A rubber hose conveying and blanking device

A blanking device and hose technology, applied in conveyors, transportation and packaging, metal processing equipment, etc., can solve the problems of slow speed, inability to ensure that the hose is not deformed, low efficiency, etc., to improve conveying efficiency, high use value and Promotion potential, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further non-limiting detail below in conjunction with the embodiments and accompanying drawings.

[0026] 1. The basic structure of a rubber hose conveying and blanking device in this embodiment

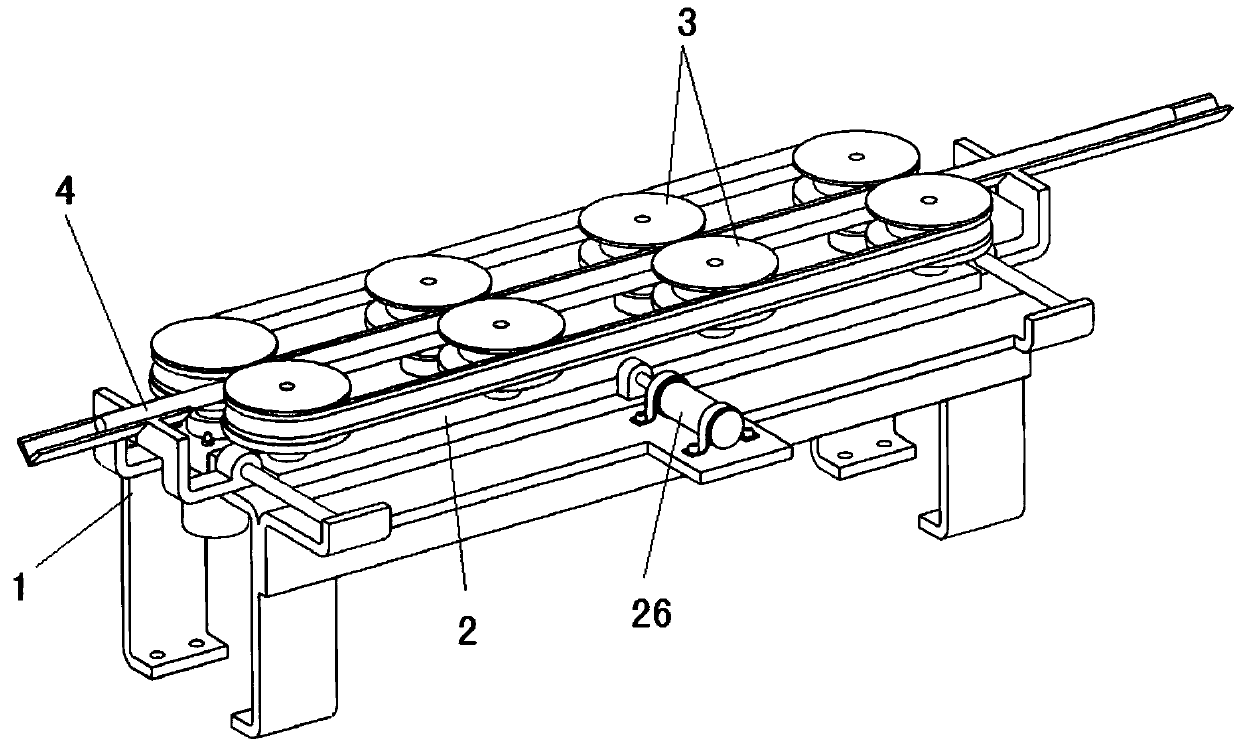

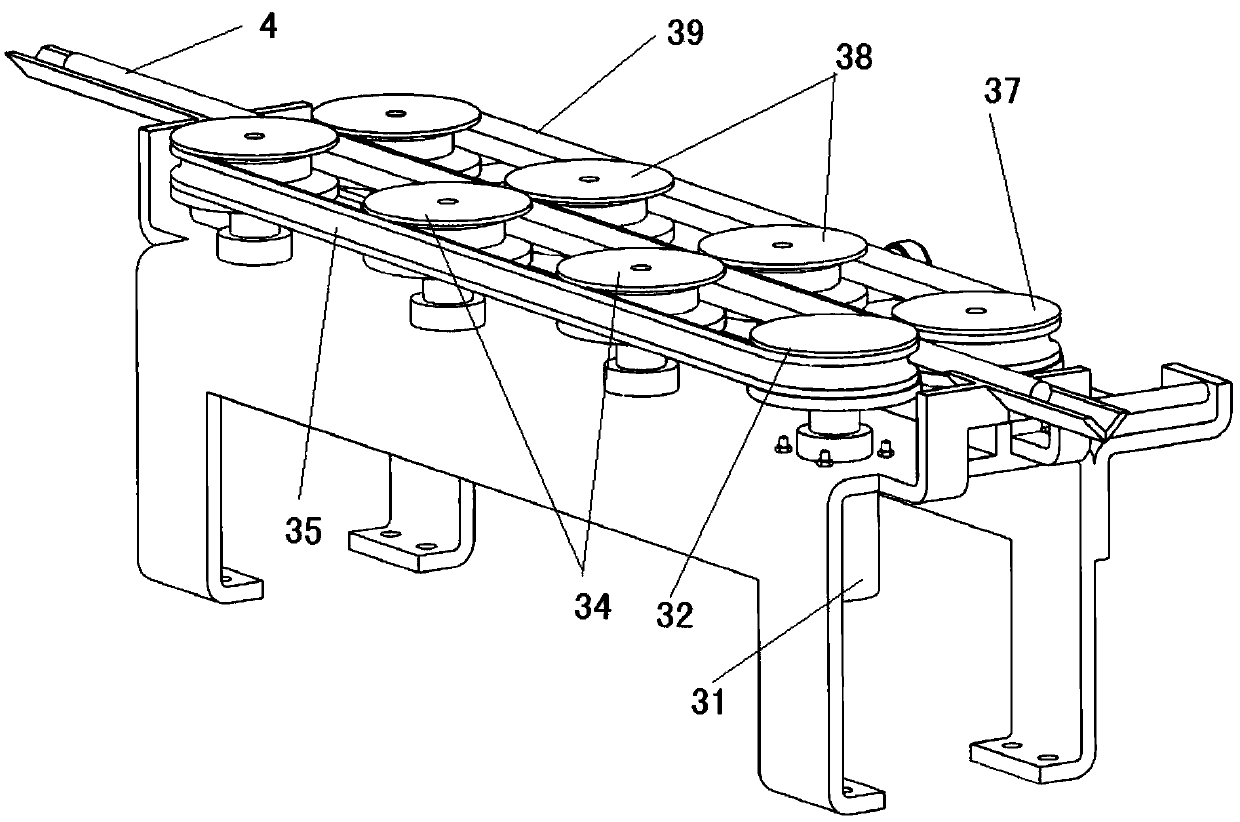

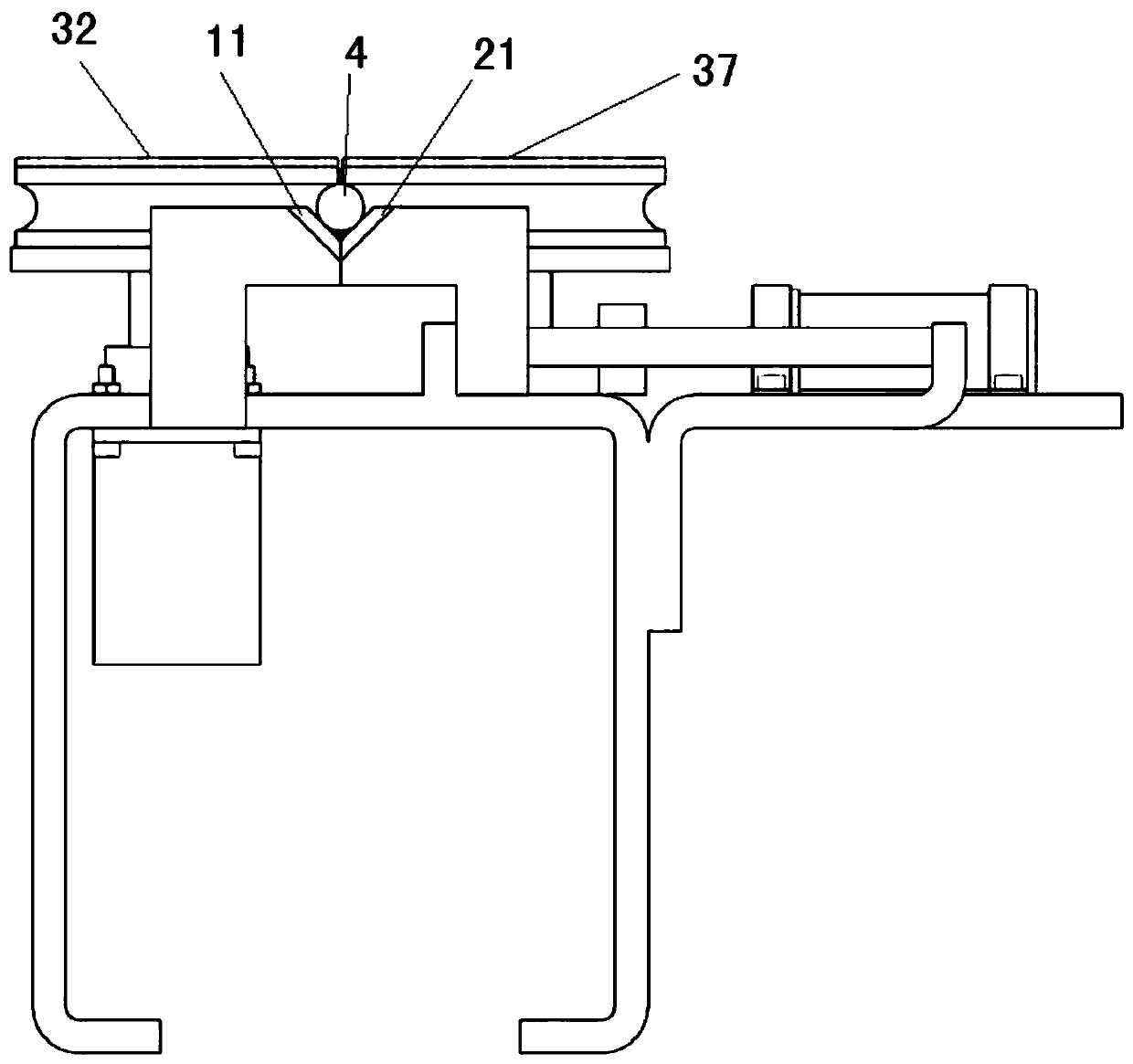

[0027] Such as Figures 1 to 5 As shown, a rubber hose conveying and blanking device includes a mounting platform 1 and a mobile blanking mechanism 2 and a belt conveying mechanism 3 installed on the upper end of the mounting platform.

[0028] The mobile blanking mechanism 2 includes a mobile platform 23, two guide rails 24 respectively fixed on the front and rear ends of the installation platform, two sliders 25 matched with the guide rails, and a cylinder 26 for driving the mobile platform to reciprocate left and right. The mobile platform 23 The two ends are slidably fixed on the guide rail 24 through the slider 25 respectively, and the cylinder 26 is fixed on the installation platform 1 through two clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com