Patents

Literature

46results about How to "Fast blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

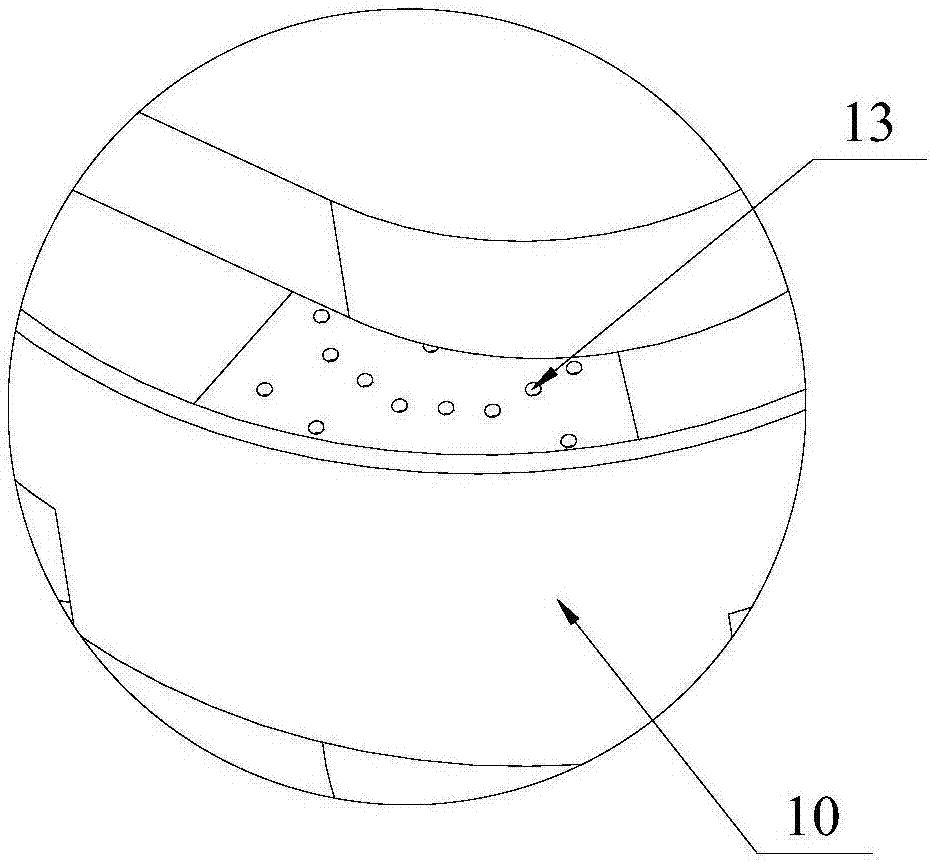

Vertical screw extruding juice extractor

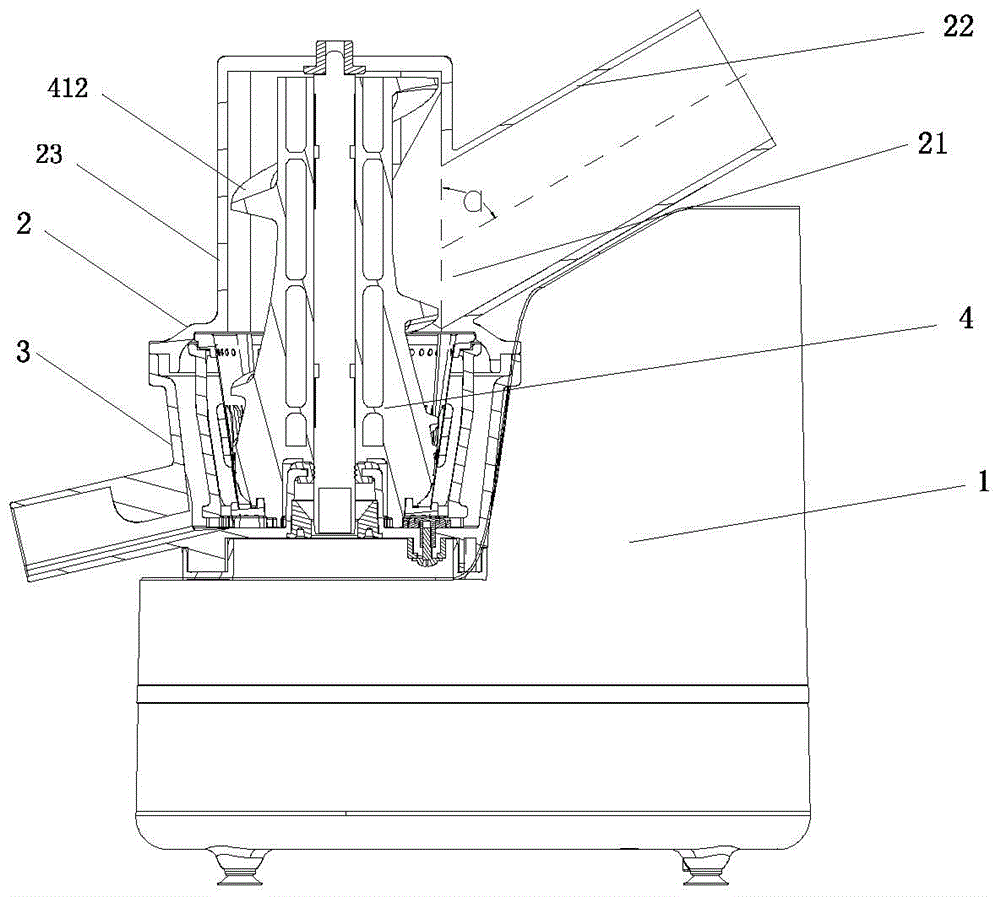

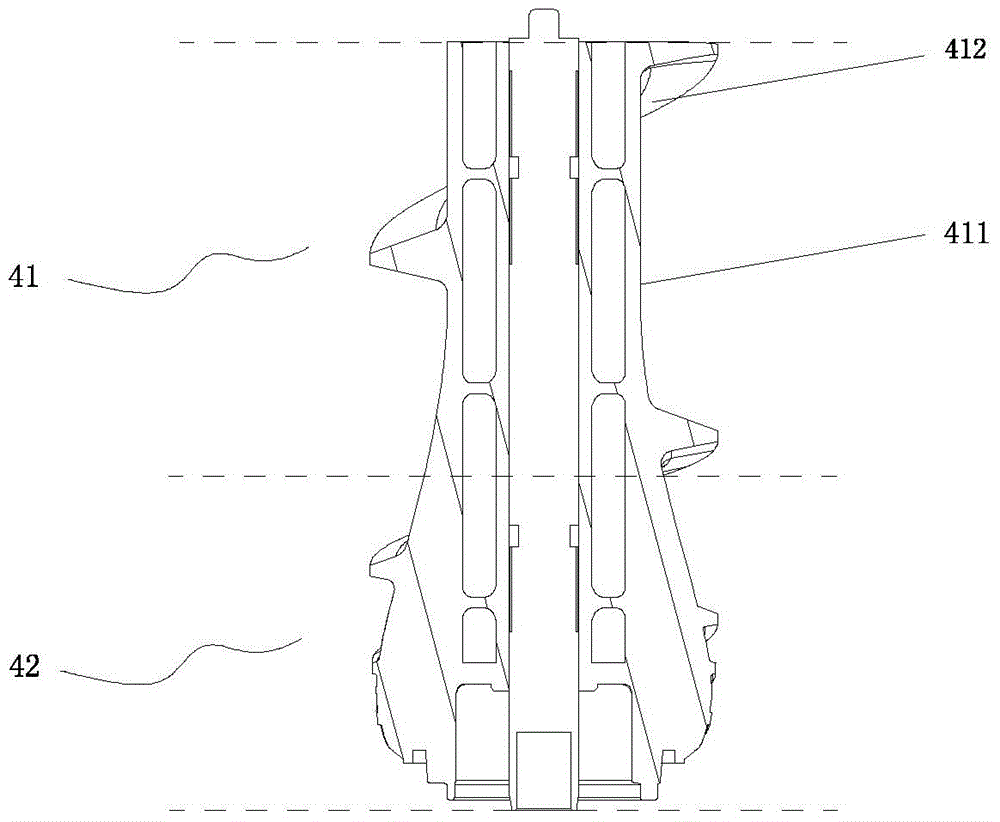

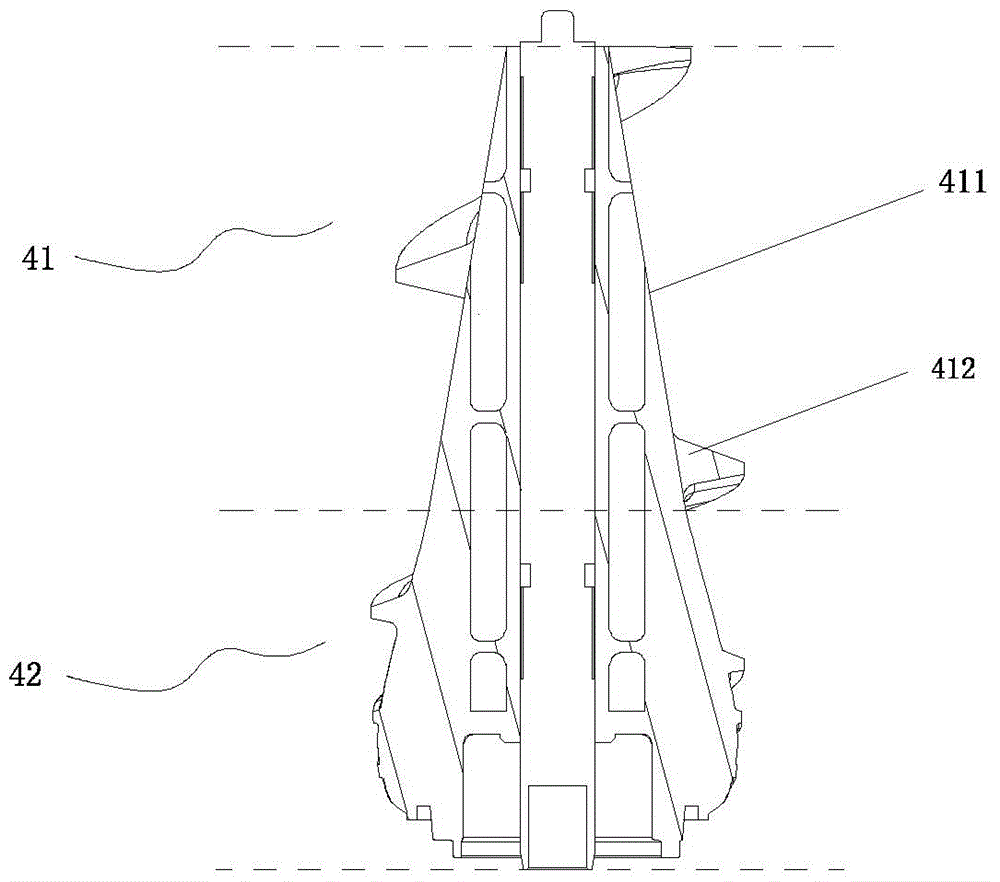

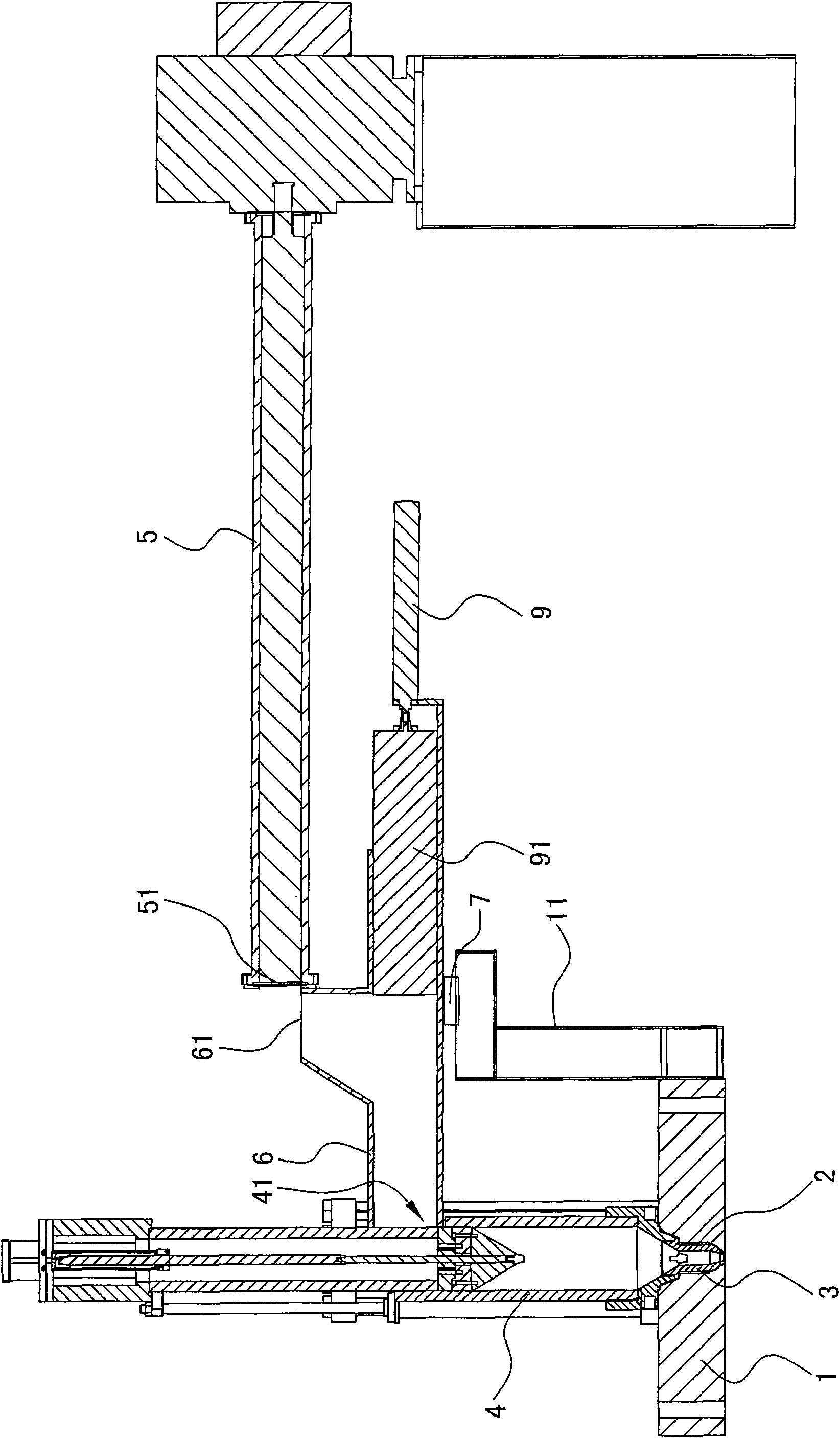

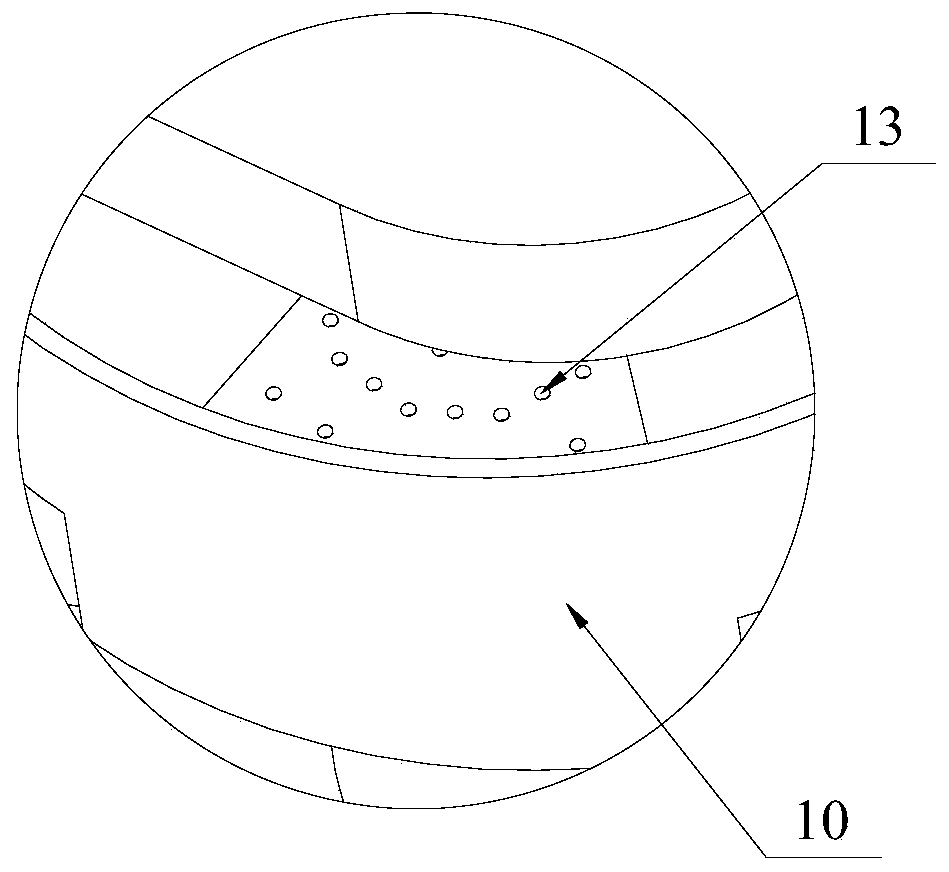

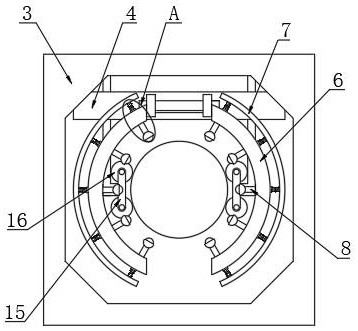

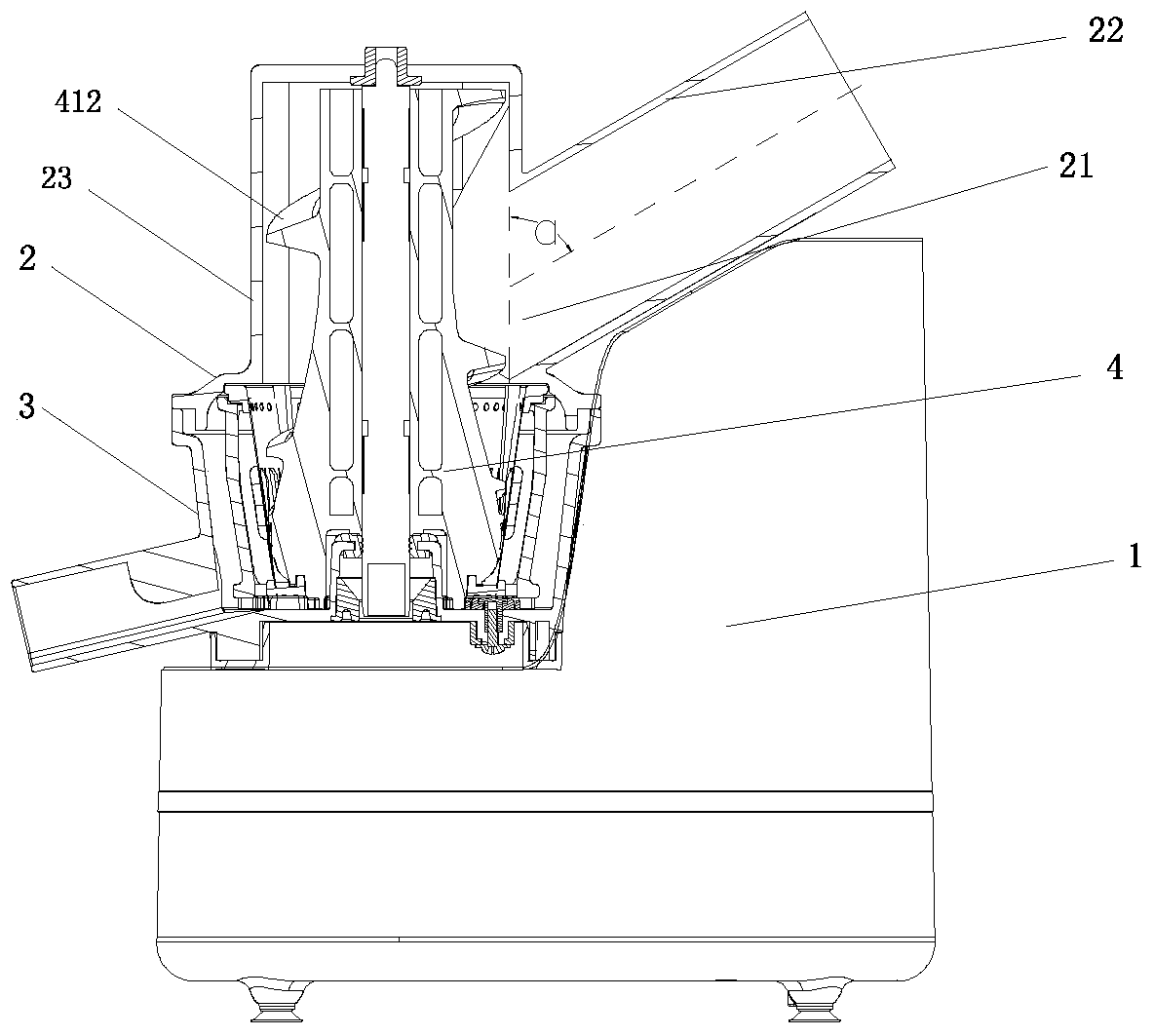

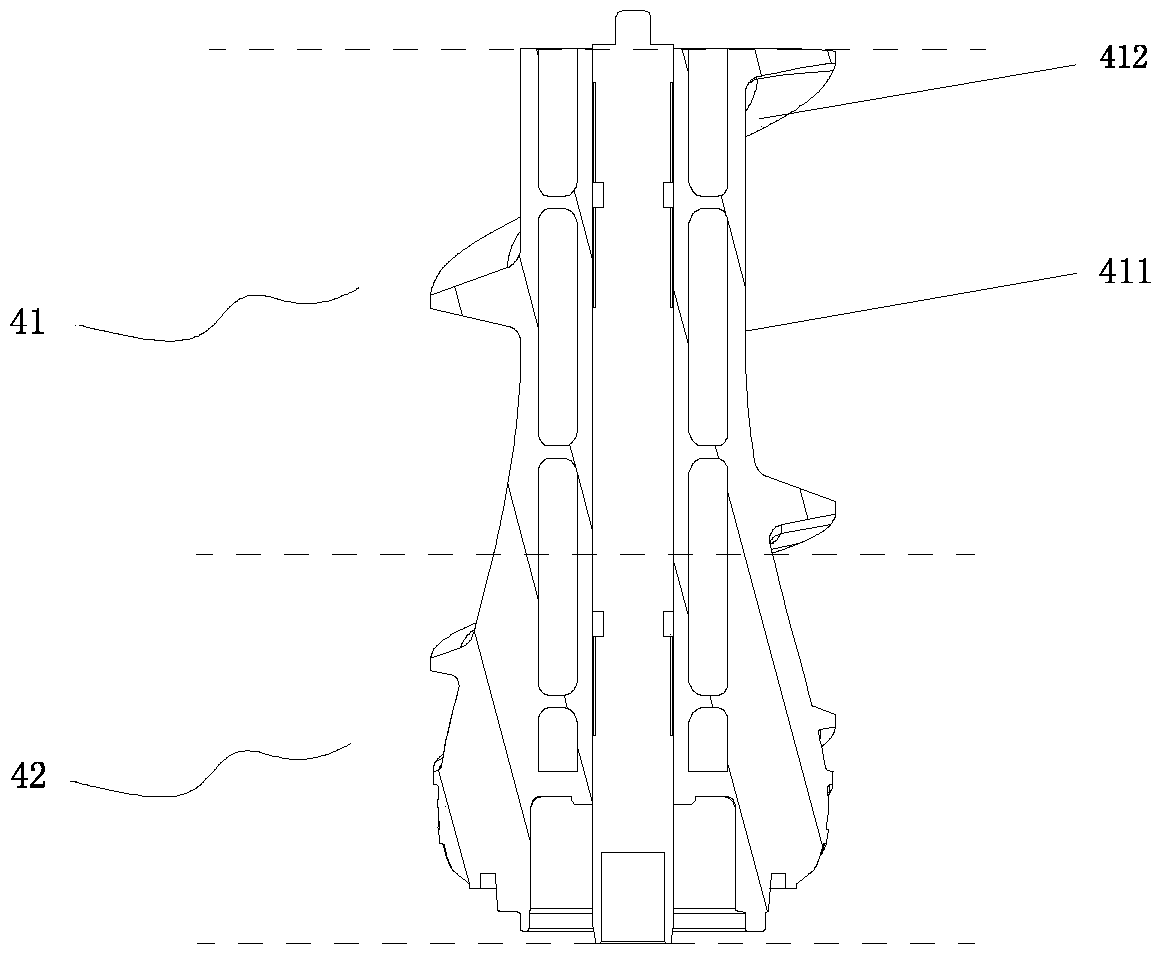

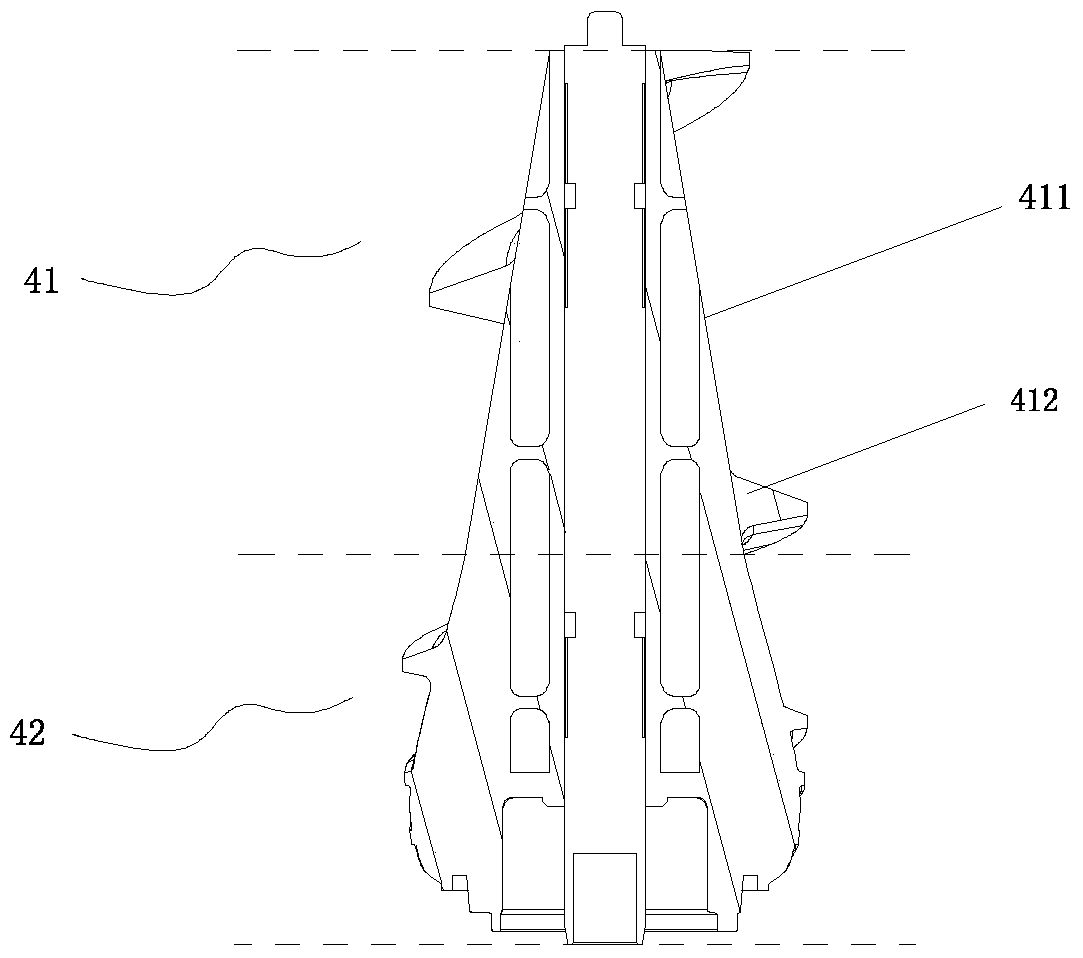

The invention discloses a vertical screw extruding juice extractor, which comprises a machine base, a motor arranged in the machine base, an extrusion screw, a pressing chamber cooperating with the extrusion screw to extrude materials, and an upper cover installed above the pressing chamber , the pressing chamber is installed on the machine base, the extruding screw is installed in the pressing chamber, the upper cover is provided with an accommodating part protruding upwards and used to accommodate the upper part of the extruding screw, and the side wall of the accommodating part is set There is a feed port and a feed channel connected to the feed port, the angle between the geometric center of the two ports of the feed channel and the vertical plane is a, 30°≤a≤60°, so that the material depends on itself The gravity can quickly enter the accommodating part directly through the feeding channel, and is quickly brought into the extrusion grinding part of the extrusion screw and the pressing chamber formed by the downward guidance of the material propulsion part at the corresponding position of the feeding port. Squeeze in the juice gap, easy to realize fast automatic feeding.

Owner:JOYOUNG CO LTD

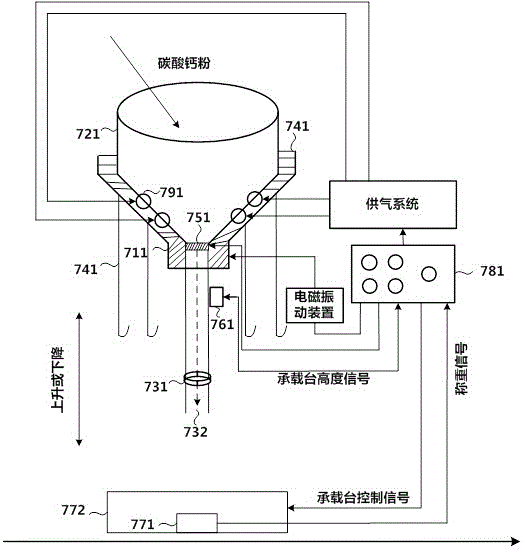

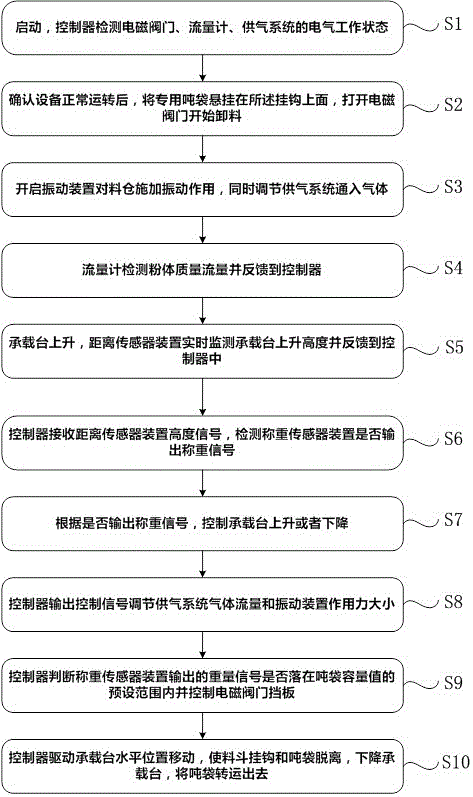

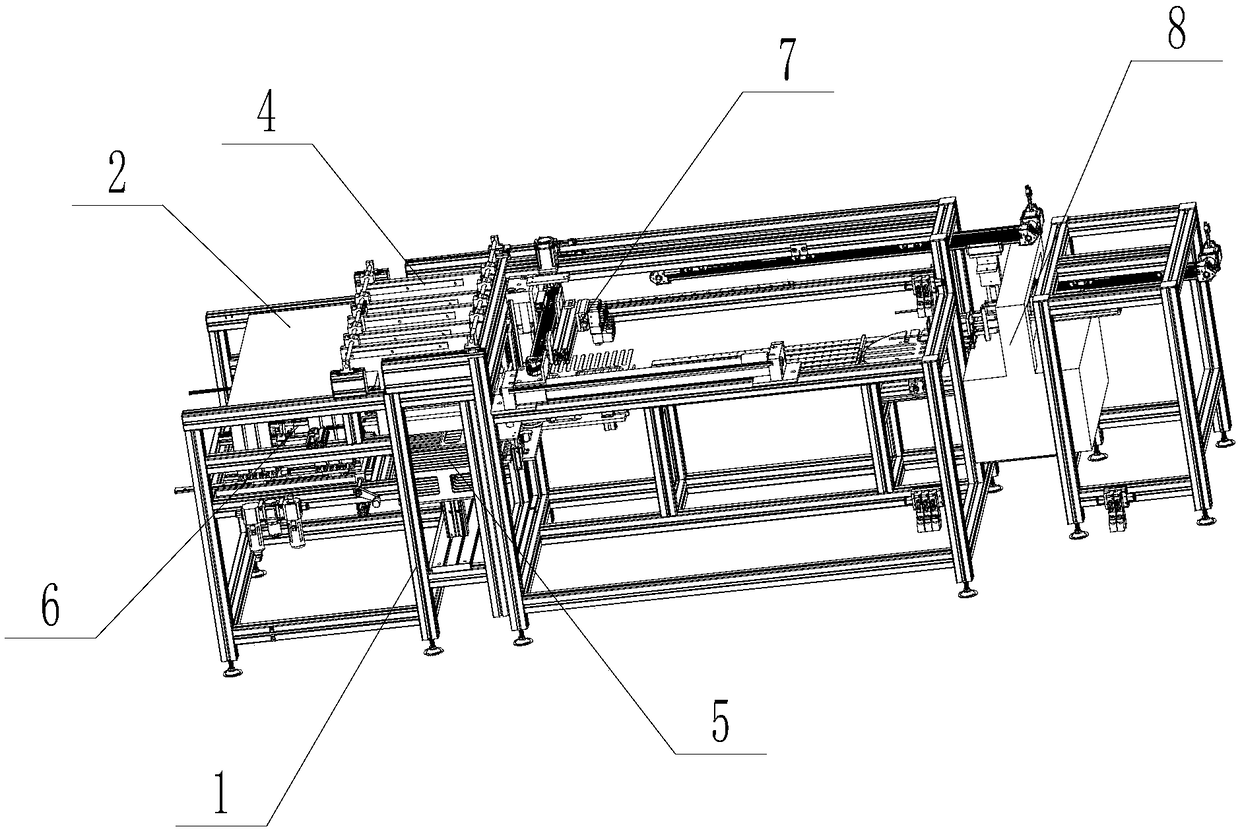

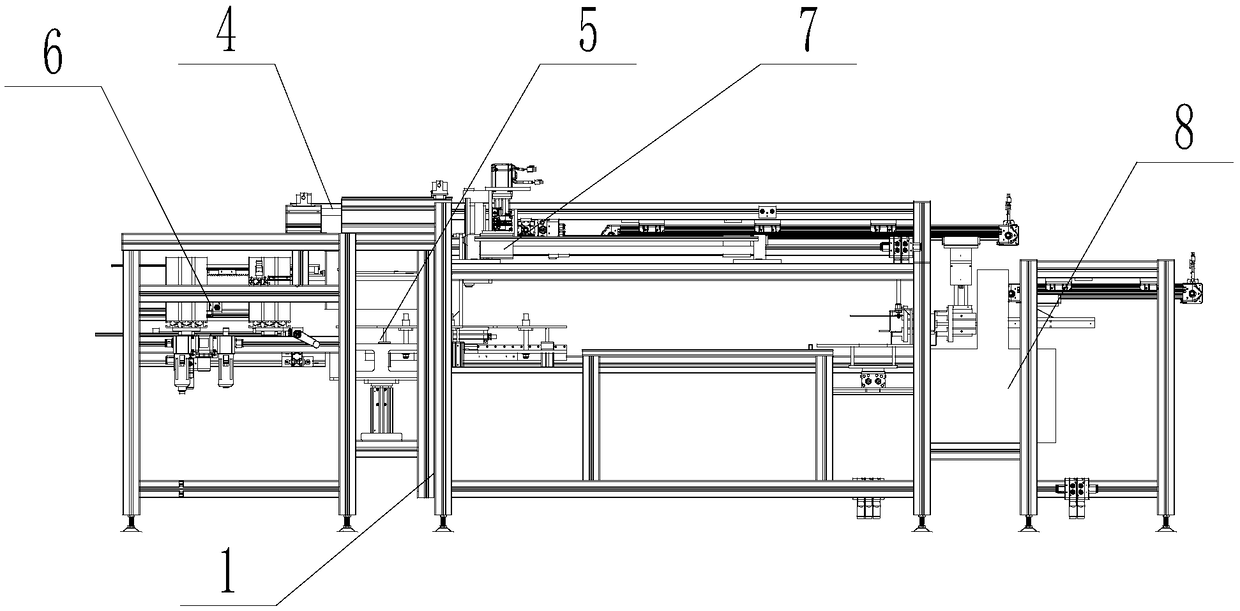

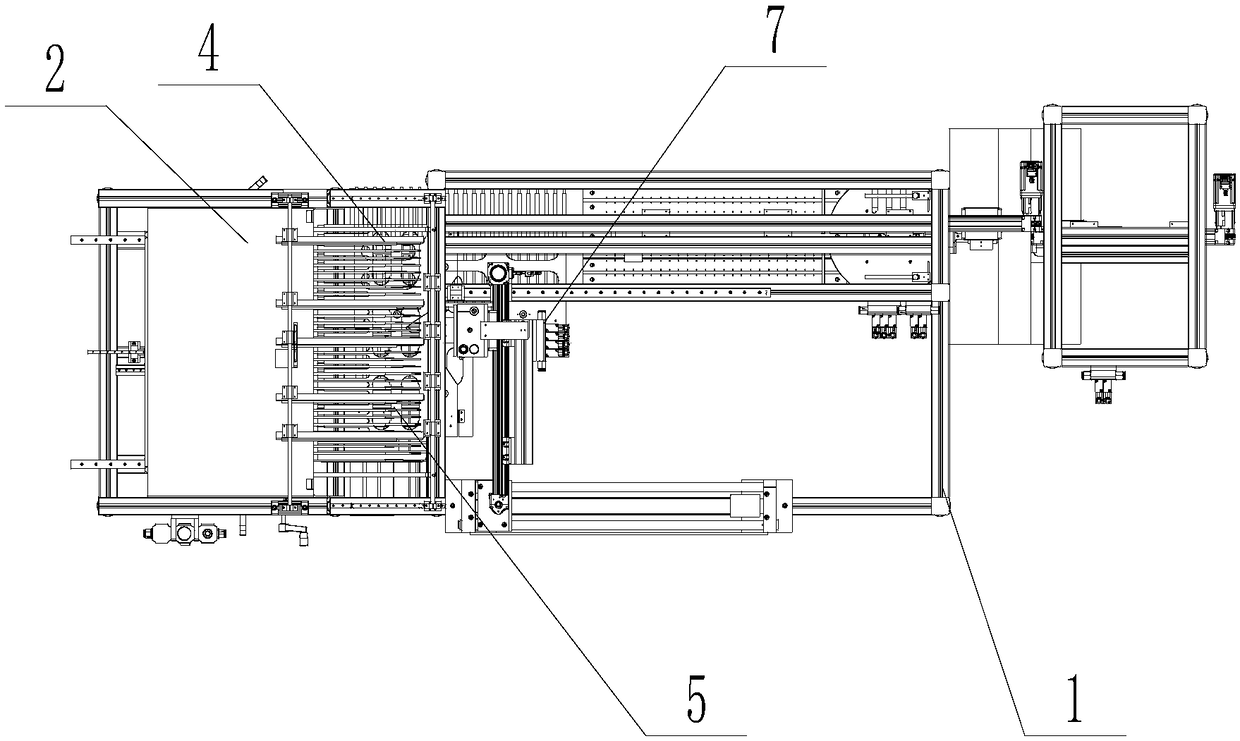

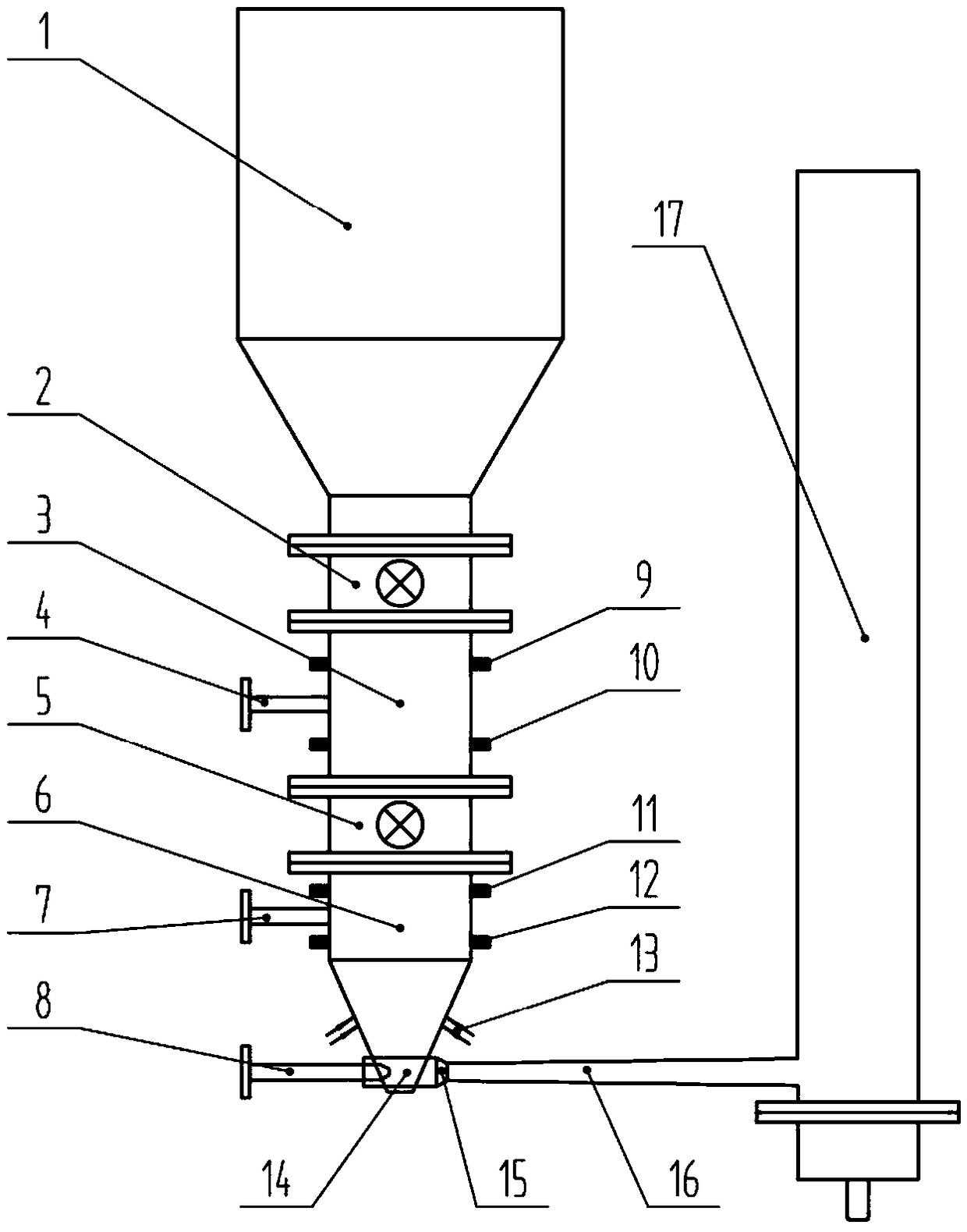

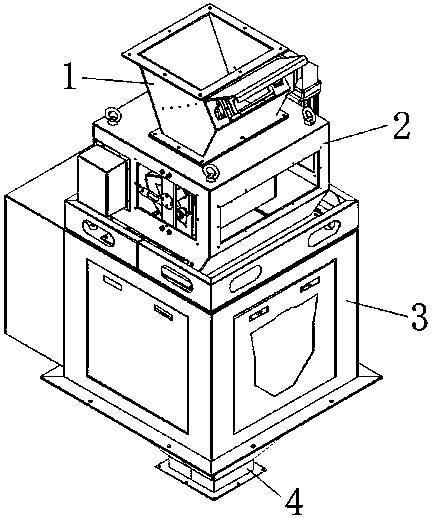

Calcium carbonate powder ton bag packaging system and packaging method

ActiveCN106742124AFast blankingSolve the problem of stagnation and slow blankingSolid materialSolenoid valveProduct gas

The invention discloses a calcium carbonate powder ton bag packaging system and packaging method. The packaging system includes a controller, a loading hopper, a vibrating device, an unloading pipeline, a solenoid valve baffle plate, a distance sensor device, a weighing sensor device, a bearing platform motion control motor, a pressure air supplying sub system and elastic members; the vibrating device is arranged on the bottom of the loading hopper; calcium carbonate powder in the loading hopper shakes under the action of the vibrating device, and is loaded to a ton bag through the unloading pipeline; air holes and a seal cover plate are arranged on the loading hopper; the pressure air supplying sub system is connected to the air holes through air pipelines, and can supply air to the loading hopper; and the seal cover plate can prevent powder in the loading hopper from flying. The method can control the electrical system by testing the weight and the flow of the calcium carbonate powder, and can achieve automatic operation of calcium carbonate powder ton bag packaging. The calcium carbonate powder ton bag packaging system is smooth in material unloading, is accurate in weighing, and is high in packaging efficiency.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

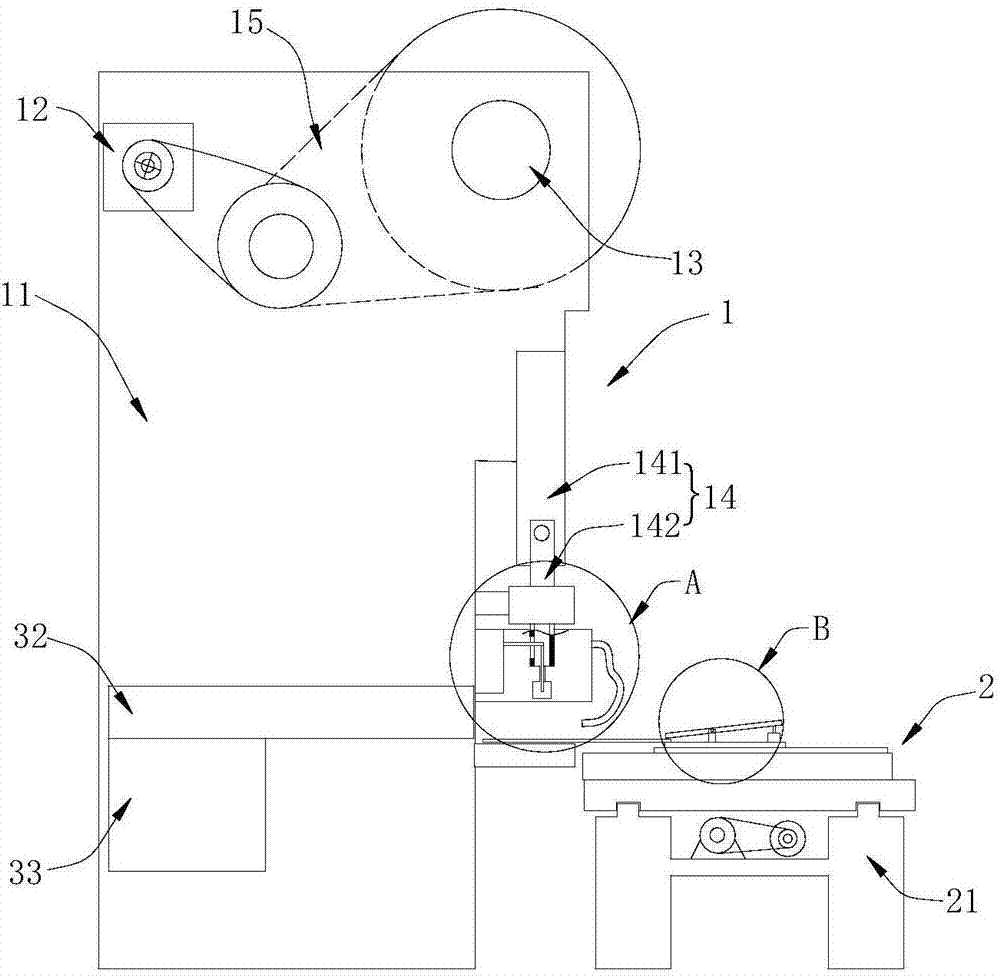

High speed continuous plastic bag strapping machine

ActiveCN108945577AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingBundling machine detailsPlastic bagEngineering

The invention discloses a high speed continuous plastic bag strapping machine. The high speed continuous plastic bag strapping machine comprises an integral rack, a supporting bottom plate at the discharge port of a bag maker, a separated baffle plate module, a blanking slot module, a reciprocating material pushing pin module, a transfer module and a strapping module. The supporting bottom plate at the discharge port of the bag maker, the separated baffle plate module, the blanking slot module, the reciprocating material pushing pin module, the transfer module and the strapping module are arranged on the integral rack. The high speed continuous plastic bag strapping machine disclosed by the invention can strap plastic bags automatically, is high in strapping efficiency and low in labor cost, and can be adjusted to be suitable for strapping the plastic bags different in width, length and thickness automatically, so that the high speed continuous plastic bag strapping machine is wide inapplication range; the high speed continuous plastic bag strapping machine can detect and remove unqualified products, and is high in removal efficiency. The high speed continuous plastic bag strapping machine disclosed by the invention can directly fit the outlet of the bag maker. The plastic bags at the outlet of the bag maker enter into a blanking slot to be accumulated, conveyed and strapped,so that the integral strapping step is canceled.

Owner:浙江创派智能科技有限公司

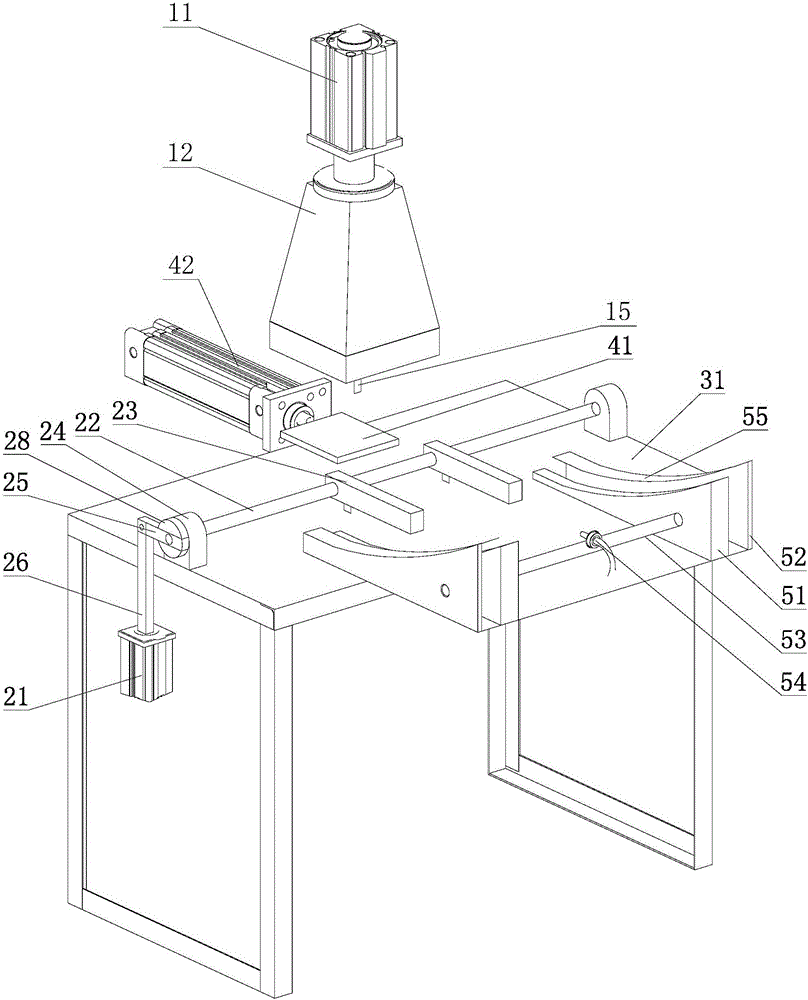

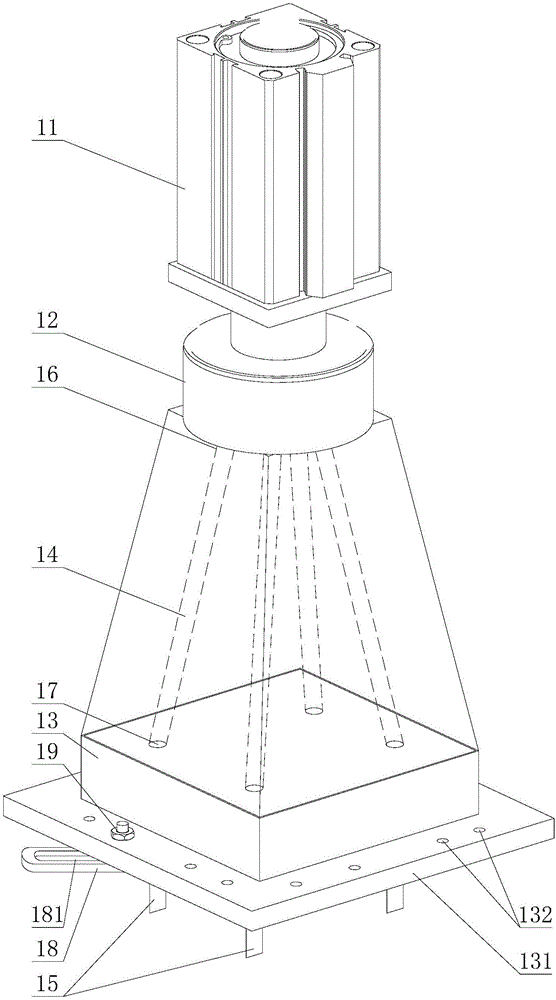

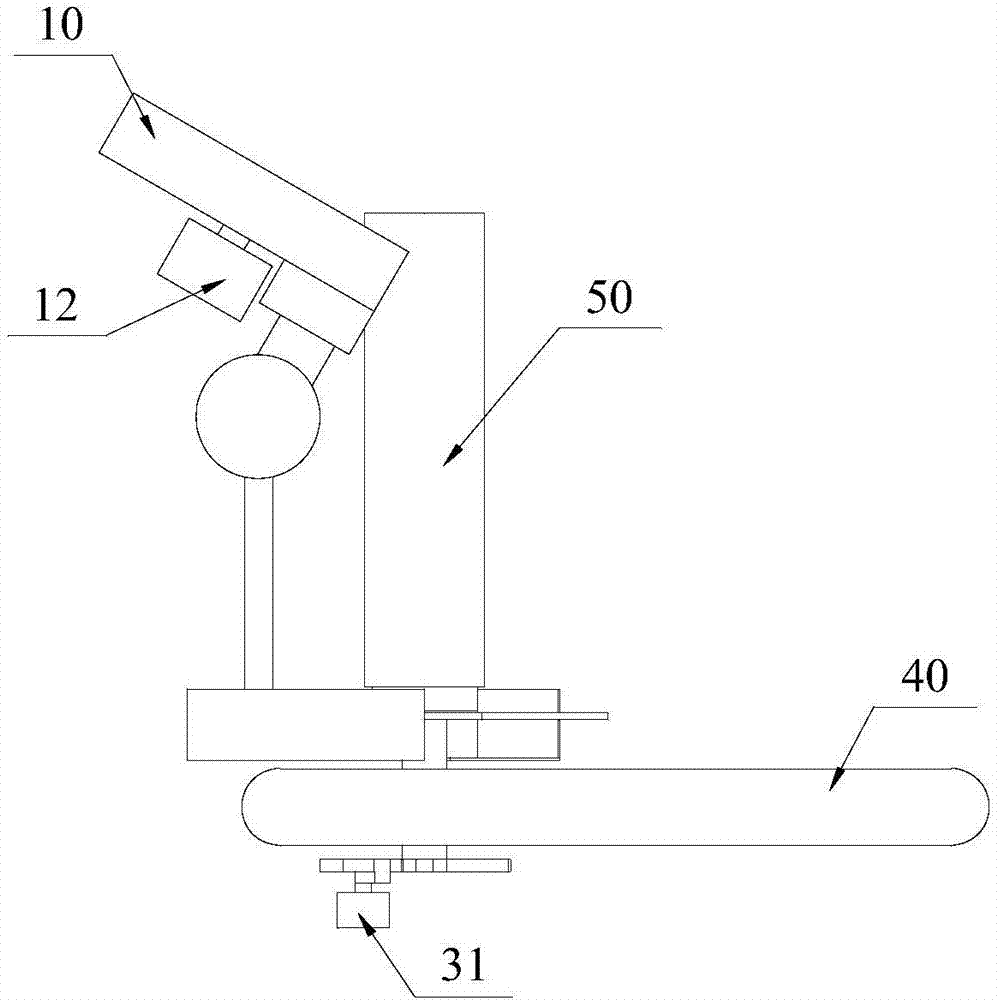

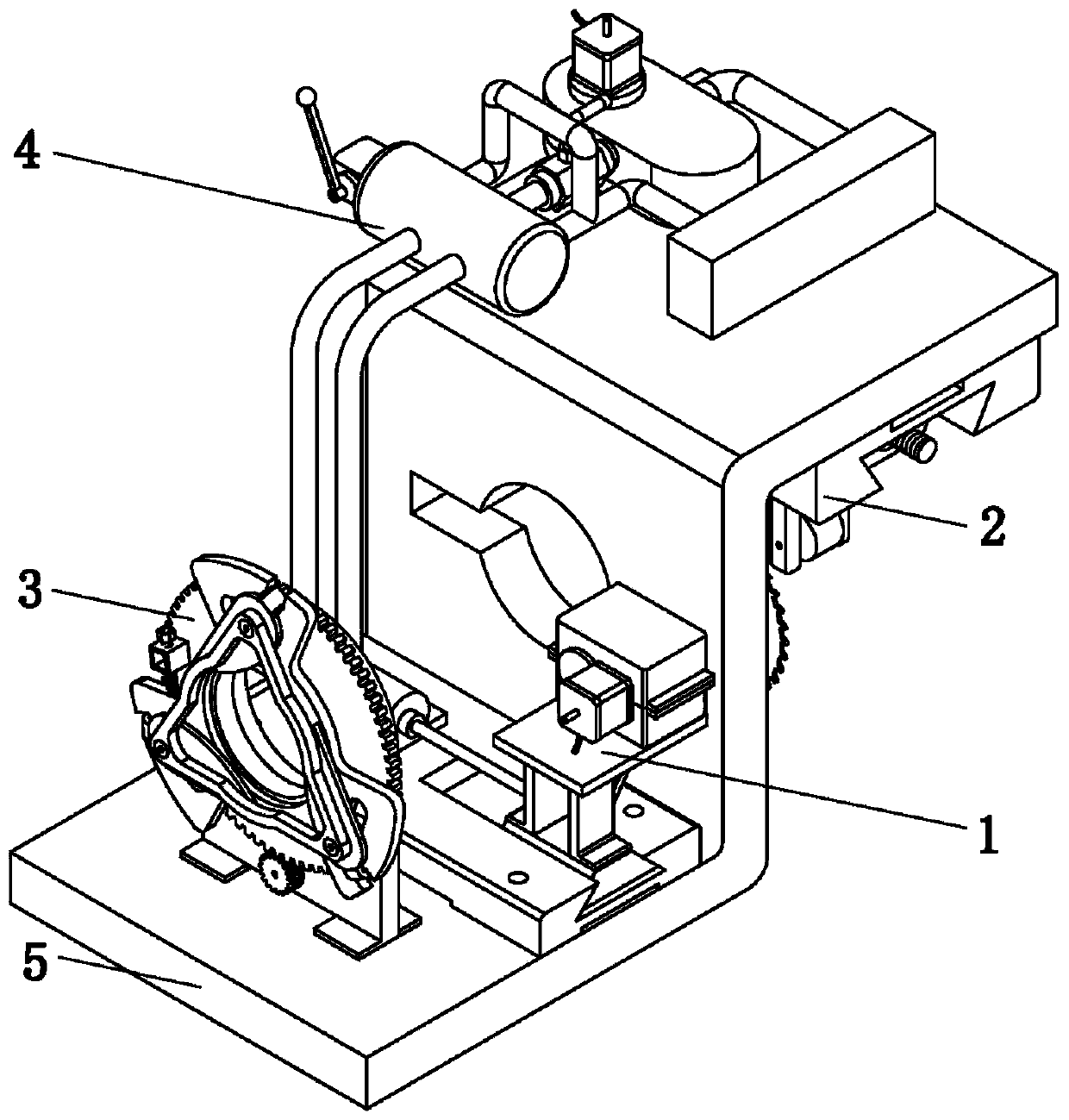

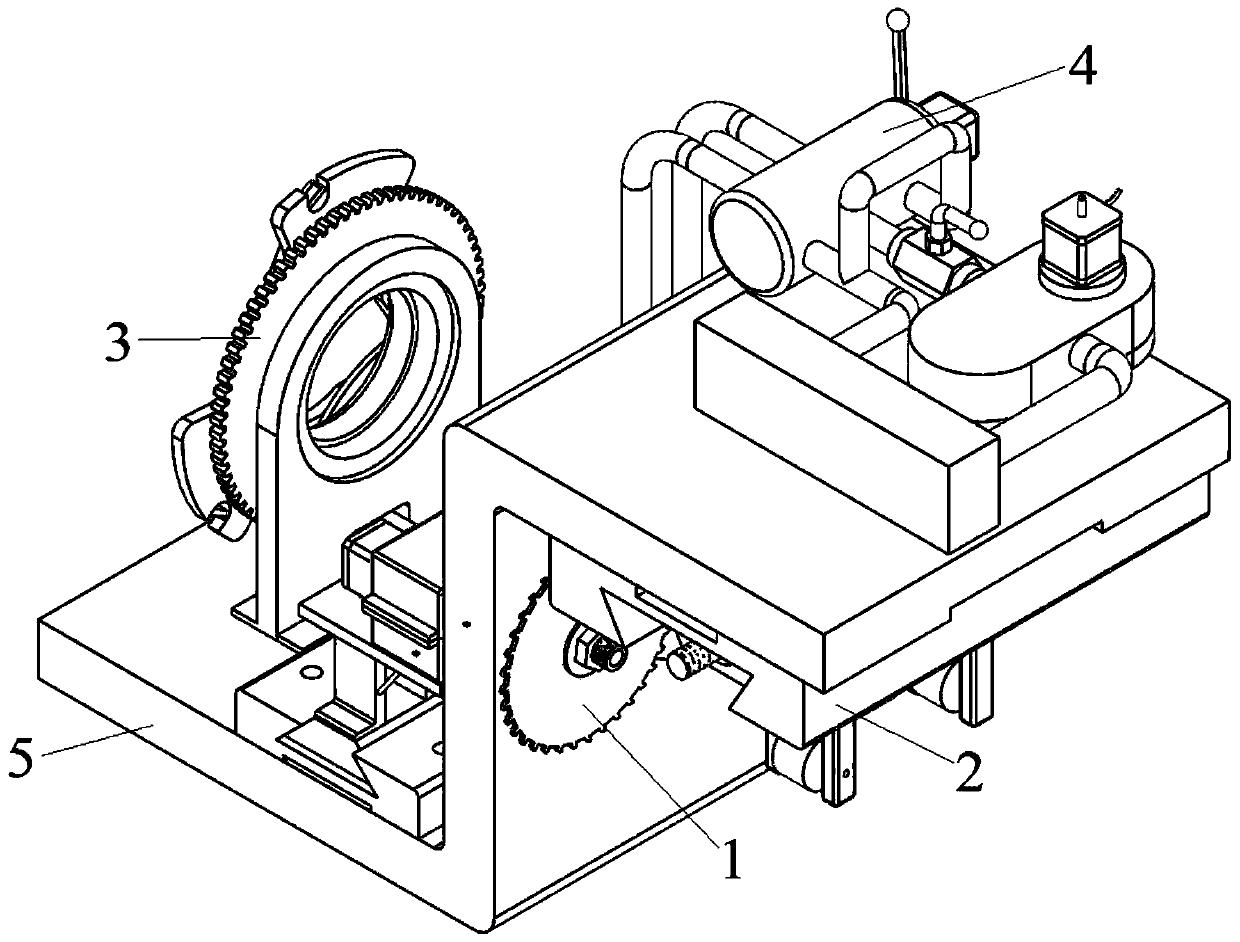

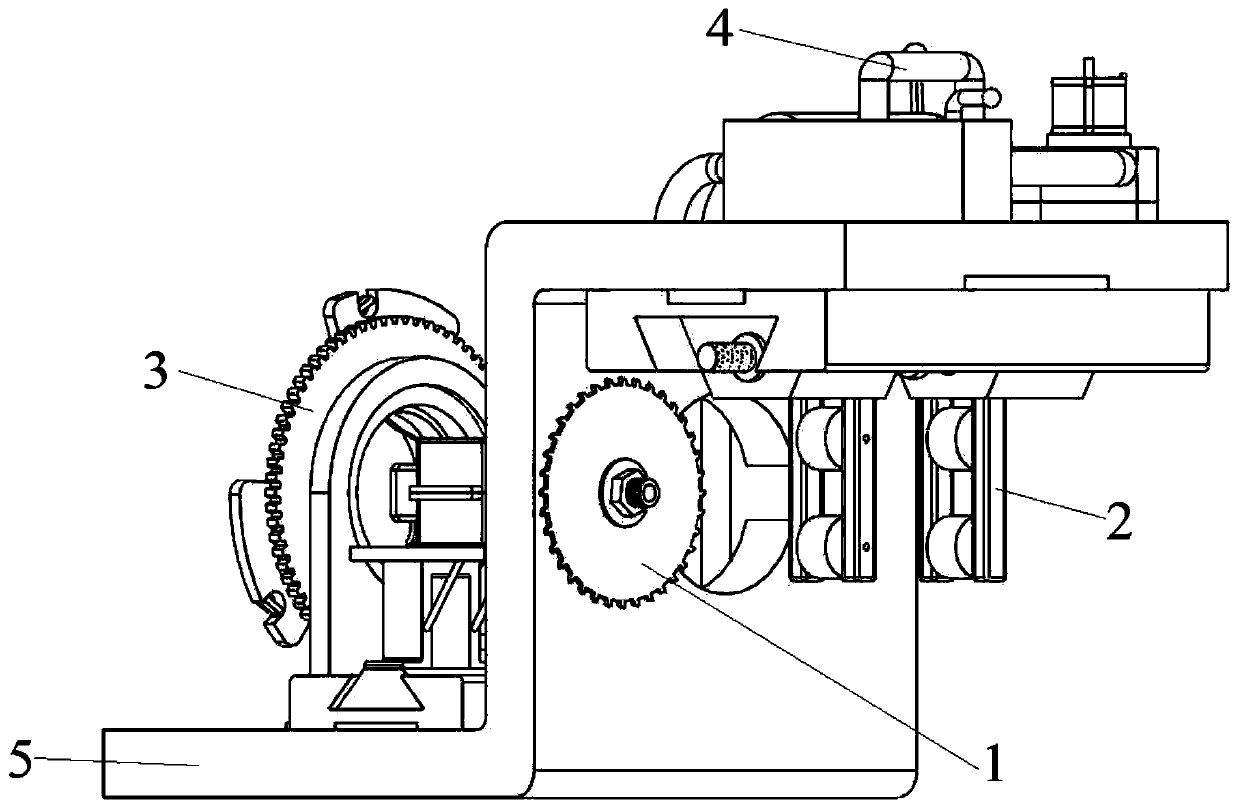

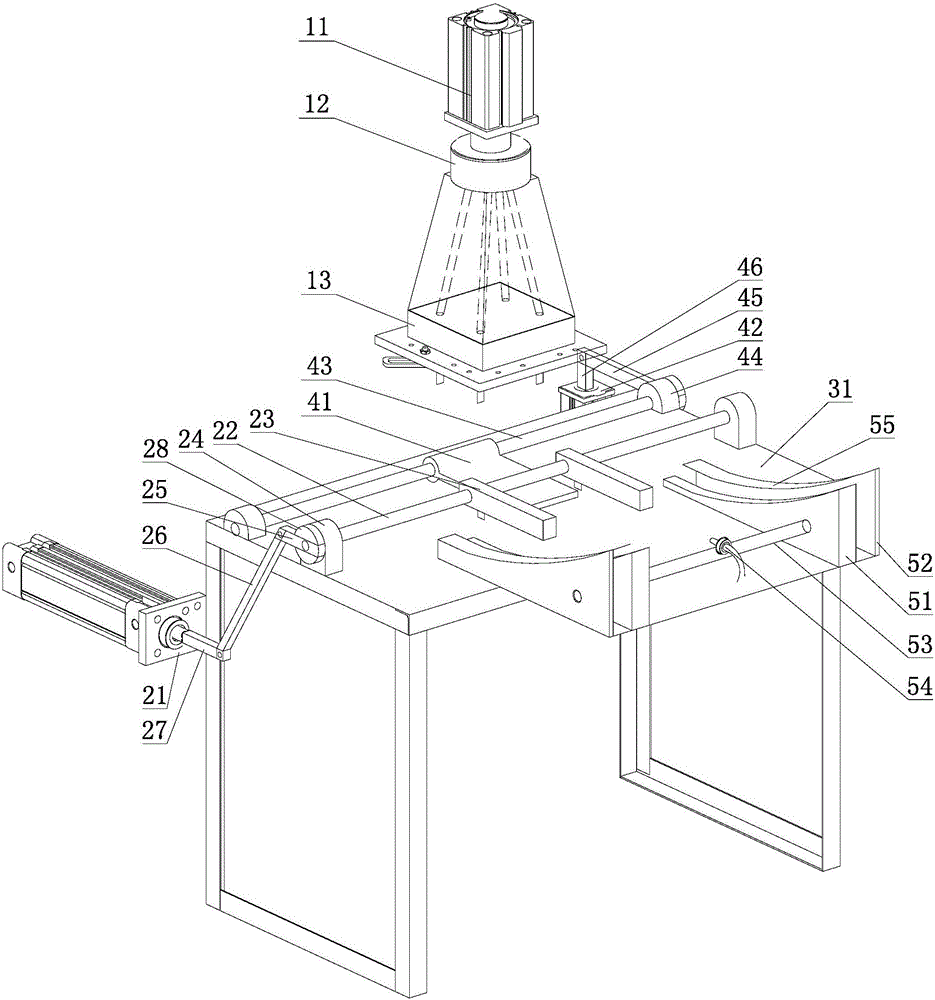

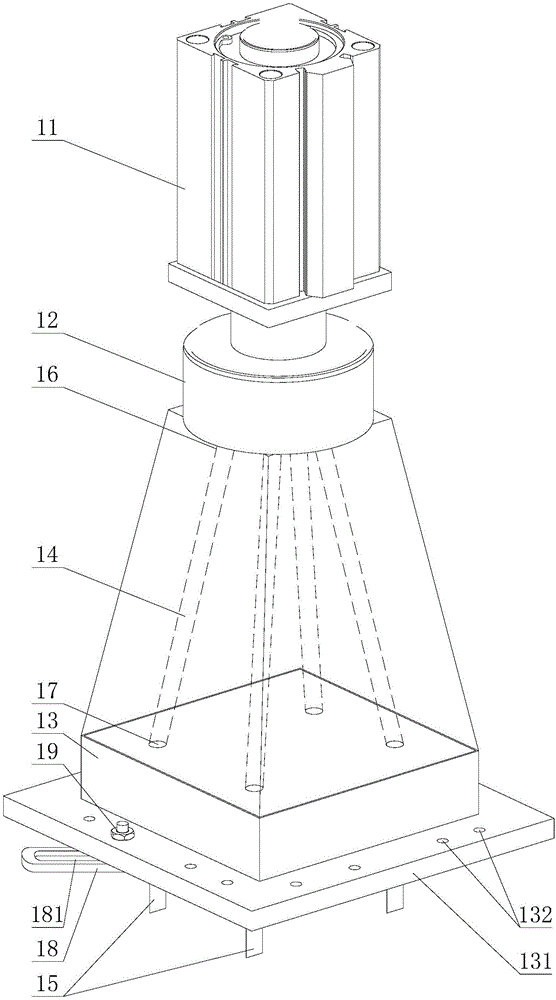

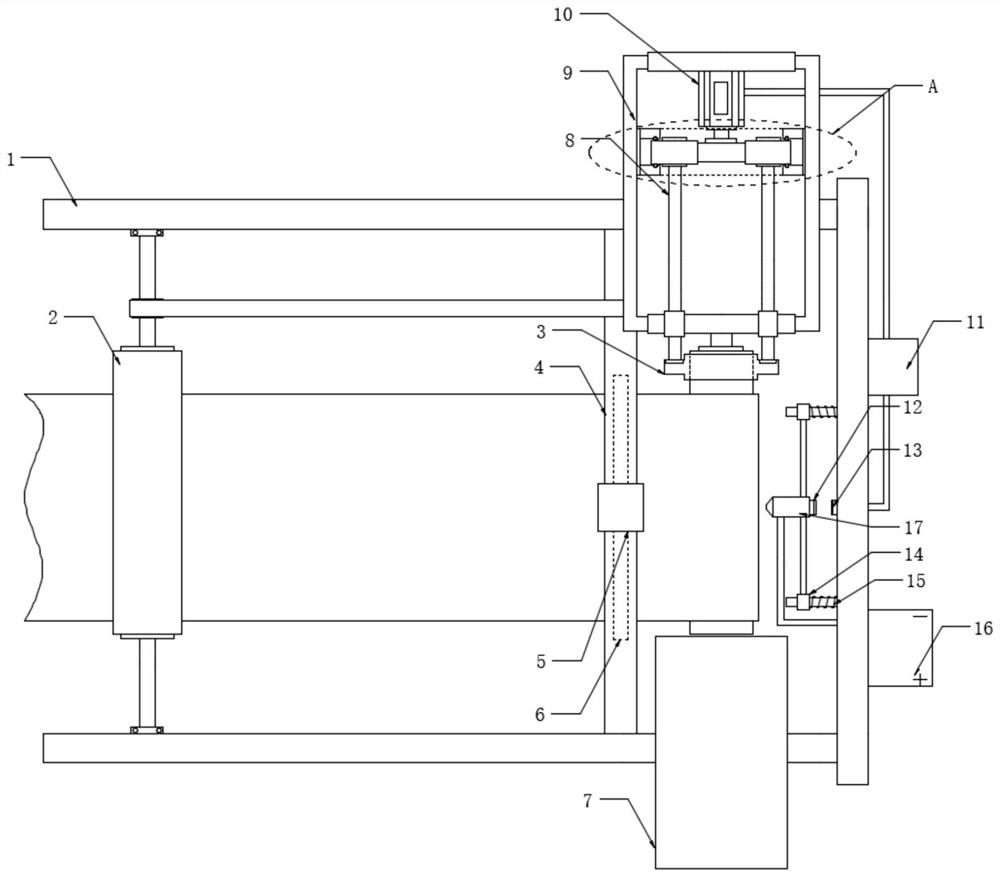

Tapping machine

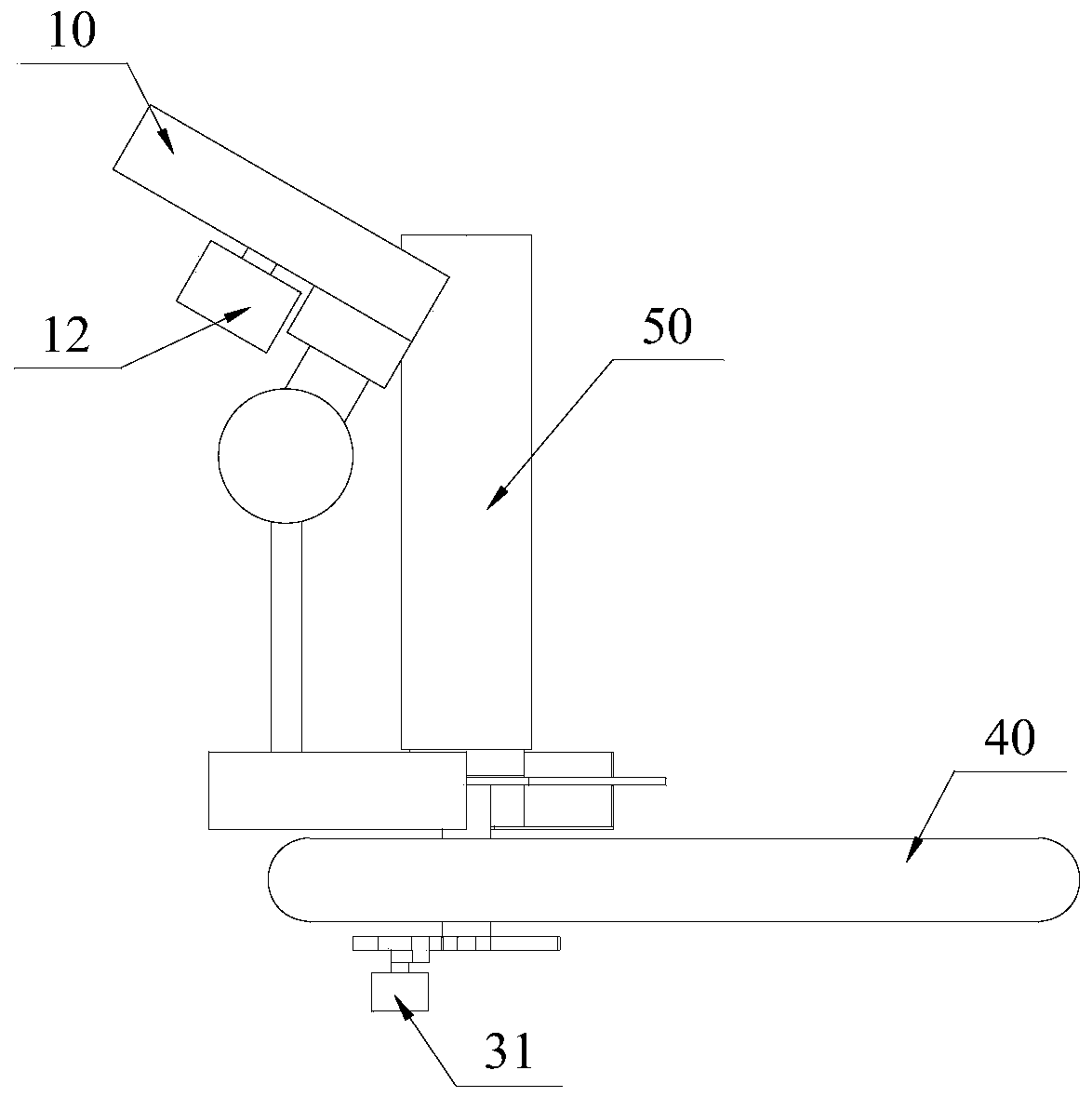

InactiveCN105945365AFast loadingFast blankingThread cutting feeding devicesThread cutting machinesMechanical engineeringPiston rod

The invention discloses a tapping machine. The tapping machine comprises a machine head assembly, a fixture, a support plate device and a guide rail device; the machine head assembly includes a motor, a base and a screw tap; the motor is fixed on the base; the tap screw is driven by the motor; the fixture includes a fixture cylinder, a first connecting rod mechanism, a first linkage rod, a pressing strip and two first linkage rod seats; the fixture cylinder and the first linkage rod seats are respectively fixed on a workbench; two ends of the first linkage rod are respectively connected with the two first linkage rod seats through bearings; the pressing strip is fixed in the middle part of the first linkage rod; the tail end of the first connecting rod mechanism is fixed to the end part of the first linkage rod; the fixture cylinder drives the first connecting rod mechanism, thereby driving the linkage rod to rotate so as to enable the pressing strip to clamp or loosen a workpiece to be machined; the support plate device includes a support plate and a support plate cylinder; the support plate is fixed on a piston rod of the support plate cylinder; the guide rail device includes two inclined surface guide rail plates and two limiting plates; the two inclined surface guide rail plates are fixed on the workbench; the two limiting plates are respectively located on the outer sides of the two inclined surface guide rail plates; and when the piston rod of the support plate cylinder stretches out, the support plate is joined with the tail ends of the inclined surface guide rail plates, and provide support for the workpiece to be machined.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

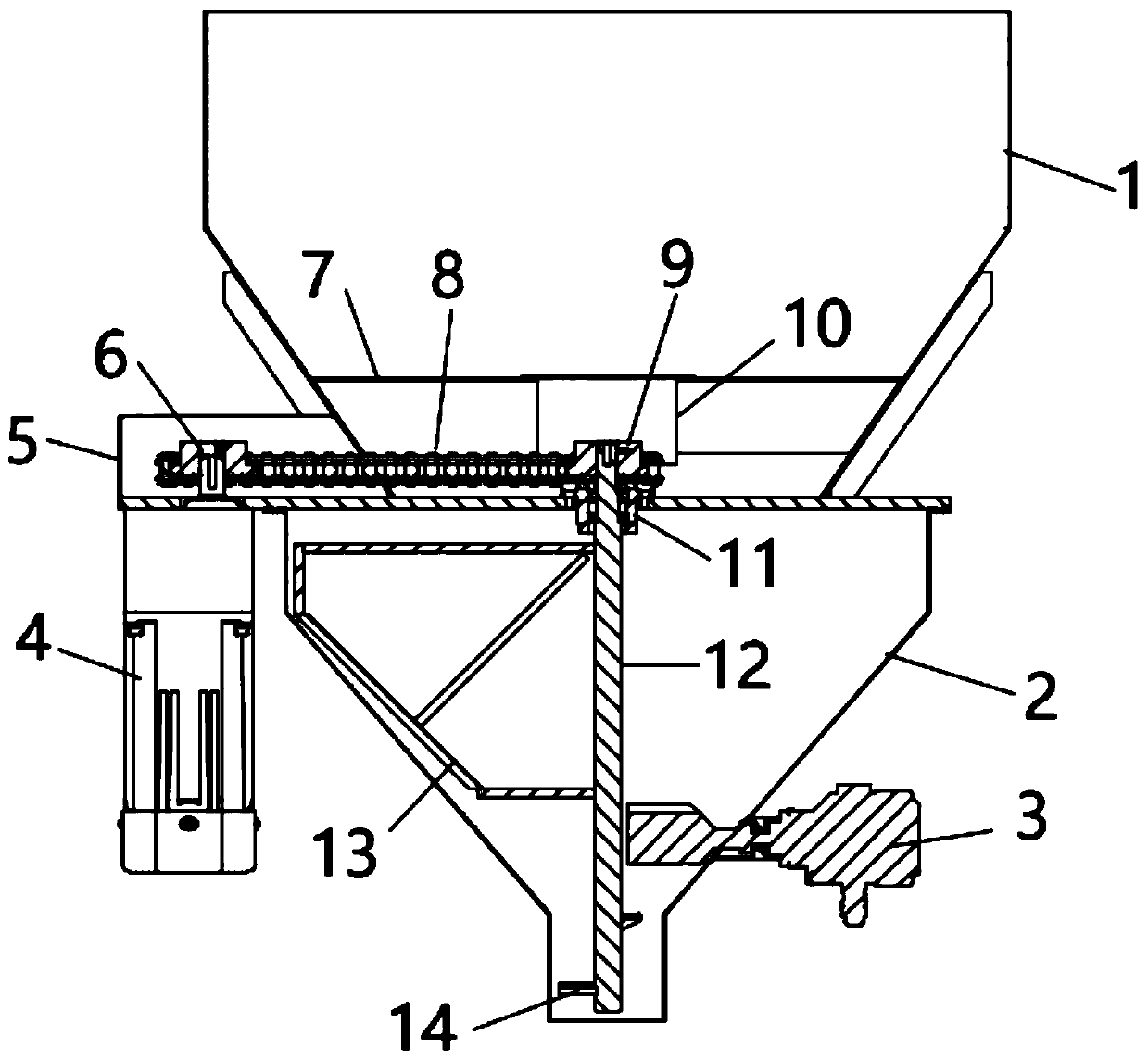

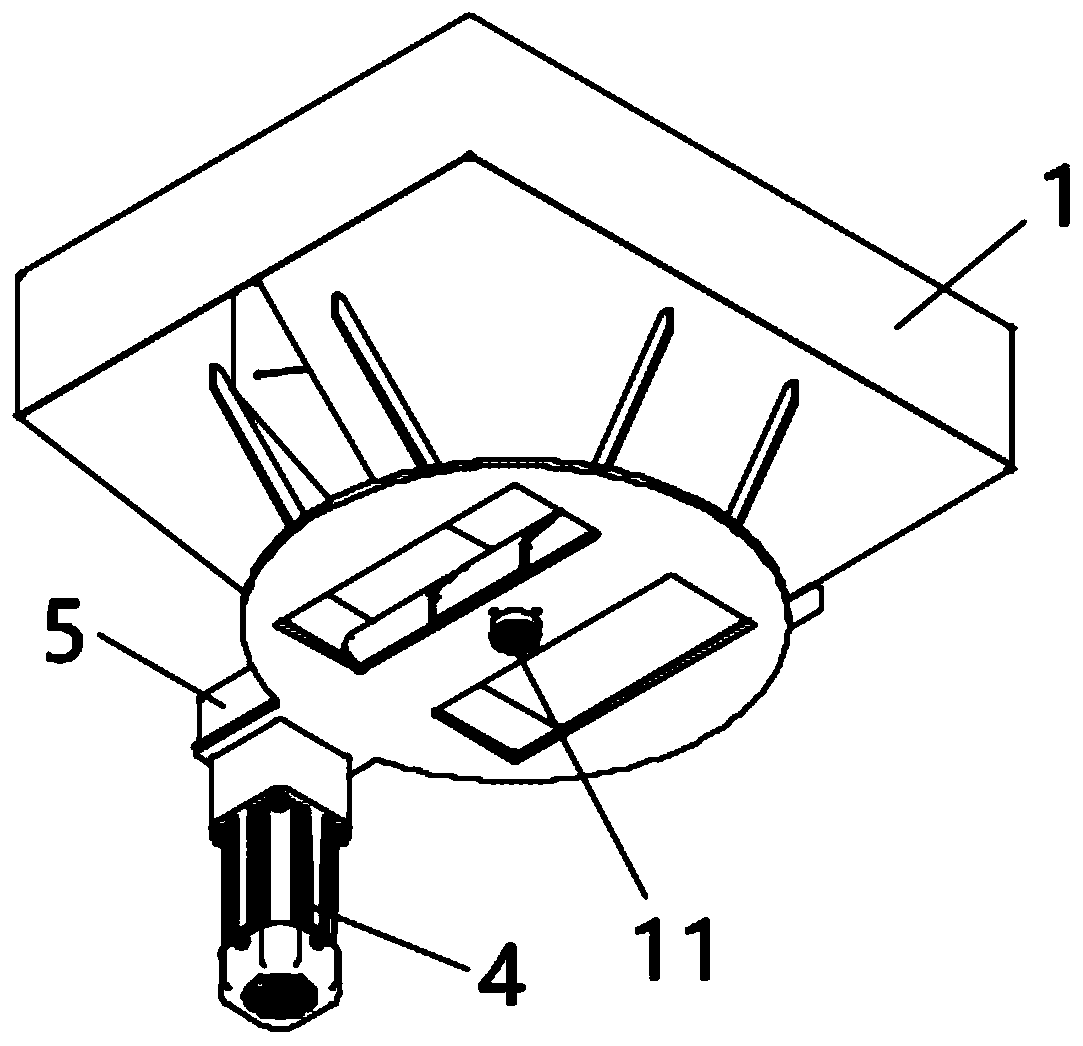

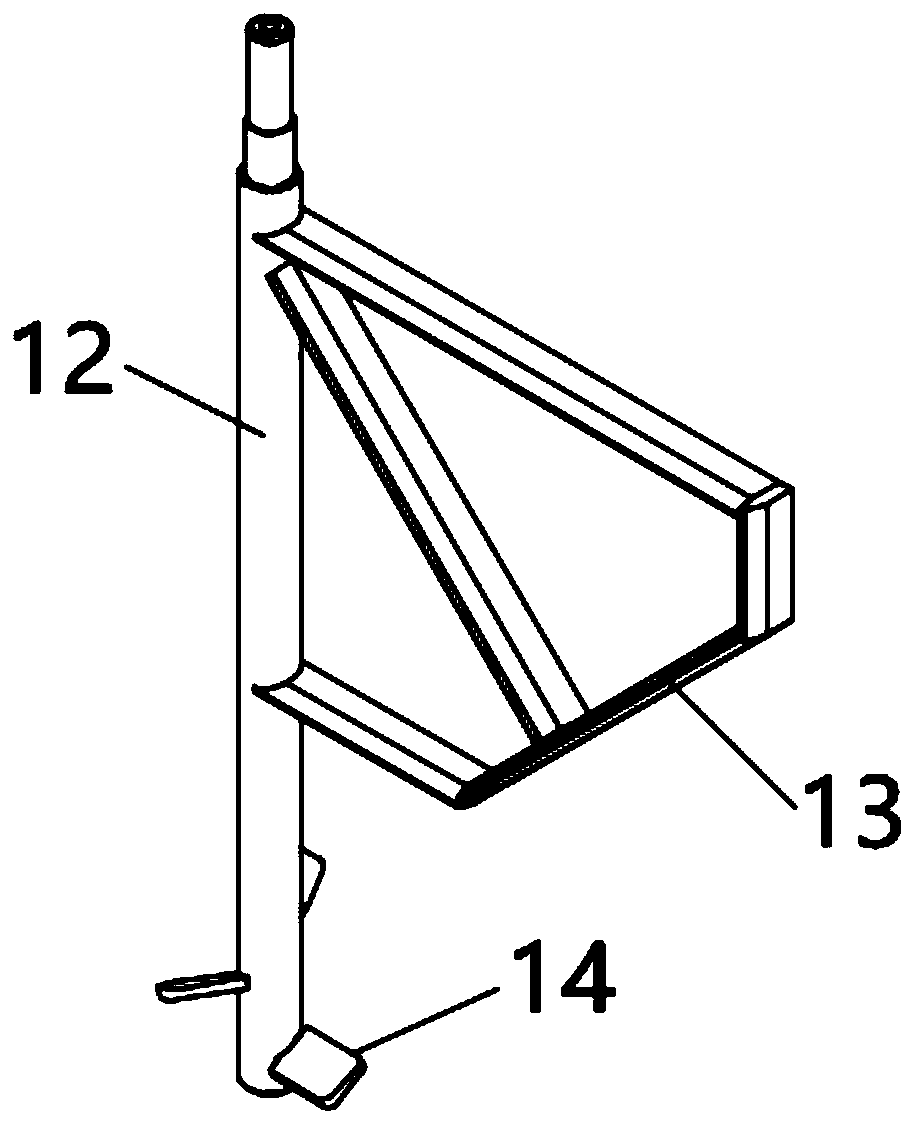

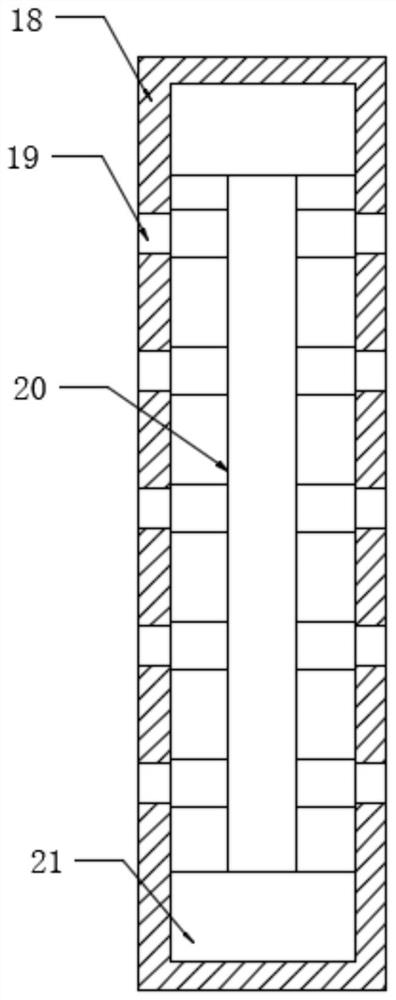

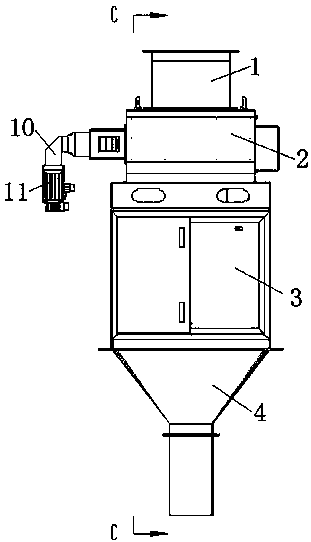

Stock bin device

InactiveCN111196509AEasy blankingFast blankingLarge containersLoading/unloadingStructural engineeringMechanical engineering

The invention relates to the technical field of production machining, in particular to a stock bin device. The device comprises a loading hopper, an unloading hoper, and a stirring assembly, the loading hopper is located above the unloading hopper, after the loading hopper carries materials, the unloading hopper is used for falling, the stirring assembly is located between the loading hopper and the unloading hopper and achieves the arch breaking function, through combined use of the loading hopper and the unloading hopper, blocky materials can be avoided, the materials can more easily fall down, in addition, the stirring assembly is mounted between the loading hopper and the unloading hopper, the material in the unloading hopper can be further assisted to rapidly and smoothly fall out, the possibility of material arching can be reduced, and work efficiency can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

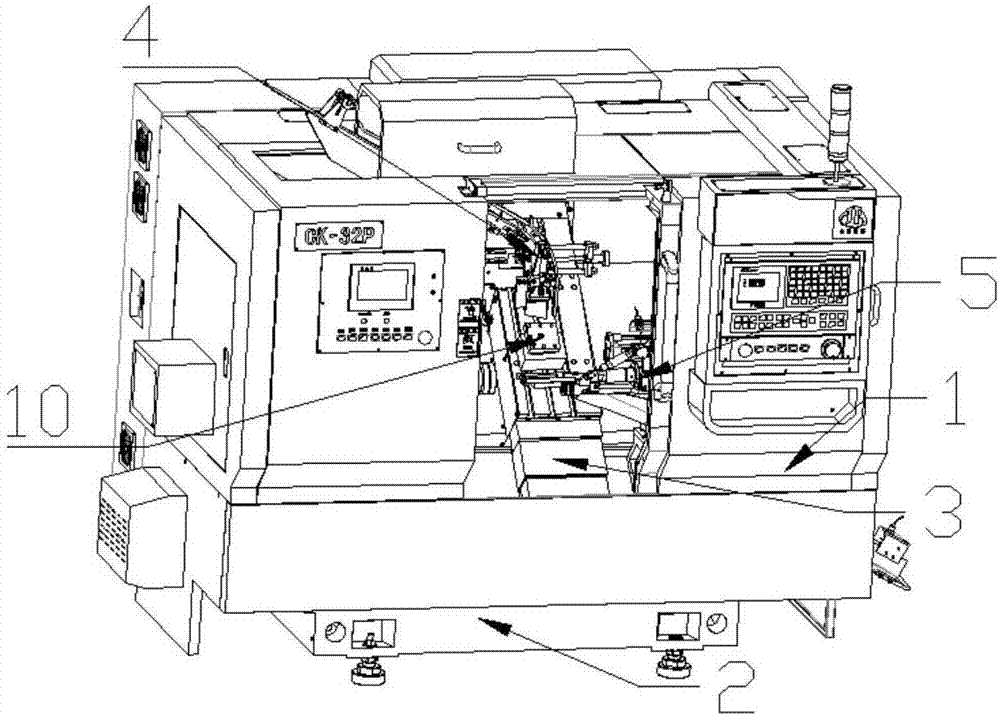

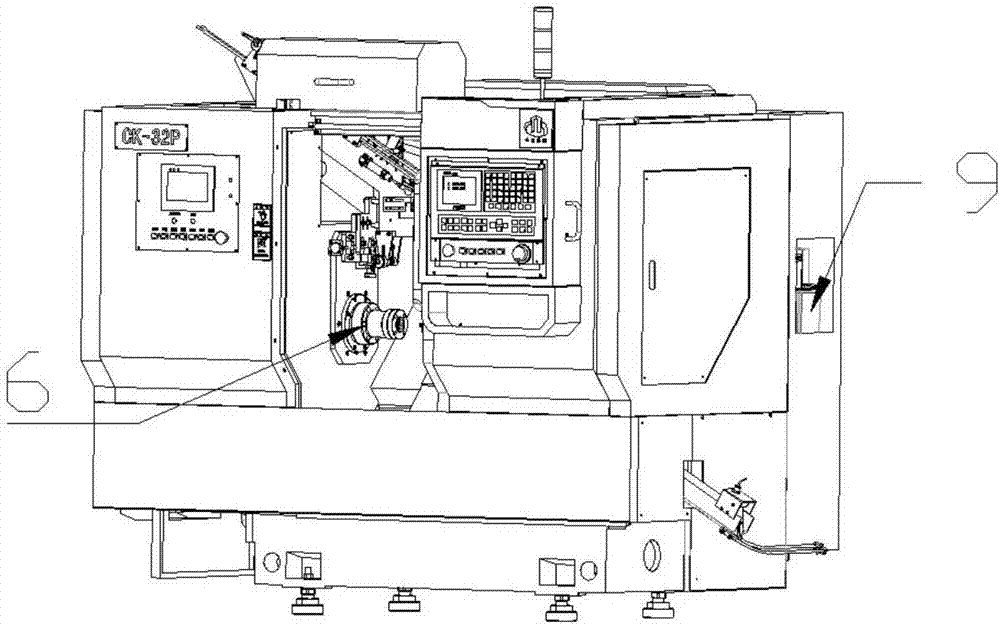

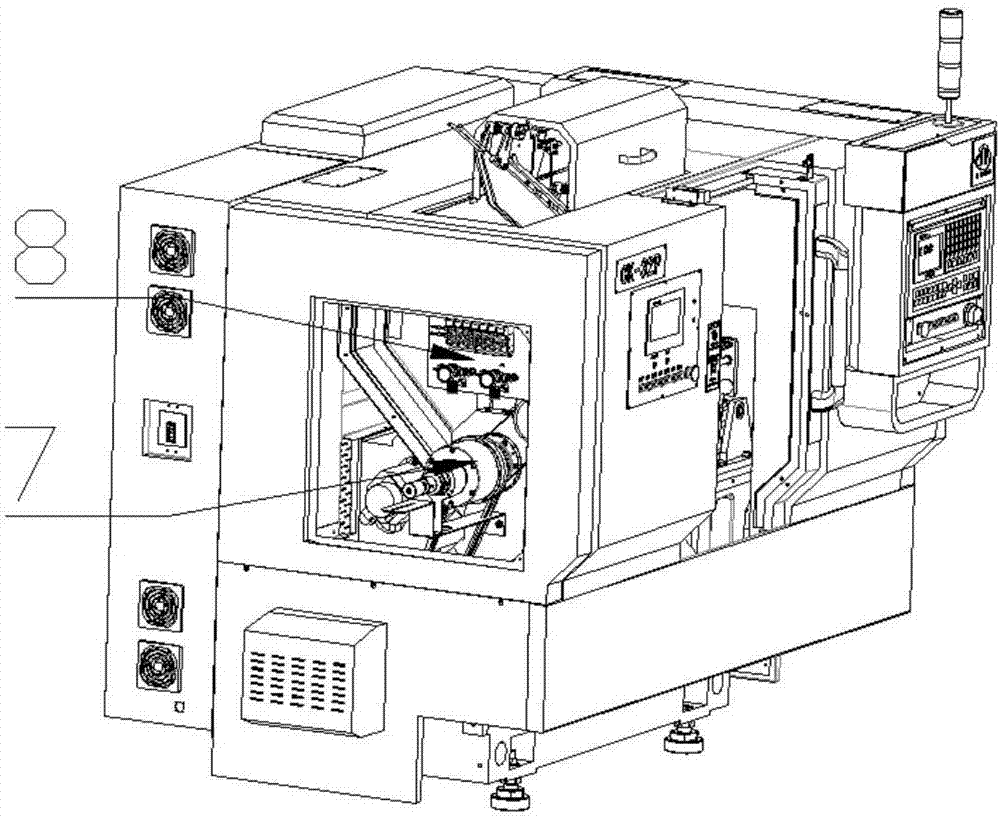

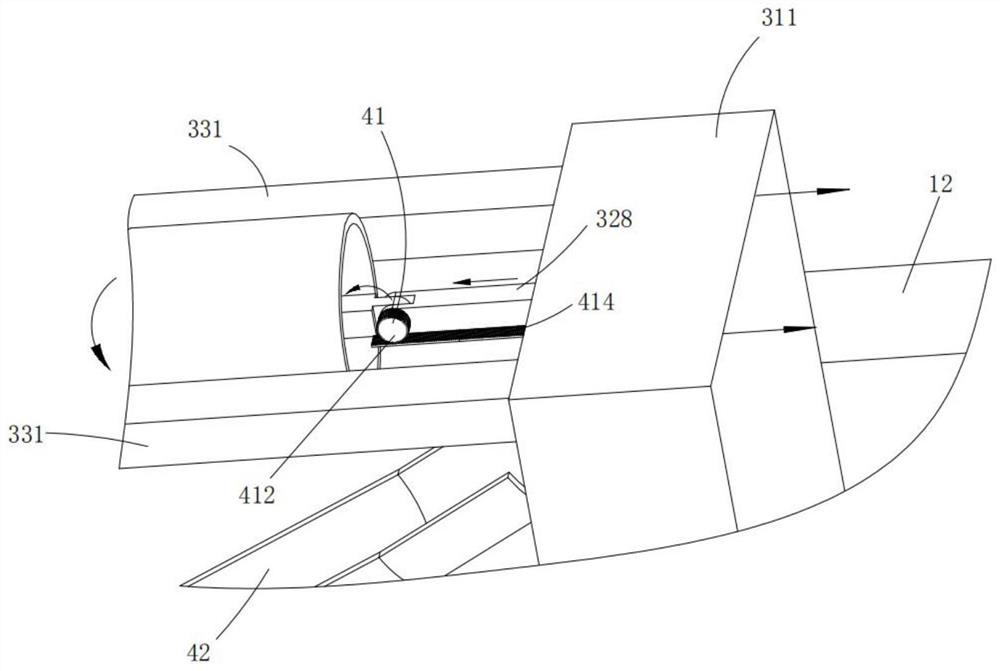

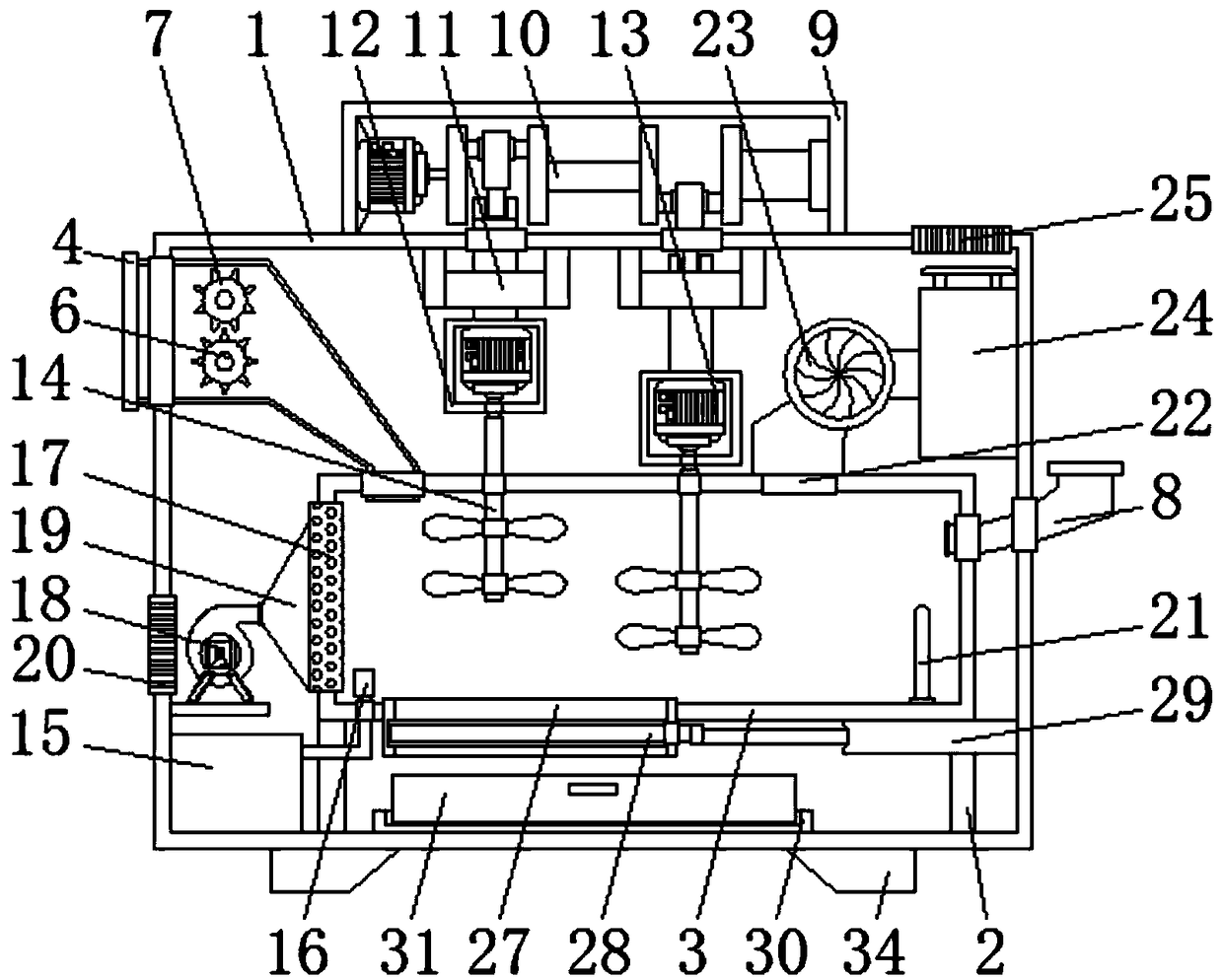

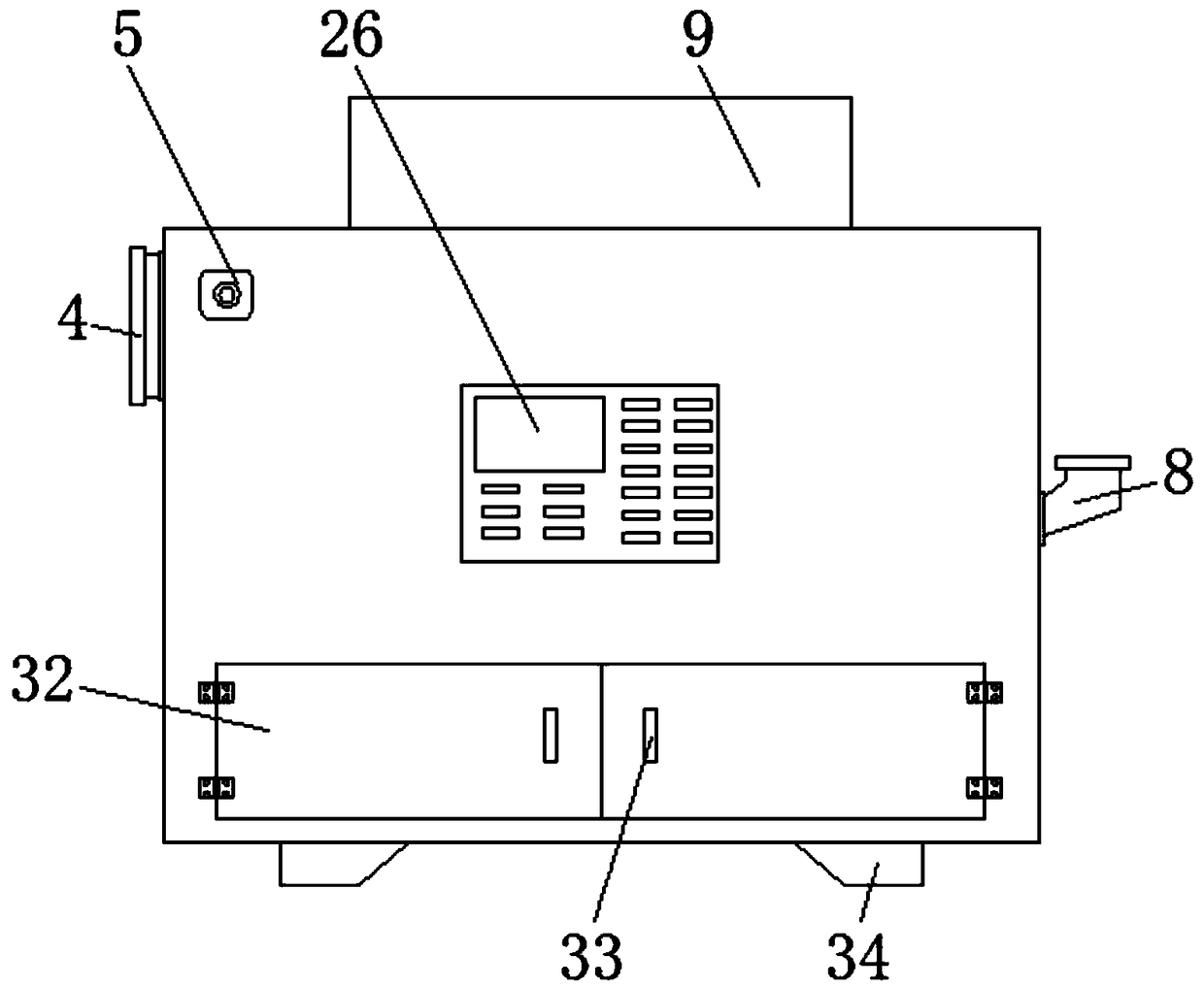

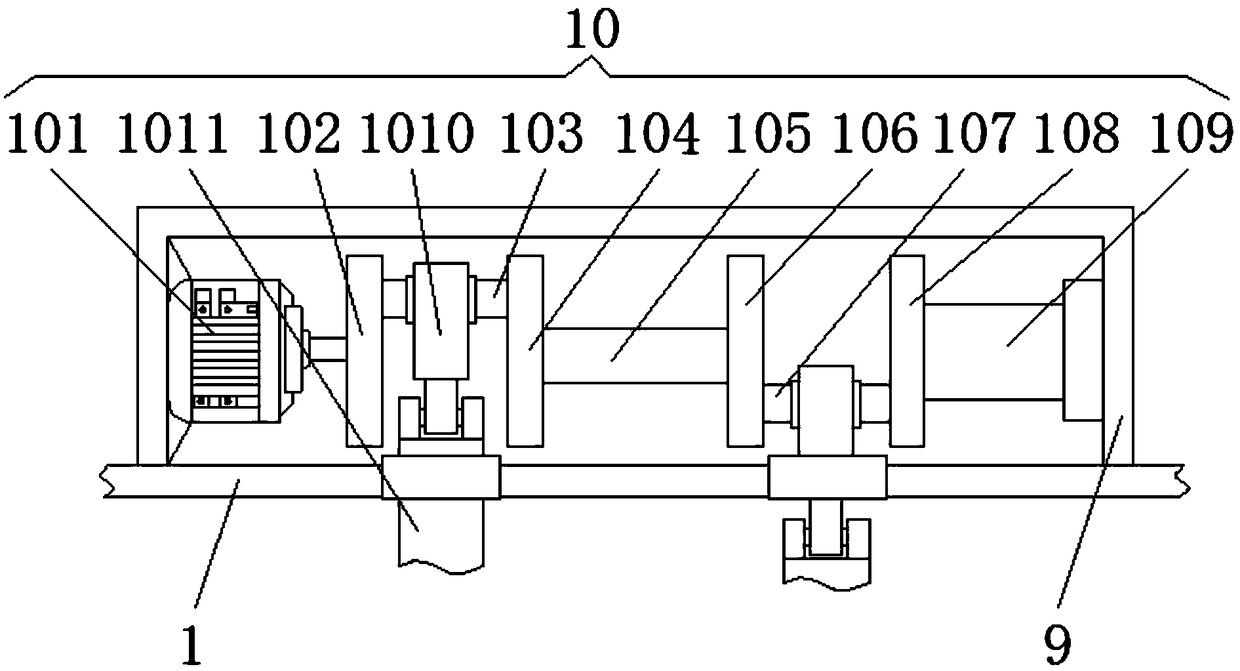

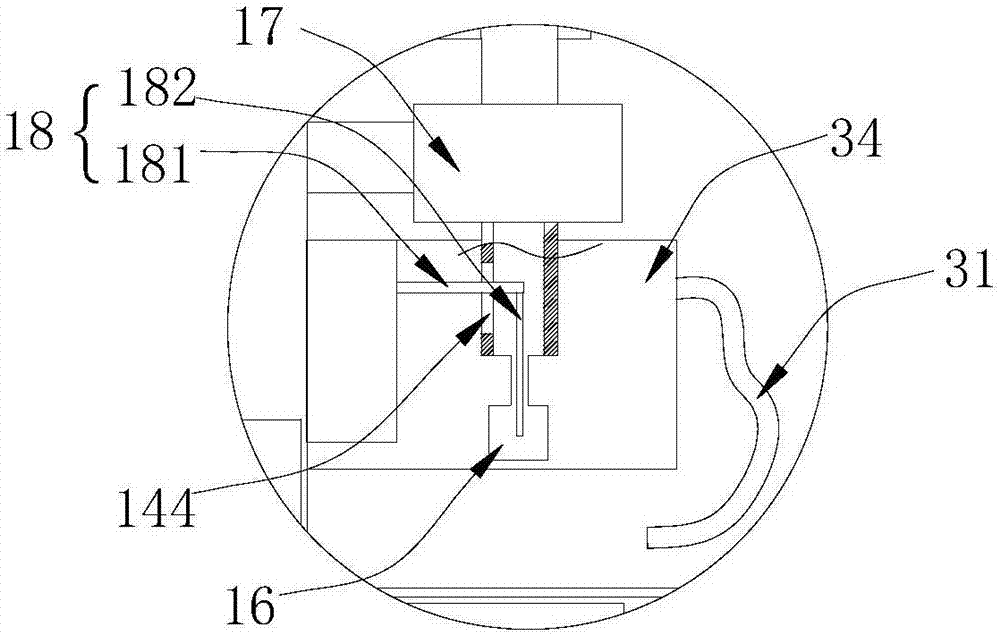

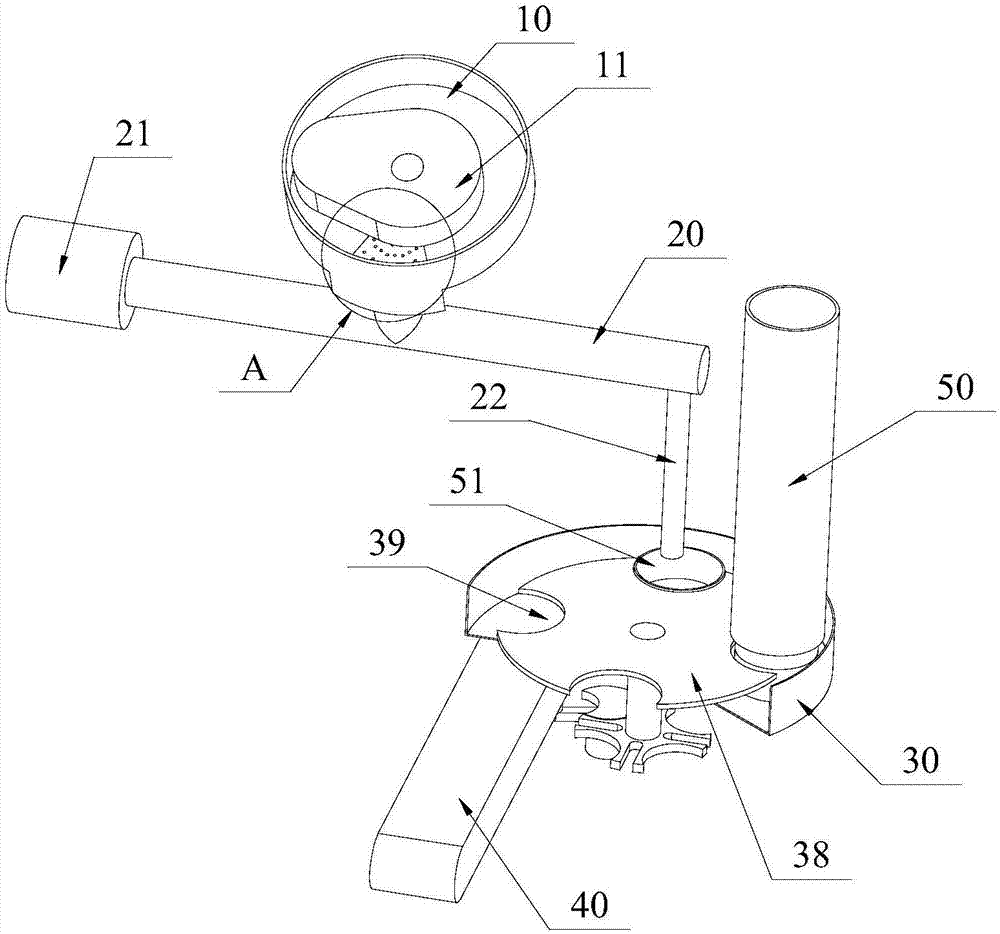

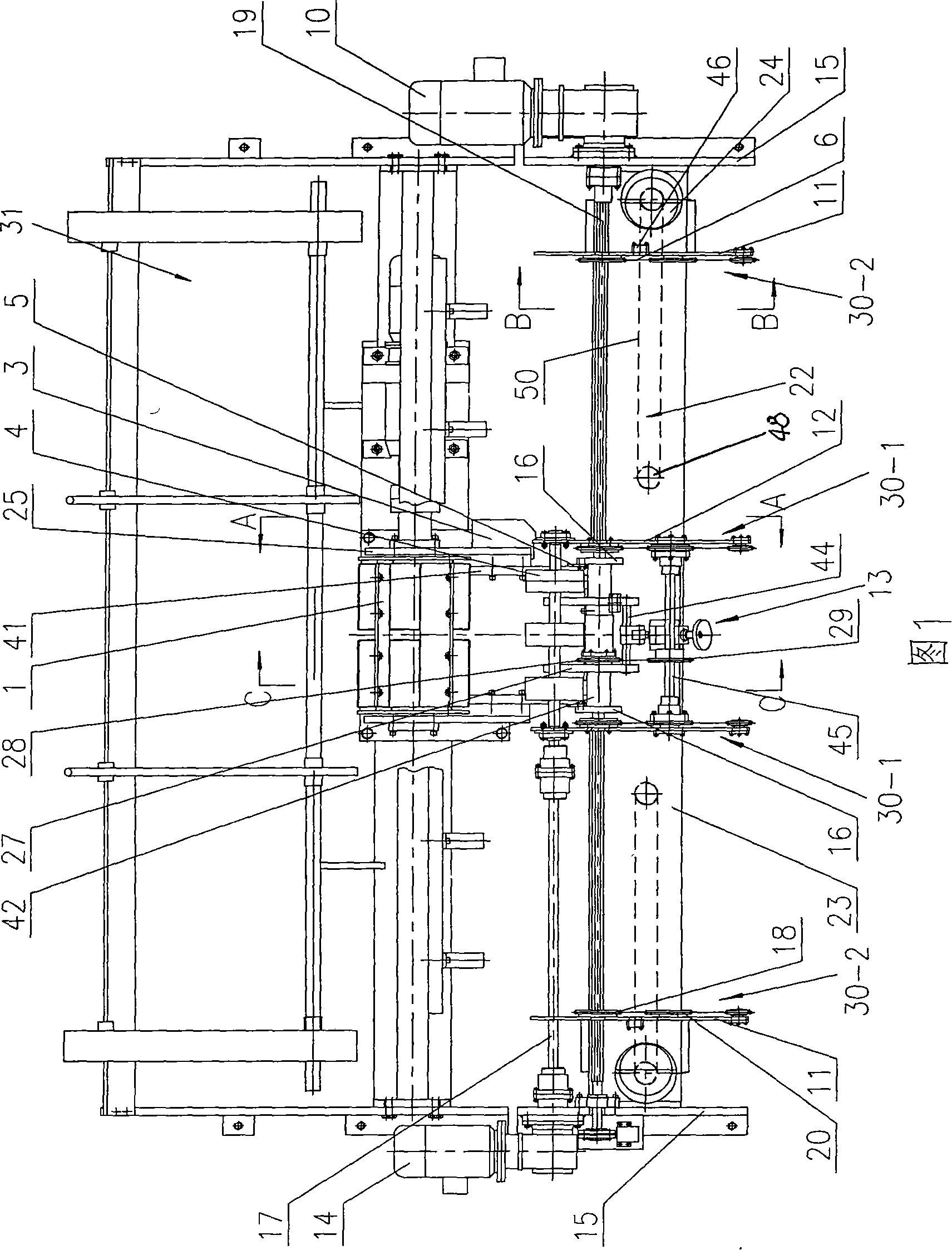

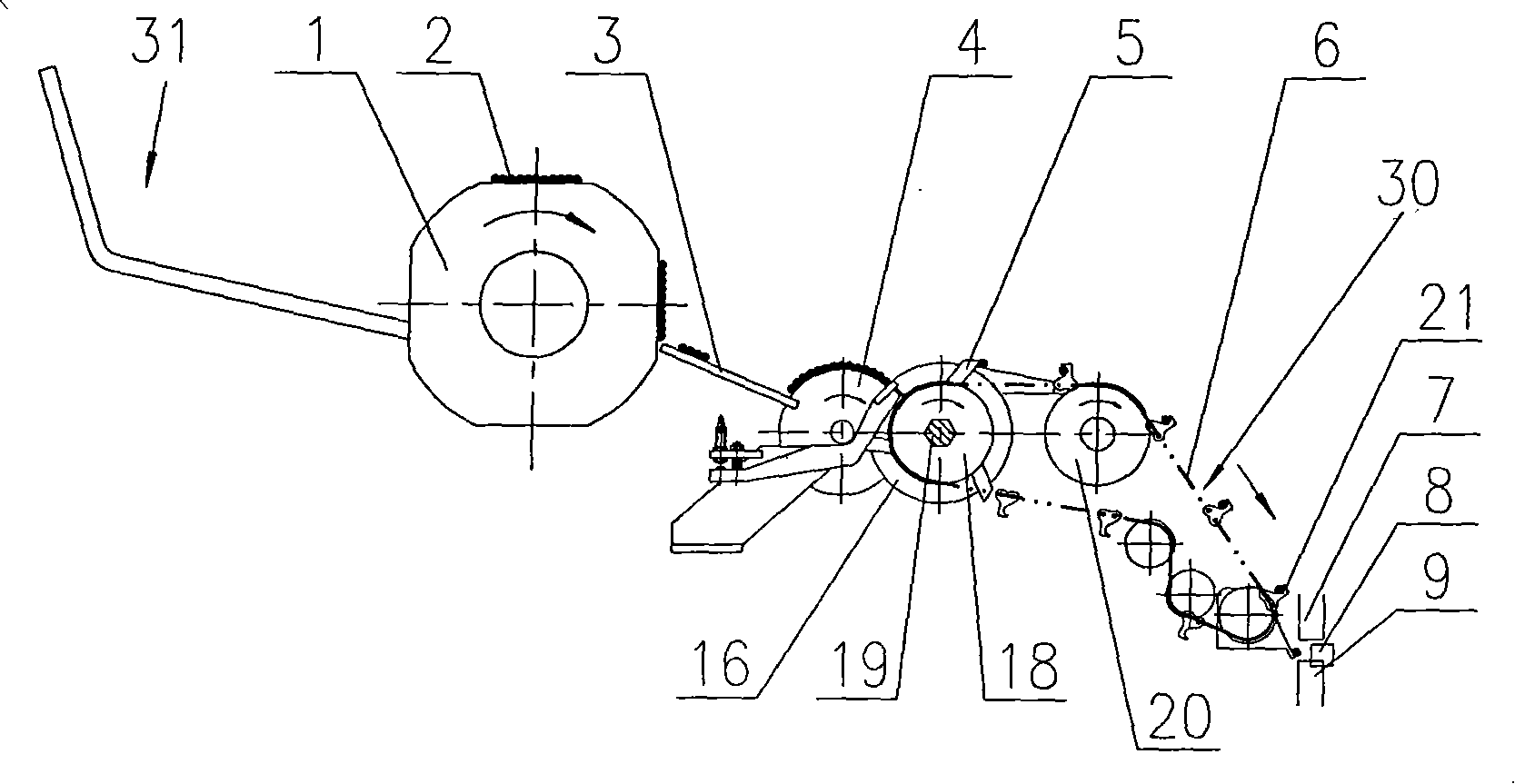

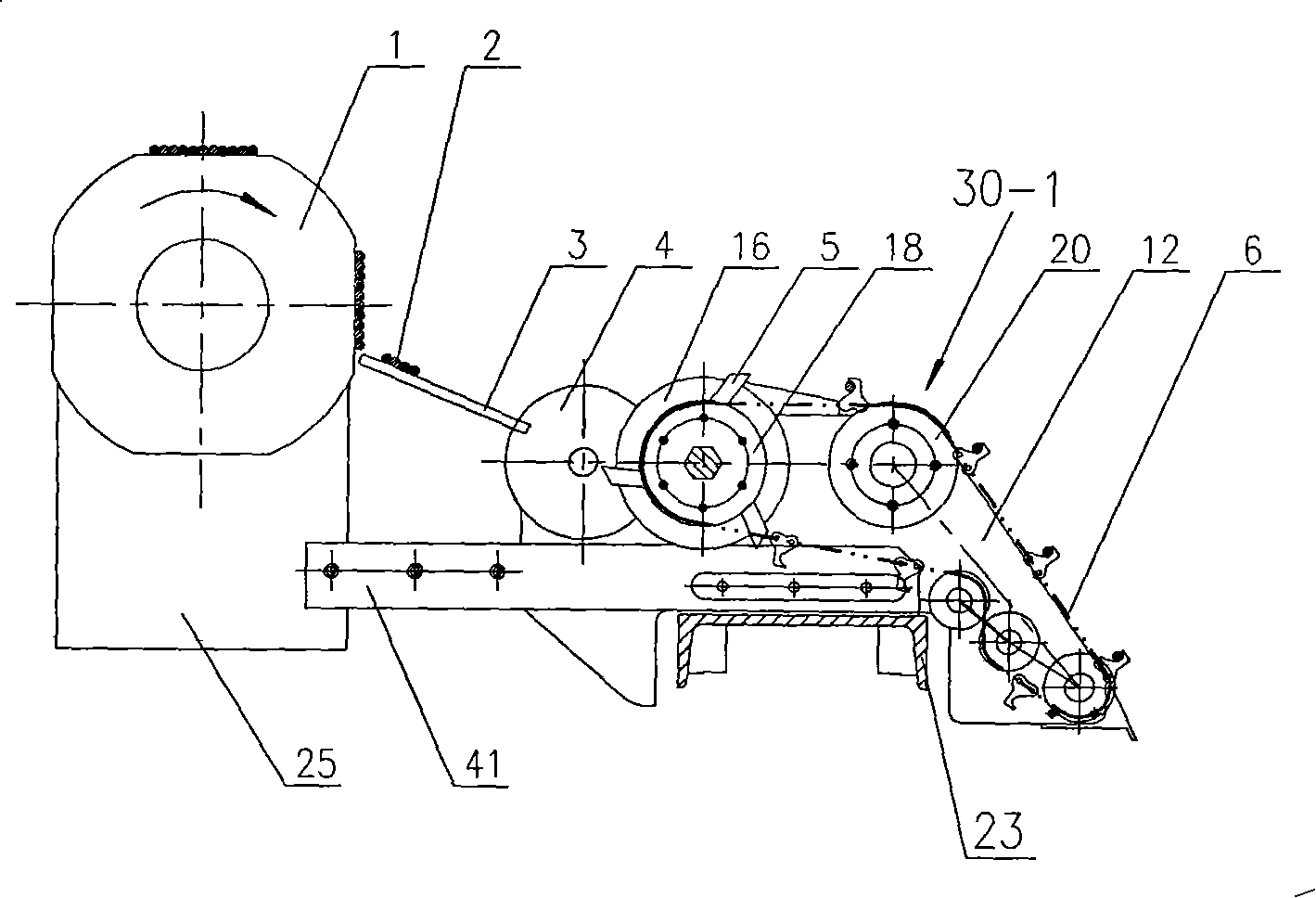

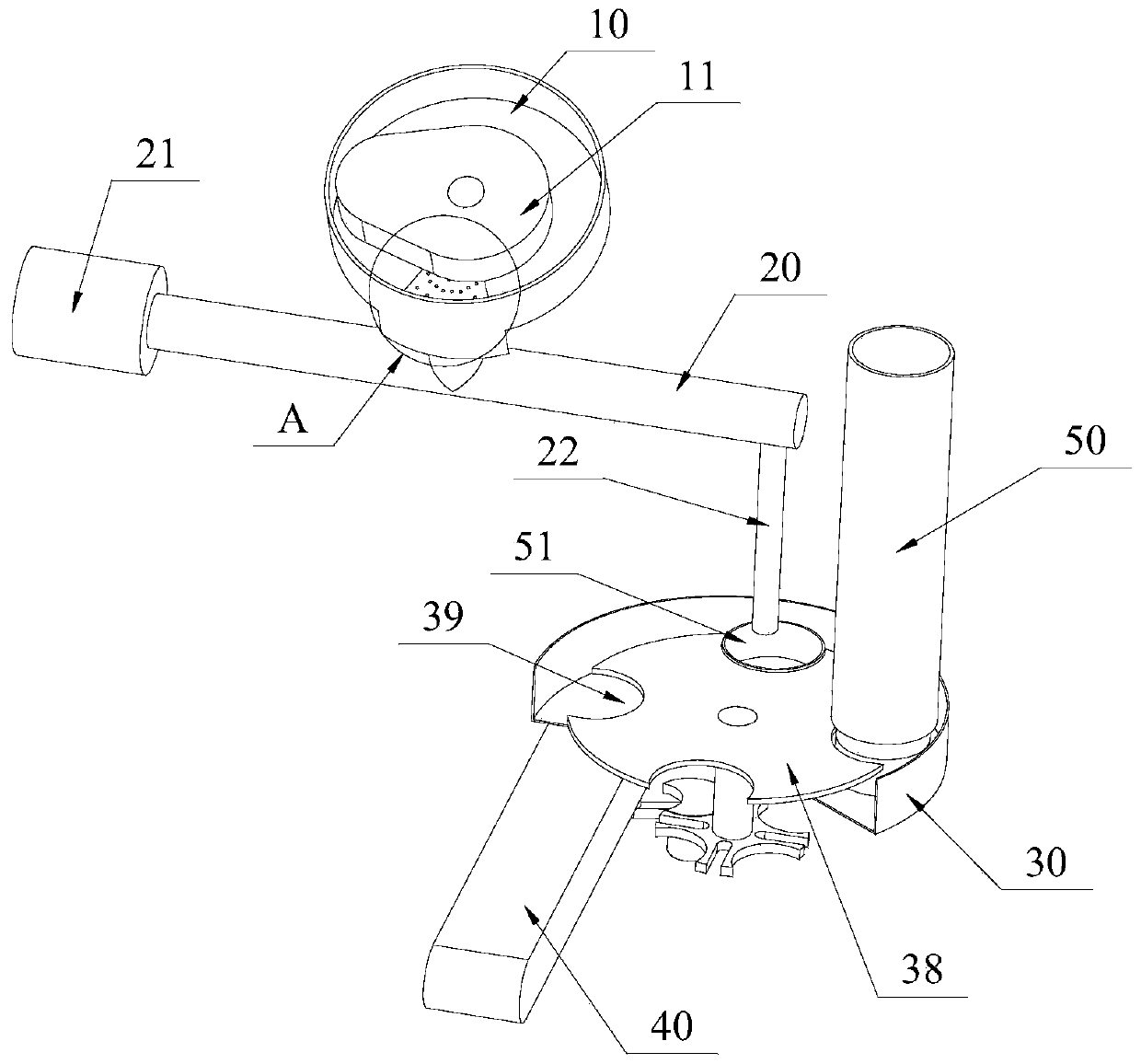

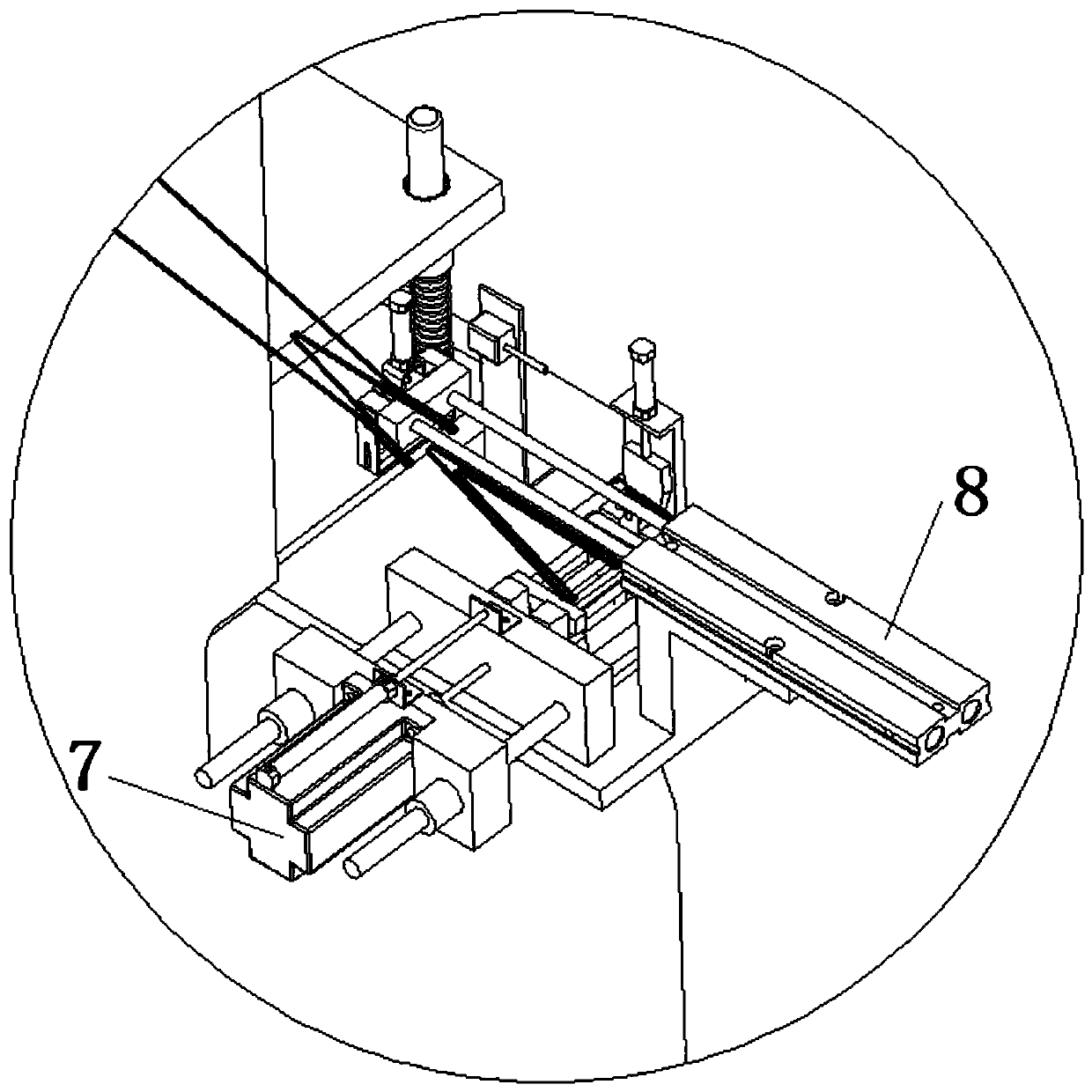

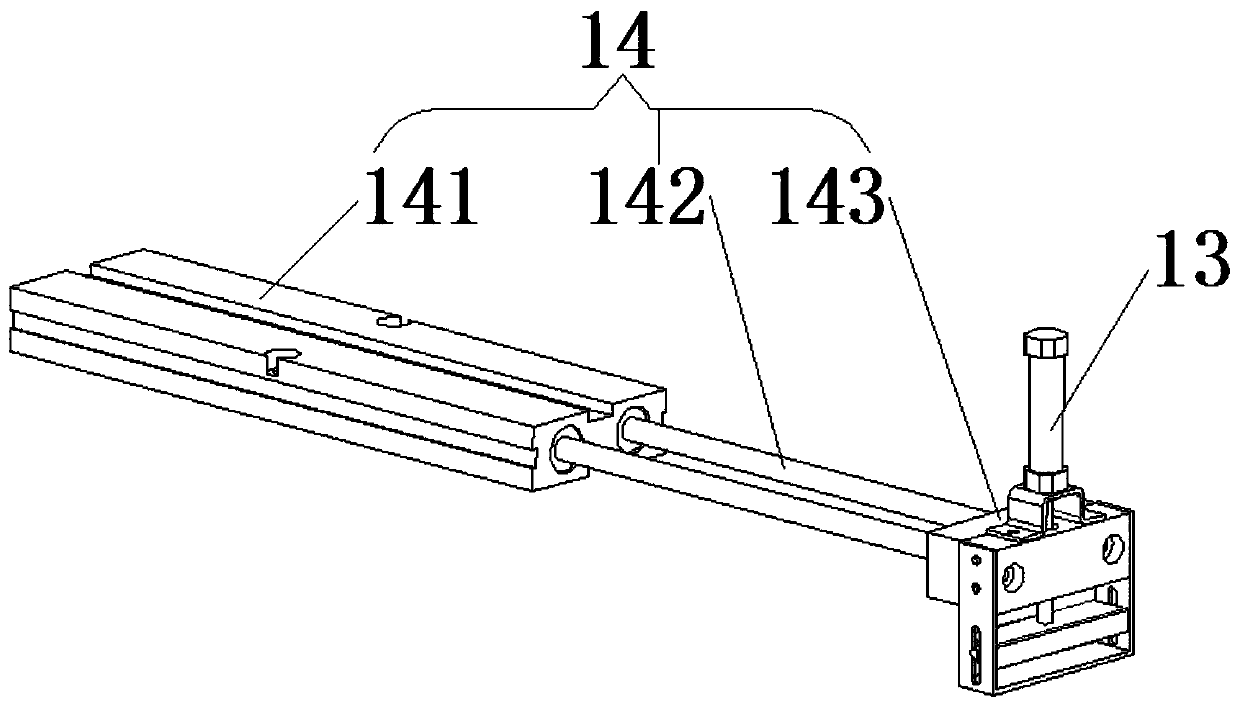

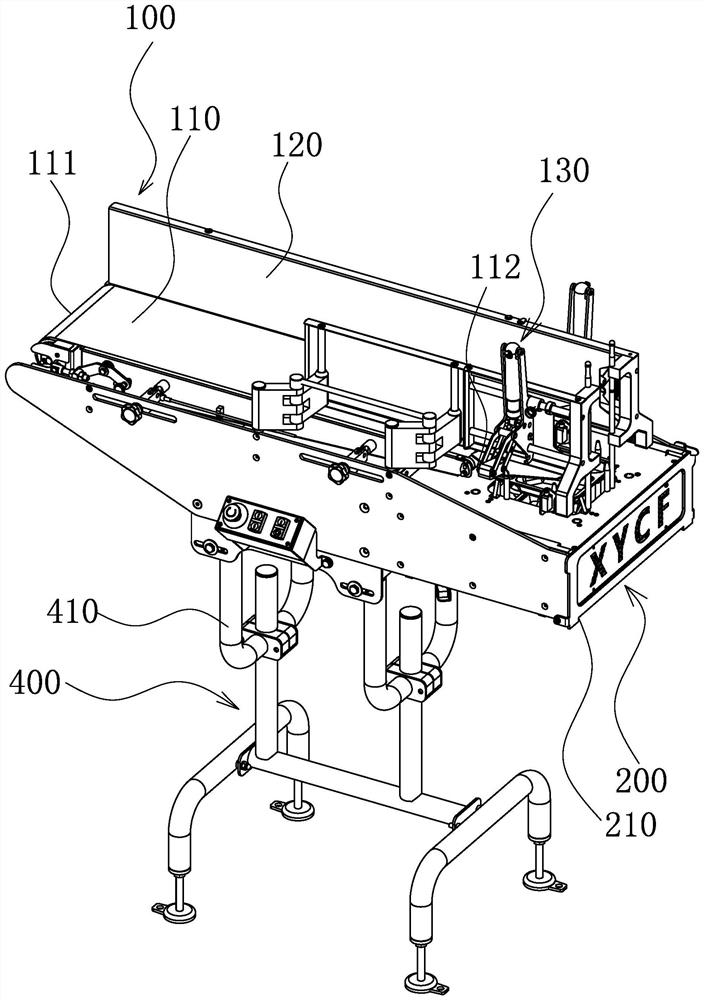

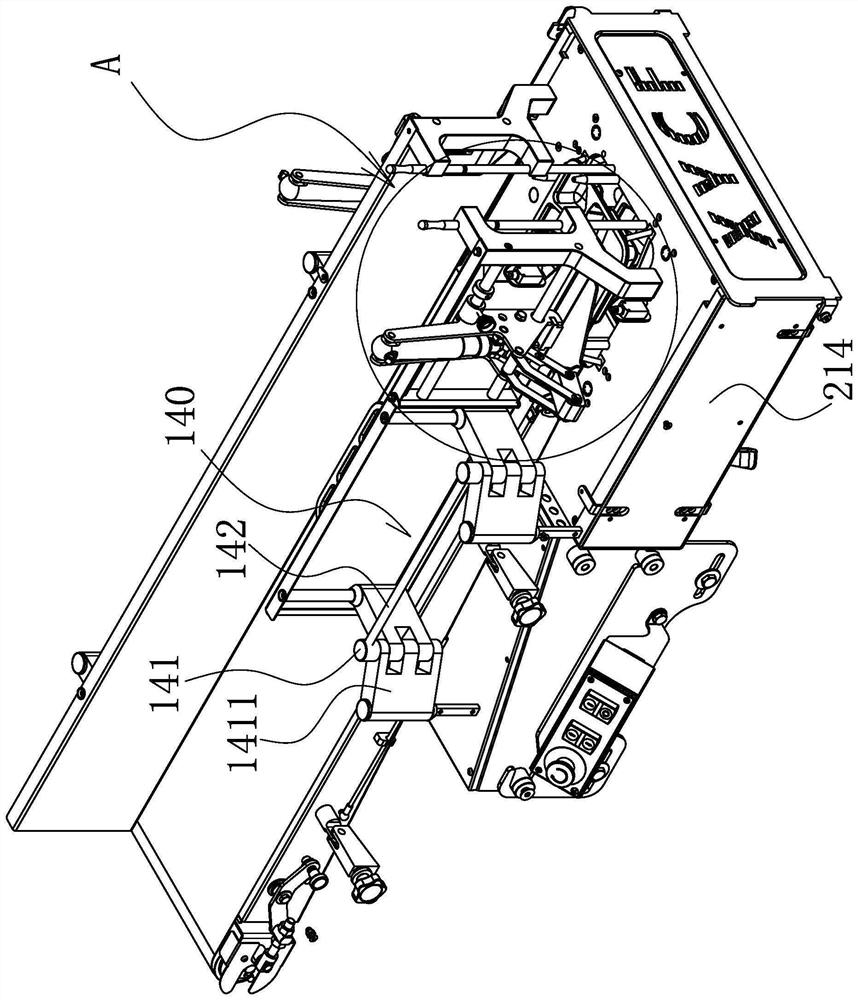

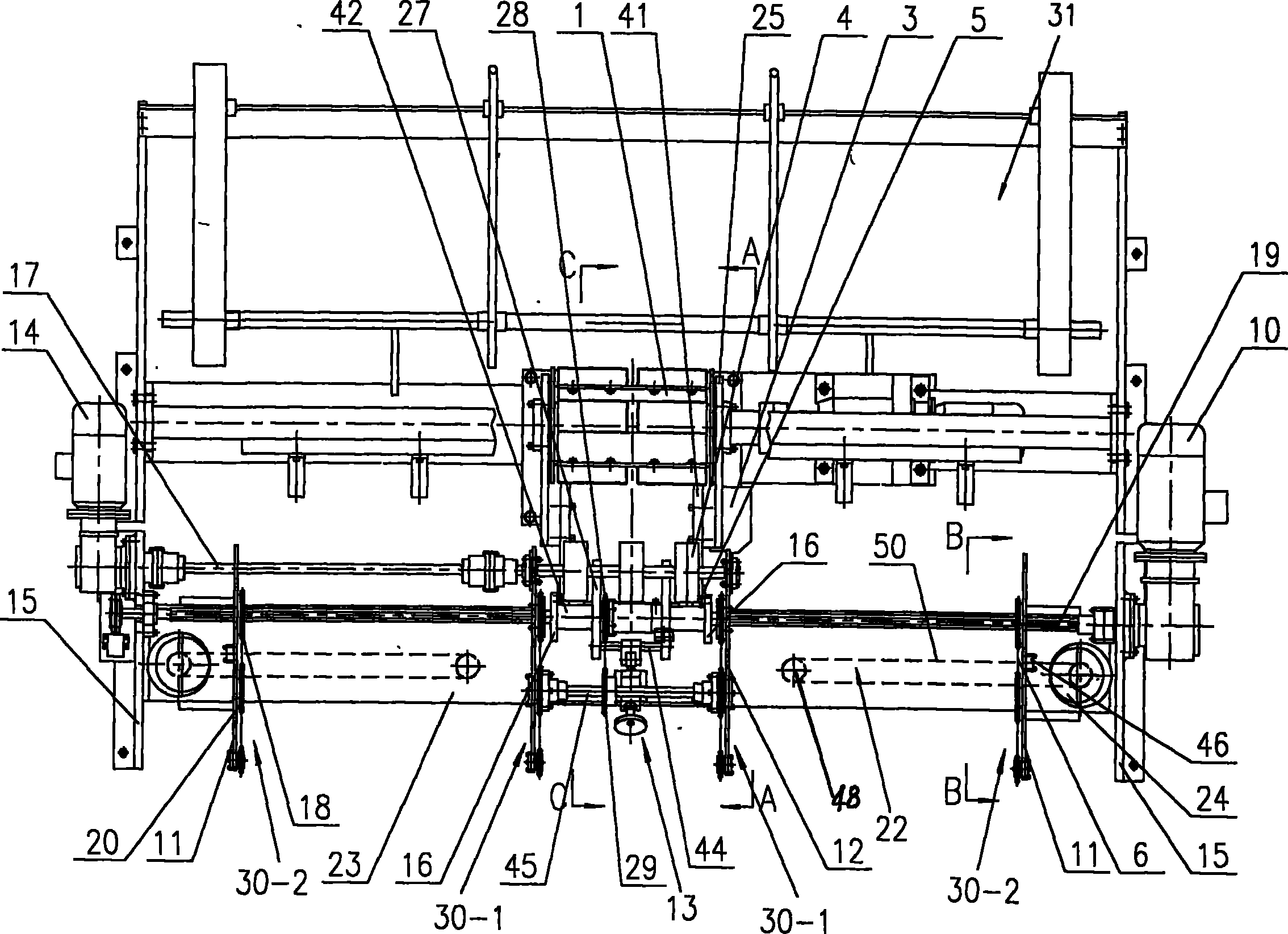

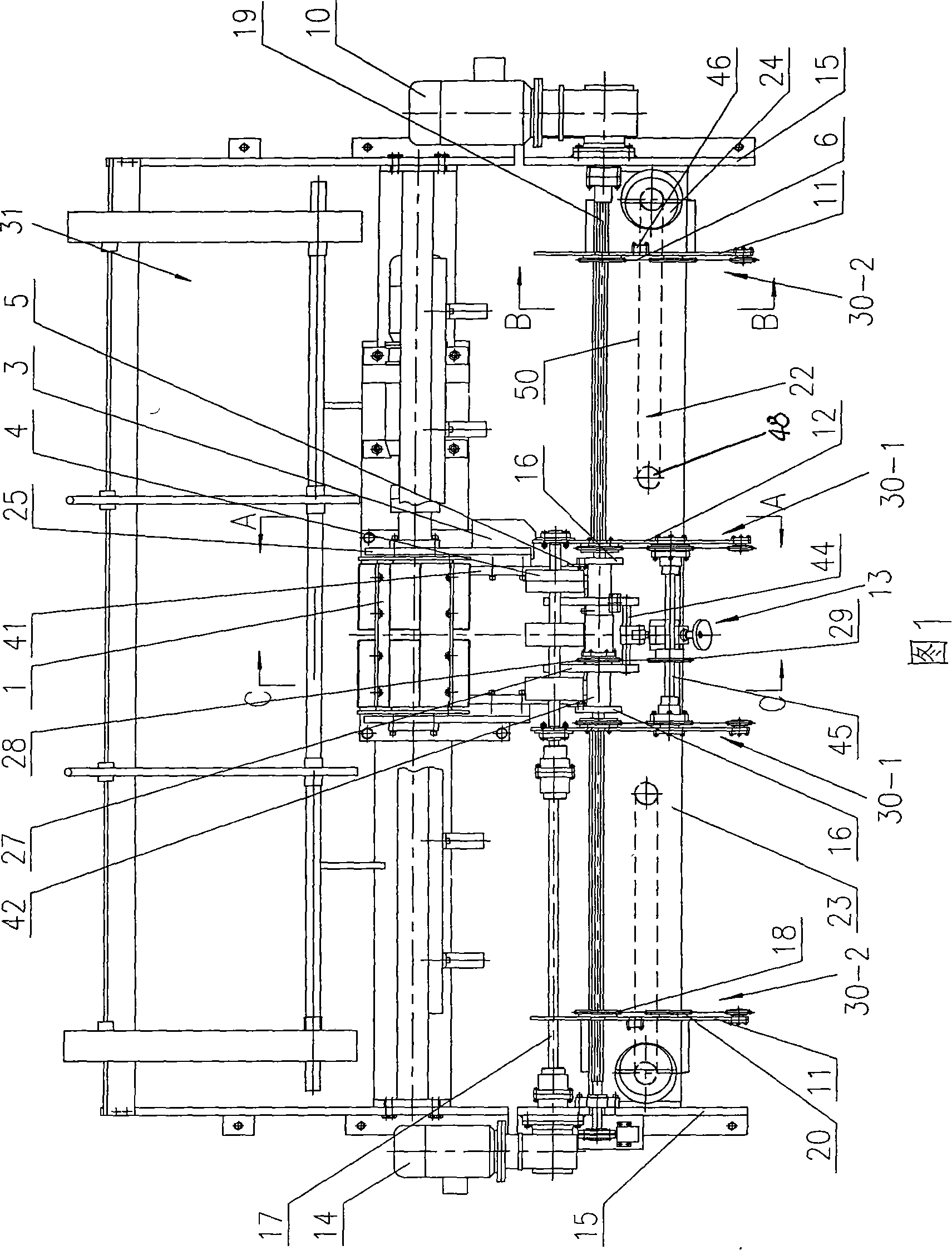

Digital controlled lathe special for engine air valve continuous full-automatic machining and method thereof

ActiveCN107570726ARealize no angle splicingReduce adverse effectsFeeding apparatusChucksThree degrees of freedomEngineering

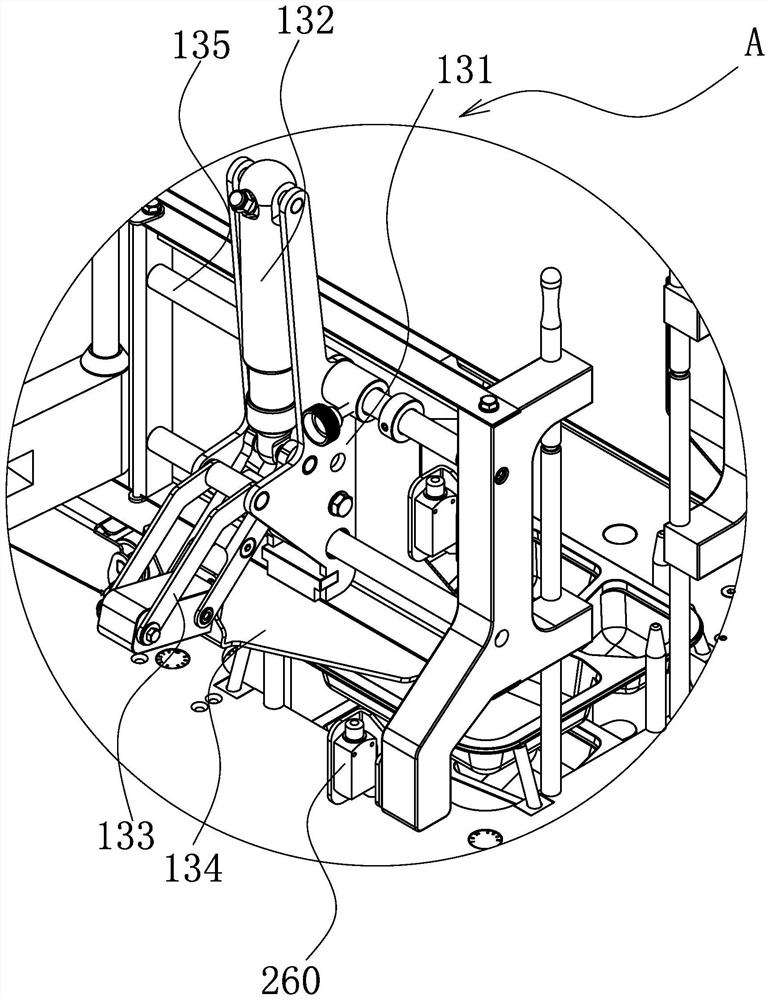

The invention discloses a digital controlled lathe special for engine air valve continuous full-automatic machining and a machining method thereof. A machine tool of the digital controlled lathe comprises a protective shell assembly, a lathe bed base assembly, a sliding saddle assembly, a material sorting and discharging assembly, a feeding and falling assembly, a main shaft assembly, a material clamping and pushing assembly, a pneumatic system assembly, a lubrication system assembly and a cutter seat assembly; the protective shell assembly protects all parts, the lathe bed base assembly supports all the parts, and three-degree-of-freedom moving of a cutter seat is realized through the sliding saddle assembly; the material sorting and discharging assembly realizes sorting of air valve workpieces and single material discharging, the feeding and falling assembly installs and clamps the air valve workpieces and collects falling finished products, and the workpieces are driven to rotate bythe main shaft assembly; the material clamping and pushing assembly clamps the workpieces and pushes the finished products, the pneumatic system assembly provides the pneumatic force, the lubricationsystem assembly lubricates all relative moving parts, and the cutter seat assembly clamps cutting tools. All the assemblies are coordinative, and full-automatic high-efficiency production of the engine air valves is realized.

Owner:ZHEJIANG JINTANG MACHINE TOOL

Bamboo pen barrel primary processing equipment

InactiveCN111805653AIncrease productivityFast blankingCane mechanical workingProfiling/shaping machinesEngineeringMechanical engineering

The invention provides bamboo pen barrel primary processing equipment. The bamboo pen barrel primary processing equipment comprises a worktable, a feeding device, a cutting device and a material receiving device, wherein the worktable comprises a main worktable and an auxiliary worktable; the feeding device comprises a fixing assembly, a power assembly and a grinding assembly; the cutting device comprises a moving assembly, a positioning assembly and a cutter assembly, and the positioning assembly comprises an installation assembly and a supporting assembly; the cutter assembly comprises a cutting head; and the material receiving device comprises a control assembly. According to the bamboo pen barrel primary processing equipment, the feeding device drives a bamboo tube to move and rotate,a supporting assembly can extend into the bamboo tube, the supporting assembly can rotate under the action of a control assembly, after the supporting assembly is in contact with a bamboo joint, the movement of the moving assembly make the cutting head abut against the outer wall of the bamboo tube, the bamboo tube rotates the cutter assembly to cut the bamboo tube and retain the bamboo joint, then the moving assembly exits, the control assembly drives the supporting assembly for discharging, and the technical problems of low production efficiency of pen barrels caused by manual cutting and stacking of the pen barrels in the prior art are solved.

Owner:临泉县金钉子生产力促进中心有限公司

Multifunctional soil remediation and incineration robot

InactiveCN108826327AImprove repair efficiencyImprove repair effectContaminated soil reclamationIncinerator apparatusFixed frameSoil remediation

The invention discloses a multifunctional soil remediation and incineration robot. The multifunctional soil remediation and incineration robot comprises a box body, a supporting column is fixedly connected to the bottom of the inner wall of the box body, and an incineration box is fixedly connected to the top end of the supporting column, a soil feeding hopper penetrates through the top of one side of the box body, a first motor is fixedly connected to the outer wall of the box body, the output shaft of the first motor is fixedly connected with a crushing wheel shaft, and the surface of the crushing wheel shaft is fixedly connected with a crushing wheel, the bottom of the soil feeding hopper is communicated with the incineration box, a feeding hopper penetrates through one side of the boxbody, and the bottom of the feeding hopper is communicated with the incineration box, and the top of the box body is fixedly connected with a fixing frame. The invention relates to the technical fieldof soil remediation. The multifunctional soil remediation and incinerating robot has the functions of soil remediation, detection and flue gas treatment and emission integration, the function of thedevice is improved, the biological fuel is used for incinerating, the soil remediation efficiency and effect are improved, and the device is very energy-saving and environment-friendly.

Owner:刘华丽

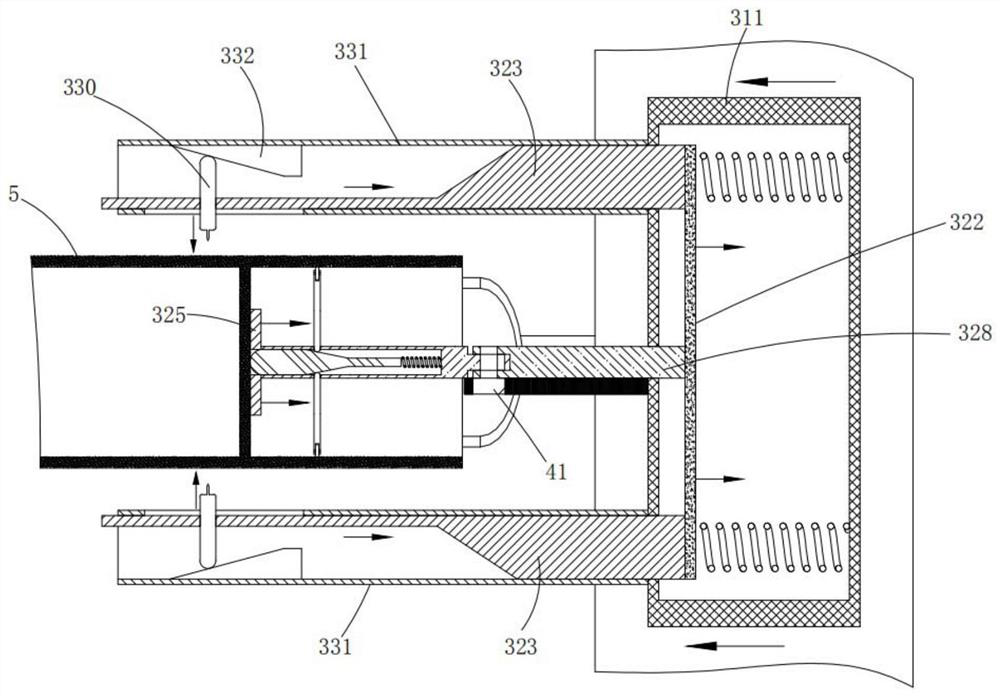

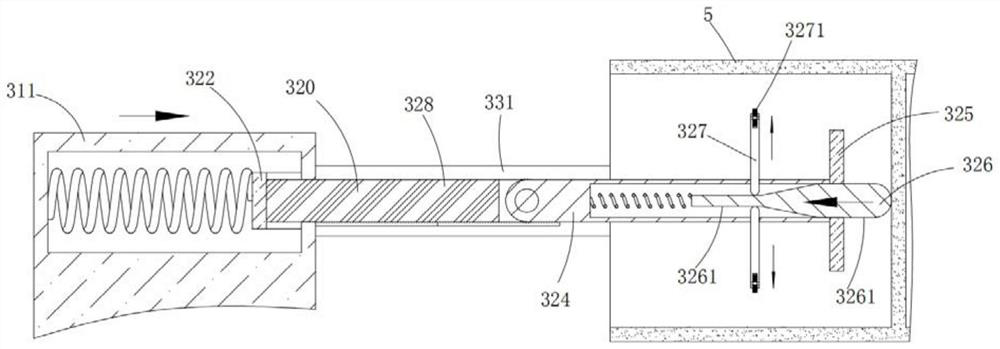

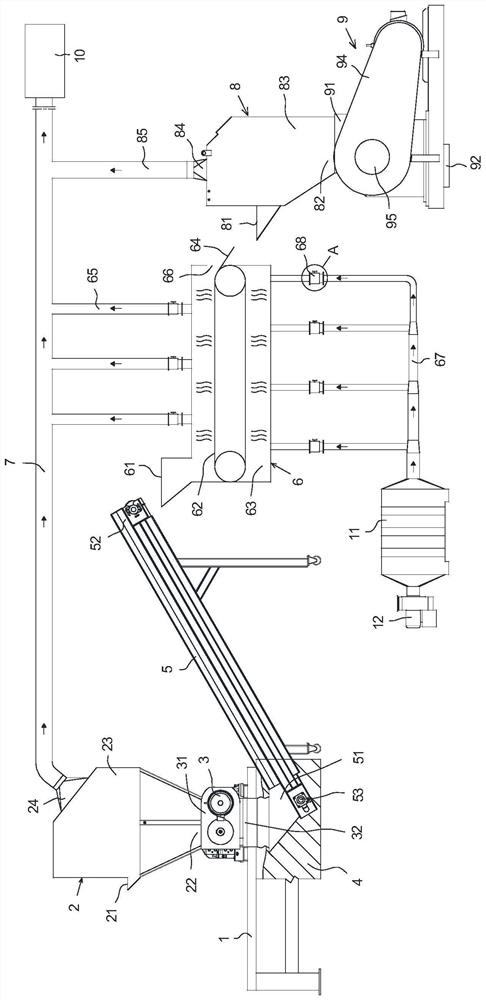

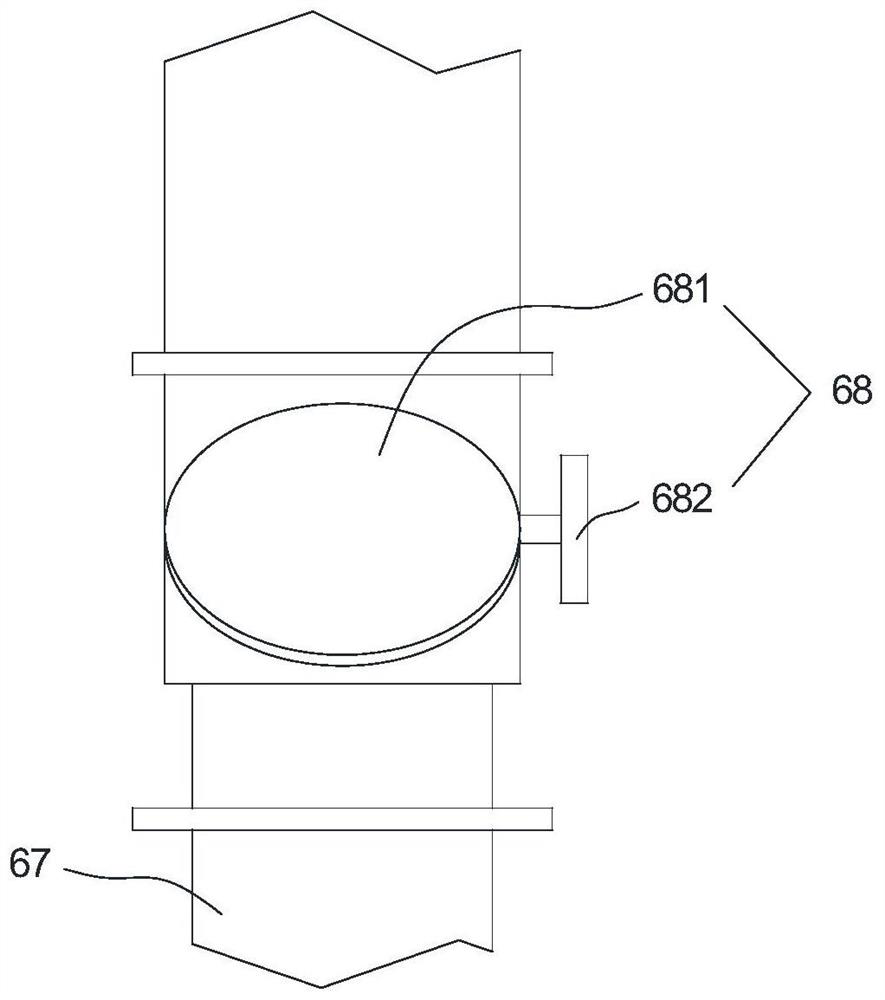

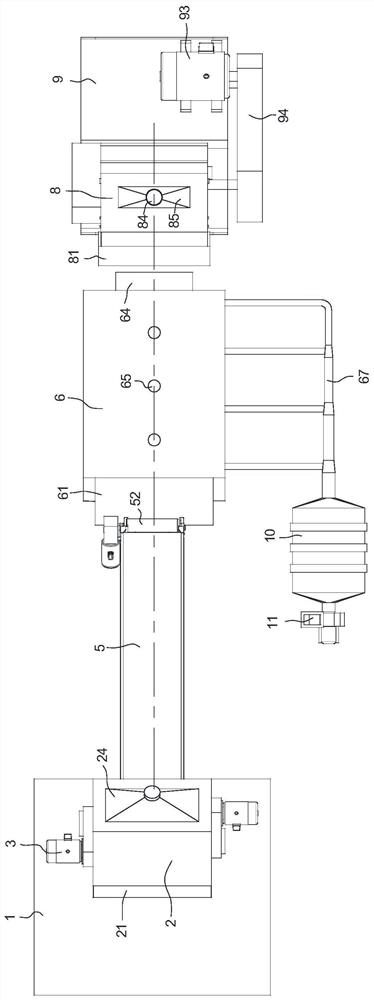

Voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking

ActiveCN109305564AThe feeding process is controllablePrevent blowbackBulk conveyorsAutomatic controlBiomass

The invention relates to a voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking, and belongs to the technical field of biomass thermal cracking. The voltagestabilization-continuous pneumatic conveying feeding system comprises a material transition bin, a conical pressure bin, a material receiving chamber and the like. A dual-material bin and a double butterfly valve design are adopted by the feeding system, so that the effects of pressure isolation, air locking and environment sealing are achieved, the feeding process is controllable, the phenomenonthat materials are reversely sprayed is avoided, and the reliability and the stability of the thermal cracking process are improved. A laser-photosensitive sensor and a PLC are used as an automatic control system, a two-stage electric butterfly valve is adopted as an execution component, and the materials automatically fall into the conical pressure bin from the material transition bin. Aerationair is added into the conical section of the conical pressure bin, and the materials in the conical pressure bin are fluidized, so that the phenomena of bridging, wall hanging and material bursting are avoided. Thermal cracking by-product non-condensable gas generated by biomass rapid thermal cracking which serves as spraying, pressurization and pressure maintaining gas is adopted by the feeding system, so that resources can be saved, self-powered energy is achieved, and pollution is avoided.

Owner:BEIJING FORESTRY UNIVERSITY

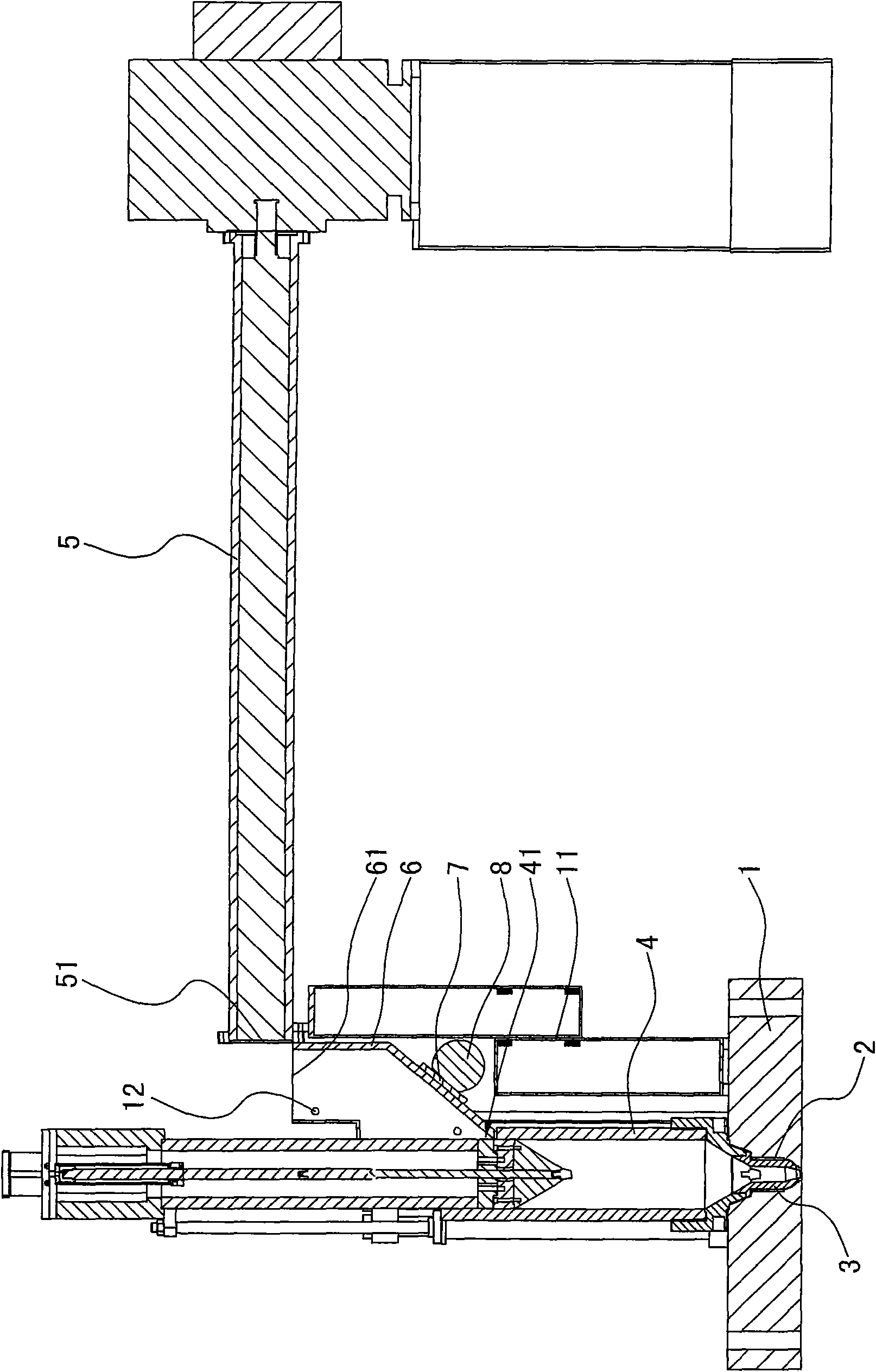

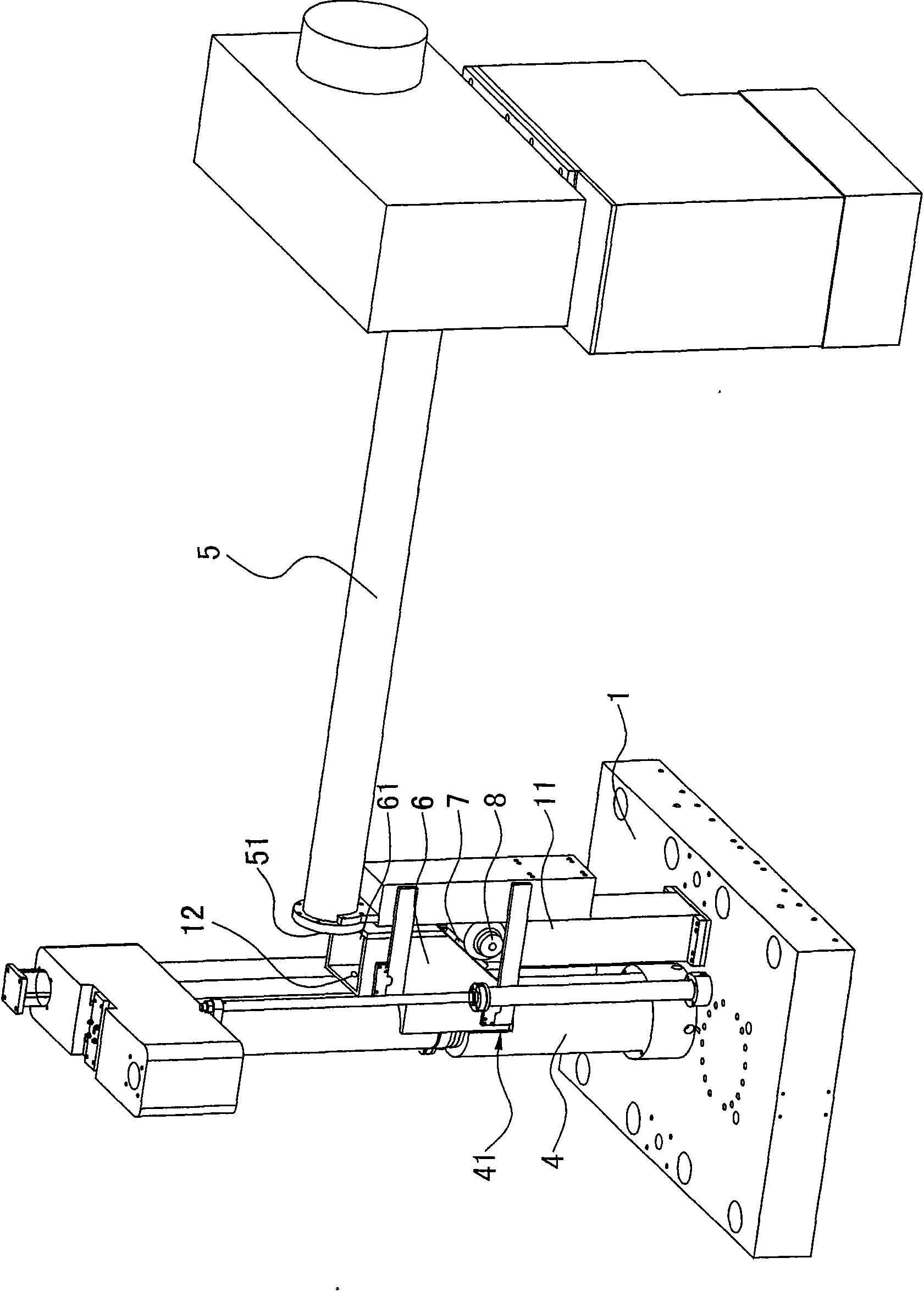

Feeding device of open-type injection molding machine

The invention relates to a feeding device of an open-type injection molding machine, comprising a template and an injection molding device, wherein the template is provided with a mould; a feeding hole is arranged in the template and is matched with an injection molding head of the injection molding device; the injection molding head is connected with a storage cylinder; a prepush device and the injection molding device are arranged in the storage cylinder; and the storage cylinder is connected with a charging barrel. The feeding device is characterized in that the mouth of the storage cylinder is provided with an opening connected with a feeding hopper; the inlet of the feeding hopper is in contact with the outlet of the charging barrel; the bottom surface of the feeding hopper is provided with an electronic scale, or the inner wall of the feeding hopper is provided with an optoelectronic switch; and the feeding hopper is provided with a blanking device. With technical scheme, the invention has the advantages that the charging barrel continuously works and blanks, and the feeding device has high feeding speed, high production efficiency, simple structure and easy connection.

Owner:蔡业

Punching machine of medicine bottle caps

InactiveCN107234163AFast blankingSimple structureMetal-working feeding devicesClosure capsPunchingMedicine bottle cap

The invention relates to the field of bottle cap processing equipment, in particular to a punching machine of medicine bottle caps. The punching machine of the medicine bottle caps comprises a punching mechanism, a feeding mechanism and a discharging mechanism. The punching mechanism comprises a rack, a punching motor, an eccentric shaft and a punching shaft, wherein the punching motor, the eccentric shaft and the punching shaft are arranged on the rack; the two ends of the eccentric shaft are positioned on the rack through bearings, and the output end of the punching motor is in transmission connection with the eccentric shaft through a transmission assembly; and the punching shaft is longitudinally and slidably positioned on the rack, the upper end of the punching shaft is connected on the eccentric shaft in a sleeving mode, a punching die used for cutting plate bodies of raw materials is arranged at the lower end of the punching shaft, and the punching die is located above the feeding mechanism. According to the punching machine of the medicine bottle caps, the structure is simple and practical, and equipment operation is stable.

Owner:浙江冠利新材料股份有限公司

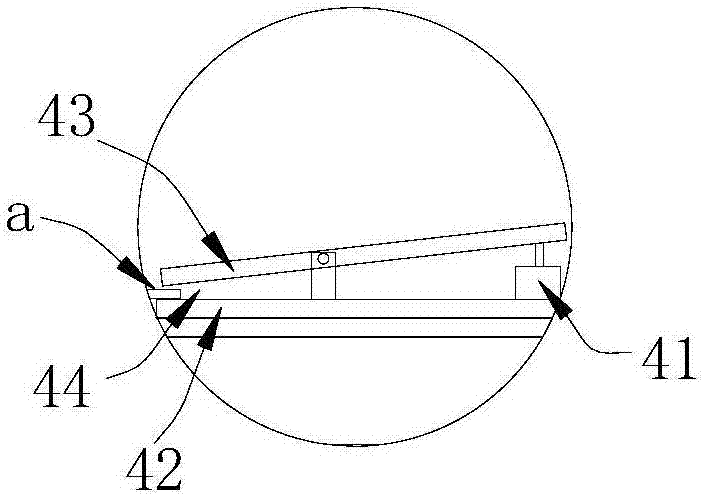

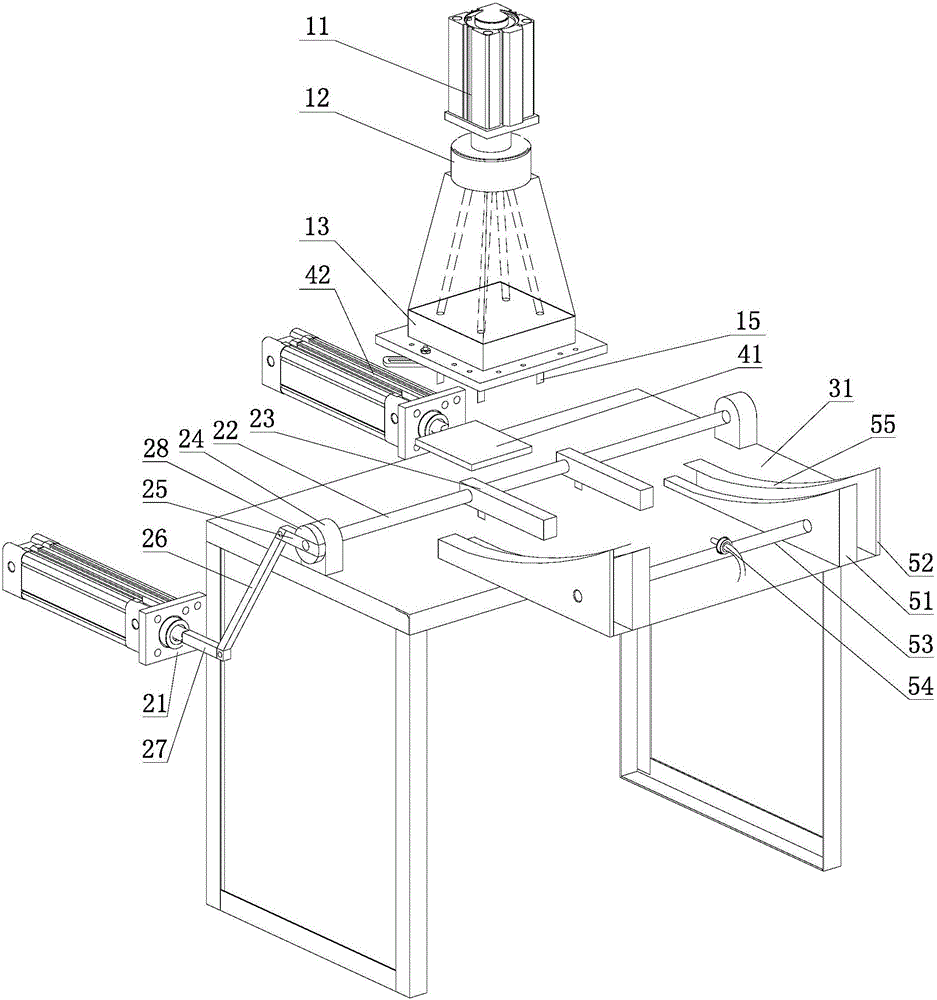

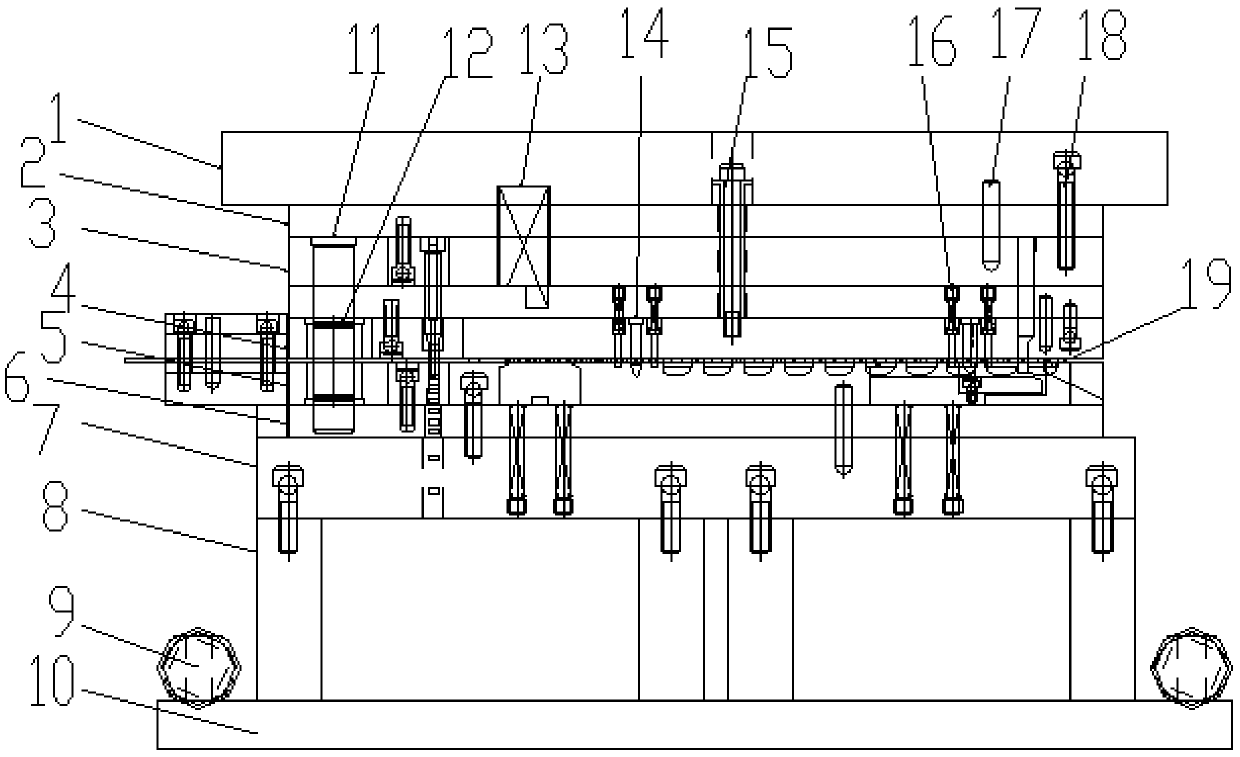

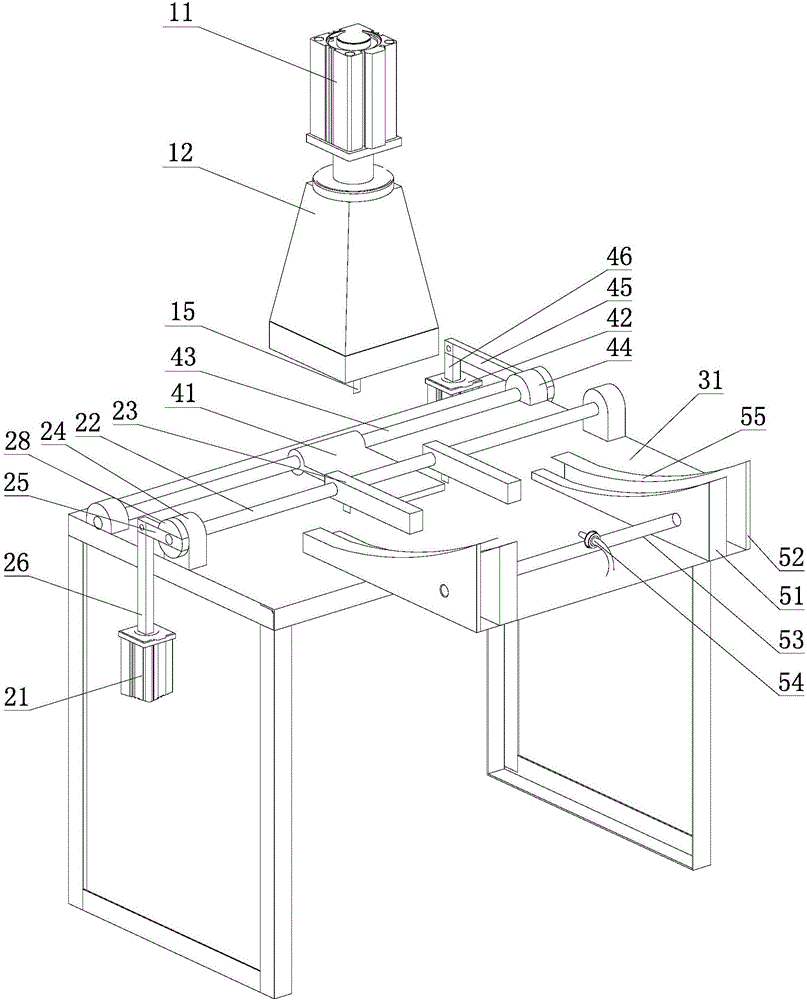

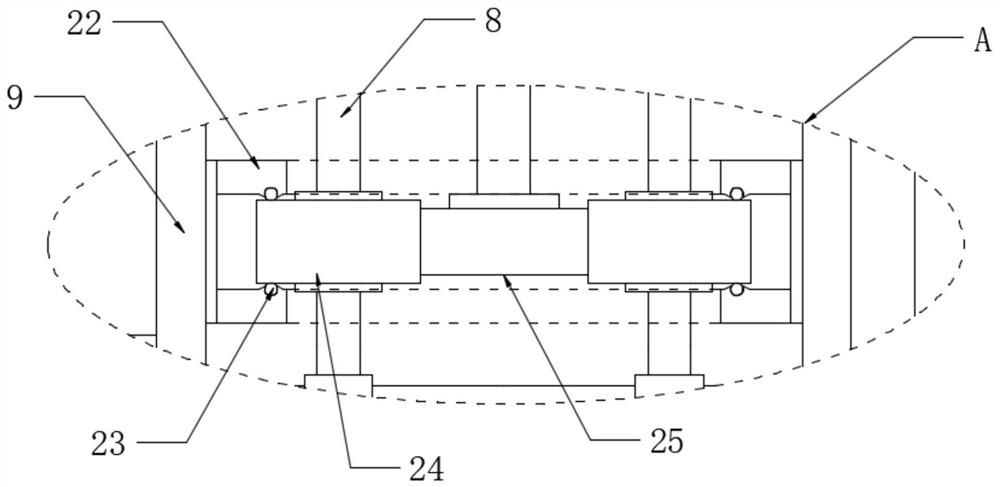

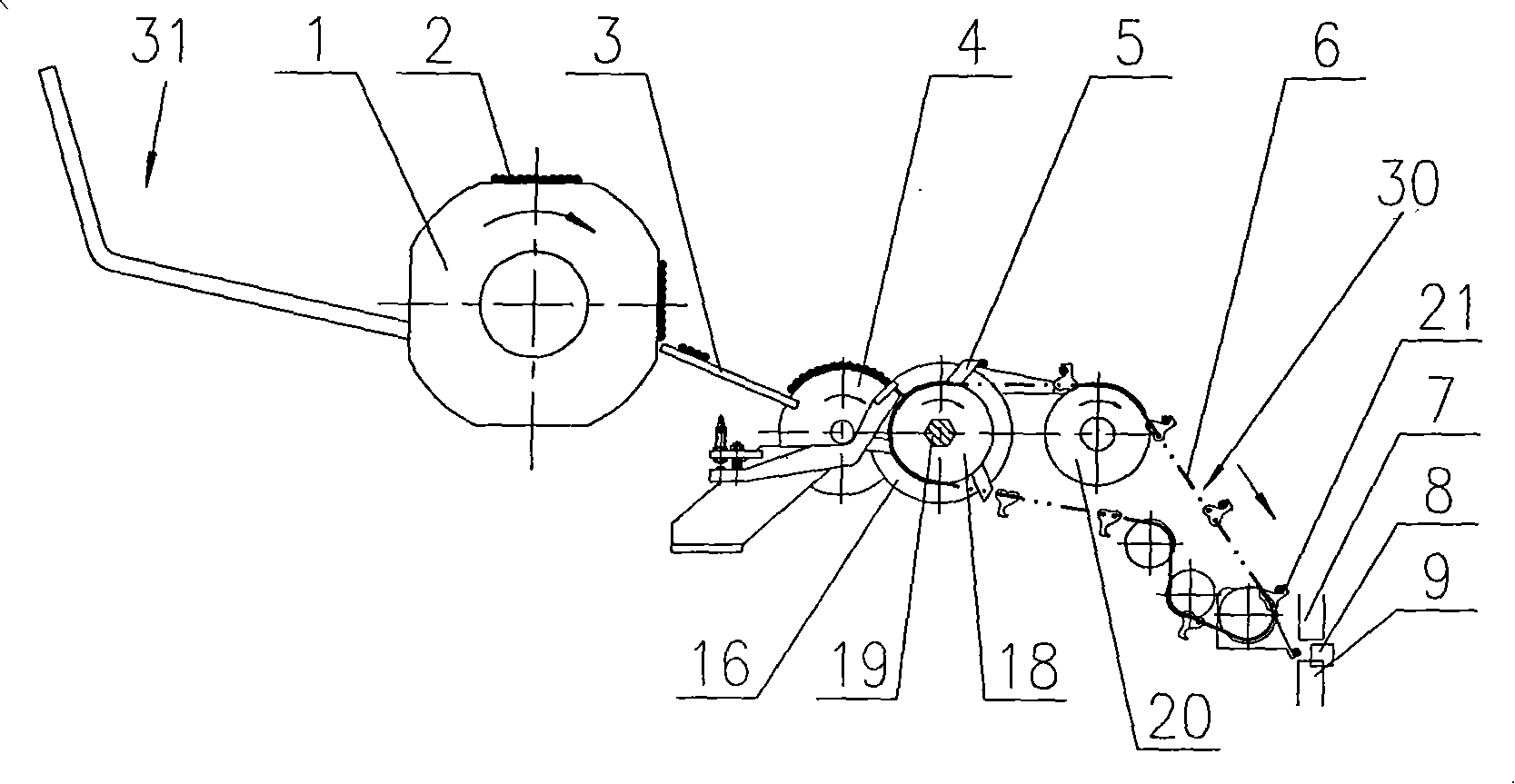

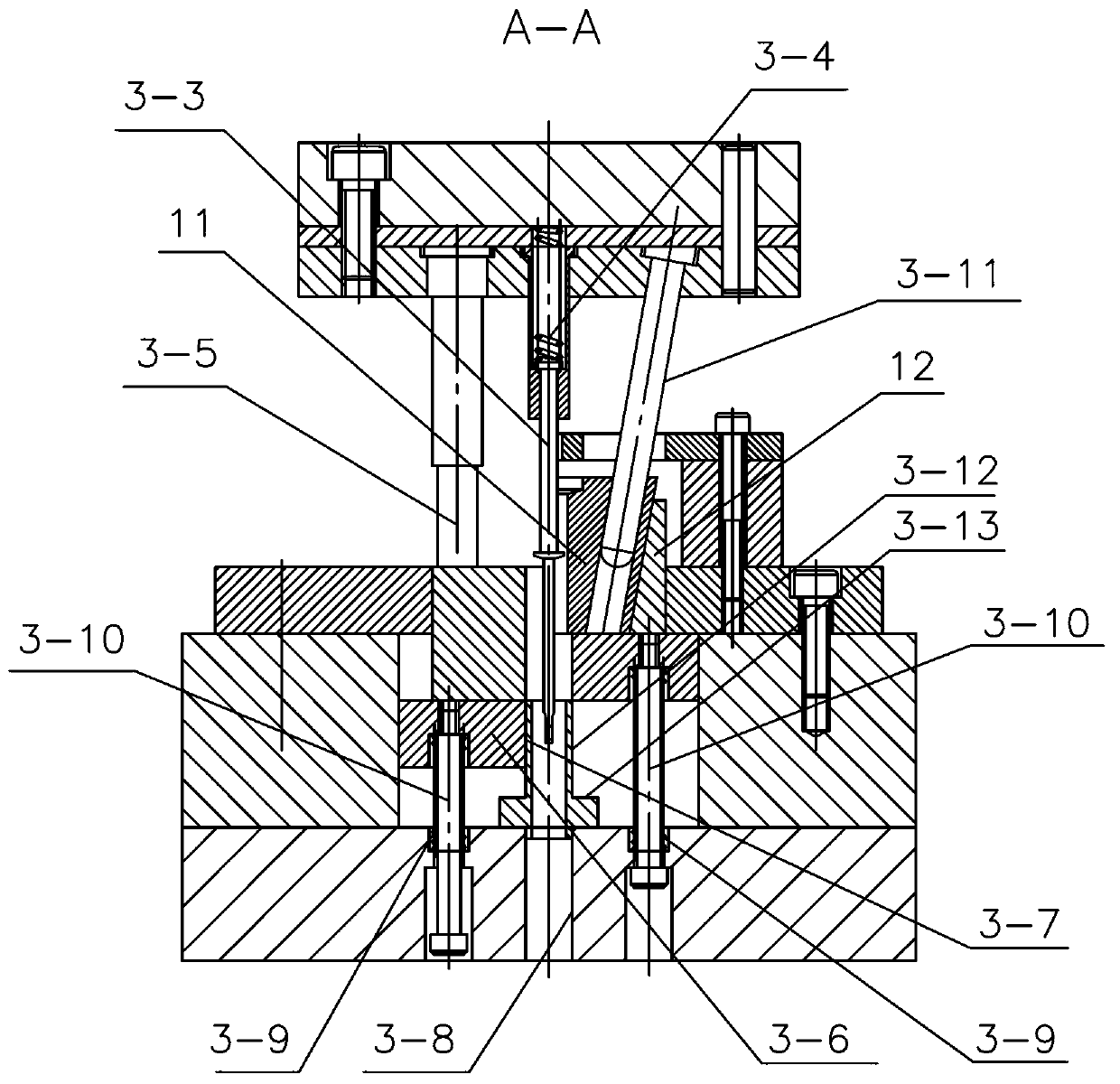

Full-automatic multi-head tapping machine

InactiveCN105834530AFast loadingFast blankingThread cutting feeding devicesThread cutting machinesEngineeringMechanical engineering

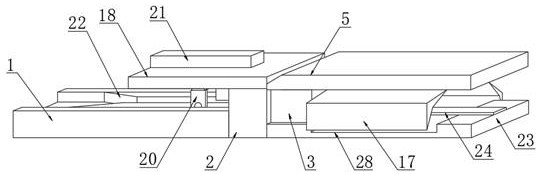

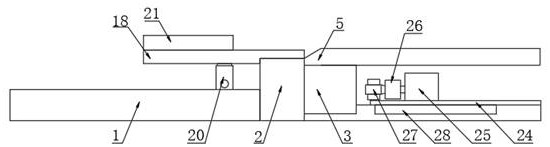

The invention discloses a full-automatic multi-head tapping machine which comprises a machine head assembly, a clamp, a supporting plate device and a guide rail device. The machine head assembly comprises a motor, a gear transmission device, an upper machine base, a lower machine base, a plurality of transmission rods and screw taps with the number corresponding to that of the transmission rods. The clamp comprises a clamp air cylinder, a first connecting rod mechanism, a first linkage rod, press strips and two first linkage rod seats. The two ends of the first linkage rod are connected with the two first linkage rod seats through bearings correspondingly. The press strips are fixed to the middle of the first linkage rod. The tail end of the first connecting rod mechanism and the end of the first linkage rod are fixed. The clamp air cylinder drives the first connecting rod mechanism, and therefore the press strips clamp or loosen a workpiece to be machined. The supporting plate device comprises a supporting plate and a supporting plate air cylinder, and the supporting plate is fixed to a piston rod of the supporting plate air cylinder. The guide rail device comprises two bevel guide rail plates and two limiting plates. The two bevel guide rail plates are fixed to a workbench, and the two limiting plates are located on the outer sides of the two bevel guide rail plates correspondingly. When the piston rod of the supporting plate air cylinder stretches out, the supporting plate is jointed with the tail ends of the bevel guide rail plates, support is provided for the workpiece to be machined, and the motor, the clamp air cylinder and the supporting plate air cylinder are controlled by a controller.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

Western medicine crushing and subpackaging machine

InactiveCN107539505AQuick smashFast blankingSolid materialGrain treatmentsWestern medicineMedical instruments

The invention discloses a western medicine crushing and subpackaging machine, and belongs to the field of medical instruments. The machine comprises a crushing mechanism, a conveying mechanism, a separation mechanism and a container conveying mechanism. In the prior art, a western medicine preparation device is quite single in function, and fast and automatic subpackaging cannot achieved. According to the western medicine crushing and subpackaging machine, fast crushing is achieved through a crushing device, blowing is achieved through the conveying mechanism, meanwhile, negative pressure is formed in a material falling pipe, crushed medicines can fall more easily, the medicines are prevented from blocking material falling holes, and automatic and fast separation is achieved through the separation mechanism; and the structure is simple, and cost is low.

Owner:PINGDINGSHAN UNIVERSITY

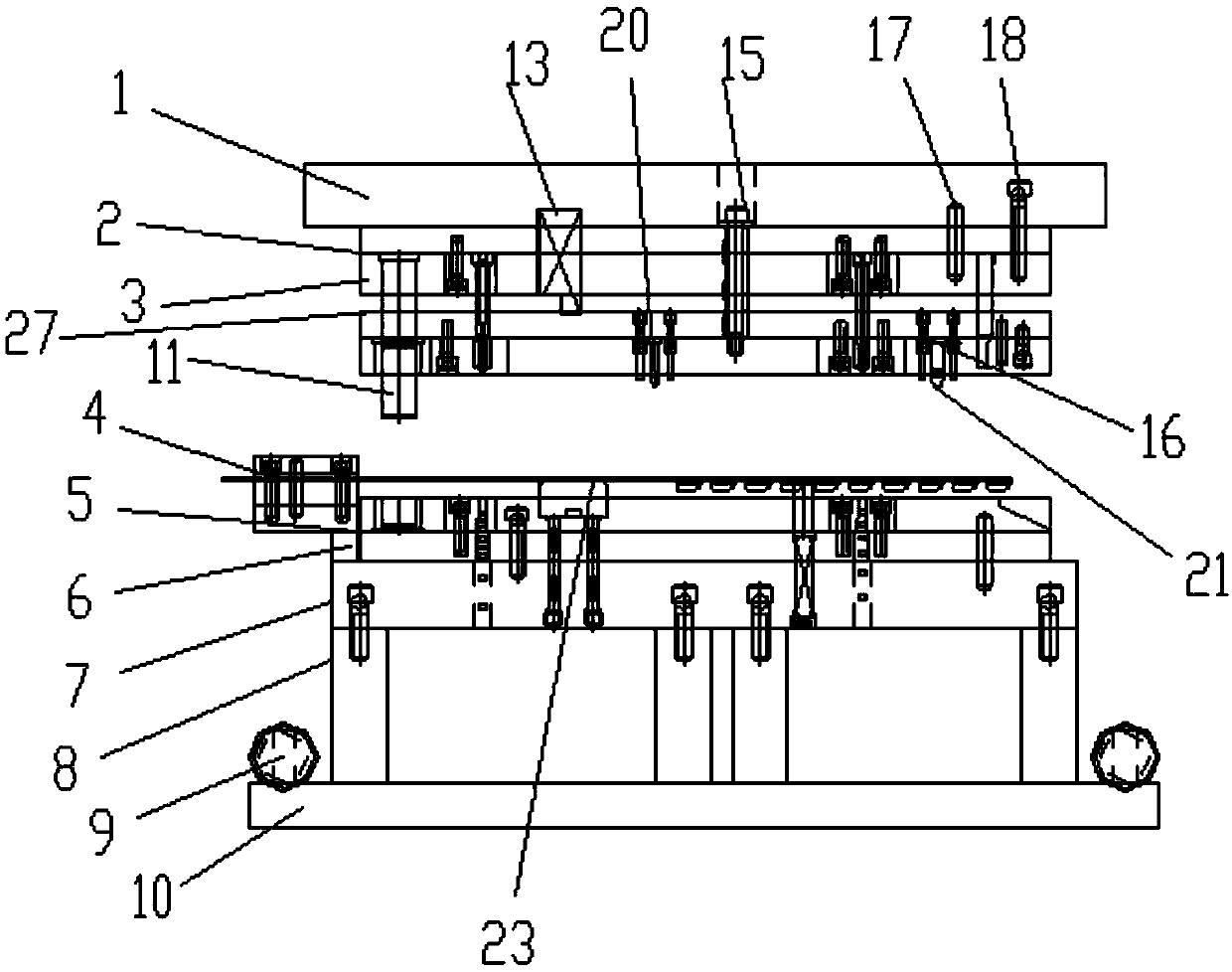

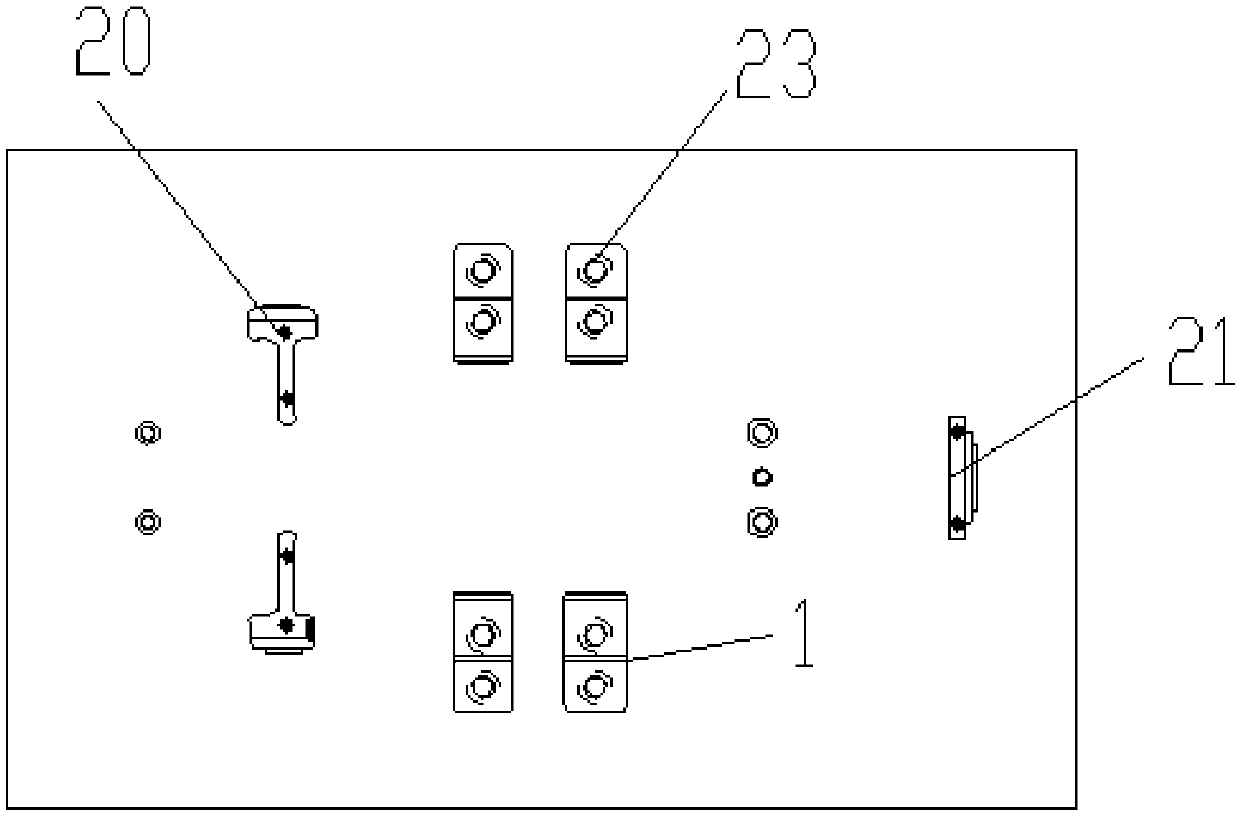

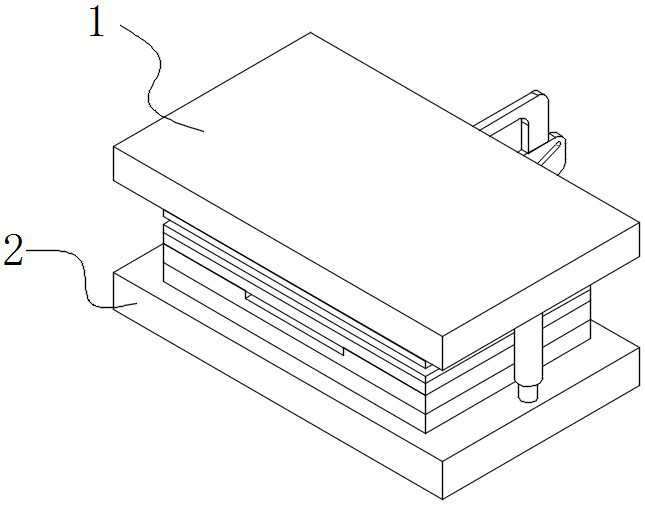

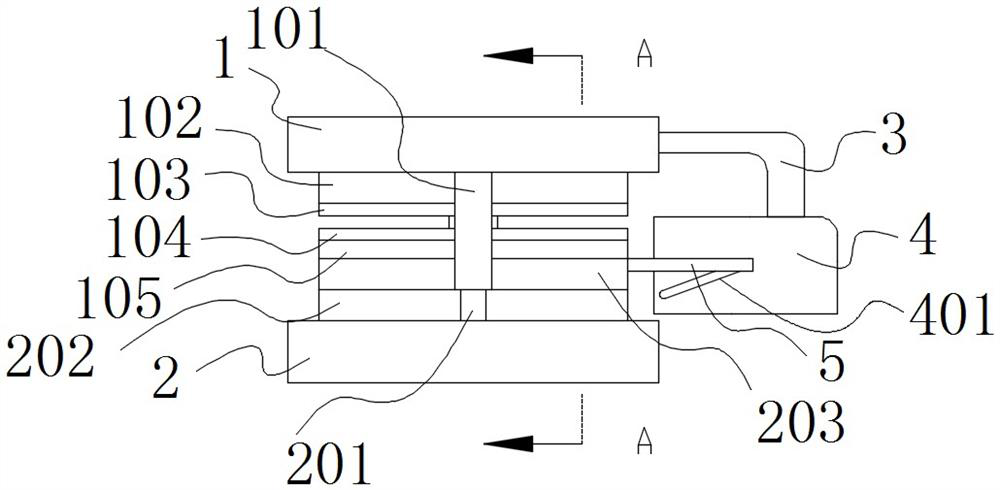

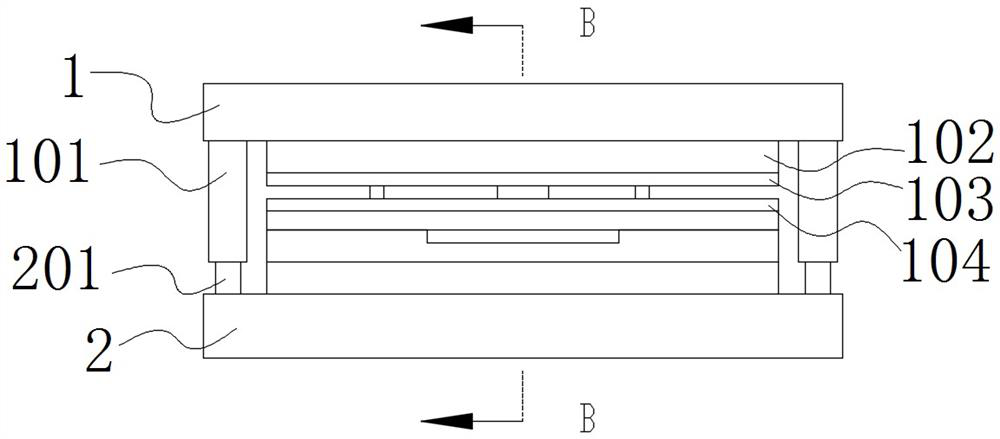

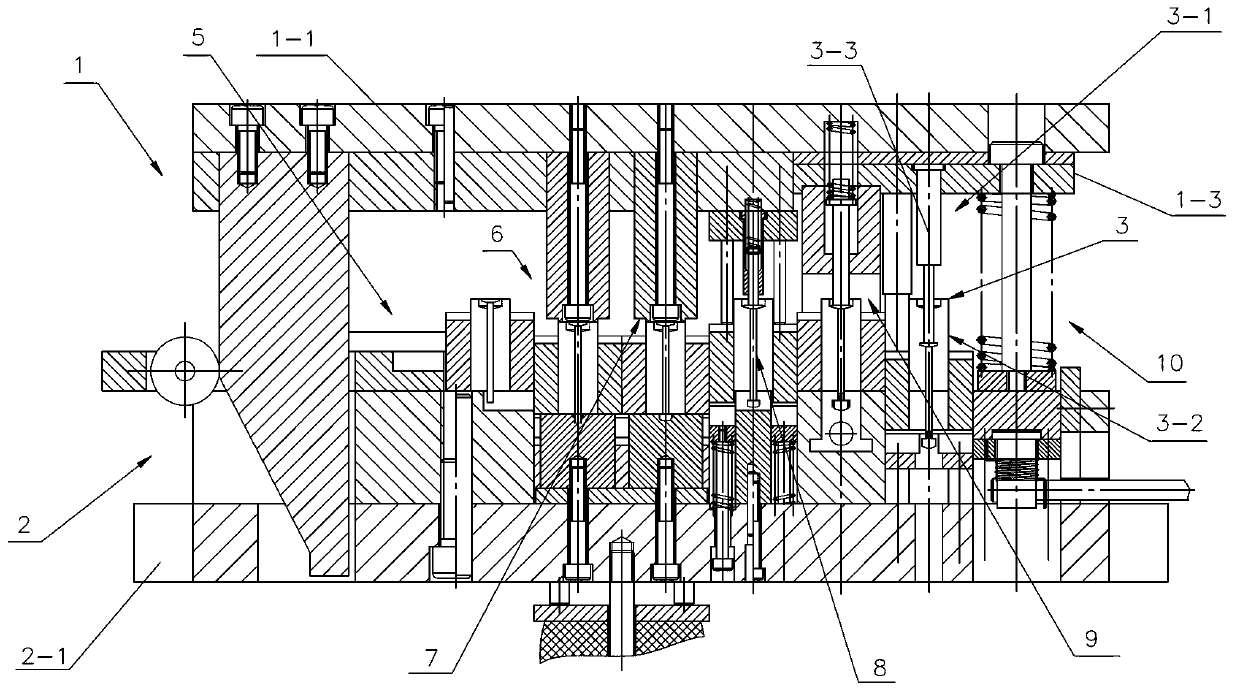

Progressive die for producing part for reinforcing square box of automobile seat

The invention provides a progressive die for producing a part for reinforcing a square box of an automobile seat. The progressive die comprises an upper die base and a lower die base, an upper clamping plate is arranged below the upper die base, an upper die plate is arranged below the upper clamping plate, and a lower die plate is arranged above the lower die base; a spring and a guide pin are arranged below the upper clamping plate, a row of hole-punching punches are sequentially arranged on the upper die plate, a cutting punch is arranged at the tail end of the upper die plate, and guide blocks are arranged at the two ends of the hole-punching punches; and inserts are arranged on the lower die plate, first positioning blocks, second positioning blocks and positioning holes are arrangedon the lower die plate, and the first positioning blocks, the second positioning blocks and the positioning holes are used for fixing a material belt. According to the progressive die, the situation that a plate material needs to be manually oriented by workers is avoided, and only one time of guiding and positioning needs to be carried out in the beginning, then automatic feeding can be achieved,and great manpower resources are saved.

Owner:WUXI MEIYER MACHINERY MFG

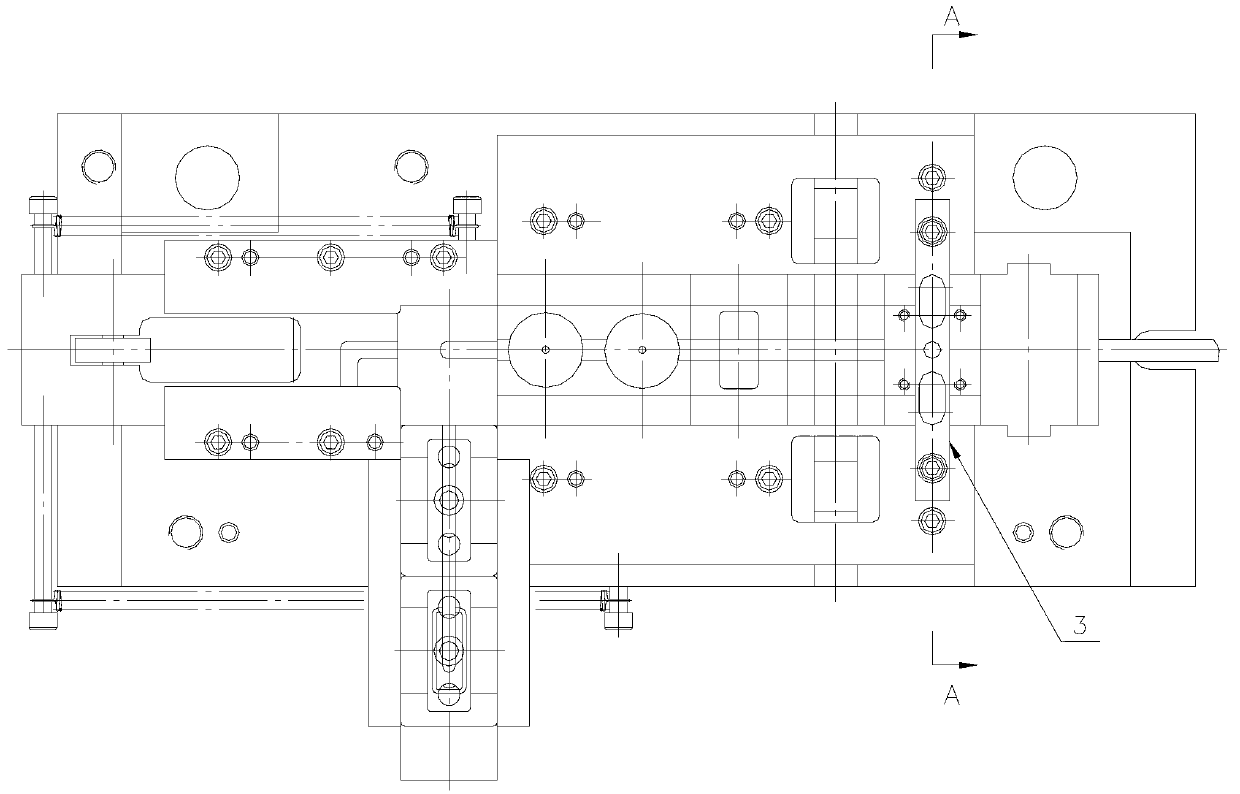

Tram silk chain manner material dropping mechanism of welding machine of mesh

ActiveCN101244501AStable blankingHigh speedWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

The invention discloses a chain blanking device of tram for a welding machine of mesh, wherein, a round magnetic drum is arranged below a square magnetic drum; a slide carriage is arranged between the square magnetic drum and one side of the round magnetic drum; the first drive sprockets of a fixed chain transport device and a shift chain transport device are fixed on the same drive shaft; one end of the drive shaft is connected with the driving motor of a carrier chain and the other end is hold by a frame; the first driven sprockets of two fixed chain transport devices are arranged on the drive shaft; a pusher dog disk and the second driven sprocket are arranged on the pusher dog shaft; an inner hole of the pusher dog shaft is intermittently sleeve-arranged on the drive shaft; the second drive sprocket connected to the second driven sprocket is arranged on the pusher dog shaft. The chain blanking device of tram has the advantages that the tram blanking can be steady, orderly and accurate with the transport hook of the transport device; the shift chain transport device can shift synchronously in lateral direction, so as to adapt to the tram with different lengths; the blanking process has good balance performance, and the productivity of the welding mesh is improved.

Owner:TJK MACHINERY TIANJIN

A kind of western medicine crushing and filling machine

InactiveCN107539505BQuick smashFast blankingSolid materialGrain treatmentsWestern medicinePharmaceutical drug

The invention discloses a western medicine crushing and subpackaging machine, and belongs to the field of medical instruments. The machine comprises a crushing mechanism, a conveying mechanism, a separation mechanism and a container conveying mechanism. In the prior art, a western medicine preparation device is quite single in function, and fast and automatic subpackaging cannot achieved. According to the western medicine crushing and subpackaging machine, fast crushing is achieved through a crushing device, blowing is achieved through the conveying mechanism, meanwhile, negative pressure is formed in a material falling pipe, crushed medicines can fall more easily, the medicines are prevented from blocking material falling holes, and automatic and fast separation is achieved through the separation mechanism; and the structure is simple, and cost is low.

Owner:PINGDINGSHAN UNIVERSITY

Binding device for packaging power cable accessories and using method thereof

ActiveCN114560131AQuick compressionFast blankingBundling machine detailsElectronic waste recyclingPower cableStructural engineering

The invention discloses a bundling device for power cable accessory packaging and a using method thereof.The bundling device comprises a conveying belt, a bundling machine, a pressing rack and an output mechanism which are communicated in sequence, and a first double-rod air cylinder is fixedly connected to an inner cavity of the pressing rack. According to the bundling device for packaging the power cable accessories and the using method of the bundling device, the surface of a wound cable connector is pressed through a pressure monitoring assembly, and along with movement of the cable connector, the positions of elastic abutting balls are different, and a first double-rod air cylinder continuously changes the position, so that the extrusion force on the cable connector is the same; according to the cable binding device, the cable connector can move along with the movement of the cable connector, follow-up type pressing is carried out, a binding belt can be rapidly pressed after binding, the cable connector can be supported, and the cable binding device can adapt to various sizes.

Owner:徐州嘉农农业发展有限公司

A vertical screw squeeze juice extractor

The invention discloses a vertical screw extruding juice extractor, comprising a motor base, and a motor, an extrusion screw, a squeezing cavity, and an upper cover in the motor base. The squeezing cavity is cooperated with the extrusion screw to extrude materials, and the upper cover is arranged on the squeezing cavity. The squeezing cavity is arranged on the motor base. The extrusion screw is arranged in the squeezing cavity. The upper cover is provided with a holding portion which protrudes upward and is used to hold the extrusion screw. The side wall of the holding portion is provided with a feed port and a feeding channel connected with the feed port. The included angle between the connecting line of the geometric centers of the two ports of the feeding channel and a vertical plane is a, and 30 DEG <= a <= 60 DEG, so that materials can rapidly and directly enter the holding portion through the feeding channel by gravity of the materials, and under downward guiding action of a material propulsion portion which is on the position corresponding to the feed port, the materials are rapidly brought in a juicing gap formed by an extrusion grinding portion of the extrusion screw and the squeezing cavity, and the materials are squeezed. The vertical screw extruding juice extractor easily realizes rapid automatic feeding.

Owner:JOYOUNG CO LTD

A metal pipe cutting device

ActiveCN110315129BAvoid damageImprove cutting accuracyTube shearing machinesShearing machine accessoriesFeeding forcePipe fitting

The invention discloses a metal pipe fitting cutting device which comprises a cutting mechanism, a first clamping mechanism, a second clamping mechanism, a feeding mechanism and a rack. The first clamping mechanism comprises a bidirectional screw rod, a support seat, a second base and a clamping part; the second clamping mechanism comprises a rotary supporting bearing, a triangular fixed frame, aclamping tooth block, a connecting pillar, a supporting seat, a pinion, a locking stud, a locking block, a second motor, a sliding plate, a positioning stud and a bolt. In the cutting process, a metalpipe fitting rotates through the second clamping mechanism, and cutting points on the metal pipe fitting are ceaselessly changed during circumferential movement, so that the occurrence of the phenomena of throats and burrs caused by notch heat deformation and a unidirectional cutting feeding force is retarded. Through a combined clamping manner of the first clamping mechanism and the second clamping mechanism, only the degree of freedom of the metal pipe fitting rotating around a center shaft is kept, so that the metal pipe fitting cannot produce radial runout, and the cutting accuracy is improved.

Owner:HEBEI UNIV OF TECH

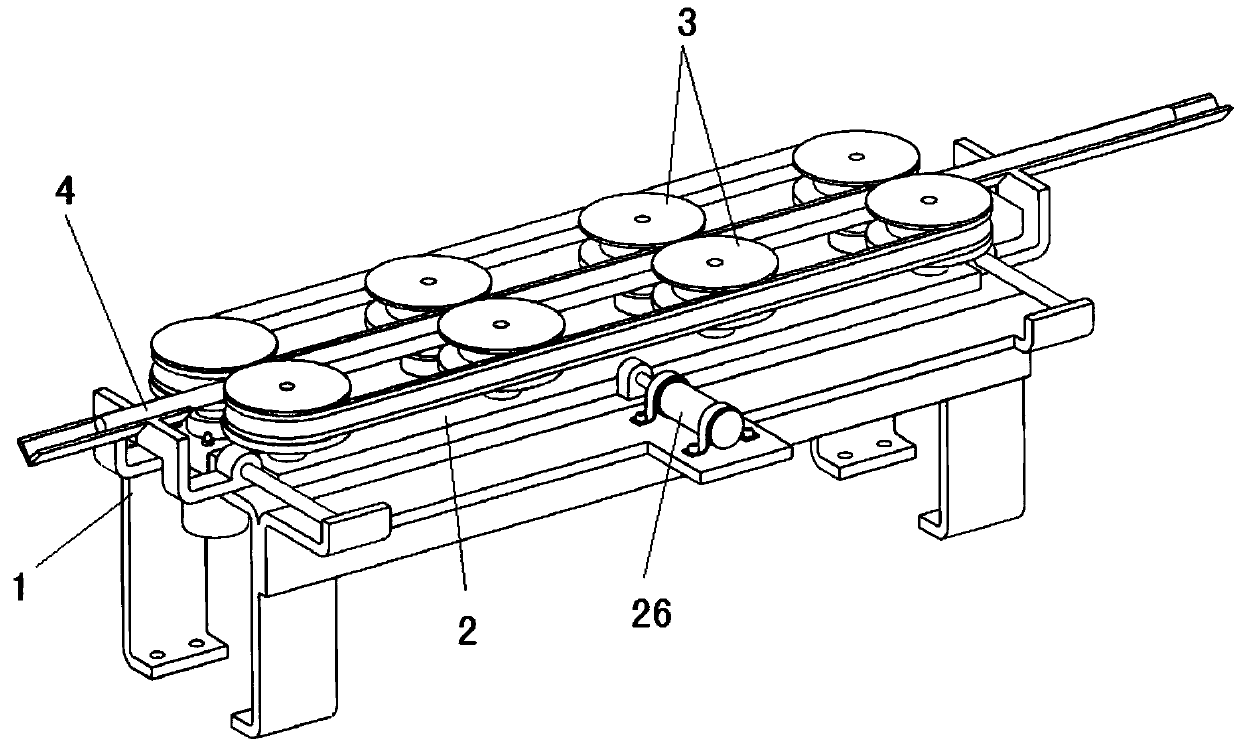

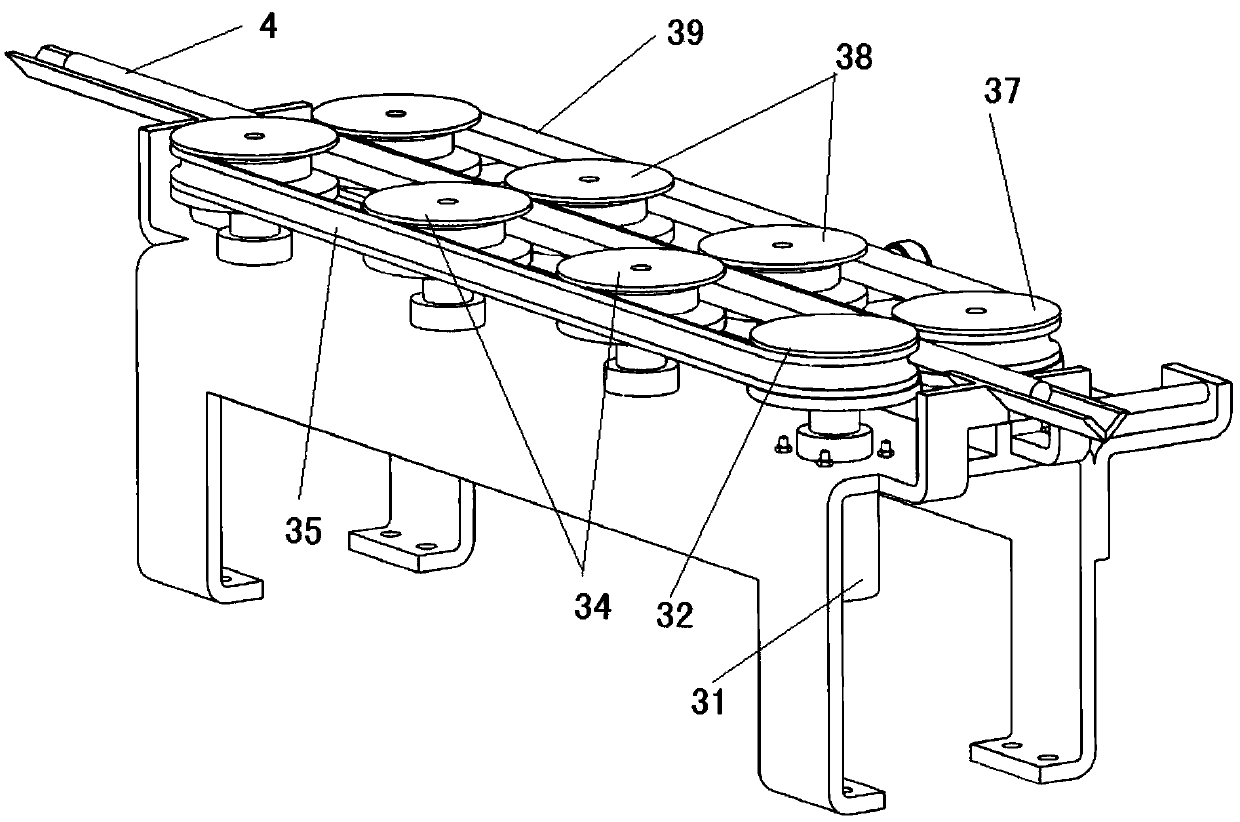

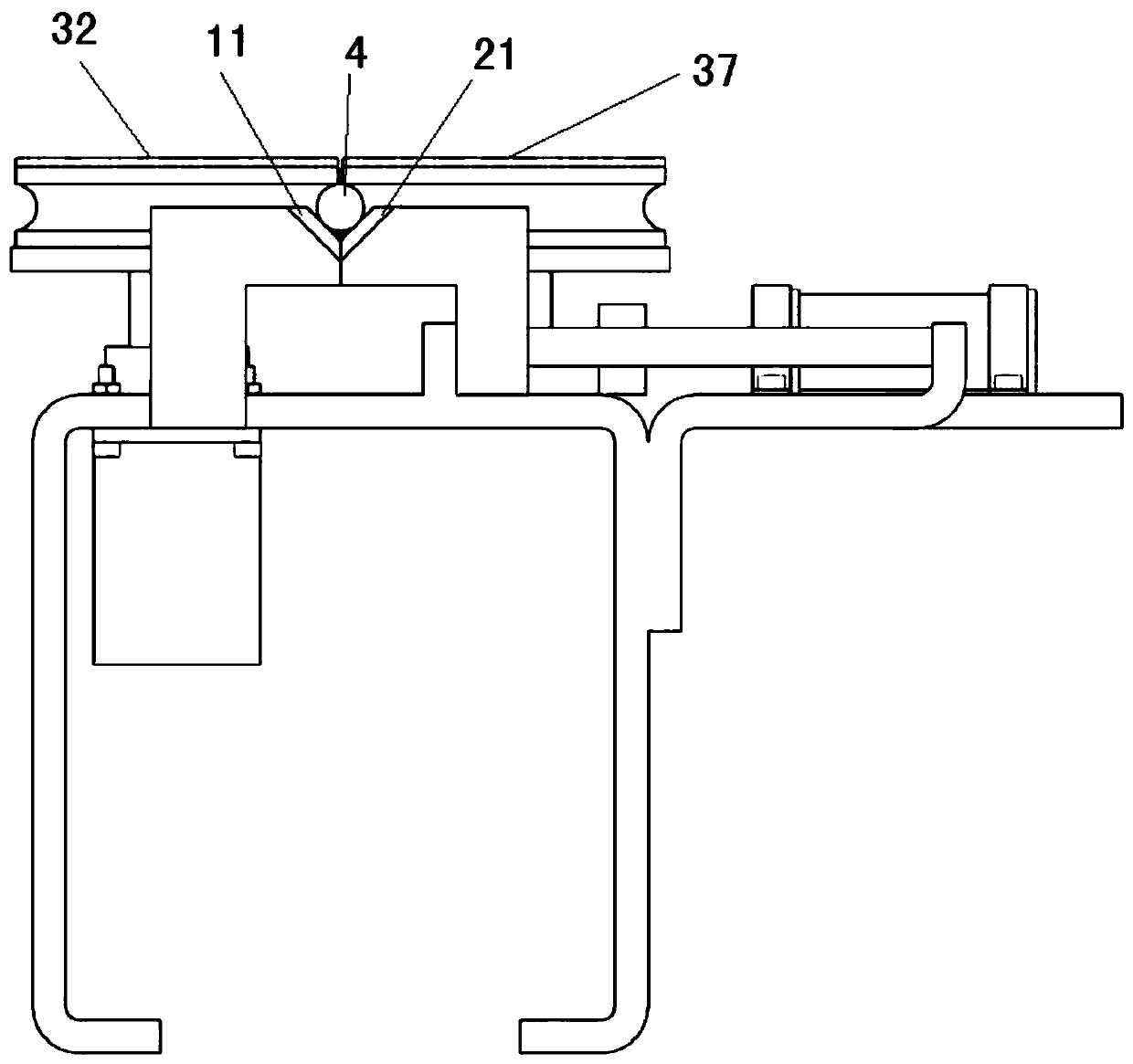

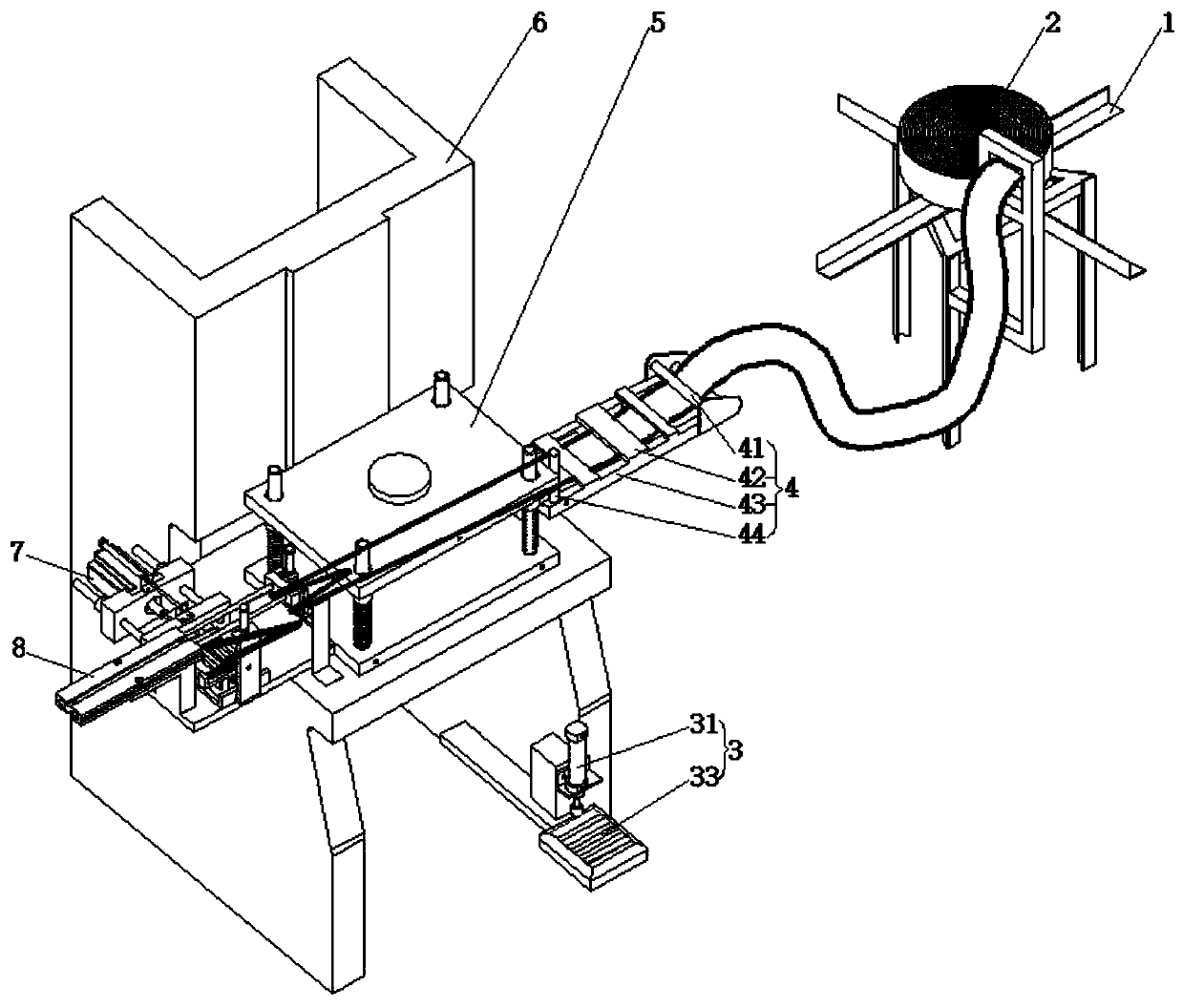

A rubber hose conveying and blanking device

ActiveCN106429182BWill not bendImprove delivery efficiencyConveyorsMetal working apparatusEngineeringMechanical engineering

The invention discloses a rubber tube conveying and discharging device which comprises an installation table, a movable discharging mechanism and a belt conveying mechanism. The movable discharging mechanism and the belt conveying mechanism are installed on the installation table. The movable discharging mechanism comprises a movable table and an air cylinder connected with the movable table and used for driving the movable table to do left-right reciprocating movement. The belt conveying mechanism comprises a first belt conveying assembly and a second belt conveying assembly which are arranged side by side in a left-tight mode. The first belt conveying assembly is installed on the installation table, the second belt conveying assembly is installed on the movable table, and the first belt conveying assembly and the second belt conveying assembly can clamp and convey a rubber tube when being close to each other. The rubber tube conveying and discharging device is simple in structure, convenient to operate and capable of achieving automatic conveying on the premise that the rubber tube is not bent or deformed, has the advantages that conveying is precise and discharging is rapid after conveying is finished, greatly improves rubber tube conveying efficiency and has a quite high using value and popularization potential.

Owner:GUANGXI UNIV

Full-automatic tapping unit

PendingCN105904041AFast loadingFast blankingThread cutting feeding devicesThread cutting machinesEngineeringMechanical engineering

The invention discloses a full-automatic tapping unit which comprises a machine head assembly, a clamp, a supporting plate device and a guide rail device. The machine head assembly comprises a motor, a gear transmission device, an upper machine base, a lower machine base, a plurality of transmission rods and screw taps corresponding to the transmission rods in number. The clamp comprises a clamp cylinder, a first connecting rod mechanism, a first linkage rod, a pressing strip and two first linkage rod seats. The two ends of the first linkage rod are connected with the two first linkage rod seats correspondingly through bearings, the pressing strip is fixed to the middle of the first linkage rod, and the tail end of the first connecting rod mechanism and the end of the first linkage rod are fixed. The clamp cylinder drives the first connecting rod mechanism so as to enable the pressing strip to clamp or release a workpiece to be machined. The supporting plate device comprises a supporting plate, a supporting plate cylinder, a second connecting rod mechanism, a second linkage rod and two second linkage rod seats. The supporting plate is fixed to the middle of the second linkage rod, the tail end of the second connecting rod mechanism and the end of the second linkage rod are fixed, and the supporting plate cylinder drives the second connecting rod mechanism.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

Tapping machine

InactiveCN106466746AFast loadingFast blankingThread cutting feeding devicesThread cutting machinesEngineeringMechanical engineering

The invention discloses a tapping machine. The tapping machine comprises a machine head assembly, a fixture, a support plate device and a guide rail device; the machine head assembly includes a motor, a stand and a screw tap; the motor is fixed on the stand; the screw tap is driven by the motor; the fixture includes a fixture cylinder, a first connecting rod mechanism, a first linkage rod, a pressing bar and two first linkage rod bases; two ends of the first linkage rod are respectively connected with the two first linkage rod bases through bearings; the pressing bar is fixed at the middle part of the first linkage rod; the tail end of the first connecting rod mechanism is fixed with the end part of the first linkage rod; the fixture cylinder drives the first connecting rod mechanism to enable the pressing bar to clamp or loosen a workpiece to be machined; the support plate device includes a support plate, a support plate cylinder, a second connecting rod mechanism, a second linkage rod and two second linkage rod bases; two ends of the second linkage rod are respectively connected with the two second linkage rod bases; the tail end of the second connecting rod mechanism is fixed with the end part of the second linkage rod; and the support plate cylinder drives the second connecting rod mechanism.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

Rapid winding device of special synthetic paper for COVID-19 test kits

The invention discloses a rapid winding device of special synthetic paper for COVID-19 test kits, and relates to the technical field of synthetic paper production and processing equipment. The rapid winding device comprises supports and further comprises a conveying assembly, a cutting assembly, a winding assembly and an unloading assembly. The conveying assembly and the winding assembly are rotationally installed between the oppositely arranged supports, so as to convey synthetic paper to a winding part for winding; in the winding process, the thickness of material wound around the surface of a winding roller is monitored through a thickness monitoring device in a control assembly; when the thickness of the wound material reaches a rated value, the control assembly controls the cutting assembly to cut the conveyed synthetic paper through a control circuit, meanwhile, the conveying assembly is controlled to stop conveying, a pushing assembly is started to push a discharging ring to move on the surface of the winding roller, and the special synthetic paper for the COVID-19 test kits wound on the surface of the winding roller is separated from the winding roller under the thrust action of the discharging ring, so that rapid winding and discharging are realized, manual stripping is not needed, the safety is higher, and the production efficiency is ensured.

Owner:阜阳市尤美新材料科技有限公司

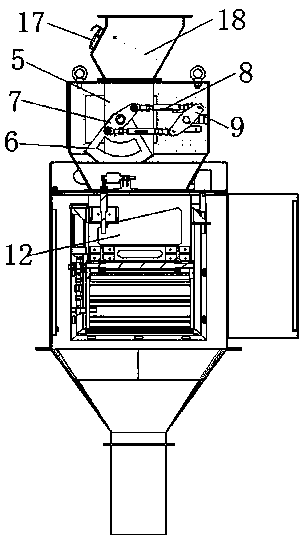

Single-servo full open weighing device

ActiveCN109987343AEasy to adjustQuick responseLarge containersWeighing apparatus detailsCouplingReducer

The invention discloses a single-servo full open weighing device. The single-servo full open weighing device comprises a feed hopper, an adjustment chamber, an operation cabinet and a discharge chamber. The adjustment chamber is located between the feed hopper and the operation cabinet. The operation cabinet is located between the adjustment chamber and the discharge chamber. A slow storage chamber communicating with the feed hopper is arranged in the adjustment chamber. The two sides of the slow storage chamber are movably connected with circular arc-shaped sealing doors through rotary shafts. The circular arc-shaped sealing doors are matched with the bottom end the slow storage chamber. Each rotary shaft is sleeved with a first rotary sheet. The two ends of the first rotary sheet are movably connected with servo connection synchronous rods correspondingly. One ends of the servo connection synchronous rods are connected with the second rotary sheet. The second rotary sheet is connected to a bipolar speed reducer arranged on one side of the adjustment chamber through a coupling. The bipolar speed reducer is connected with a servo motor. The single-servo full open weighing device has the advantages of being high in response speed, accurate in discharge control, more remarkable in sealing control, faster in discharge and higher in production efficiency.

Owner:安徽步乐自动化设备有限公司

A new type of coil spring system

ActiveCN106734441BRealize automated productionIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressCoil spring

The invention discloses a novel spring coiling system, and belongs to the field of specially-shaped spring processing. The novel spring coiling system comprises a working platform and further comprises a feeding mechanism, a forming mechanism and a spring coiling mechanism, wherein the feeding mechanism comprises a material frame, a feeder and a feeding machine; the feeder and the feeding machine are separately arranged at the two ends of the working platform; the forming mechanism comprises a blanking mould and a punching machine; the blanking mould and the punching machine are positioned on the middle part of the working platform; the spring coiling mechanism comprises a spring coiling machine which is matched with the feeding machine to work; coiled materials are arranged on the material frame; the coiled materials are transmitted to a blanking station through the feeder, and the coiled materials on the blanking station are prepared into a coil spring semi-finished product through the forming mechanism; the coiled spring semi-finished product is transmitted to a spring coiling station through the feeding machine; the coil spring semi-finished product on the spring coiling station is processed into a coil spring finished product; and the working platform is further equipped with a control unit. The novel spring coiling system can realize automatic production of coil springs; and the scheme obviously improves production efficiency, product quality and consistency.

Owner:中山市鹏耀五金制品有限公司

An automatic box sorting machine

ActiveCN112693682BBox implementationImprove box efficiencyConveyorsPackagingEngineeringMechanical engineering

The invention provides an automatic box sorting machine, which belongs to the technical field of machinery. It includes: a transmission mechanism for transporting stacked lunch boxes, the two ends of the transmission mechanism are respectively a feed end and a discharge end; a box-dividing mechanism is arranged obliquely below the discharge end, and the box-dividing mechanism includes a shell, and The sub-box assembly installed in the casing, wherein the casing is provided with a receiving end for receiving stacked lunch boxes on the discharge end and a blanking end for outputting a single lunch box, and the sub-box assembly is located at the receiving end Between the blanking end, the box divider assembly includes box dividers corresponding to the four corners of the lunch box, and each box divider is provided with a box divider for separating the upper and lower adjacent lunch boxes; One side of the box mechanism is provided with a drive mechanism, and the output end of the drive mechanism drives each box divider to rotate synchronously. An automatic box sorting machine provided by the invention realizes the automatic box sorting of lunch boxes, thereby improving the efficiency of box sorting.

Owner:ZHEJIANG XIANGYING CENT KITCHEN EQUIP CO LTD

Punching and trimming type single punching die for automobile brake disc brake wheel

InactiveCN112264530AImprove securityFast blankingShaping toolsMetal-working feeding devicesStampingGear wheel

The invention discloses a punching and trimming type single stamping die for an automobile brake disc brake wheel, and relates to the technical field of stamping dies. The punching and trimming type single stamping die comprises an upper die base and a lower die base, an upper padding plate is installed on the lower surface of the upper die base, an upper clamping plate is installed on the lower surface of the upper padding plate, a stopping plate is arranged on the lower side of the upper clamping plate, an upper die plate is installed on the lower surface of the stopping plate, and a stamping head is further installed in the center of the upper die base. According to the punching and trimming type single stamping die, a lifting plate, a first connecting frame and a movable die are used,when the upper die base rises, the lifting plate enables a sliding rod to push the movable die, and the movable die is made to be away from the stamping head, so that the safety is higher when a worker takes a workpiece; and a second connecting frame, a rack, a gear and a spiral roller are used, after a stamping stub bar enters a falling groove, a part of burrs are possibly accumulated in the falling groove, at the moment, the second connecting frame is driven by the movable die to slide, and then the second connecting frame drives the spiral roller to rotate through the action of the rack andthe gear, the burrs are cut, rapid falling is achieved, and blocking is avoided.

Owner:烟台美丰机械集团有限公司

Combination method and device for charged crushing of waste lithium-ion power batteries

ActiveCN112820968BShort stayFast blankingSolid waste disposalTransportation and packagingPower batteryElectrical battery

The invention provides a combined method and device for charged crushing of waste lithium-ion power batteries, which is to put waste lithium-ion power batteries into the inner chamber of the first crusher with an open bottom outlet through a feeding platform, so that the batteries are sheared and shredded for pretreatment into coarse Then the battery coarse material is quickly dropped into the corrosion-resistant water tank docked with the discharge port of the first crusher, so that the battery coarse material will fail under immersion in water; the battery coarse material falling in the water tank is soaked in the The conveyor belt in the water tank is sent to the belt dryer, and the conveyor belt set in the drying chamber of the belt conveyor is dried at the same time as it is transferred, and then sent to the second crusher for further crushing into fine materials. The invention adopts coarse crushing pretreatment and water immersion to protect the safety of lithium battery crushing, eliminates potential safety hazards in the processing process, and avoids the disadvantage of being unable to sort due to overhumidity of materials through subsequent drying, which is safe and reliable , high degree of automation, no waste water outflow, effectively avoiding environmental pollution.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Tram silk chain manner material dropping mechanism of welding machine of mesh

ActiveCN101244501BStable blankingHigh speedWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftDrive motor

The invention discloses a chain blanking device of tram for a welding machine of mesh, wherein, a round magnetic drum is arranged below a square magnetic drum; a slide carriage is arranged between the square magnetic drum and one side of the round magnetic drum; the first drive sprockets of a fixed chain transport device and a shift chain transport device are fixed on the same drive shaft; one end of the drive shaft is connected with the driving motor of a carrier chain and the other end is hold by a frame; the first driven sprockets of two fixed chain transport devices are arranged on the drive shaft; a pusher dog disk and the second driven sprocket are arranged on the pusher dog shaft; an inner hole of the pusher dog shaft is intermittently sleeve-arranged on the drive shaft; the seconddrive sprocket connected to the second driven sprocket is arranged on the pusher dog shaft. The chain blanking device of tram has the advantages that the tram blanking can be steady, orderly and accurate with the transport hook of the transport device; the shift chain transport device can shift synchronously in lateral direction, so as to adapt to the tram with different lengths; the blanking process has good balance performance, and the productivity of the welding mesh is improved.

Owner:TJK MACHINERY TIANJIN

Blanking mechanisms of pressing pin head part molding progressive die

InactiveCN103128177APlay the role of free fallSimple structureShaping toolsEjection devicesEngineeringMechanical engineering

Owner:CHANGZHOU INST OF LIGHT IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com