Vertical screw extruding juice extractor

A technology of screw extrusion and juicer, which is applied in household machinery for filtering food, household appliances, applications, etc., and can solve unfavorable disassembly and cleaning of the juicer, affecting extrusion and crushing, and long life loss of the juicer, etc. problem, to achieve the effect of improving juice output efficiency and rate, reducing motor load, and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

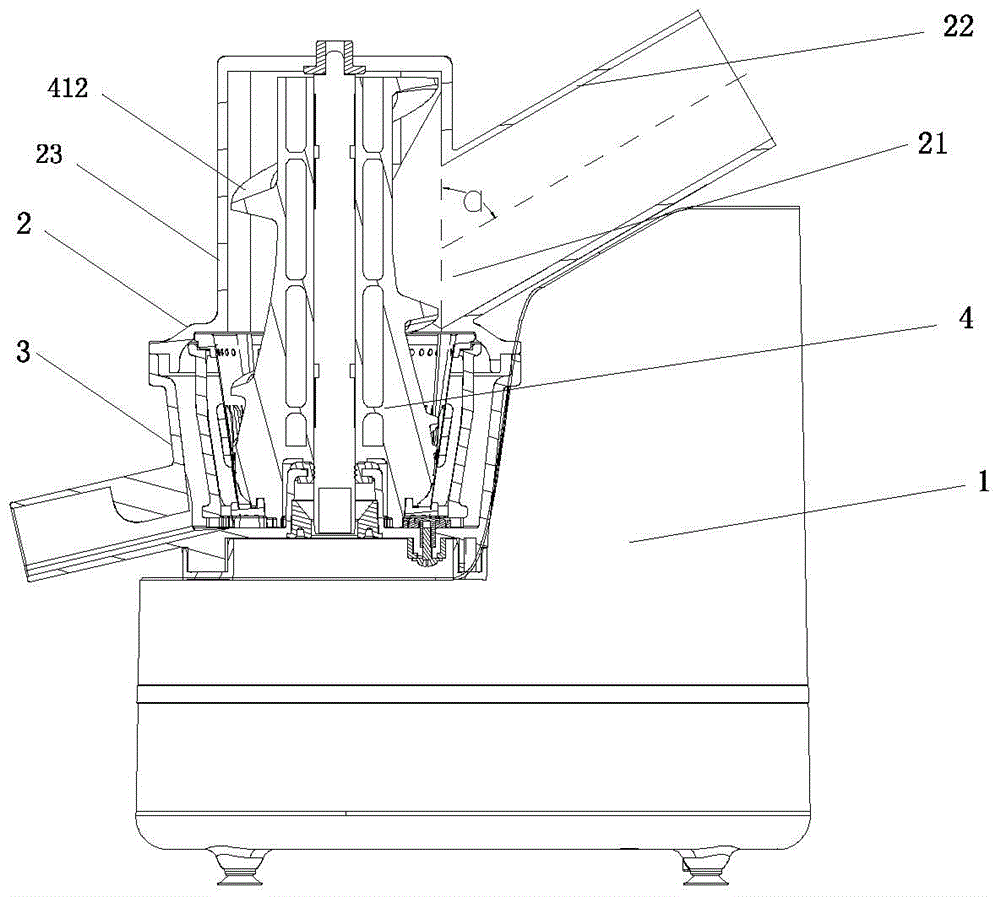

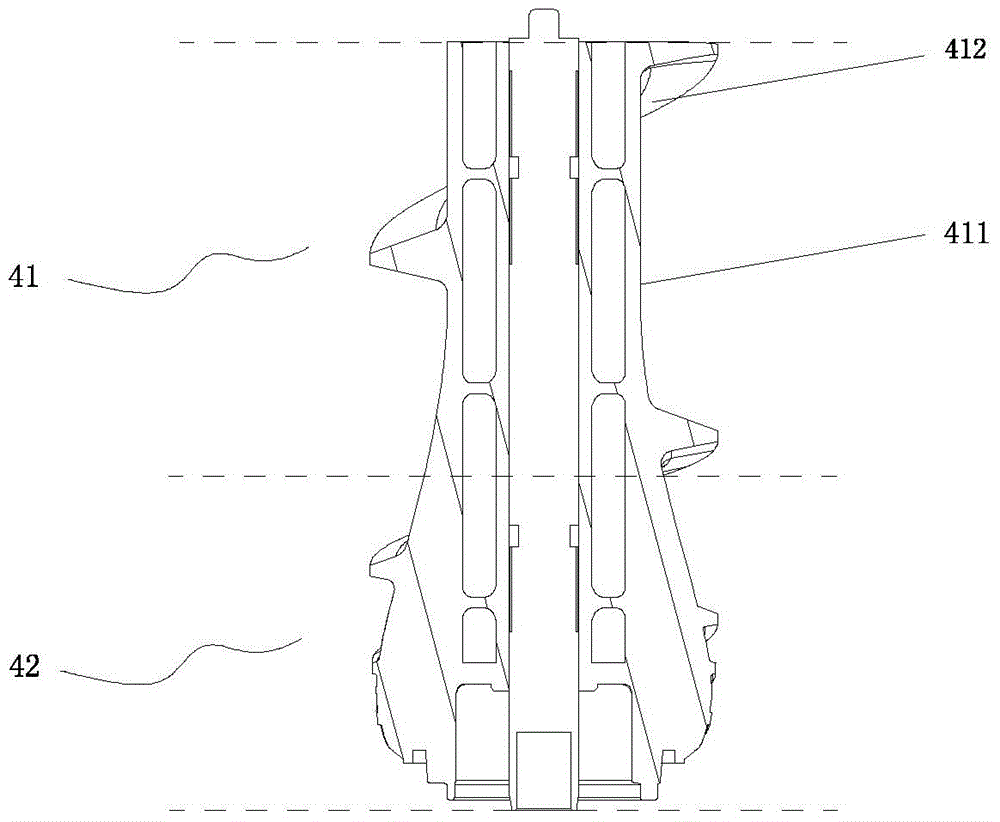

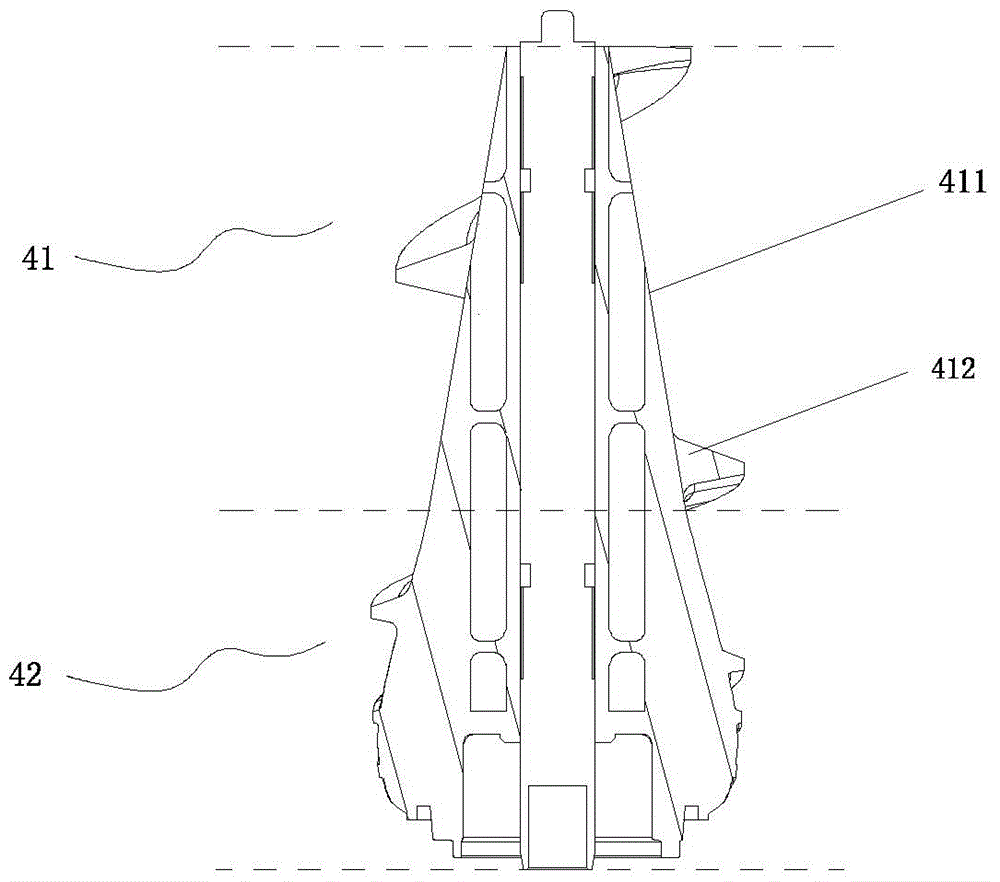

[0040] Such as figure 1 , 2 As shown, the present invention discloses a vertical screw extrusion juicer with fast feeding, including a machine base 1, a motor arranged in the machine base, an extrusion screw 4, and a squeezer that cooperates with the extrusion screw 4 to extrude materials. chamber 3 and the upper cover 2 installed above the pressing chamber 3, the pressing chamber 3 is installed on the machine base 1, the extrusion screw 4 is installed in the pressing chamber 3, and the extrusion screw 4 includes a material propulsion part 41 and extruding grinding part 42, the upper cover 2 is provided with an accommodating part 23 that protrudes upwards and is used to accommodate the upper part of the extruding screw 4. The setting of the accommodating part 23 increases the accommodating space of the material, and the material passes through the feed channel 22 Finally, it enters the accommodation part 23 under the action of gravity to ensure that there is sufficient materi...

Embodiment 2

[0056] Such as Figure 4 , 5 As shown, the difference between this embodiment and Embodiment 1 is that the equivalent diameter range of the feed inlet 21 is 79 mm to 84 mm, and the equivalent diameter range of the accommodating portion 23 is 80 mm to 85 mm. When the effective diameter is less than 79mm, the demand for juicing the whole fruit cannot be fully met. When the equivalent diameter of the feed port 21 is greater than 84mm, the material is easily stuck in the accommodating part 23 after passing through the lower port, and cannot enter the propulsion screw 412 for juicing. , and the equivalent diameter of the feed port 21 is too large to affect the overall appearance of the juice extractor. In this embodiment, the ratio of the equivalent diameter of the feed port to the equivalent diameter of the housing portion is 81 / 82, and the equivalent diameter of the feed port 21 is 81mm. Correspondingly, the feed channel The diameter of the upper port of 22 is also 81mm, and th...

Embodiment 3

[0064] Such as Figure 6 As shown, the difference between the present embodiment and the second embodiment is that the feed channel 22 includes a connecting section 221 and a feeding section 222, and both the connecting section 221 and the feeding section 222 are straight cylindrical. The included angle between the centerline of the connecting section 221 and the vertical plane is a, 30°≤a≤60°, one end of the connecting section 221 is connected to the feeding port 21 , and the other end is smoothly connected to the feeding section 222 . The feeding section 222 is arranged vertically, the upper port of the feeding section is used for feeding materials, and the other end is smoothly connected with the connecting section 221 .

[0065] The feeding section 222 is vertically arranged so that the upper port of the feeding section 222 is in a horizontal position, so that feeding from the vertical direction can better adapt to the user's operating habits, and the feeding is fast and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com