Flow guide device in mineral conveying vehicle

A technology of diversion device and conveying vehicle, which is applied in the field of mining supports, can solve the problems of high labor intensity of the staff, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

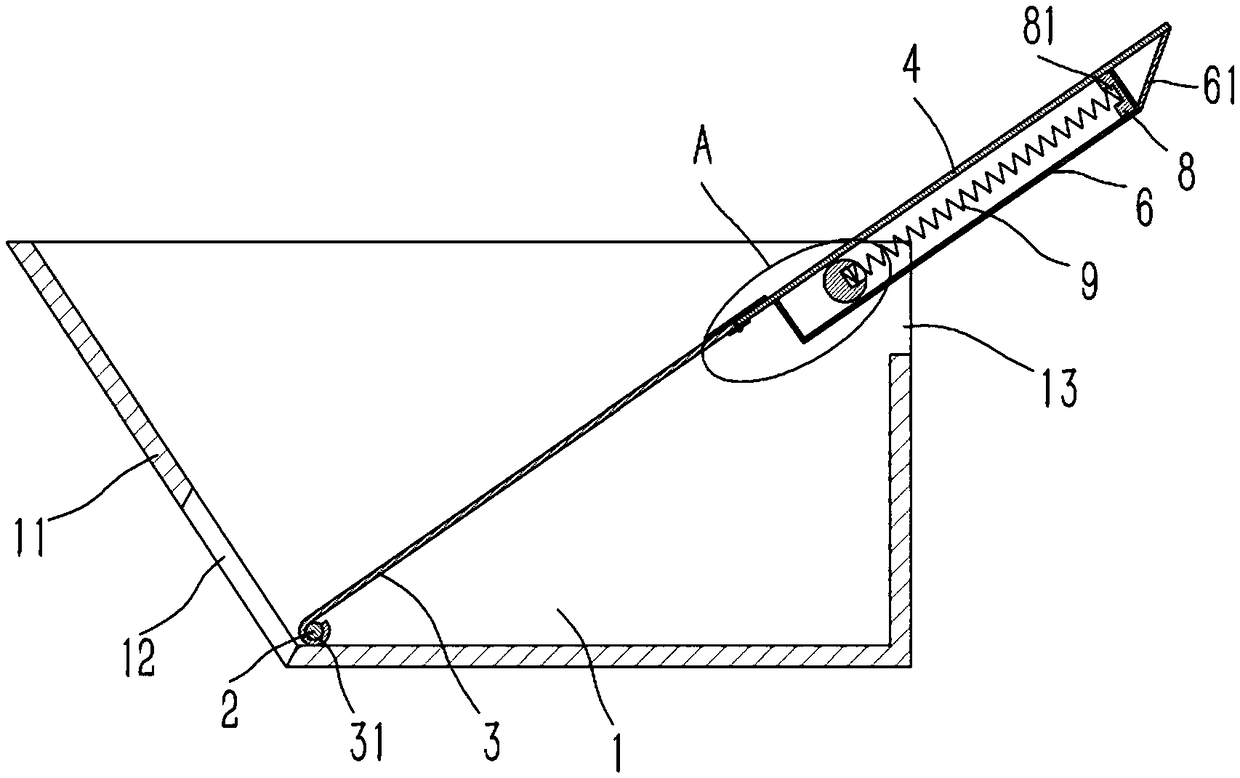

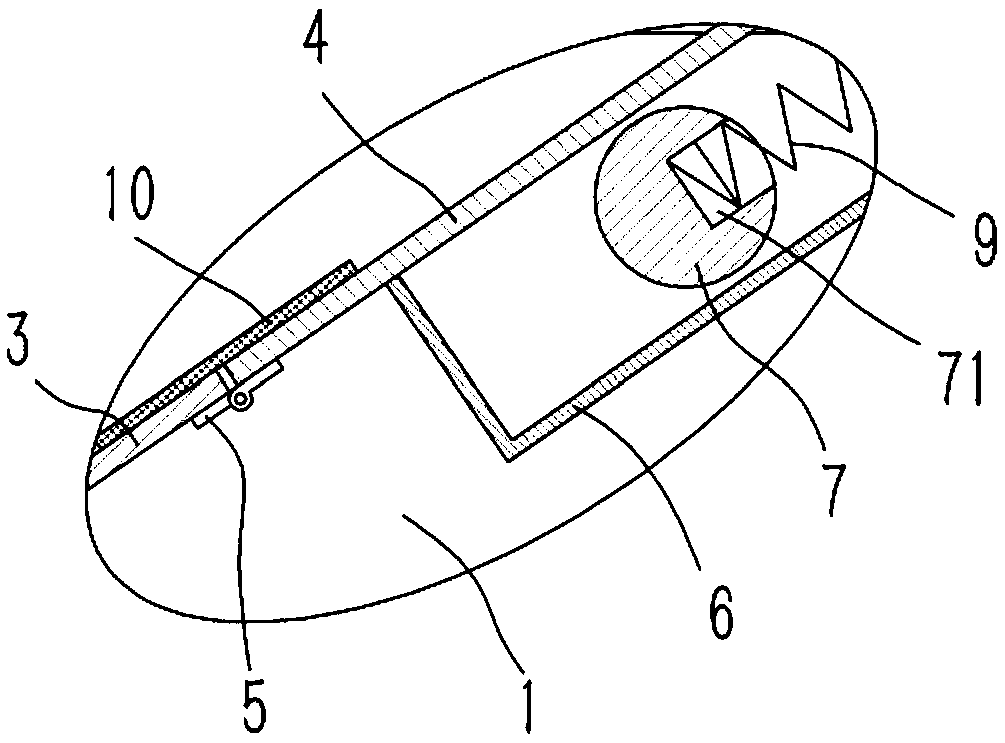

[0015] Example: see figure 1 , 2 As shown, a diversion device in a mineral transport vehicle includes a vehicle bucket 1, one side of the vehicle bucket 1 is formed with an inclined side wall 11, and the lower end of the inclined side wall 11 is formed with a discharge port 12, and the vehicle bucket 1 is close to the discharge port. A horizontal support shaft 2 is plugged into the feed port 12, and a lower deflector 3 and an upper deflector 4 are arranged obliquely in the bucket 1, and the upper side of the lower deflector 3 passes through several hinges 5 and The lower side of the upper deflector 4 is hinged, and the lower side of the lower deflector 3 is bent to form an arc-shaped bushing 31, which is inserted on the supporting shaft 2, and the two ends of the supporting shaft 2 It is plugged and fixed on the opposite side walls of the car bucket 1; the lower end surface of the upper deflector 4 is fixed with a "匚"-shaped guide frame 6, and a horizontal guide roller shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com