A self-unloading blanking device

A blanking device and self-unloading technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency, inability to ensure accurate transportation of steel balls, time-consuming and laborious, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

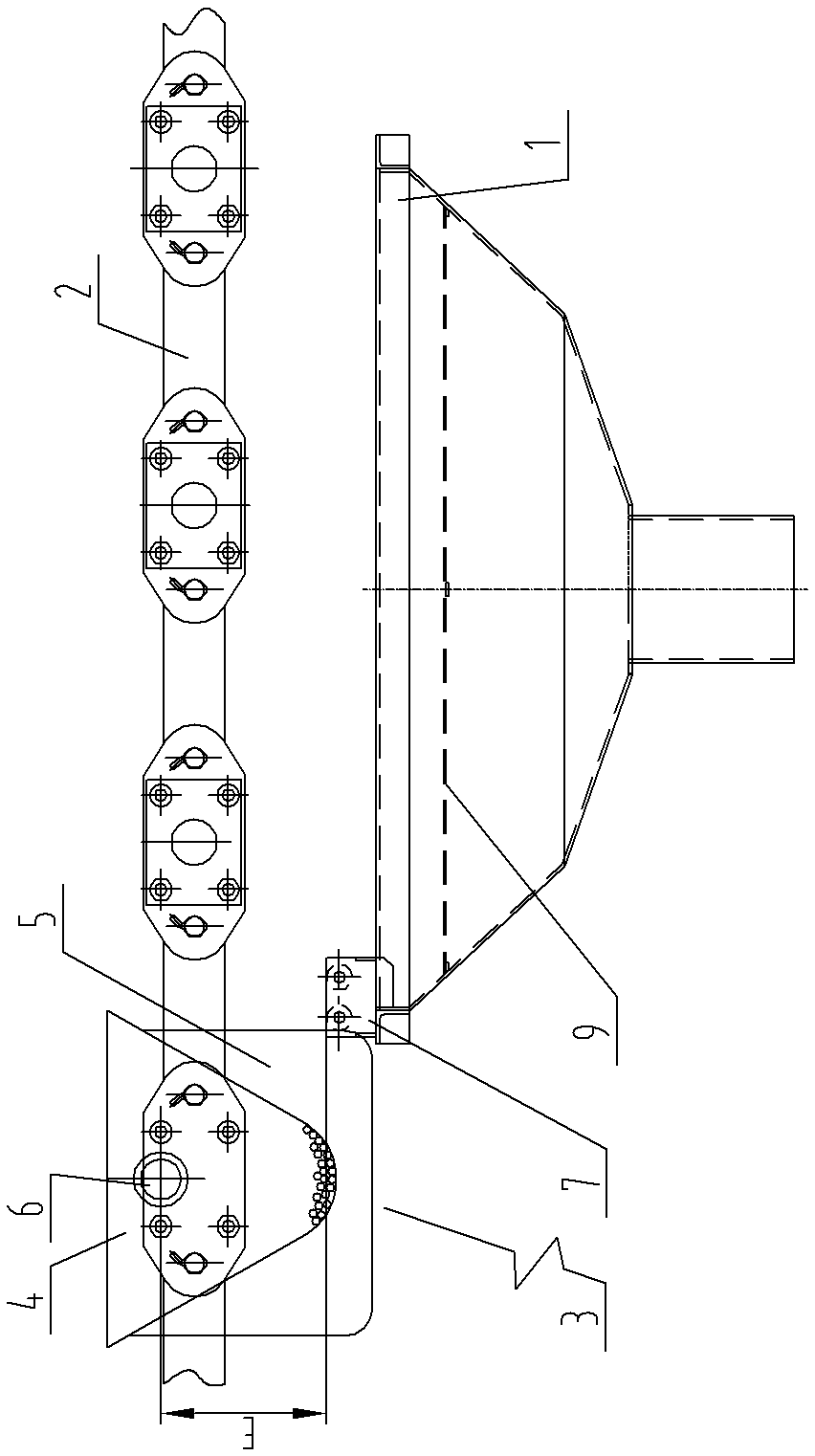

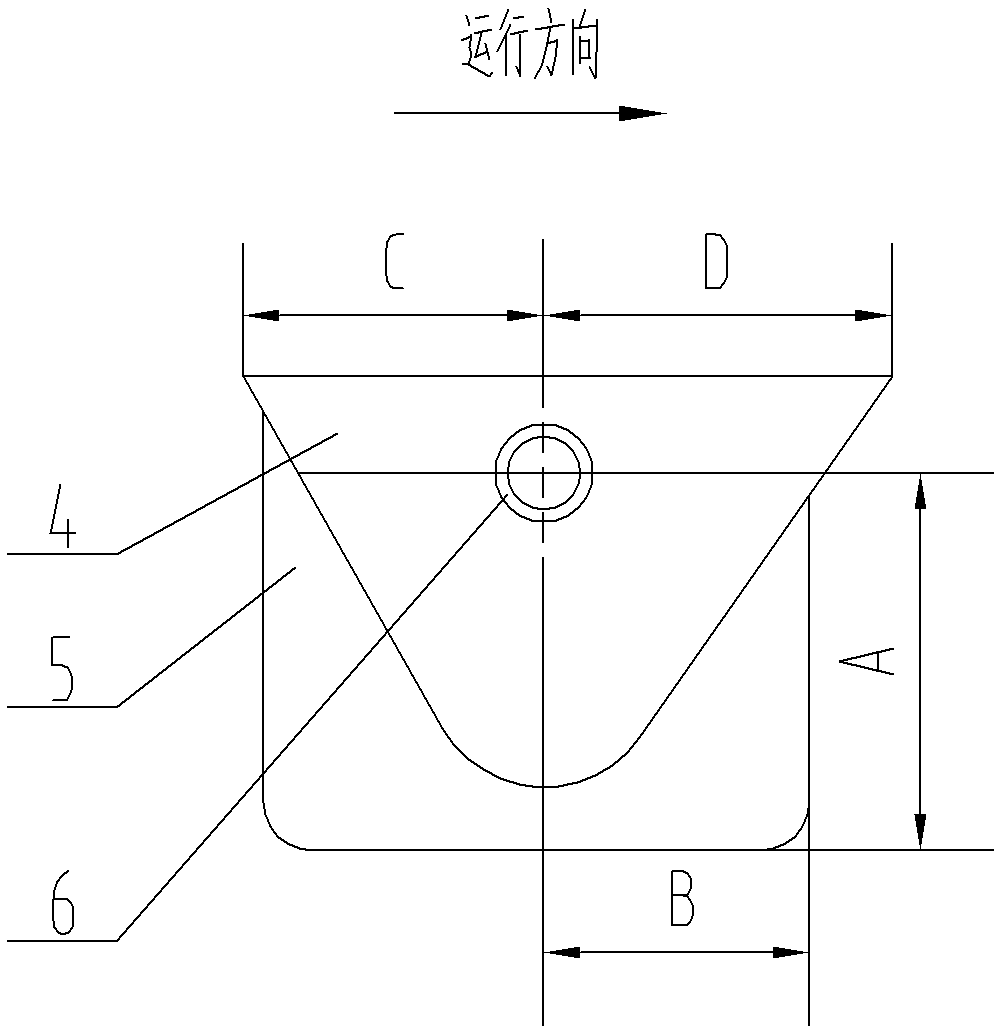

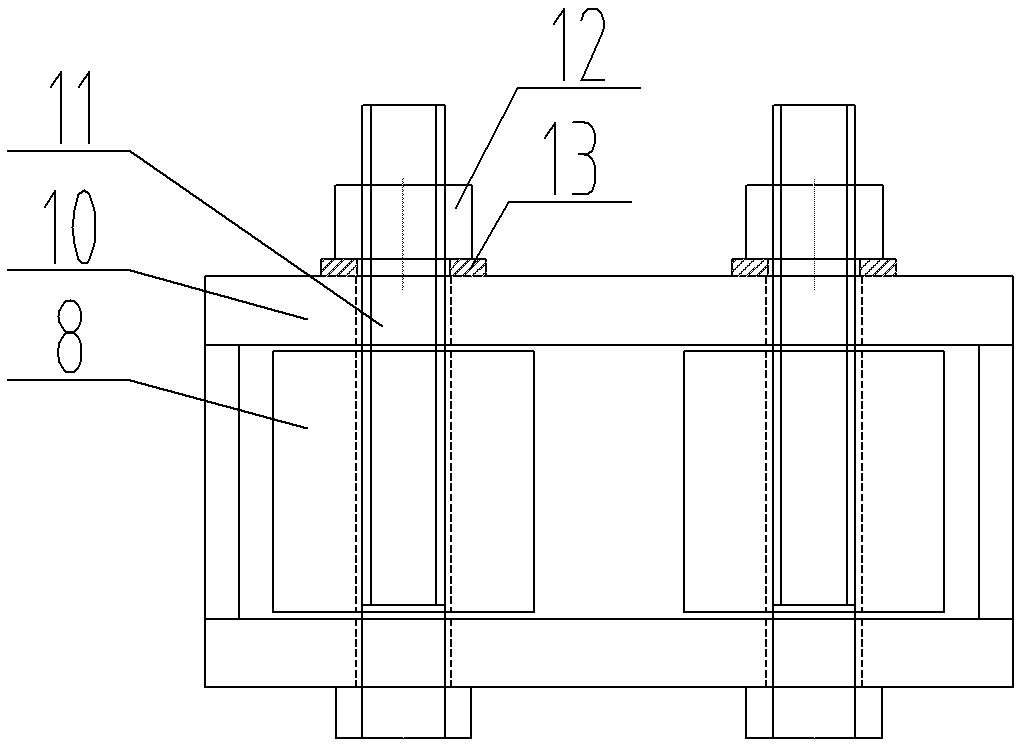

[0015] See Figure 1~3 , which includes a feeding hopper 1, the lower part of the feeding hopper 1 leads to a dust removal device (not shown in the figure, which belongs to the existing mature structure), the upper part of the feeding hopper 1 is provided with a conveying chain 2, and the conveying chain 2 is equipped with The material transport vehicle 3, the material transport vehicle 3 includes a transport hopper 4, a guide plate 5, and a turning bearing 6. The outer side of the transport hopper 4 is provided with a guide plate 5, and the both sides of the upper center of the transport hopper 4 are penetrated by a turning bearing 6 , the overturning bearing 6, the guide plate 5, and the transport hopper 4 form the material transport vehicle 3 with a fixed positional relationship, the overturning bearing 6 is supported in the positioning groove of the conveying chain 2, and the transport hopper 4 is a closing structure with a large upper part and a smaller one at the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com