Mesh piece lifting, steering and feeding execution mechanism

An actuator and feeding technology, which is applied in the field of feeding actuator, actuator, steering, and mesh feeding, can solve the problems of heavy mesh plate weight and inconvenient steering, and achieve the effect of ensuring accurate implementation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

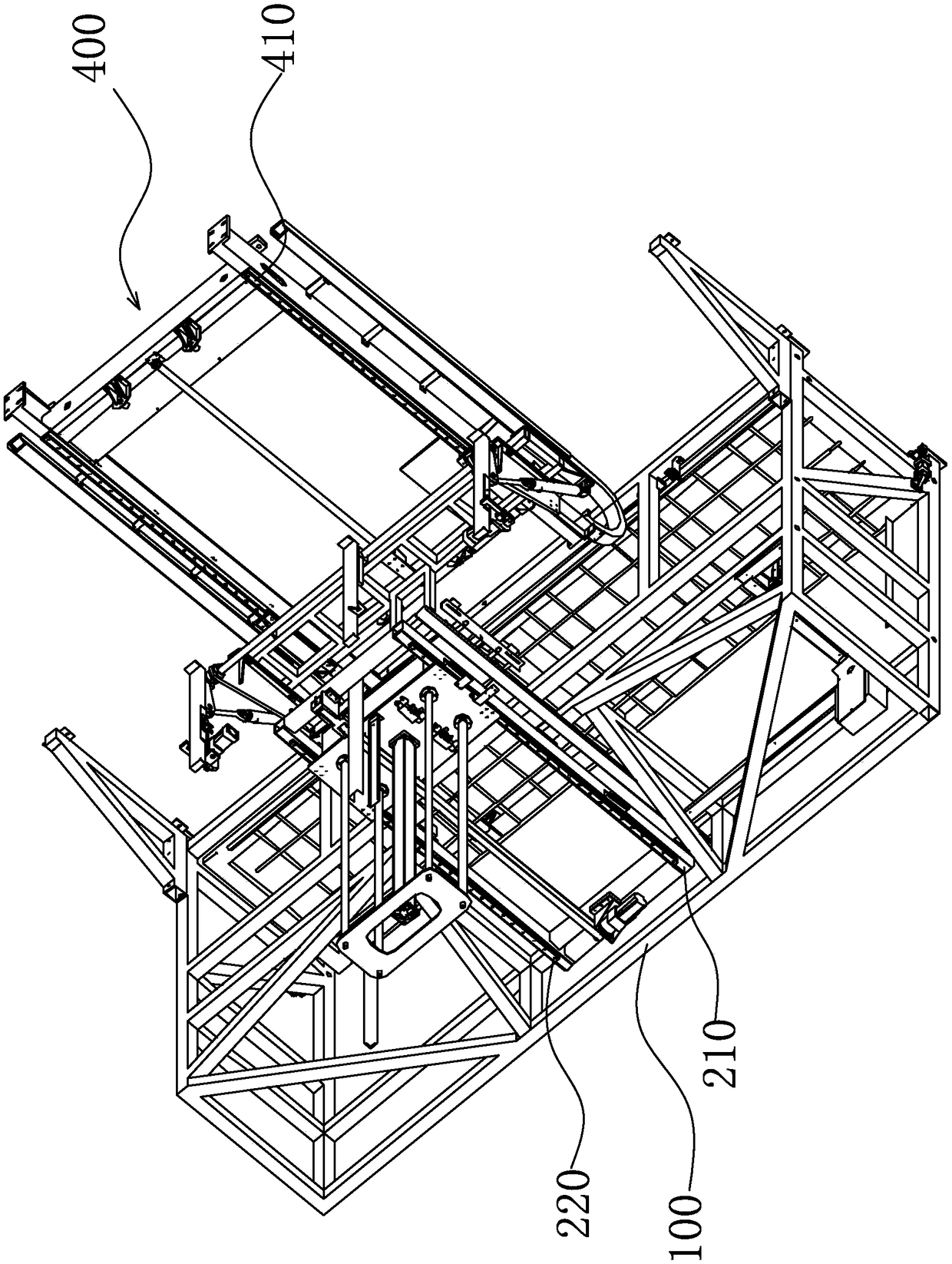

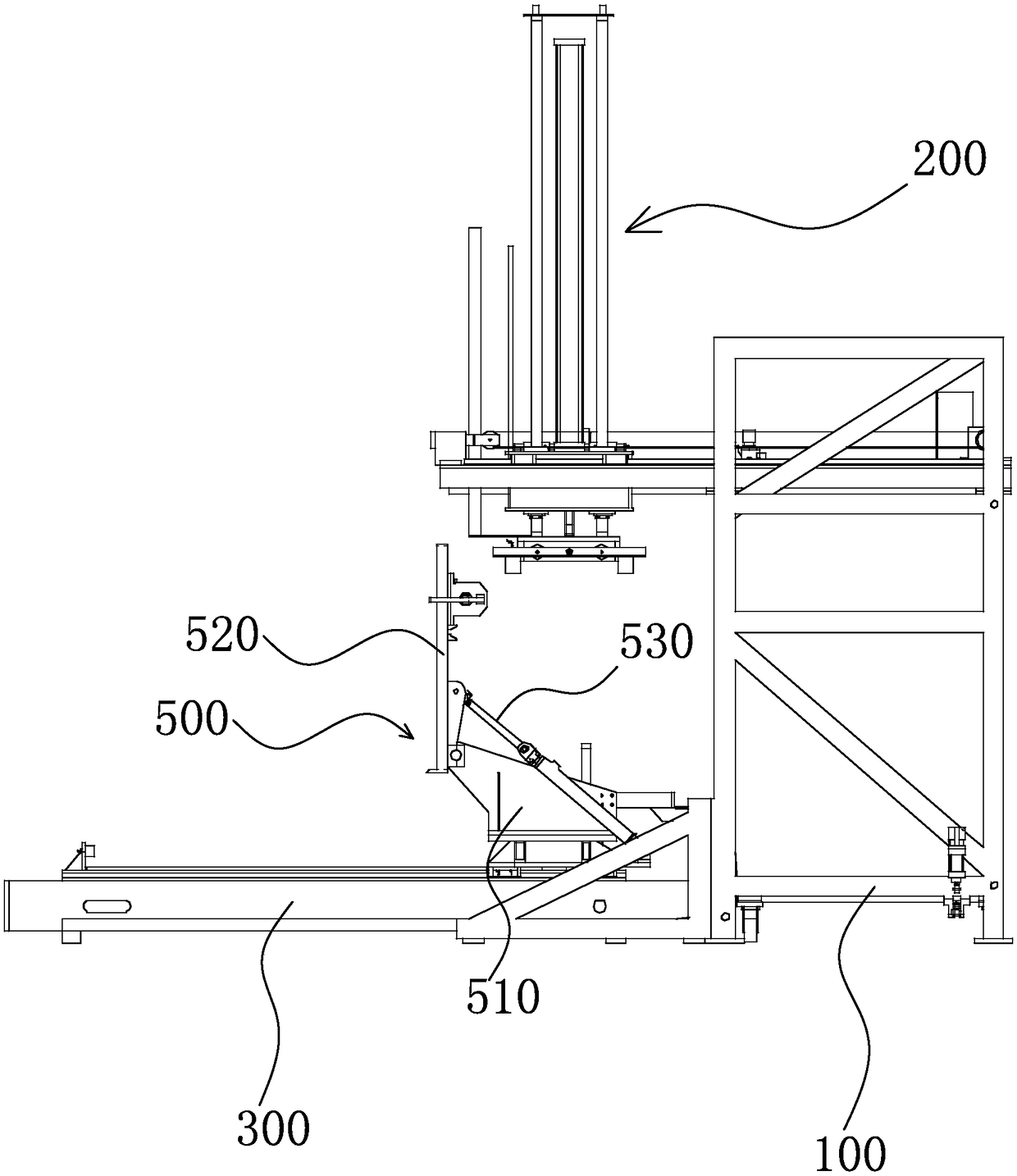

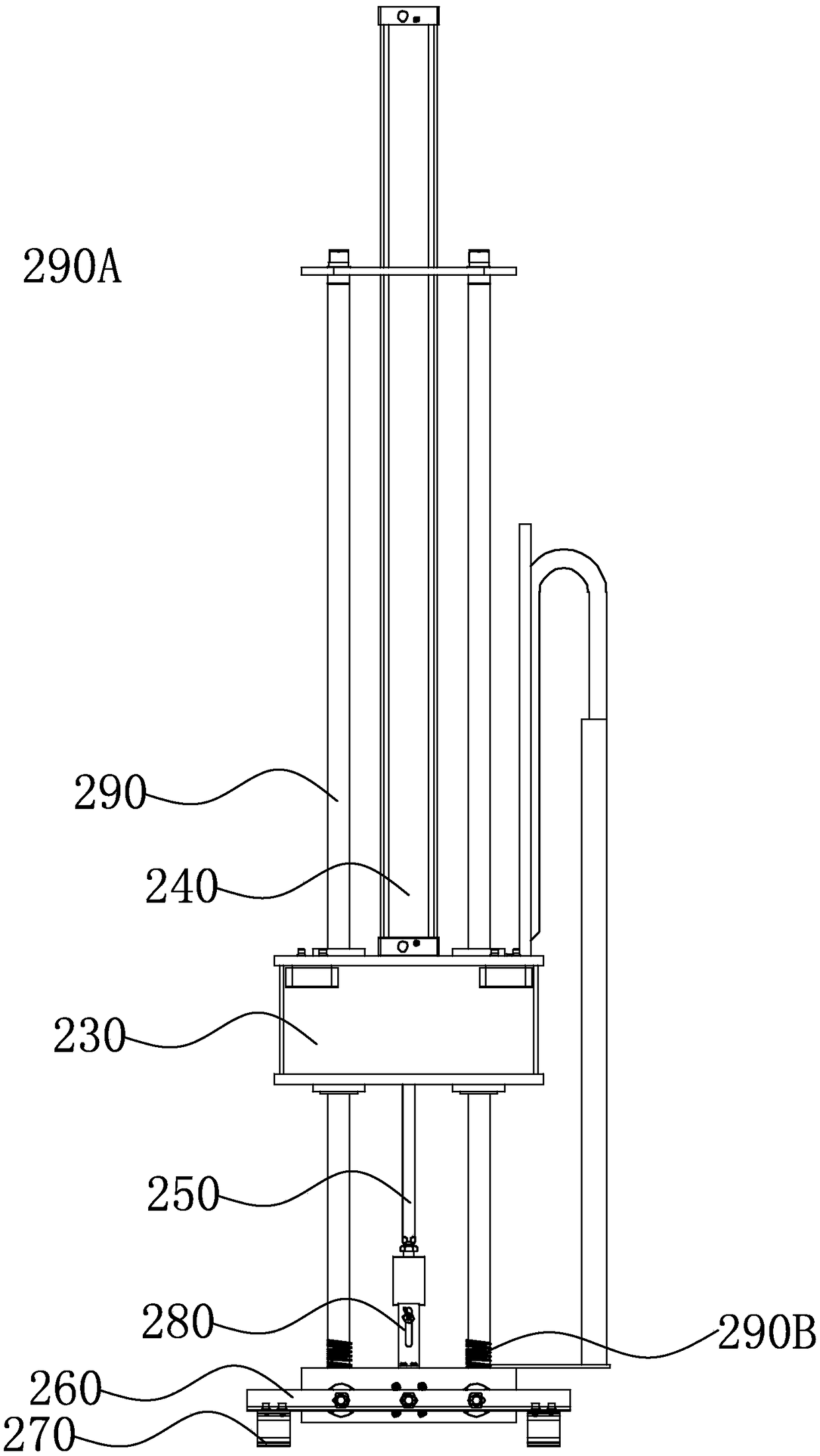

[0020] like Figure 1 to Figure 3 As shown, a kind of mesh lifting, turning, and feeding actuator provided by the present invention includes: a storage rack 100 placed on the ground for storing the grid in a horizontal state, and connected to the storage rack 100 A material lifting assembly 200, wherein, the material lifting assembly 200 can move along the vertical direction and the horizontal direction of the support; the feeding support 300 is located in front of the material storage support 100, and the feeding support 300 is provided with a feeding assembly 400, used With conveying the web plate (the web plate of vertical state) after steering; Steering assembly 500, one end is fixedly connected on the feeding support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com