Manufacturing process of comprehensively-glazed ceramic

A preparation process and a comprehensive technology, applied in the field of preparation of fully glazed ceramics, can solve the problems of wasting glaze, reducing the efficiency of dipping glaze, and reducing efficiency, so as to achieve comprehensive glaze application, improve glaze application efficiency, and prevent ceramics from falling or breaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

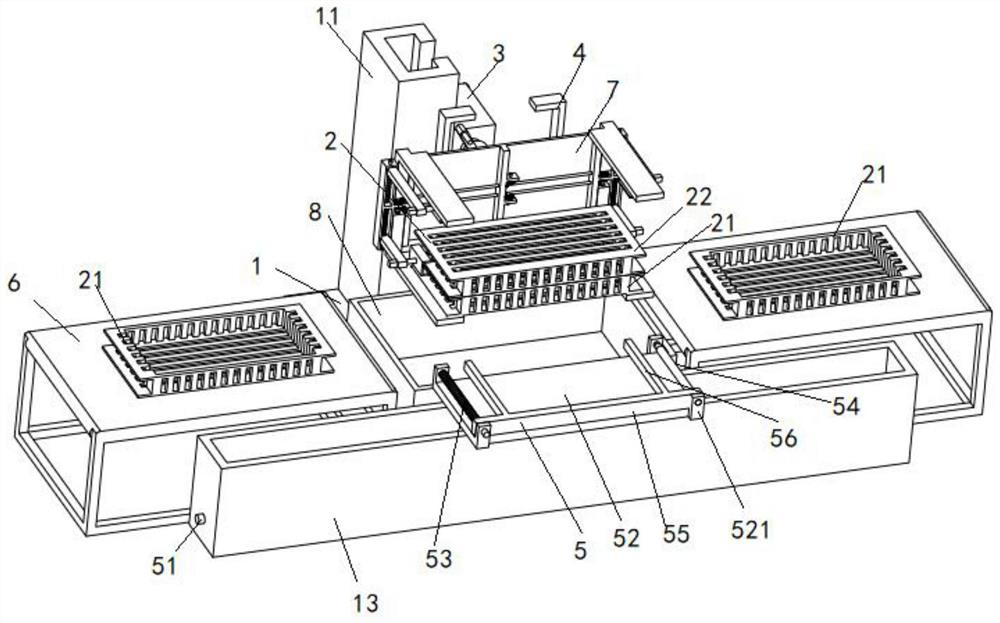

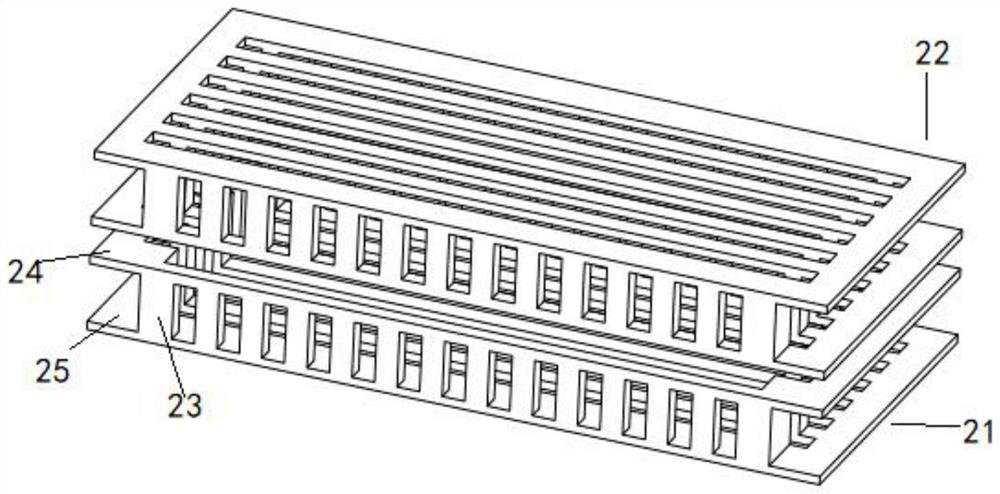

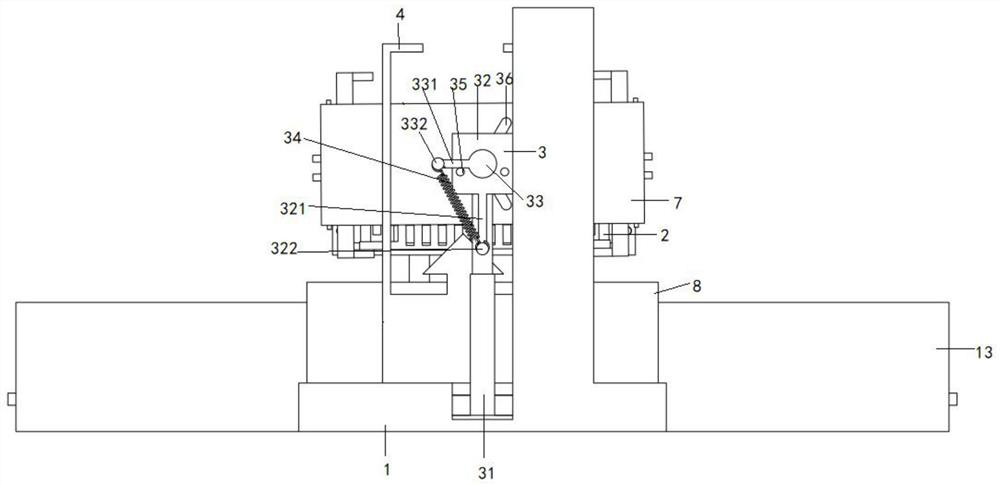

[0032] A preparation process for full-glazed ceramics. During the preparation of ceramics, the ceramics need to be fully glazed, such as Figure 1-4 As shown, the flip-type full-scale glazing device includes a limit-fixed substrate 1 and a bearing frame assembly 2 for holding ceramics. On the surface side of the limit-fixed substrate 1, a lifting and turning mechanism 3 and a positioning component used in conjunction with the lifting and turning mechanism 3 are installed. 4. Through the positioning function of the positioning component 4, the lifting and turning mechanism 3 can be lifted to a certain height and then turned over; the other side of the surface of the limiting and fixed substrate 1 is provided with a telescopic ceramic transfer mechanism 5, and at the same time, the middle of the surface of the limiting and fixed substrate 1 A glaze storage box 8 is placed, and the glaze material is stored in the glaze storage box 8. At the same time, a conveyor belt conveyor 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com