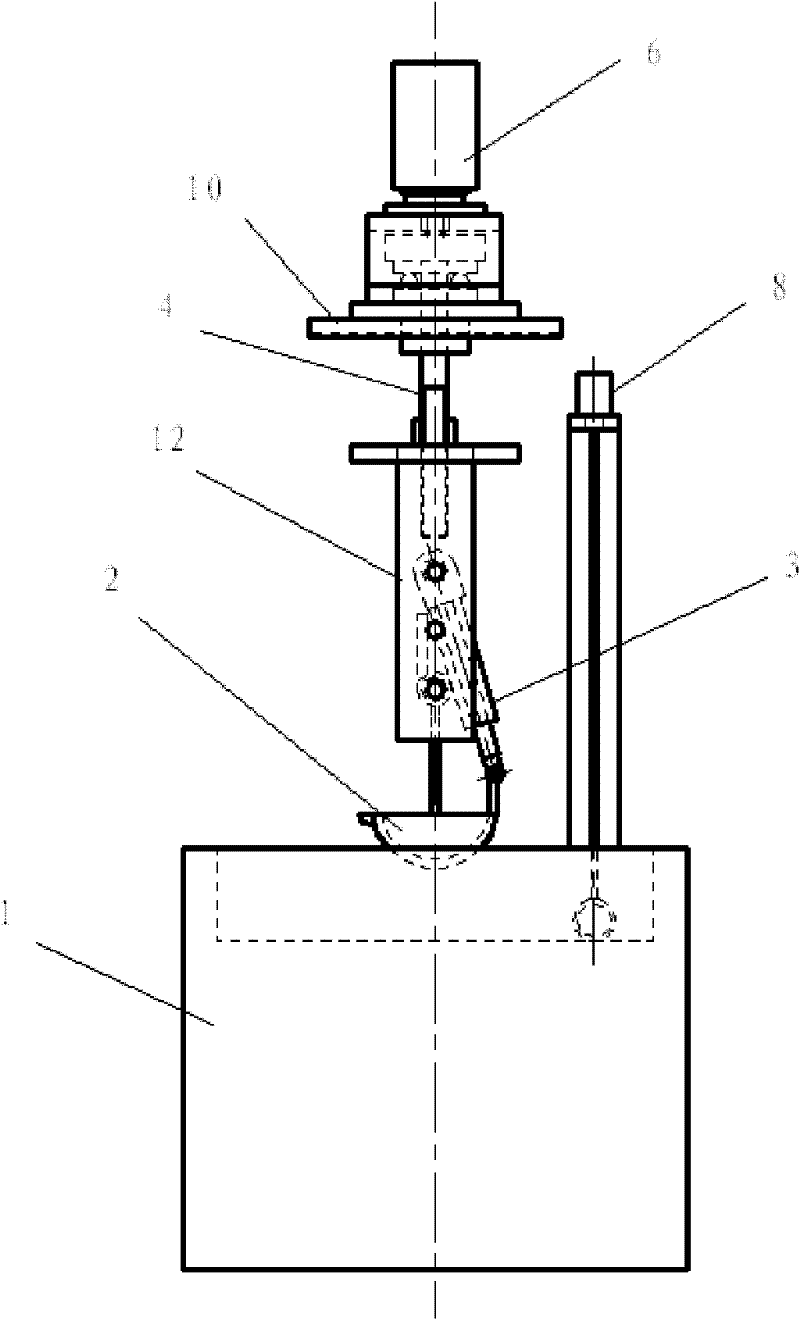

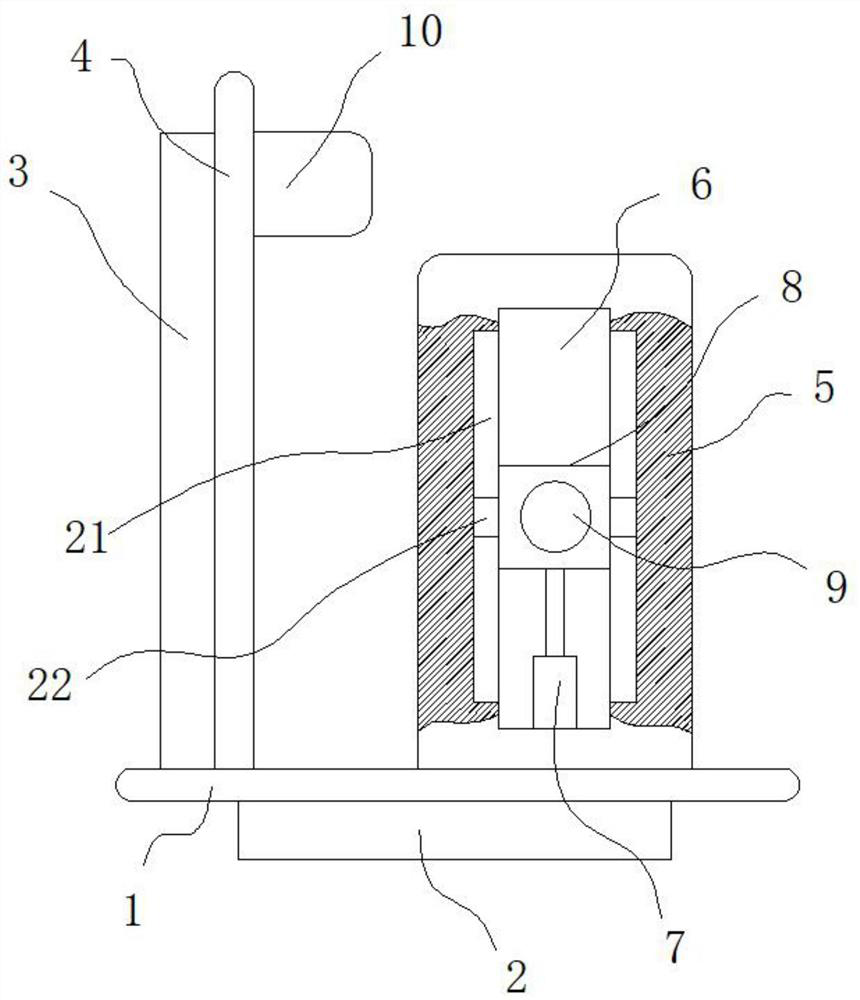

Automatic casting machine of cadmium ingot

InactiveCN101890494ARealize taking liquidAchieve improvementMould handling equipmentsMolten metal conveying equipmentsButt jointIngot

The invention discloses an automatic casting machine of cadmium ingot. A bracket (10) is provided with a variable frequency motor (6) and a guide rod (11); the variable frequency motor (6) is connected with a screw structure (4) which is provided with a screw lifting bracket (12) in guide connection with the guide rod (11); the screw lifting bracket (12) is provided with a bailer rotating shaft (13) which is at least provided with a bailer (2); a bailer cylinder (3) is connected between the bailer (2) and the screw lifting bracket (12); a cadmium liquid pool (1) is provided with a liquid level sensor (8); a rotating shaft (16) is provided with a casting mould (15) and is connected with an overturn mechanism; the motor (14) is connected with a conveyer belt (18); and the casting machine operated on the guide rail (7) can be in butt joint with the cadmium liquid pool (1) and the casting mould (15). The invention has low labor intensity and high casting efficiency, can prevent oxidation of cadmium liquid, and ensures stable and accurate casting amount.

Owner:ZHUZHOU SMELTER GRP +1

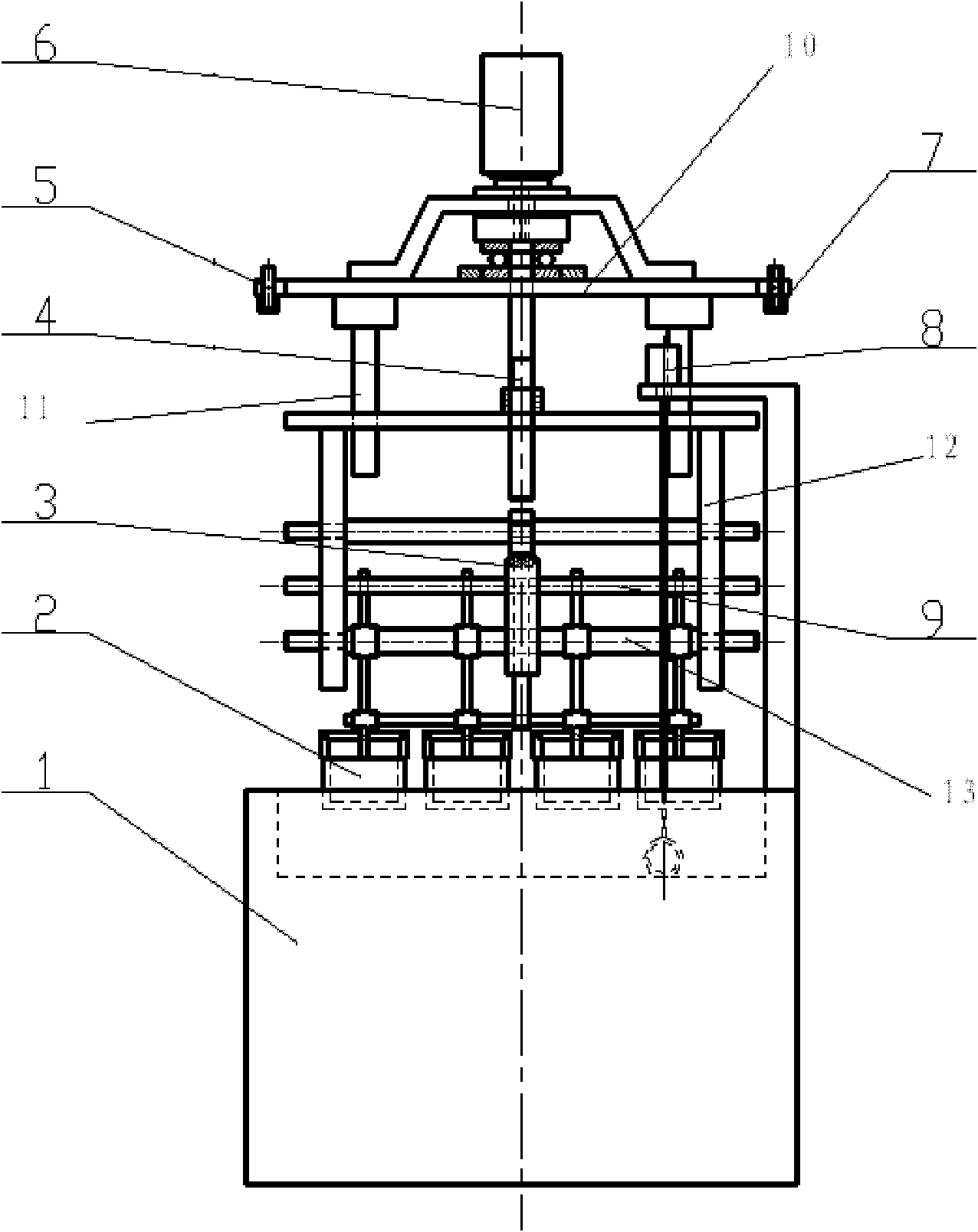

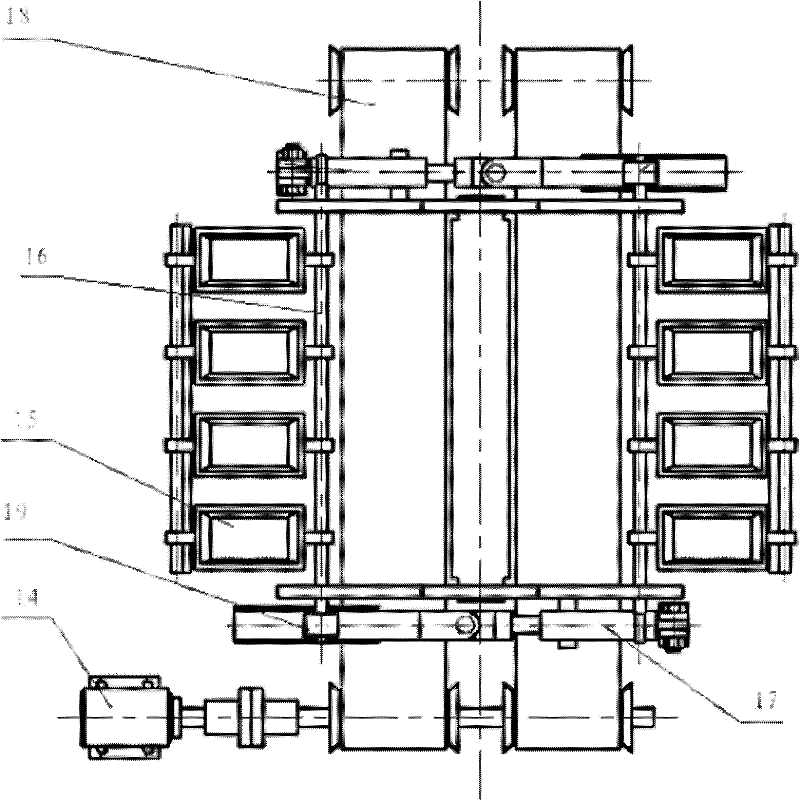

Water pouring device for electroplating travelling crane

InactiveCN102154677AImprove plating qualityAvoid mutual contaminationElectrolysis componentsEngineeringMechanical engineering

The invention relates to a water pouring device for an electroplating travelling crane. The water pouring device comprises a gantry, wherein the gantry is positioned on an electroplating bath; and a jig for accommodating a workpiece to be plated is arranged in the gantry, and is suspended on a top beam of the gantry through a suspension bracket. The water pouring device is characterized in that: the top of the suspension bracket is hinged with the top of the gantry, and can swing in the gantry along a hinge point between the suspension bracket and the gantry; two vertical walls of the gantry are provided with axle seats on the same side; the two axle seats are provided with coaxial axle holes; a connecting rod is arranged between the two axle seats; the two ends of the connecting rod are rotationally inserted into the axle holes on corresponding axle seats respectively; and one end of the connecting rod is connected with a power mechanism. The middle of the connecting rod is provided with a U-shaped bent section, so that the U-shaped bent section is discontinuously contacted with the jig in the rotating process of the connecting rod. Due to the adopting of the water pouring device for the electroplating travelling crane, the electroplating quality of the plated workpiece can be enhanced. The water pouring device is suitable for pouring electroplate liquid remained in the plated workpiece out when the jig accommodating the plated workpiece is lifted from the electroplating bath in the electroplating industry.

Owner:JIANGSU HONGLIAN ENVIRONMENTAL PROTECTION TECH CO LTD

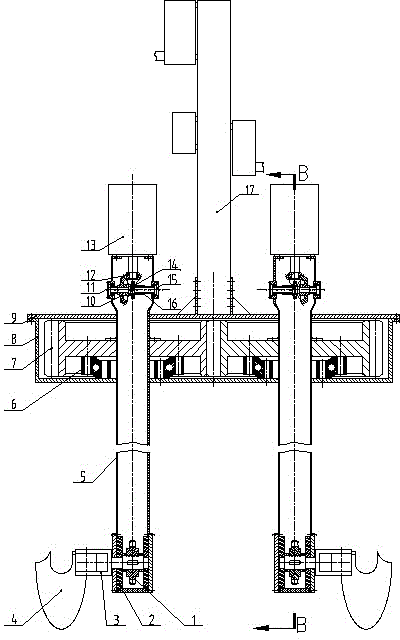

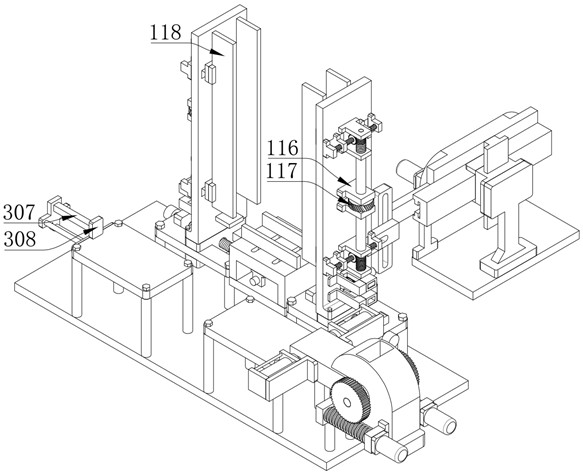

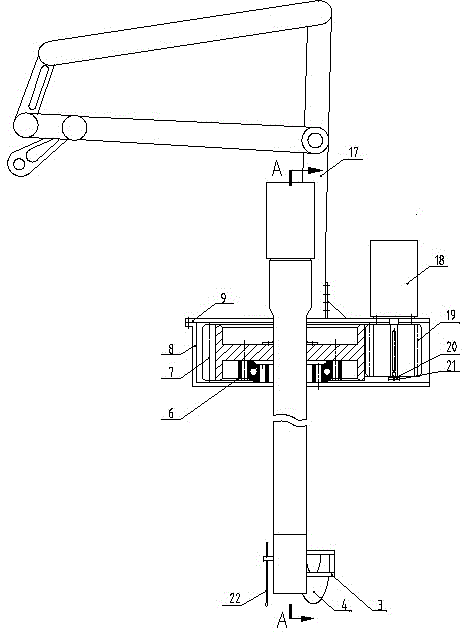

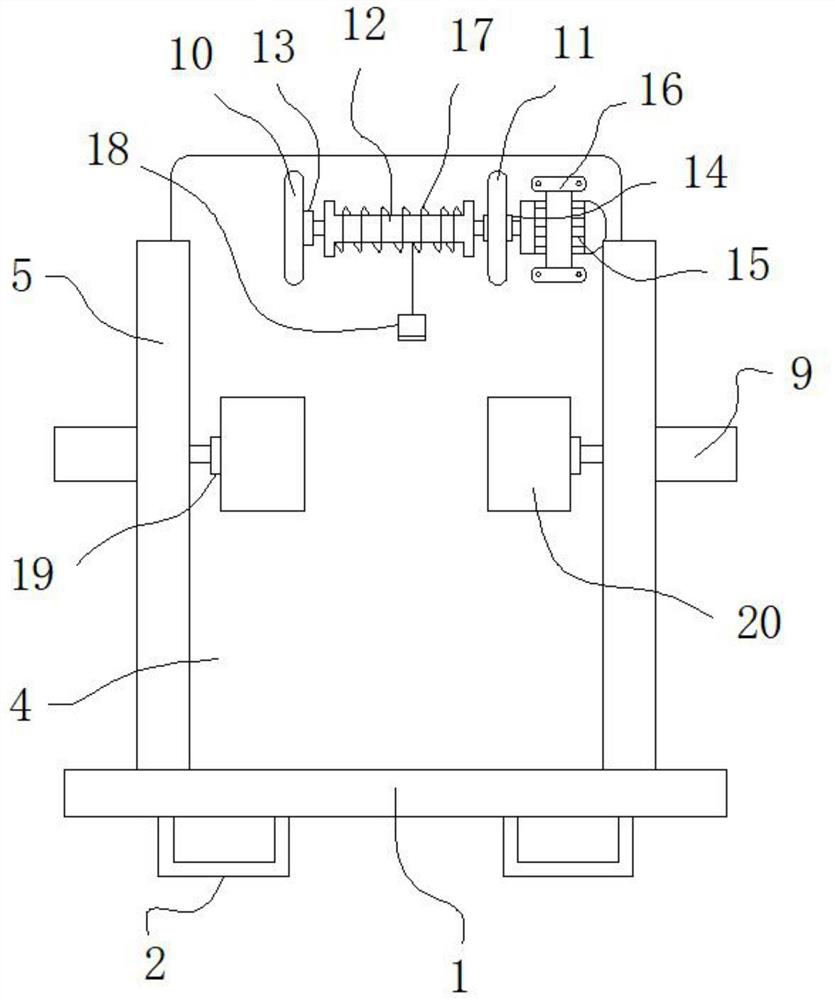

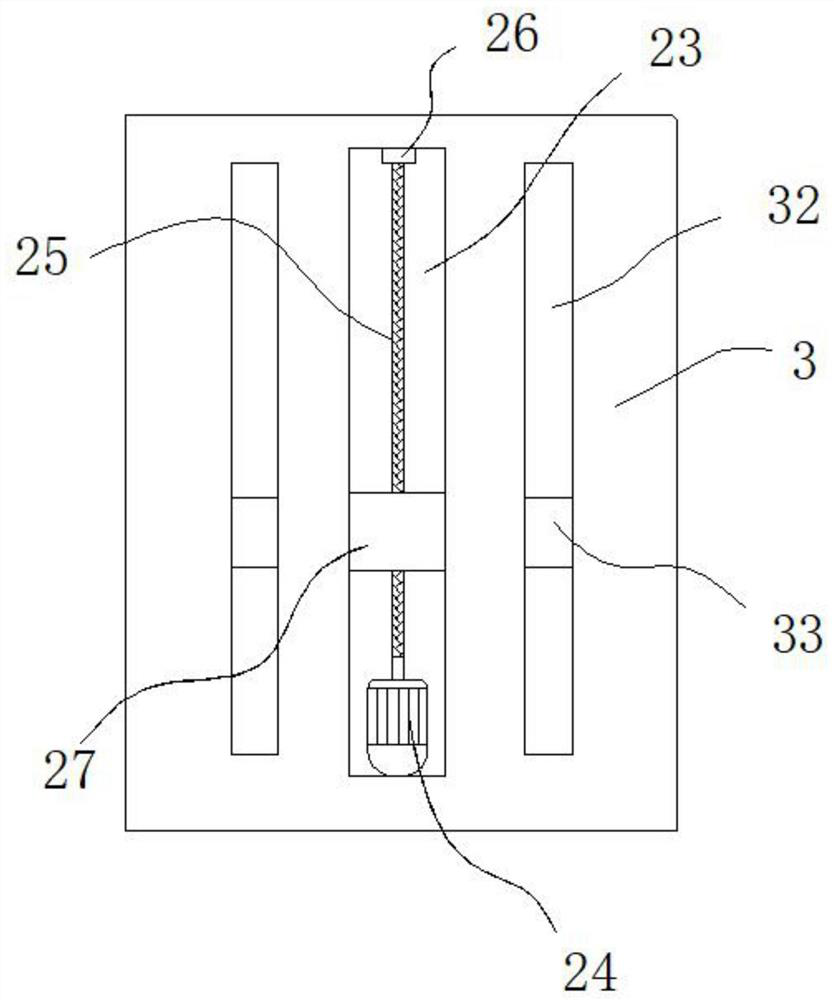

Five-rod fluid feeding machine double-pony ladle mechanical arm

ActiveCN103949623AAvoid interferenceSave production spaceMolten metal conveying equipmentsGear wheelEngineering

The invention discloses a five-rod fluid feeding machine double-pony ladle mechanical arm. The five-rod fluid feeding machine double-pony ladle mechanical arm comprises an arm driving mechanism and a pony ladle driving mechanism, wherein the arm driving mechanism is connected to a fixed plate; a gear mechanism is driven to rotate by a servo motor so as to drive the rotation of the mechanical arm; the pony ladle driving mechanism utilizes the servo motor to drive the gear mechanism to realize meshing motion, sprocket wheels on a sprocket shaft are driven, a sprocket wheel chain mechanism is driven, a pony ladle adjusting plate and a pony ladle are driven to rotate, and fluid fetching and injection actions are realized; the micro change of a position is realized by changing mounting holes in the adjusting plate, and the position is more accurate. The five-rod fluid feeding machine double-pony ladle mechanical arm is matched with a solution furnace with a small size for use, the problem that a mechanical arm double-pony ladle device intervenes with the solution furnace is solved, moulds with different distance sprues are poured, the mechanical arm can be mounted on a five-rod fluid feeding machine for use, the production cost is reduced, and the production efficiency is improved.

Owner:东台城东科技创业园管理有限公司

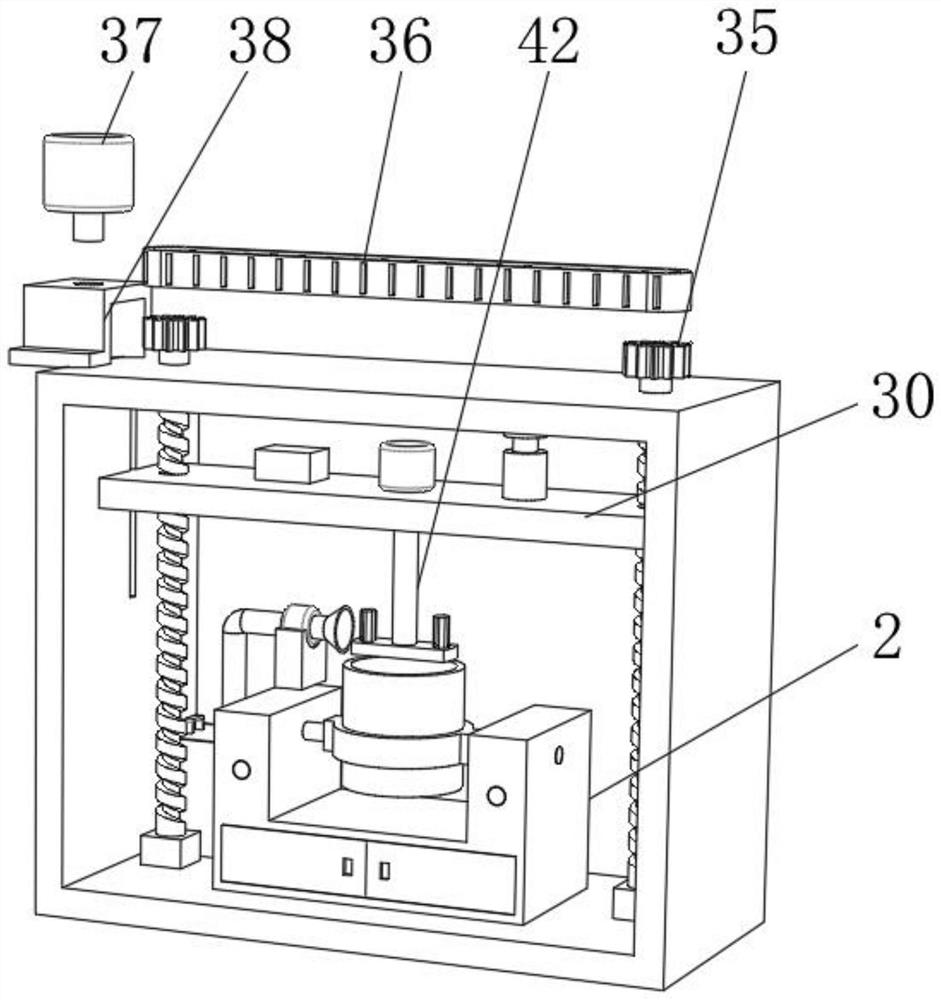

Anti-collision carrying device of robot

InactiveCN107879280AAvoid damageEasy to unloadSafety devices for lifting equipmentsLifting framesEngineeringSlide plate

The invention discloses an anti-collision handling device for a robot, which comprises a mounting cylinder vertically arranged on the side of the robot, a vertical threaded rod is movably installed on the inner wall of the mounting cylinder, and the lower part of the threaded rod is equidistantly threaded and socketed. There are three threaded sleeves, one side of the threaded sleeve is fixed with a sliding block, the side of the sliding plate is fixed with an overturning plate, the top of the overturning plate is hinged on the side away from the sliding plate with a bottom plate, and both sides of the bottom plate are fixed with a first side plate , the side of the two first side plates away from the sliding plate is fixed with a second side plate, and the lower end of the second side plate is fixed on the top side of the bottom plate, and the other end of the push rod motor is hinged on the bottom of the second side plate, The side of the second side plate away from the sliding plate is fixed with a mounting plate, the side of the mounting plate away from the second side plate is uniformly fixed with an anti-collision device, and the end of the anti-collision device away from the mounting plate is fixed with an anti-collision plate. The invention has unique structure, ingenious design, high creativity and is suitable for popularization.

Owner:王静静

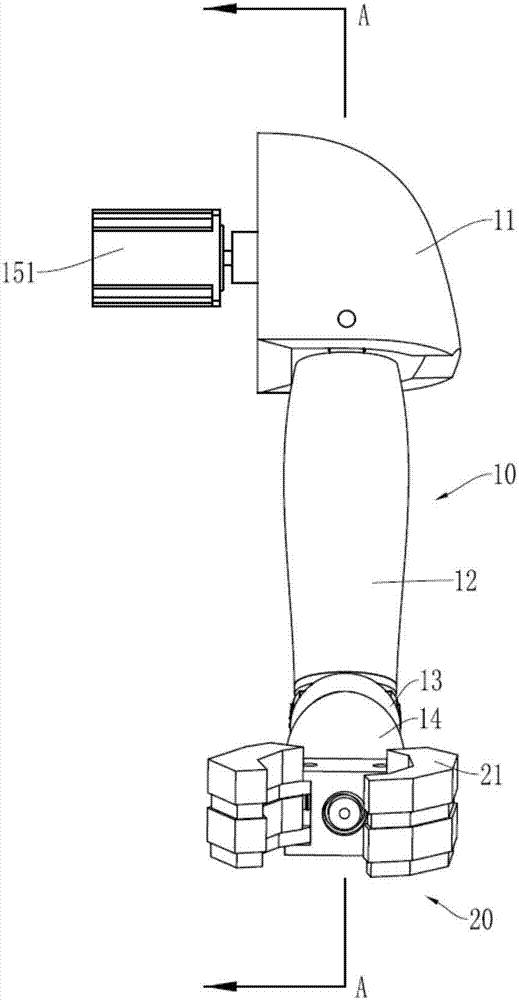

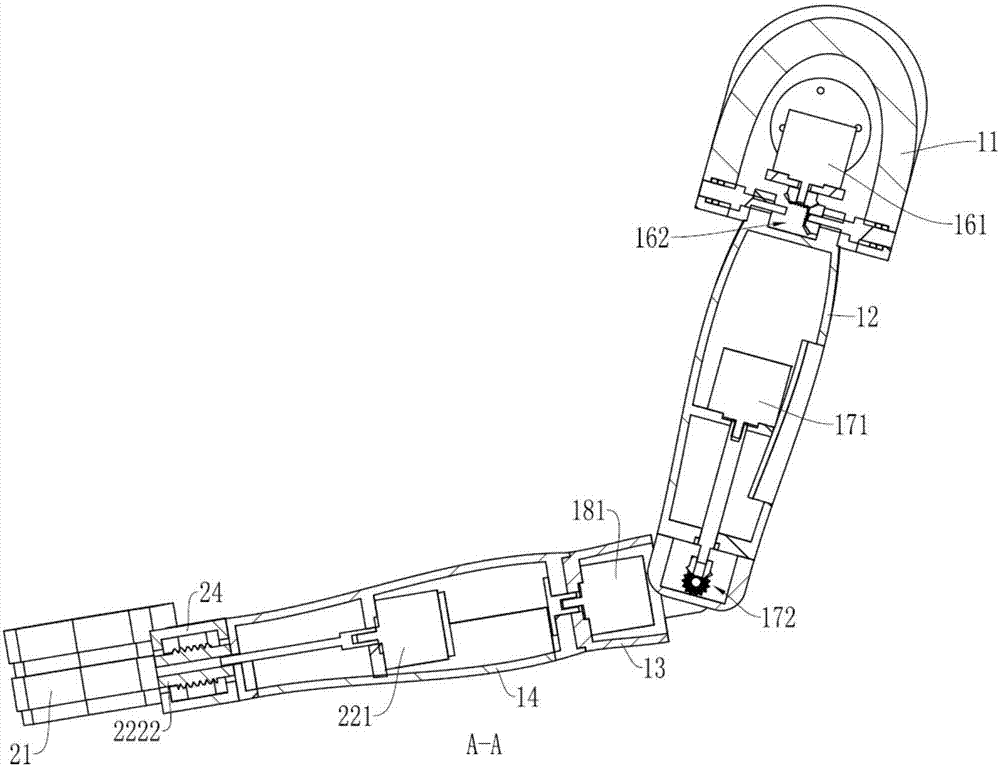

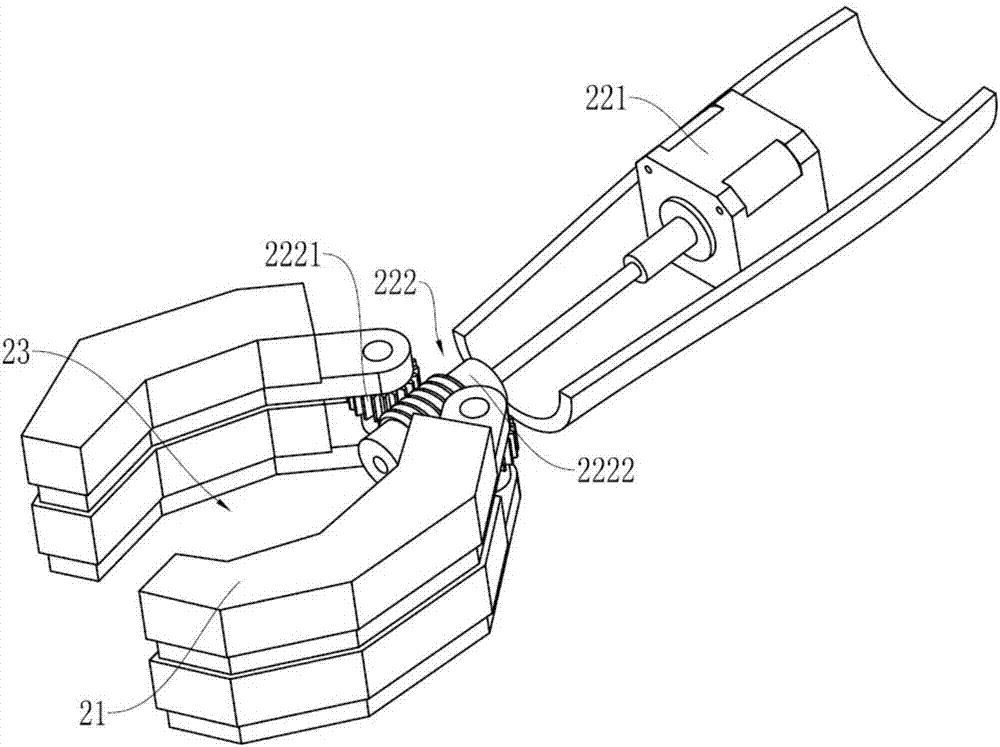

Mechanical arm structure of robot

The invention relates the technical field of robots, and discloses a mechanical arm structure of a robot. The mechanical arm structure comprises a arm structure and a mechanical claw structure, wherein the arm structure comprises a shoulder part, a first arm, a second arm and a third arm which are rotationally connected with one another in sequence to form four degrees of freedom, wherein the shoulder part is used for being rotationally connected to a robot body so as to realize front-and-back swing of the whole arm structure; the first arm can rotate around the shoulder part to realize the swing toward the inner side and outer side of the robot; the second arm can rotate around the first arm to enable the arm structure to be lifted or put down; the third arm can rotate around the second arm to enable the third arm to rotate in left-and-right sides; the mechanical claw comprises a clamping claw which is rotatably arranged on the third arm; and the clamping claw can rotate to realize grabbing of wine bottles. The mechanical arm structure of the robot has the beneficial effects that after the wine bottles are grabbed by the mechanical claw, and a series of actions of wine pouring canbe completed by utilizing the four-degree-of-freedom arm structure to move the wine bottles; the wine pouring efficiency is high, and wine pouring is not required to be carried out by dragging a pipeline.

Owner:GUANGZHOU COLLEGE OF SOUTH CHINA UNIV OF TECH

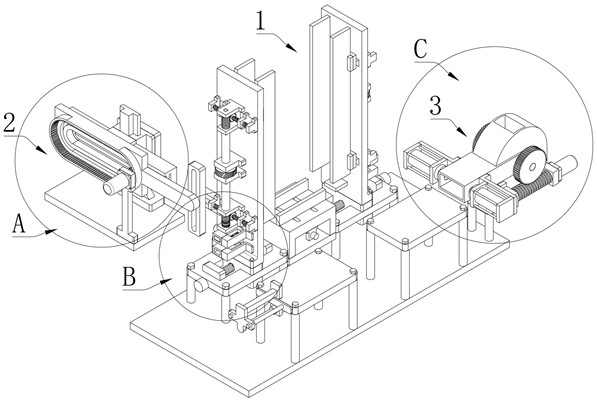

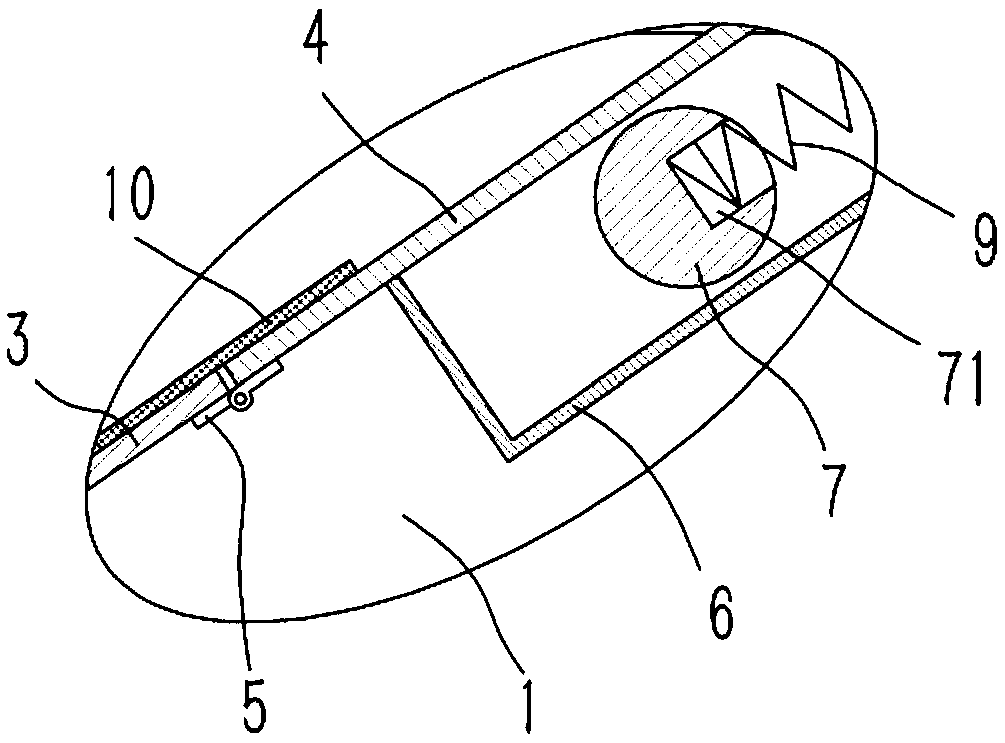

Cap opening self destroying type anti-fake bottle cap

ActiveCN109502178AEasy to useSolving Recycling ProblemsPackage recyclingContainer decorationsEngineeringBottle cap

The invention discloses a cap opening self destroying type anti-fake bottle cap, and belongs to the technical field of bottle caps. The cap opening self destroying type anti-fake bottle cap comprisesan upper cap, a lower cap and a self destroying device; the upper cap is provided with an anti-fake zone for pasting an anti-fake label and is movably connected with the lower cap; the upper cap and the lower cap are internally provided with cavities penetrating through the top walls of the upper cap and the lower cap, and the self destroying device is movably arranged in the cavities; the self destroying device comprises an upper fixing plate, a fixing column connected with the upper fixing plate and a self destroying rod, and the upper fixing plate is arranged at the top of the upper cover;the fixing column is arranged in the upper cap and the lower cap and movably connected with the inner wall of the lower cap; the anti-fake label is arranged at the tops of the upper fixing plate and the upper cap; and one end of the self destroying rod is connected to the upper fixing plate, and the other end of the self destroying rod extends to the top of the upper cap and abuts against the anti-fake label. According to the cap opening self destroying type anti-fake bottle cap, the effect that the anti-fake label is destroyed when the cap is opened in the first time, self destroying is achieved, the bottle cap cannot be recycled, and the disassembling prevention effect is realized; and the structure is stable, using is convenient, and the practicality is high.

Owner:HANGZHOU WOPUWULIAN SCI & TECH

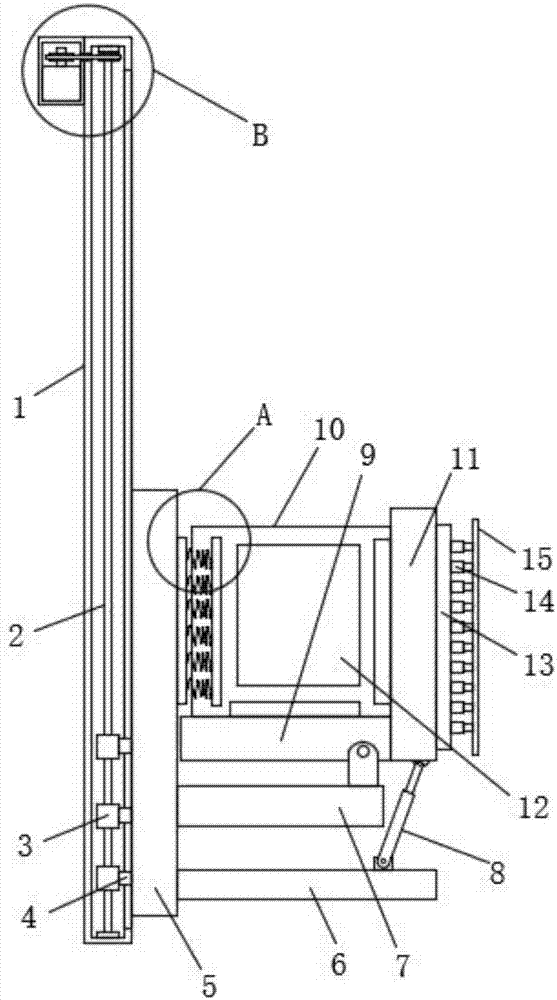

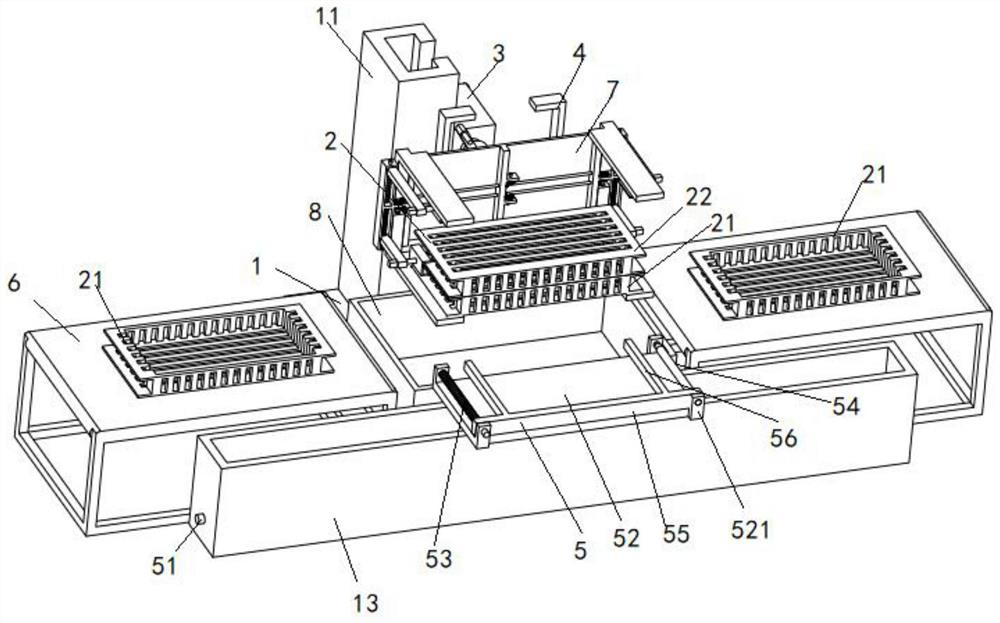

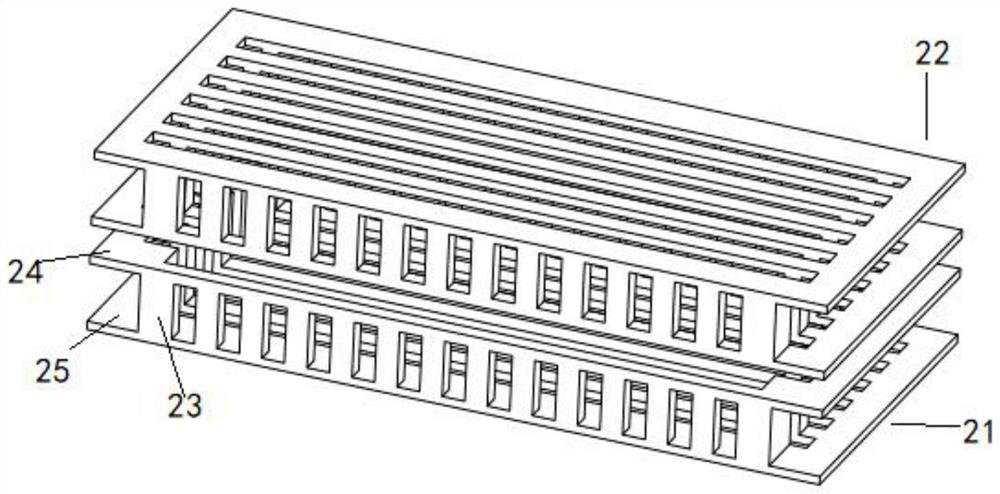

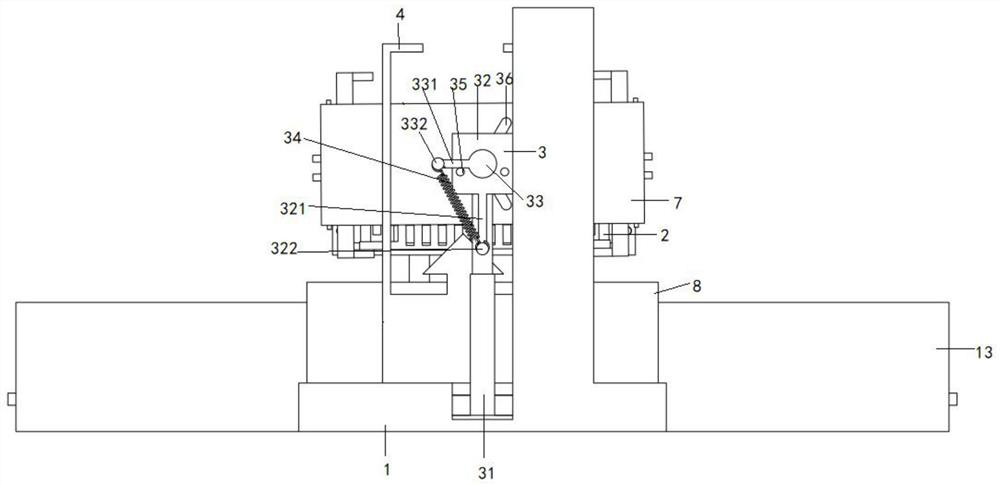

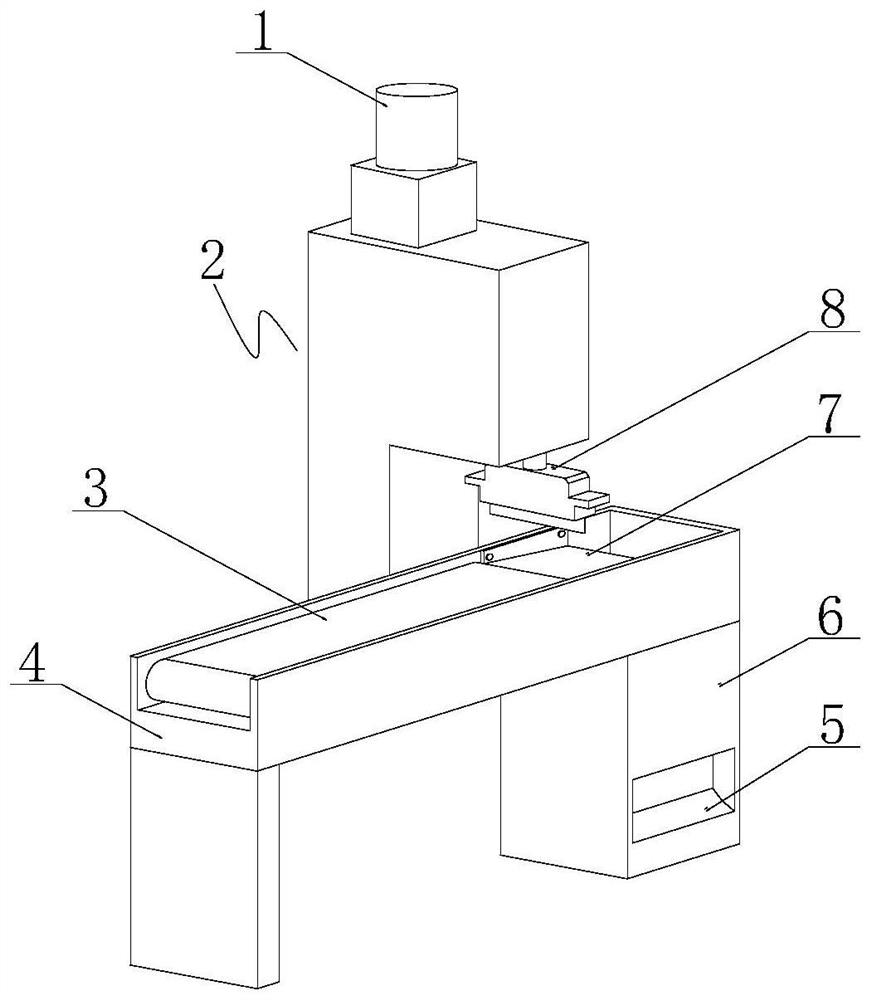

IC chip detecting loading tool

ActiveCN113816118AEasy to operateGuaranteed accuracyConveyorsElectronic circuit testingReciprocating motionEmbedded system

The invention discloses an IC chip detecting loading tool, and belongs to the related technical field of semiconductor detection or material conveying. The tool comprises a placing assembly, a feeding assembly is arranged at one side of the placing assembly, and a pouring-out assembly is arranged at the other side of the placing assembly. When the IC chip detecting loading tool is used for IC chip detection, loading operation of an IC chip is facilitated, when IC chip loading is carried out, self-adaptive adjustment can be carried out according to the specific structure of a packaging box, then the loading accuracy of the packaging box is ensured, meanwhile, stable discharging can be carried out, the packaging box is pushed in a reciprocating motion manner, the packaging box pushing efficiency is improved, the packaging box can be automatically overturned, pouring out of the IC chip in the packaging box is achieved, meanwhile, when the IC chip is poured out, one end of the packaging box can be limited, so that the stability of the packaging box during overturning is ensured, and higher practicability is achieved.

Owner:四川明泰微电子科技股份有限公司

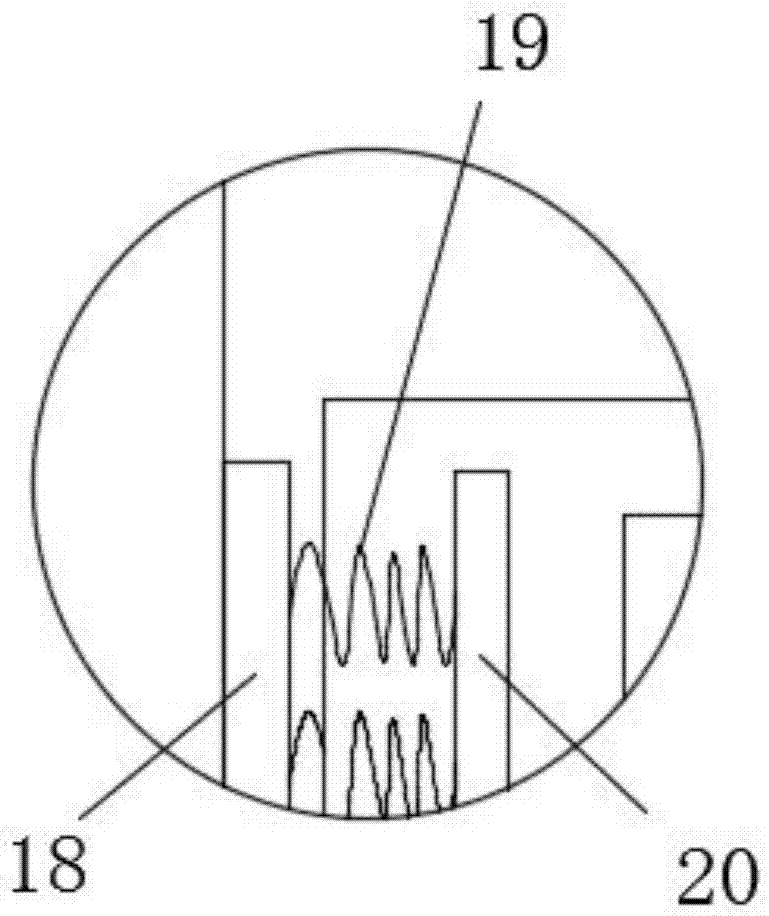

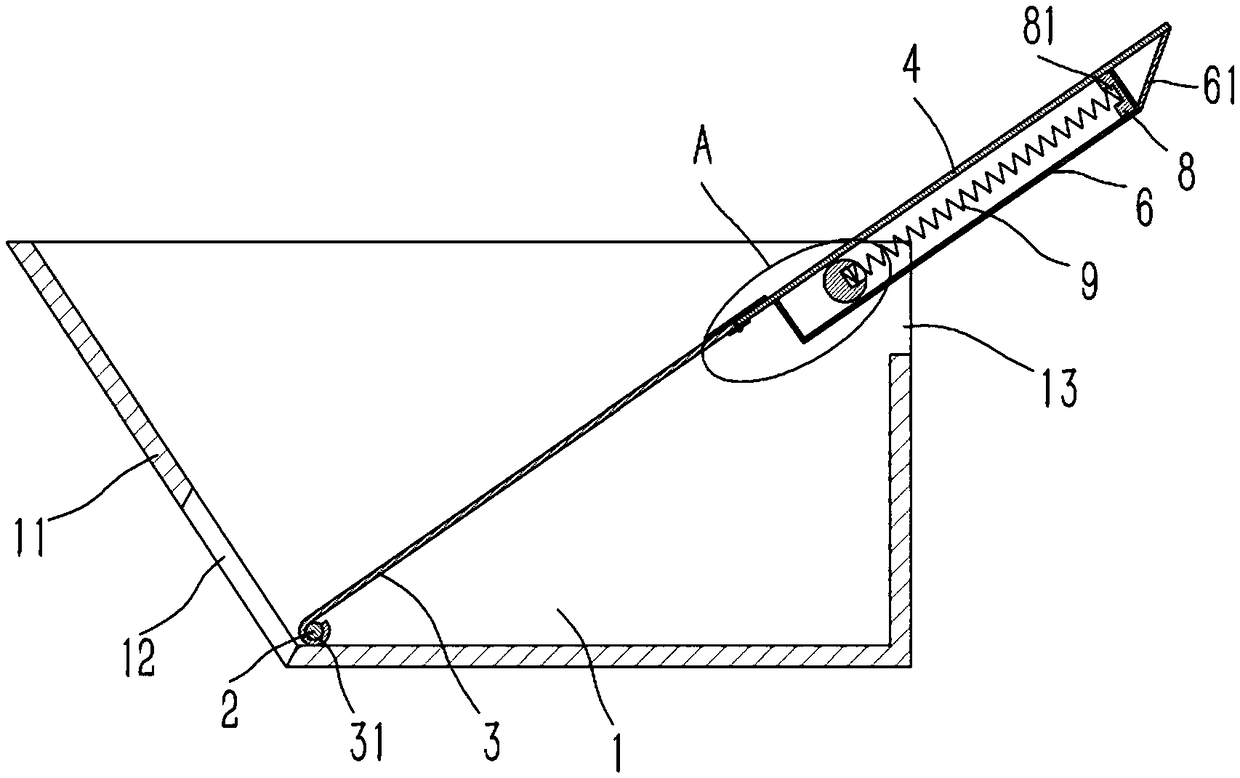

Flow guide device in mineral conveying vehicle

The invention discloses a flow guide device in a mineral conveying vehicle. The flow guide device comprises a car hopper. An inclined side wall is formed on one side of the car hopper. A discharge port is formed in the lower end of the inclined side wall. A horizontal supporting shaft is inserted into the portion, close to the discharge port, of the car hopper. An inclined lower flow guide plate and an inclined upper flow guide plate are arranged in the car hopper. The upper side of the lower flow guide plate is hinged with the lower side of the upper flow guide plate through a plurality of hinges. The lower side of the lower flow guide plate is bent to form a circular-arc-shaped shaft sleeve. The supporting shaft is sleeved with the shaft sleeve in an inserting manner. The two ends of thesupporting shaft are fixedly inserted into the two opposite side walls of the car hopper. A right-angled-C-shaped guide outer frame is fixed on the lower end face of the upper flow guide plate. A horizontal guide roller shaft is inserted into the guide outer frame, and both ends of the guide roller shaft are hinged on the two opposite side walls of the car hopper and distributed at the upper endof the car hopper. The flow guide device capable of automatically discharging minerals in a turnover transport vehicle can realize the purpose that all the minerals in the turnover transport vehicle can be poured out of the transport vehicle without manpower.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

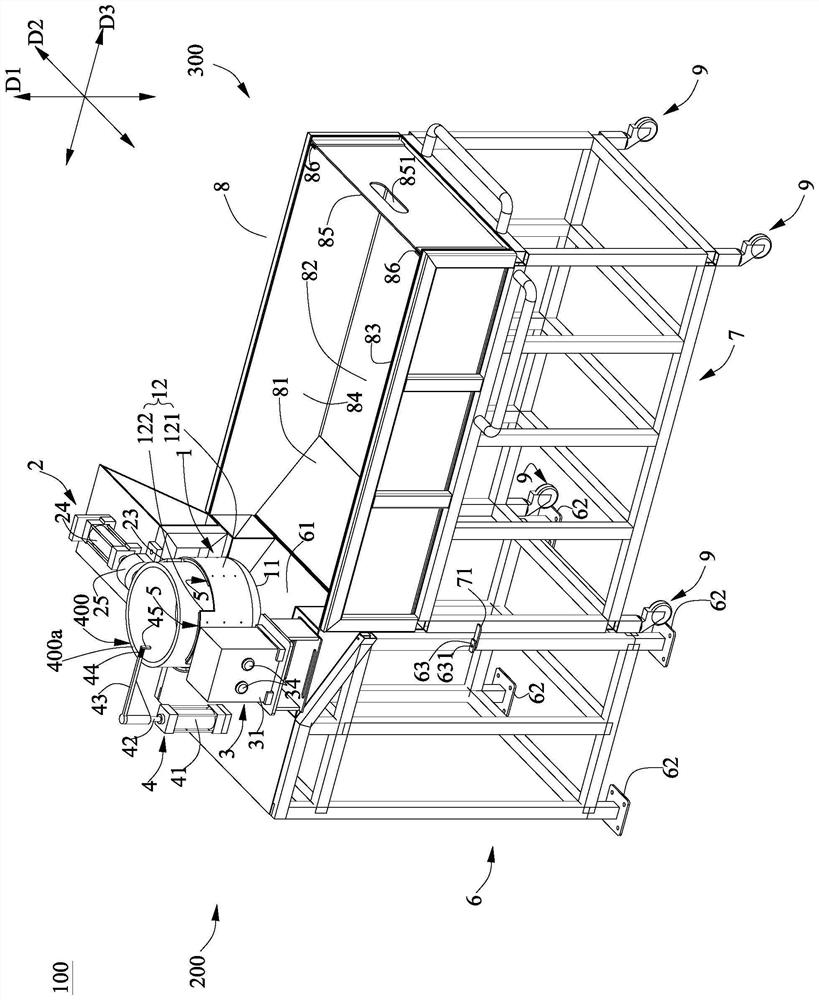

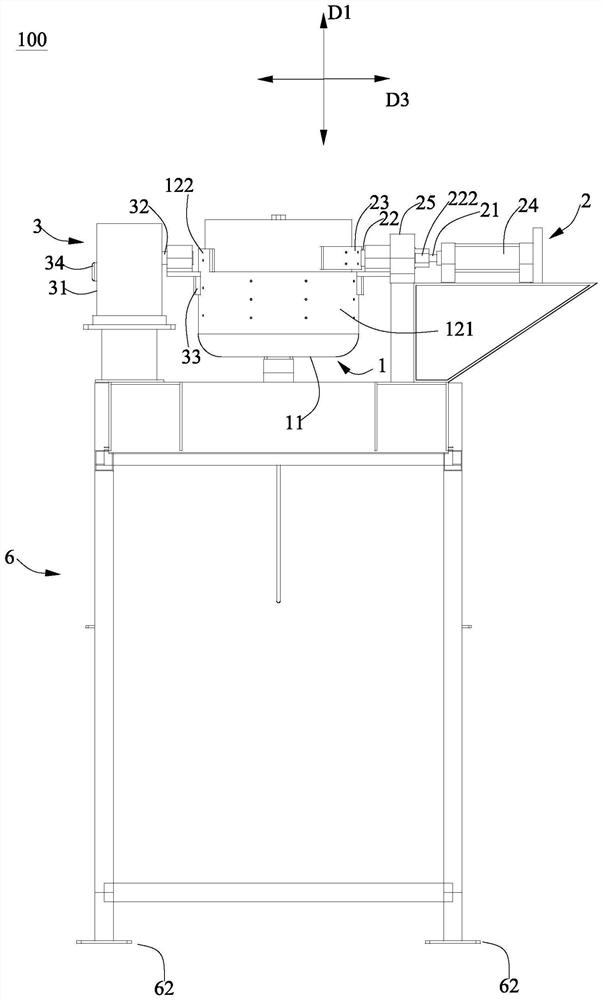

Automatic unpacking, unloading and recycling device for ton bags and working method

PendingCN111994400AImprove work efficiencyReduce labor intensityFlexible bulk container emptying systemsMechanical engineeringSuspender belt

The invention relates to an automatic unpacking, unloading and recycling device for ton bags and a working method. The automatic unpacking, unloading and recycling device comprises a lifting mechanism, wherein the lifting mechanism is connected with a lifting vehicle; the lifting vehicle is rotatably connected with a charging barrel; the charging barrel is connected with a turnover driving mechanism arranged on the lifting vehicle; a hook driving mechanism is arranged on the bottom of the charging barrel; the hook driving mechanism is connected with a hook; the hook can hold a hanging belt arranged on the bottom of a ton bag; a hopper is arranged below the tail end of the lifting mechanism; a guide grate which is arranged in an inclined mode is arranged in the hopper; a material conveyingmechanism is arranged below a discharge hole of the hopper; and a ton bag packing machine is arranged at one side of the tail end of the guide grate. The automatic unpacking, unloading and recycling device is high in working efficiency, is low in labor intensity, and avoids resource waste.

Owner:山东森烨生态工程有限公司

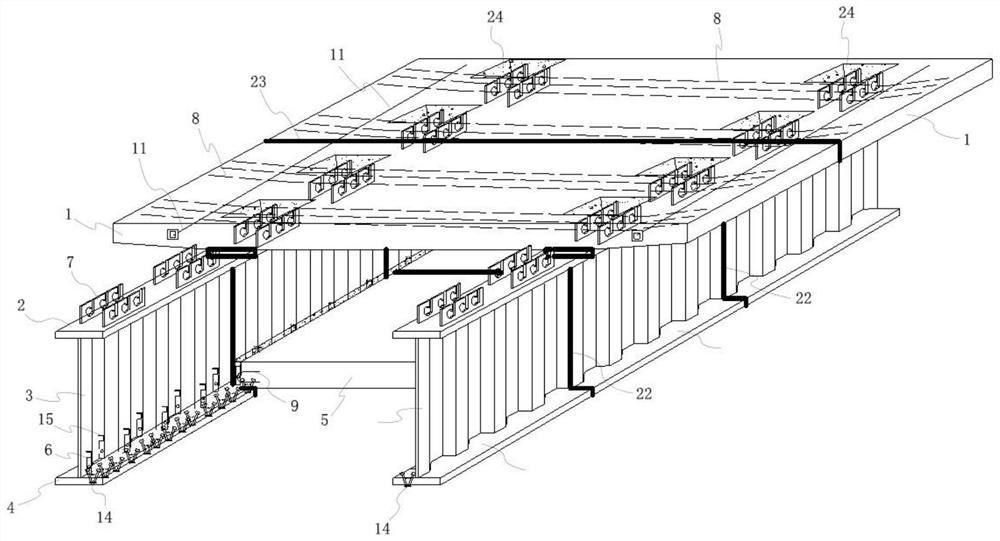

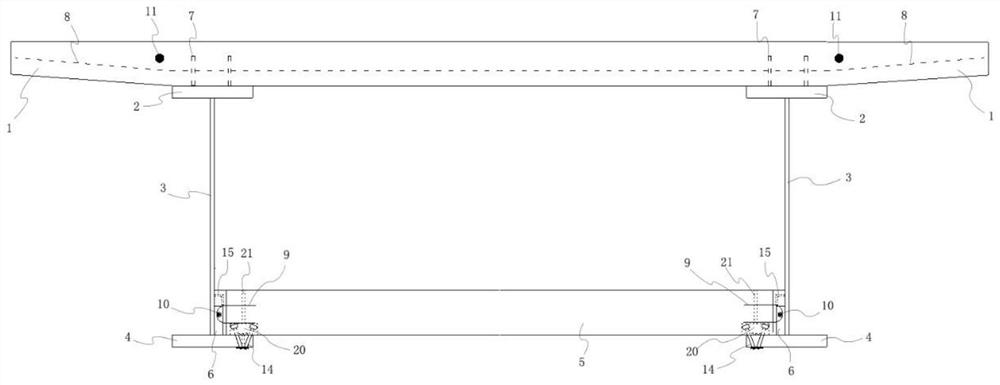

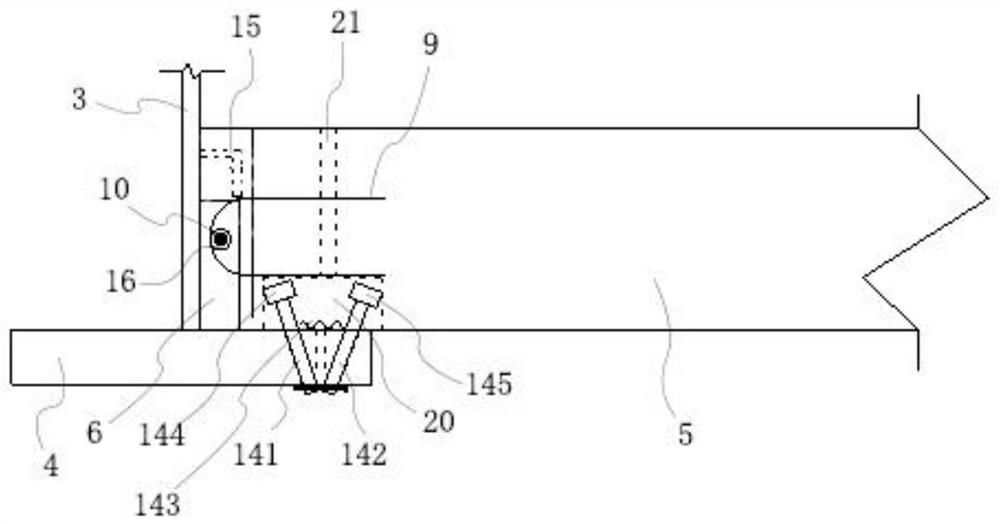

Assembly type corrugated steel web cantilever prefabricated assembled bridge structure and construction method

ActiveCN113565005AImprove integrityImprove reliabilityBridge structural detailsBridge erection/assemblyBridge engineeringEngineering

The invention discloses an assembly type corrugated steel web cantilever prefabricated assembly bridge structure and a construction method, and belongs to the technical field of bridge engineering construction.The assembly structure comprises corrugated I-shaped steel, a prefabricated top plate, an upper flange steel plate fixedly arranged on the top of the corrugated I-shaped steel, and a prefabricated bottom plate; the prefabricated top plate is fixedly arranged on a lower flange steel plate at the bottom of the corrugated I-shaped steel; the prefabricated bottom plate is close to the side end and is positioned and connected to the lower flange steel plate through a plurality of self-adjusting connecting pieces in the longitudinal direction, and a concrete pouring gap is formed between the side end of the prefabricated bottom plate and the corrugated I-shaped steel. In a concrete pouring gap, the corrugated I-shaped steel is fixedly provided with a plurality of outer wrapping connecting pieces provided with first through holes in the longitudinal direction, the side end of the prefabricated bottom plate is fixedly provided with a plurality of U-shaped steel bars in the longitudinal direction, and the U-shaped steel bars and the first through holes are arranged in a staggered mode in the longitudinal direction and are arranged on the same longitudinal steel bar in a penetrating and sleeving mode. According to the splicing structure, the bridge and the method, the structural integrity, the construction efficiency and the construction precision are improved.

Owner:JSTI GRP CO LTD +1

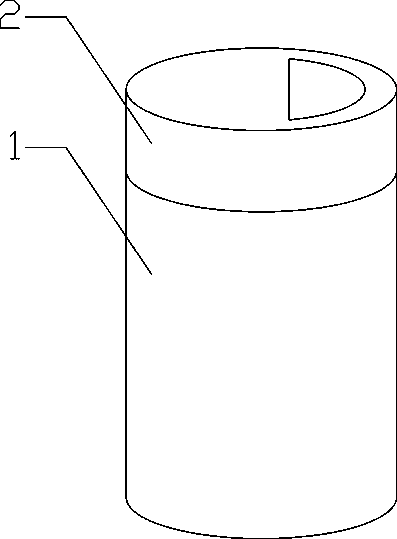

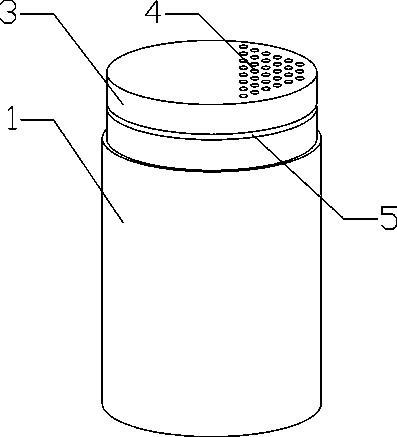

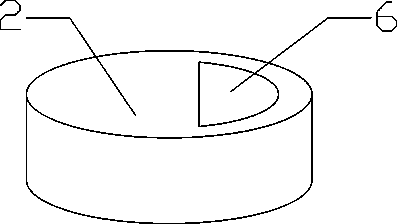

Storage tank

The invention discloses a storage tank. The storage tank comprises a tank body, an inner cover is arranged on the tank body, and is in threaded connection with the tank body, first through holes are formed in the top face of the inner cover, the inner cover is also sleeved with the outer cover, and a second through hole is formed in the outer cover. A sliding groove is formed in the outer side wall of the inner cover, a sliding block is arranged on the inner side wall of the outer cover, the outer cover is connected with the inner cover through the sliding groove and the sliding block, and theouter cover can axially rotate on the inner cover. The hole diameter of the multiple first through holes is 1 cm to 2 cm, the second through hole is a semi-elliptical through hole, and the first through holes fall into the second through hole under the static state of the outer cover. According to the structure, by rotating the outer cover, the second through hole in the outer cover is aligned with the first through holes in the inner cover, pouring out of materials can be achieved, and meanwhile the pouring-out flow quantity of materials can be controlled according to the quantity of the aligned first through holes; when materials are not required to be poured out, materials in the tank body can also be ventilated through the through holes, and mildew caused by the airproof effect of cereal materials is avoided.

Owner:郑书宜

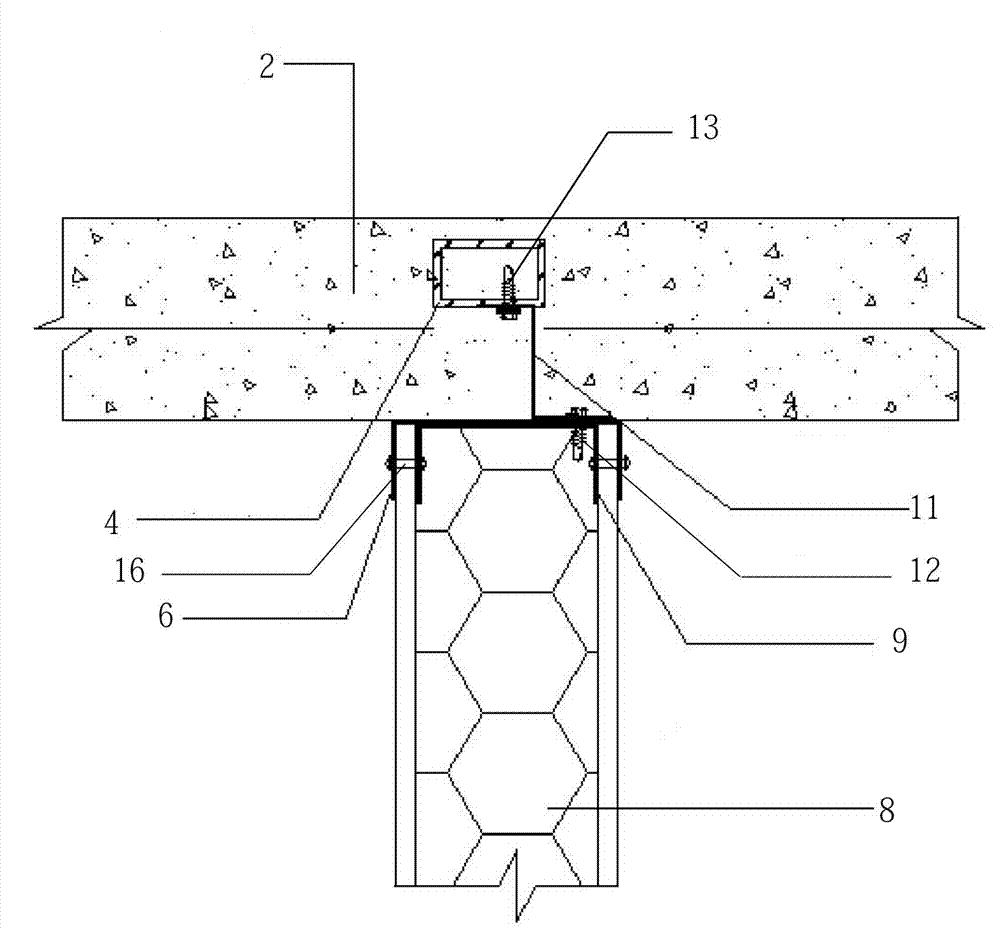

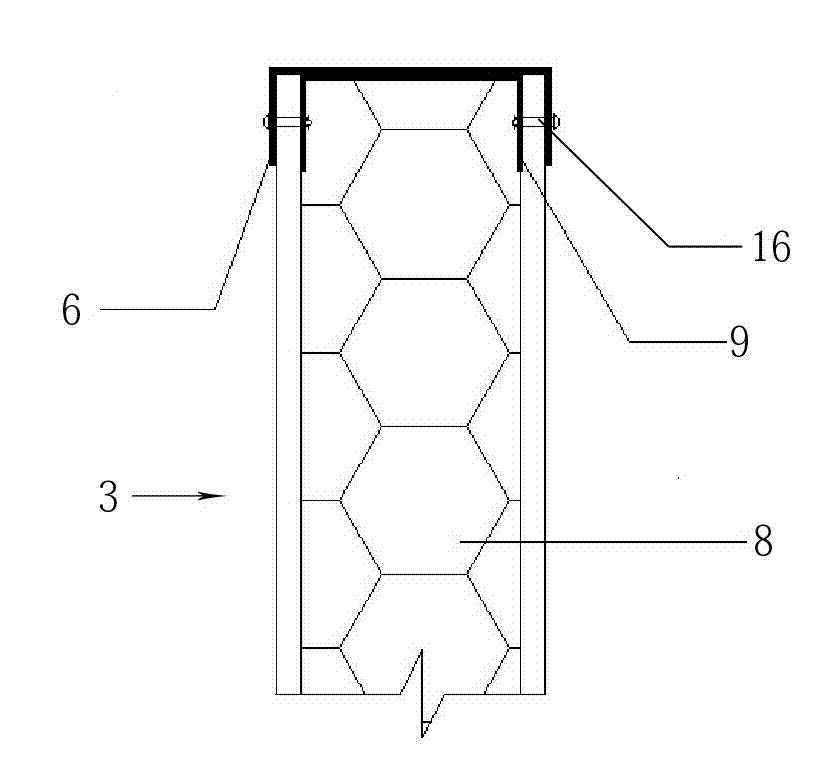

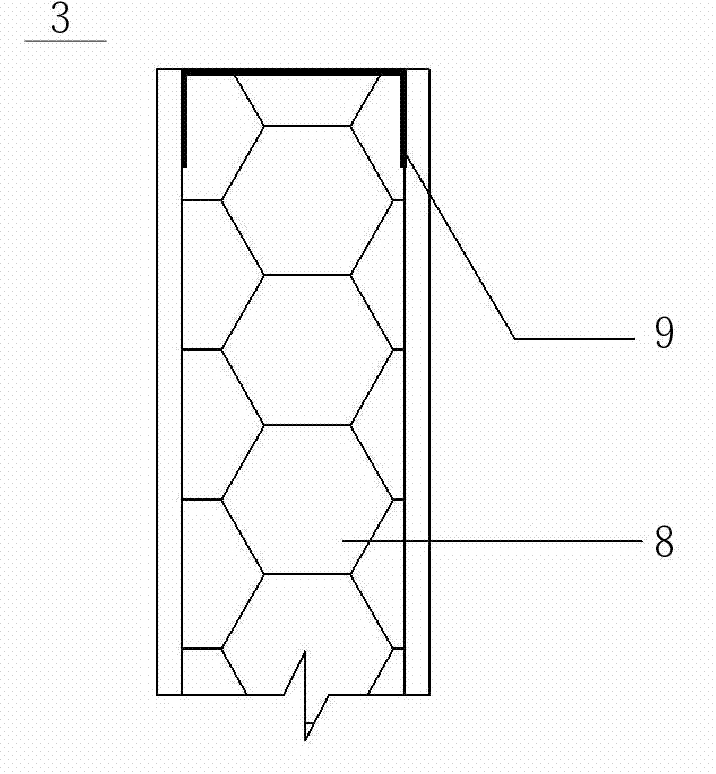

Method for connecting wall body and floor slab, special connecting structure thereof and prefabricated house

ActiveCN103031893AAchieve pouringSimple connection structureBuilding constructionsFloor slabPre embedding

The invention discloses a method for connecting a wall body and floor slabs, a special connecting structure thereof and a prefabricated house, wherein the prefabricated house comprises pre-embedded parts which are pre-embedded in the floor slabs, connecting embedded parts which are fixed at the top of the wallboard, connectors which are bridged between the connecting embedded parts and the pre-embedded parts, connecting grooves which are formed on the connecting embedded parts and extend in the length direction of the wall body; the connecting embedded parts are fixed on the wallboard through first fasteners; the lower ends of the connectors are fixed on the connecting embedded parts through second fasteners; and the upper ends of the connectors are fixed on the pre-embedded parts through third fasteners. Accordingly, the wallboard is installed and positioned and the floor slabs are formed by casting, the connecting structure between the wall body and the floor slabs is simplified, and the efficiency of building construction is increased.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

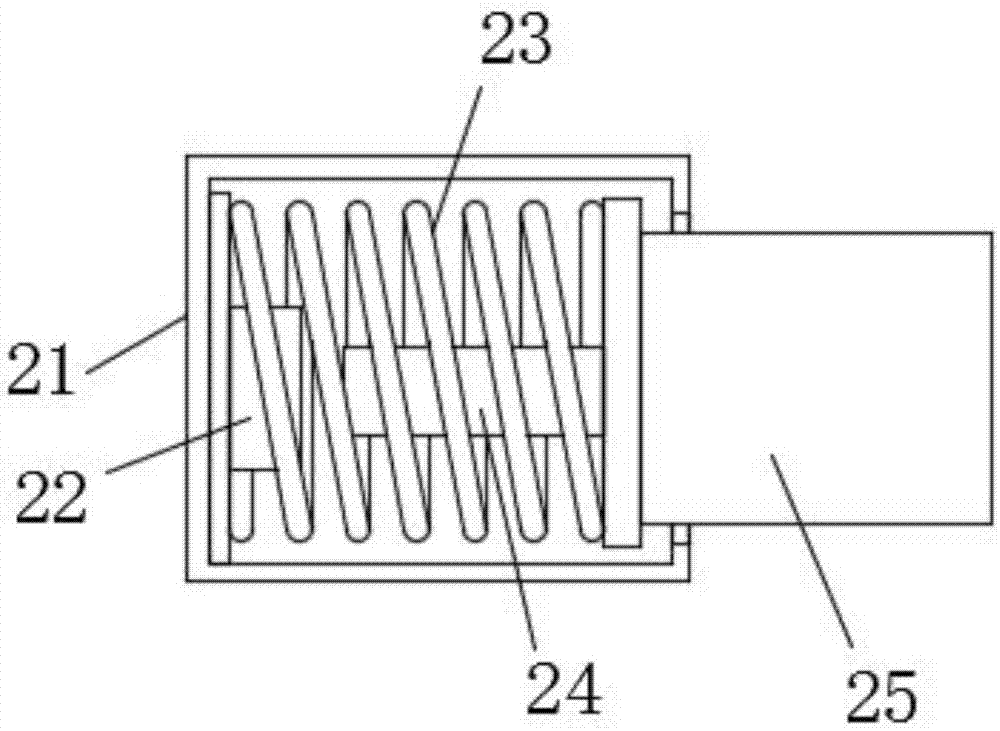

Manufacturing process of comprehensively-glazed ceramic

ActiveCN112339088AFull GlazingNo manual deliveryAuxillary shaping apparatusGlazeMechanical engineering

The invention discloses a manufacturing process of comprehensively-glazed ceramic. The ceramic is comprehensively glazed through an overturning type comprehensive glazing device in the ceramic manufacturing process. The overturning type comprehensive glazing device comprises a limiting and fixing base plate and a bearing frame assembly for containing the ceramic. A lifting and overturning mechanism and a positioning assembly used in cooperation with the lifting and overturning mechanism are installed on one side of the surface of the limiting and fixing base plate, and an adjusting and fixingglazing mechanism is installed on the lifting and overturning mechanism. By means of the overturning type comprehensive glazing device, the ceramic can be overturned after being glazed by dipping, then glaze in the ceramic with grooves is poured out in the overturning process; and then glazing by dipping is conducted, and therefore a contact part of the ceramic can also be dipped with the glaze.

Owner:广东顺辉新型材料科技有限公司

Water pouring device for electroplating travelling crane

InactiveCN102154677BImprove plating qualityAvoid mutual contaminationElectrolysis componentsEngineeringMechanical engineering

The invention relates to a water pouring device for an electroplating travelling crane. The water pouring device comprises a gantry, wherein the gantry is positioned on an electroplating bath; and a jig for accommodating a workpiece to be plated is arranged in the gantry, and is suspended on a top beam of the gantry through a suspension bracket. The water pouring device is characterized in that: the top of the suspension bracket is hinged with the top of the gantry, and can swing in the gantry along a hinge point between the suspension bracket and the gantry; two vertical walls of the gantry are provided with axle seats on the same side; the two axle seats are provided with coaxial axle holes; a connecting rod is arranged between the two axle seats; the two ends of the connecting rod are rotationally inserted into the axle holes on corresponding axle seats respectively; and one end of the connecting rod is connected with a power mechanism. The middle of the connecting rod is provided with a U-shaped bent section, so that the U-shaped bent section is discontinuously contacted with the jig in the rotating process of the connecting rod. Due to the adopting of the water pouring devicefor the electroplating travelling crane, the electroplating quality of the plated workpiece can be enhanced. The water pouring device is suitable for pouring electroplate liquid remained in the plated workpiece out when the jig accommodating the plated workpiece is lifted from the electroplating bath in the electroplating industry.

Owner:JIANGSU HONGLIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Crucible pouring device

The invention provides a crucible pouring device. The crucible pouring device comprises a crucible frame, a clamping mechanism, a driving mechanism and a restraining mechanism. The crucible rack is used for accommodating a crucible containing a liquid substance; the clamping mechanism comprises a clamping piece, the clamping piece is used for pushing the part, exposed out of the crucible frame, of the crucible from one side in the radial direction of the crucible, and the clamping piece can rotate around the axis of the clamping piece; the driving mechanism is arranged on the opposite side of the crucible frame relative to the clamping mechanism, the driving mechanism is connected to the crucible frame, and the driving mechanism is used for driving the crucible frame and the crucible to rotate so as to pour out the liquid substance in the crucible; the restraining mechanism is arranged around the crucible frame and used for restraining the end wall of the opening of the crucible so as to restrain the crucible from sliding downwards in the axial direction of the crucible relative to the crucible frame when the crucible rotates to pour out the liquid matter in the crucible. Therefore, the crucible can be prevented from falling off from the crucible rack.

Owner:广东长信精密设备有限公司

Plastic medicine bottle cover

ActiveCN110723409AReasonable structureRealize pour on demandSmall article dispensingClosure with auxillary devicesMedicine bottle capEngineering

The invention discloses a plastic medicine bottle cover which comprises a cover body and is characterized in that a medicine storing sleeve connected with the center of the cover body is arranged at the upper end of the cover body; a cap is arranged at the upper port of the medicine storing sleeve; an annular cavity is formed between the lower end face of the medicine storing sleeve and the upperend face of the cover body; an adjusting sleeve is rotatably arranged on the periphery of the annular cavity; a control ring and a distance piece are arranged in the annular cavity; axial sliding andcircumferential drive joint are realized between the periphery of the control ring and the internal circumference of the adjusting sleeve; circumferential limiting and axial sliding fit are realized between the inner end of the distance piece and the center of the medicine storing sleeve; the outer end of the distance piece is arranged on the control ring in a relative rotation and penetrating manner; an elastic resetting piece is arranged between the distance piece and the medicine storing sleeve; an annular medicine discharging groove is formed in the upper end face of the cover body; a medicine inlet is formed in the lower end face of the cover body; a C shaped check ring is arranged in the medicine discharging groove; and a first area, a second area and a third area sequentially connected clockwise are arranged in the discharging groove corresponding to the opening of the C shaped check ring. The plastic medicine bottle cover is reasonable in structure and controllable in medicinedischarging quantity.

Owner:常熟市正天塑料制品有限公司

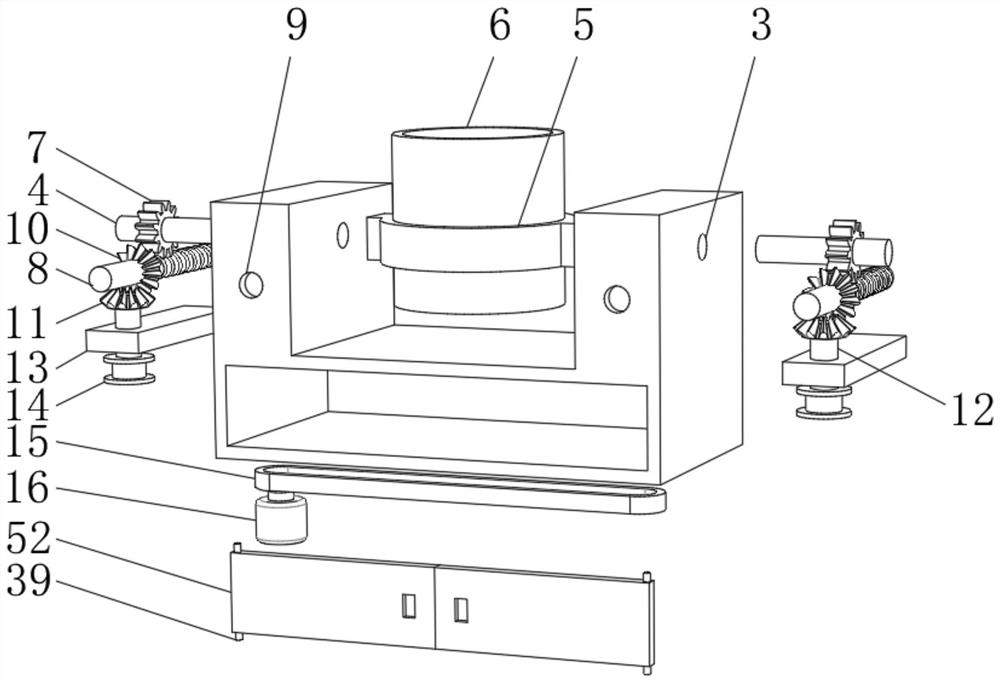

Broad bean frying machine for broad bean stir-frying processing and broad bean food processing method

InactiveCN112602951AAchieve pouringShorten the timeDispersed particle filtrationFood treatmentGear wheelElectric machinery

The invention relates to the technical field of broad bean stir-frying processing, and discloses a broad bean frying machine for broad bean stir-frying processing and a broad bean food processing method; the broad bean frying machine comprises an outer frame, the middle of the bottom of the inner wall of the outer frame is fixedly connected with a main body, and the main body is U-shaped. A first motor is started, a rotating shaft of the first motor drives gear shafts to rotate, the gear shafts on the two sides of the main body synchronously rotate under the matching effect of a synchronous wheel and a synchronous belt, then a second bevel gear is driven to rotate, and a first bevel gear is driven to rotate through meshing of the first bevel gear and the second bevel gear; a worm is driven to rotate under the matching action of a through hole, so that the turbine is driven to rotate, the rotating shaft is driven to drive a stir-frying box to turn over under the action of the shaft hole, broad beans in the stir-frying box are poured out, and problems that time and labor are wasted and the efficiency is low due to the fact that broad beans in the box need to be taken out manually through auxiliary tools are solved; the broad bean processing time is saved, the working efficiency is improved, and the processing speed is increased.

Owner:蒋浩澎

A New Concrete Mixer Convenient for Discharging

ActiveCN109955360BAchieve pouringAchieve left and right shakingCement mixing apparatusGear wheelTypes of concrete

The invention discloses a new type of concrete mixer convenient for discharging, which comprises a base, a mixing chamber, an eccentric wheel and a sector gear, a sleeve is fixedly connected to the top of the base, a movable rod is arranged inside the sleeve, and the bottom of the movable rod mixing chamber moves connection, the inner ring of the first connection bearing is inserted with the first connection shaft, the sector gear is sleeved on the first connection shaft, the sector gear meshes with the rack, the top of the second connection rod is installed with the second connection bearing, the second An eccentric wheel is sleeved on the connecting shaft, and the eccentric wheel is fixedly connected with a fixed rod at a position deviated from the center of the circle. Connected with the bottom plate of the mixing chamber, the second motor drives the movement of the sector gear to realize the left and right shaking of the mixing chamber to achieve uniform mixing. Opening the right wall of the mixing chamber can realize the complete pouring of the concrete, which is convenient for operation.

Owner:NANJING ROBOTICS RES INST CO LTD

A packaging medicine bottle

The invention discloses a packaging medicine bottle, which includes a bottle body and a cover body, and is characterized in that a drug storage sleeve connected to the center is arranged above the cover body, a cap is provided on the upper port of the drug storage sleeve, and the cover body and the drug storage body There is a ring-shaped scraper to rotate between the sleeves, and the outer circumference of the ring-shaped scraper is connected with a rotation adjustment sleeve; the upper end surface of the cover is provided with an annular locking groove and an annular drug guide groove arranged inside and outside the coaxial line, and the drug guide groove has a clockwise The first area, the second area and the third area are successively connected, and the lower end surface of the cover body is provided with a drug inlet hole, which is connected to the first area of the drug guide groove; the lower end surface of the scraper is provided with a number of equal intervals. Push piece, the push piece extends into the drug guide groove, and an isolation cavity is formed between two adjacent push pieces, the first drug outlet hole is provided on the scraper corresponding to the isolation cavity, and the corresponding drug storage sleeve above the third area of the drug guide groove The bottom is provided with a second medicine outlet hole, and the first medicine outlet hole can be rotatably connected to the second medicine outlet hole. The invention has an ingenious structure and realizes controllable medicine quantity.

Owner:永嘉企达知识产权咨询有限公司

Magnetic repulsion type liquid container based on inclined opening

The invention discloses a magnetic repulsion type liquid container based on inclined opening, and relates to the technical field of liquid containers. The magnetic repulsion type liquid container comprises a supporting mechanism, a storage mechanism and a sealing mechanism; the storage mechanism is located over the supporting mechanism and fixedly connected with the supporting mechanism; the sealing mechanism is located over the storage mechanism and connected with the storage mechanism in a clamped manner; the supporting mechanism is composed of a supporting assembly and a limiting assembly which are fixedly connected; the supporting assembly is fixedly connected with the storage mechanism; and the limiting assembly is clamped with the storage mechanism. Through the design of a first mounting groove, an elastic connecting piece, a driving magnet, a liquid discharging nozzle, a liquid outlet hole, a sealing elastic piece, a sealing magnet, a positioning ring and a sealing plug, the liquid pouring efficiency is greatly improved, meanwhile, a liquid discharging nozzle does not need to be opened by hands, pollution of the hands to the liquid discharging nozzle is effectively avoided, and the safety of taking the stored liquid is greatly improved.

Owner:合肥德纳达信息科技有限公司

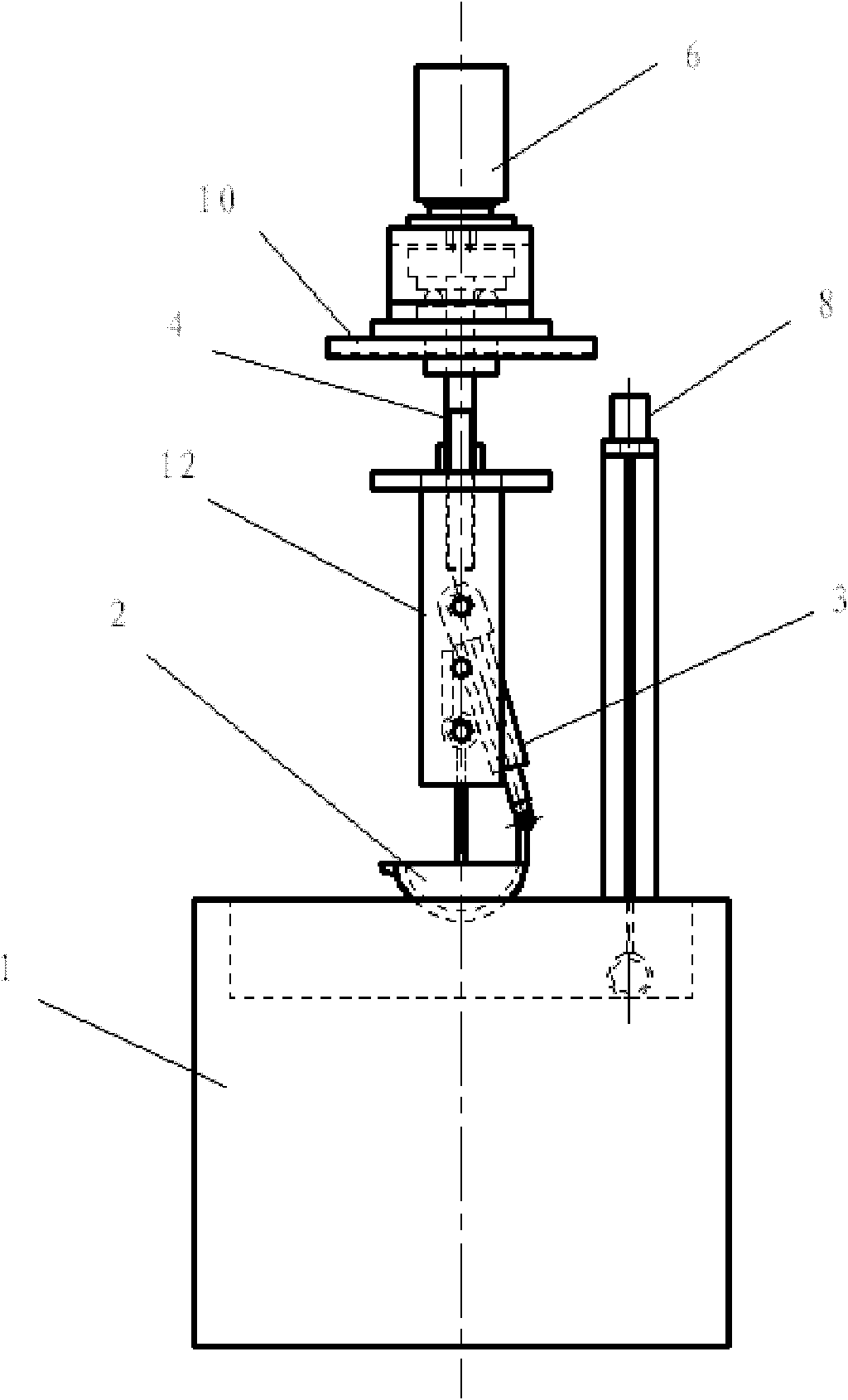

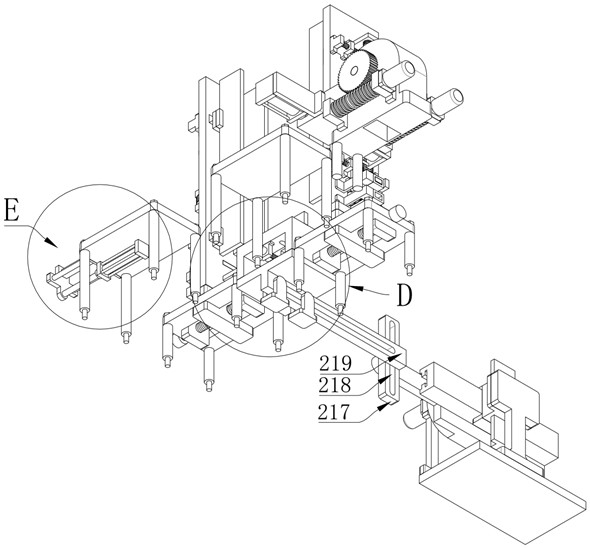

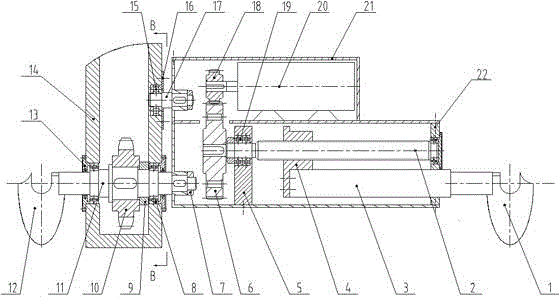

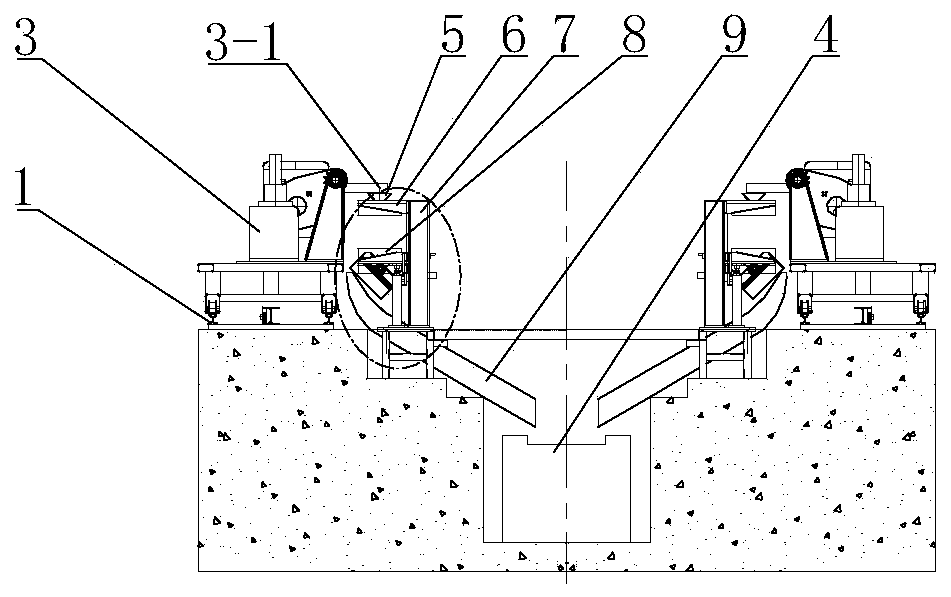

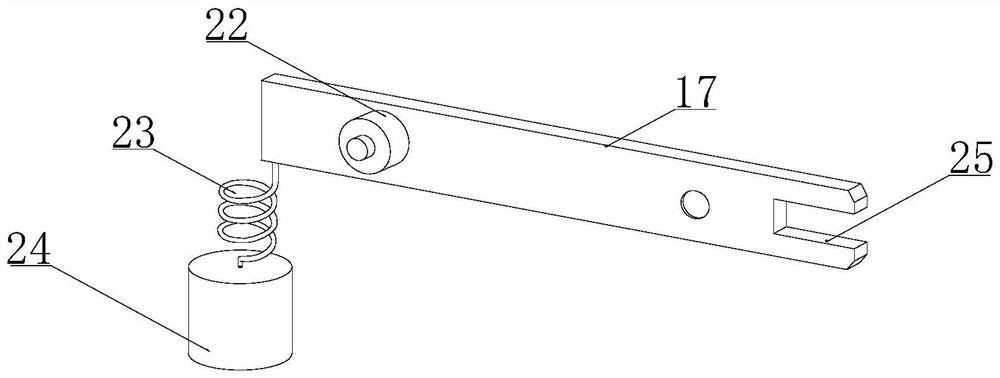

A New Type of Gravity Casting Soup Feeding Machine Double Pouring Spoon Manipulator

ActiveCN103949622BAvoid interferenceSave production spaceMolten metal conveying equipmentsSprocketEngineering

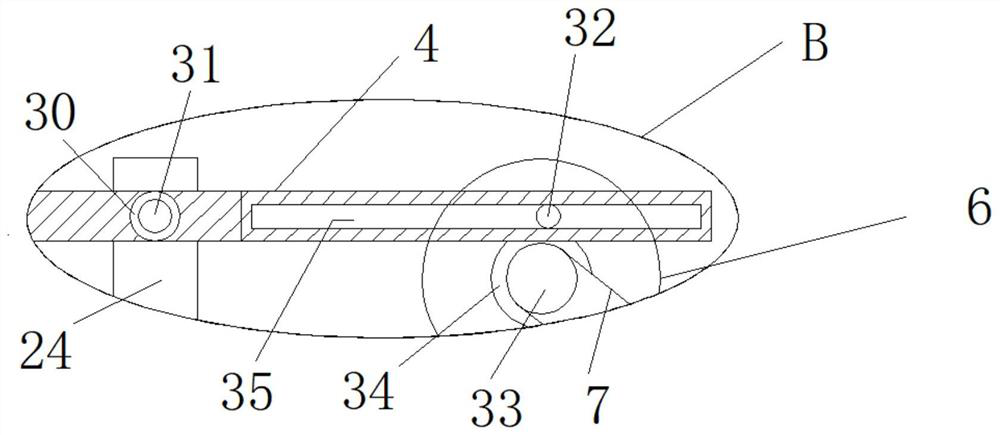

The invention discloses a novel double-pouring ladle mechanical arm for a gravity casting fluid feeding machine. The mechanical arm comprises a working arm, a first pouring ladle, a second pouring ladle driving mechanism and a second pouring ladle, wherein the first pouring ladle is fixedly connected with the left end of a sprocket shaft, and the second pouring ladle driving mechanism is fixedly connected with the right end of the sprocket shaft; the second pouring ladle driving mechanism comprises a shell, a servo motor, a pinion, a bull gear, a lead screw, a ball nut, a connecting plate, a front support and a rear support, and the second pouring ladle is fixedly connected with the right end of the connecting plate. The double-pouring ladle mechanical arm is novel and reasonable, simple in structure, and fast and stable in operation, and can be matched with a small-size melt furnace for use; the problem that the double-pouring ladle device of the mechanical arm is interfered with the melt furnace is solved, pouring at sprues with different distances in gravity casting is realized, the mechanical arm can be mounted on a five-rod fluid feeding machine for use, massive manpower is saved, the production cost is reduced, the production efficiency is improved, and the technical content is high.

Owner:东台安速智能科技有限公司

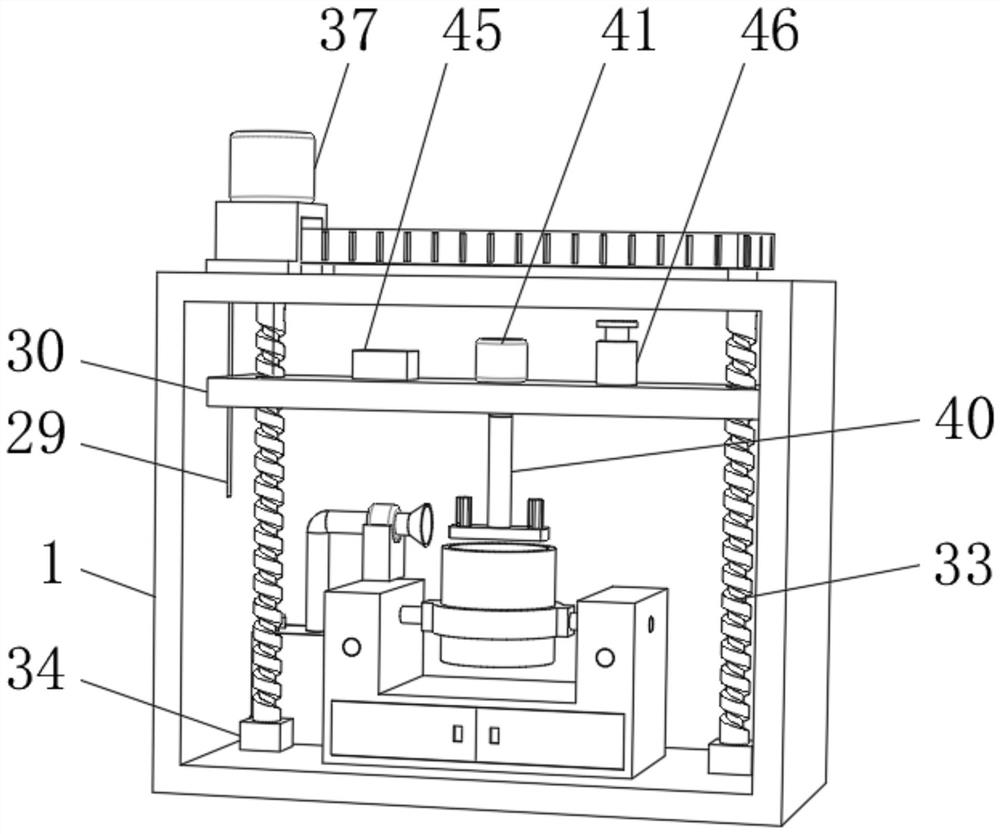

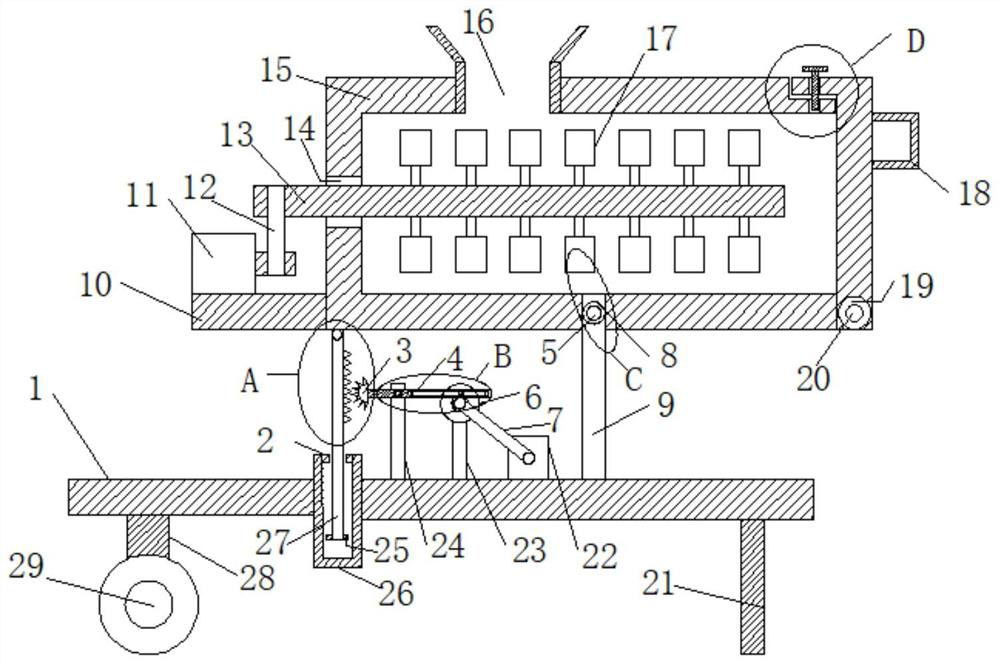

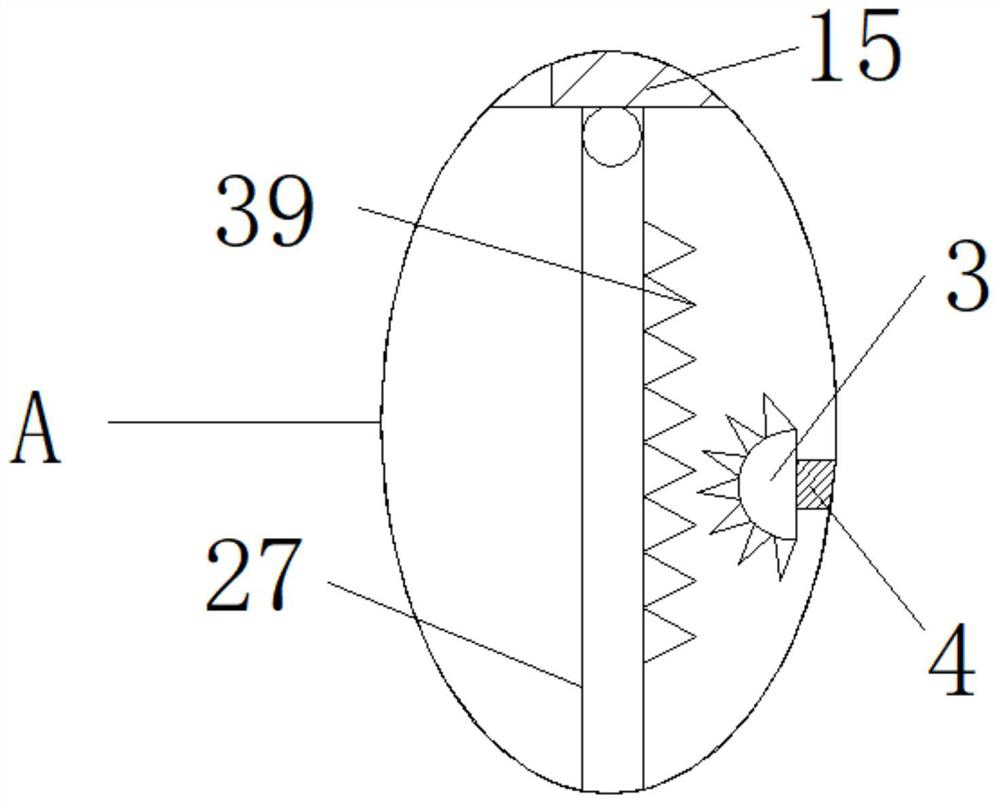

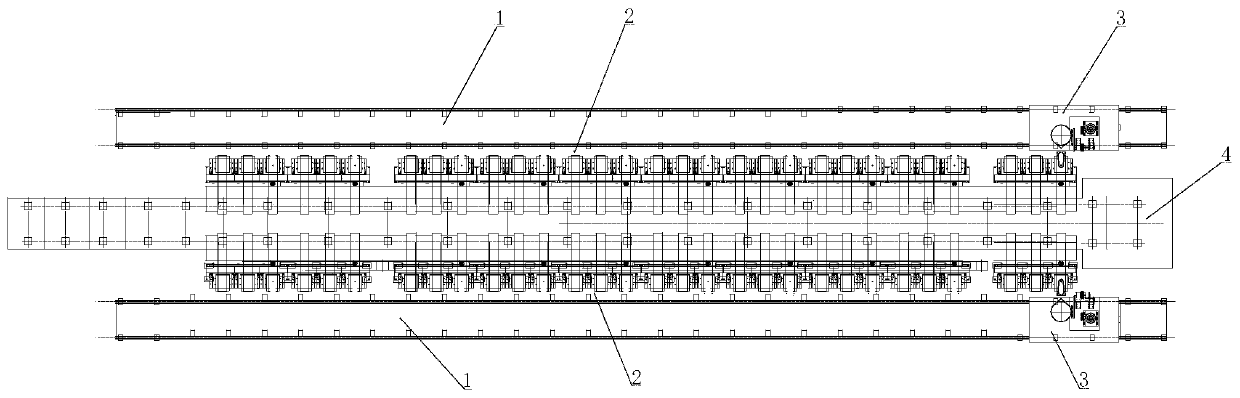

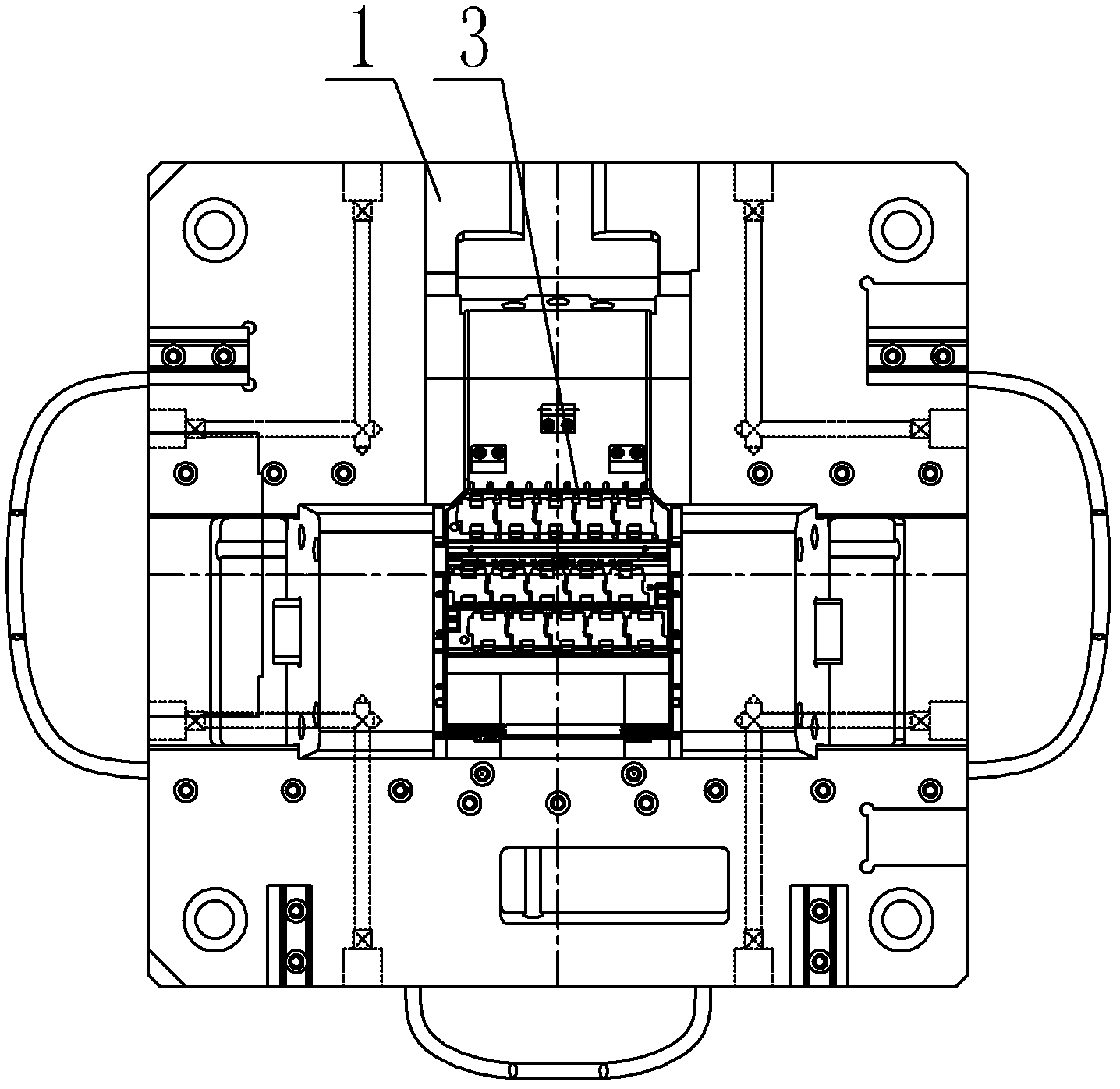

Automatic austempered grinding ball forming and producing equipment

PendingCN110064749AGuarantee molding qualityPrevent movementCasting plantsFoundry mouldsEngineeringMechanical engineering

The invention relates to automatic austempered grinding ball forming and producing equipment. Conveying tracks are included. A pouring machine is arranged above each conveying track. A pouring outputport of each pouring machine stretches out of one side of the upper portion of the corresponding conveying track, the side of each conveying track is externally provided with a plurality of pouring positions in the direction parallel to the conveying track at intervals, and a pouring line is formed. A steel die support is arranged at each pouring position and provided with an upper fixed die and alower movable die, wherein in the die assembly state, a plurality of grinding ball forming cavities are formed between the two dies, a pouring gate is arranged in the upper fixed die and the lower movable die and communicates with the grinding ball forming cavities and the upper end of the upper fixed die, and a pouring cup is arranged above the pouring gate. The pouring machines move to the positions right opposite to the pouring positions, the pouring output ports are in up-down linkage with the pouring cups. The lower position, corresponding to each lower movable die, of the correspondingpouring position is provided with a slide carriage, the slide carriages are outwards obliquely arranged in the direction away from the corresponding conveying tracks, and a conveyor is arranged beloweach slide carriage. By means of the equipment, the product pouring quality is guaranteed, and high production efficiency is achieved.

Owner:CHENGDE RONGMAO CAST STEEL +1

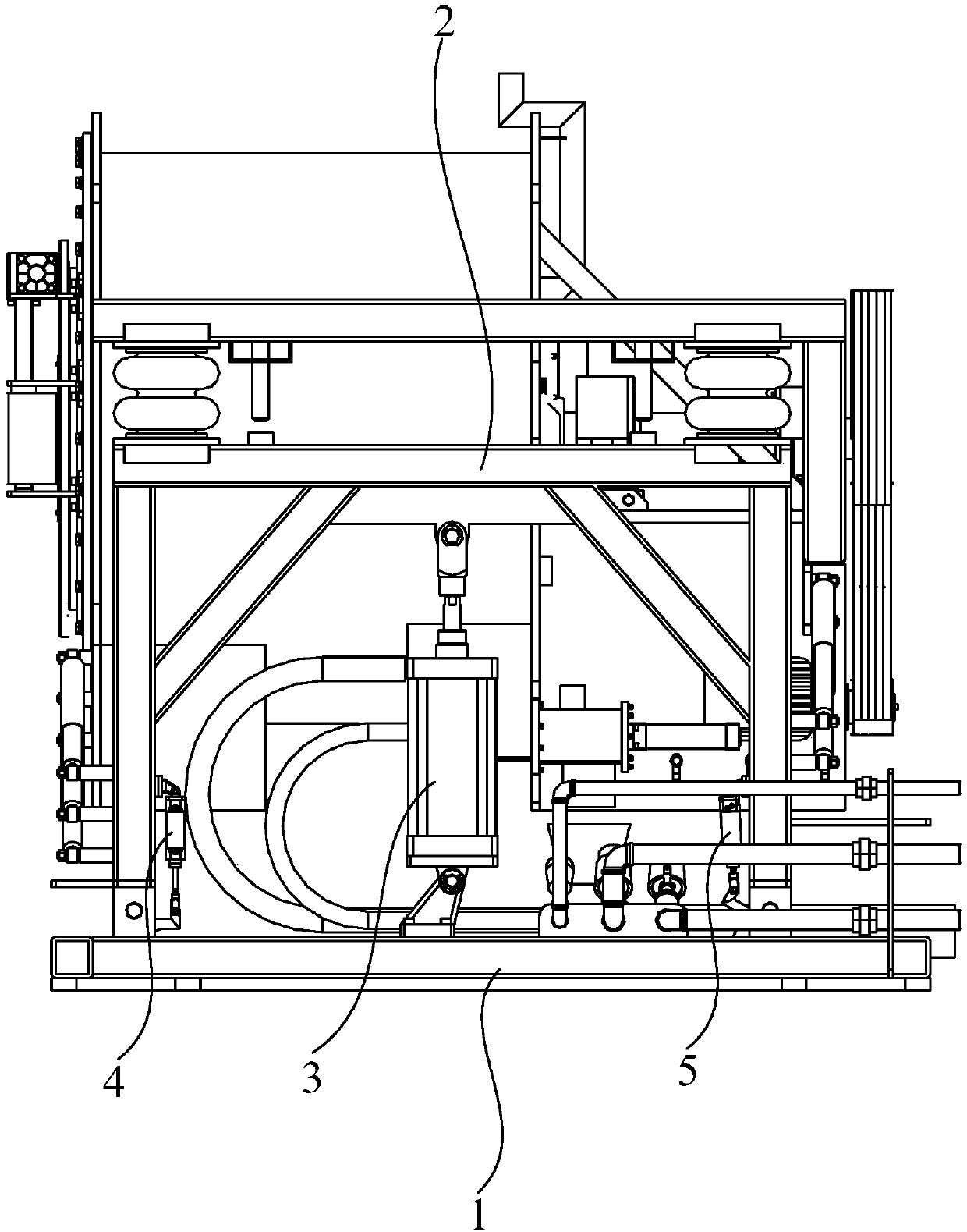

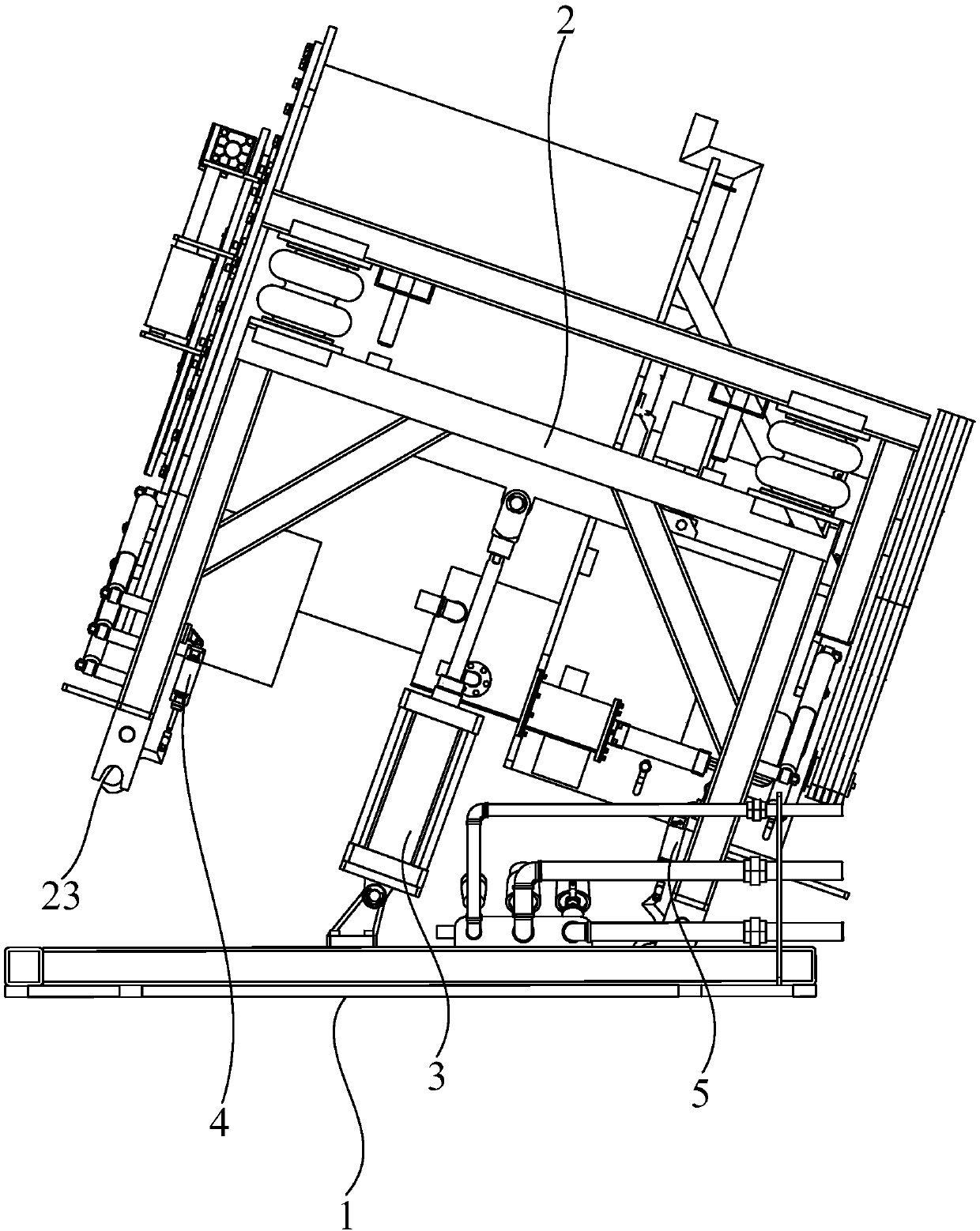

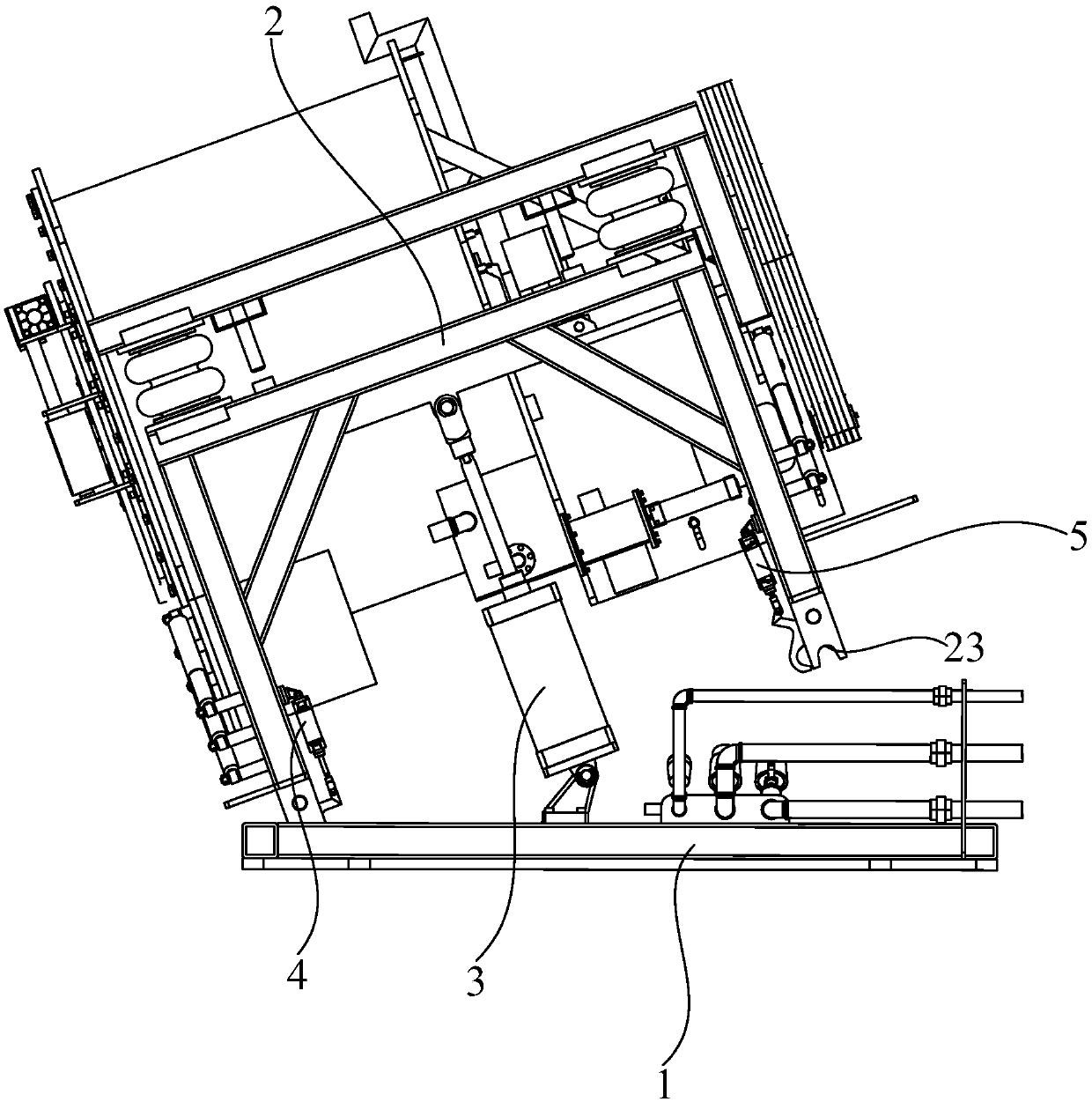

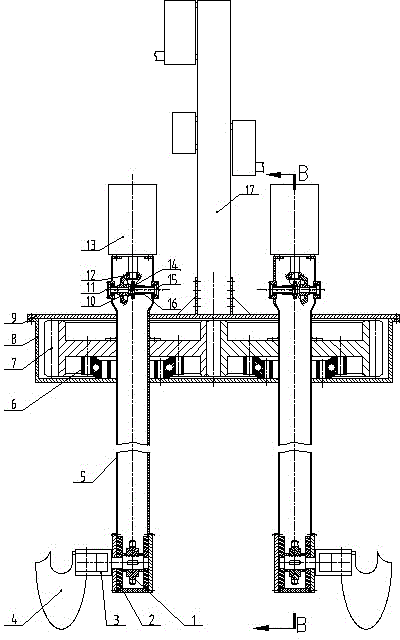

Tilting device and washer-extractor comprising same

PendingCN110359236AImprove work efficiencyAchieve pouringOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a tilting device and a washer-extractor comprising the same. The tilting device comprises a base, a tilting component, at least one lifting mechanism, at least one first latchmechanism and at least one second latch mechanism, wherein the tilting component is positioned at the top of the base, the bottom of the lifting mechanism is connected to the base, the top of the lifting mechanism is connected to the tilting component and used for driving the tilting component to lift, the first latch mechanisms and the second latch mechanisms are positioned on two sides of the lifting mechanism, the tops of the first latch mechanisms and the second latch mechanisms are connected to two ends of the tilting component, and the bottoms of the first latch mechanisms and the secondlatch mechanisms are detachably connected to the base. The washer-extractor comprises the tilting device. Automatic loading and unloading are realized, time and labor are saved, and working efficiency is improved.

Owner:上海雅森洗涤设备有限公司

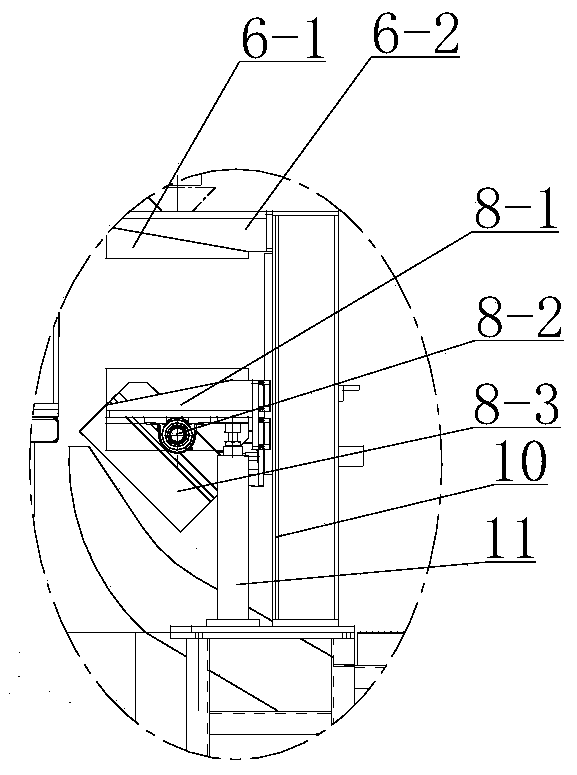

A five-link soup machine with double pouring ladle mechanical arm

ActiveCN103949623BAvoid interferenceSave production spaceMolten metal conveying equipmentsSprocketEngineering

The invention discloses a five-rod fluid feeding machine double-pony ladle mechanical arm. The five-rod fluid feeding machine double-pony ladle mechanical arm comprises an arm driving mechanism and a pony ladle driving mechanism, wherein the arm driving mechanism is connected to a fixed plate; a gear mechanism is driven to rotate by a servo motor so as to drive the rotation of the mechanical arm; the pony ladle driving mechanism utilizes the servo motor to drive the gear mechanism to realize meshing motion, sprocket wheels on a sprocket shaft are driven, a sprocket wheel chain mechanism is driven, a pony ladle adjusting plate and a pony ladle are driven to rotate, and fluid fetching and injection actions are realized; the micro change of a position is realized by changing mounting holes in the adjusting plate, and the position is more accurate. The five-rod fluid feeding machine double-pony ladle mechanical arm is matched with a solution furnace with a small size for use, the problem that a mechanical arm double-pony ladle device intervenes with the solution furnace is solved, moulds with different distance sprues are poured, the mechanical arm can be mounted on a five-rod fluid feeding machine for use, the production cost is reduced, and the production efficiency is improved.

Owner:东台城东科技创业园管理有限公司

Recycling device for 3D printing supplies

PendingCN114211752AGood for subsequent crushingPrevent the problem of insufficient crushingAdditive manufacturing apparatusPlastic recyclingReciprocating motionEngineering

The invention discloses a 3D printing consumable recycling device, and belongs to the technical field of recycling devices.The 3D printing consumable recycling device comprises a support and a cutting-off mechanism, a crawler belt, a cutting table and a smashing box are sequentially installed on the support, the cutting-off mechanism is installed on the portion, located on one side of the cutting table, of the outer surface of the support, and the upper surface of the cutting table and the lower surface of the crawler belt are located at the same height; and a cutter is mounted on the cutting-off mechanism and located above the cutting table, and a discharging opening is formed in the lower end of the side face of the smashing box. Waste is cut off through the arranged cutting-off mechanism, the problem that smashing is not thorough enough due to the fact that the size of the waste is too large is solved, the cutting-off mechanism drives a lever to conduct circulating motion through reciprocating motion according to the lever principle, and therefore a cutter is controlled to achieve cutting off; and through the arranged smashing box, the cut waste can be further ground and smashed, so that the waste is processed and smashed more thoroughly, and the situation that due to the fact that the size is too large during melting, the waste is caked during melting is prevented.

Owner:康硕(德阳)智能制造有限公司

Automatic casting machine of cadmium ingot

InactiveCN101890494BRealize taking liquidAchieve improvementMould handling equipmentsMolten metal conveying equipmentsButt jointIngot

The invention discloses an automatic casting machine of cadmium ingot. A bracket (10) is provided with a variable frequency motor (6) and a guide rod (11); the variable frequency motor (6) is connected with a screw structure (4) which is provided with a screw lifting bracket (12) in guide connection with the guide rod (11); the screw lifting bracket (12) is provided with a bailer rotating shaft (13) which is at least provided with a bailer (2); a bailer cylinder (3) is connected between the bailer (2) and the screw lifting bracket (12); a cadmium liquid pool (1) is provided with a liquid level sensor (8); a rotating shaft (16) is provided with a casting mould (15) and is connected with an overturn mechanism; the motor (14) is connected with a conveyer belt (18); and the casting machine operated on the guide rail (7) can be in butt joint with the cadmium liquid pool (1) and the casting mould (15). The invention has low labor intensity and high casting efficiency, can prevent oxidation of cadmium liquid, and ensures stable and accurate casting amount.

Owner:ZHUZHOU SMELTER GRP +1

Pouring device for shower gel production

The invention belongs to the field of shower gel production, and particularly relates to a pouring device for shower gel production. The pouring device comprises a base, limiting shells are fixedly welded on two sides of the top of the base, a supporting plate is fixedly mounted on one side of the top of the base, a lifting plate is connected to the inner wall of the supporting plate, a first fixing plate and a second fixing plate are fixedly mounted on the two sides of the surface of the lifting plate correspondingly, a servo motor is fixedly mounted on one side of the surface of the lifting plate, a transmission shaft of a servo motor penetrates through the second fixing plate and is fixedly connected with a winding shaft, and the transmission shaft of the servo motor penetrates through the second fixing plate and is rotationally connected through a first bearing. Compared with a specific pouring device, the designed device is low in cost, can be combined with a forklift and is easy to operate, meanwhile, when the device is not used, the forklift can move the device to a designated area, and therefore space is effectively saved.

Owner:上海涤宝科技有限公司

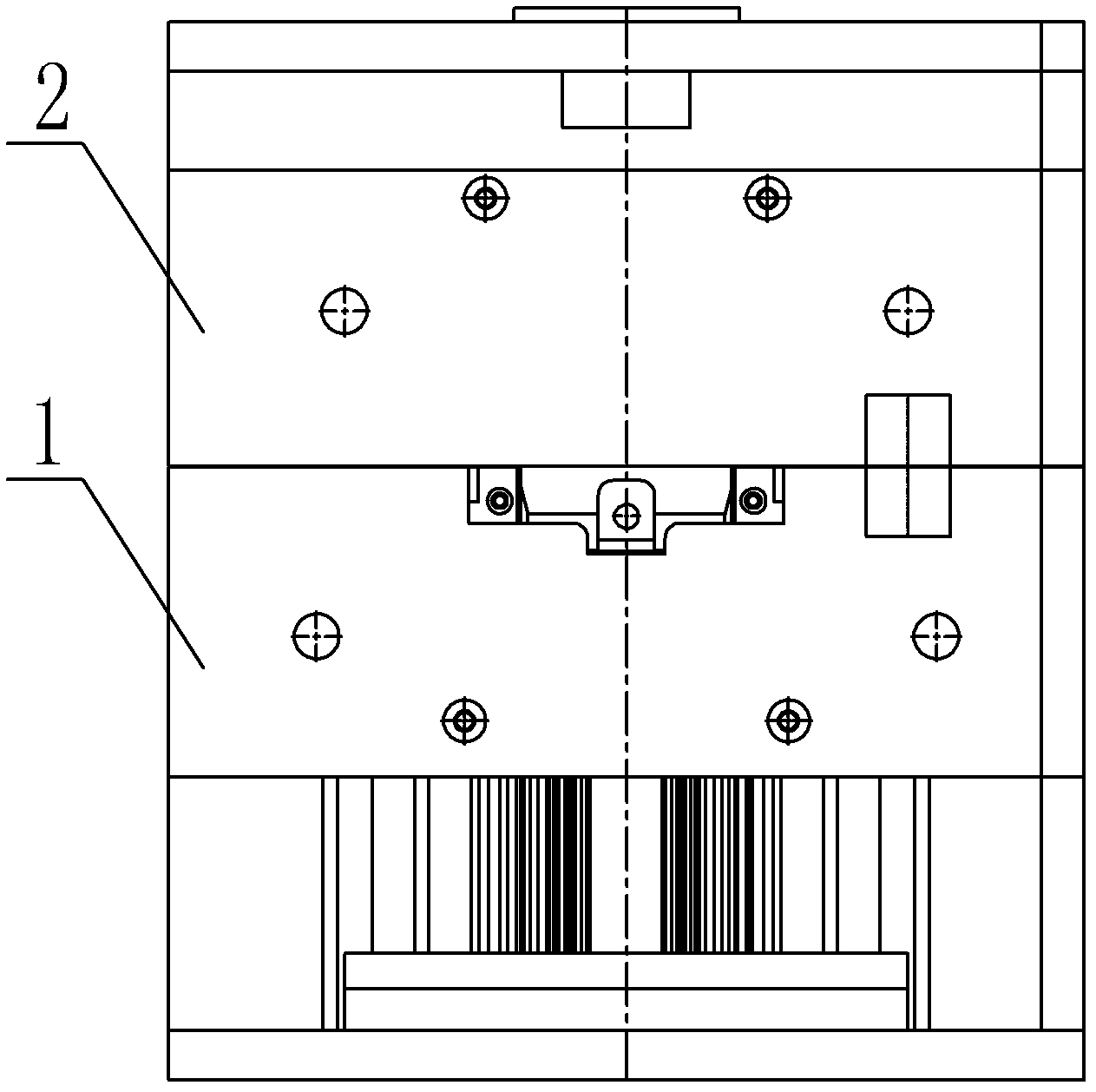

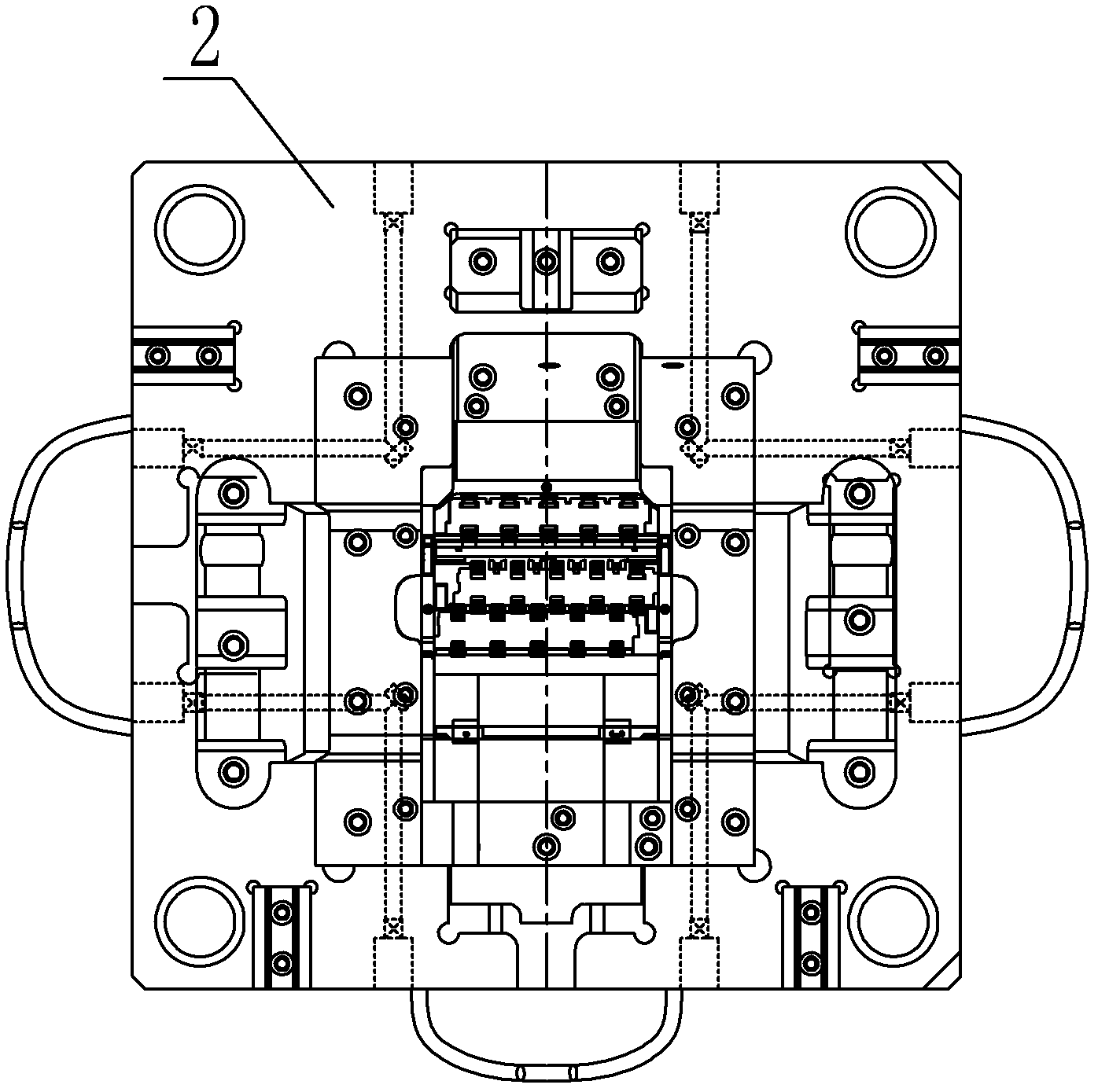

Special die for controller supports of auto electric appliances

The invention relates to a special die for controller supports of auto electric appliances, comprising a fixed die, a moving die and a die core, wherein a die cavity is formed by the die core and a compound die of the fixed die and the moving die; a cooling pipeline in which cooling liquid passes is arranged on the fixed die and the moving die; a cooling system for supplying the cooling liquid to the cooling pipeline is provided; and the cooling pipeline is provided with an inlet and an outlet which are circularly communicated with the cooling system. The special die for the controller supports of the auto electric appliances, disclosed by the invention, is provided with the cooling pipeline to ensure that the die can be poured at a constant temperature and the accelerated cooling can be realized after the pouring is completed, therefore, the production capacity is increased.

Owner:JIANGSU RIYING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com