Patents

Literature

107 results about "Medicine bottle cap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

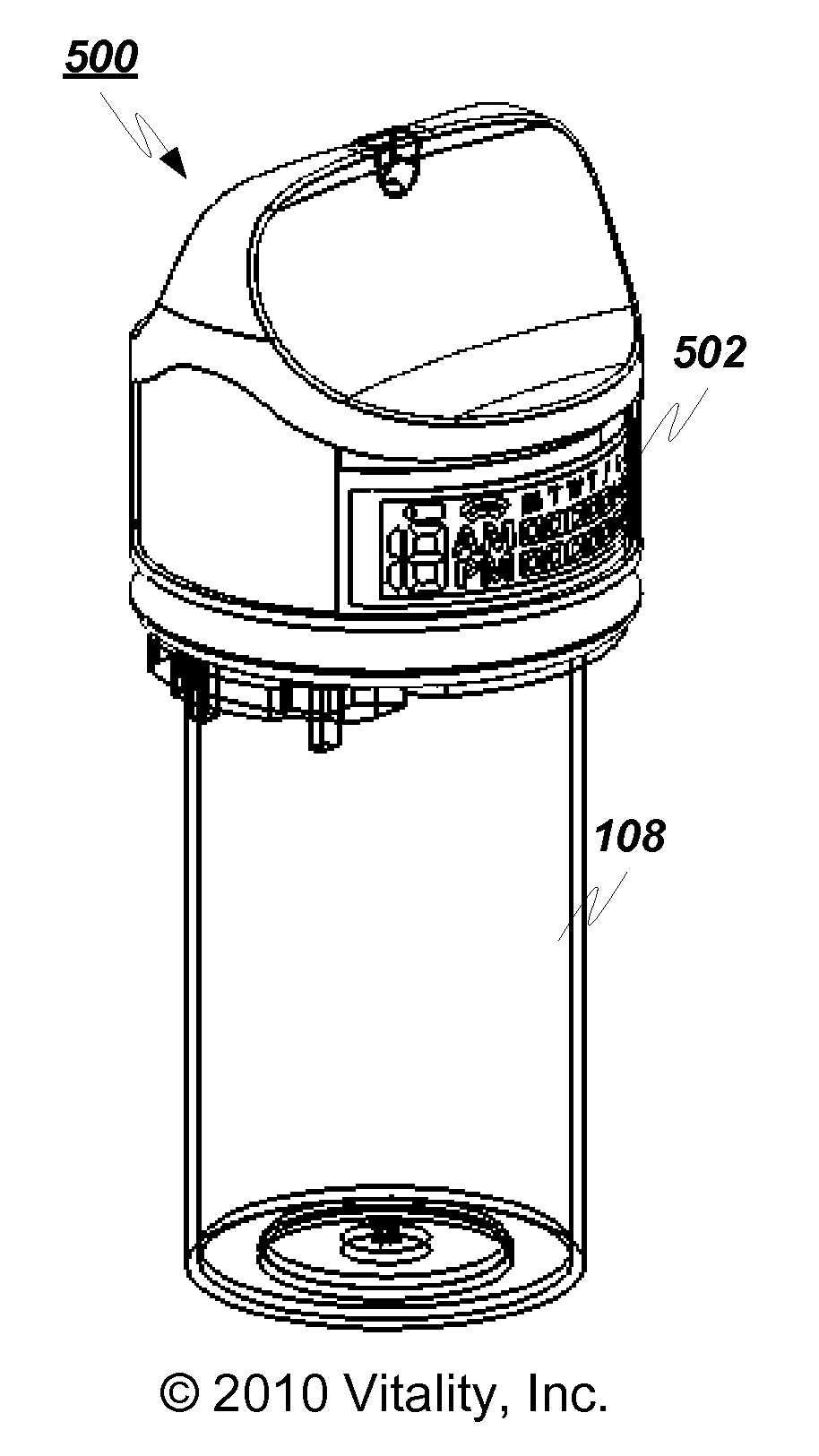

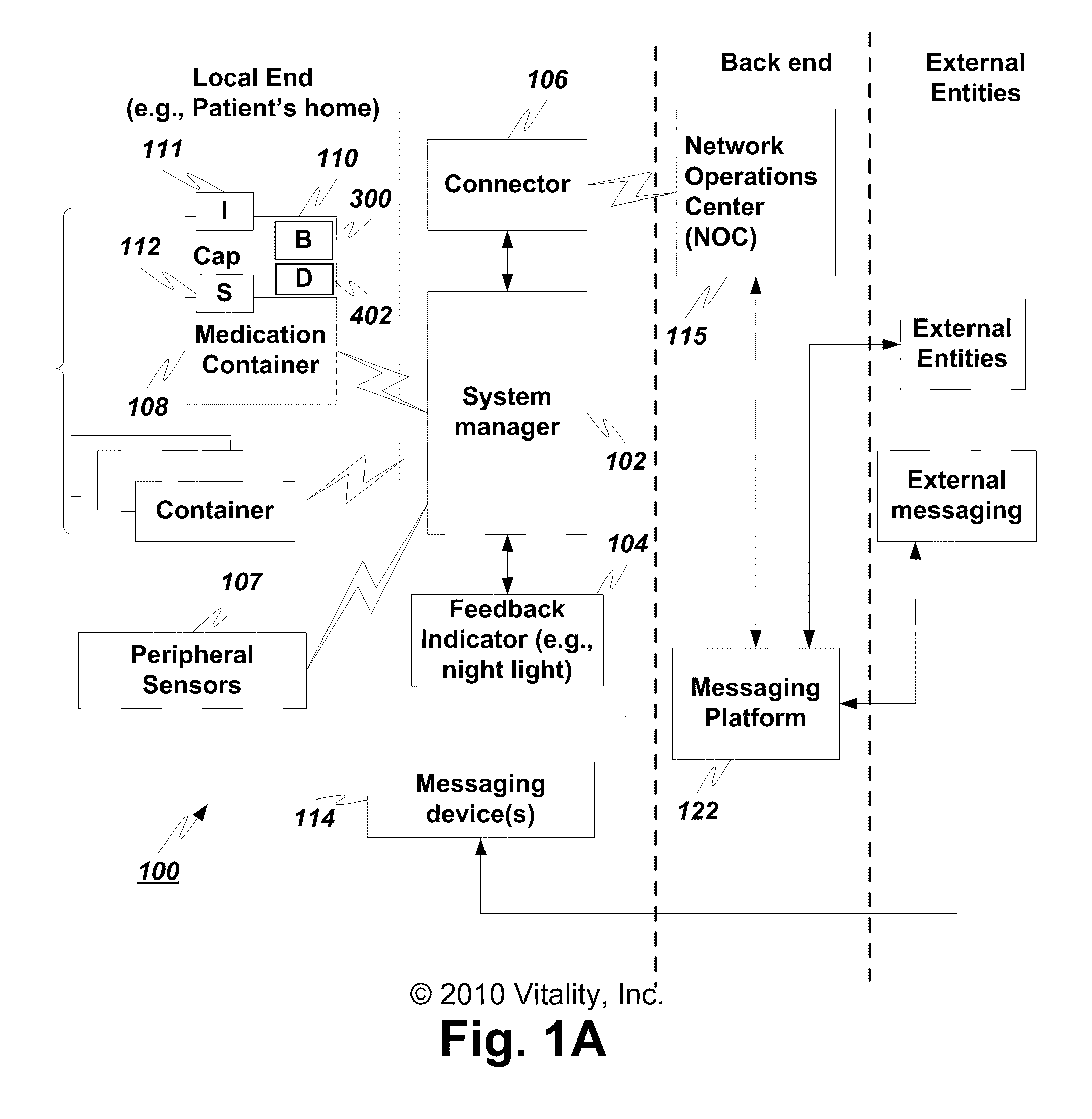

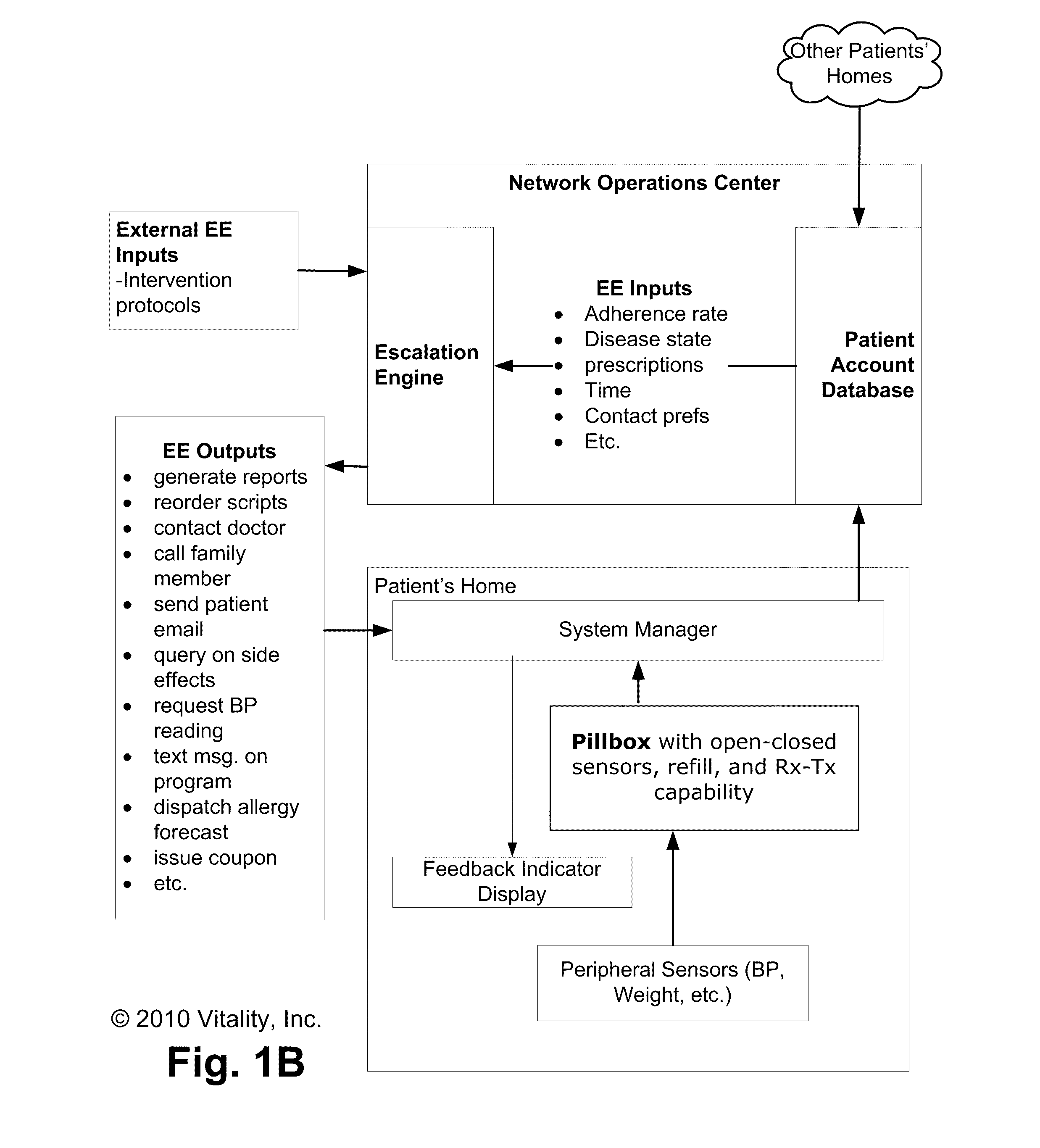

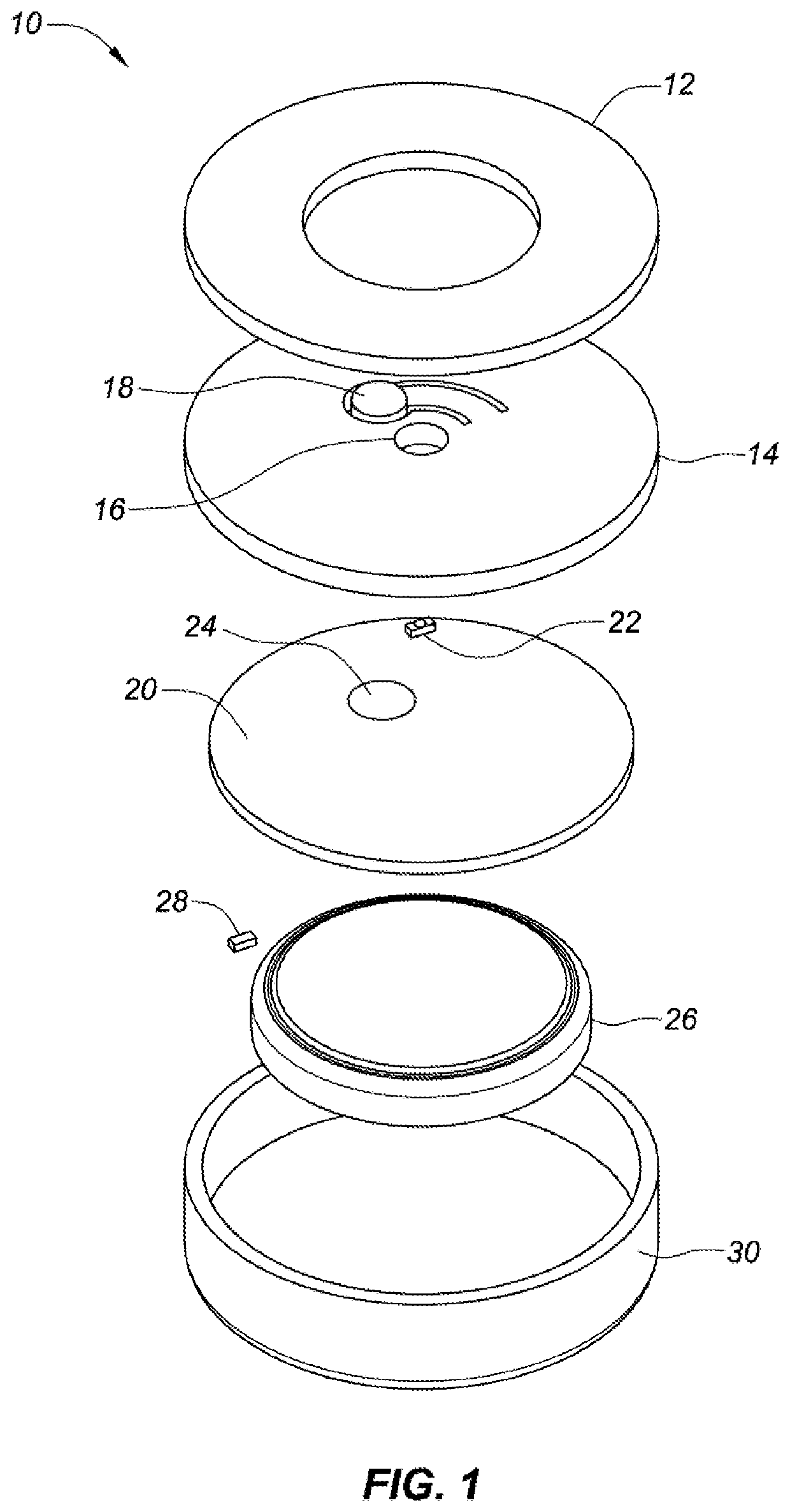

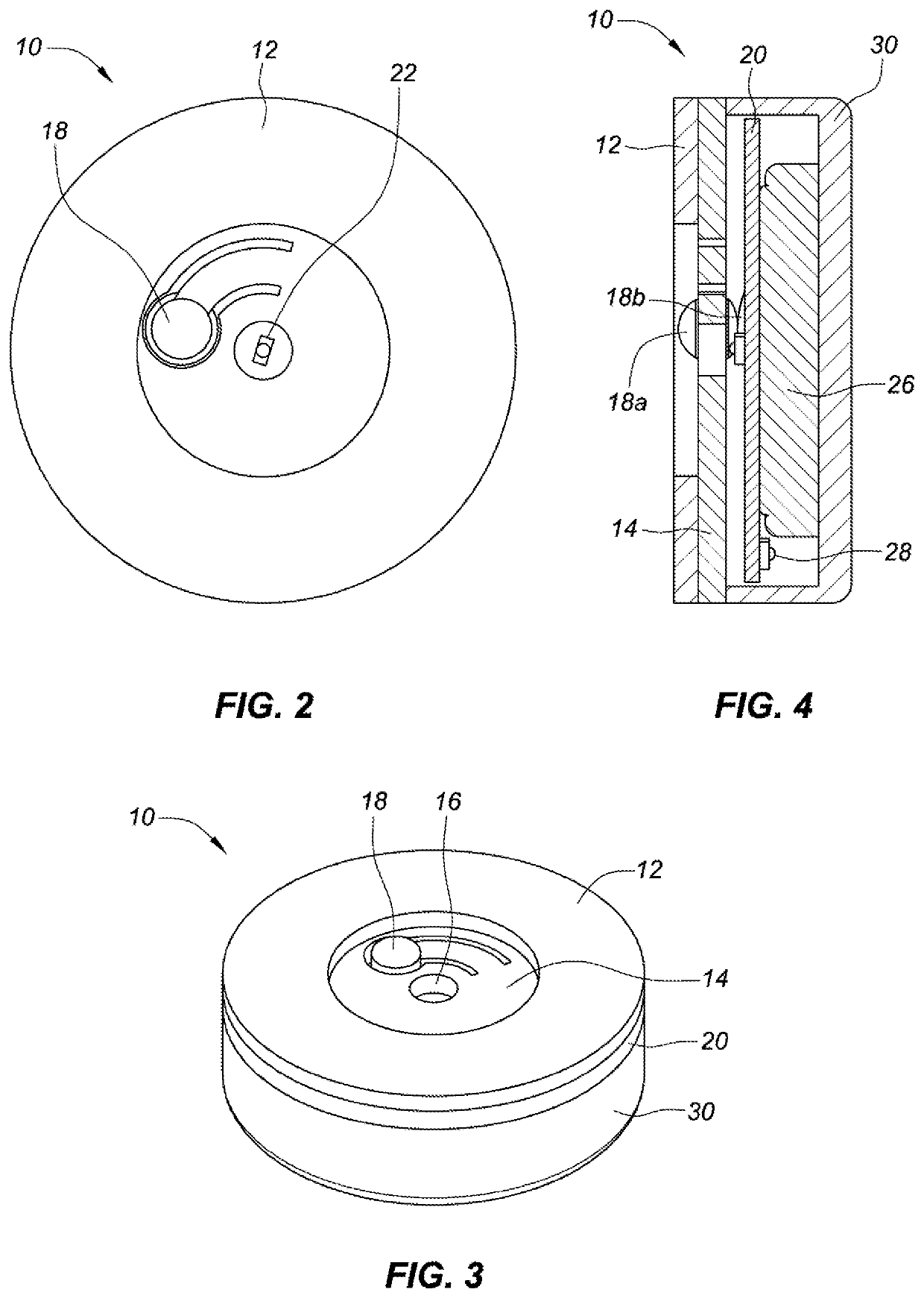

Medicine Bottle Cap With Electronic Embedded Curved Display

A cap for a medicine container includes a base portion having a curved outer surface and being connectable to a medicine container, the base having an indented portion on at least a part of said curved outer surface. An electronic display fits in the indented portion of the base portion and electronically connected to circuitry within the cap. A clear portion covers the electronic display. A multi-color light-emitting diode (LED) electronically connected to the circuitry within the cap.

Owner:VCCB HLDG INC

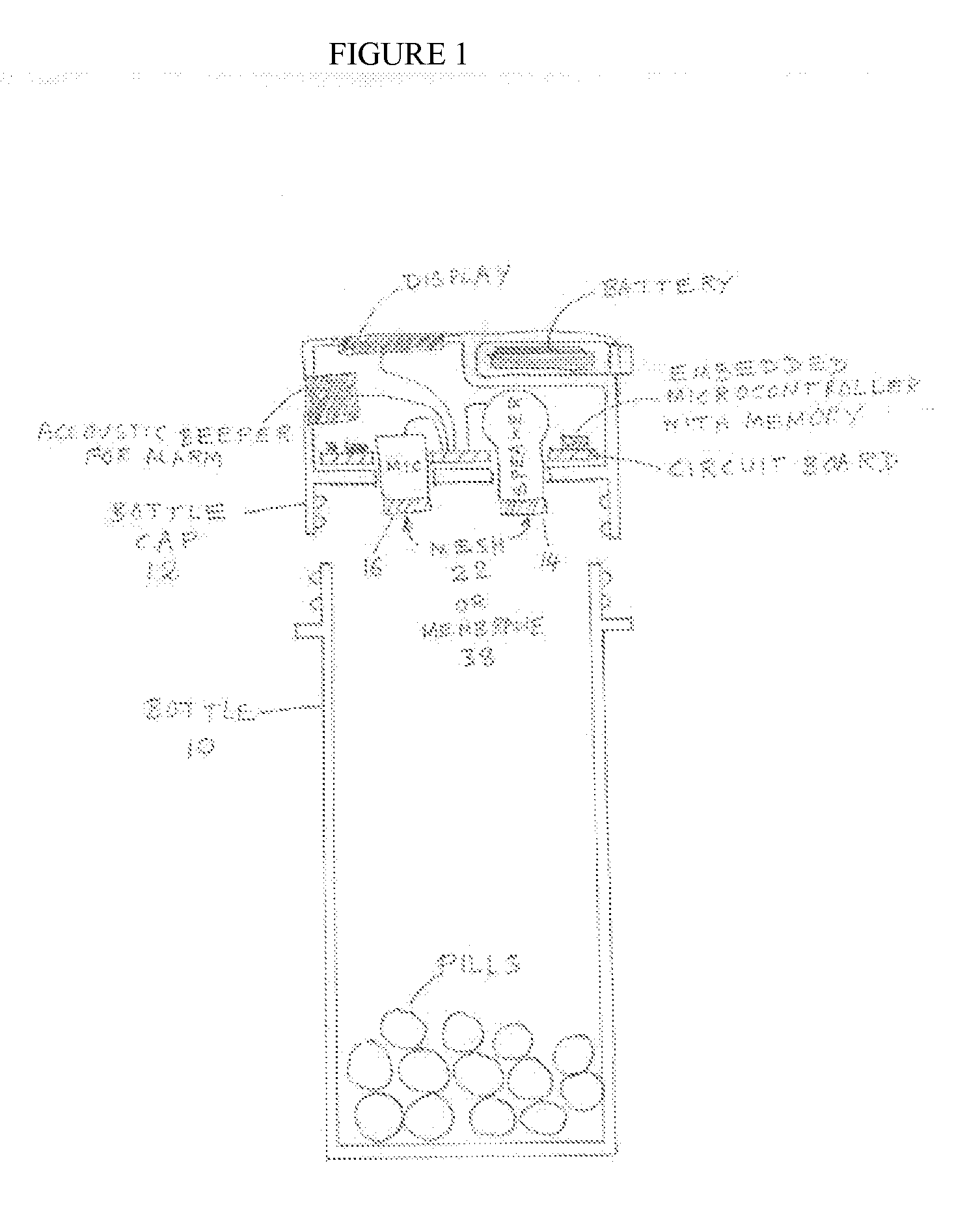

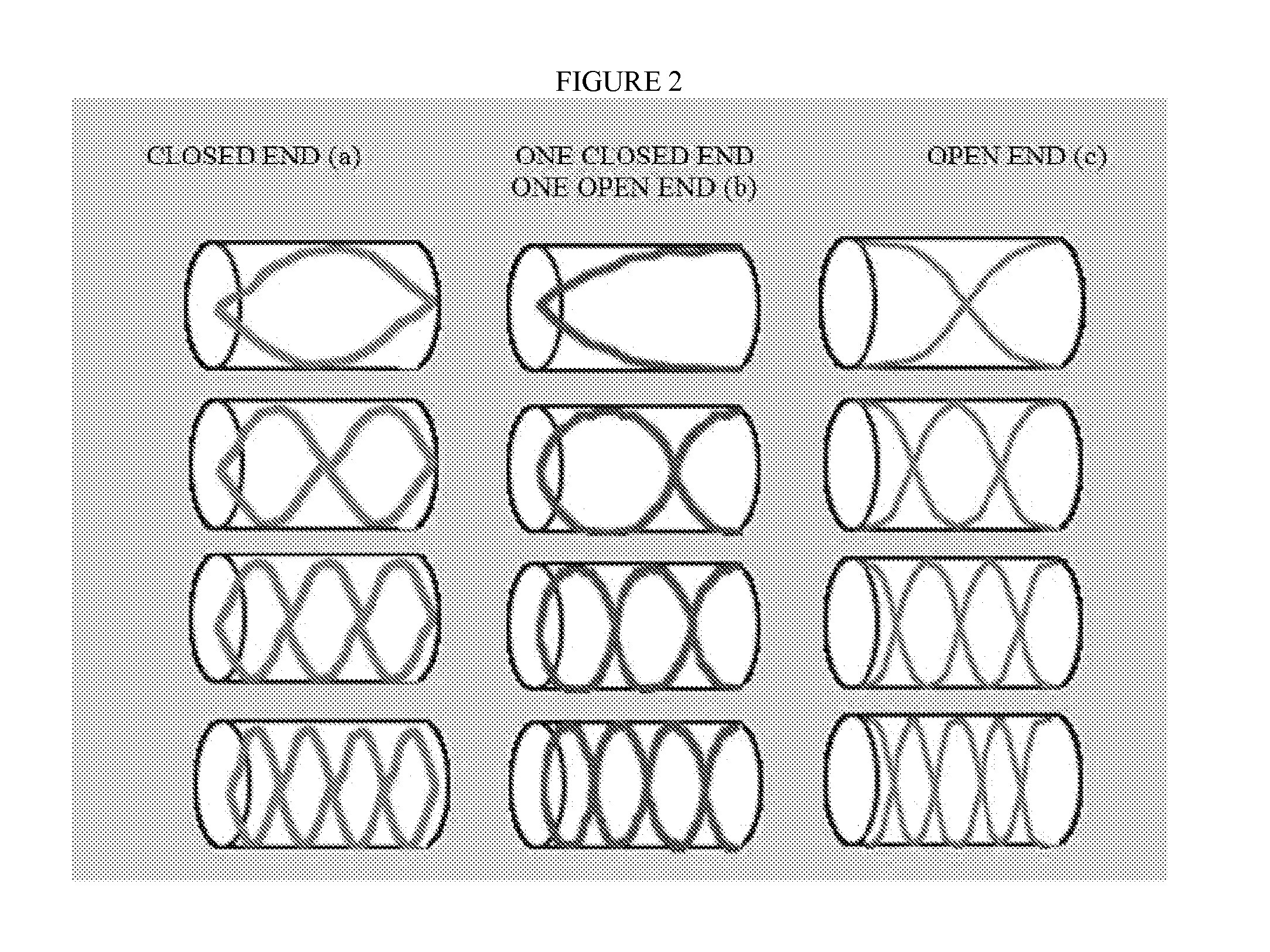

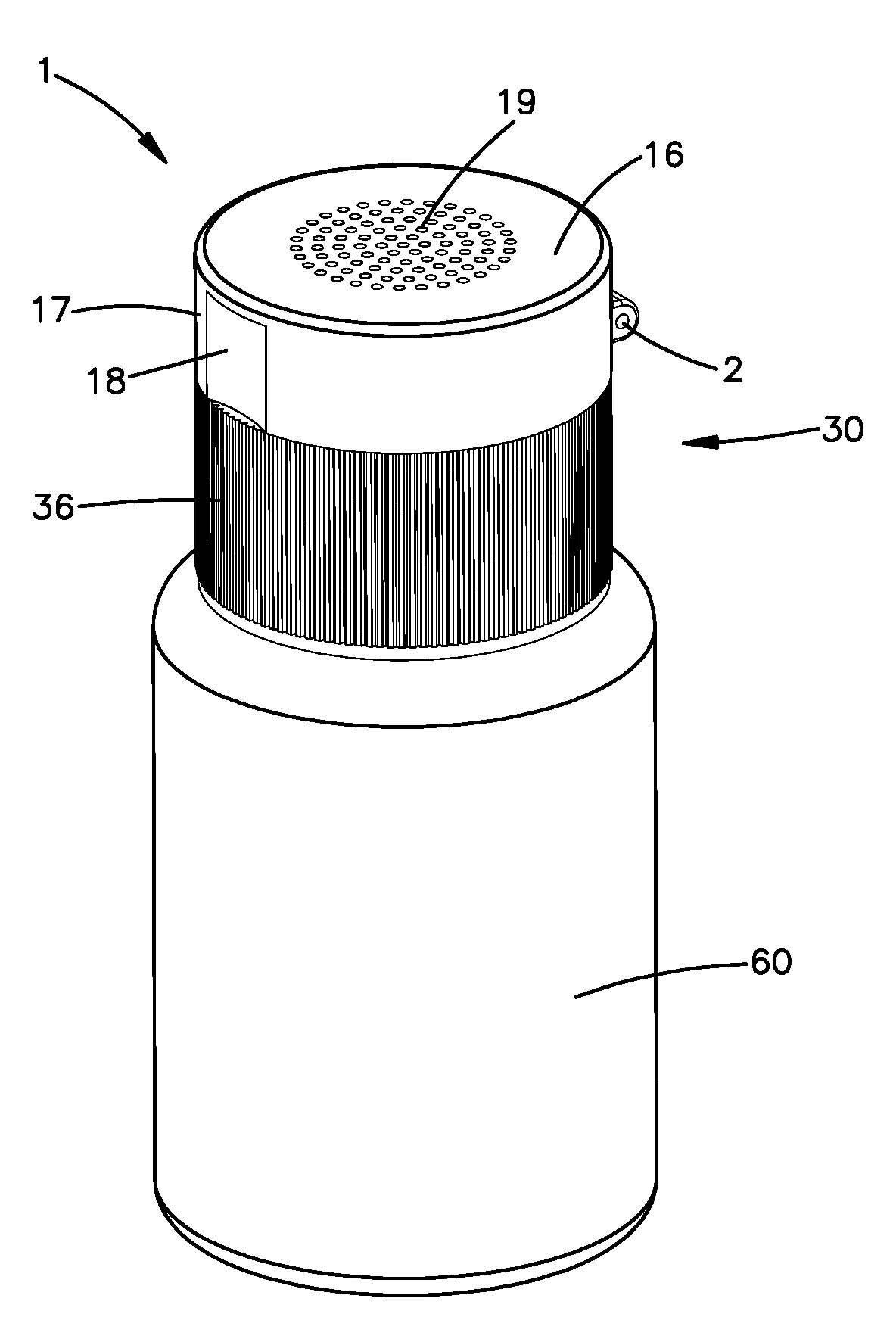

Dual purpose pill reminder and tamper detector

InactiveUS20140341411A1Reduce peak powerHigh transmission powerDrug and medicationsBurglar alarmCapacitanceCompliance Monitoring

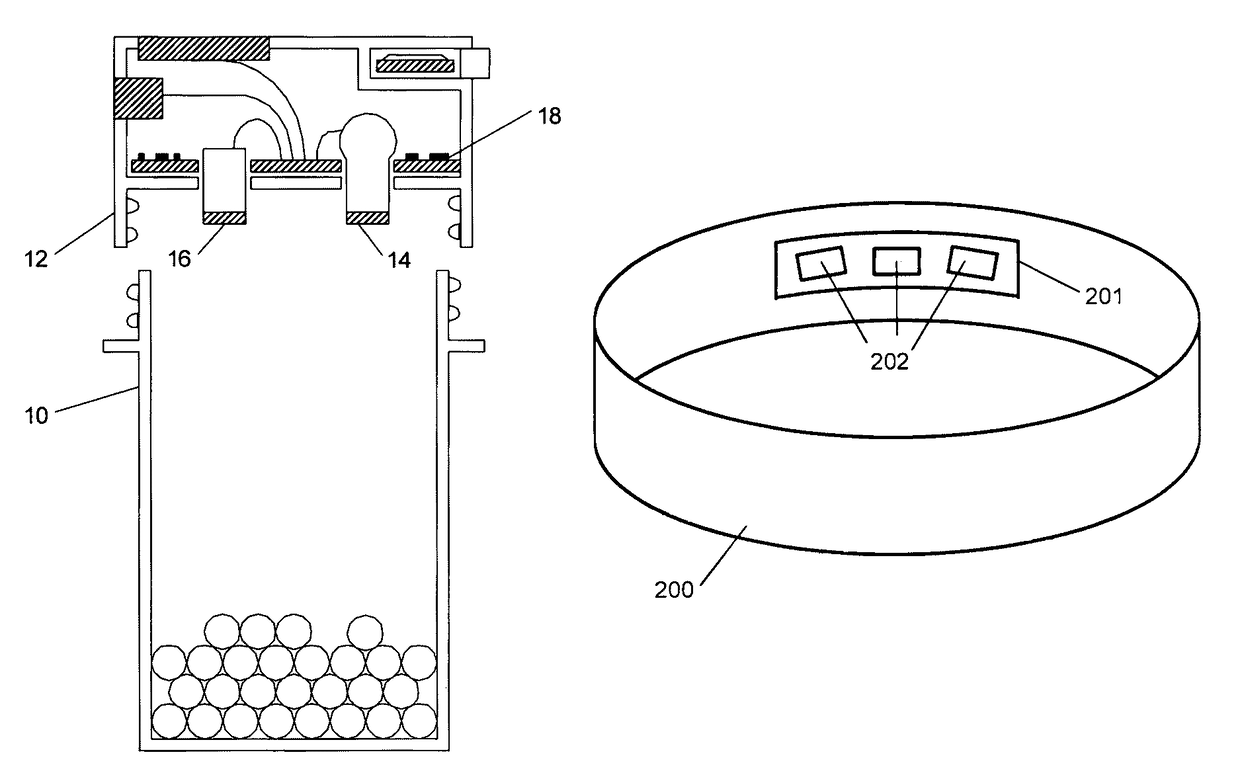

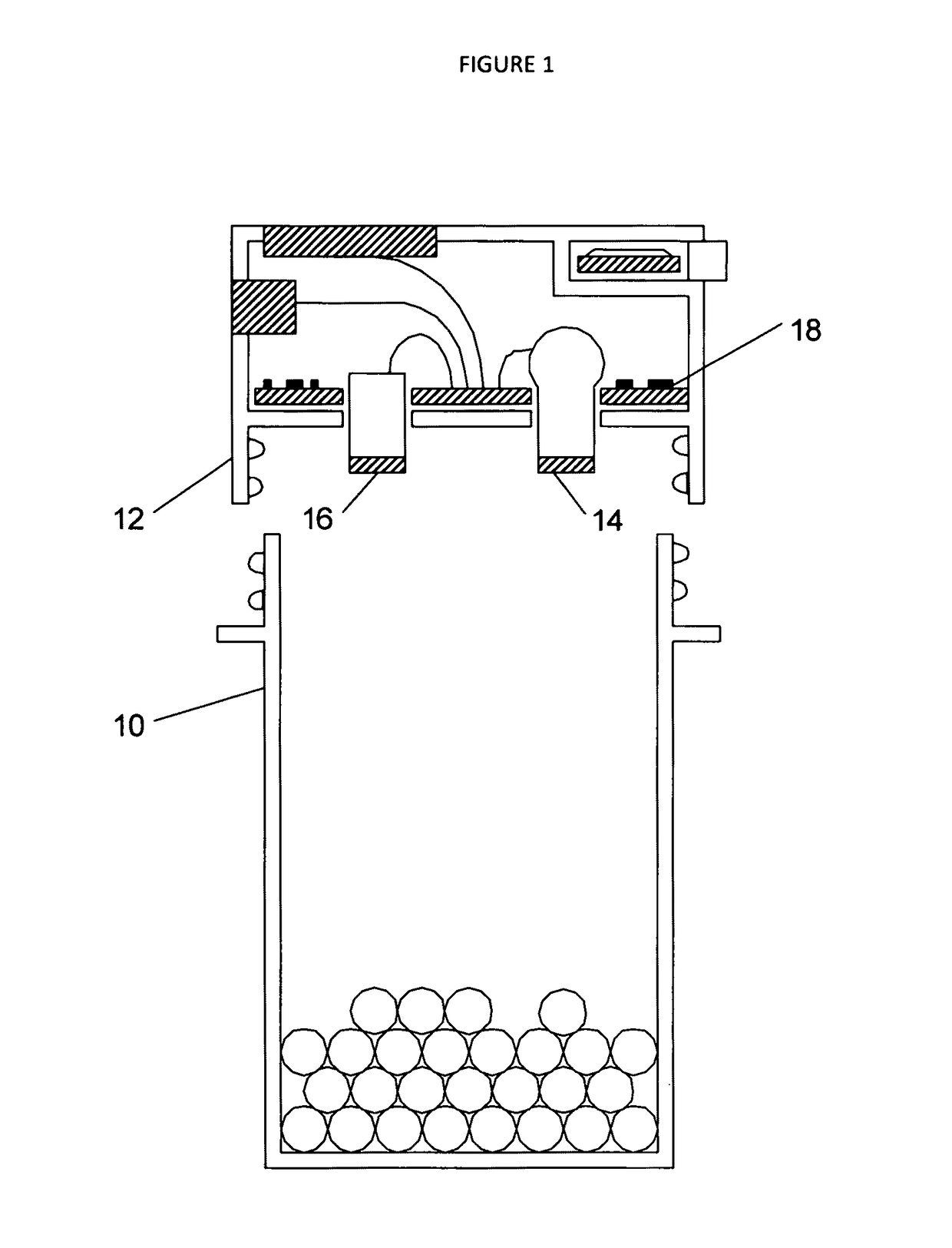

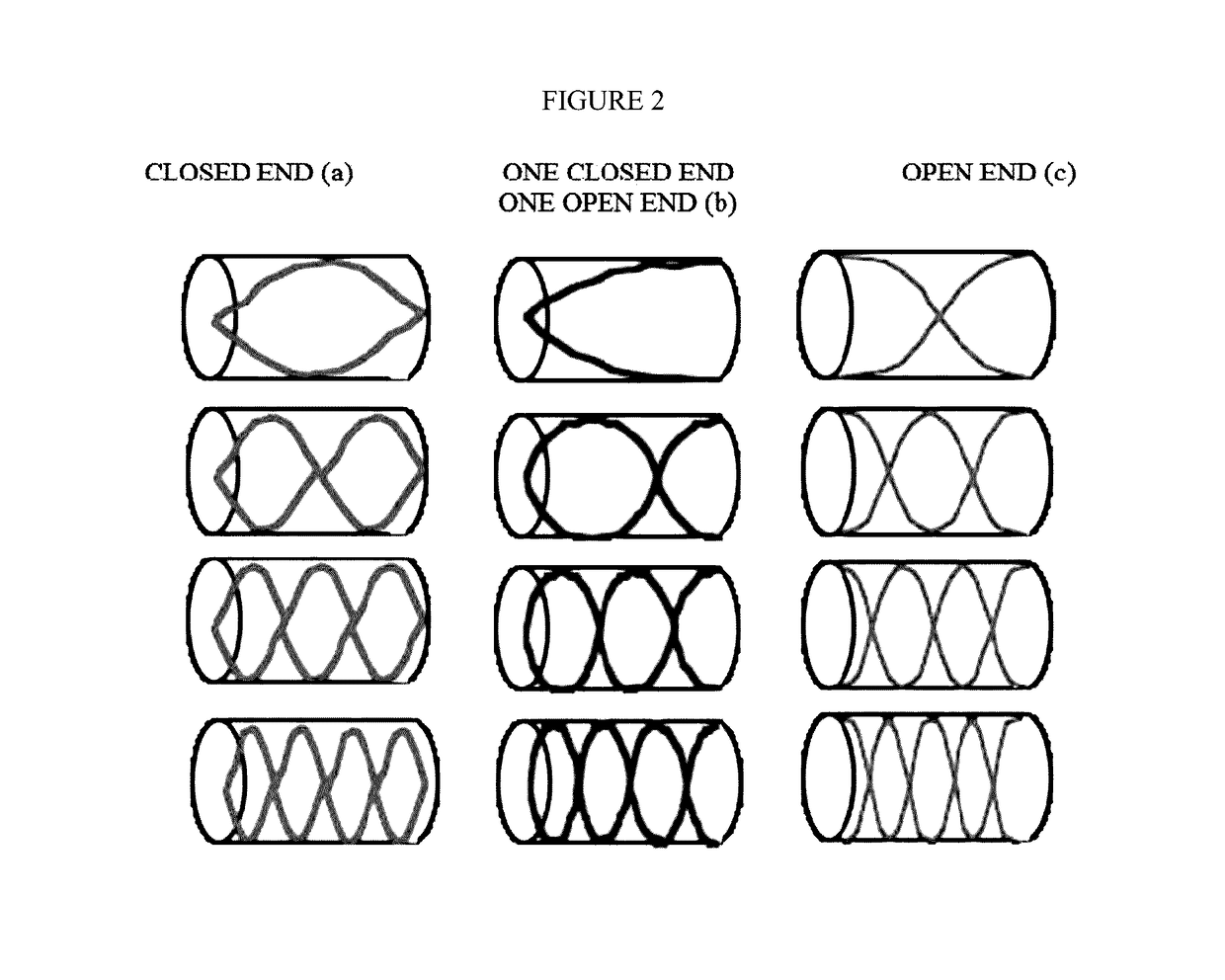

An audio signal analysis method is provided for detecting the opening and closing of a medicine bottle cap in a robust manner using a micro speaker and a microphone along with associated mixed signal electronics. It is also used for robust tamper detection and for monitoring liquid medication consumption accurately. In a preferred embodiment an un-modulated OFDM signal is used that covers the entire operating audio spectrum. In another embodiment, Complimentary code based phase encoding of the subcarrier phases is used to reduce the peak to average power of the OFDM signal, thereby enabling higher transmit power of the audio signal to mitigate against interference. A suitable wireless device can be co-located with the mixed signal electronics for sending the bottle usage, medication reminder alarm, and tamper status to the medication compliance monitoring system or to the user's cell phone. In some embodiments of the patent, electrical capacitance sensing is used to determine if the bottle is opened or closed.

Owner:MOHINDRA RAJKUMARI

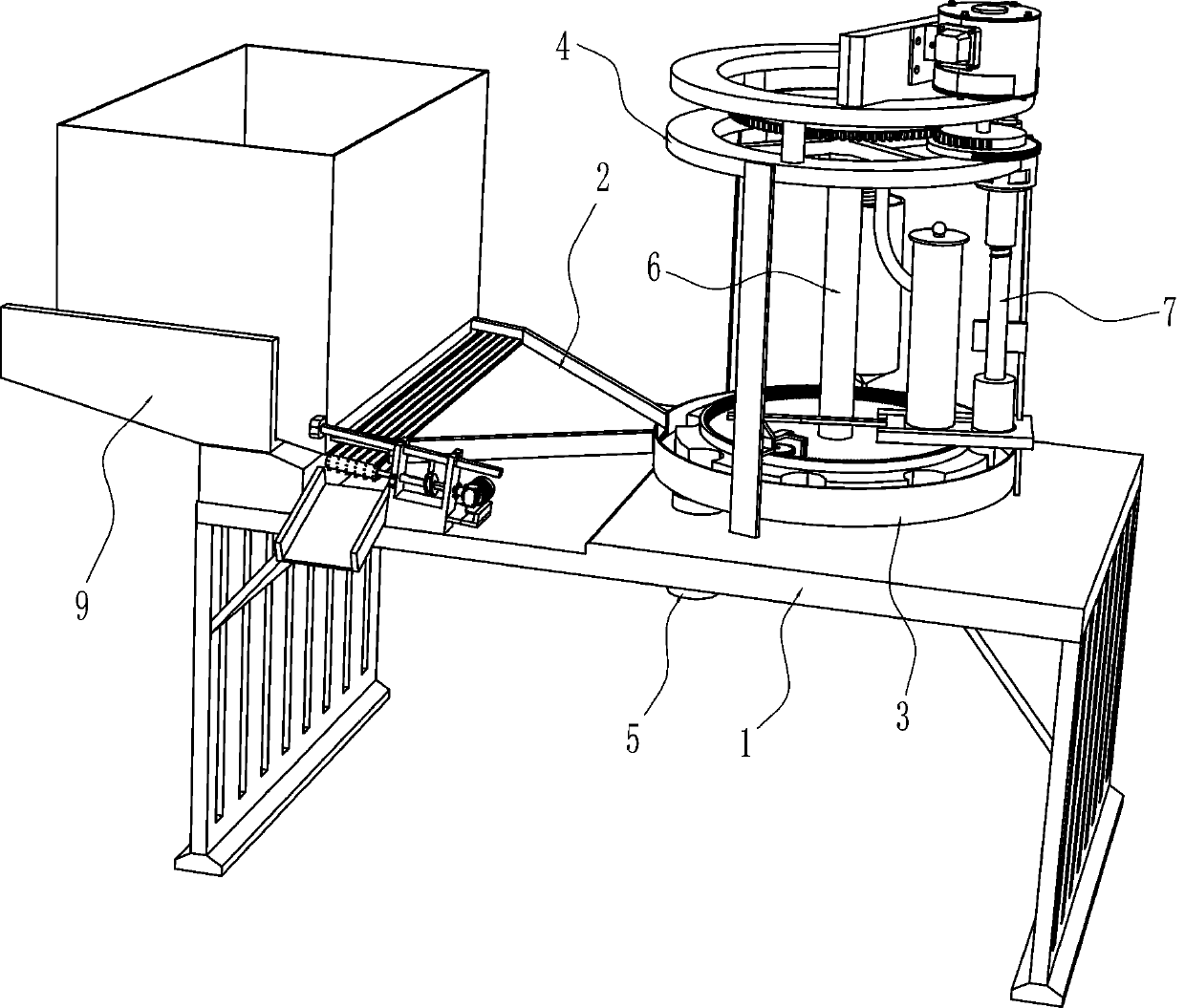

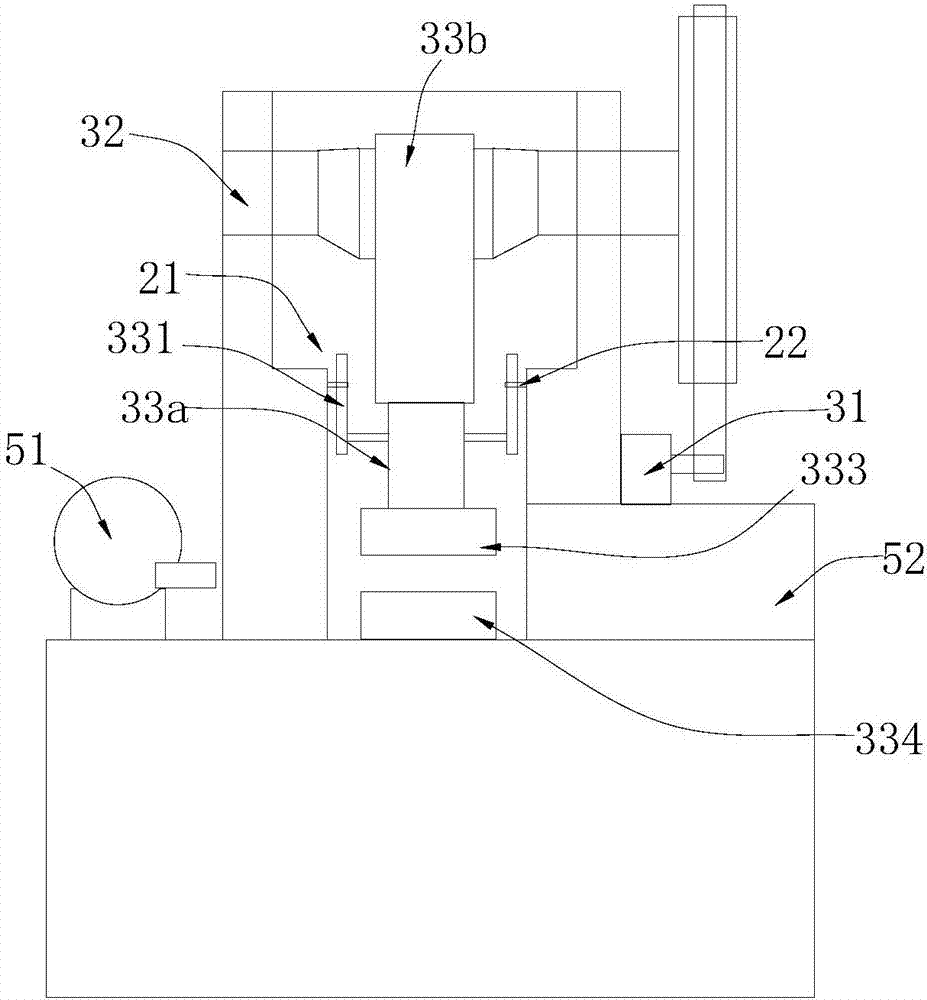

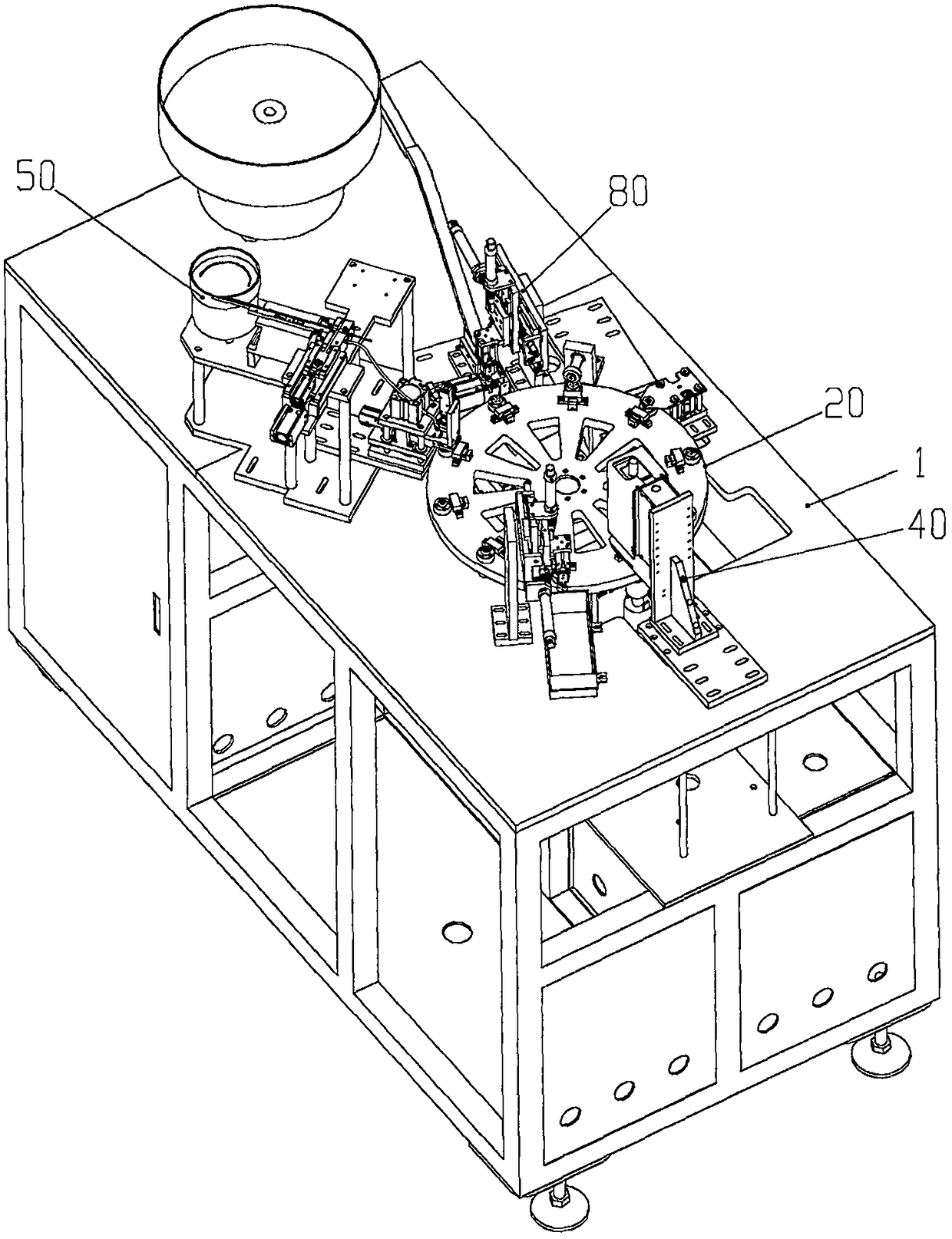

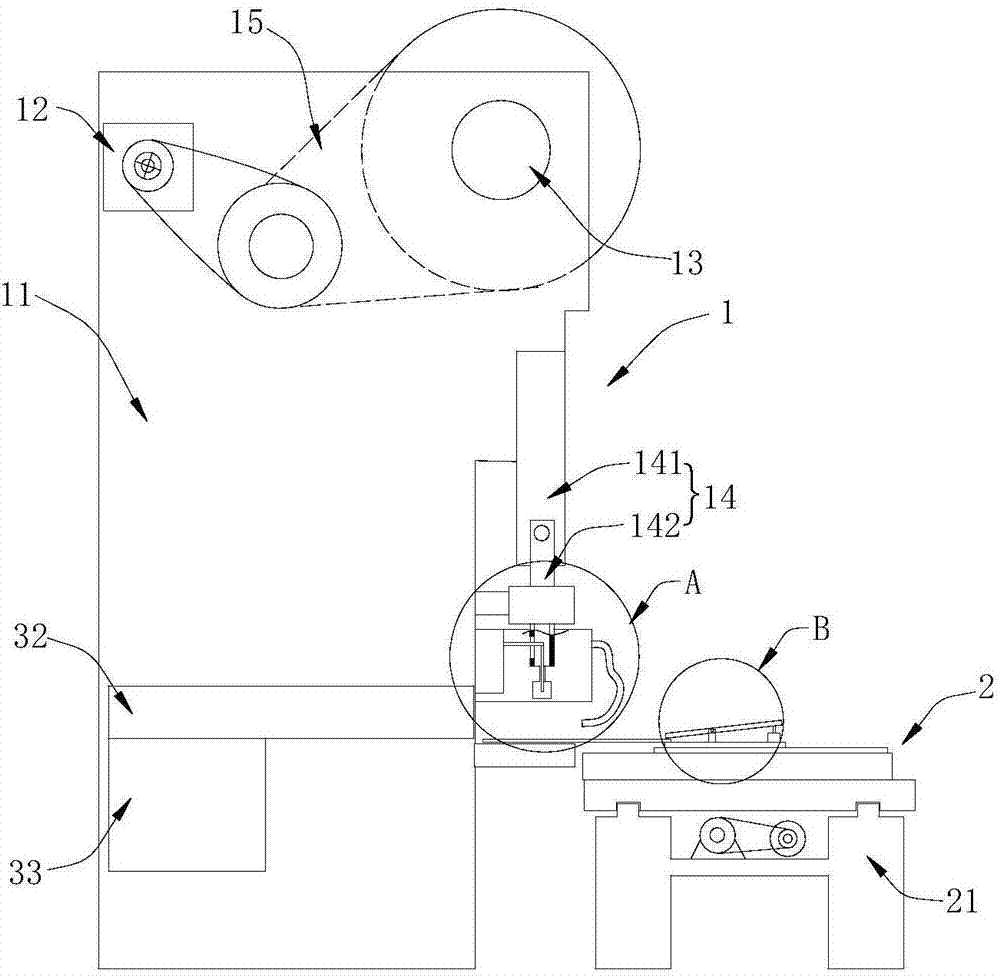

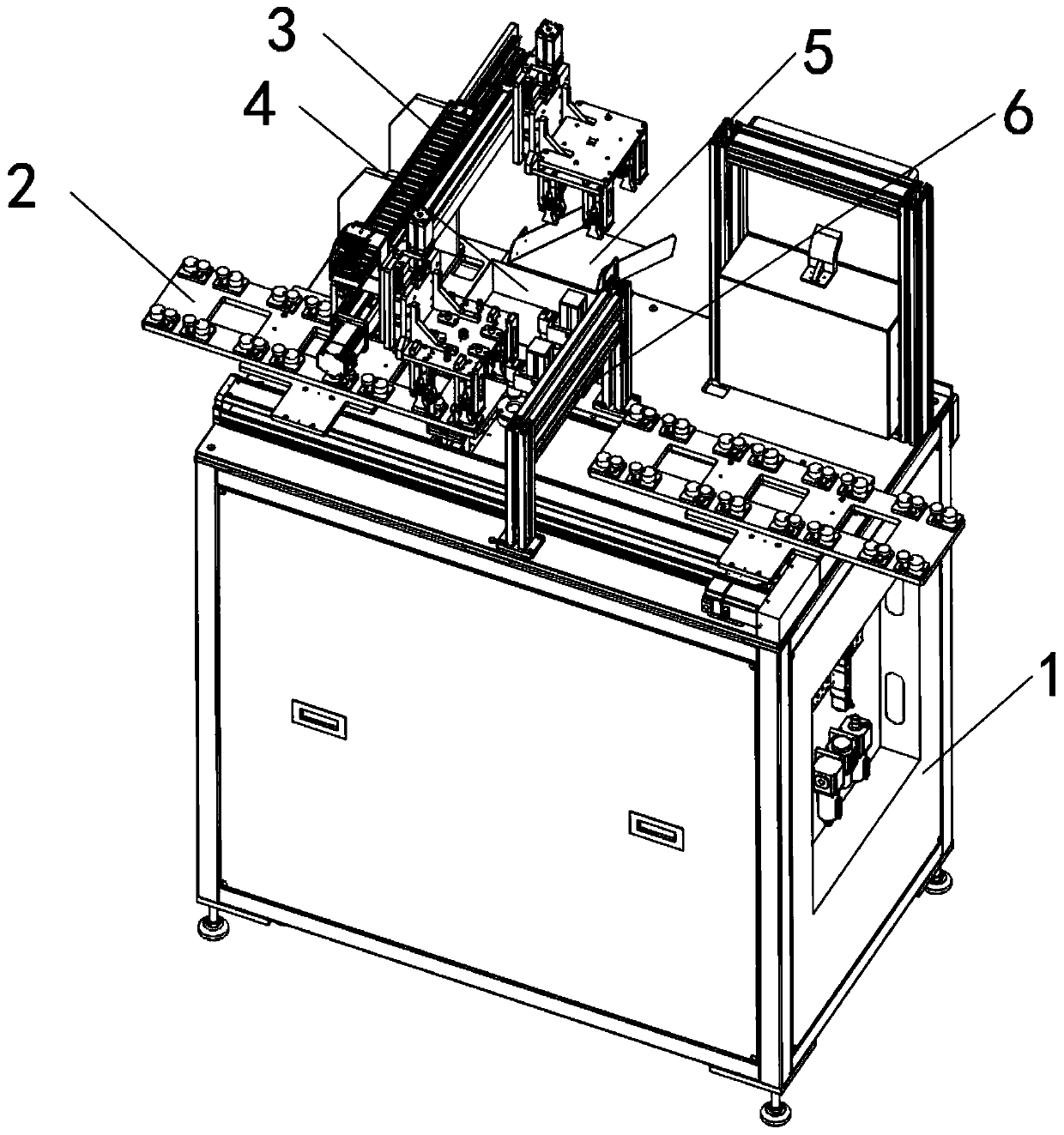

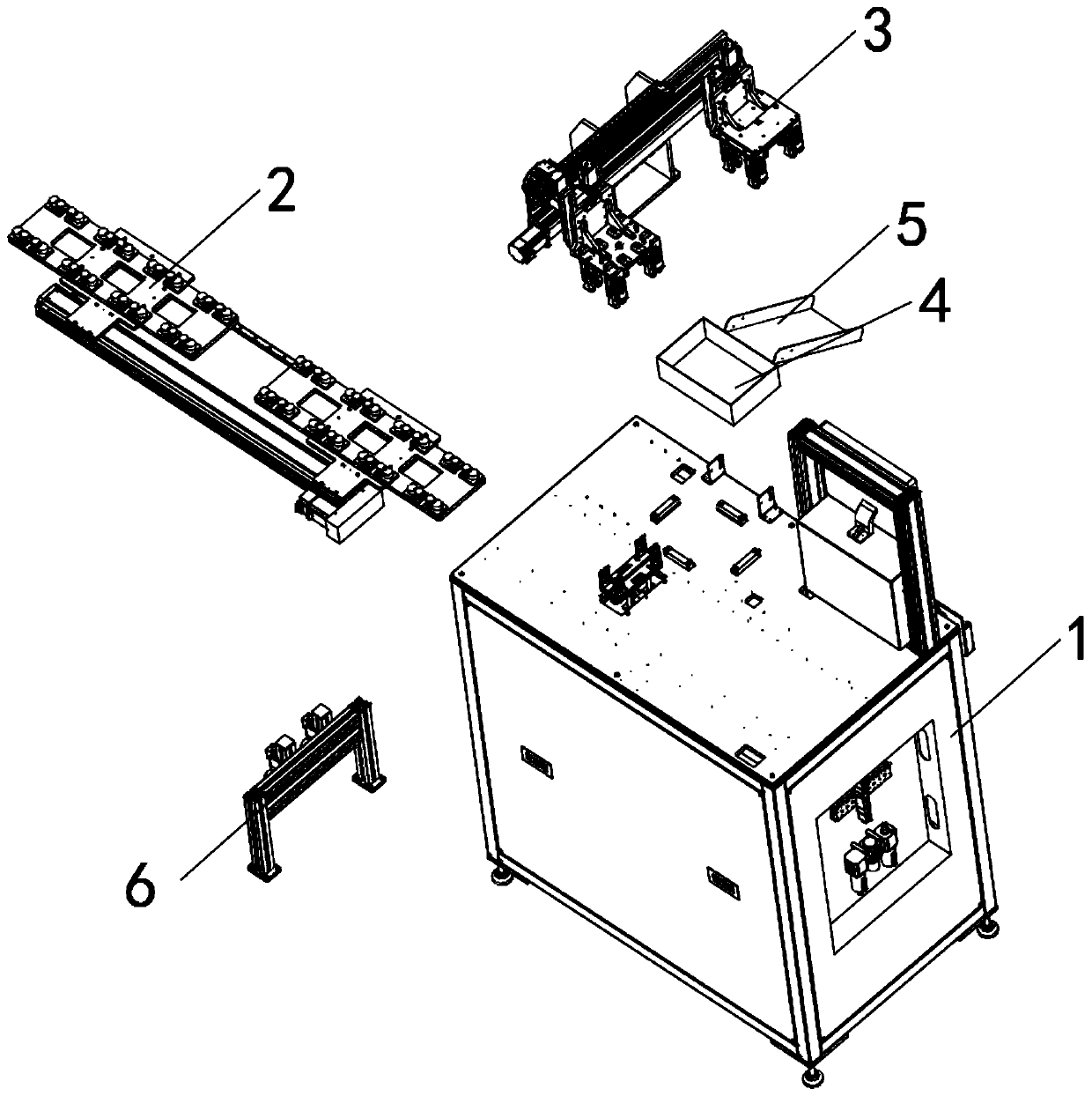

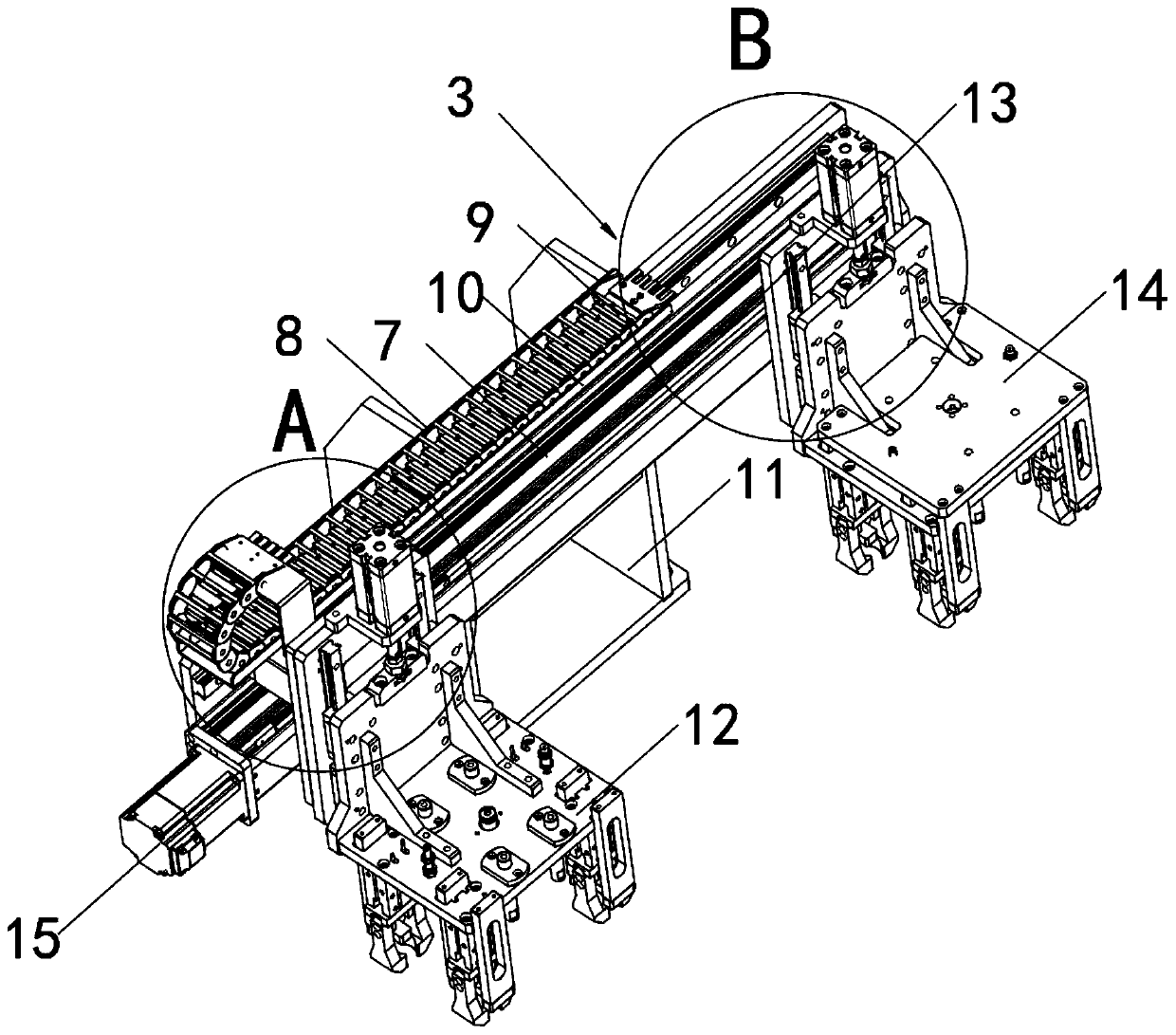

Production equipment for packaging bottled antibacterial fluid and production method thereof

ActiveCN104443496AHigh degree of automationReduce labor intensityCapsClosure using capsProduction lineMedicine bottle cap

The invention relates to production equipment for packaging bottled antibacterial fluid and a production method thereof. The production equipment for packaging bottled antibacterial fluid and the production method thereof are characterized in that the production equipment comprises a medicine bottle orientation arranging and conveying device, a medicine bottle material injection device, a medicine bottle pair-wise output control device, a bottle cap orientation arranging and conveying device, a bottle cap mounting mechanism, a medicine bottle cap screwing device, a charged medicine bottle output device and a medicine bottle label pasting and conveying device. By the adoption of the production equipment, human factor damage can be reduced in production, the automation degree of the beverage-packaging production line is improved, the labor intensity of workers is lowered, and the production cost is lowered.

Owner:LANJIATANG BIOLOGICAL MEDICINE FUJIAN CO LTD

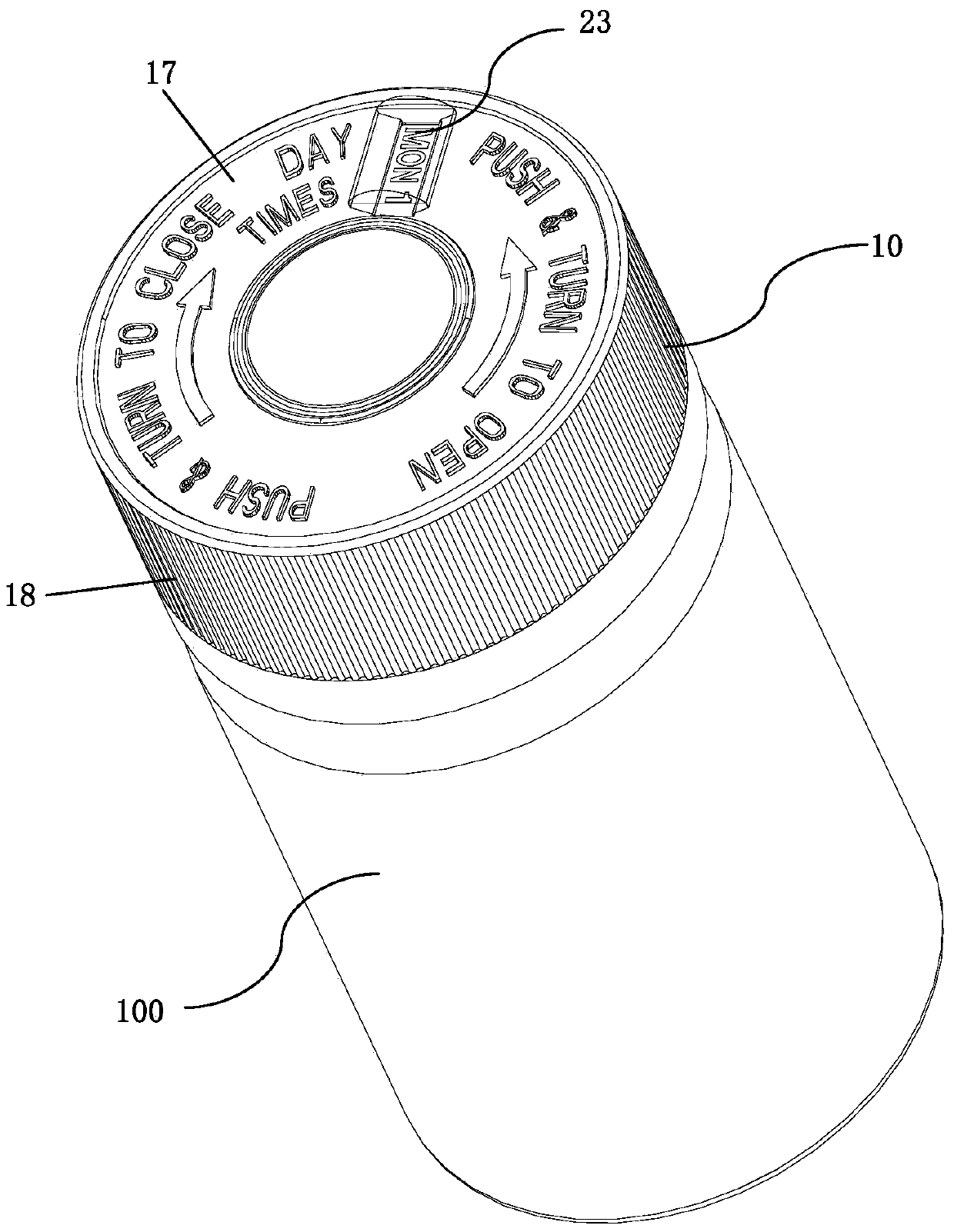

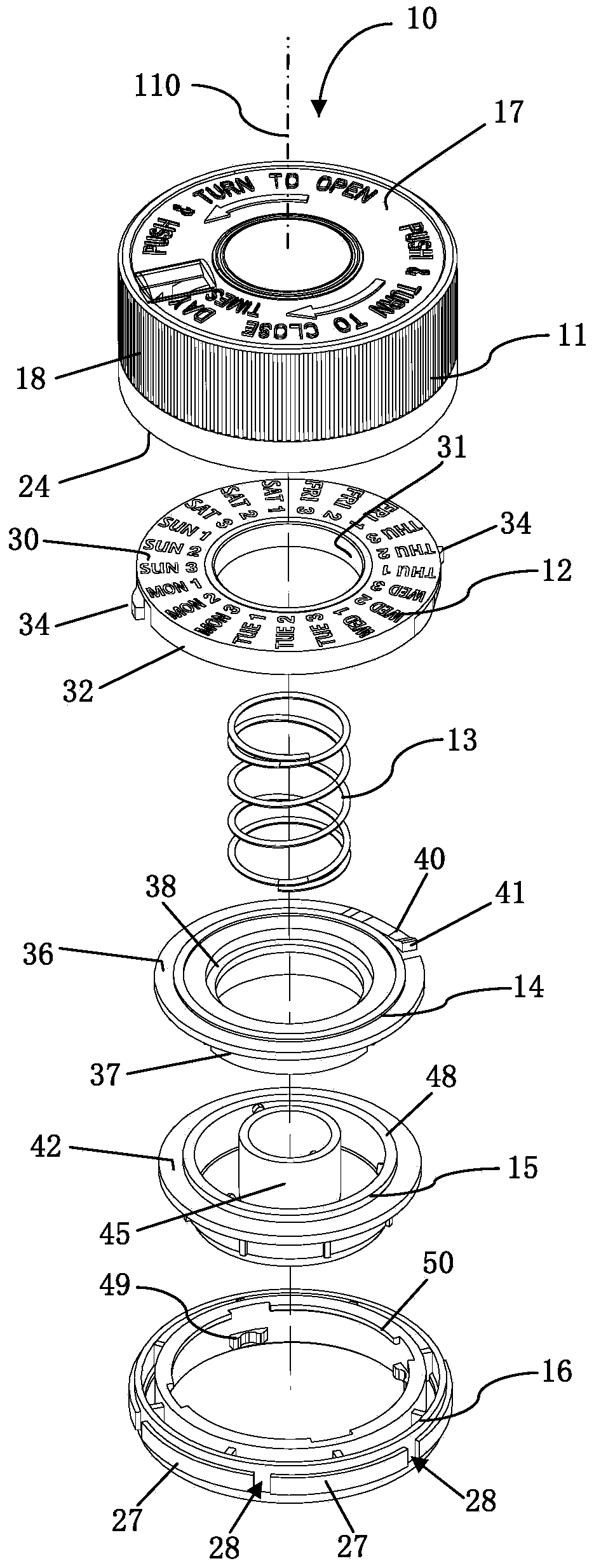

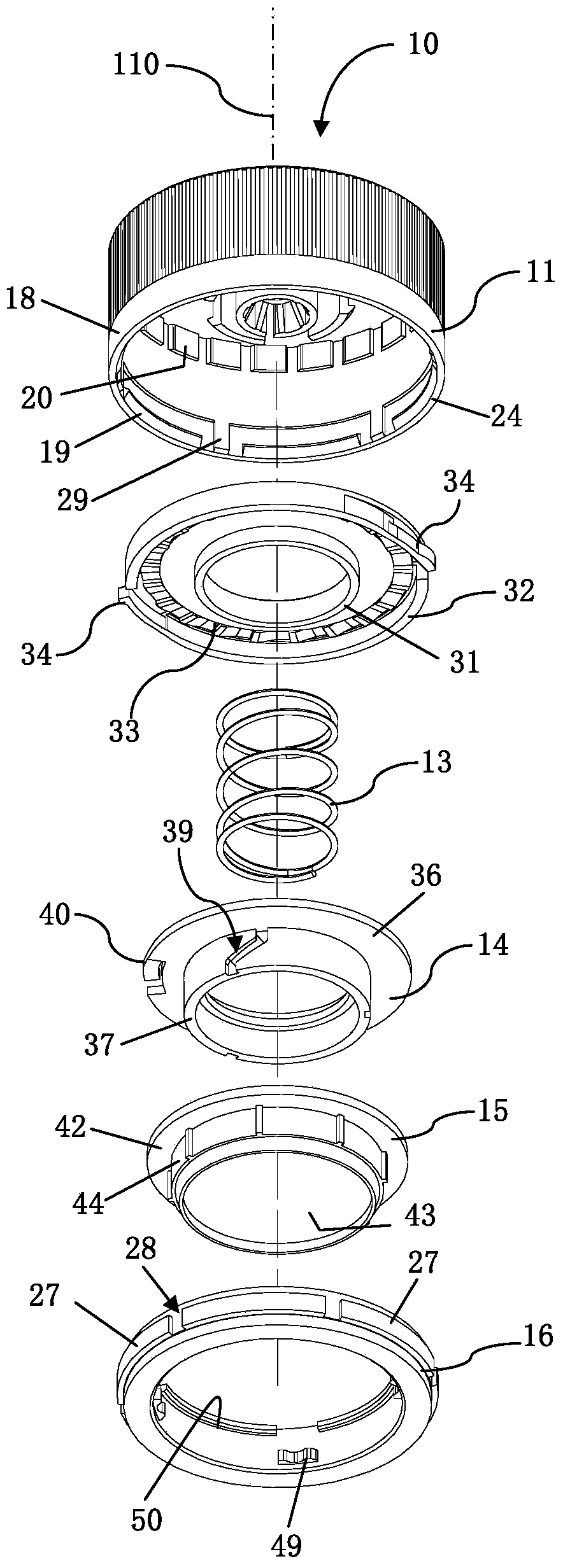

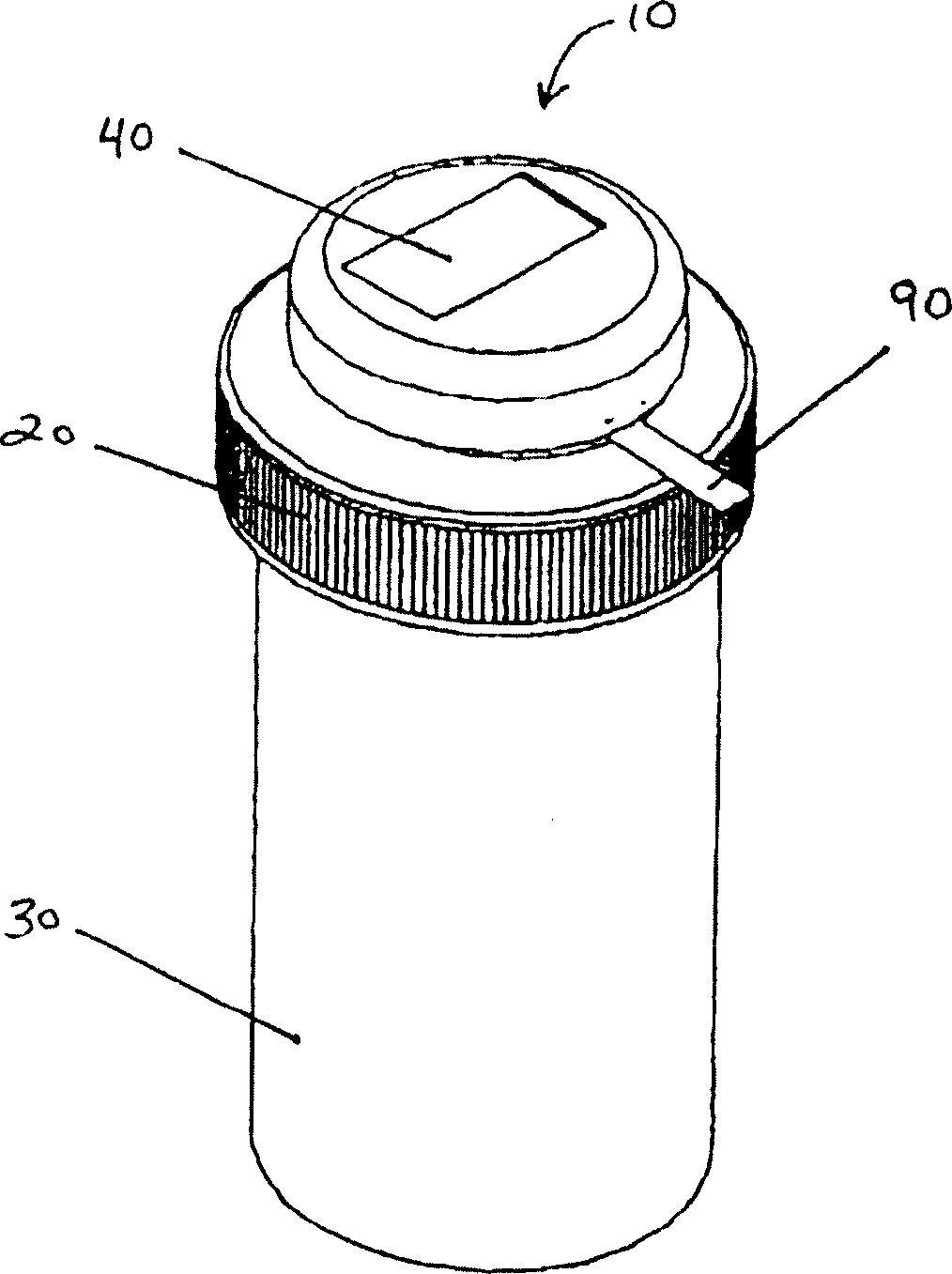

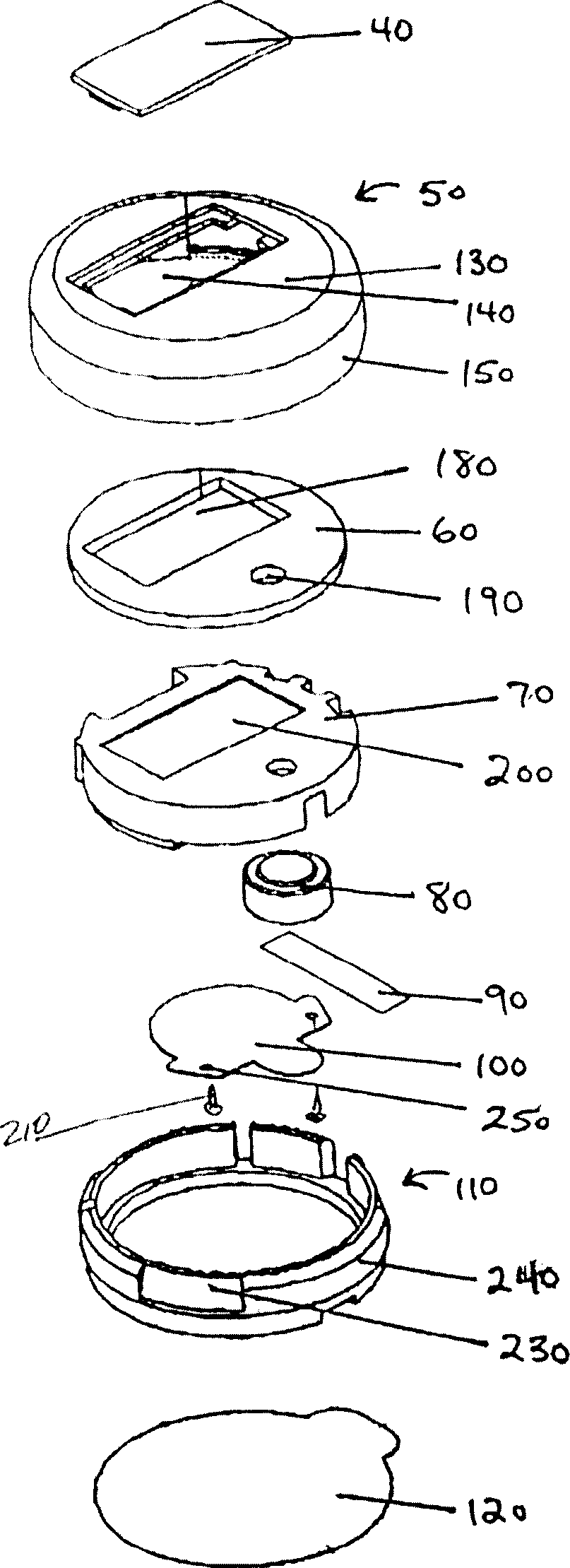

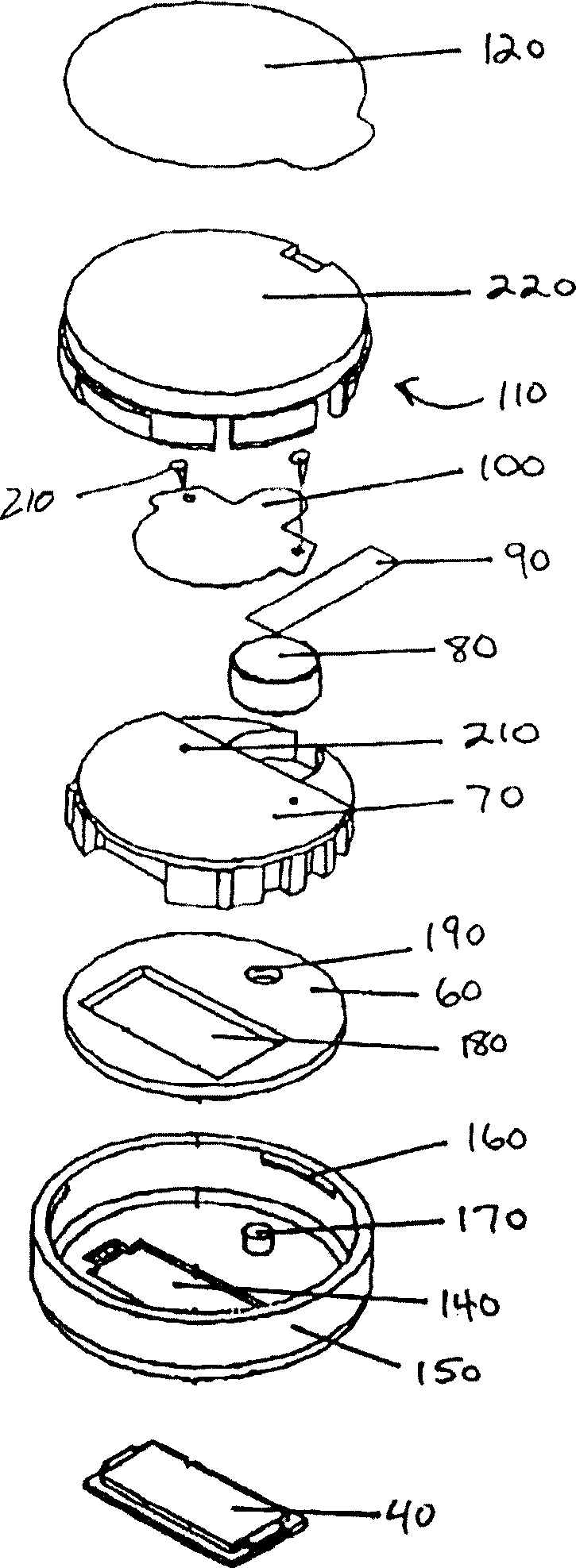

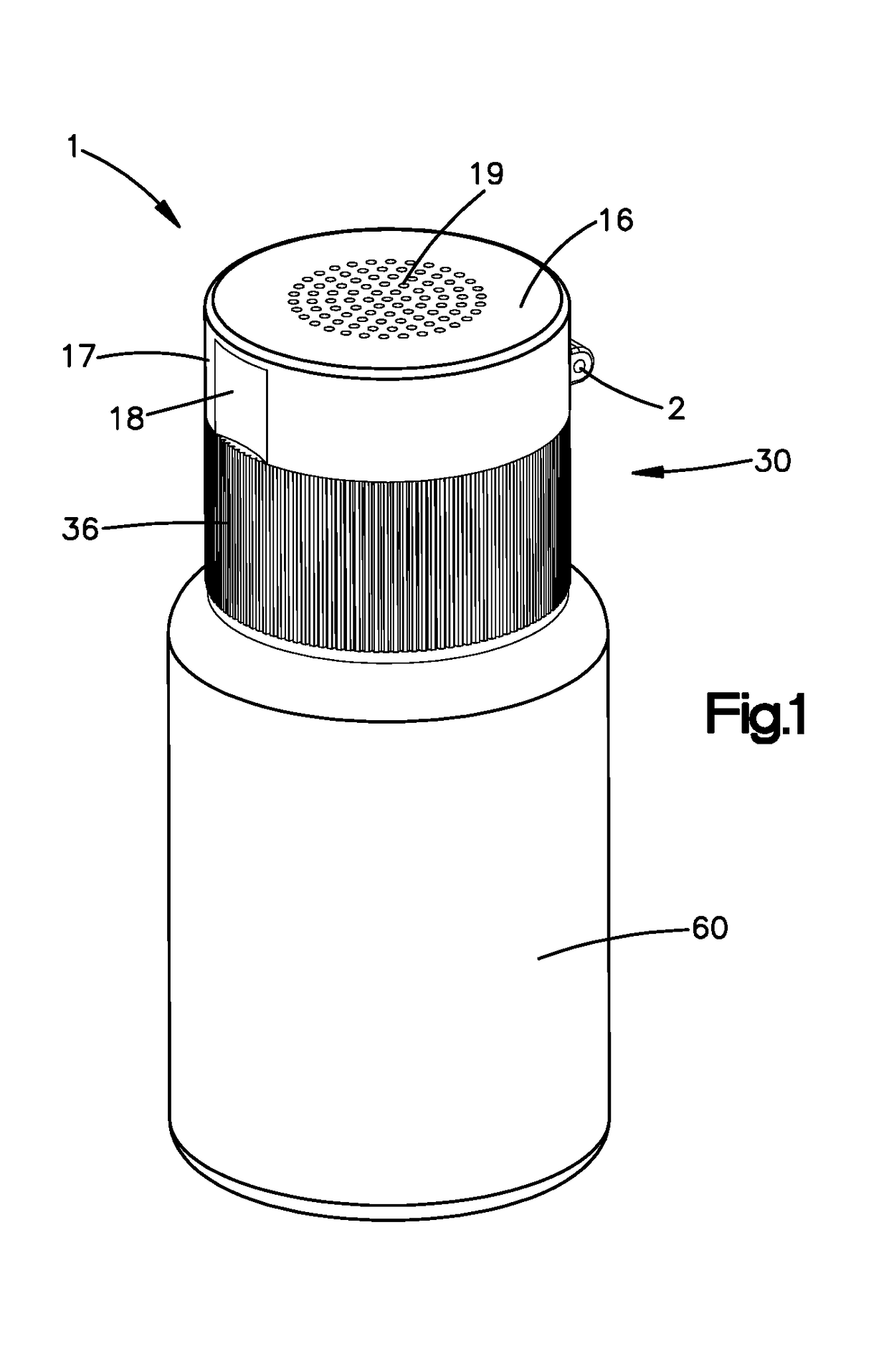

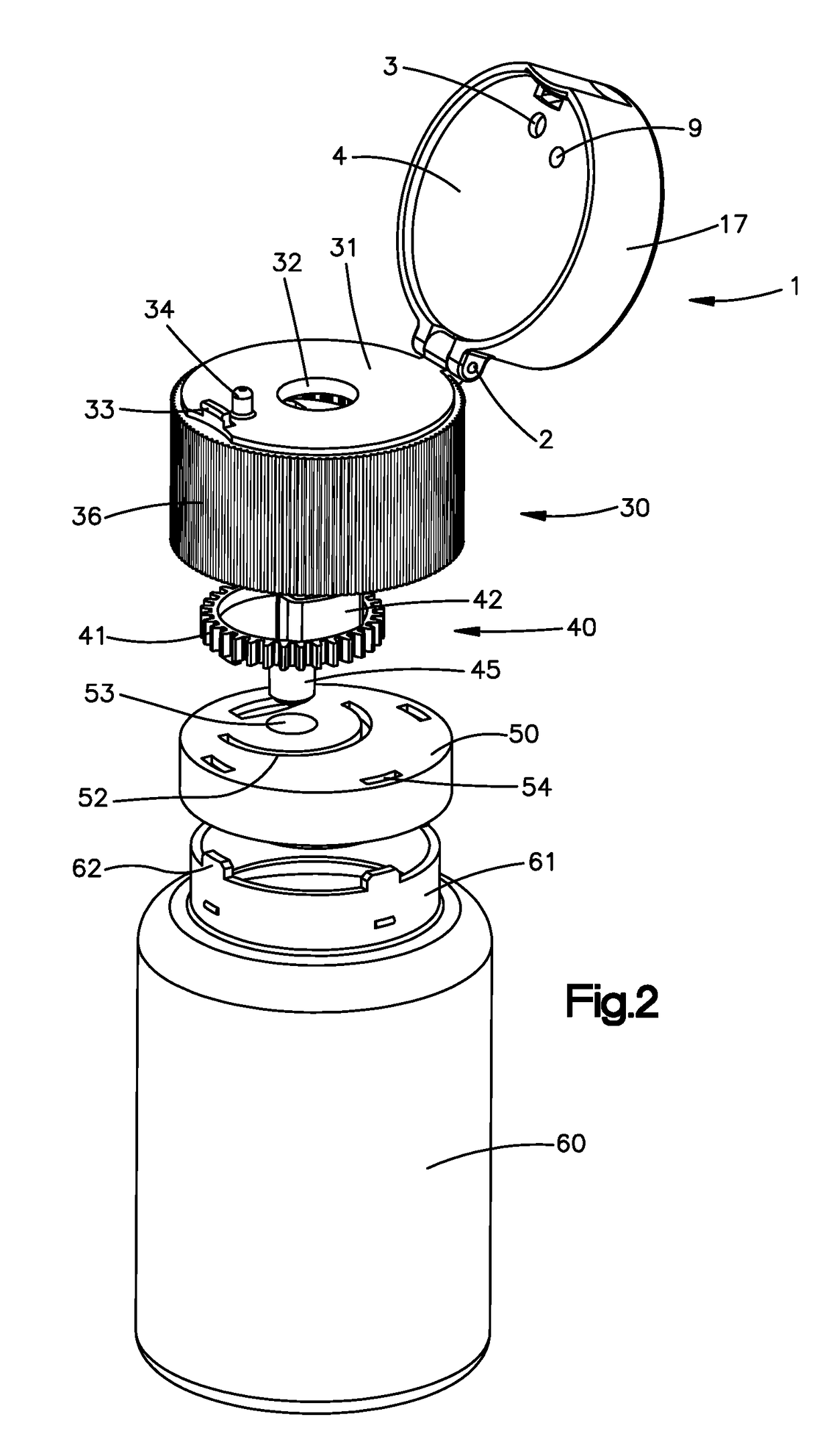

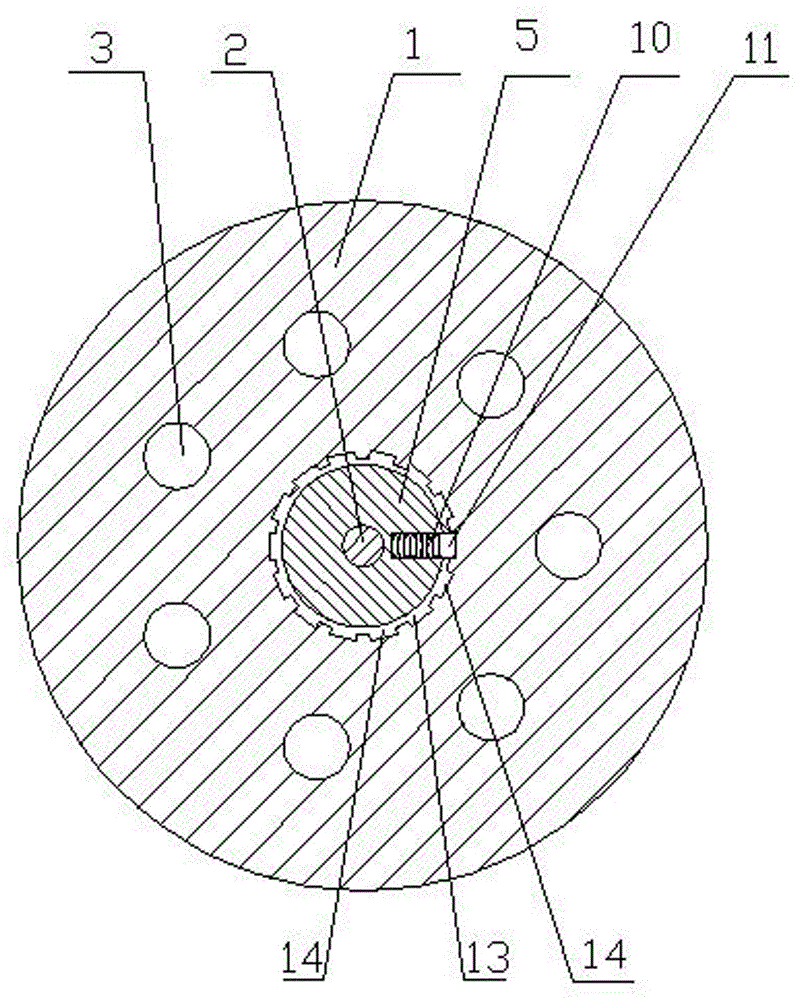

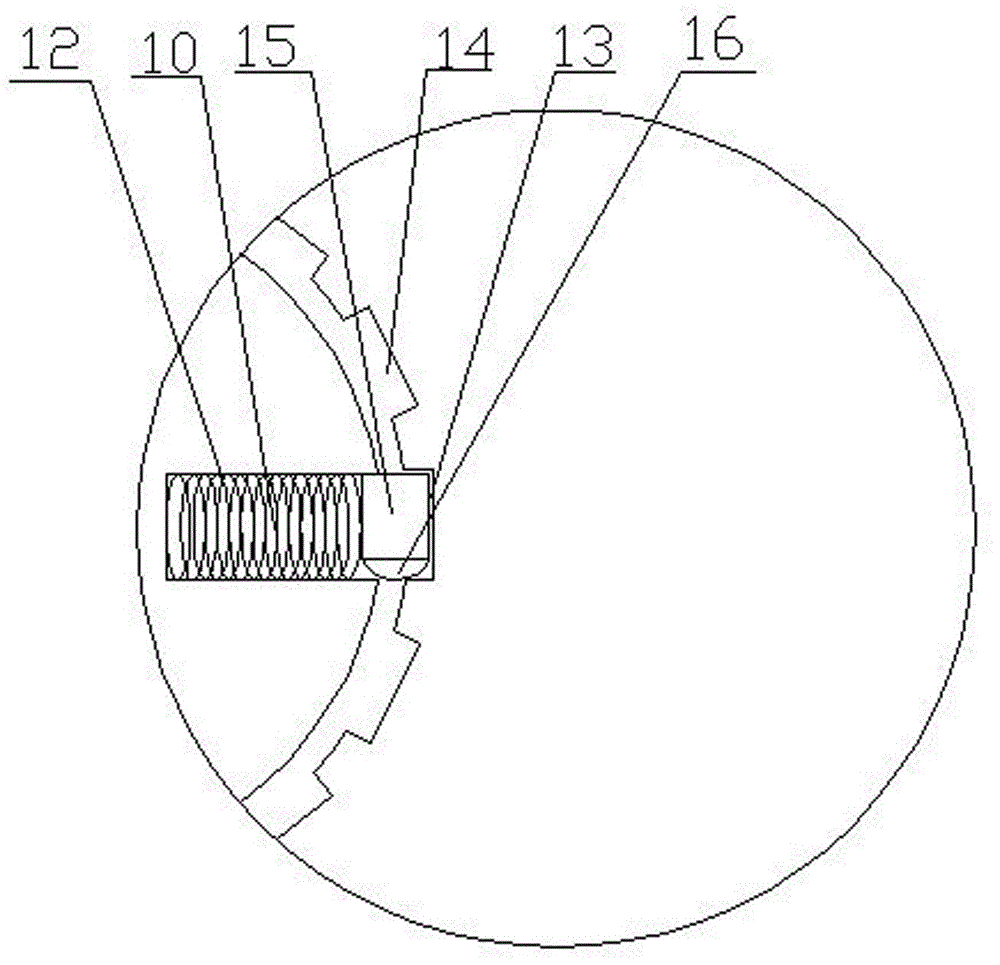

Indexing bottle cap for use with a container

The invention relates to a medicine bottle cap combination with a counting function for use with a medicine bottle. When used as a medicine bottle, medicine bottle may help users track taking times of pills in the medicine bottle so as to ensure the users to take medicine with proper dosageon time. The counting bottle cap basically comprises six components, including a bottle cap cover, an information plate, a cylindrical compression spring, a push plate, an annular fluted disc or swing plate, and an assembly ring. The bottle cap cover and theassembly ring are joined together to open or close the bottle cap with the other coaxial parts. The information plate is rotatively received within the bottle cap such that axial displacements of the push plate advance the information plate and indicia upon its upper surface are sequentially revealed by way of the window formed in the bottle cap cover.

Owner:徐涛 +2

Improved bottle cap indicator and method thereof

InactiveCN1498829ASimple designReduce manufacturing costMechanical clocksDispensing apparatusMedicine bottle capTimer

An adherent timer device for mounting upon a prescription medicine bottle cap. The device comprises a cover having an aperture through the cover and a skirt extending from the cover with a lip portion inwardly protruding from the skirt. An electronic counting means having an electronic display viewable through the aperture of the cover resides within the skirt. A battery powering the electronic counting means is springably engaged with the electronic counting means. A reset post for breaking engagement of the battery with the electronic counting means extends from the cover. An insulating pull tab is placed between the battery and a spring contact plate interrupting flow of energy from the battery to the electronic counting means. A mounting face has structure for snap fit engagement with the inner lip of the skirt and an adhesive backing for securing the mounting face to a prescription medicine bottle cap.

Owner:艾伯特·F.·迪茨格

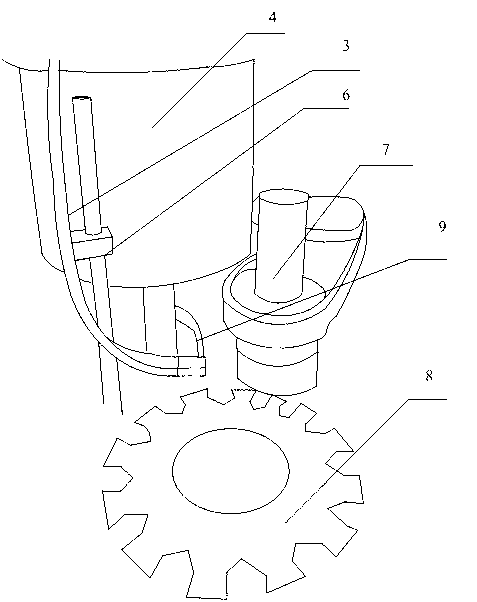

Medicine bottle cap

A medicine bottle cap includes a flip-top assembly and an outer cap pivotably attached to the flip top assembly and having an interior wall of the side wall that includes gear teeth. The medicine bottle cap further includes a pill delivery gear having gear teeth that engage the gear teeth in the outer cap and an inner cap having a slot for receiving a tab from the pill delivery gear for rotation thereof.

Owner:VELTRI DOUGLAS

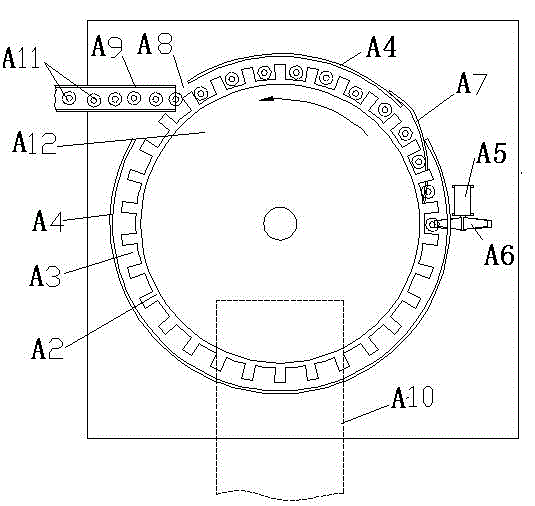

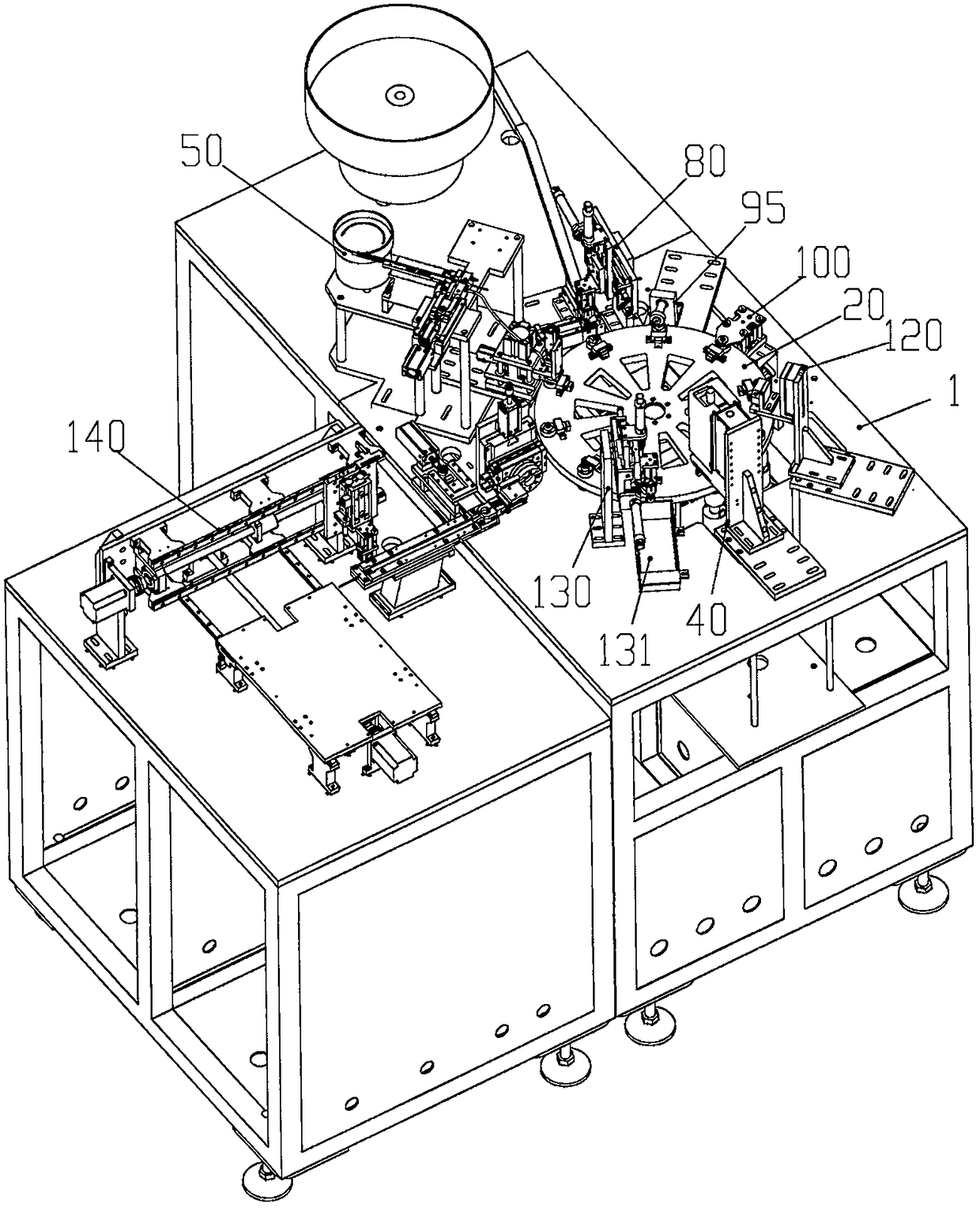

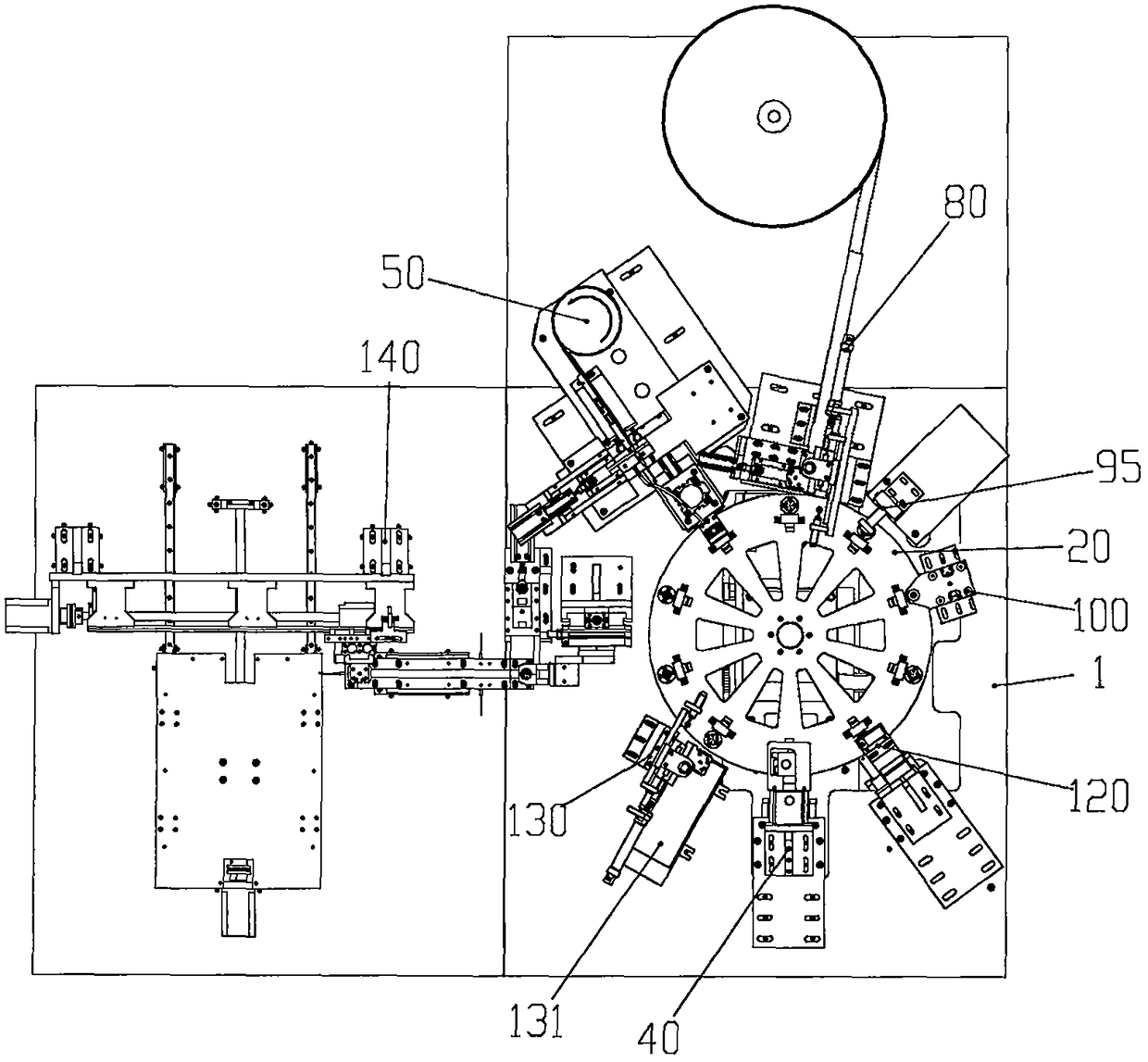

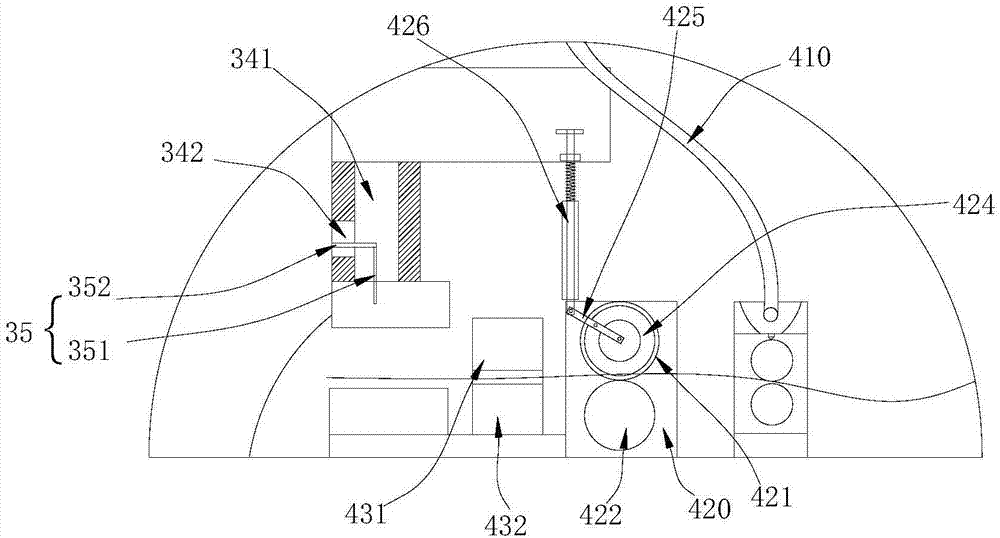

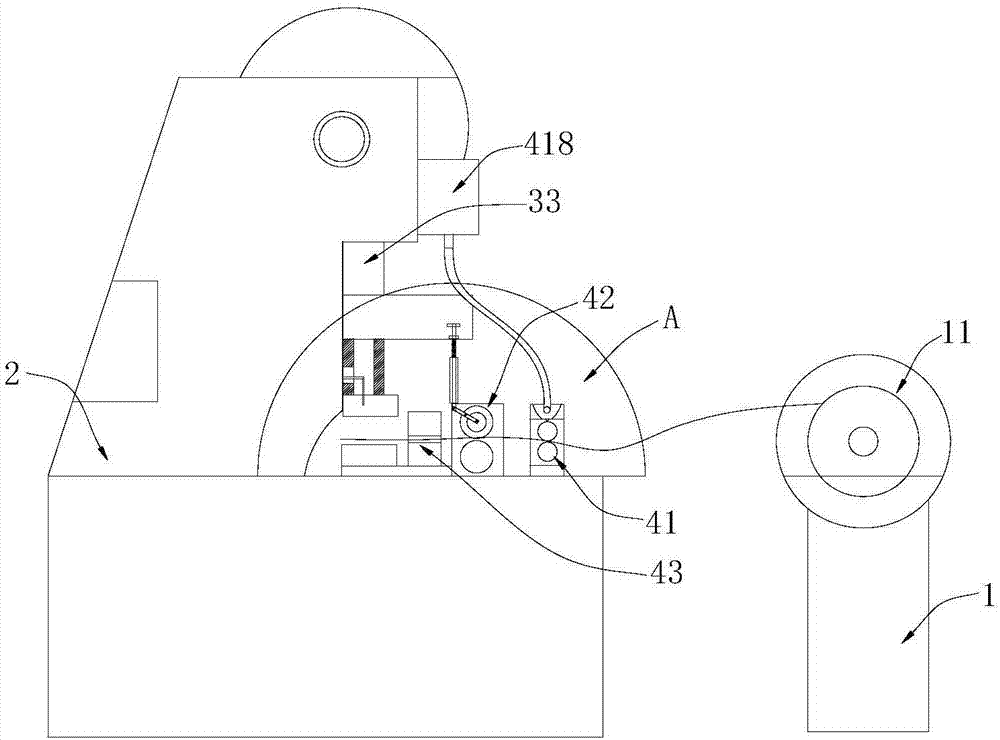

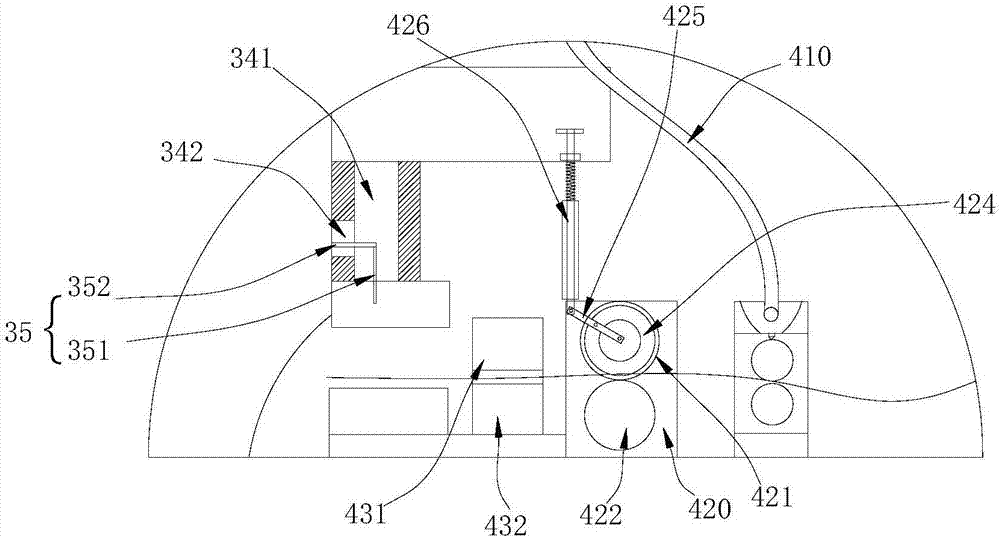

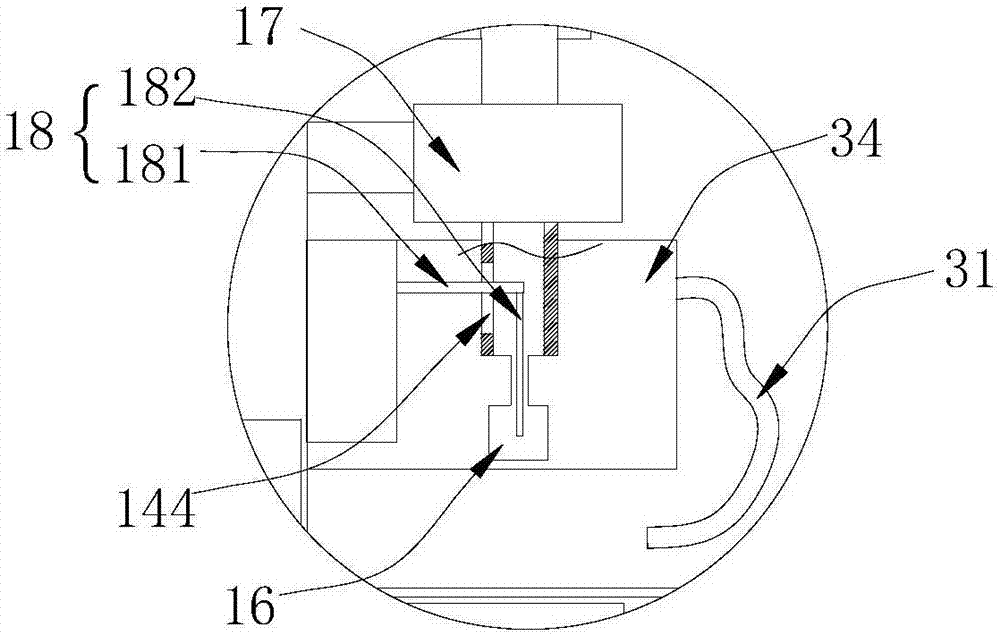

Medical vessel as well as intelligent manufacturing line and online detection technique thereof

The invention relates to a medical article and a manufacturing process thereof, and in particular to a medicine bottle cap as well as manufacturing and online detection processes thereof. The medicalvessel as well as an intelligent manufacturing line and the online detection technique thereof comprise a medicine bottle as well as manufacturing and online detection processes applied to partial structures of the medicine bottle, wherein the medicine bottle comprises a dropper, the bottle cap and a bottle body; the dropper is fixedly connected to the bottle cap; and the bottle cap is connected to the bottle body via a screw thread; the manufacturing and online detection processes comprise manfacturing and detection equipment and technological parameters thereof; and the manufacturing and detection equipment includes a workbench, a rotary disc mechanism, a visual localizing module, a dropper feeding mechanism, a bottle cap feeding mechanism for assembling the bottle cap onto a tooling clamp, a roller flattening mechanism which is used for leveling the upper surface of the bottle cap, a welding mechanism for achieving welding and binding of the dropper and the bottle cap, and a flatness detecting mechanism for implementing flatness online detection on the surface of the bottle cap.

Owner:湖南大圣宠医生物科技有限公司

Personalized lid for prescription bottles

ActiveUS10872482B1Reduce abuseEasy to implementCapsClosure capsMedicine bottle capPharmaceutical drug

A universal pill bottle cap for securely locking up medications with a high-risk factor for abuse and theft. The pill bottle cap includes a unique locking mechanism, a biometric scanning locking mechanism, a one-step opening process, and a universal applicability. The unique locking mechanism includes a sliding latch on the underside of the cap that will allow a pill bottle to be inserted and the cap to lock around the pill bottle until an authorized user follows a prompt to unlock the cap from the bottle. The biometric scanner opens either the sliding mechanism to allow the pill bottle to be removed or opens the lid to allow access to the contents of the bottle. This depends on a button on the underside of the pill bottle cap. The pill bottle has a microprocessor that drives the functionality of the cap.

Owner:COLTON ALEXANDER MONTGOMERY +1

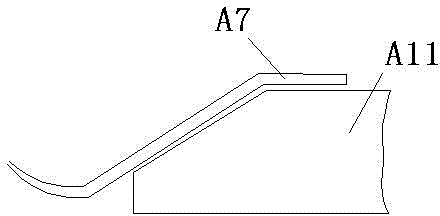

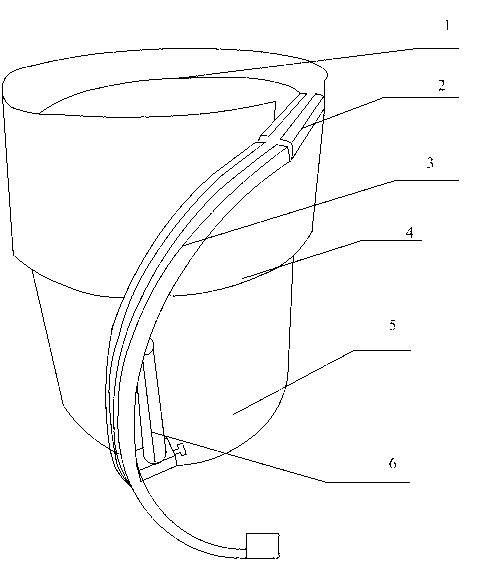

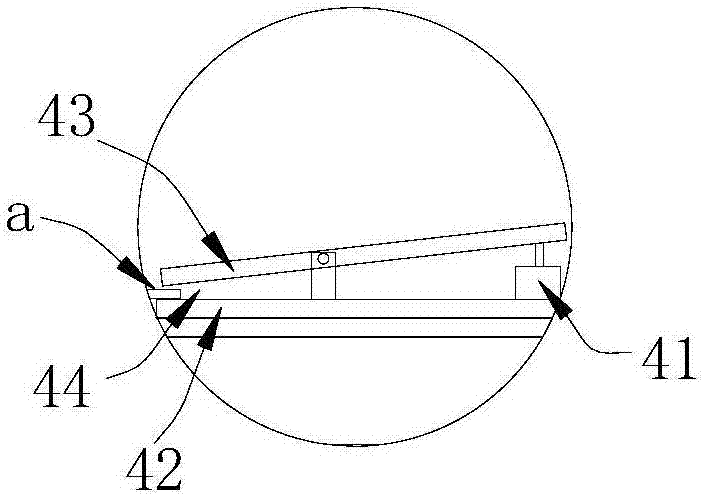

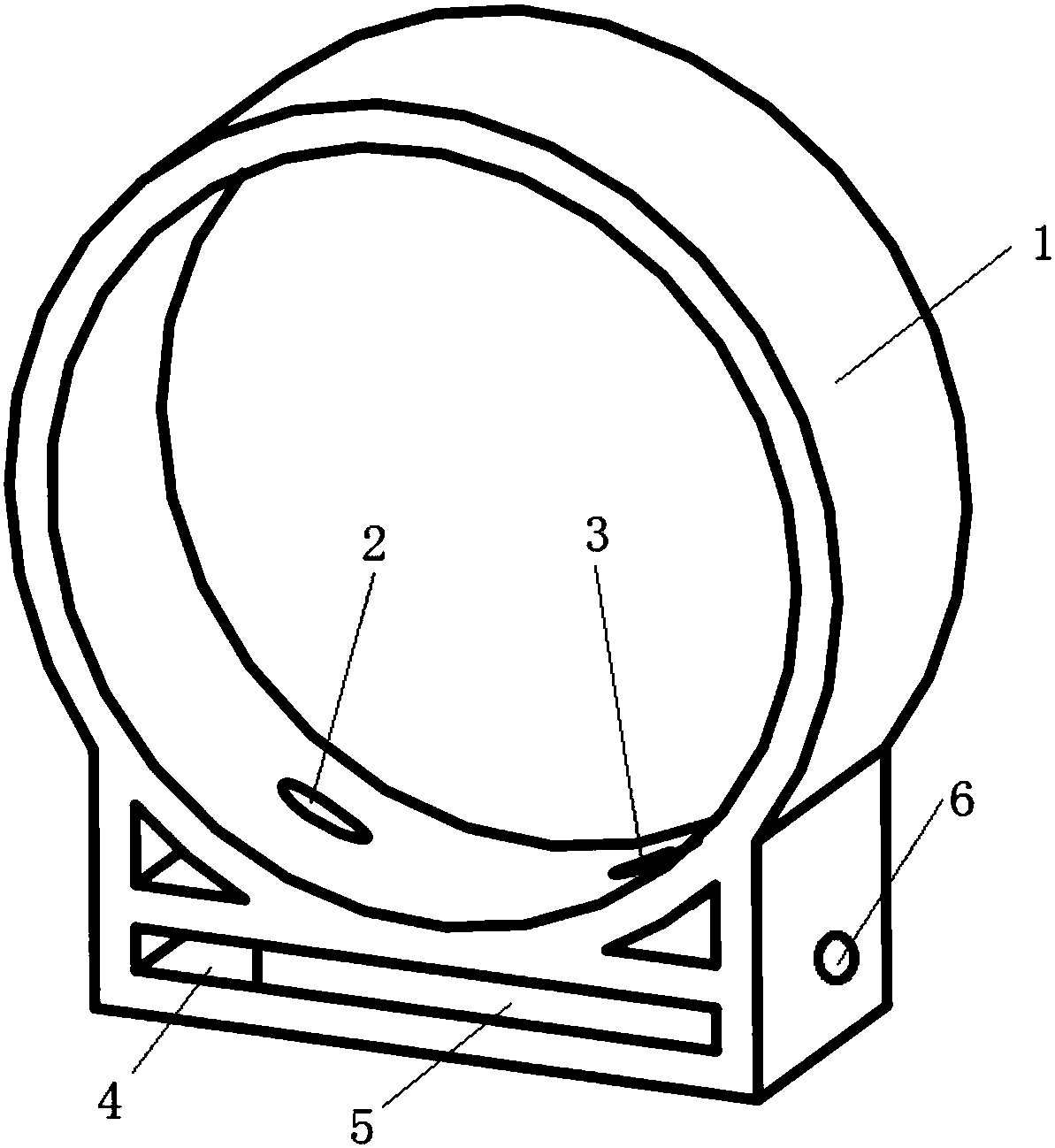

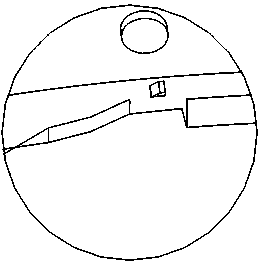

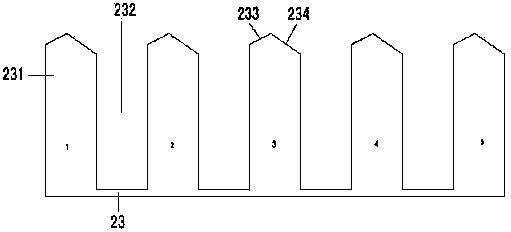

Conveying device applied to aluminum medicine bottle caps

InactiveCN103241694ASimple structureEasy to operateFlanged caps applicationJigging conveyorsMedicine bottle capEngineering

The invention discloses a conveying device applied to aluminum medicine bottle caps. The conveying device applied to aluminum medicine bottle caps comprises a bottle cap conveying track. The bottle cap conveying track comprises a spiral track, a straight-section track and a C-shaped track, wherein the spiral track, the straight-section track and the C-shaped track are connected in sequence. One end of the C-shaped track away from the straight-section track serves as the tail end of the bottle cap conveying track. The conveying device applied to aluminum medicine bottle caps further comprises a circular bottle cap containing bucket, the spiral track spirals down along the inner diameter surface of a circular bottle cap containing bucket until arriving at the bottom surface of the circular bottle cap containing bucket, and a downward-pressing retaining plate is arranged at the tail end of the C-shaped track. The conveying device applied to aluminum medicine bottle caps has the advantages of being simple in structure, easy to operate and low in construction cost.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

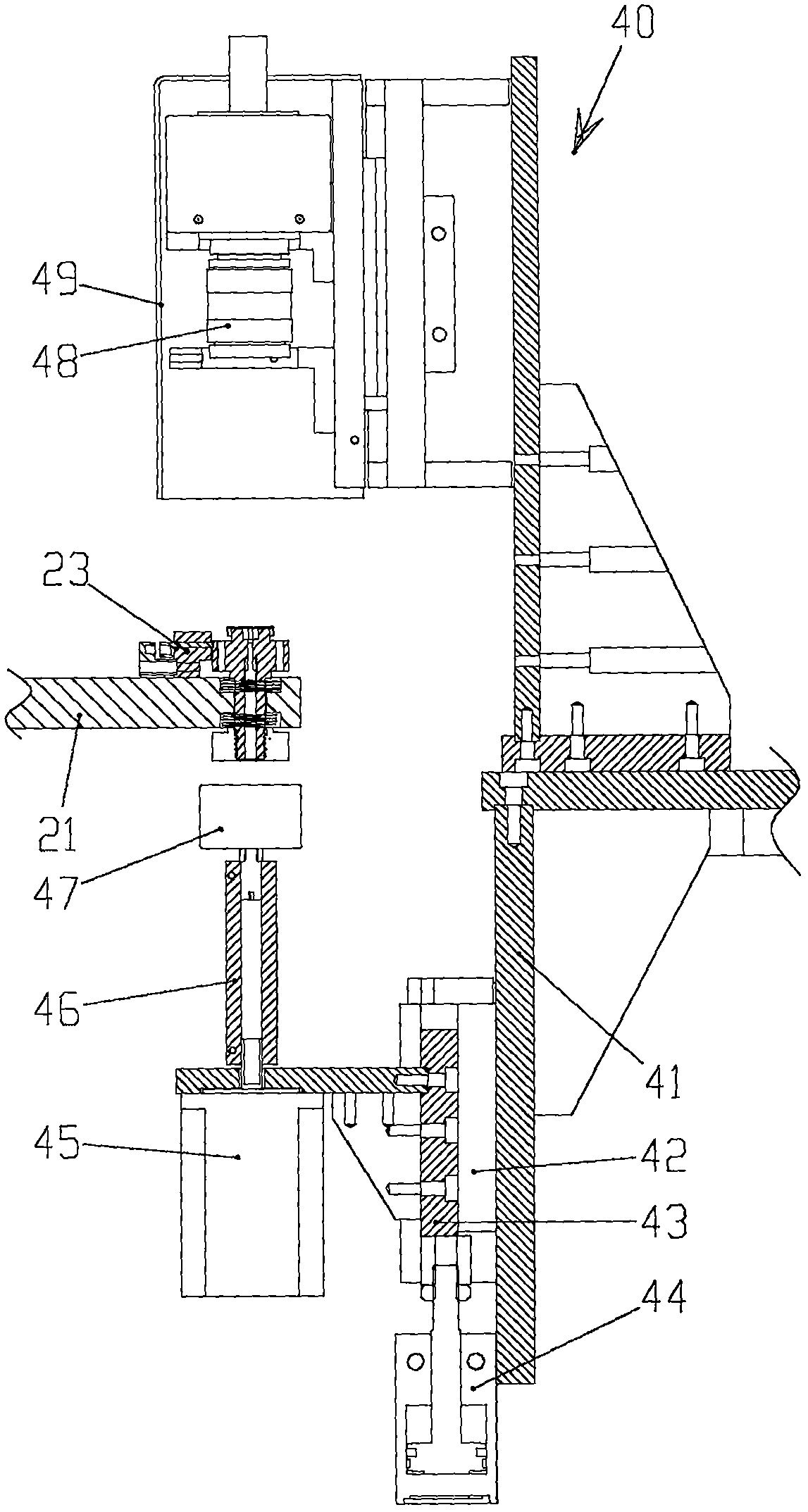

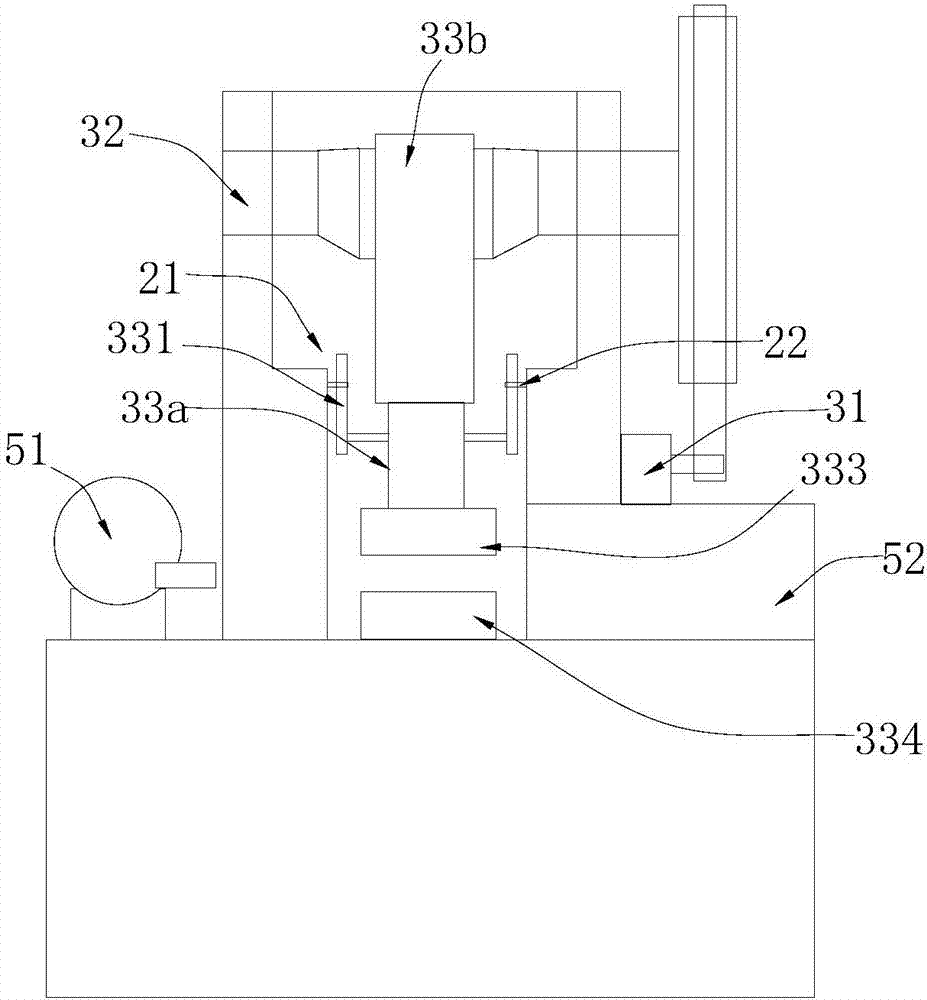

Medicine bottle cap punch

InactiveCN107413921ASimple structureEasy to operateShaping toolsMetal-working feeding devicesPunchingMedicine bottle cap

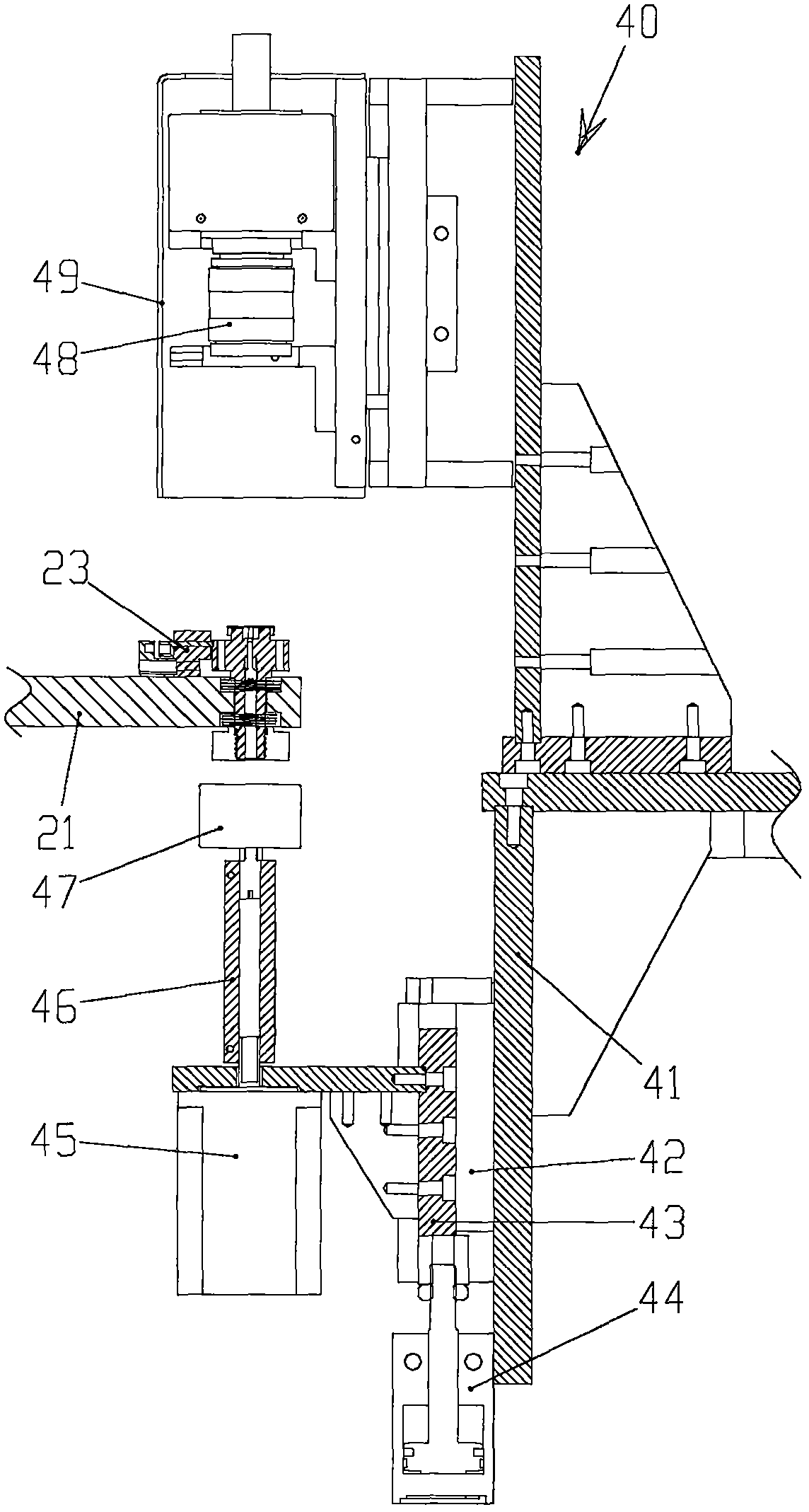

The invention relates to the field of bottle cap processing, in particular to a punching machine for medicine bottle caps. A punching machine for medicine bottle caps, comprising a tray rack, a punching frame, and a punching mechanism, a feeding mechanism, and a blanking mechanism arranged on the punching frame; the punching mechanism includes a punching motor, an eccentric shaft and a punching shaft, and the eccentric The two ends of the shaft are positioned on the punching frame through bearings, and the punching frame is provided with a punching cavity, and the eccentric part of the eccentric shaft is located in the upper end of the punching cavity, and the output end of the punching motor is connected to the eccentric shaft through a transmission assembly; The mechanism includes a lubricating roller group, a feeding roller group and a pressing plate group sequentially arranged between the tray frame and the punching station; the medicine bottle cap punching machine has a novel structure, is easy to control, and the quality of the punched product is better.

Owner:浙江冠利新材料股份有限公司

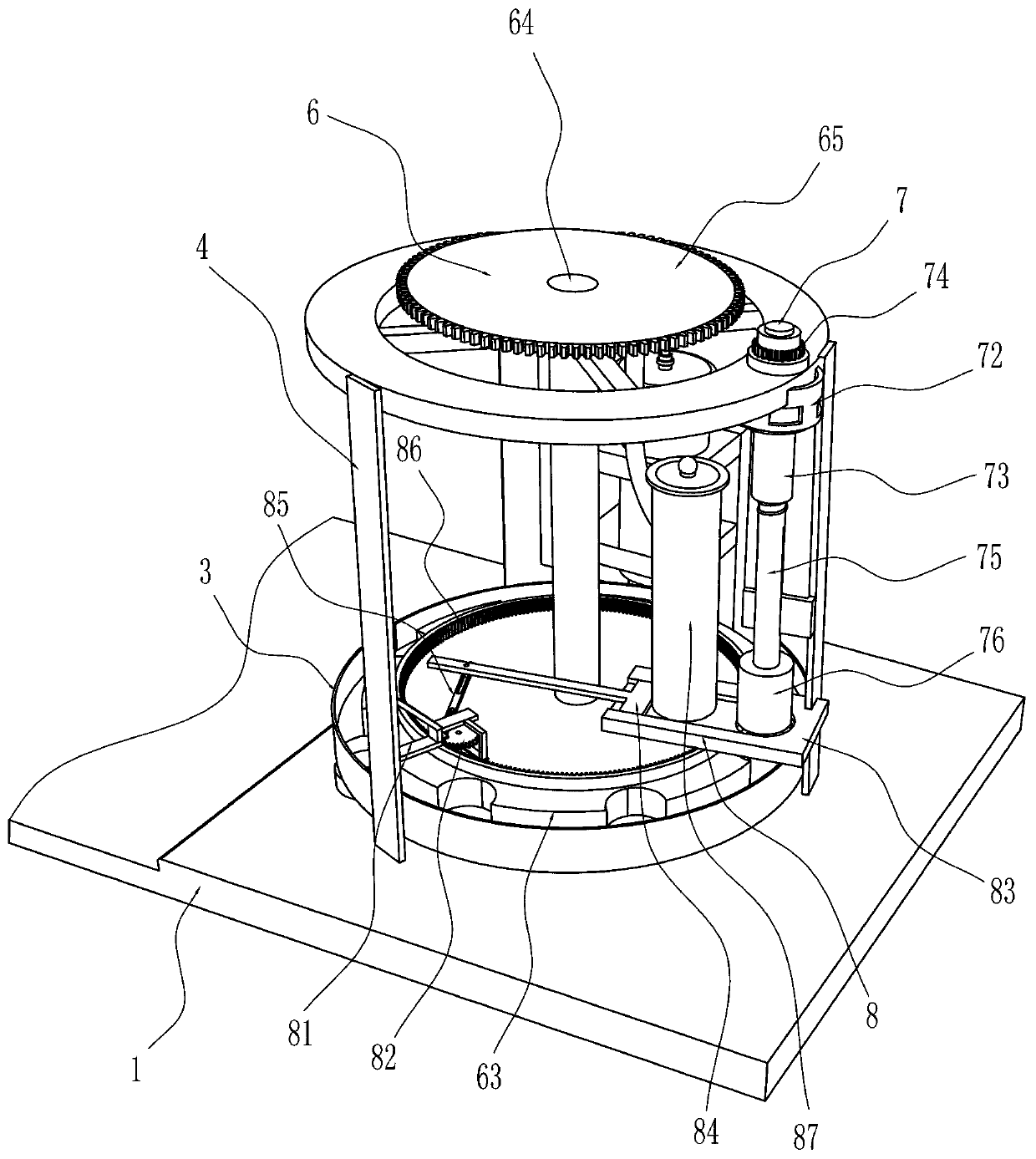

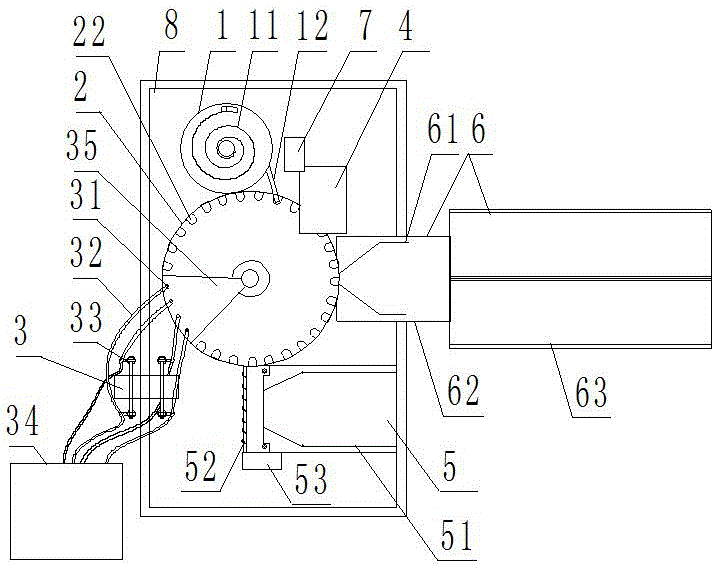

Fully-automatic gasket-adding equipment for medical bottle cap sealing gaskets

ActiveCN111360743APress to reachSave human effortMetal-working hand toolsCircular discMedicine bottle cap

The invention relates to gasket adding equipment, in particular to fully-automatic gasket adding equipment for medical bottle cap sealing gaskets, and aims to design fully-automatic gasket adding equipment for medical bottle cap sealing gaskets, which is easy to operate and does not need manual placement of bottle caps one by one. The fully-automatic gasket adding equipment for medical bottle capsealing gaskets comprises a frame, a bracket, a blanking pipe and a conveying mechanism, wherein the top of the frame is connected with a carrying tray and a circular disc; the discharging position ofthe carrying tray is connected with the circular disc; the bracket is connected to the top of the frame; the circular disc is positioned in the bracket; the blanking pipe is connected to the frame; the feeding hole of the blanking pipe is positioned under the circular disc; the discharging hole of the blanking pipe passes through the frame; and the conveying mechanism is arranged on the bracket.According to the gasket adding equipment, gaskets are pressed into bottle caps through cooperation of the conveying mechanism and a pressing mechanism, so that the effect of pressing the gaskets intothe bottle caps is achieved.

Owner:青岛市第五人民医院

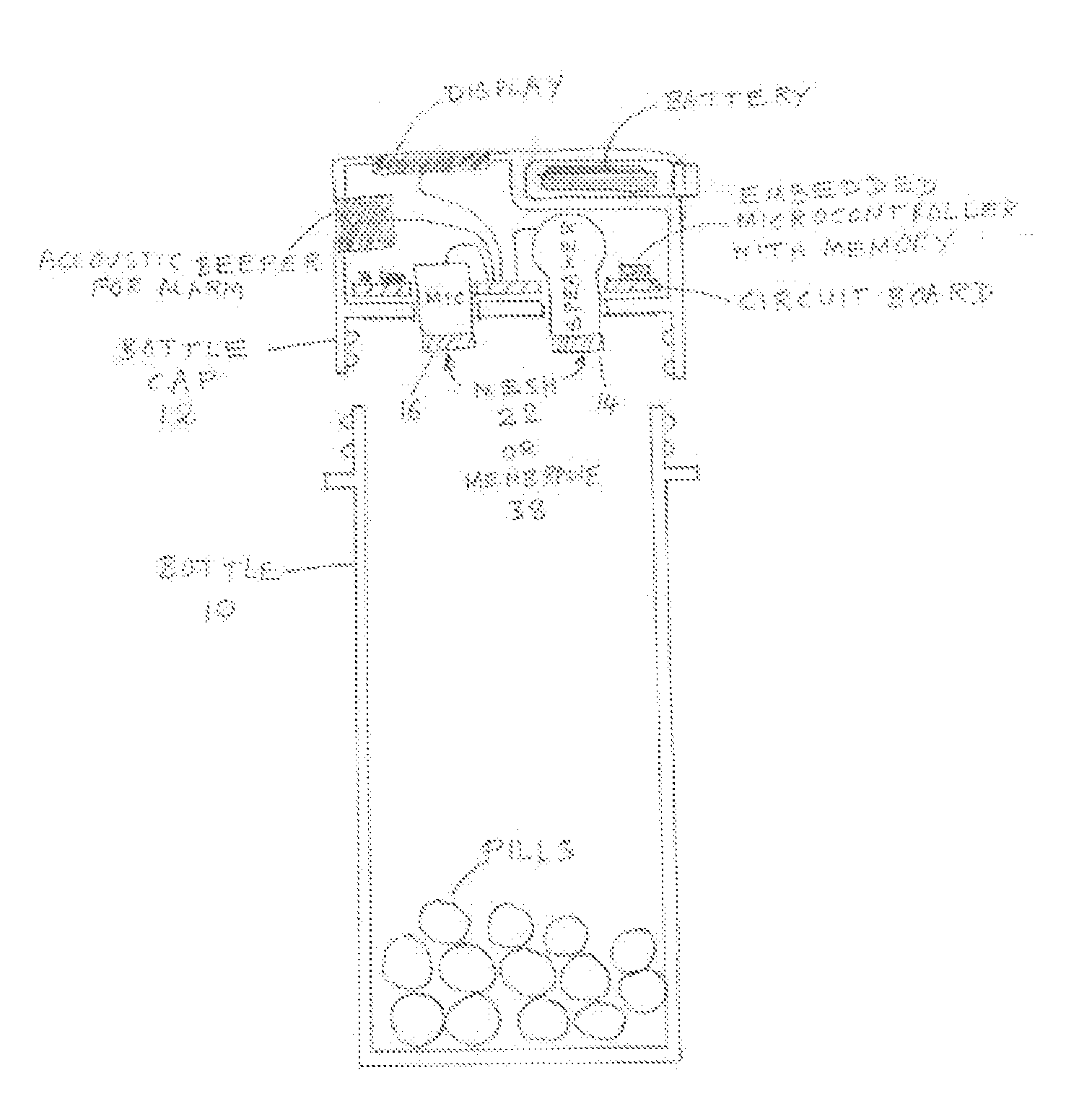

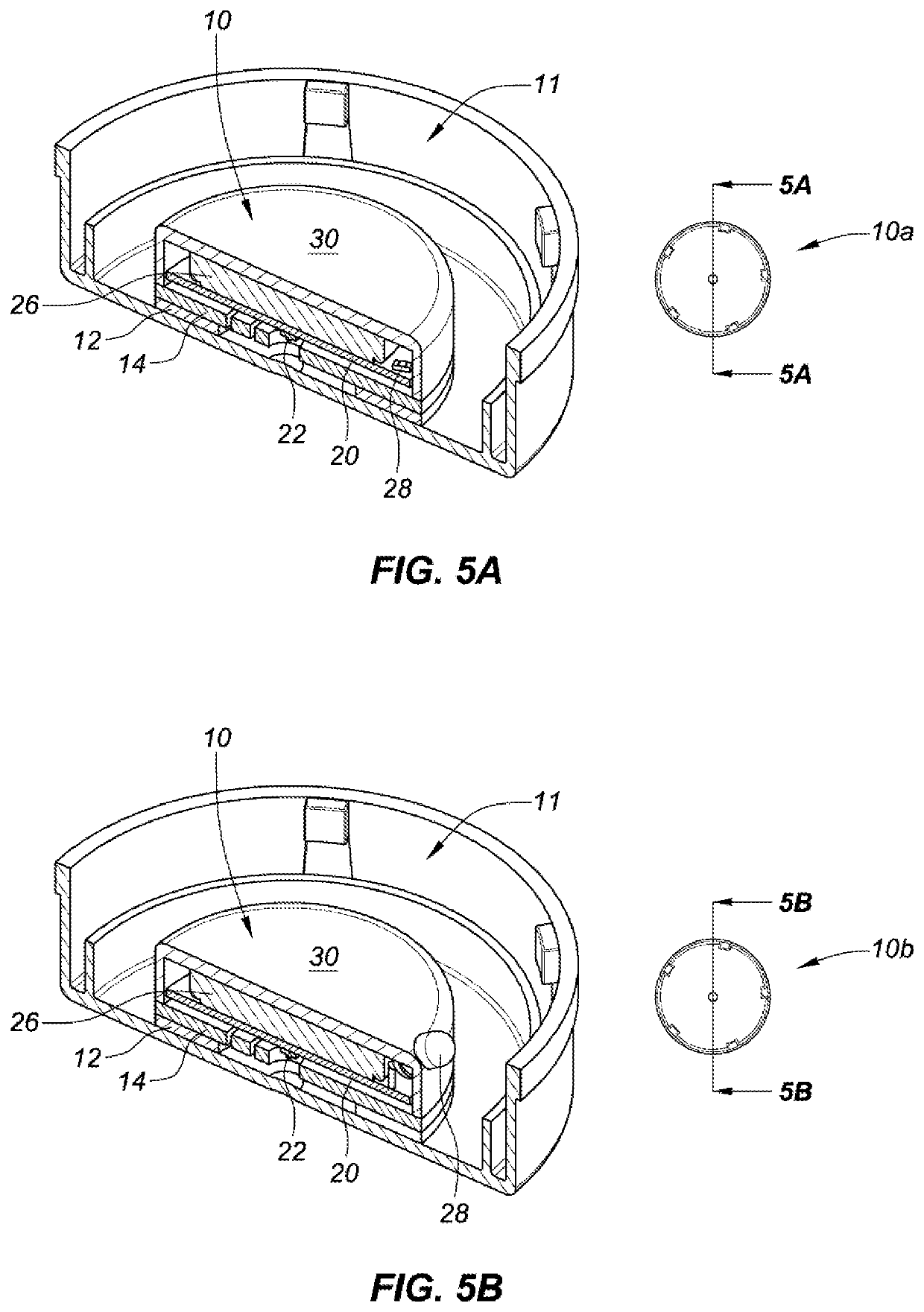

Dual purpose pill reminder and tamper detector

InactiveUS9621974B2Reduce peak powerHigh transmission powerDrug and medicationsContainer/bottle contructionCapacitanceCompliance Monitoring

An audio signal analysis method is provided for detecting the opening and closing of a medicine bottle cap in a robust manner using a micro speaker and a microphone along with associated mixed signal electronics. It is also used for robust tamper detection and for monitoring liquid medication consumption accurately. In a preferred embodiment an un-modulated OFDM signal is used that covers the entire operating audio spectrum. In another embodiment, Complimentary code based phase encoding of the subcarrier phases is used to reduce the peak to average power of the OFDM signal, thereby enabling higher transmit power of the audio signal to mitigate against interference. A suitable wireless device can be co-located with the mixed signal electronics for sending the bottle usage, medication reminder alarm, and tamper status to the medication compliance monitoring system or to the user's cell phone. In some embodiments of the patent, electrical capacitance sensing is used to determine if the bottle is opened or closed.

Owner:MOHINDRA RAJKUMARI

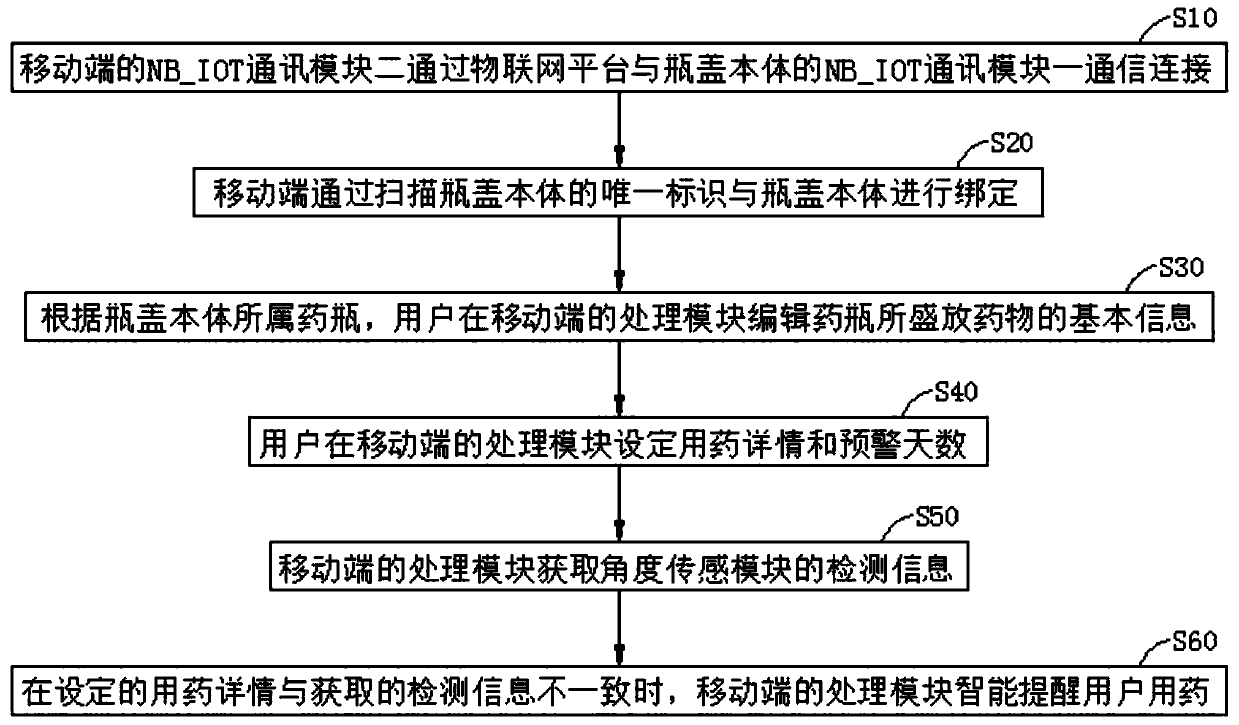

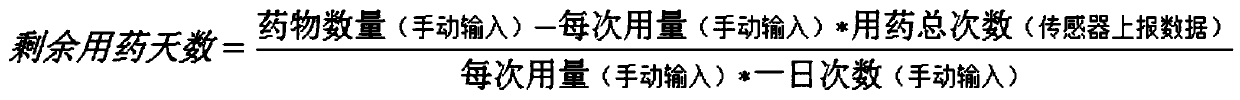

Medicine bottle cap capable of achieving intelligent medicine reminding based on NB_IOT

InactiveCN110534205AAvoid situations where medication memory is confusedPharmaceutical containersMedical packagingMedicineUnique identifier

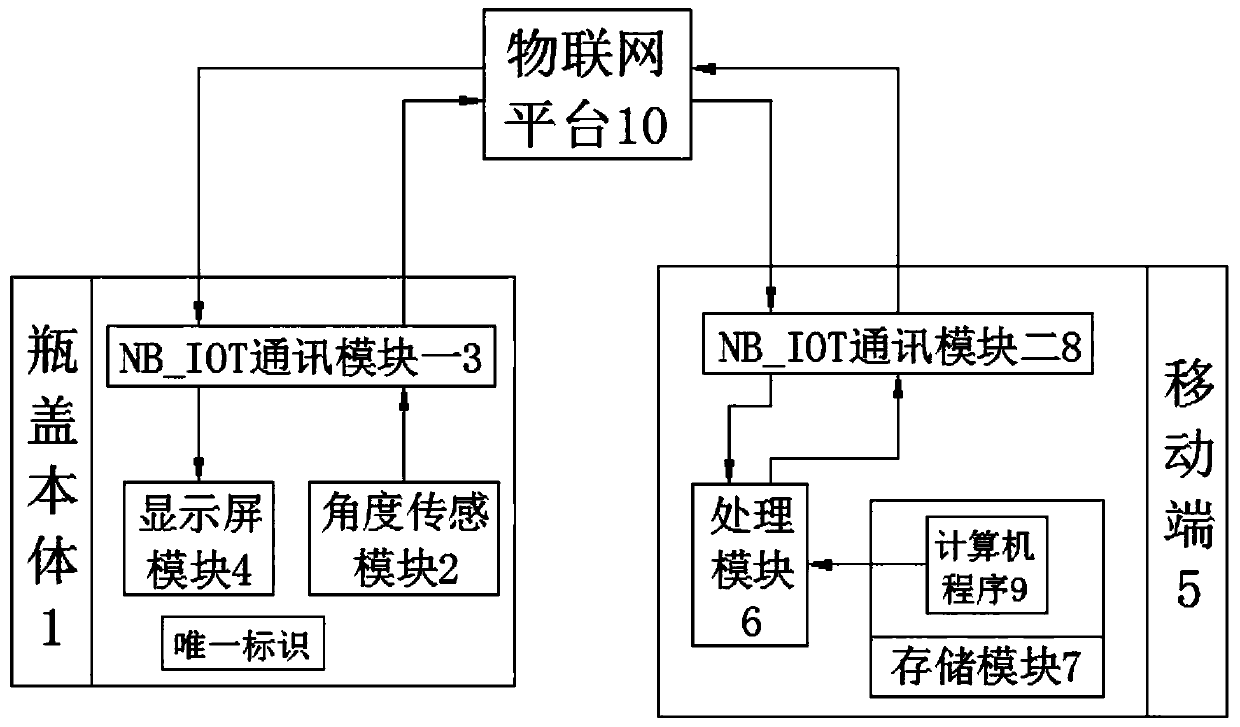

The invention discloses a medicine bottle cap capable of achieving intelligent medicine reminding based on NB_IOT, and relates to the technical field of NB_IOT. According to the technical scheme, themedicine bottle cap comprises a bottle cap body with a unique identifier, an angle sensing module, a first NB_IOT communication module and a display screen module; the angle sensing module is used fordetecting opening and closing of the bottle cap body; the medicine bottle cap also comprises a processing module, a storage module and a second NB_IOT communication module which are deployed at a mobile terminal, and a computer program which is stored in the storage module and can run on the processing module; when the processing module executes the program, the second NB_IOT communication moduleis in communication connection with the first NB_IOT communication module through the Internet of Things platform; the mobile terminal obtains medicine information of a medicine bottle to which the bottle cap body belongs by scanning the unique identification of the bottle cap body, a user sets medicine details and early warning days in the processing module, the processing module obtains detection information of the angle sensing module; when the set medicine details are inconsistent with the obtained detection information, the processing module intelligently reminds the user. The medicine bottle cap can intelligently manage the medicines and recommend the medicines.

Owner:INSPUR ARTIFICIAL INTELLIGENCE RES INST CO LTD SHANDONG CHINA

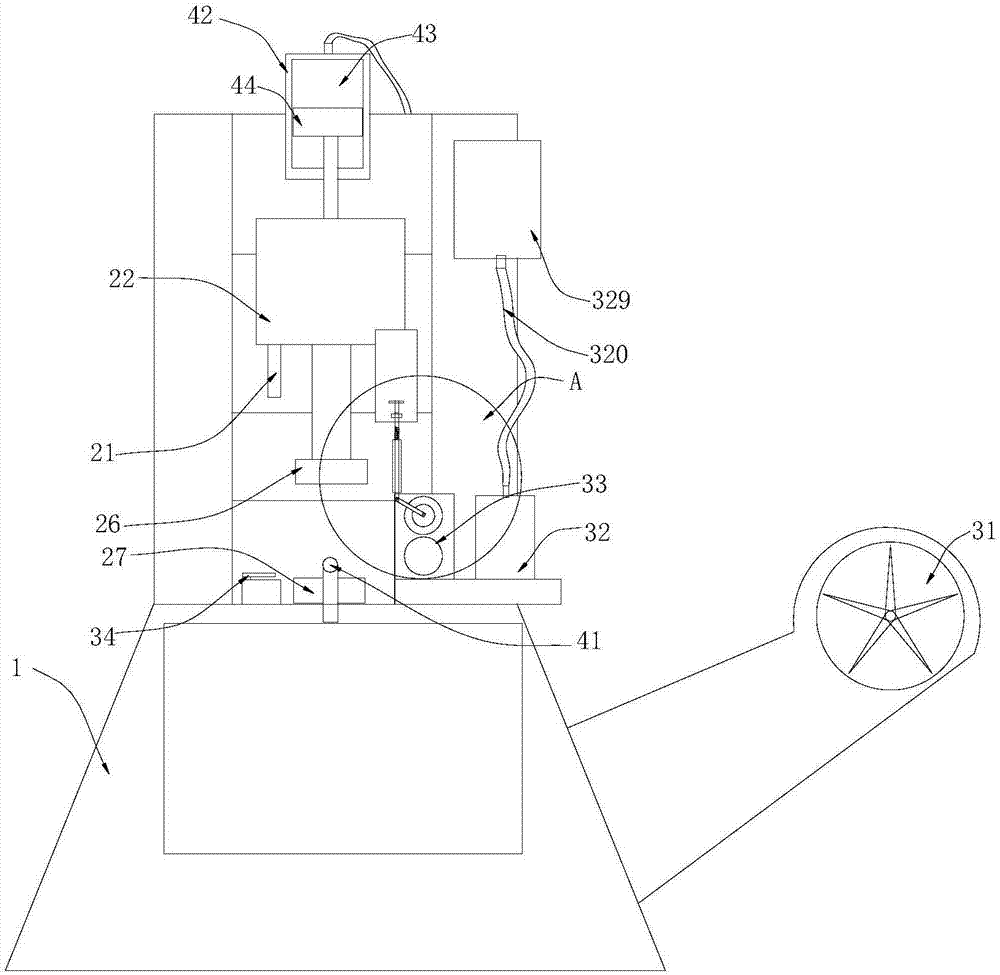

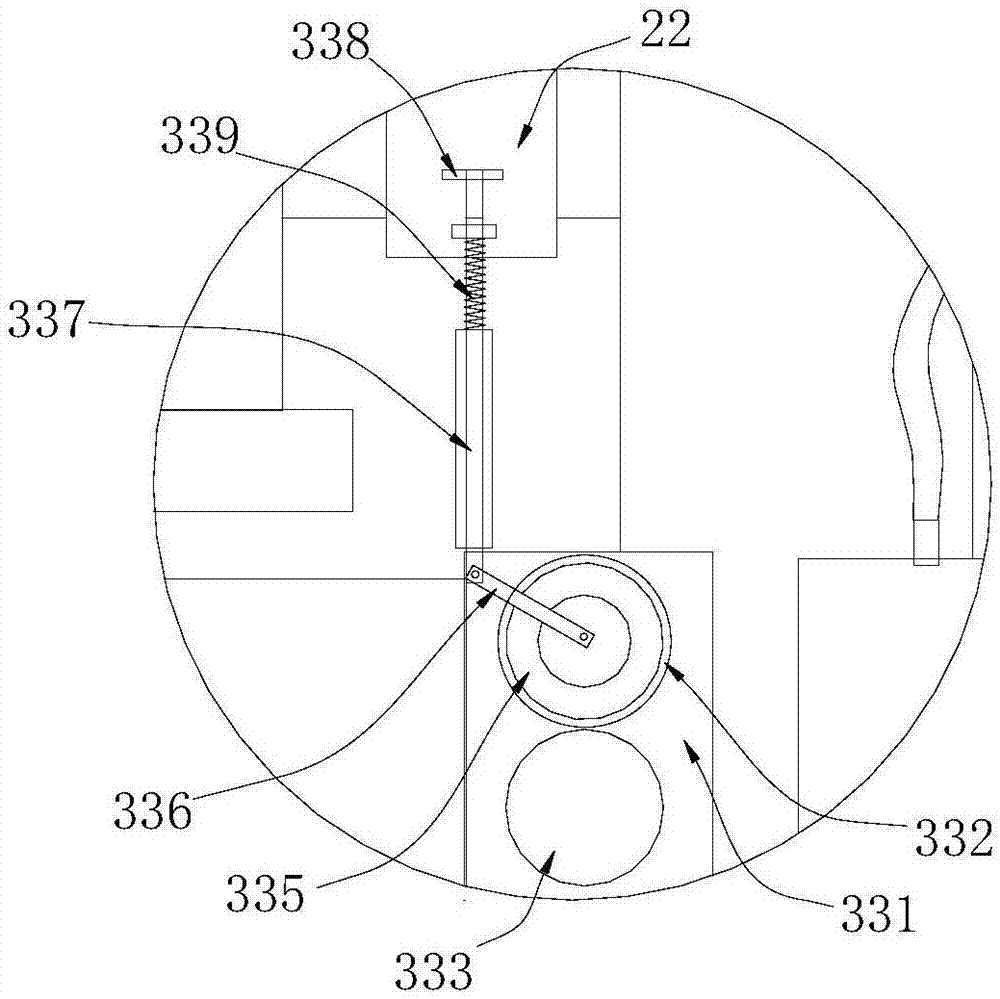

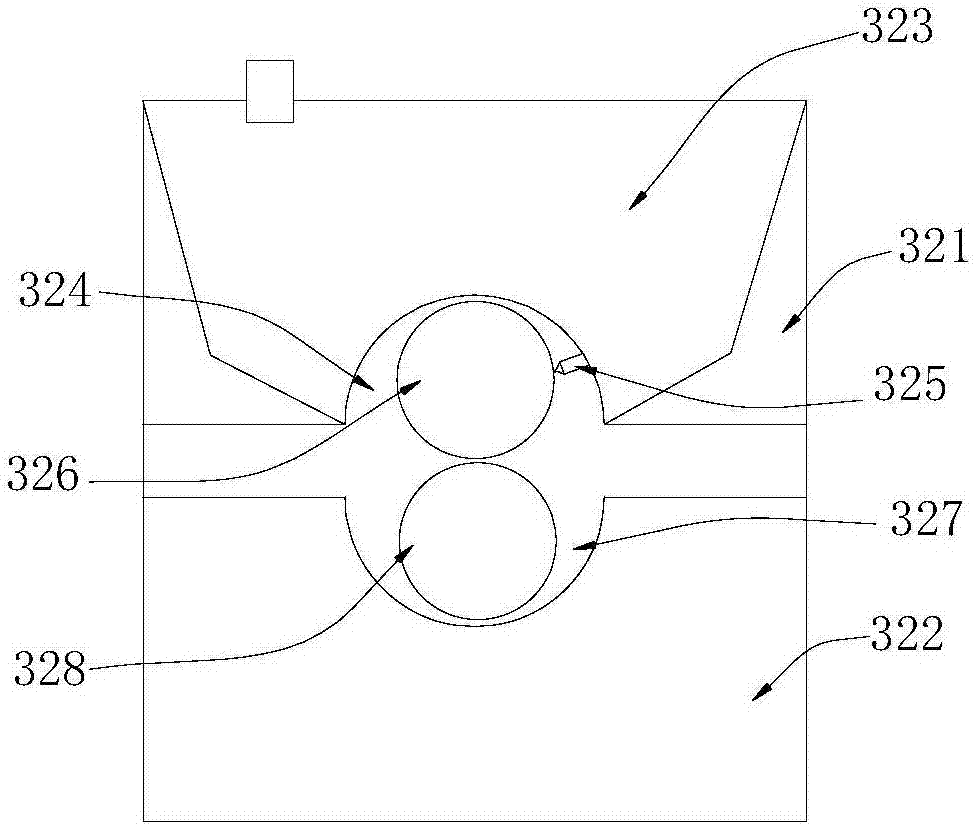

Stamping equipment for medicine bottle cap

InactiveCN107335708ASimple structureEasy to operateMetal-working feeding devicesClosure capsPunch pressMedicine bottle cap

The invention relates to the field of bottle cap processing. The medicine bottle cap punching equipment includes a punching mechanism and a feeding mechanism; the punching mechanism includes a punching motor, an eccentric shaft and a punching shaft, and the two ends of the eccentric shaft are positioned on the punching frame through bearings. The output end of the stamping motor is connected to the eccentric shaft through a transmission assembly; the feeding mechanism includes a lubricating roller group, a feeding roller group and a pressing plate group arranged sequentially between the tray frame and the punching station; the feeding roller The set includes a base, and a driving feeding roller and a driven feeding roller positioned on the base, and the other end of the driving feeding roller is linked with the stamping part through a swing arm assembly. The stamping mechanism of the medicine bottle cap stamping equipment has a novel structure, is easy to control and has high stability; in addition, the feeding roller group is linked with the stamping mechanism to ensure the synchronization of the stamping work and the feeding work, to ensure the quality of the stamping, and to facilitate the control of a single The length of the sheet to be fed is conducive to improving the utilization rate of raw aluminum sheets.

Owner:浙江冠利新材料股份有限公司

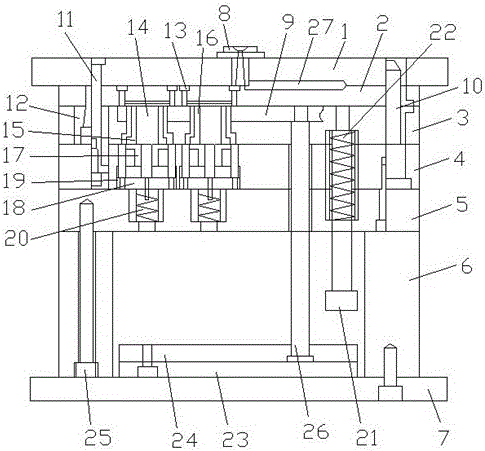

Medicine bottle cap injection mold

InactiveCN105128278AEase of ejectionWith the function of grinding tabletsMedicine bottle capEngineering

The invention discloses a medicine bottle cap injection mold which comprises a fixed mold base plate, a fixed mold plate, a movable plate, a movable mold plate, a movable mold base plate, a mold foot and a mold foot plate which are sequentially arranged from top to bottom. The mold foot is fixedly connected with the mold foot plate. A sprue bush is arranged on the fixed mold base plate. A push plate is arranged inside the movable plate. A guide column and an auxiliary guide column are arranged on the outer side of the movable mold base plate. A plastic drag hook is arranged on the outer side of the auxiliary guide column. A cavity insert ring is arranged inside the fixed mold plate. A core is arranged below the cavity insert ring. An inner mold sleeve and an outer mold sleeve are arranged on the outer side of the core. A flower disc mold sleeve and a limiting plate are arranged below the core. The two sides of the limiting plate are provided with return rods. The bottom of the limiting plate is provided with a short spring. The medicine bottle cap injection mold is high in machining efficiency, the product is formed at a time, it is ensured that a flower disc is formed on the inner side of a bottle cap, and tablets are ground conveniently when a user takes medicine.

Owner:WUHU HENGFENG TECH

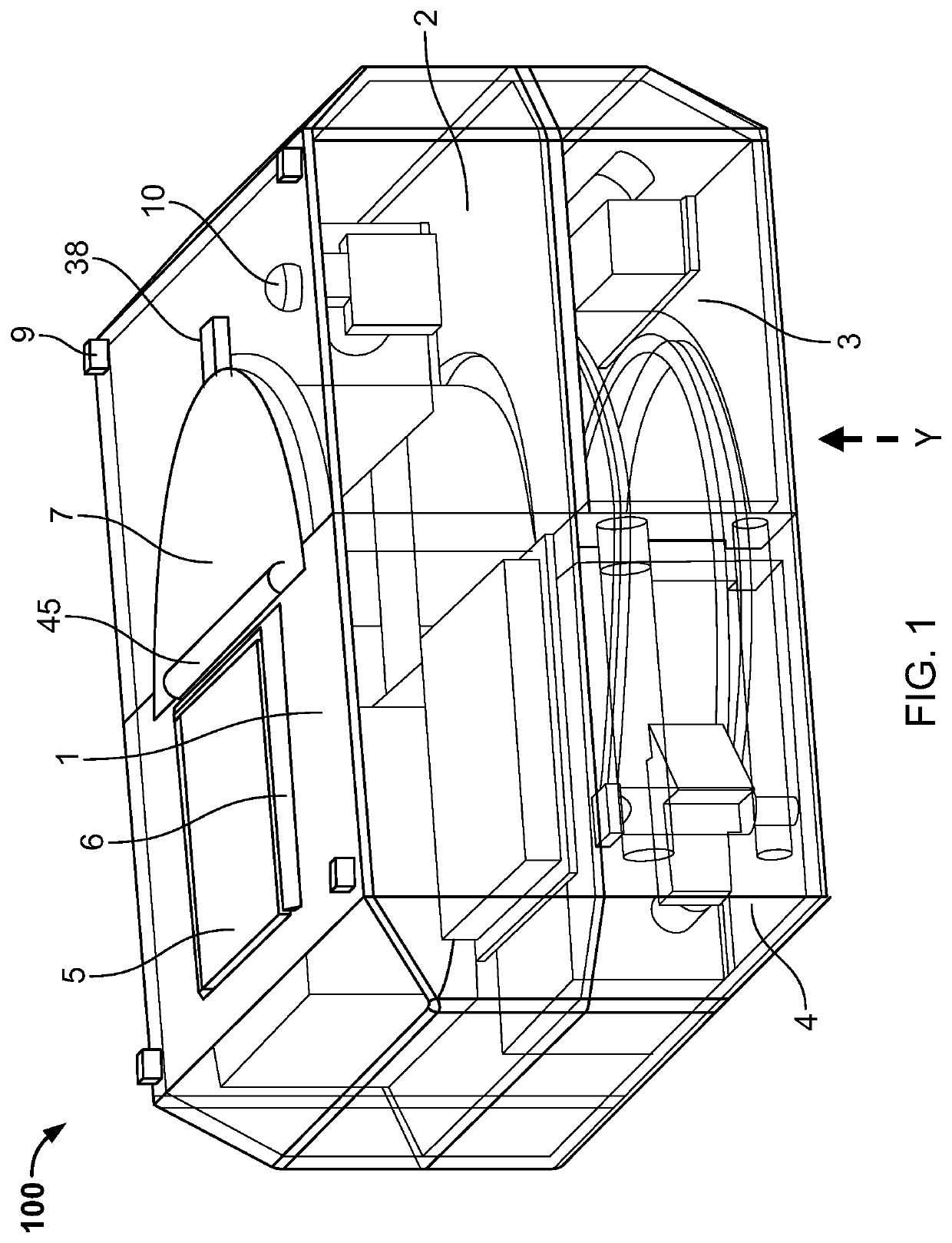

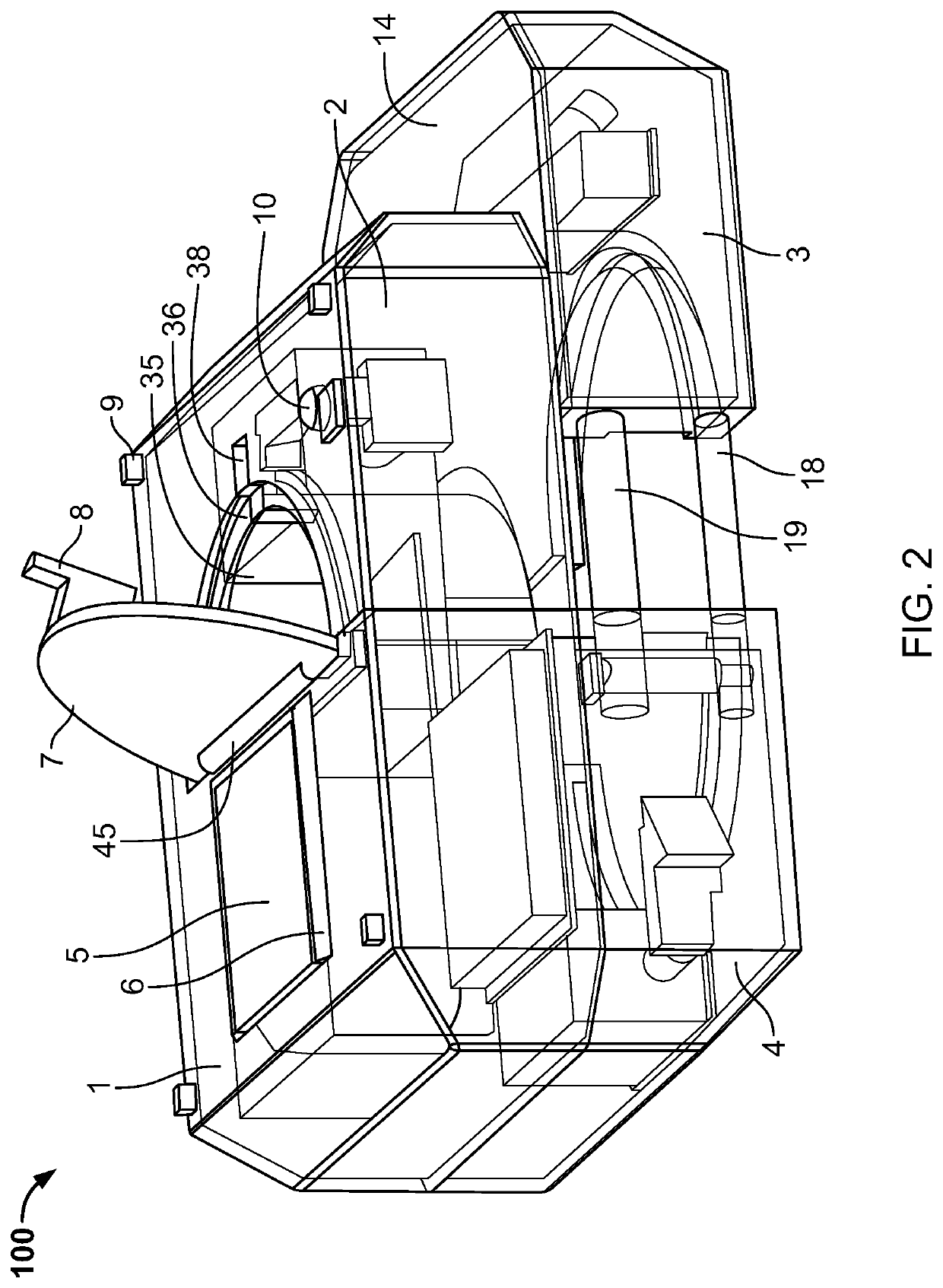

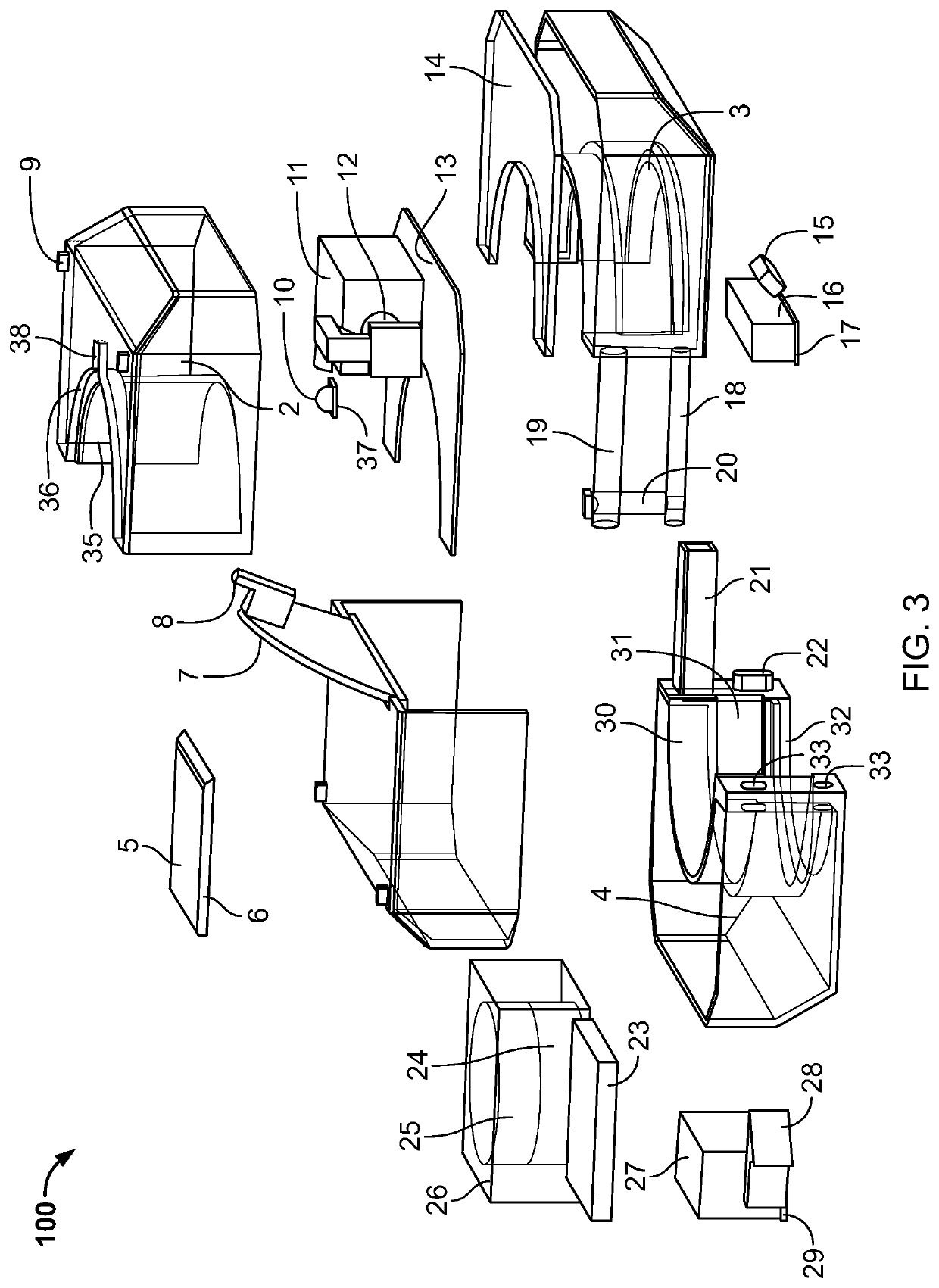

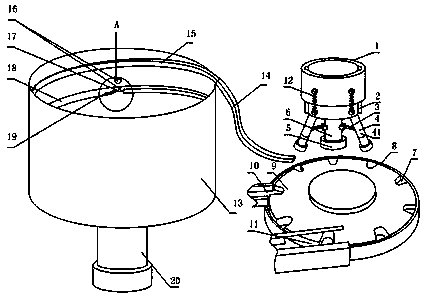

Automatic oral liquid filling system

InactiveCN106145000AQuantitativeAdvanced technologyBottle-handling machinesLiquid bottlingMedicine bottle capEngineering

The invention relates to the technical field of food processing machinery, in particular to an automatic oral liquid filling system. The automatic oral liquid filling system is characterized in that a workbench is included; a medical bottle capping bucket, a bottle turning plate, a bottle filling device, a cap pressing device, a medicine bottle conveying device, a product discharging device and a controller are mounted on the workbench; the bottle turning plate is located in the middle of the workbench; the medicine bottle capping bucket, the cap pressing device and the controller are mounted on one side of the bottle turning plate; the bottle filling device and the medicine bottle conveying device are mounted on the other side of the bottle turning plate; and the product discharging device is mounted right in front of the bottle turning plate. the automatic oral liquid filling system is advanced in process, high in automation degree, high in yield, and capable of achieving automatic filling of oral liquid in quantitative and constant-speed modes; and the filling process is conducted in a clean area, so that the safety, cleanliness and quality of products are guaranteed, and mass production is facilitated.

Owner:山东东阿东盛阿胶产品科技开发有限公司

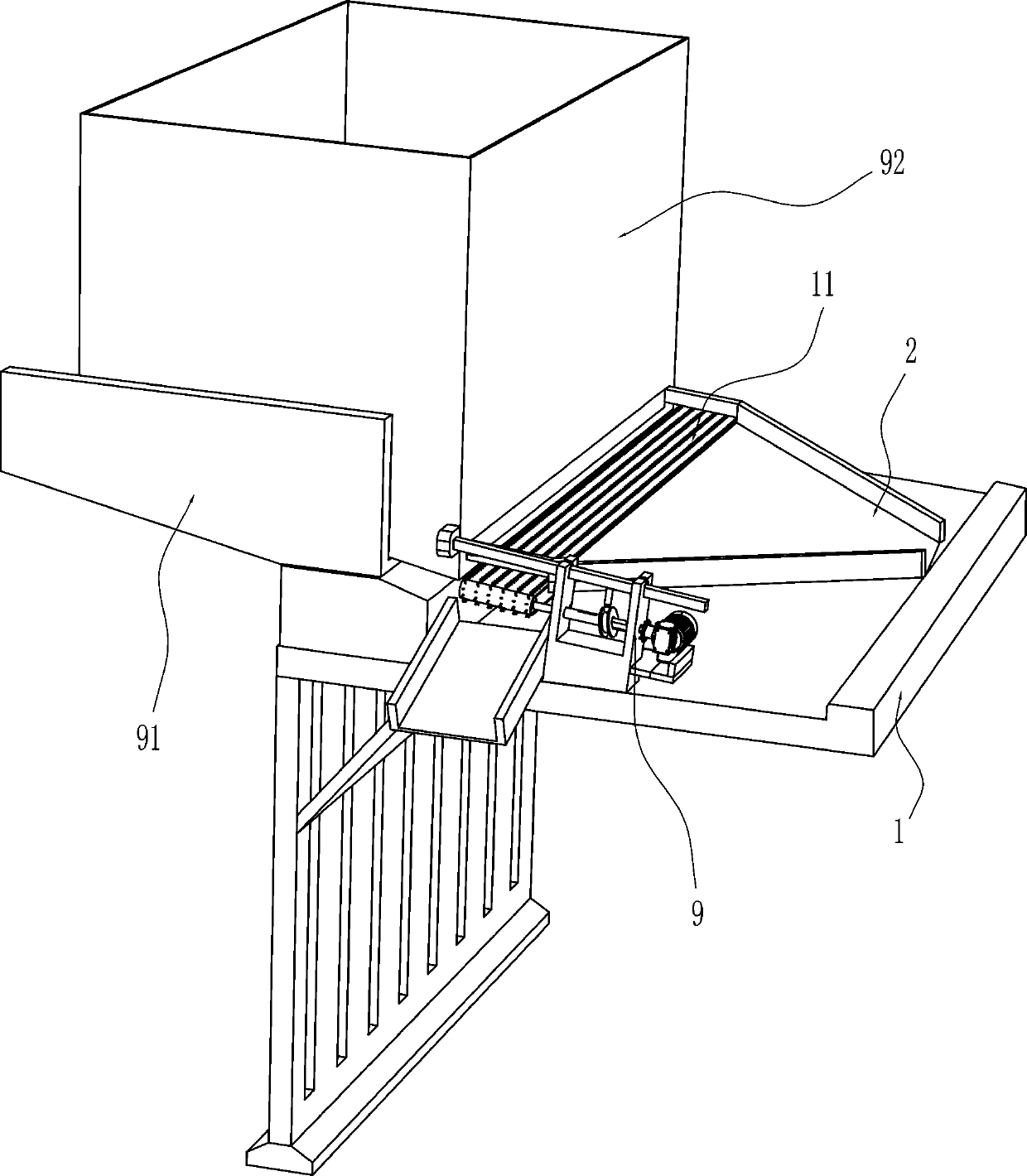

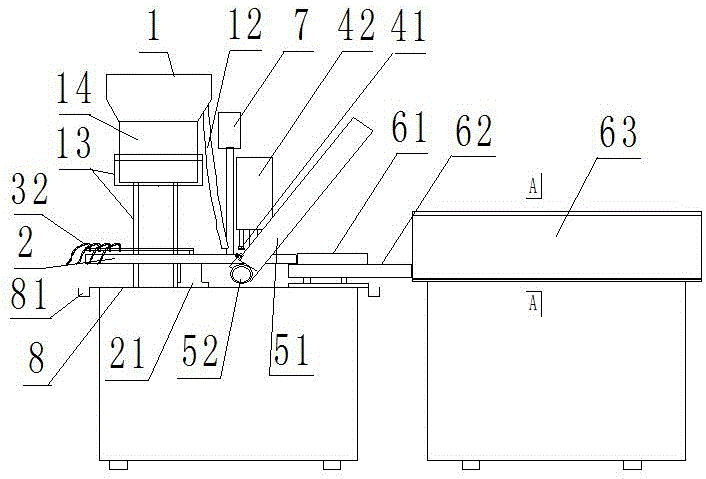

Medicine bottle cap punch forming equipment with synchronization of punching and discharging

InactiveCN107377807ASimple structureSimplify the blanking structureSievingMetal-working feeding devicesPunchingMedicine bottle cap

The invention relates to the field of processing of bottle caps, in particular to medicine bottle cap punch forming equipment with synchronization of punching and discharging. The medicine bottle cap punch forming equipment comprises a frame, a punching mechanism, a feeding mechanism and a discharging mechanism; the punching mechanism, the feeding mechanism and the discharging mechanism are arranged on the frame. The punching mechanism comprises a punching slide rail fixed to the frame, a punching platform slidably arranged on the punching slide rail and a driving motor driving the punching platform to move along the punching slide rail. The discharging mechanism comprises a blowing assembly and a receiving assembly; the blowing assembly comprises a blowing tube arranged beside the punching station and a blowing cylinder connected with the blowing tube and fixed at the position above the punching mechanism; the inside of the blowing cylinder is provided with an air cavity, the body of the blowing cylinder is provided with an air inlet, a piston is arranged in the air cavity, and an external rod of the piston is connected to the punching platform of the punching mechanism. The medicine bottle cap punch forming equipment realizes linkage synchronization of the punching procedure and the discharging procedure, thereby simplifying structure and saving time for regulation.

Owner:浙江冠利新材料股份有限公司

Medicine bottle cap

The invention provides a medicine bottle cap. The medicine bottle cap comprises the following raw materials in parts by weight: 60-80 parts of polyethylene particles, 0.2-0.4 part of phthalate, 0.5-0.8 part of lead salt and 0.3-0.5 part of coupling agent or comprises the following raw materials in parts by weight: 60-70 parts of polyethylene particles, 0.2-0.3 part of phthalate, 0.5-0.6 part of lead salt and 0.3-0.4 part of coupling agent or comprises the following raw materials in parts by weight: 70-80 parts of polyethylene particles, 0.3-0.4 part of phthalate, 0.6-0.8 part of lead salt and 0.4-0.5 part of coupling agent. The medicine bottle cap is simple in proportioning and has high production efficiency and excellent quality.

Owner:青岛浩恩医药耗材有限公司

Medicine bottle cap capable of measuring pill number of taking medicine

InactiveCN1957875BSimple and fast operationReduce preparation timeSmall article dispensingCapsMedicine bottle capBiomedical engineering

Owner:张茁

Medicine bottle cap having memory function

InactiveCN106314995ASimple structureEasy to implementSmall article dispensingClosure with auxillary devicesAxial displacementMedicine bottle cap

The invention relates to the technical field of medicine packaging and discloses a medicine bottle cap having the memory function. The medicine bottle cap comprises a bottle cap body and a rotating shaft. A shaft hole is formed in the center of the end wall of the bottle cap body. Multiple medicine outlet holes are formed in the end wall of the bottle cap body at intervals with the shaft hole as the circle center. Distinguishing identification is arranged beside each medicine outlet hole. The rotating shaft is arranged in the shaft hole of the bottle cap body in a sleeved manner and mounted through cooperation between a boss arranged in the middle of the rotating shaft and a groove formed in the wall of the shaft hole, so that axial displacement, relative to the bottle cap body, of the rotating shaft is limited. A pointer is fixedly arranged at the top end of the rotating shaft and used for indicating the corresponding medicine outlet hole and the distinguishing identification corresponding to the medicine outlet hole. A distribution disc concentric with the rotating shaft is fixedly arranged at the bottom end of the rotating shaft. A distribution hole is formed in the distribution disc and communicates with any medicine outlet hole pointed by the pointer. The medicine bottle cap is simple in structure and easy to implement; by observing comparison between the date indicated by the pointer and the actual date, whether a patient takes the medicine or not on the same day can be determined; and the medicine bottle cap is easy to operate and clear at a glance.

Owner:张煜爽

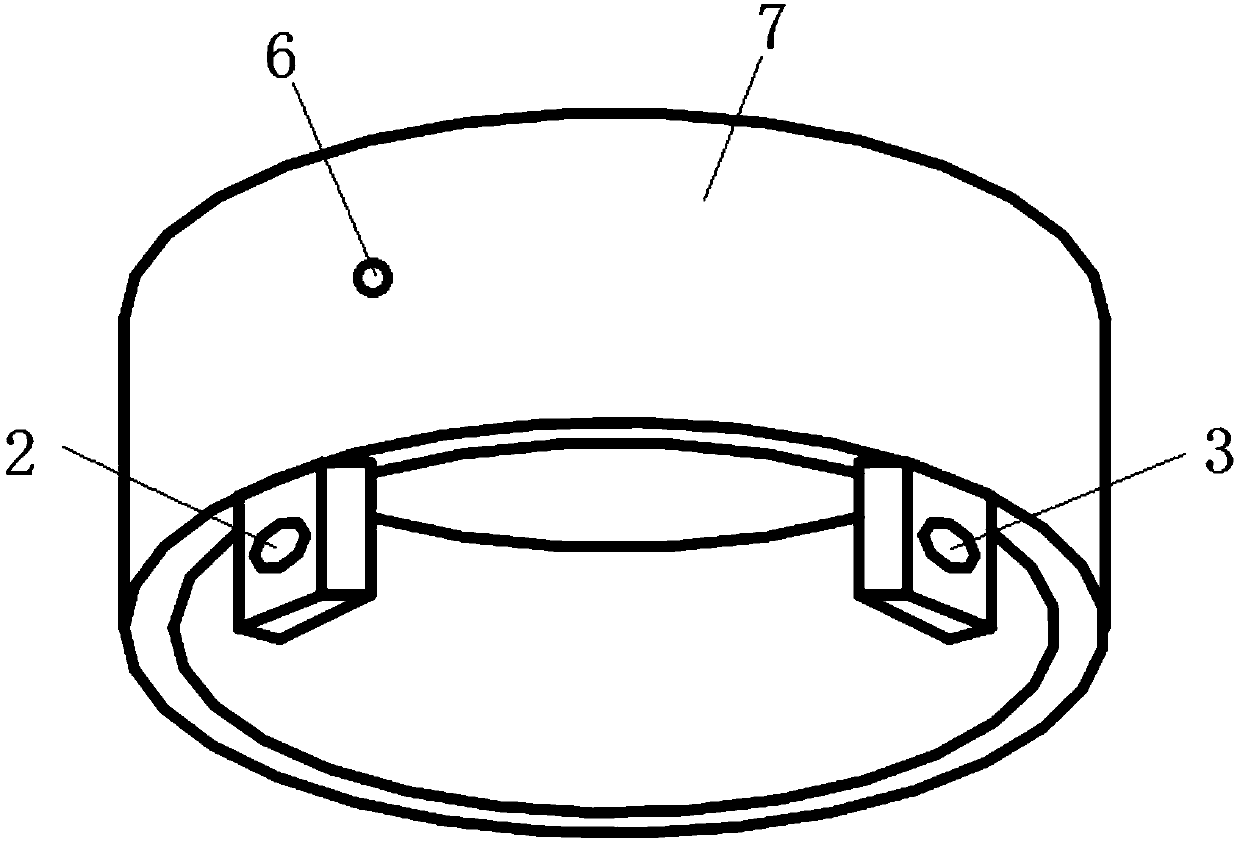

Medicine bottle cap pressing device convenient to adjust

ActiveCN108529527ASimple structureEasy to operateFlanged caps applicationMedicine bottle capEngineering

The invention discloses a medicine bottle cap pressing device convenient to adjust. The medicine bottle cap pressing device comprises a driving belt, a base, a fixing rod, a limiting disc, a cap pressing disc, an air cylinder, a plurality of lower pressing rods, a fixing disc and an output frame. The cap pressing plate, the limiting disc and the fixing disc are sequentially arranged on the outer side of the fixing rod from top to bottom, an air cylinder is arranged on the upper part of the cap pressing disc, a plurality of through holes are formed in the limiting disc, the lower pressing rodsare arranged on the bottom surface of the cap pressing disc. A plurality of fixing holes are formed in the fixing disc, the through holes, the lower pressing rods and the fixing holes are correspondedin position. A conveying belt and the output frame are arranged on two sides of the fixing disc respectively, the fixing disc is mounted on the base. The medicine bottle cap pressing device has the advantages that the cap pressing disc, the limiting disc and the fixing disc are arranged on the fixing rod sequentially, the lower pressing rods used for compressing are mounted at the bottom of the cap pressing disc, the descending height of the cap pressing disc for cap pressing is limited by the below limiting disc, and the limiting disc is adjusted through an adjusting thread to conveniently adjust the cap pressing height, so that repeated mounting is avoided, and cap pressing efficiency is improved.

Owner:ANHUI XIANQIU PHARMA

Electronic pill bottle tag

PendingUS20210154103A1Drug and medicationsPharmaceutical containersMedicine bottle capPharmaceutical drug

An electronic device, method of use, and system for improving medication compliance are disclosed. The device may comprise an upper cover configured to adhere to a pill bottle cap; a printed circuit board (PCB); a battery communicatively linked to the PCB; a sensor communicatively linked to the PCB; and a lower cover through which the sensor is configured to transmit and receive signals.

Owner:HELIOS CENT OF ENG EXCELLENCE INC

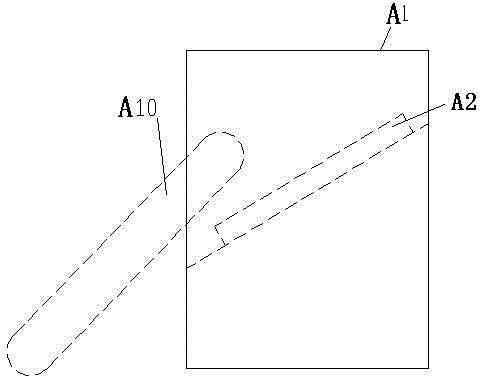

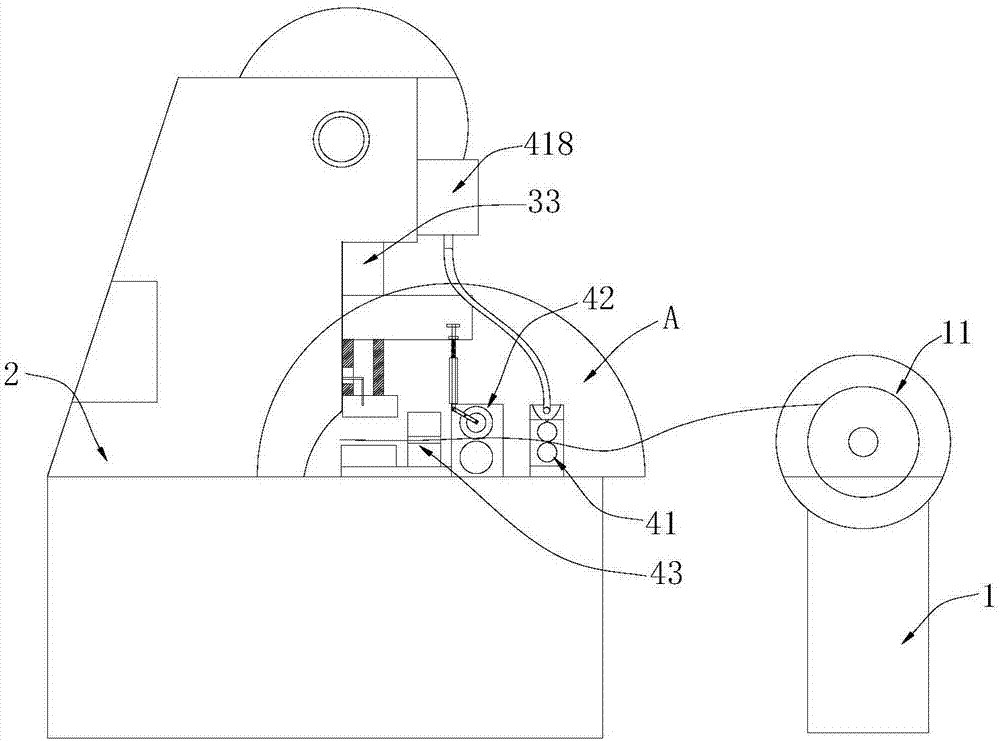

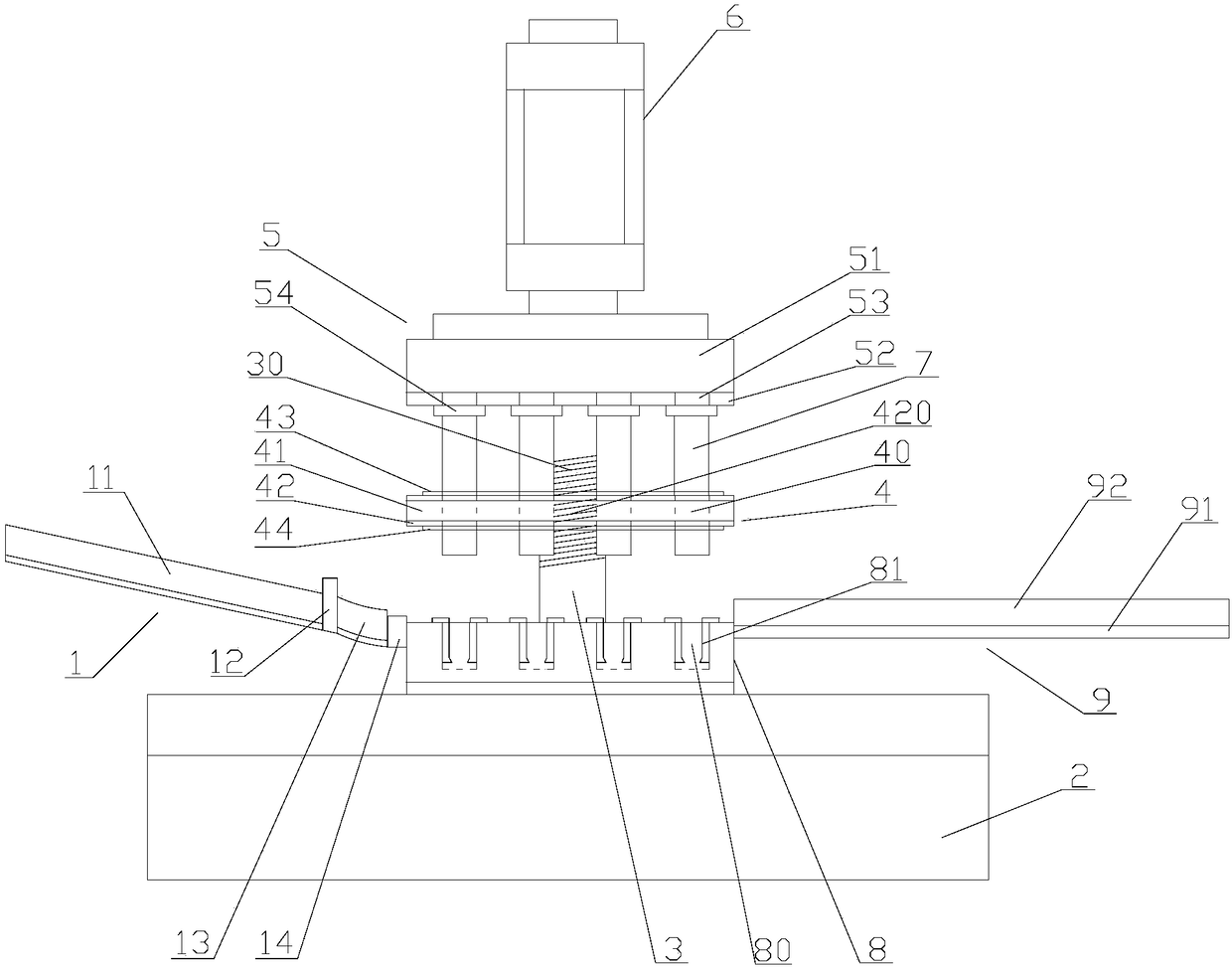

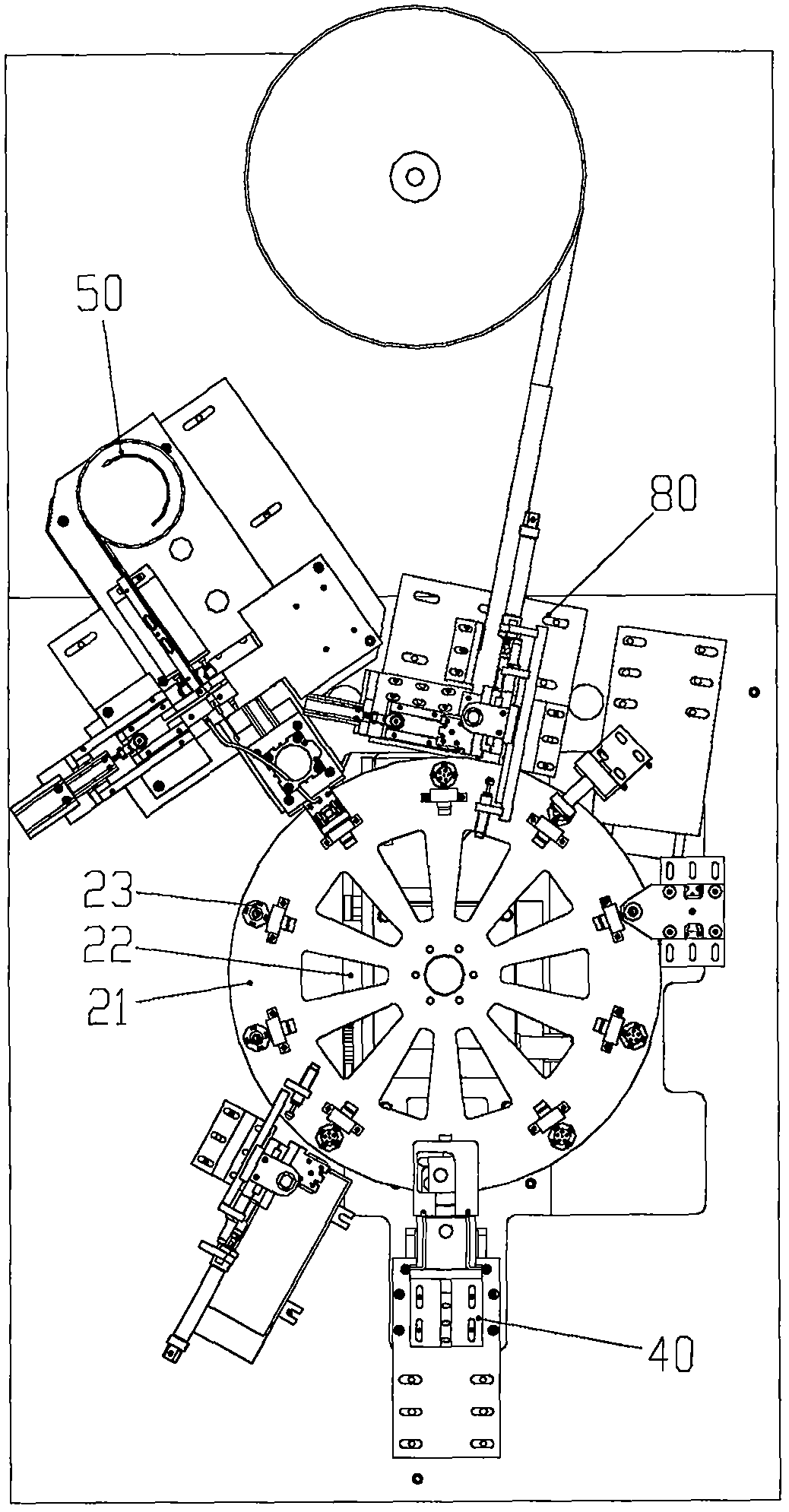

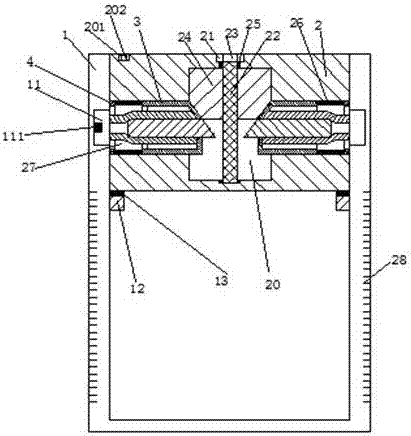

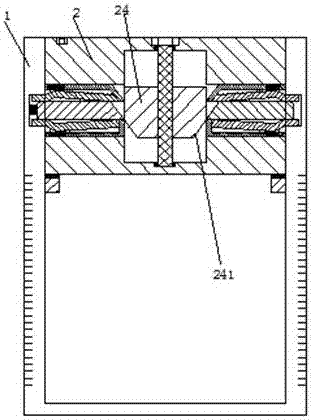

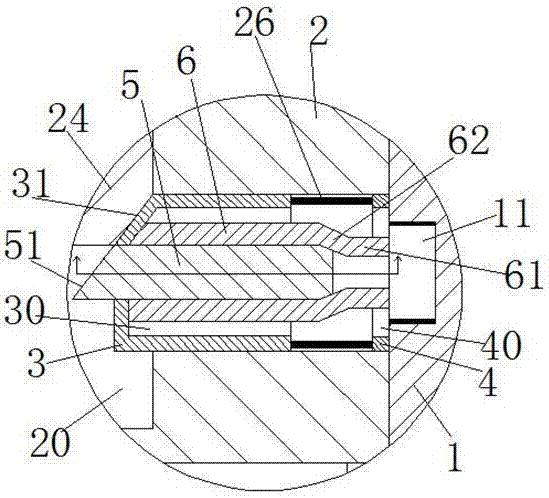

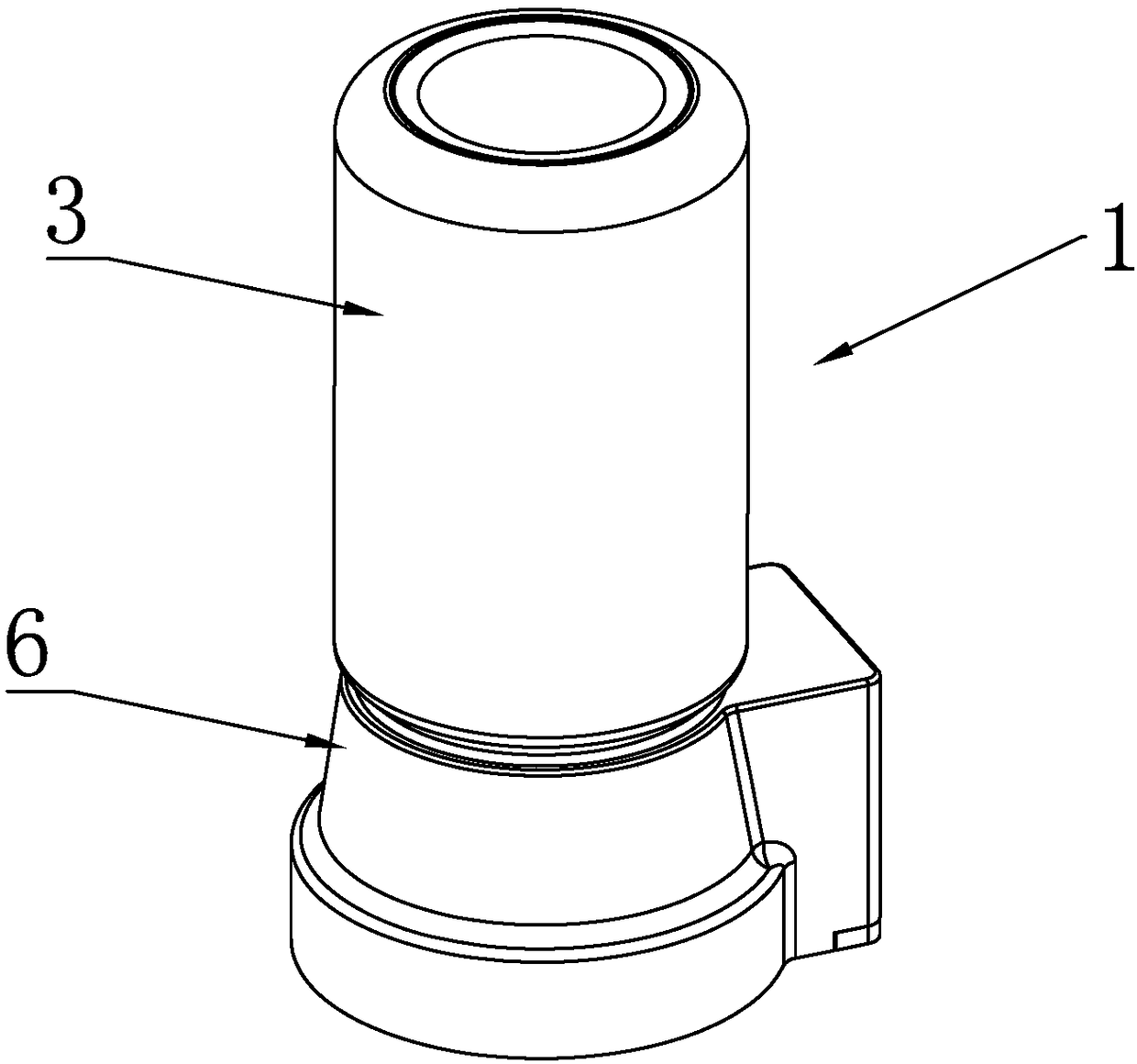

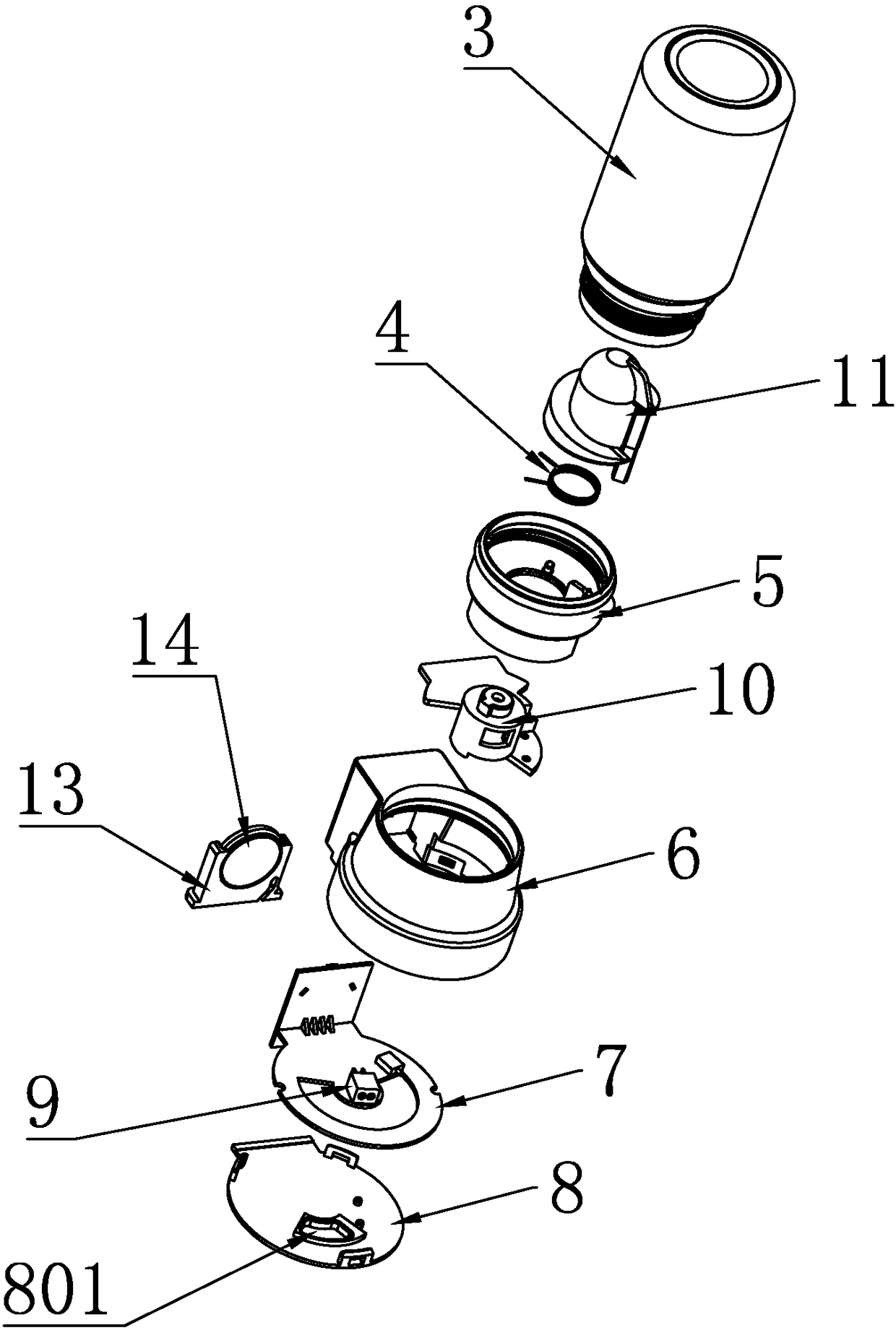

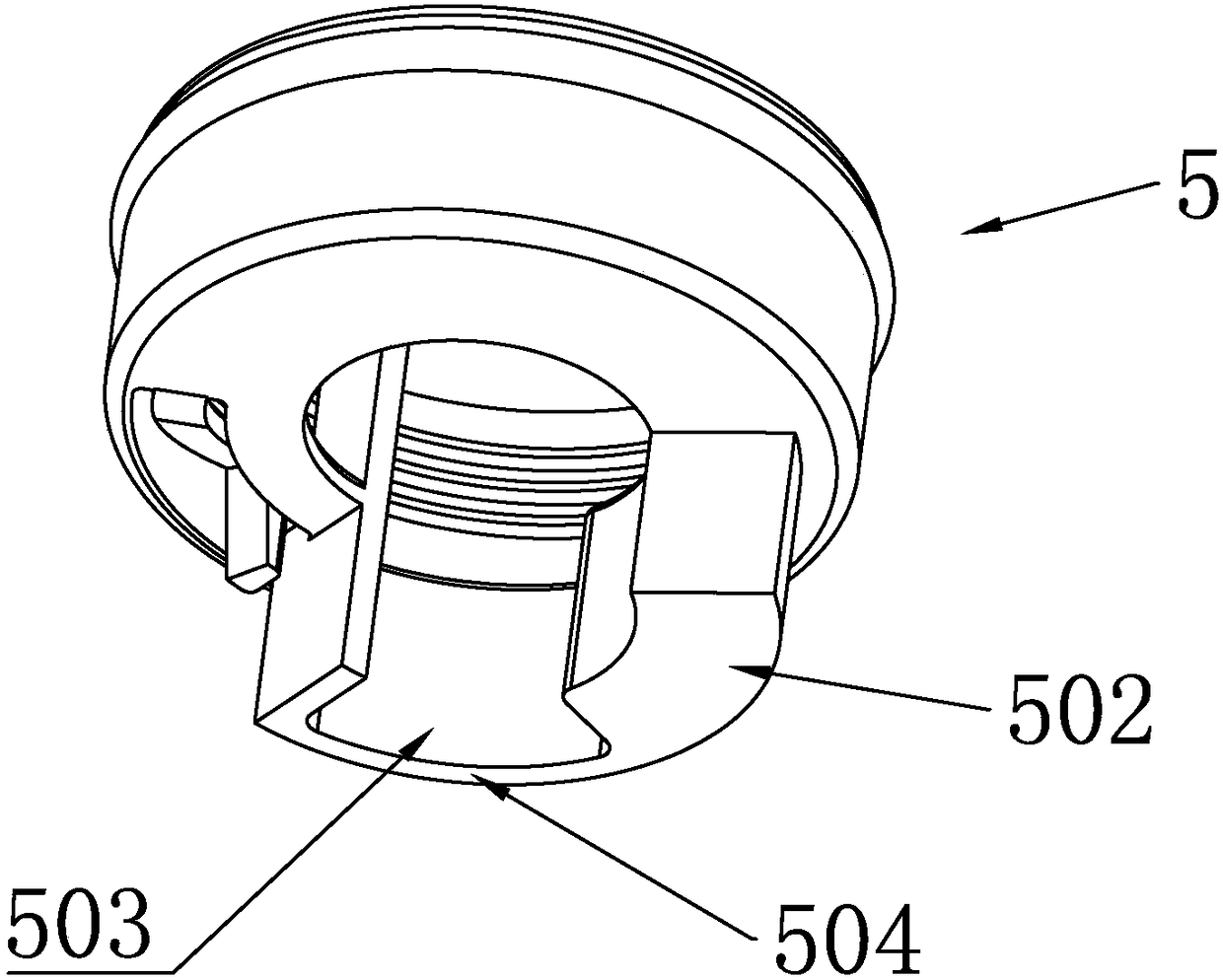

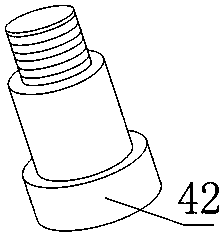

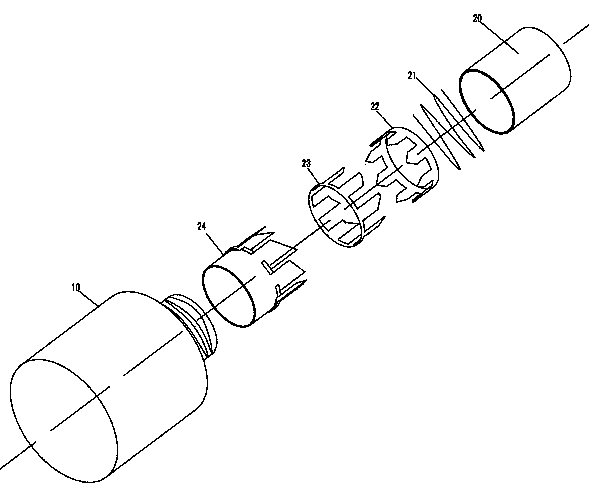

Medical container and automatic assembling technology thereof

The invention relates to a medical supply and a manufacturing technology of the medical product, in particular to a medicine bottle cap and an automatic assembling technology of the medicine bottle cap, and discloses a medical container and an automatic assembling technology of the medical container. The medical container is involved, and the technology achieves automatic assembling for one part of the structure of the medical container. The automatic assembling technology comprises a bottle cap automatic assembling machine and technological parameters of the bottle cap automatic assembling machine, the bottle cap automatic assembling machine comprises a workbench, a rotating disc mechanism used for driving a tool clamp to do equal division rotation, a vision positioning module used for precisely adjusting the angle of the tool clamp, a drip tube feeding mechanism used for assembling a drip tube to the tool clamp, and a bottle cap feeding mechanism used for assembling a bottle cap to the tool clamp. According to the medical container and the automatic assembling technology of the medical container, vertical placement of the container is achieved through a bottle body with the stable bottom, the container is sealed through the bottle cap, liquid or paste discharge is achieved through the drip tube, and automatic assembling of the bottle cap and the drip tube is achieved throughautomatic assembling equipment.

Owner:WENZHOU POLYTECHNIC

Punching machine of medicine bottle caps

InactiveCN107234163AFast blankingSimple structureMetal-working feeding devicesClosure capsPunchingMedicine bottle cap

The invention relates to the field of bottle cap processing equipment, in particular to a punching machine of medicine bottle caps. The punching machine of the medicine bottle caps comprises a punching mechanism, a feeding mechanism and a discharging mechanism. The punching mechanism comprises a rack, a punching motor, an eccentric shaft and a punching shaft, wherein the punching motor, the eccentric shaft and the punching shaft are arranged on the rack; the two ends of the eccentric shaft are positioned on the rack through bearings, and the output end of the punching motor is in transmission connection with the eccentric shaft through a transmission assembly; and the punching shaft is longitudinally and slidably positioned on the rack, the upper end of the punching shaft is connected on the eccentric shaft in a sleeving mode, a punching die used for cutting plate bodies of raw materials is arranged at the lower end of the punching shaft, and the punching die is located above the feeding mechanism. According to the punching machine of the medicine bottle caps, the structure is simple and practical, and equipment operation is stable.

Owner:浙江冠利新材料股份有限公司

Safe medicine bottle cap device

InactiveCN107440907ALock firmlyAccidental ingestionClosuresPharmaceutical containersMedicine bottle capEngineering

The invention provides a safe medicine bottle cap device. The safe medicine bottle cap device comprises a bottle body for storing medicines, and a bottle cap, wherein a clamping convex ring and a concave ring positioned above the clamping convex ring are arranged in the inner wall of the bottle body, the bottle body is transparent, and graduated scales are arranged on two side walls of the bottle body; a sliding cavity extending up and down is arranged in the bottle cap, a sliding block is mounted in the sliding cavity in a vertically sliding manner, a screw rod is mounted at the middle end of the sliding block in spiral thread match manner, the lower end of the screw rod is rotationally mounted in the bottom wall of the sliding cavity, the upper end of the screw rod is rotationally mounted in the top wall of the sliding cavity, the upper end of the screw rod extends upwards to be arranged in a middle end groove at the middle end of the top wall of the bottle cap, transverse side sliding grooves extending left and right are correspondingly arranged in the bottle cap left and right, the transverse side sliding grooves communicate with the sliding cavity and the outside, and clamping devices are mounted in the transverse side sliding grooves. For the safe medicine bottle cap device, the fixing is stable, children can not open the bottle cap at will, therefore, the possibility that the children eat medicines by mistake is eliminated, and thus the safety is greatly improved.

Owner:广州燃烧医疗技术开发有限公司

Intelligent medicine bottle and medicine taking monitoring system

PendingCN108498340AStop falling outLearn about medicationOral administration deviceDomestic articlesMedicine bottle capMonitoring system

The invention discloses an intelligent medicine bottle, for overcoming the defect that in the prior art, a recording means for the medicine taking amount and medicine taking time of a patient is not available. The invention provides the intelligent medicine bottle with which the medicine taking amount and medicine taking time of the patient can be recorded each time. The intelligent medicine bottle comprises a medicine bottle main body, wherein the medicine bottle main body comprises a bottle body, a reset mechanism, a positioning center pillar, a medicine bottle inner cap, a medicine cap outer shell, a circuit substrate and a medicine bottle cap buckle plate; the bottle body is arranged above the medicine bottle inner cap in an inverted manner, the opening of the bottle body is in threaded connection to the medicine bottle inner cap, the top end and the bottom end of the medicine cap outer shell are open, the medicine bottle inner cap rotatably sleeves in the opening at the top end ofthe medicine cap outer shell, the medicine bottle cap buckle plate is arranged at the opening of the bottom of the medicine cap outer shell, the medicine bottle inner cap is provided with a first medicine outlet, the medicine bottle cap buckle plate is provided with a second medicine outlet, the circuit substrate is provided with a counting sensor, the counting sensor is arranged between the medicine bottle inner cap and the medicine bottle cap buckle plate, and the reset mechanism is arranged between the medicine bottle inner cap and the positioning center pillar.

Owner:张俊华 +1

Intelligent detecting device for medicine bottle cap

InactiveCN109932756AEasy to useHigh degree of intelligenceOptical detectionUser needsMedication information

The invention discloses an intelligent detecting device for a medicine bottle cap. The detecting device comprises an infrared pair tube, a microprocessor unit, a storage module and an interaction module. The infrared pair tube includes an infrared transmitting tube and a photosensitive receiving tube; and the infrared transmitting tube and the photosensitive receiving tube are arranged at the sides of a medicine bottle cap integrated with the bottle body in pair. When the bottle cap is closed with the bottle body, a light path signal between the infrared transmitting tube and the photosensitive receiving tube is just blocked by the bottle body; when the bottle cap is opened, a light path signal between the infrared transmitting tube and the photosensitive receiving tube is not blocked; themicroprocessor unit monitors the medication information through the infrared pair tube, the information is stored and external interaction is carried out; and whether the user needs to be warned by the interaction module after processing and determination. According to the invention, the medication condition of the patient can be determined accurately; the energy consumption and the cost is low;the performance is stable; and the intelligent detecting device has the great commercial promotion value.

Owner:SHANGHAI MSENSE HEALTH TECH INC

Cap screwing and moving mechanism for Chinese patent medicine bottle body processing

ActiveCN109911823AIncrease capacityImprove efficiencyThreaded caps applicationConveyorsSocial benefitsCarrying capacity

The invention discloses a cap screwing and moving mechanism for Chinese patent medicine bottle body processing. A supporting and arranging table, a conveying disc, a workbench and a piece dischargingsliding hopper are included. The conveying disc is horizontally arranged on the upper end face of the supporting and arranging table, and the workbench is vertically arranged above the conveying discin the longitudinal direction. The cap screwing and moving mechanism has the beneficial effects that two movable plates clamped and connected to the conveying disc move front and back to the positionbelow a cap screwing frame for cap screwing at the same time, it is guaranteed that the carrying capacity is higher when the mechanism conducts cap screwing on medicine bottles, and the space utilization rate is increased. Four second motors at the four corners of the bottom of the cap screwing frame are matched with clamping claws to synchronously conduct cap screwing on the medicine bottles on different bottle sleeving bases, and the high efficiency of the cap screwing work of the mechanism is improved. Two pressing sheets are used for extruding the medicine bottle caps on two cap pressing bases correspondingly, it is guaranteed that the bottle caps are screwed and fixed more firmly, and it is guaranteed that the efficiency of pressing and extruding of the bottle caps on the medicine bottles is higher; and the mechanism is convenient to operate, good social benefits and economic benefits are achieved, and the cap screwing and moving mechanism is suitable for usage and popularization.

Owner:六安市舒杰科技信息咨询有限公司

Medicine bottle cap packaging device

ActiveCN104030206AConducive to package transfer efficiencySimple structureFlanged caps applicationMedicine bottle capMedicine bottles

The invention discloses a medicine bottle cap packaging device. The medicine bottle cap packaging device comprises a bottle conveying mechanism, a bottle cap tightening mechanism and a cap conveying mechanism. The bottle conveying mechanism comprises a rotary table barrel, a rotary table and bottle mounting clamping openings. The bottle cap tightening mechanism comprises a rotating shaft, tightening wheels, a first rotating shaft, an elastic part, a reset spring and pull rods. Each tightening wheel comprises a tightening wheel seat and a rolling wheel. The cap conveying mechanism comprises a cap conveying barrel which is in a barrel shape, the inner wall of the cap conveying barrel is fixedly connected with a spiral cap outlet guide rail, and a power output device used for braking the movement of bottle caps is further arranged at the bottom of the cap conveying barrel. The outlet end of the spiral cap outlet guide rail is further connected with a cap outlet guide rail, and the tail end of the cap outlet guide rail is placed over the rotary table. The medicine bottle cap packaging device is high in working efficiency and simple in structural style, thereby being easy to operate and maintain.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

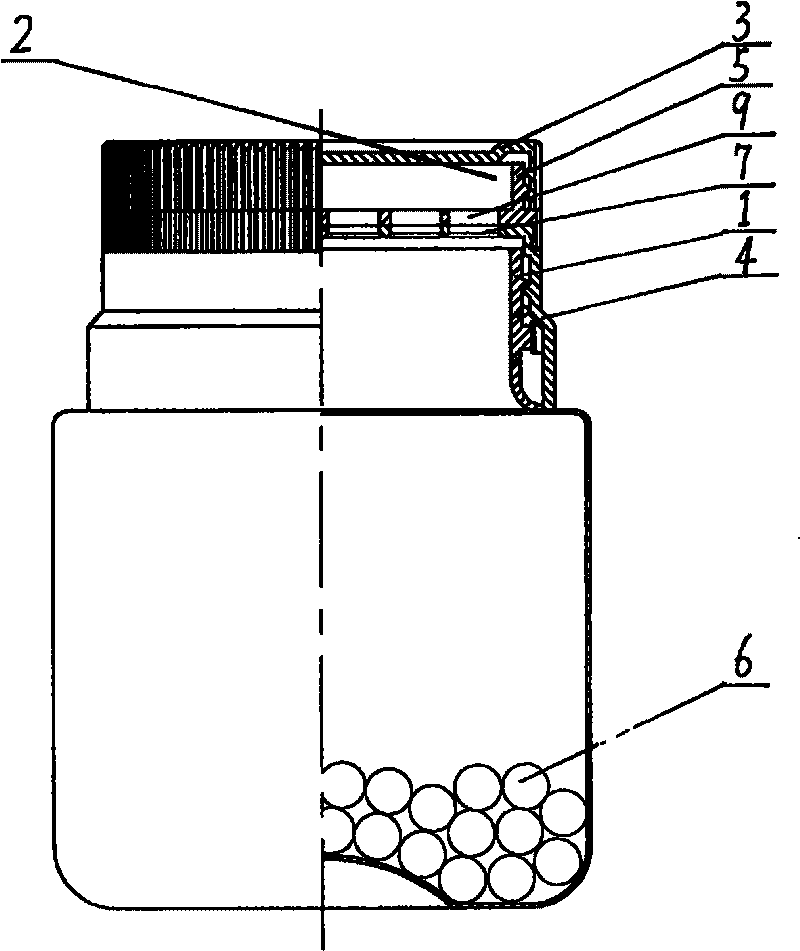

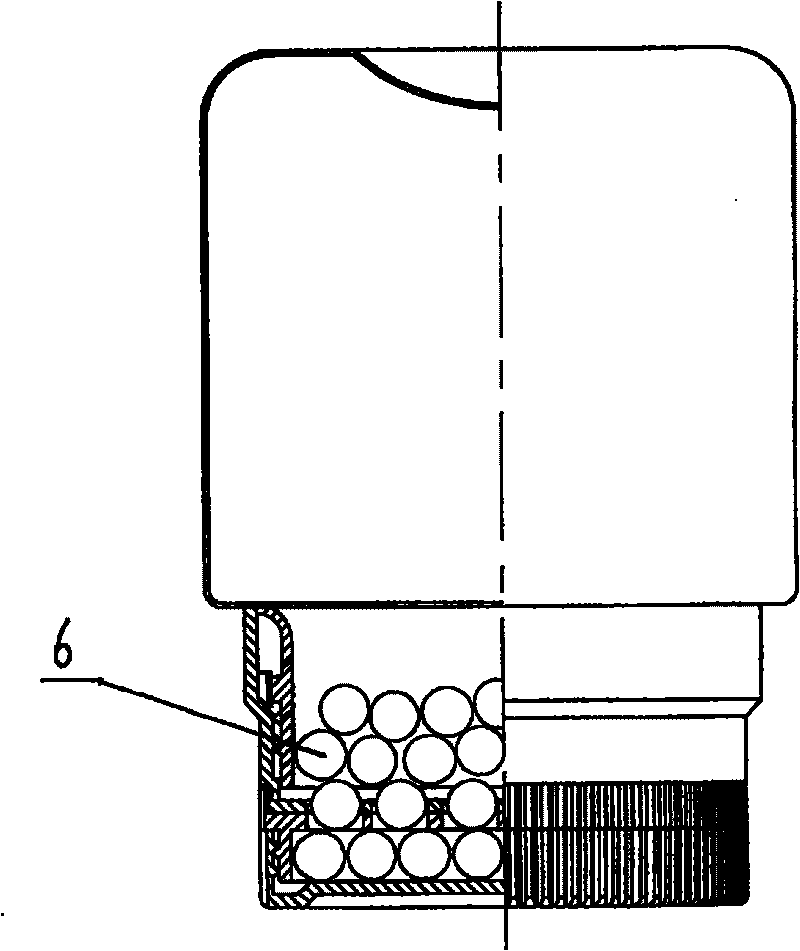

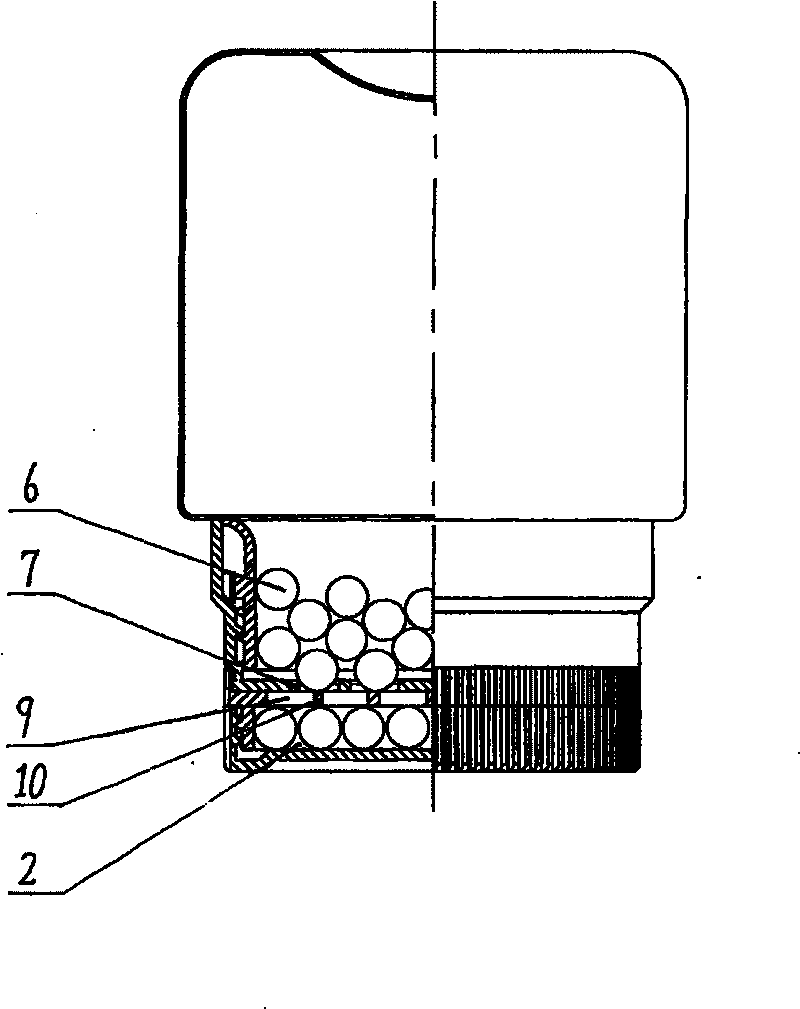

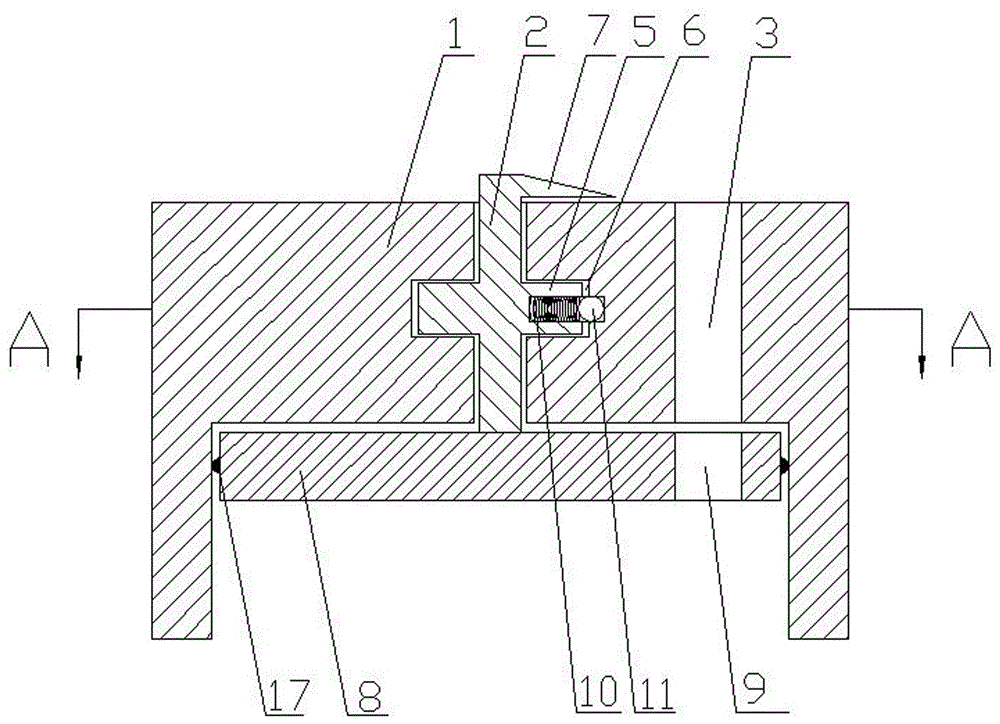

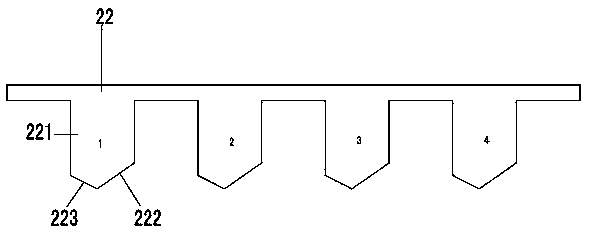

Medicine bottle cap with counting function

InactiveCN103387085AReduce security risksAchieve Stealth CountingCapsClosure capsMedicine bottle capClinical research

The invention discloses a medicine bottle cap with a counting function. A counting device is sleeved in the bottle cap; the counting device comprises a biasing piece, a rotating piece, a guiding piece and a pushing piece; the pushing piece and the biasing piece apply pushing force and the biasing force to the rotating piece; and in the screwing and unscrewing process of the bottle cap, the rotating piece is matched with the guiding piece under the actions of the pushing force and biasing force, and rotate relative to the guiding piece and the pushing piece to count once. The medicine bottle cap is simple in structure, and is convenient for making; hidden count is realized; a judgment on whether a subject takes medicines or not according to a research scheme can be made by recovering the medicine bottle according to data recorded data in the bottle cap, so that the potential safety hazards of new medicines are reduced; and the medicine bottle cap is suitable for clinical research.

Owner:INST OF BASIC RES & CLINICAL MEDICINE CHINA ACAD OF CHINESE MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com