Cap opening self destroying type anti-fake bottle cap

An anti-counterfeiting bottle cap and self-destructing technology, which is applied to bottle/can parts, containers, packaging recycling, etc., can solve the problems of destroying the anti-counterfeiting structure, illegal elements recycling fraud, and illegal elements unable to recycle, etc., to improve Sealing effect, easy to use, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

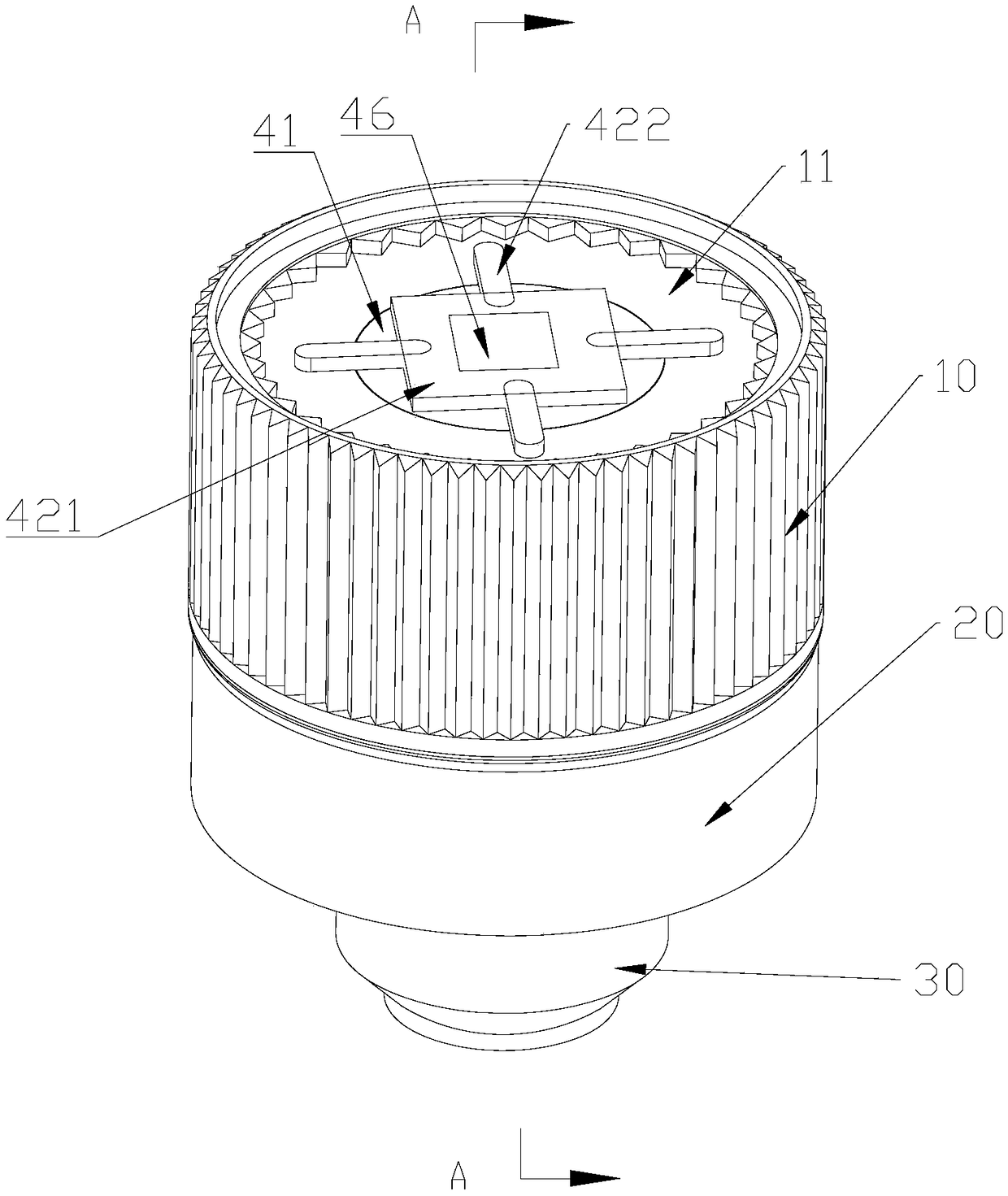

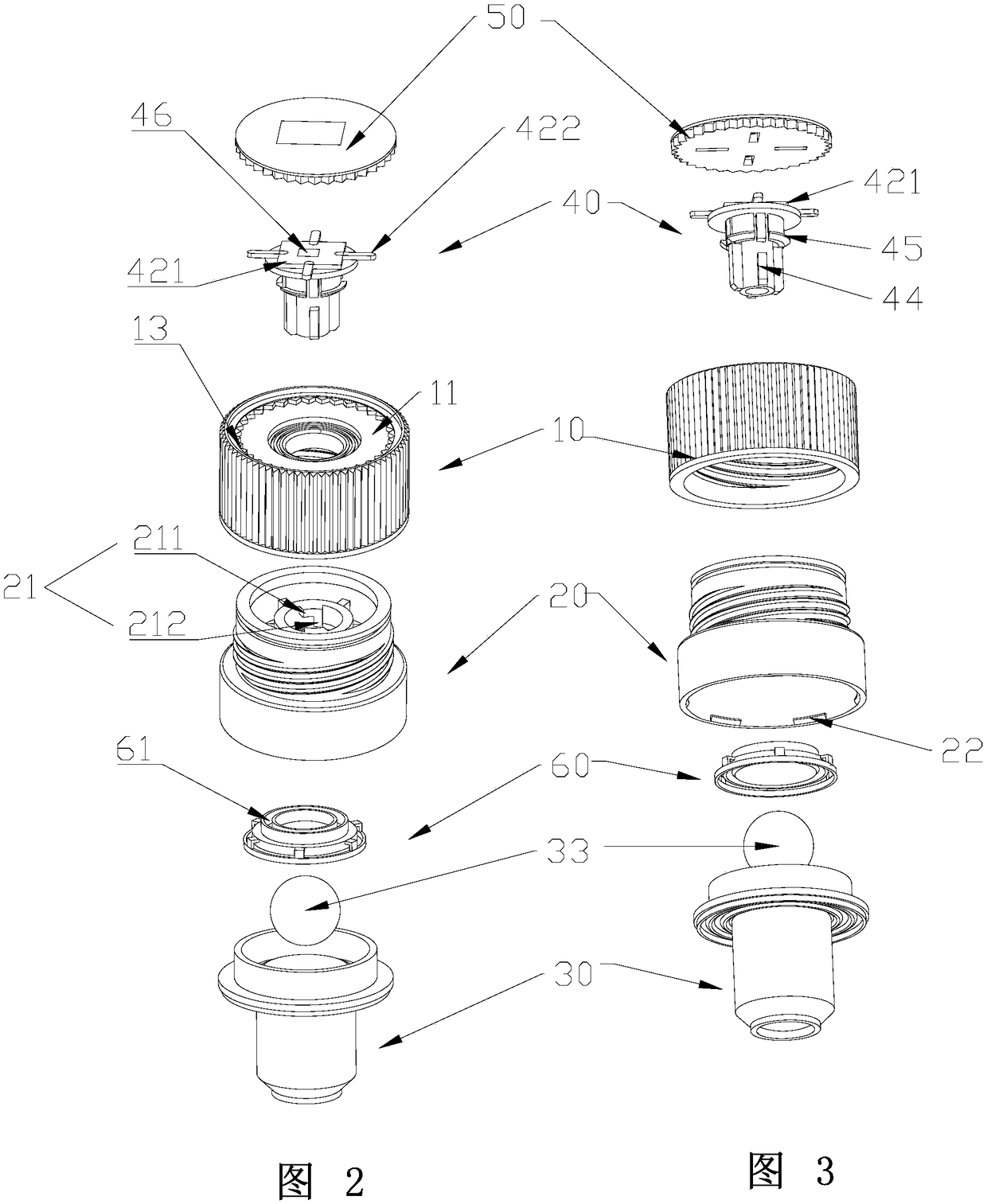

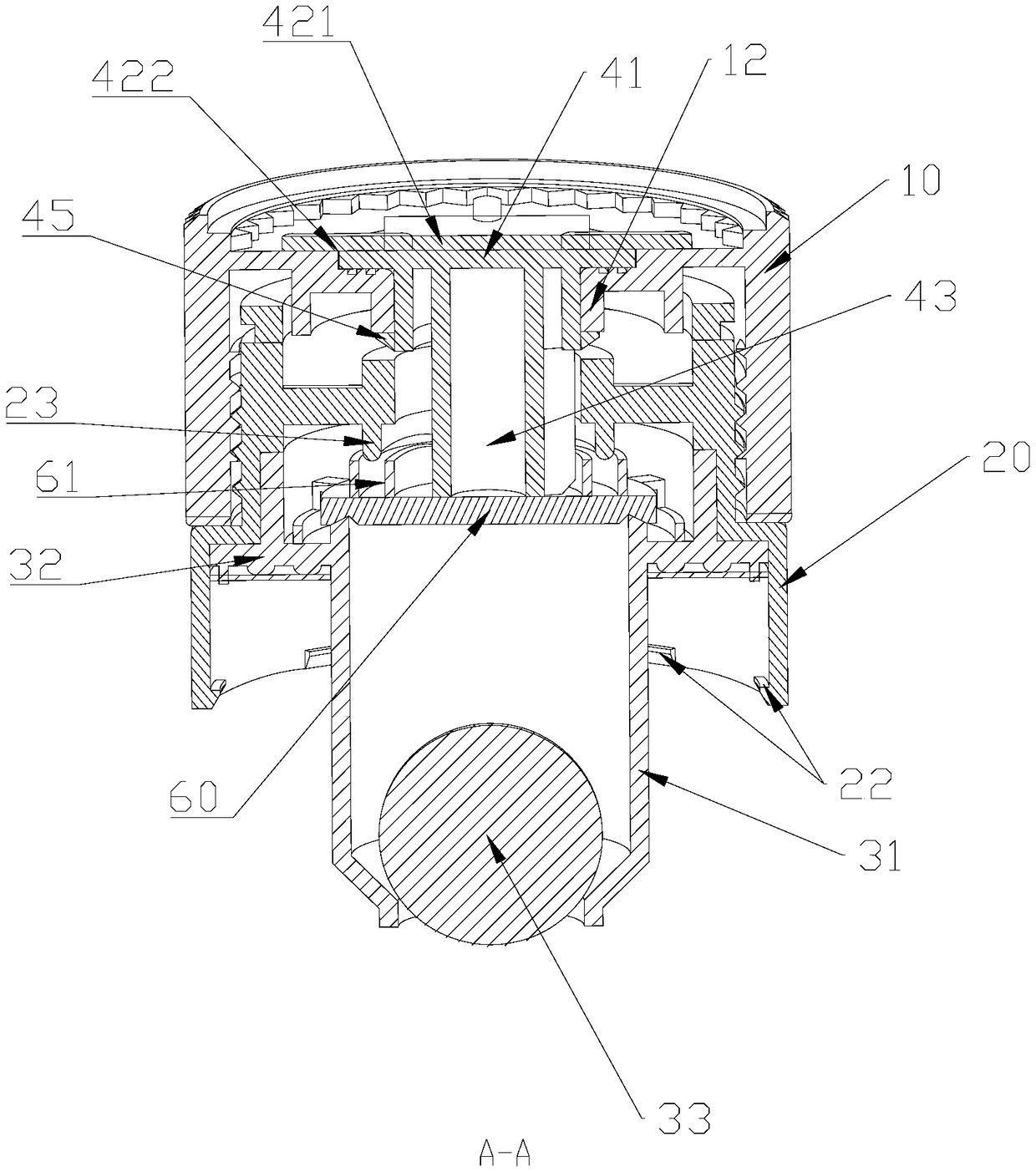

[0034] Such as Figure 1-6As shown, a self-destruction anti-counterfeiting bottle cap of the present embodiment includes an upper cover 10 , a lower cover 20 , and a self-destruction device 40 . The upper cover 10 and the lower cover 20 are flexibly connected. In this embodiment, the upper cover 10 and the lower cover 20 are both circular, the upper cover 10 includes a top wall and a side wall, the lower end of the side wall of the upper cover 10 is provided with internal threads, and the upper end of the lower cover 20 is provided with external threads, The upper cover 10 and the lower cover 20 are rotatably connected through cooperation of internal threads and external threads. The lower end of the lower cover 20 is connected to the mouth of the bottle. Specifically, a buckle 22 is provided on the outer wall of the lower cover 20 to be fixed on the mouth of the bottle through the buckle 22 . An anti-counterfeit area 11 for affixing an anti-counterfeit label 50 is provided ...

Embodiment 2

[0038] Such as Figure 5-6 As shown, the present embodiment adds an annular boss 45 on the basis of Embodiment 1, and further defines the lower cover stopper 21 . Specifically, the lower cover stopper 21 is composed of a first stopper 211 and a second stopper 212 connected to each other, the first stopper 211 is located above the second stopper 212, and the first stopper 211 and the second stopper 212 An angle is formed between them; the clamping block 44 is engaged at the angle between the first blocking block 211 and the second blocking block 212 . In this embodiment, the first stopper 211 is in the horizontal direction, the second stopper 212 is in the vertical direction, and the second stopper 212 is connected to the right end of the first stopper 211, and the clamping block 44 is engaged in the second The right angle between the first stopper 211 and the second stopper 212 ; and there are two lower cover stoppers 21 , which are evenly arranged on the inner wall of the lo...

Embodiment 3

[0042] Such as Figure 1~4 As shown, this embodiment adds an inner cap 30 and a sealing cap 60 on the basis of Embodiment 2, specifically, the bottle cap also includes a sealing cap 60 and a hollow inner cap 30, and the inner cap 30 and the sealing cap 60 They are all arranged inside the lower cover 20 . A pressing block is provided on the inner wall of the lower cover 20 to interfere with the upper end of the inner cover 30 so as to compress the inner cover 30 downward.

[0043] The inner cap 30 includes a hollow sealing tube 31 and an inner cap block 32 arranged on the outer wall of the sealing tube 31, the outer diameter of the sealing tube 31 is smaller than the inner diameter of the bottle mouth, and the outer diameter of the inner cover block 32 is greater than the inner diameter of the bottle mouth; The sealing tube 31 can extend into the bottle mouth, and the inner cover block 32 is clamped on the bottle mouth. Sealing tube 31 is provided with sealing ball 33, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com