Novel turnover type material conveying cart

A flip-up, feeding car technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of inability to meet the needs of conveying concrete, waste of materials, and the inability of feeding cars to walk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

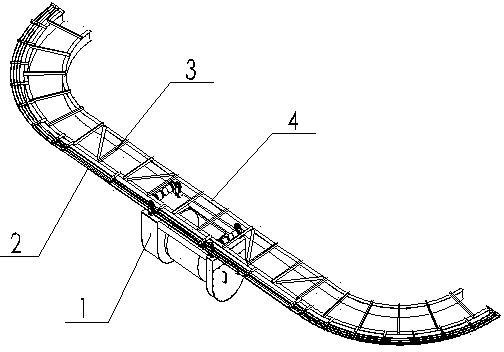

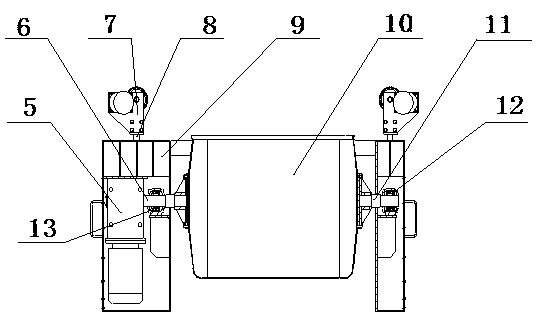

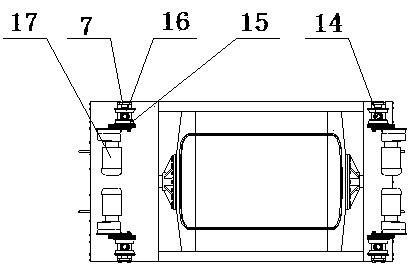

[0017] see figure 1 — image 3 , the new flip feeding car of the present invention adopts a cylindrical or quasi-cylindrical tank as a container for containing concrete, opens a discharge port on the surface of the container, and connects and fixes the long semi-axis and short shaft at both ends of the container. The half shaft, the long half shaft and the short half shaft are respectively connected with the long half shaft bearing seat and the short half shaft bearing seat installed in a hanging frame. A motor reducer is installed on the long half shaft, and the four corners of the hanging frame pass through it. The four booms are respectively connected to the four boom bearing seats, and the four boom bearing seats are respectively connected to the four sets of driving and driven wheels through hanging plates. The four sets of driving and driven wheels are hung on two parallel shafts. On the steel track, the driving wheel has a large gear, and the pinion gears of the four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com