Crucible pouring device

A technology of feeding device and crucible, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as safety hazards and crucible falling, and achieve the effect of preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The drawings illustrate embodiments of the disclosure and it is to be understood that the disclosed embodiments are merely examples of the disclosure, which may be embodied in various forms and therefore specific details disclosed herein should not be construed as limiting. , but merely as a basis for the claims and as a representative basis for teaching one of ordinary skill in the art to variously employ the present disclosure.

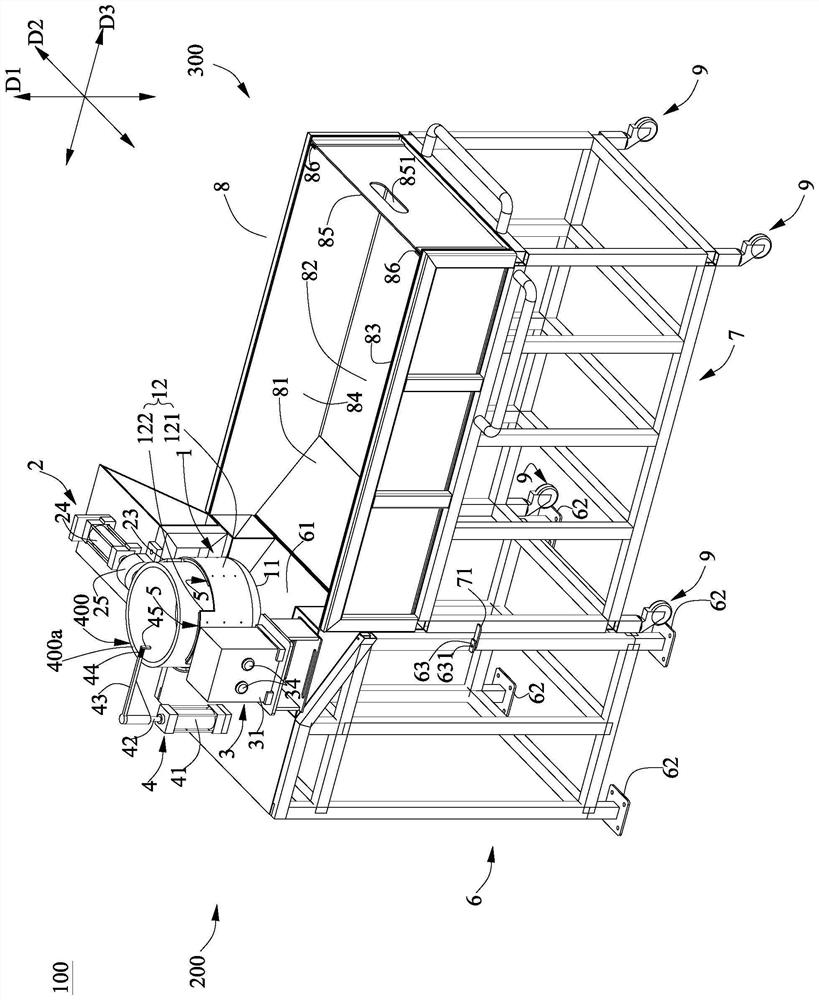

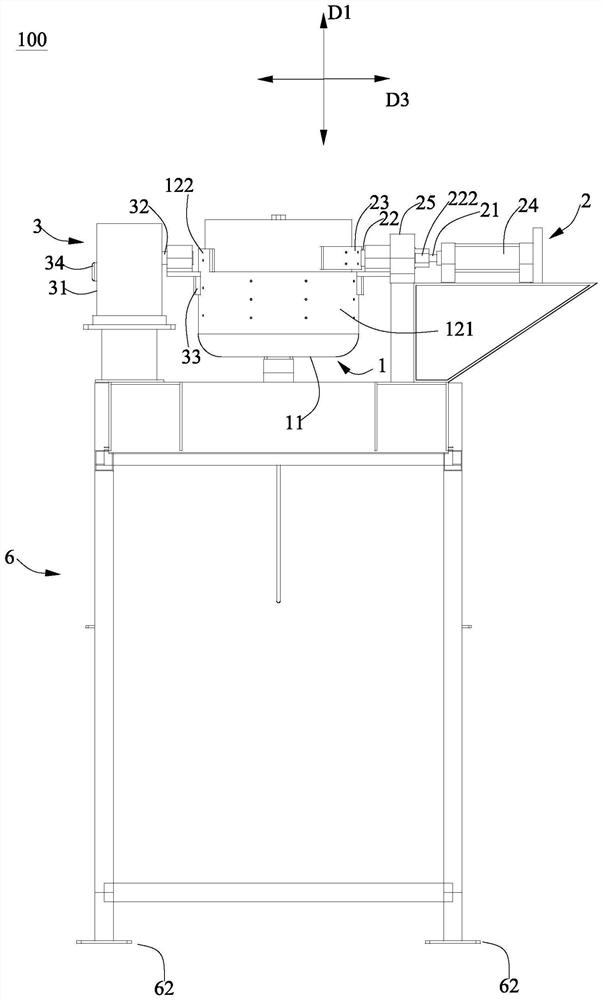

[0044] refer to figure 1 with figure 2 , The crucible receiving system 100 includes a crucible discharging device 200 and a receiving device 300 .

[0045] The crucible unloading device 200 includes a crucible frame 1 , a clamping mechanism 2 and a driving mechanism 3 . The crucible frame 1 is used for accommodating a crucible 400 filled with liquid substances. The clamping mechanism 2 includes a clamping piece. The clamping piece is used to push the part of the crucible 400 exposed from the crucible holder 1 from one side along the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com