Automatic oral liquid filling system

A filling system and oral liquid technology, applied in the field of food machinery processing, can solve problems such as inconvenient operation, inaccurate filling, unstable weight, etc., to improve quality and output, automatic filling at fixed speed, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

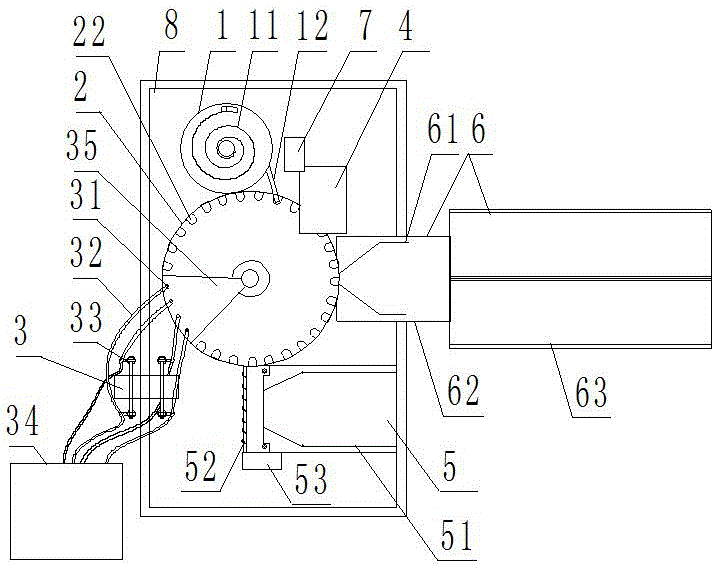

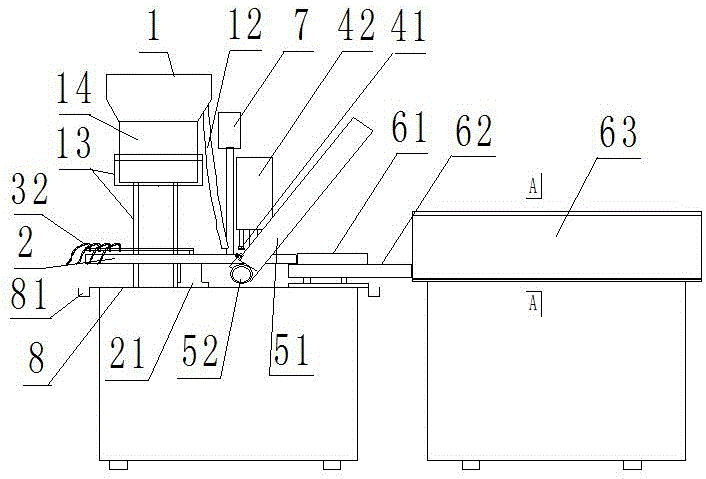

[0020] An automatic oral liquid filling system is characterized in that it includes a workbench 8 on which a medicine bottle capping bucket 1, a bottle rotating disc 2, a bottle filling device 3, a capping device 4, and a medicine bottle conveying device 5 are installed , the product off-shelf device 6 and the controller 7; the bottle turntable 2 is located in the middle of the workbench 8, and the bottle top bucket 1, the capping device 4 and the controller 7 are installed on one side of the turntable 2, and the other side A bottle filling device 3 and a medicine bottle conveying device 5 are installed, and a product unloading device 6 is installed in front of it;

[0021] The medicine bottle conveying device 5 includes a medicine bottle storage tank 51 and a rotating screw 52, the rotating screw 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com