Automatic casting machine of cadmium ingot

A casting machine and automatic technology, applied in casting equipment, equipment for transporting molds, equipment for feeding molten metal into molds, etc., can solve problems such as low efficiency, high labor intensity, and adverse effects on workers' health, and achieve The effect of low system cost, low labor intensity and novel mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

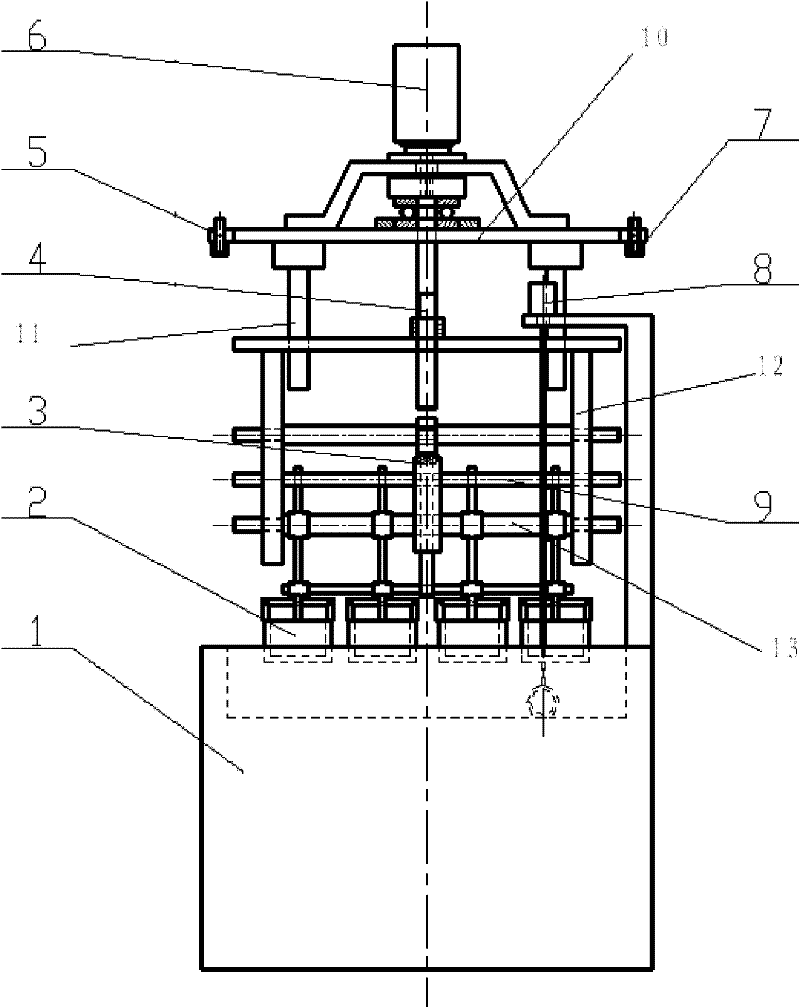

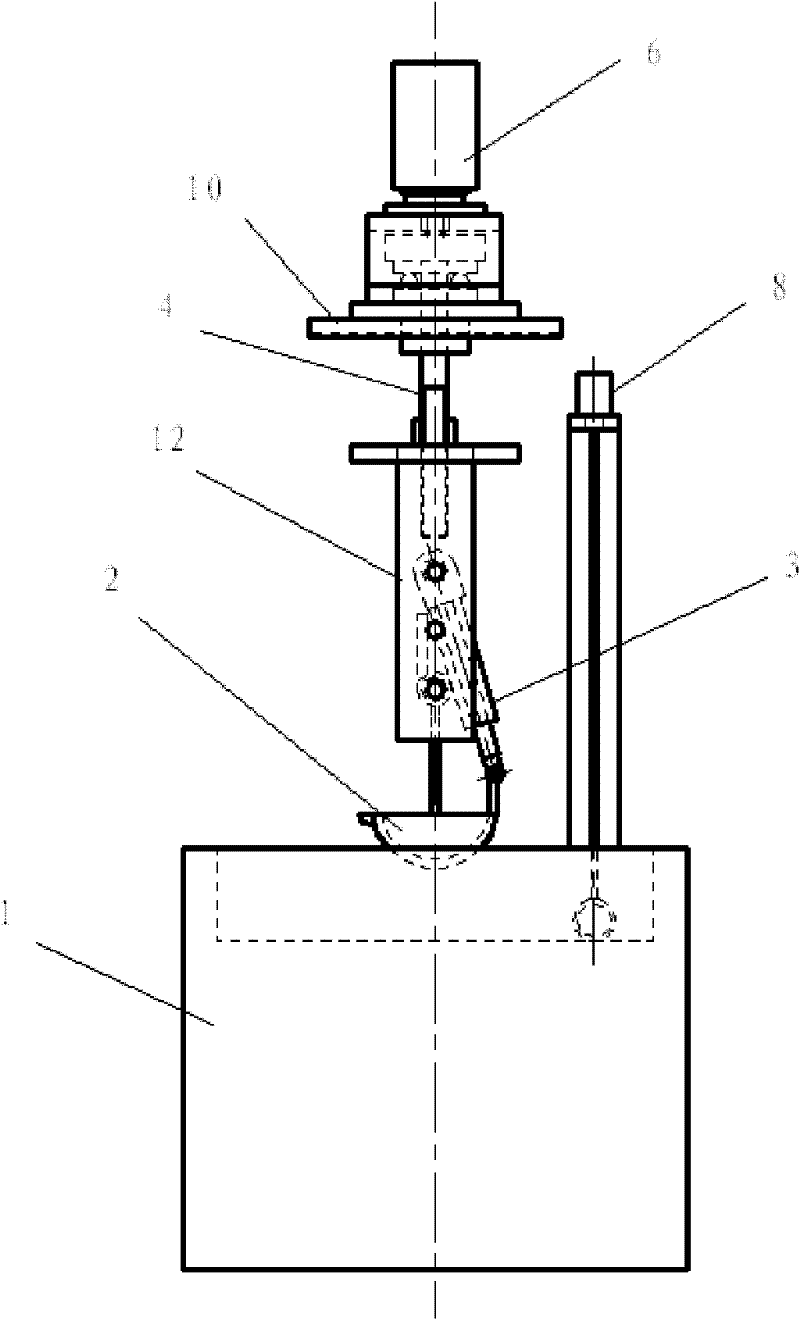

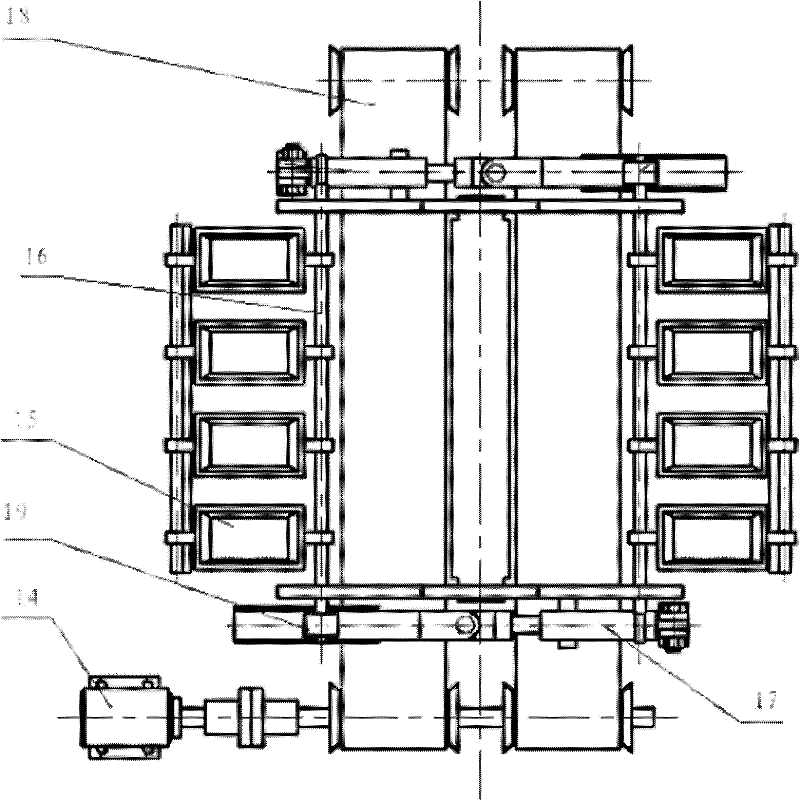

[0016] see figure 1 , figure 2 and image 3 , the structure of the pouring machine is that the bracket 10 is rolled and installed on the guide rail 7 through the roller 5, the frequency conversion motor 6 and the guide rod 11 are installed on the bracket 10, the main shaft of the frequency conversion motor 6 is connected with the screw structure 4, and the screw structure 4 is installed with the The threaded lifting bracket 12 connected by transmission, the threaded lifting bracket 12 is guided and connected with the guide rod 11, the scoop rotating shaft 13 is installed on the threaded lifting bracket 12, four scoops 2 are arranged on the scoop rotating shaft 13, and the scoops 2 A scoop cylinder 3 is connected to the threaded lifting support 12, and a liquid level sensor 8 is installed on the cadmium liquid pool 1; the turning mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com