A New Type of Gravity Casting Soup Feeding Machine Double Pouring Spoon Manipulator

A technology of gravity casting and soup feeding machine, which is applied to casting equipment, manufacturing tools, and equipment for feeding molten metal into molds, etc. It can solve the problems of fixed distance, interference, and high price, so as to reduce production costs and save The effect of production space and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

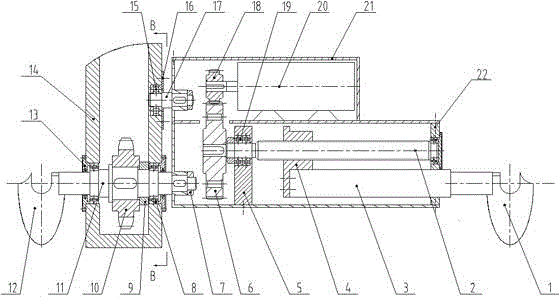

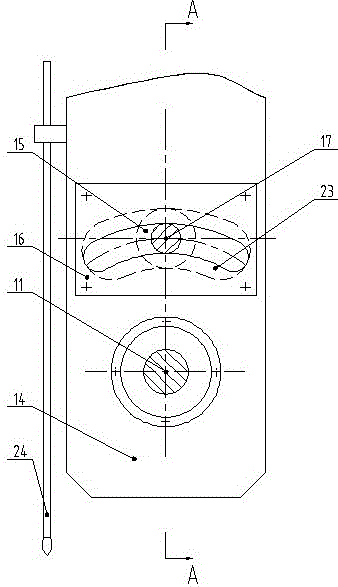

[0020] Such as Figure 1 to Figure 2 Shown, a kind of novel gravity casting soup machine double pouring spoon mechanical arm, comprises working arm 14, the first pouring spoon 12, the second pouring spoon 1 and the second pouring spoon drive mechanism; Wherein working arm 14 comprises sprocket shaft 11 and The sprocket 10 set in the middle section of the sprocket shaft 11 has two through holes at the position corresponding to the level on the working arm 14, and the two through holes are respectively built in two deep groove ball bearings 8, and the shaft of the sprocket shaft 11 The two deep groove ball bearings 8 run through both sides of the end, and the sprocket 10 has a sleeve 9 on the side close to the second ladle driving mechanism, and the sleeve 9 is sleeved on the sprocket shaft 11, and the sprocket 10 The wheel shaft 11 is axially fixed with the seal cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com