Automatic austempered grinding ball forming and producing equipment

A technology of automatic molding and production equipment, which is applied to casting molding equipment, equipment for transporting molds, equipment for feeding molten metal into molds, etc. Product production efficiency and other issues, to achieve the effect of improving production efficiency, avoiding the misalignment of upper and lower molds, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

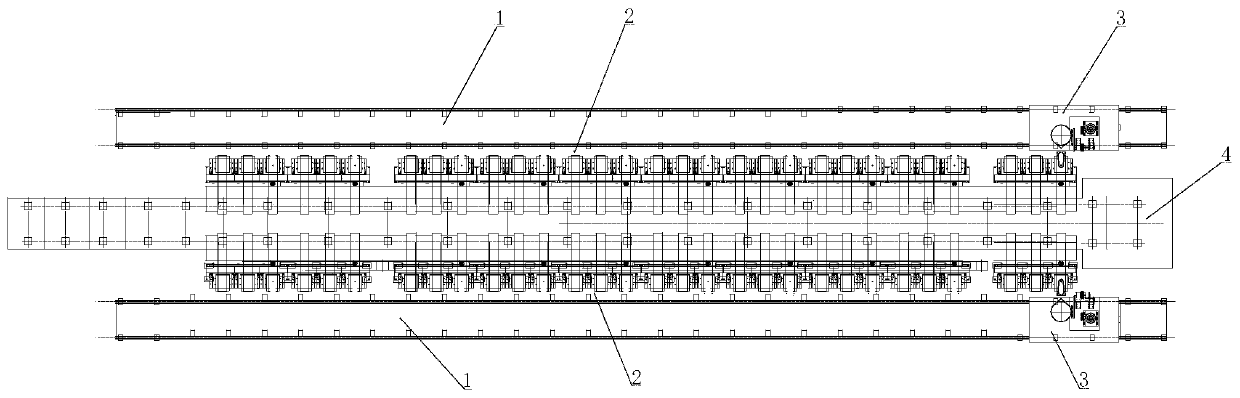

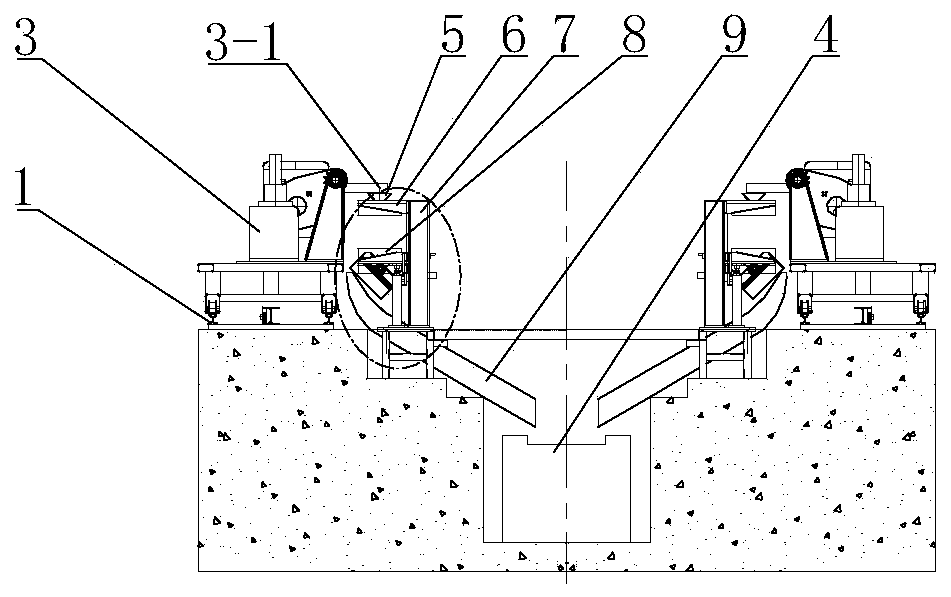

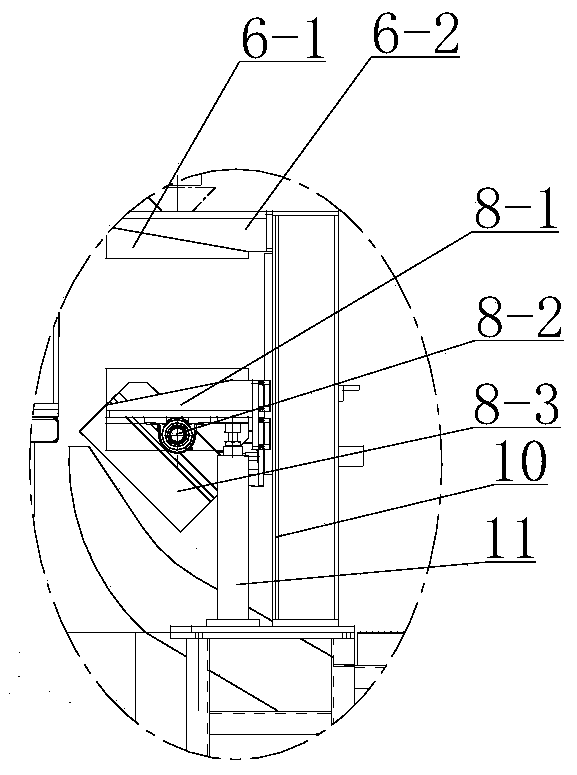

[0035] A kind of Aubei grinding ball automatic forming production equipment, please refer to Figure 1-10 , its invention point is:

[0036] It includes a conveying track 1 arranged in a straight line, and a pouring machine 3 that can move along the conveying track is installed above the conveying track. The pouring outlet of the pouring machine protrudes from the side above the conveying track, and is parallel to A plurality of pouring positions are arranged at intervals in the direction of the conveying track to form a pouring line 2 . Each pouring position is all equipped with a steel mold support 7, and upper fixed mold 6 and the lower movable mold 8 that can realize moving up and down and tippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com