Storage tank

A storage tank and tank body technology, which is applied in the field of kitchen utensils, can solve the problems of difficult opening, large unscrewing stroke, and the storage tank cannot fully meet the needs of ventilation, so as to avoid mildew and facilitate opening and closing of the cover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

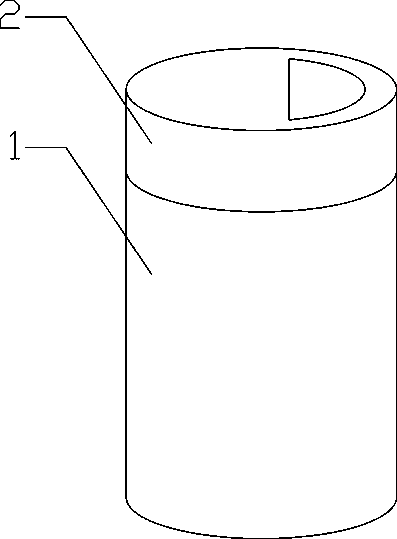

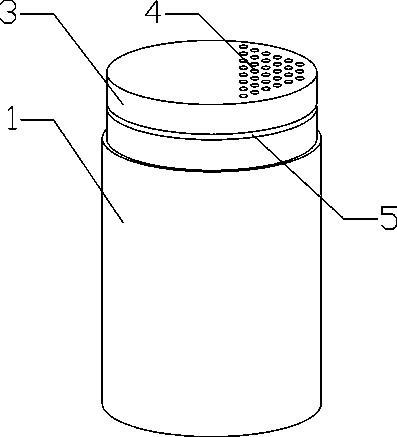

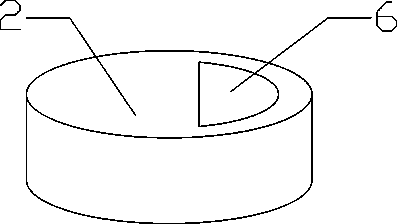

[0015] As shown in the figure, a storage tank includes a tank body 1, an inner cover 3 is provided on the tank body 1, the inner cover 3 and the tank body 1 are connected by threads, and the top surface of the inner cover 3 is provided with a first through hole 4. The inner cover 3 is also socketed with the outer cover 2, and the outer cover 2 is provided with a second through hole 6.

[0016] In a preferred solution, a chute 5 is provided on the outer side wall of the inner cover 3, a slider is provided on the inner side wall of the outer cover 2, and the outer cover 2 and the inner cover 3 are connected by the chute 5 and the slider. The outer cover 2 can rotate axially on the inner cover 3 .

[0017] In a preferred solution, there are multiple first through holes 4, the diameter of the first through hole 4 is 1-2 cm, and the second through hole 6 is a semi-elliptical through hole. , the first through holes 4 all fall in the second through holes 6 .

[0018] By adopting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com