Medical container and automatic assembling technology thereof

An automatic assembly and medical container technology, applied in the field of medical supplies and its manufacturing process, can solve the problem that bottles cannot be placed vertically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

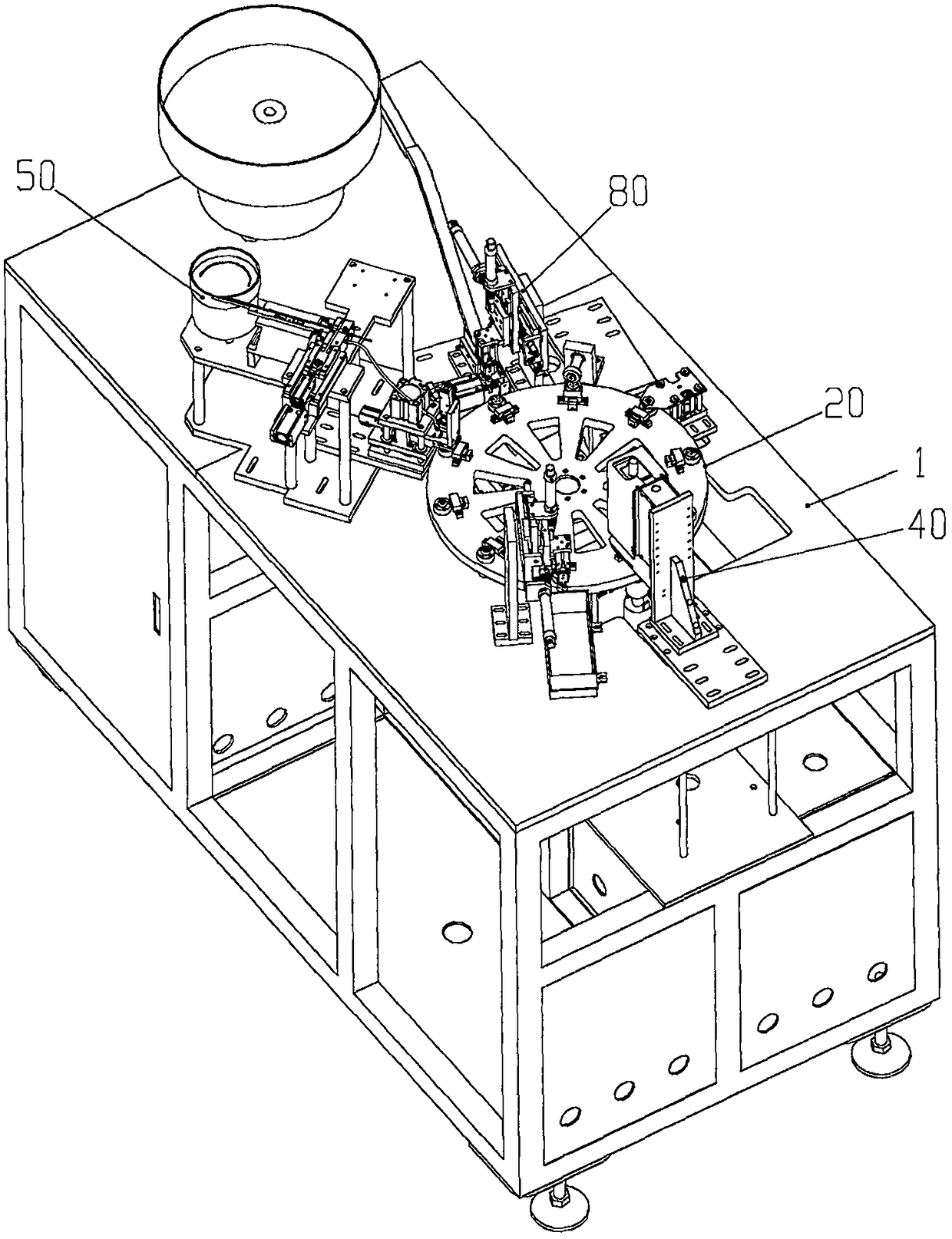

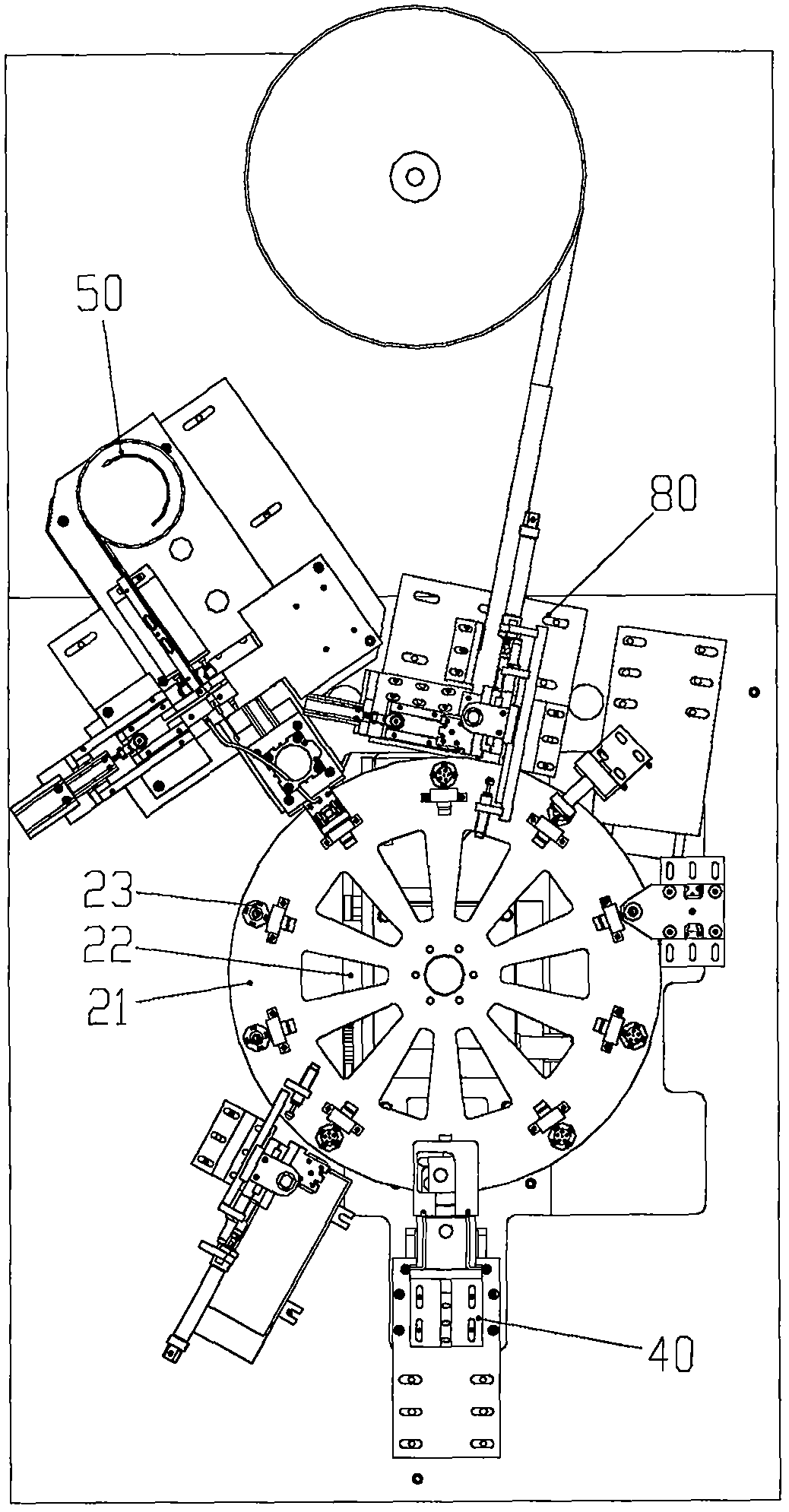

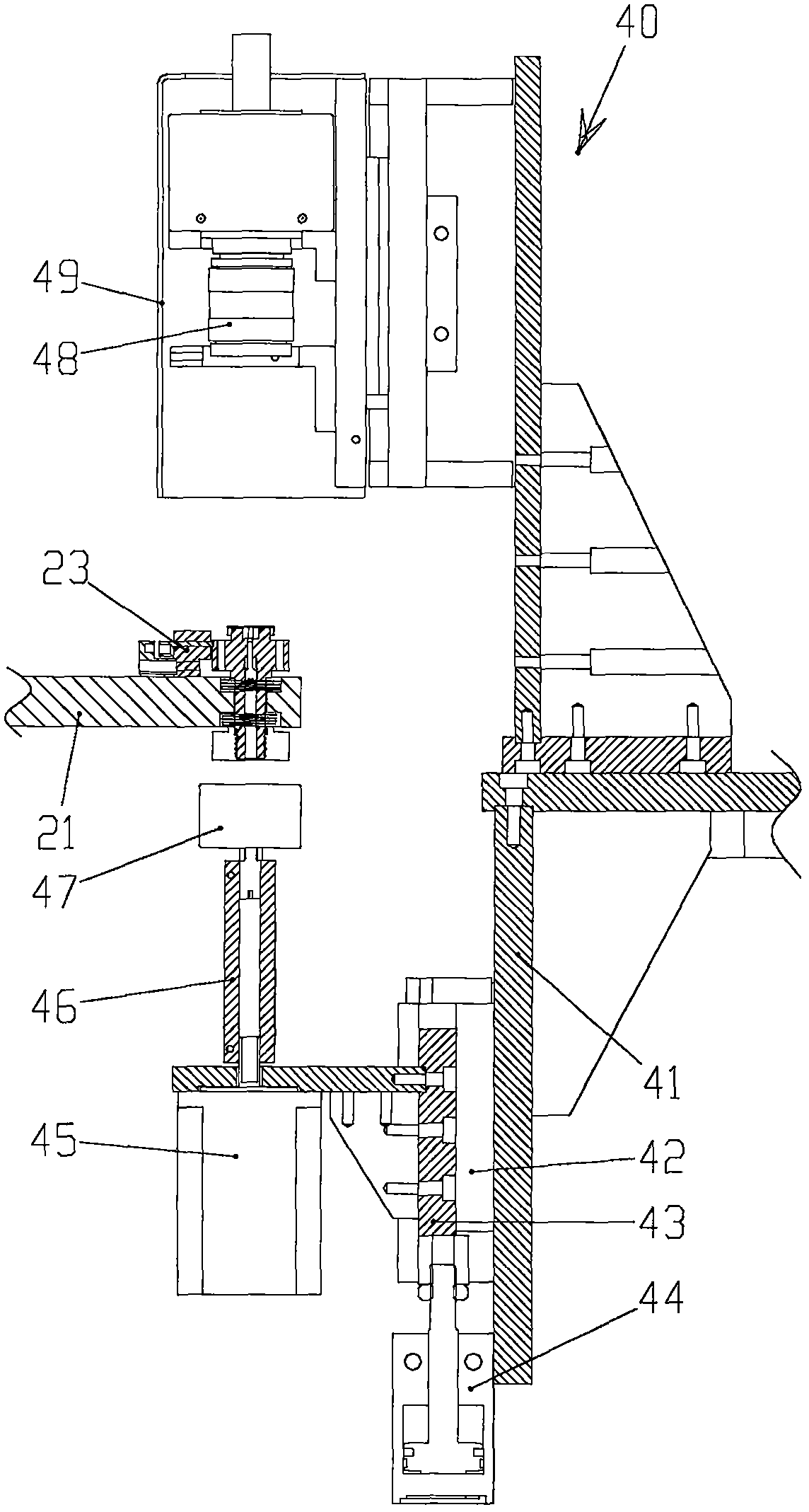

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a medical container and its automatic assembly process, which are applied in the medical field. The present invention discloses a bottle cap for containing medical ointment and its manufacturing process. The medical container and its automatic assembly process of the present invention use the bottle body with a stable bottom to realize the vertical placement of the container, use the bottle cap to realize the sealing of the container, and use the dropper to realize the discharge of liquid or paste; use the automatic assembly equipment to realize the bottle cap and automatic assembly of the dropper.

[0019] figure 1 , 2 It is a structural schematic diagram of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com