Automatic unpacking, unloading and recycling device for ton bags and working method

A recycling device and a technology for ton bags, applied in the field of ton bag unpacking equipment, can solve the problems of inability to realize the recycling and reuse of ton bags, low work efficiency, high labor intensity, etc., saving resources, high work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

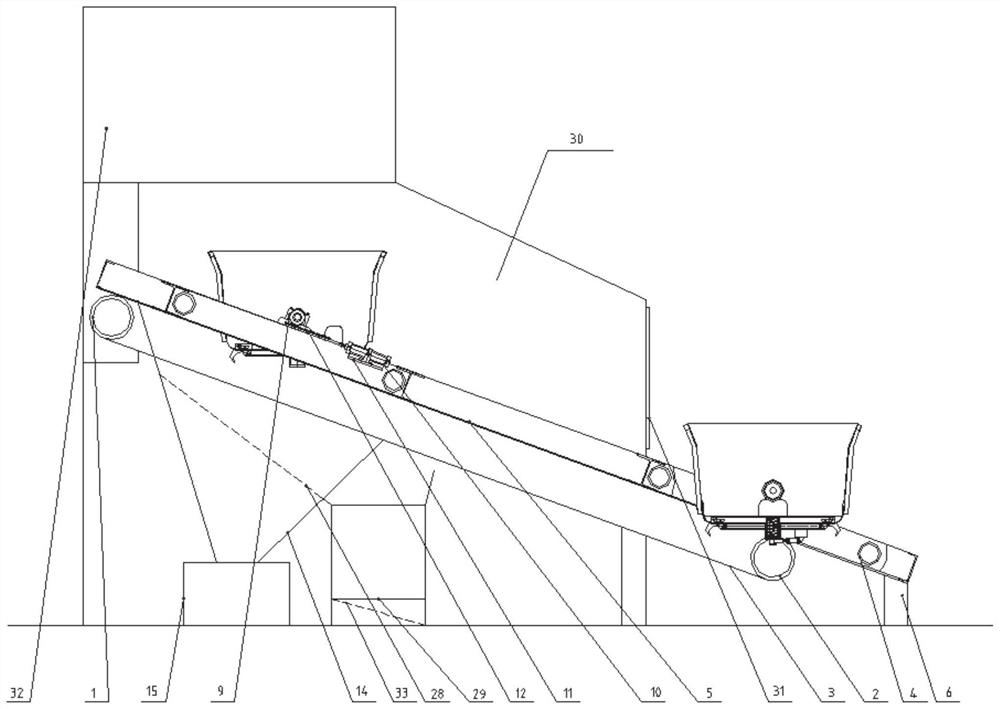

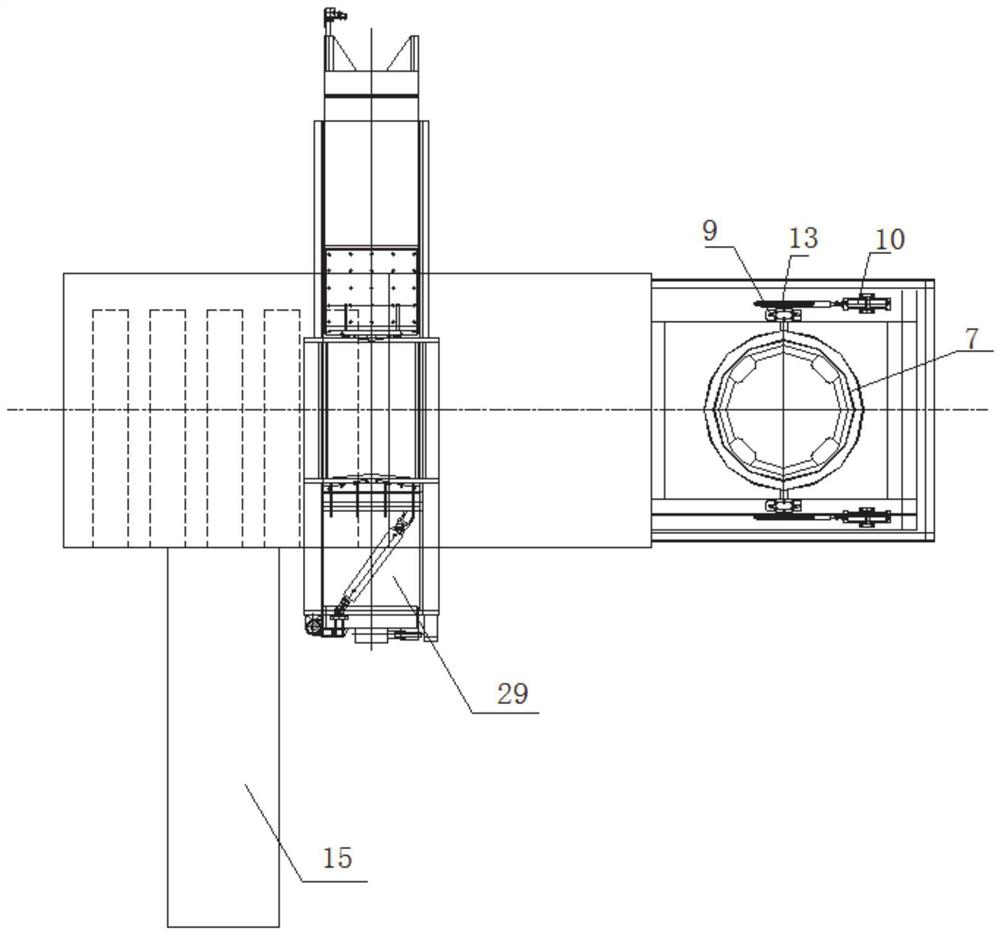

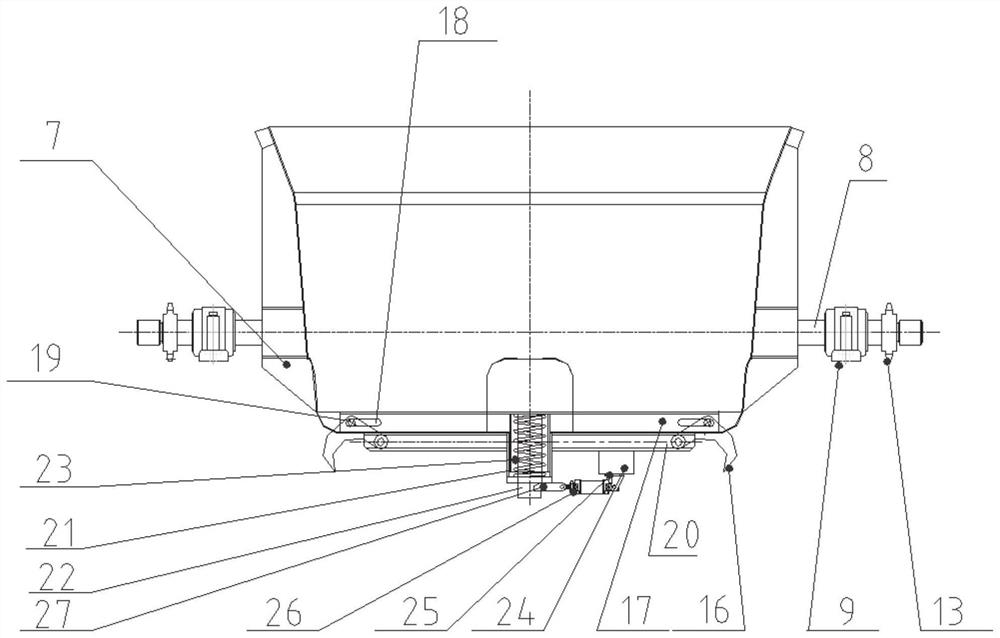

Method used

Image

Examples

Embodiment 2

[0043] This embodiment discloses the working method of the ton bag automatic unpacking and unpacking and recycling device described in Embodiment 1:

[0044] The staff puts the ton bag containing the material into the material barrel through a forklift, and the gravity plate compresses the spring under the gravity of the ton bag, so that the gravity plate is at the position closest to the bottom of the material barrel, and the staff puts the sling at the bottom of the ton bag Pass through the opening of the barrel and hang on the hook. At this time, the barrel is in a horizontal state. The control system controls the operation of the locking cylinder. The locking pin is inserted into the locking hole of the locking column to lock and fix the gravity plate. The control system The driving motor of the control chain transmission mechanism works, the transmission chain drives the elevator car to rise along the guide rail, and the elevator car drives the material cylinder to rise. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com