Connector intelligent transportation and assembly equipment

A connector and a complete set of technology, applied in the field of automatic assembly line equipment, can solve problems such as damage to the surface quality of connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

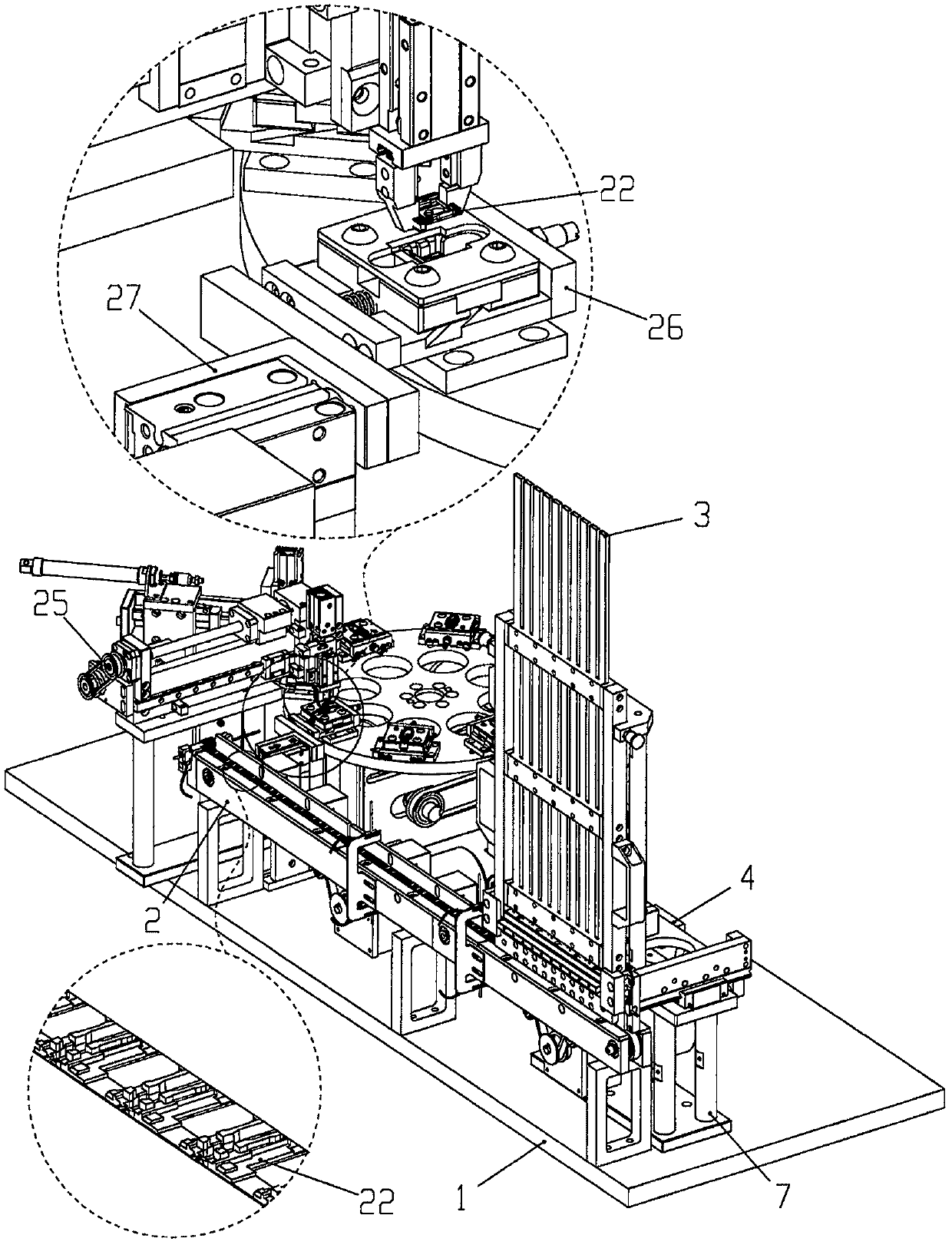

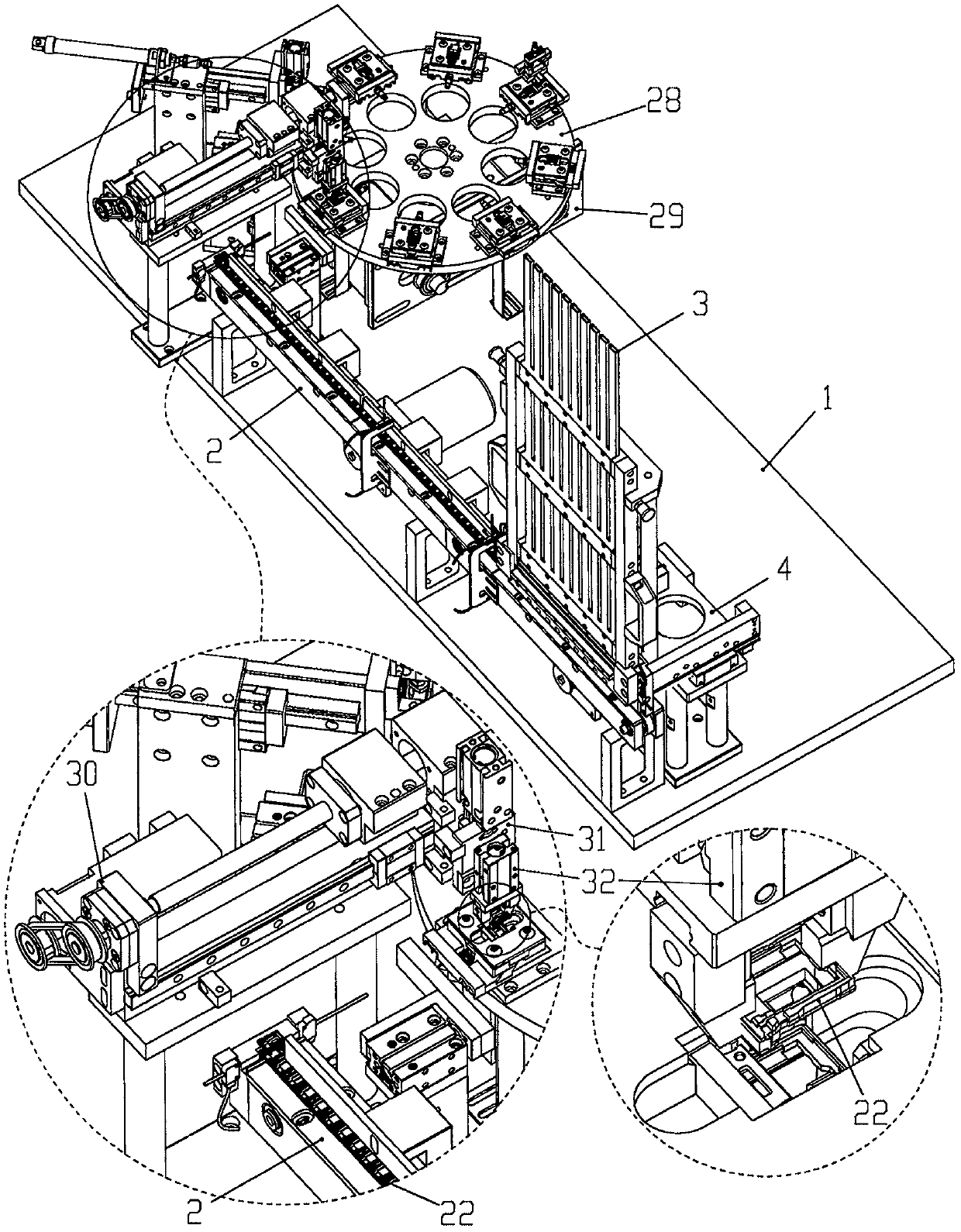

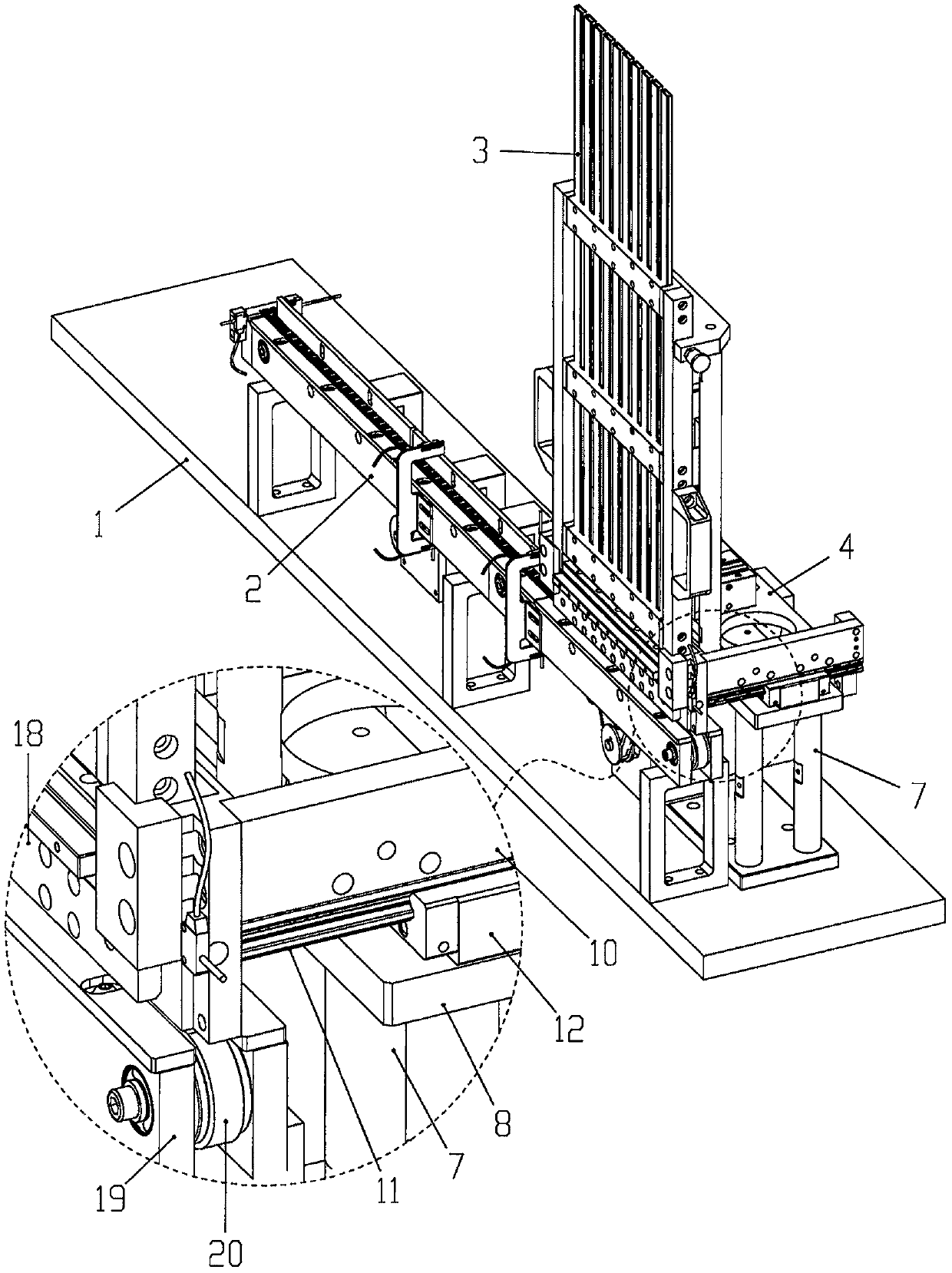

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a complete set of equipment for intelligent transportation and assembly of connectors. In the automatic assembly production of electronic products, the connectors are output to the conveyor belt in an orderly manner, thereby realizing automatic feeding. The feeding robot will The connector is assembled to the automatic clamping mechanism. The complete set of equipment for the intelligent transportation and assembly of the connectors in the present invention realizes the orderly output of the connectors. After the connectors are adjusted to a predetermined angle, they are placed on the conveyor belt, and the movement process of the connectors is guaranteed by the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com