Voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking

A biomass pyrolysis and pneumatic conveying technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of uneven conveying, blockage, instability, etc., and achieve controllable feeding process and avoid racking bridge, avoid labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

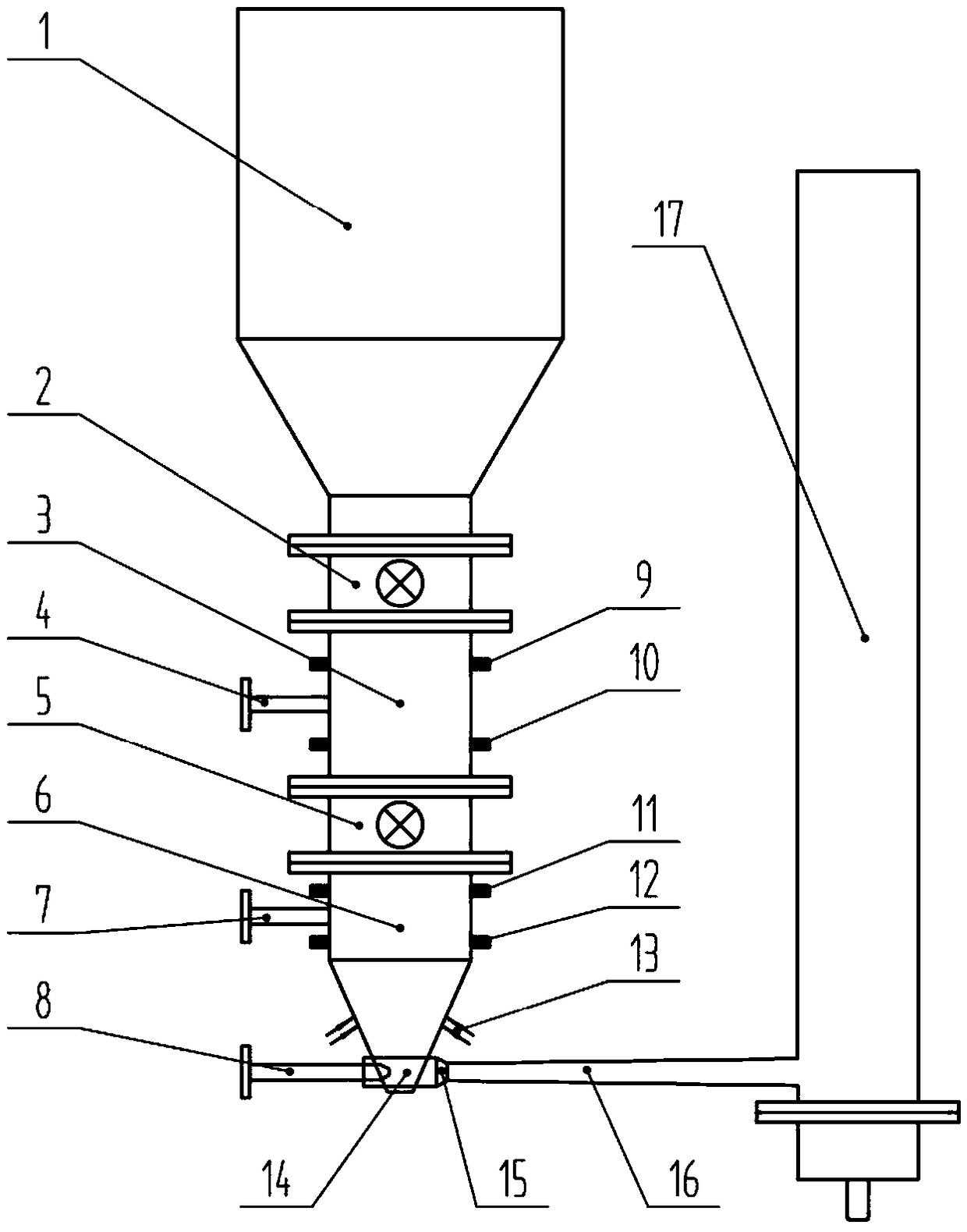

[0019] The steady pressure-continuous pneumatic conveying feeding system that the present invention proposes is used for biomass pyrolysis, and its structure is as follows figure 1 As shown, it includes a storage hopper 1 , a material transition bin 3 , a conical pressure bin 6 and a material receiving chamber 14 . The storage hopper 1, the material transition chamber 3 and the conical pressure chamber 6 are coaxially installed from top to bottom, and the first-stage electric butterfly valve 2 is installed between the storage hopper 1 and the material transition chamber 3 through the flange, the material transition chamber 3 and the conical pressure chamber. Two-stage electric butterfly valves 5 are installed between the warehouses 6 through flanges. A pair of primary laser-photosensitive sensors 9 and a pair of secondary laser-photosensitive sensors 10 are installed on the warehouse wall of the material transition warehouse 3 , and a pressure maintaining pipe 4 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com