A new type of coil spring system

A new type of coil spring technology, applied in feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of not giving technical enlightenment on the production efficiency, product quality and consistency of coil springs, to ensure safety and reliability. Fluency, simple and practical structure, ensuring the effect of working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

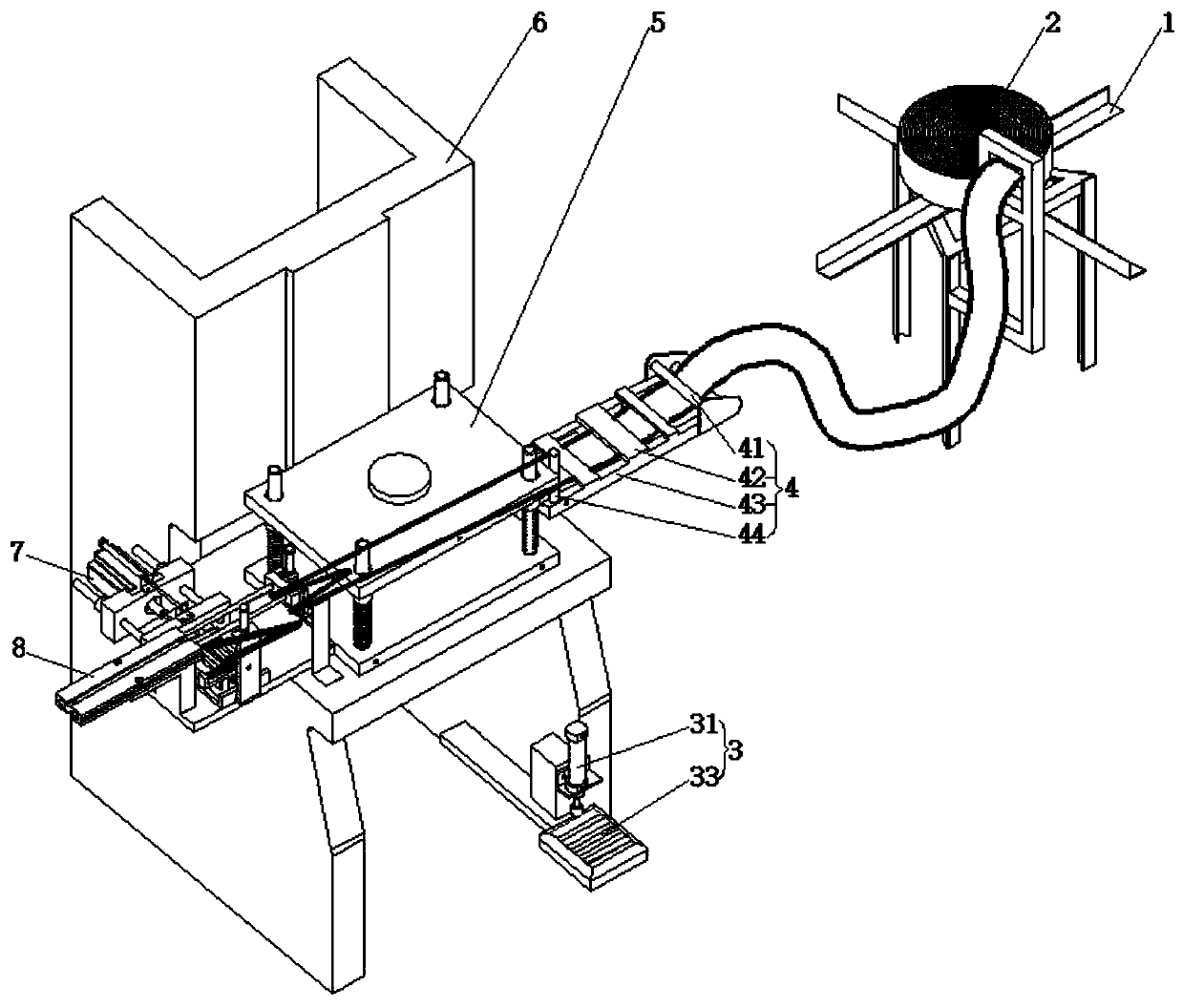

[0037] Embodiment 1, a kind of novel coil spring system, as figure 1 As shown, it includes a working platform, and also includes a feeding mechanism, a forming mechanism and a coil spring mechanism. The feeding mechanism includes a material rack 1, a feeder 4 and a feeder 8, and the feeder 4 and the feeder 8 are respectively arranged in the working position. two ends of the platform; the molding mechanism includes a blanking die 5 and a punch 6, and the blanking die 5 and the punch 6 are located in the middle of the working platform; the coil spring mechanism includes a coil spring machine 7, and the coil spring machine 7 is connected with the feeding The machine 8 cooperates to work; the coil material 2 is placed on the material rack 1, and the coil material 2 is transferred to the blanking station through the feeder 4, and the coil material 2 of the blanking station is made into a coil spring by a forming mechanism The semi-finished product, the coil spring semi-finished pro...

Embodiment 2

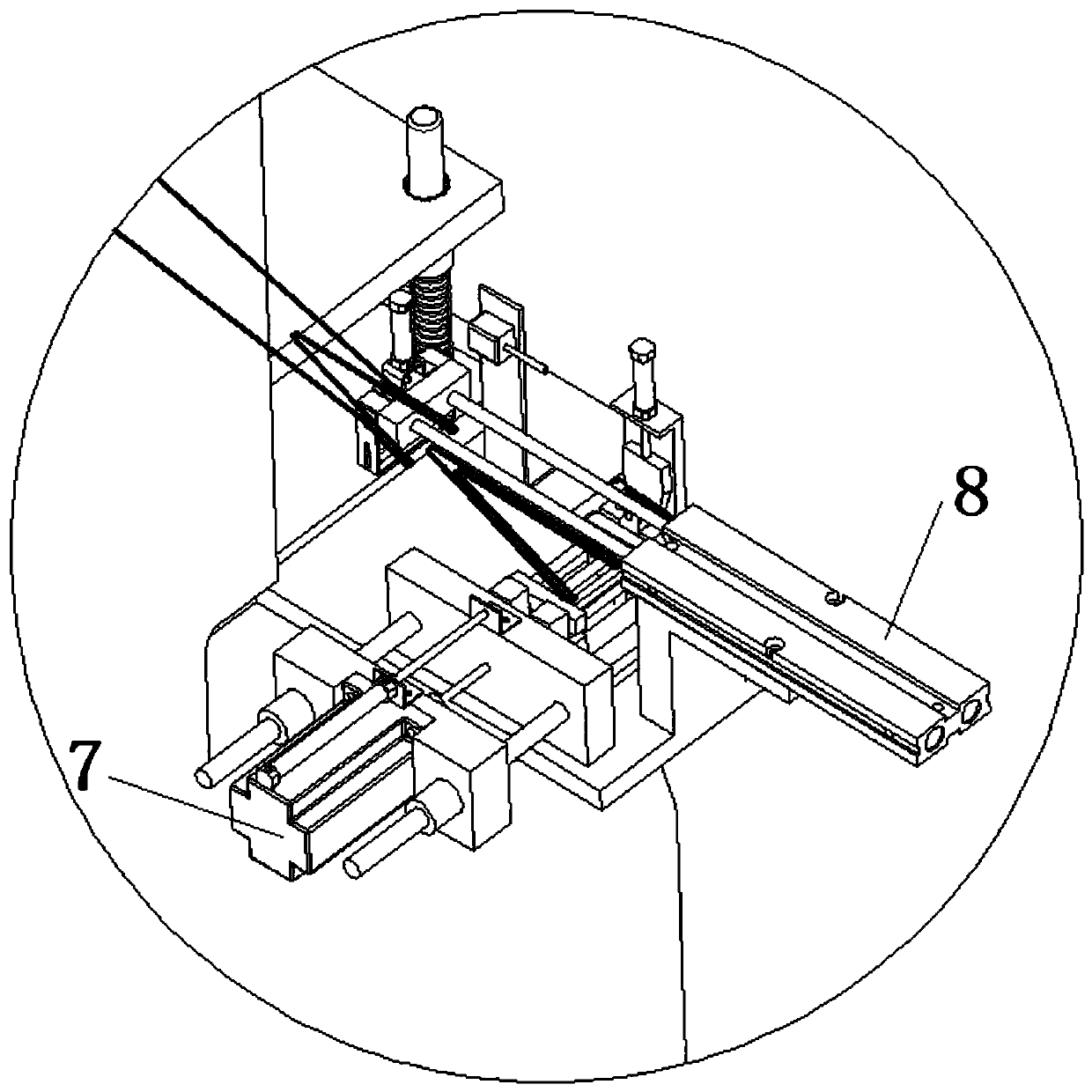

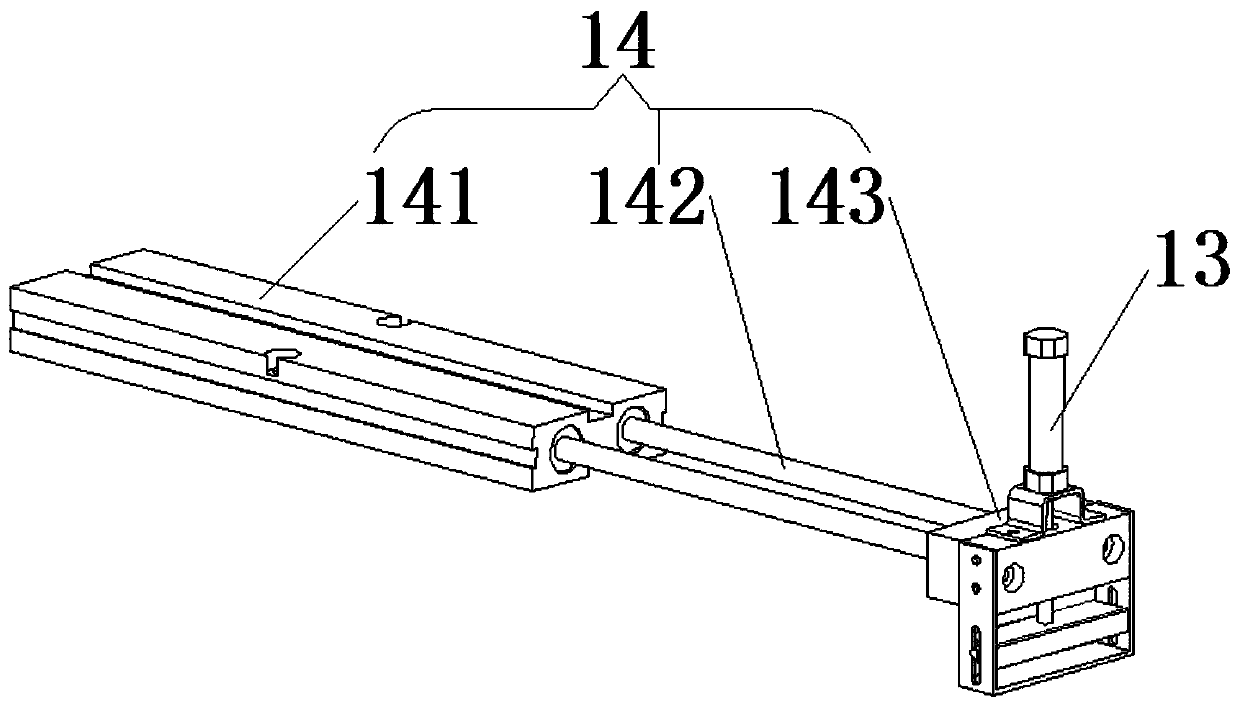

[0038] Embodiment 2, a kind of novel coil spring system, as Figure 1 to Figure 4 As shown, it includes a working platform, and also includes a feeding mechanism, a forming mechanism and a coil spring mechanism. The feeding mechanism includes a material rack 1, a feeder 4 and a feeder 8, and the feeder 4 and the feeder 8 are respectively arranged on the working platform. two ends; the forming mechanism includes a blanking die 5 and a punch 6, and the blanking die 5 and the punch 6 are located in the middle of the working platform; the coil spring mechanism includes a coil spring machine 7, and the coil spring machine 7 is connected with a feed 8 Cooperate with the work; the coil material 2 is placed on the material rack 1, and the coil material 2 is transferred to the blanking station through the feeder 4, and the coil material 2 of the blanking station is made into a coil spring semi-finished product by a forming mechanism , the coil spring semi-finished product is conveyed t...

Embodiment 3

[0040] Embodiment 3, a kind of novel coil spring system, as figure 1 , figure 2 , Figure 5 and Image 6 As shown, it includes a working platform, and also includes a feeding mechanism, a forming mechanism and a coil spring mechanism. The feeding mechanism includes a material rack 1, a feeder 4 and a feeder 8, and the feeder 4 and the feeder 8 are respectively arranged on the working platform. two ends; the forming mechanism includes a blanking die 5 and a punch 6, and the blanking die 5 and the punch 6 are located in the middle of the working platform; the coil spring mechanism includes a coil spring machine 7, and the coil spring machine 7 is connected with a feed 8 Cooperate with the work; the coil material 2 is placed on the material rack 1, and the coil material 2 is transferred to the blanking station through the feeder 4, and the coil material 2 of the blanking station is made into a coil spring semi-finished product by a forming mechanism , the coil spring semi-fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com