Tapping machine

A technology for a tapping machine and a machine base, which is applied in the field of tapping machines, can solve the problems of unfavorable processing of workpieces to be processed, increased labor costs, low production efficiency, etc., and achieves the effects of simple structure, high production efficiency, and fast feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

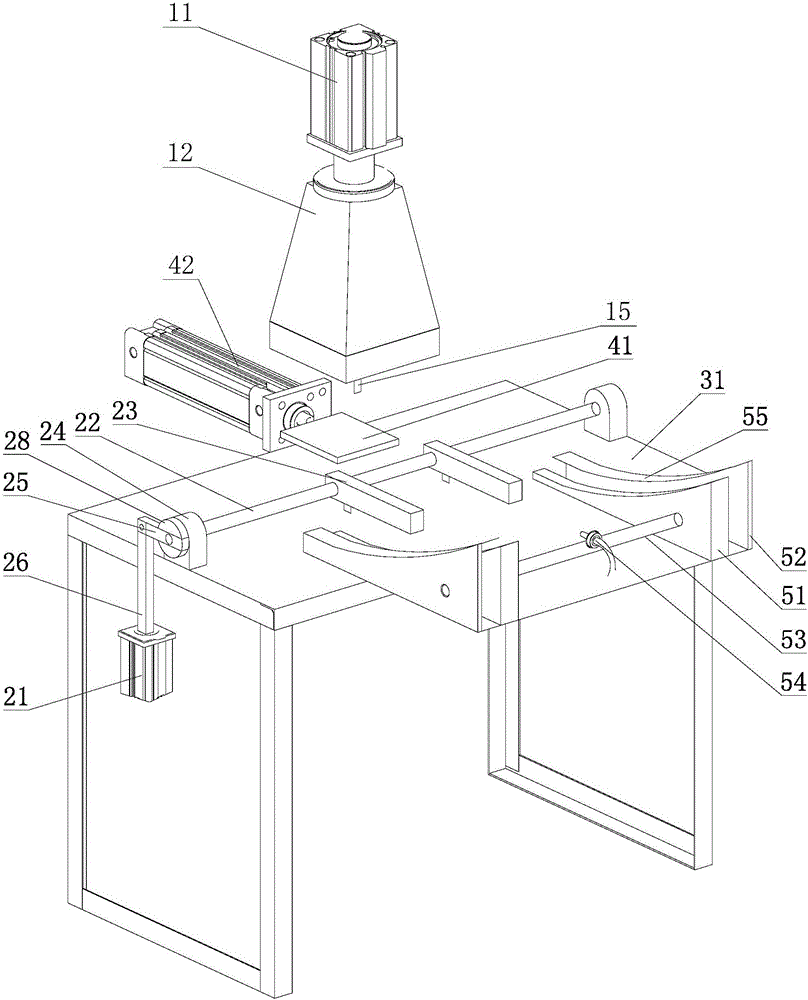

[0014] Such as figure 1 As shown, the tapping machine includes a head assembly, a clamp, a support plate device and a guide rail device, and the head assembly includes a motor 11, a support 12 and a tap 15, and the motor is fixed on the support, The tap is driven by the motor, and the clamp includes a clamp cylinder 21, a first linkage mechanism, a first linkage rod 22, a bead 23 and two first linkage rod seats 24, and the clamp cylinder and the first linkage rod The seats are respectively fixed on the workbench 31, the two ends of the first linkage rod are respectively connected with the two first linkage rod seats through bearings, the bead is fixed on the middle part of the first linkage rod, and the first linkage rod The tail end of a link mechanism is fixed to the end of the first linkage rod, the clamp cylinder drives the first linkage mechanism, and then drives the linkage rod to rotate, thereby clamping or loosening the bead The workpiece to be processed, the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com