Conveying device applied to aluminum medicine bottle caps

A technology for conveying equipment and bottle caps, which is applied to flange-type bottle caps, conveyors, vibrating conveyors, etc., can solve the problems of complex operation, high cost, and complex structure, and achieves simple operation, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

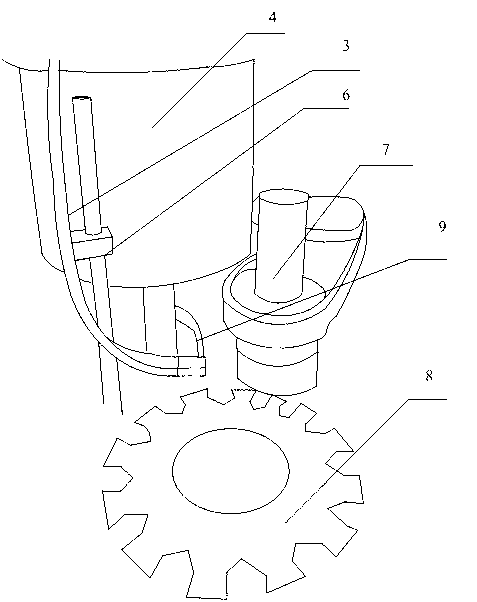

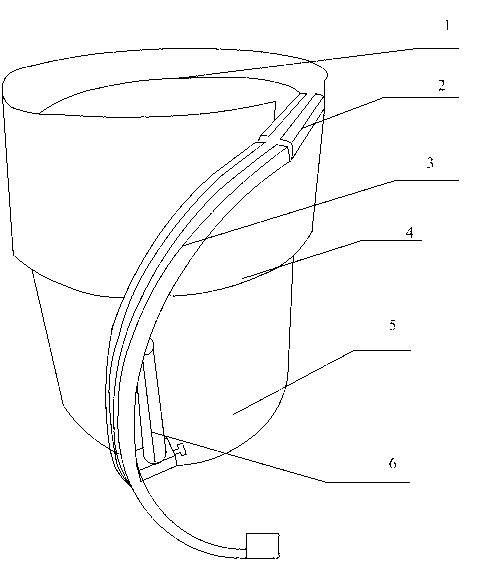

[0021] Such as figure 1 and figure 2 shown.

[0022] Conveying equipment applied to aluminum caps of medicine bottles, including a bottle cap transportation track, the bottle cap transport track includes a spiral track 1, a straight track 2, and a C-shaped track 3 connected in sequence, and the C-shaped track is far away from the straight track 2 One end is the end of the bottle cap transport track; also includes a circular bottle cap storage bucket 4, and the spiral track 1 spirals down along the inner diameter surface of the circular bottle cap storage bucket 4 until the bottom of the circular bottle cap storage bucket 4 As far as the bottom surface, the end of the C-shaped track 3 is provided with a downward blocking piece. Also comprise the motor vibrator 5 that is positioned at below the circular bottle cap storage bucket 4 and is connected with the circular bottle cap storage bucket 4. It also includes a support device positioned below the motor vibrator 5 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com