Patents

Literature

35results about How to "Improve glazing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic atomization glaze spraying device for ceramic ornaments

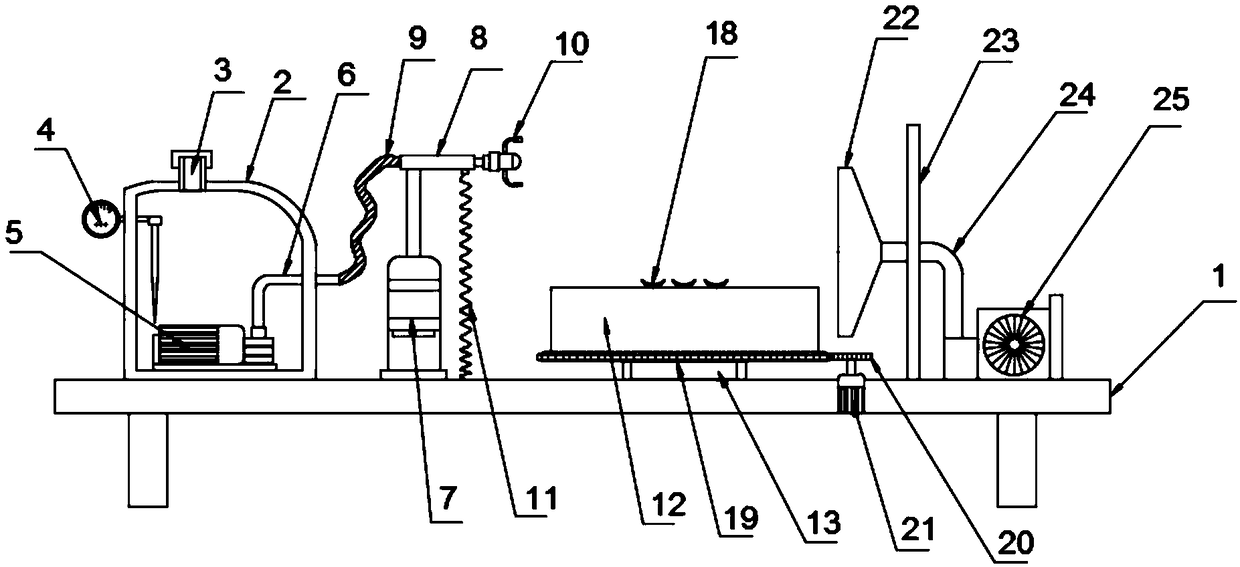

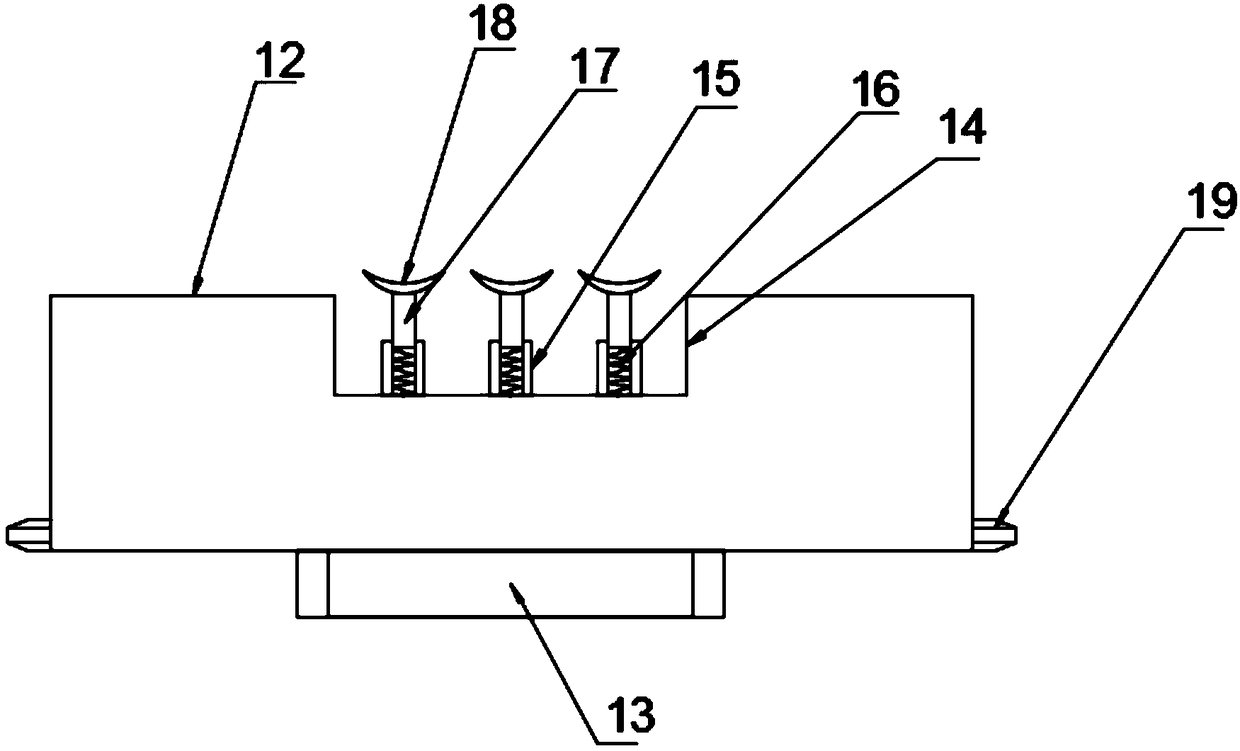

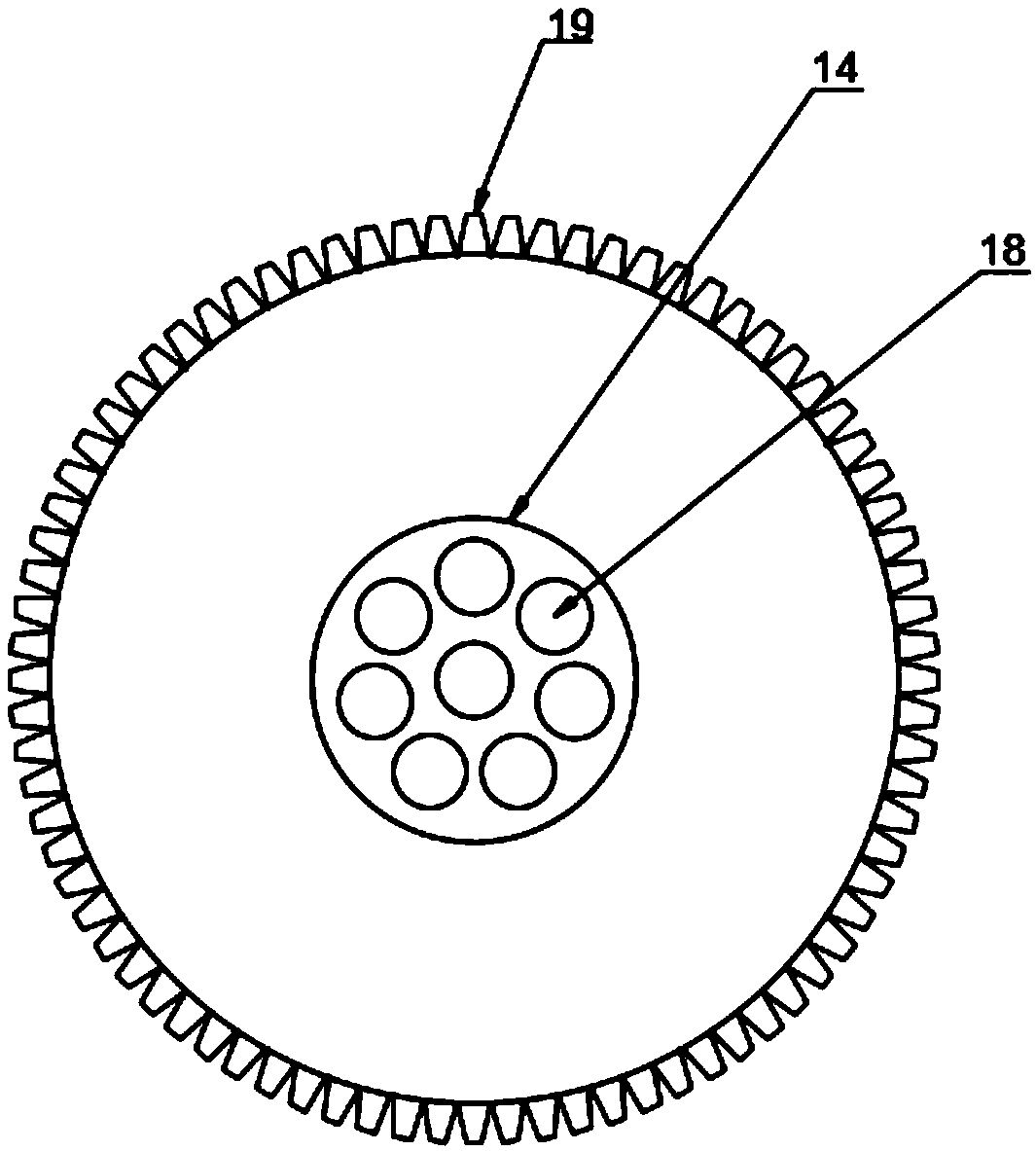

The invention discloses a full-automatic atomization glaze spraying device for ceramic ornaments. The full-automatic atomization glaze spraying device for ceramic ornaments comprises a workbench. A glaze can is arranged on the workbench. A feeding pipe is arranged on the top of the glaze can. A liquid indicator is arranged on the glaze can. A pressure pump is arranged at the bottom of an inner chamber of the glaze can. A first connecting pipe is arranged on the pressure pump. A linear actuator is arranged on one side of the glaze can. A second connecting pipe is arranged at the top end of thelinear actuator. A connecting hose is arranged at one end of the second connecting pipe. A rotary sprayer is arranged at the other end of the second connecting pipe. Isolation cloth is arranged on oneside of the linear actuator. A placement platform is arranged on one side of the isolation cloth. With the full-automatic atomization glaze spraying device for ceramic ornaments, a blank can be placed more steadily, and is not prone to shaking during glaze spraying operation, and therefore, the glazing quality of the blank is improved; and a driving motor is used for working, a first gear is driven by a second gear at the end of an output shaft of the driving motor to rotate so that the blank placed on the workbench can be enabled to rotate to receive more uniform glaze spraying during operation, the blank is glazed more uniform, and the glazing efficiency is improved at the same time.

Owner:FOSHAN KEFENG CULTURE COMM CO LTD

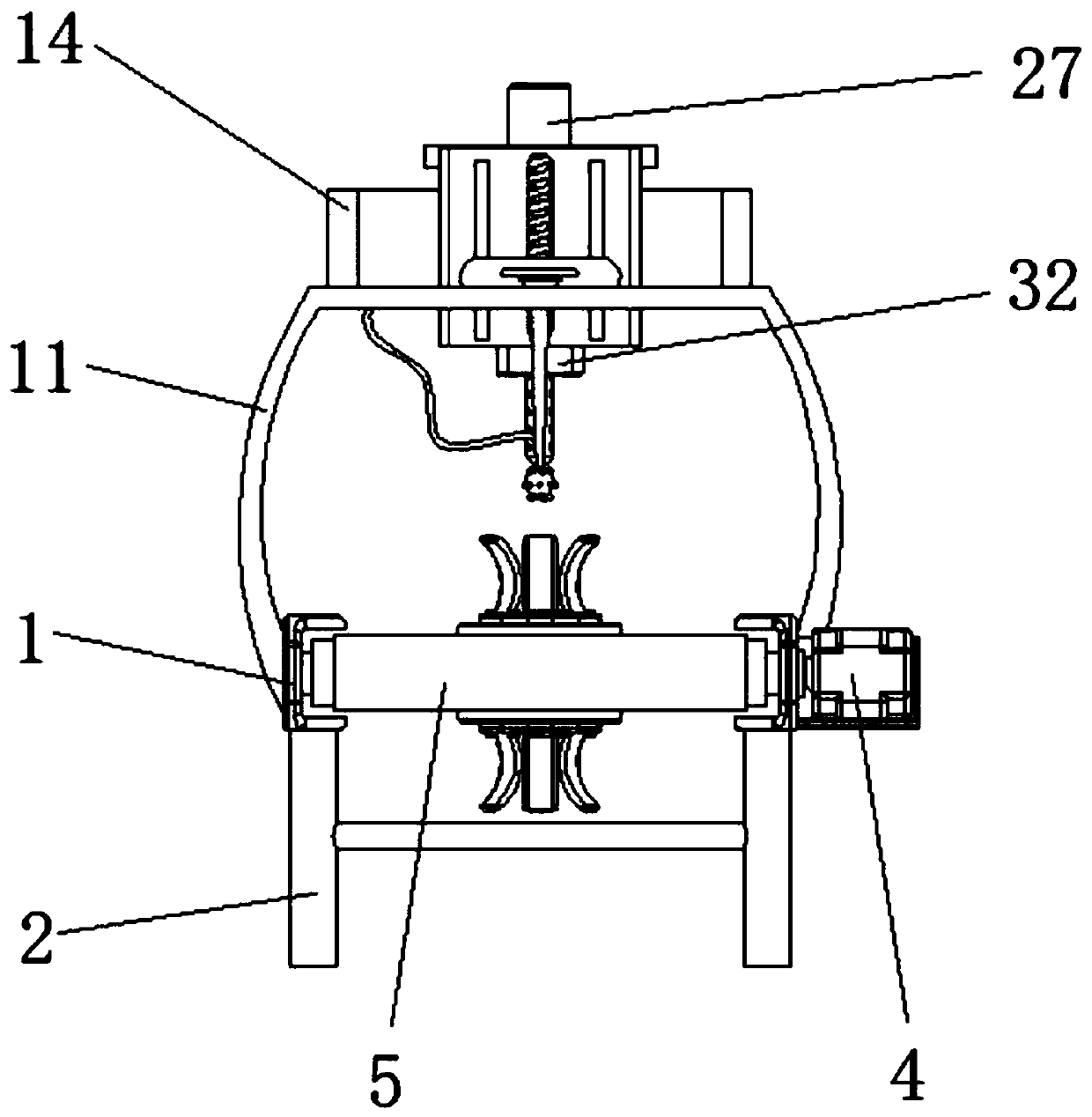

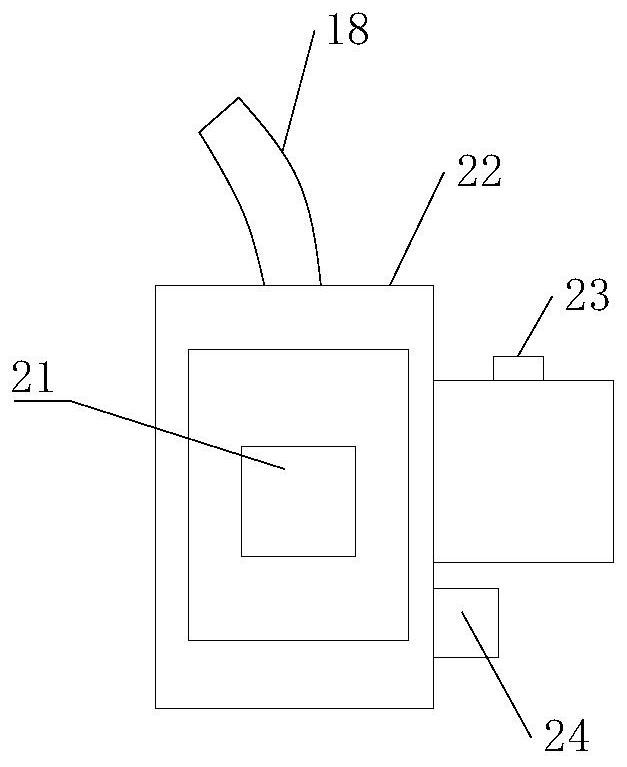

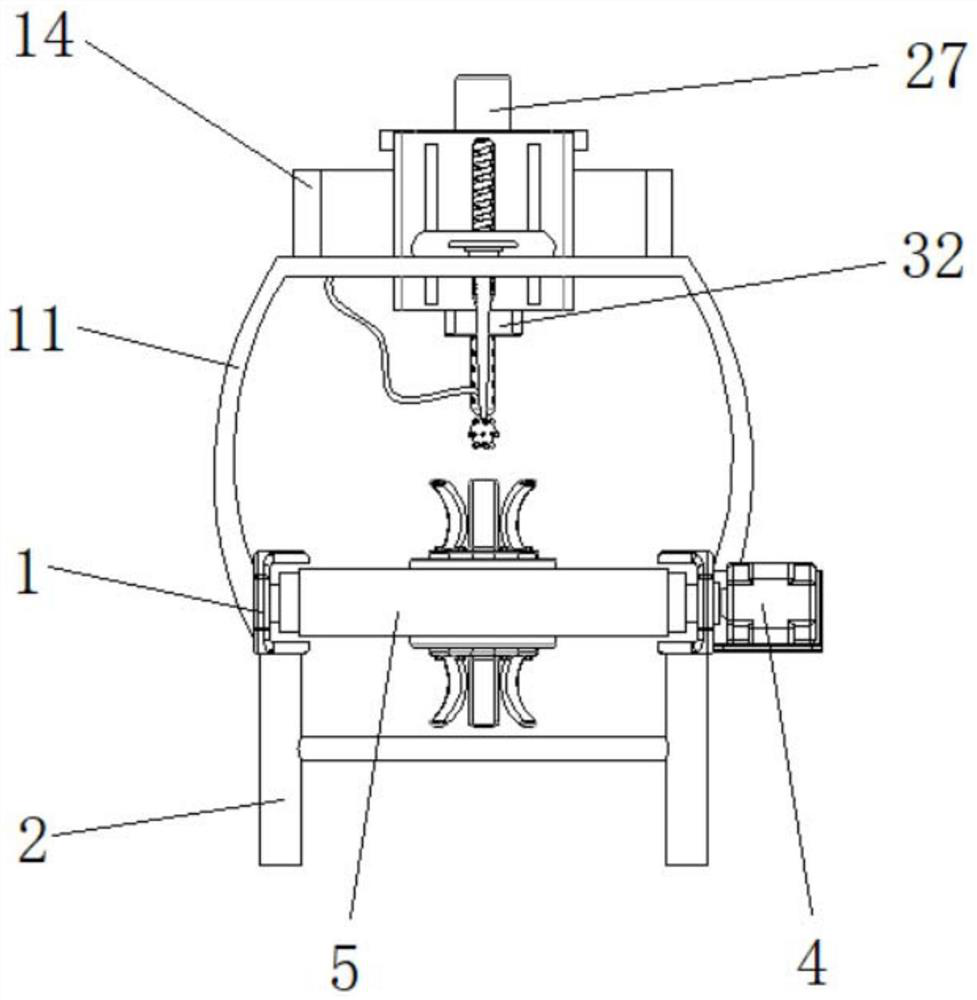

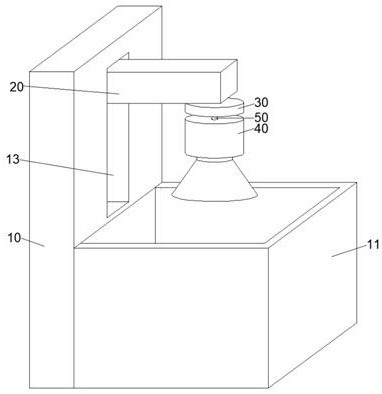

Ceramic bottle internal glaze spraying equipment for process ceramic production

ActiveCN111113649AAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

The invention belongs to the technical field of glaze spraying equipment, in particular to ceramic bottle internal glaze spraying equipment for process ceramic production. The ceramic bottle internalglaze spraying equipment comprises a protection support plate, wherein supporting legs are arranged at the bottom of the protection support plate, and an L-shaped supporting plate is arranged on one side of the protection support plate; a first motor is arranged at the top of the L-shaped supporting plate, and the output end of the first motor penetrates through the protection support plate. A ceramic bottle internal glaze spraying mechanism is arranged, on the one hand, storage and placement of glaze for glazing the surface of a ceramic bottle can be achieved through a material storage box, paint can be conveniently provided for glazing and spraying on the internal surface of the ceramic bottle, and meanwhile, the material storage box is used for storing the glaze so that the working amount of repeated adding of the glaze by an operator can be relieved; and on the other hand, a guide supporting cylinder can be conveniently inserted into the interior of the ceramic bottle through the mode that a transmission screw is adopted to move up and down for adjustment, and uniform glaze spraying treatment is carried out on the inner wall of the ceramic bottle by using a spherical glaze spraying joint.

Owner:广东金润源陶瓷股份有限公司

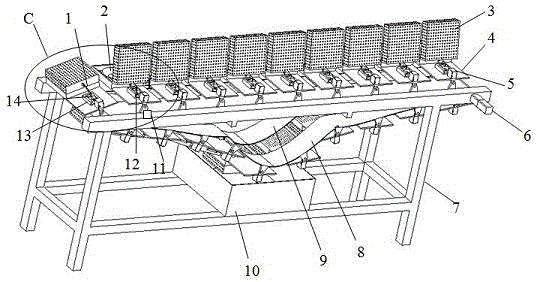

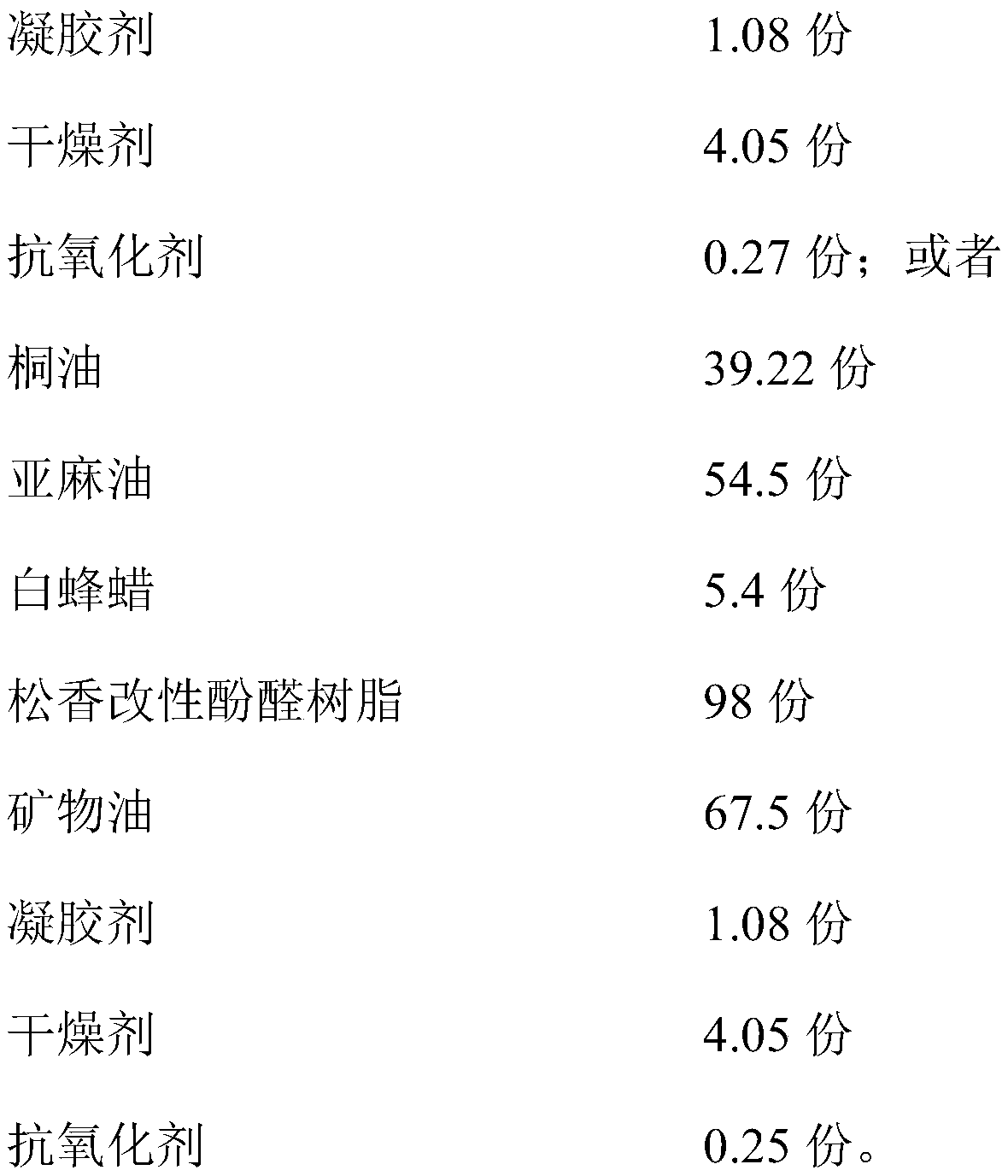

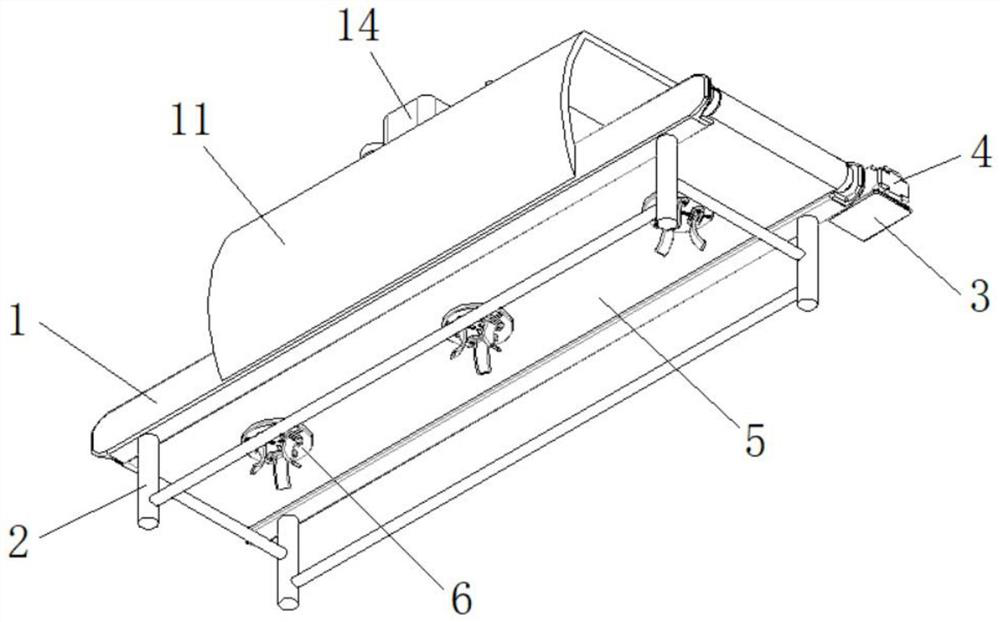

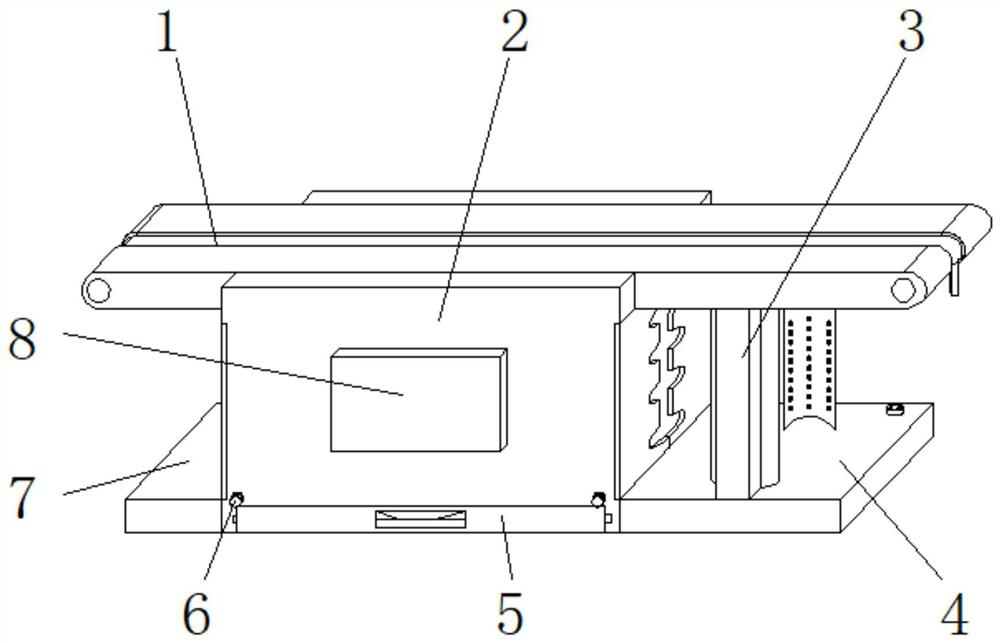

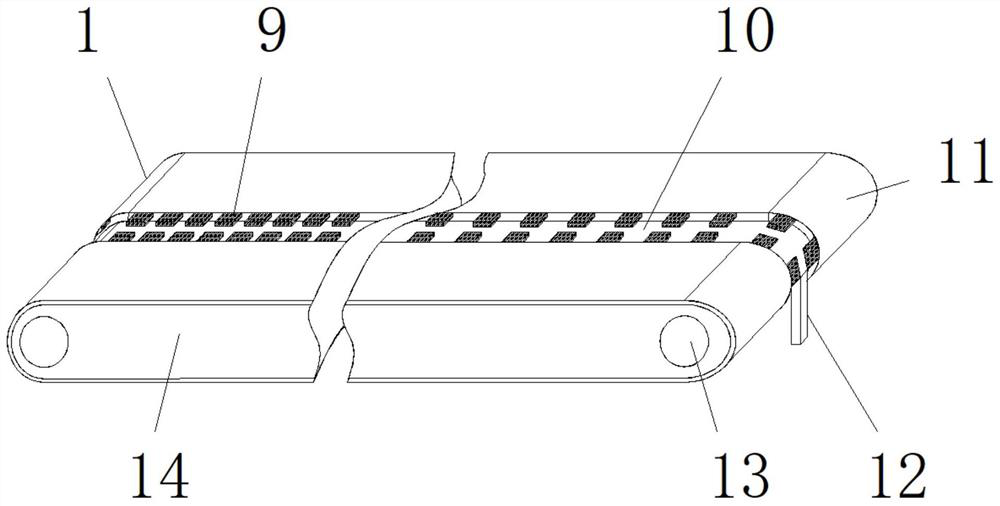

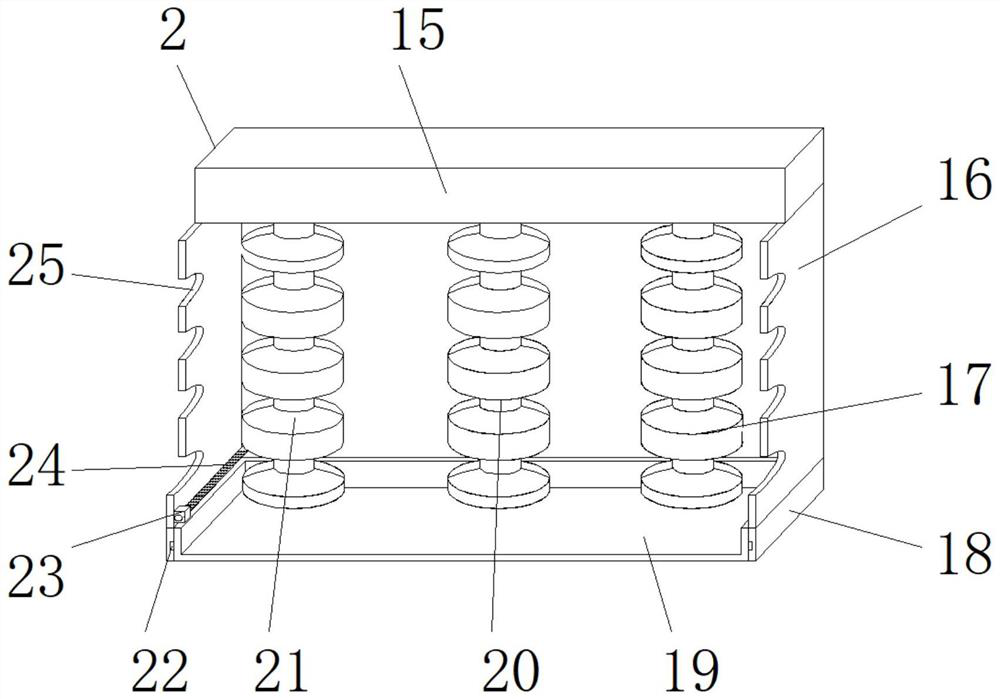

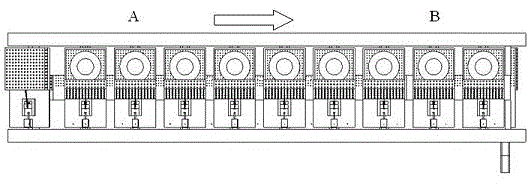

Conveying belt type box-shaped glaze dipping device

The invention provides a conveying belt type box-shaped glaze dipping device which comprises a pull rod and a bowl blank, wherein a low-speed motor drives a conveying belt I and a low-speed motor II to simultaneously move, a bowl blank containing mechanism articulated with the conveying belt I and the conveying belt II limits the position of the bowl blank within a certain region, the bowl blank is glazed when the bowl blank containing mechanism is dipped in a glaze pool positioned at the bottom of an integral support frame, then the conveying belt I and the conveying belt II can take the bowl blank containing mechanism out of the glaze pool, a position sensor detects the bowl blank containing mechanism when the bowl blank containing mechanism moves to the station A, an electromagnet attracts a slide block, the slide block drives the pull rod to open a bowl cover, and a worker takes out the bowl blank, so that the integral glazing process is completed. The conveying belt type box-shaped glaze dipping device disclosed by the invention can be used for an automatic glazing procedure of a domestic ceramic production process and overcomes such defects of certain glazing devices used in a plant at present as complicated driving mechanism, low glazing efficiency and glazing dead angle.

Owner:徐州兴梁农业发展有限公司

Glazing device for artware ceramic

The invention relates to a glazing device for artware, in particular to a glazing device for artware ceramic. The glazing device for the artware ceramic is easy to operate, high in glazing efficiencyand capable of reducing the labor intensity of workers. The glazing device for the artware ceramic comprises a bottom plate, a material loading and unloading moving mechanism and a glazing mechanism,wherein a mounting column is mounted on the bottom plate, the material loading and unloading moving mechanism is mounted on the mounting column, and the glazing mechanism is mounted at the top of thebottom plate. Ceramic can be fixed to the material loading and unloading moving mechanism through a clamping mechanism, the ceramic can be glazed through mutual cooperation of the material loading andunloading moving mechanism and the glazing mechanism, redundant glaze substances on the ceramic can be recycled through an excess material recycling structure, waste of the glaze substances is prevented, therefore, the glazing device only needs to manually place and take down the ceramic, is simple to operate and high in glazing efficiency, and reduces the labor intensity of workers.

Owner:曾群英

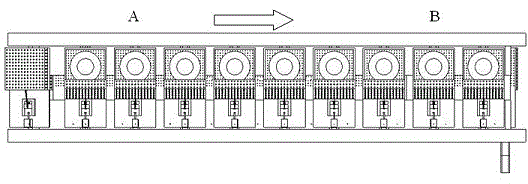

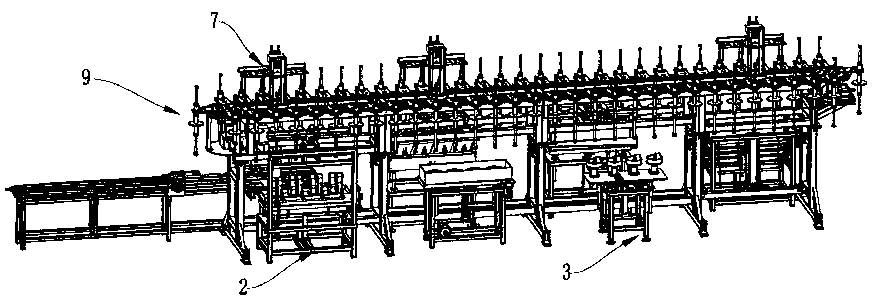

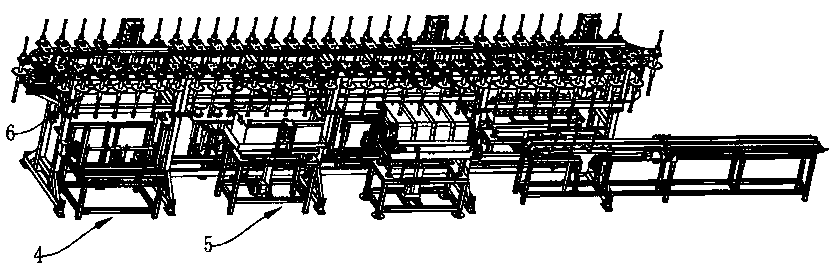

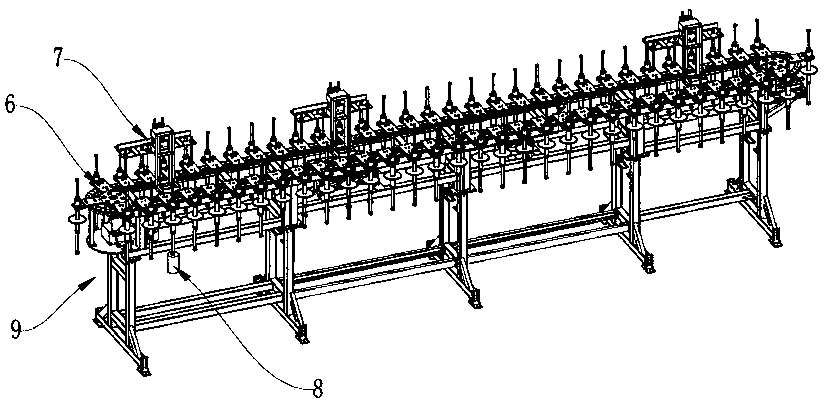

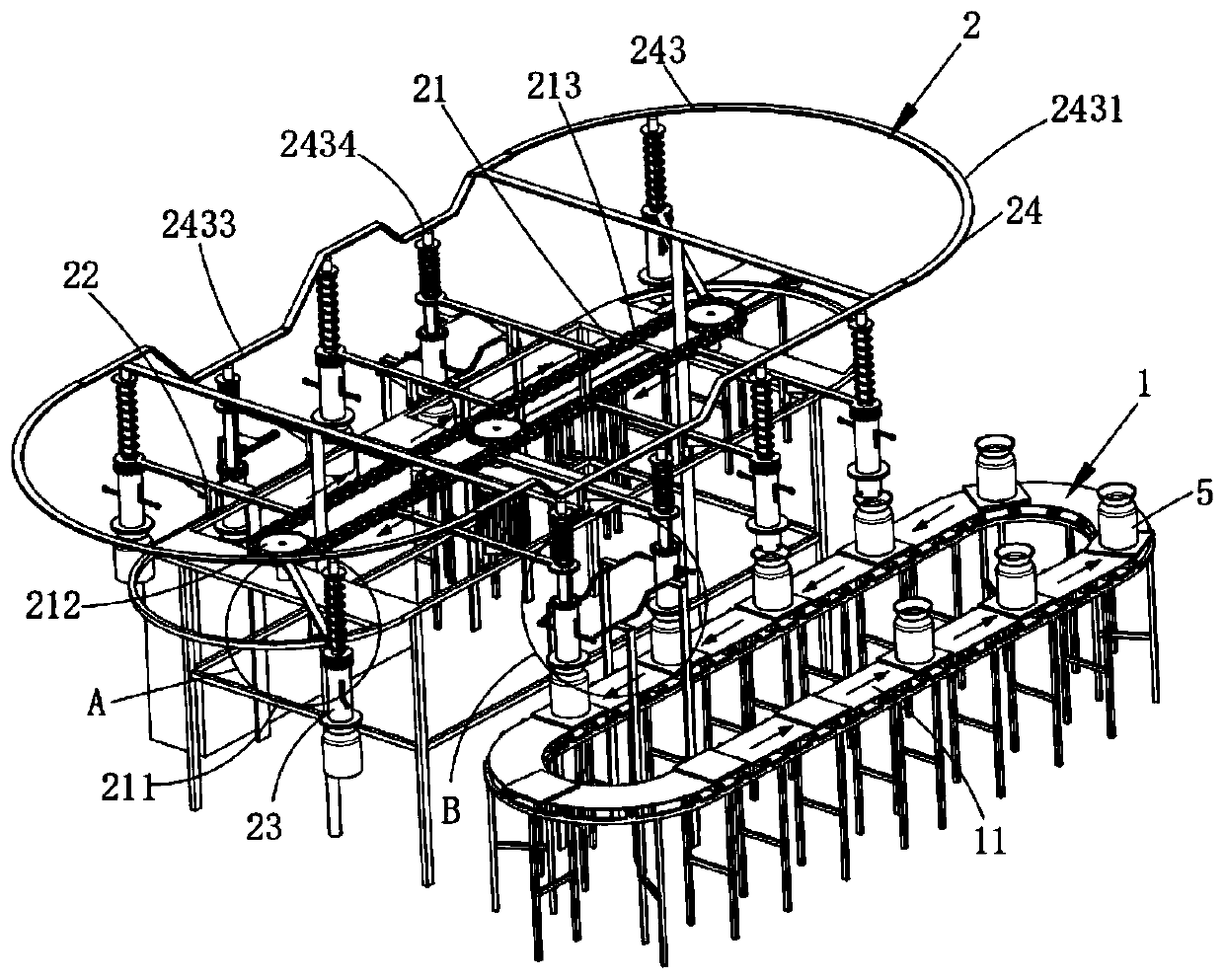

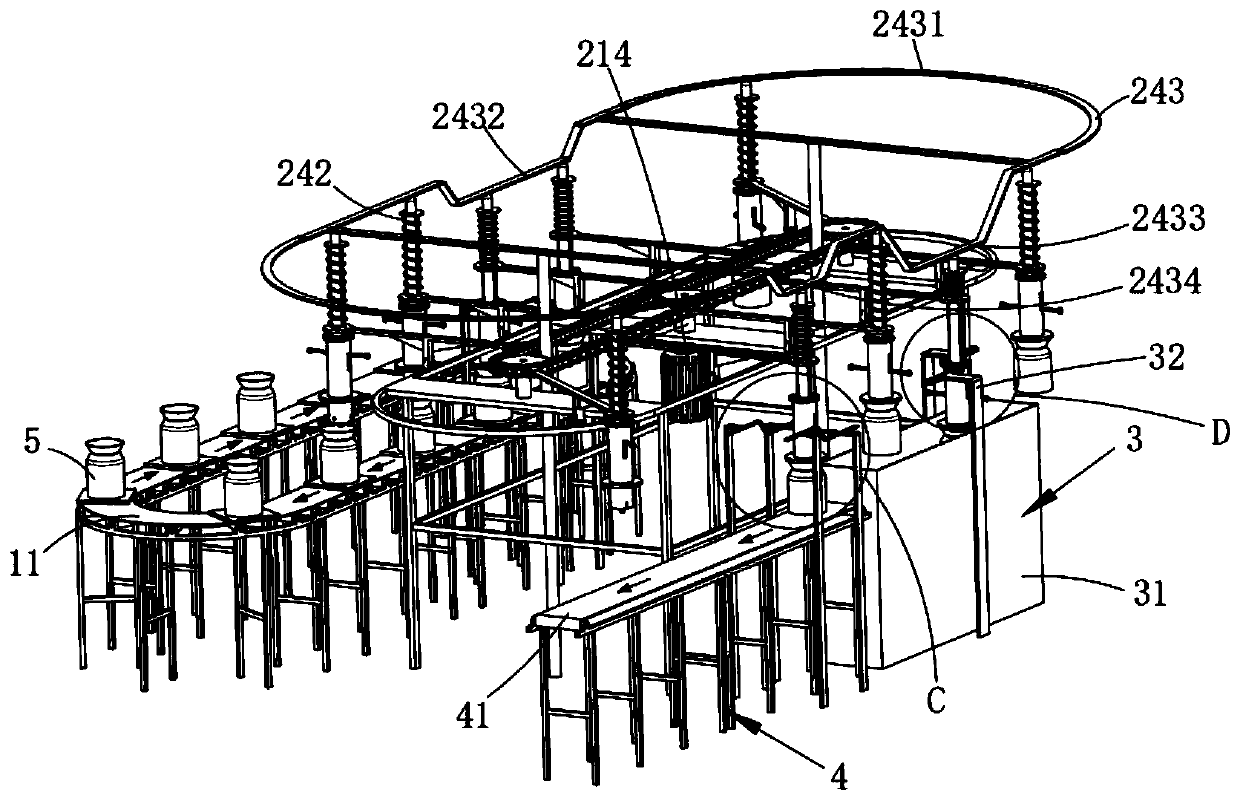

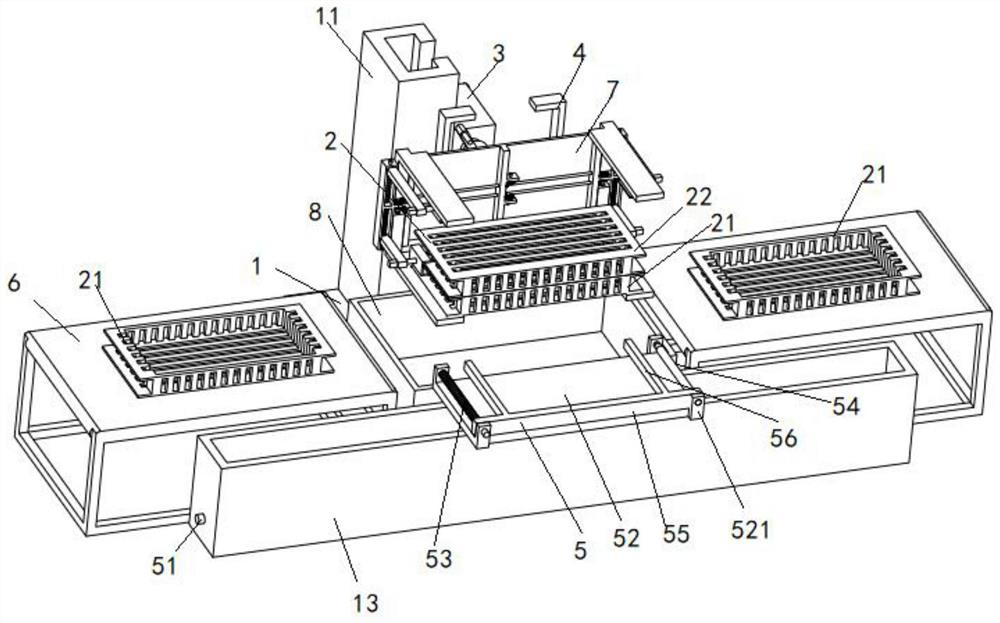

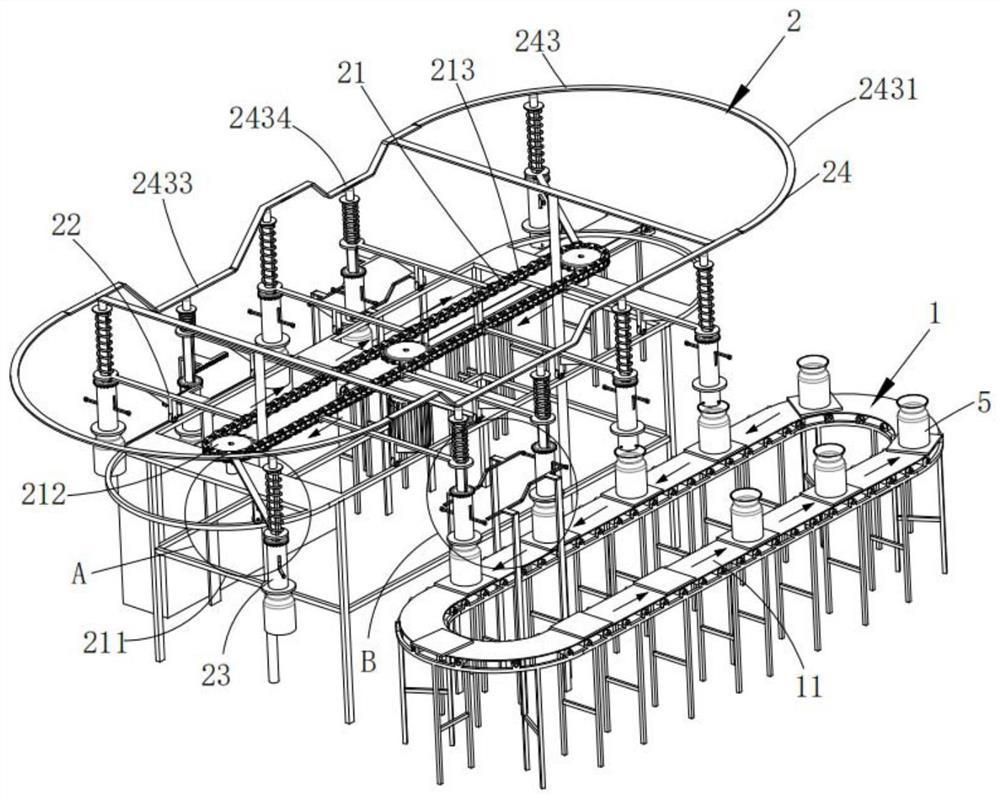

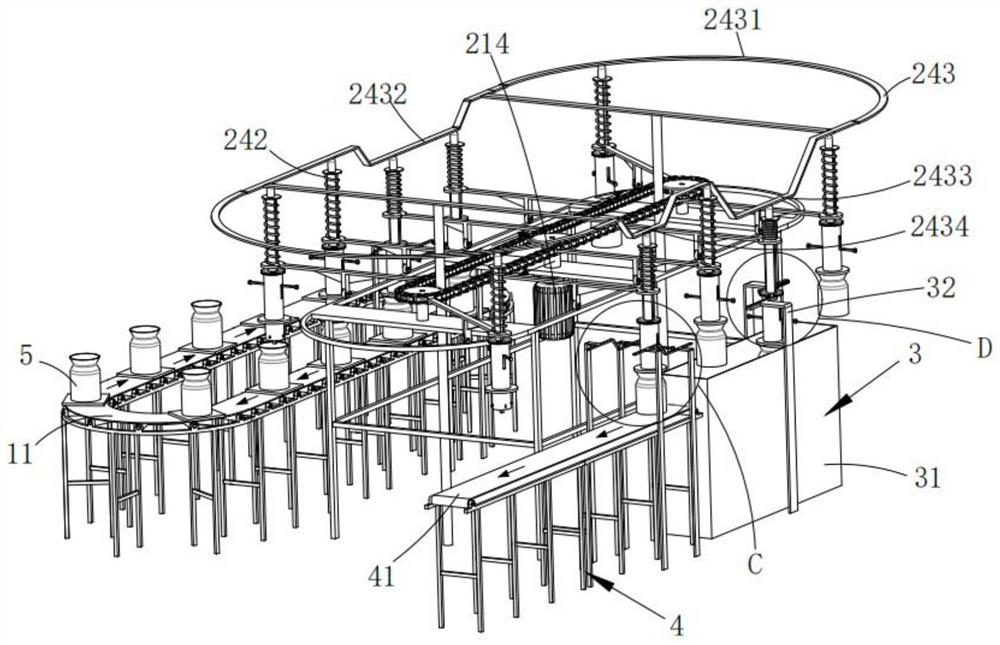

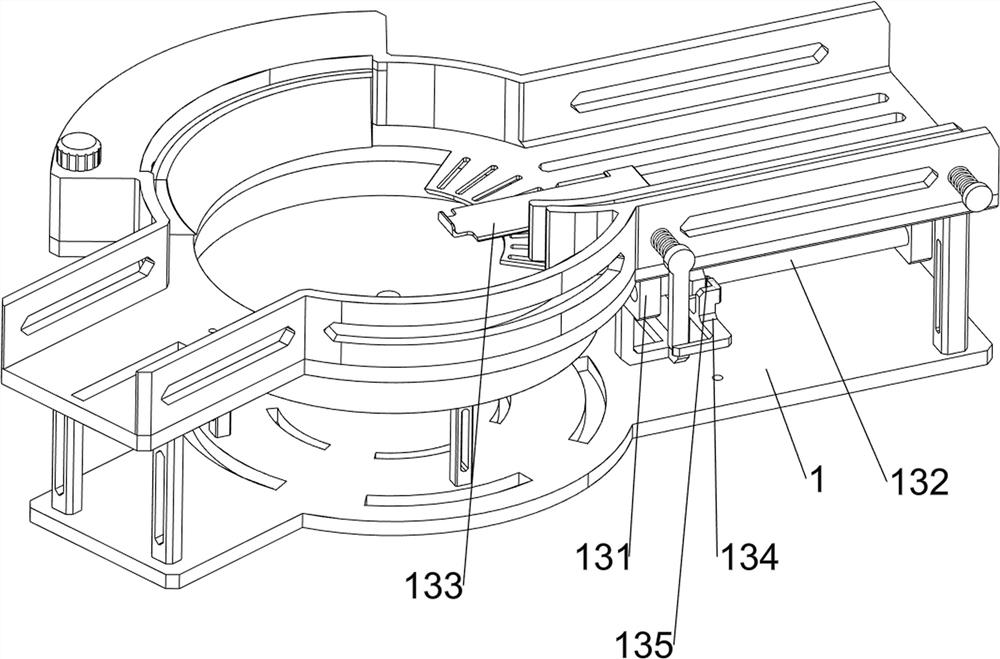

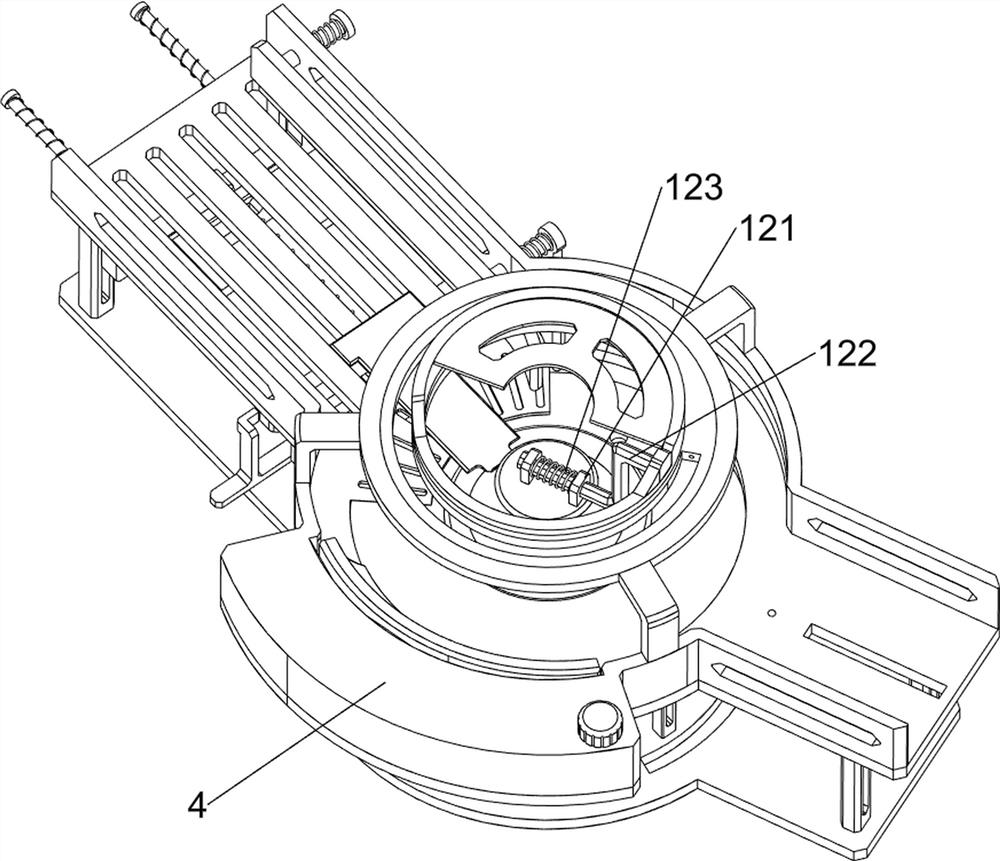

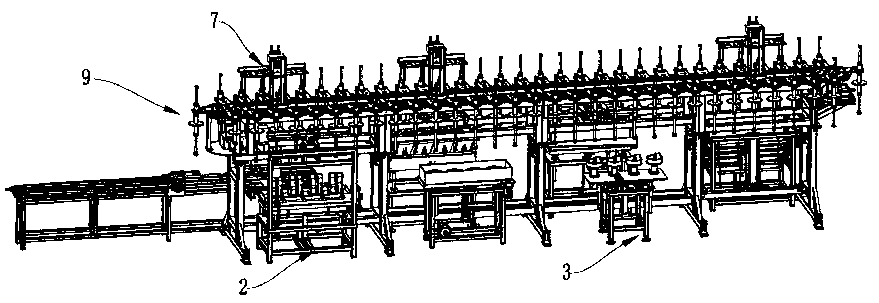

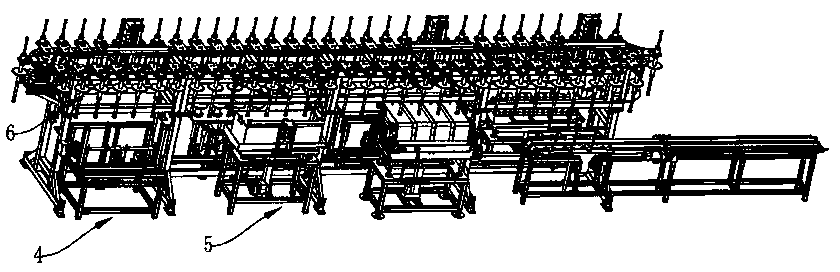

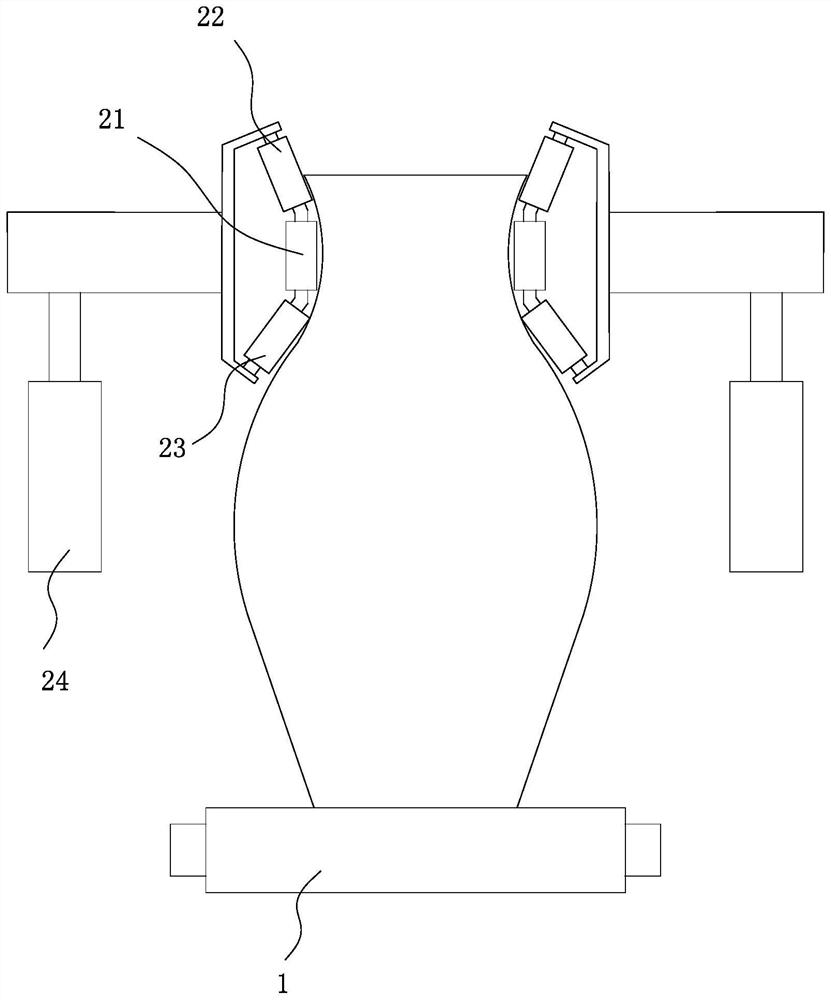

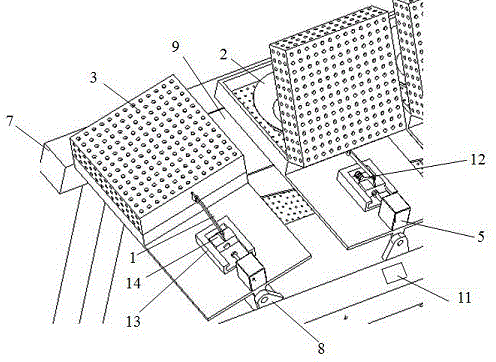

Annular glazing line

ActiveCN111055374AImprove glazing efficiencyEffective connectionCeramic shaping plantsTransfer lineComposite material

The invention relates to an annular glazing line. The annular glazing line comprises an annular conveying line, a cup opening edge grinding device, a roller type opening glaze device, a turnover device and a glaze stirring device, wherein the cup opening edge grinding device, the roller type opening glaze device, the turnover device and the glaze stirring device are distributed along the annular conveying line. According to the invention, the annular glazing line is provided, so that the functions realized by each station can be effectively connected, and glazing efficiency of ceramic cups iseffectively improved.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

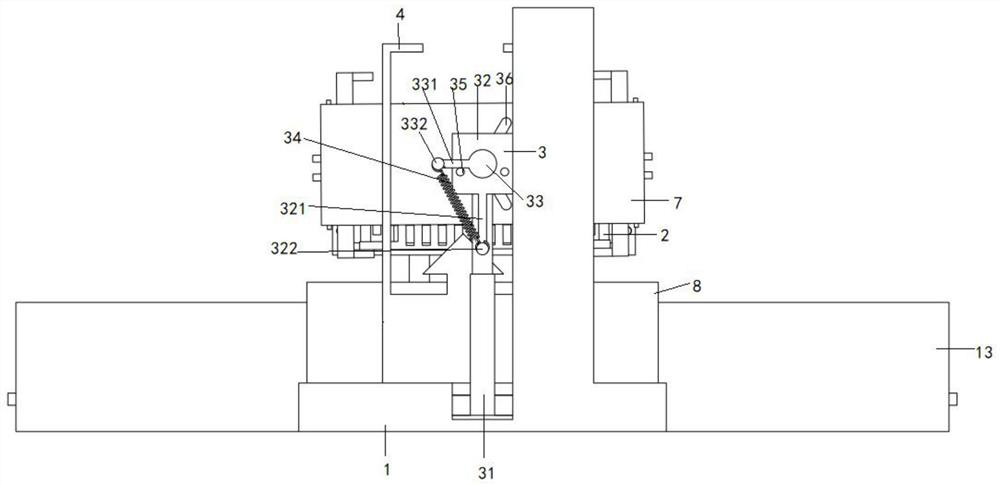

Rotatable automatic enameller

The invention provides a rotatable automatic enameller. The rotatable automatic enameller comprises an underframe, a rotatable frame, a motor used for driving the rotatable frame to rotate, and an enamel spraying device, wherein a support used for supporting the rotatable frame is arranged on the underframe; the rotatable frame is movably connected with support; the rotatable support comprises a rotatable shaft, a plurality of ratchet and I-shaped frames; the ratchetes are arranged surrounding the rotatable shaft uniformly; one end of each ratchet is fixed onto the rotatable shaft; the other end of each ratchet is connected with each I-shaped frame; the enamel spraying device is fixed onto the underframe, and comprises an enamel box, a pump, and a plurality of spraying pipes; the inlet of the pump is communicated with the enamel box; the output of the pump is communicated with the spraying pipes. The rotatable automatic enameller can realize automatic enameling of workblanks, and can effectively increase enameling of the workblanks by separating uploading and blanking for the I-shaped frames through the rotatable I-shaped frames.

Owner:简厚诚

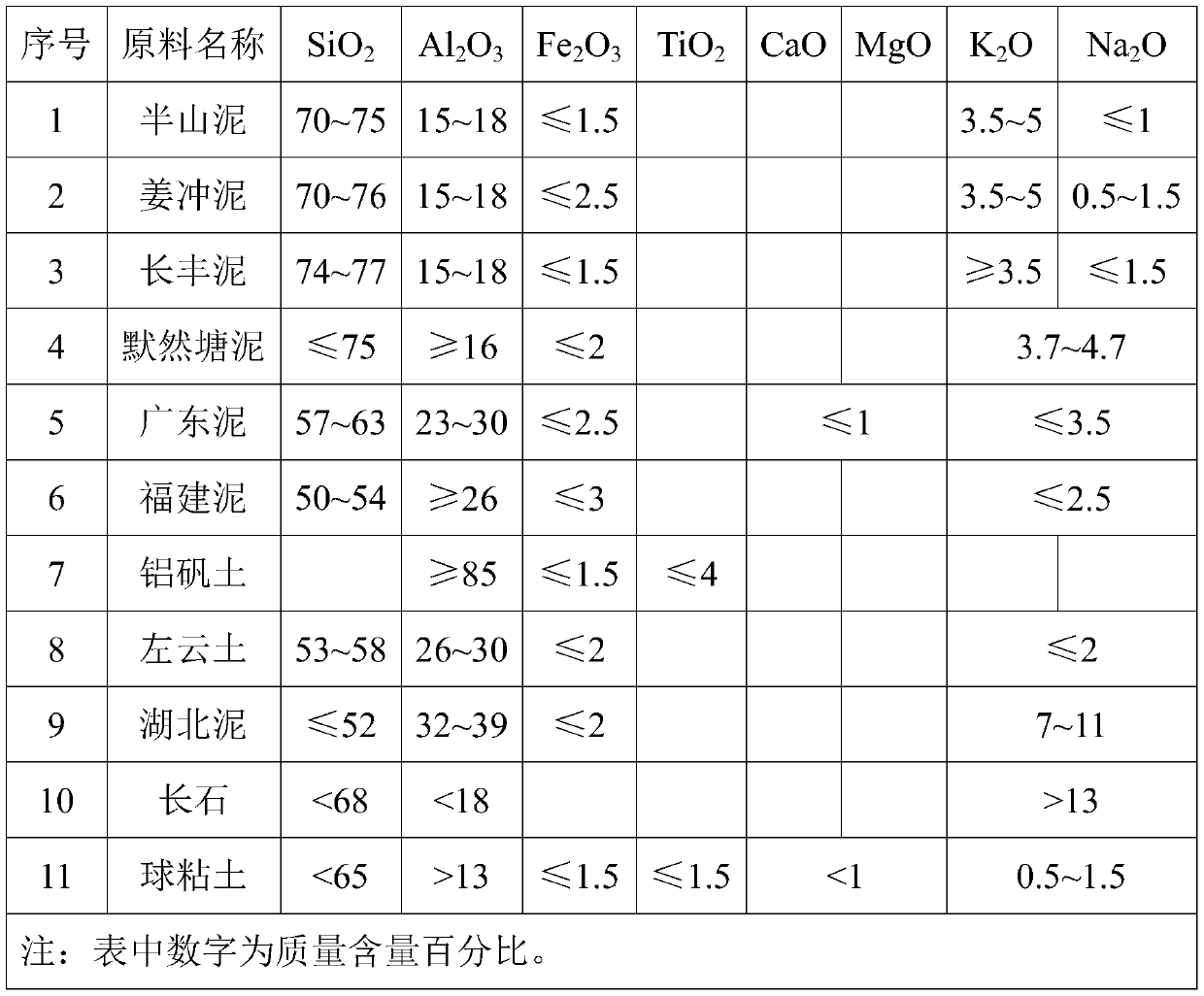

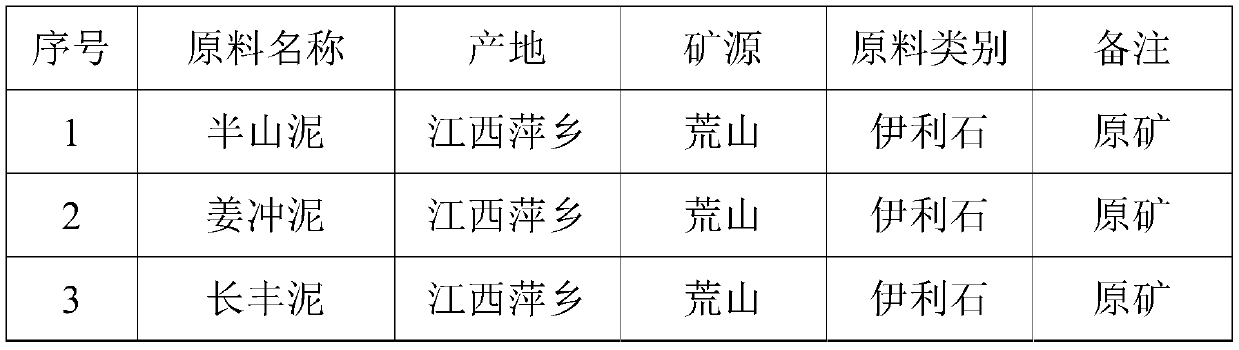

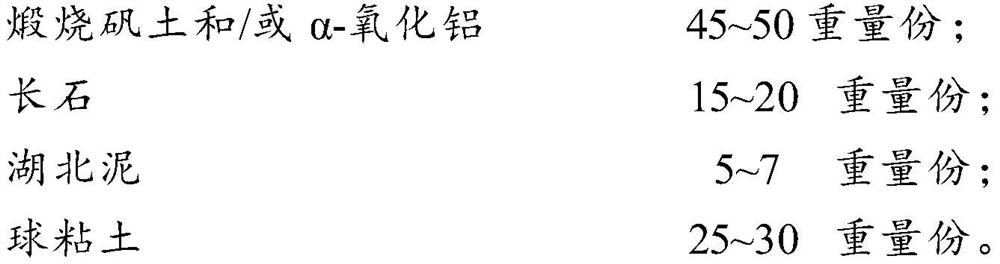

Medium and high strength insulator material formula and preparation method thereof

ActiveCN110194656AWide range of applicationsRich varietyCeramic materials productionClaywaresHigh sodiumIon

The invention provides a medium and high strength insulator material formula, which comprises 12 to 18 parts of banshan mud, 12 to 16 parts of jiangchong mud, 13 to 18 parts of Changfeng mud, 12 to 17parts of morantang mud, 16 to 23 parts of Guangdong mud, 3 to 9 parts of Fujian mud, 4 to 8 parts of bauxite, 5 to 11 parts of Zuoyun soil and 3 to 10 parts of Hubei mud. A large amount of clay or feldspar with high plasticity and high binding force in the traditional formula are not needed, the firing temperature of a blank is reduced to 1280-1320 DEG C, and energy is saved. A glaze pouring method is adopted, and glazing is fast and pollution-free. The medium and high strength insulator material can still ensure high mechanical strength and puncture resistance under the condition of higher sodium ion content (1-5%). Compared with the traditional process, the total cost of the medium and high strength insulator material is saved by about 45%, the production period is shortened by about 20%, and the prepared insulator has uniform porcelain structure, small dispersibility and high mechanical strength and electrical strength.

Owner:江西新龙电瓷电器制造有限公司

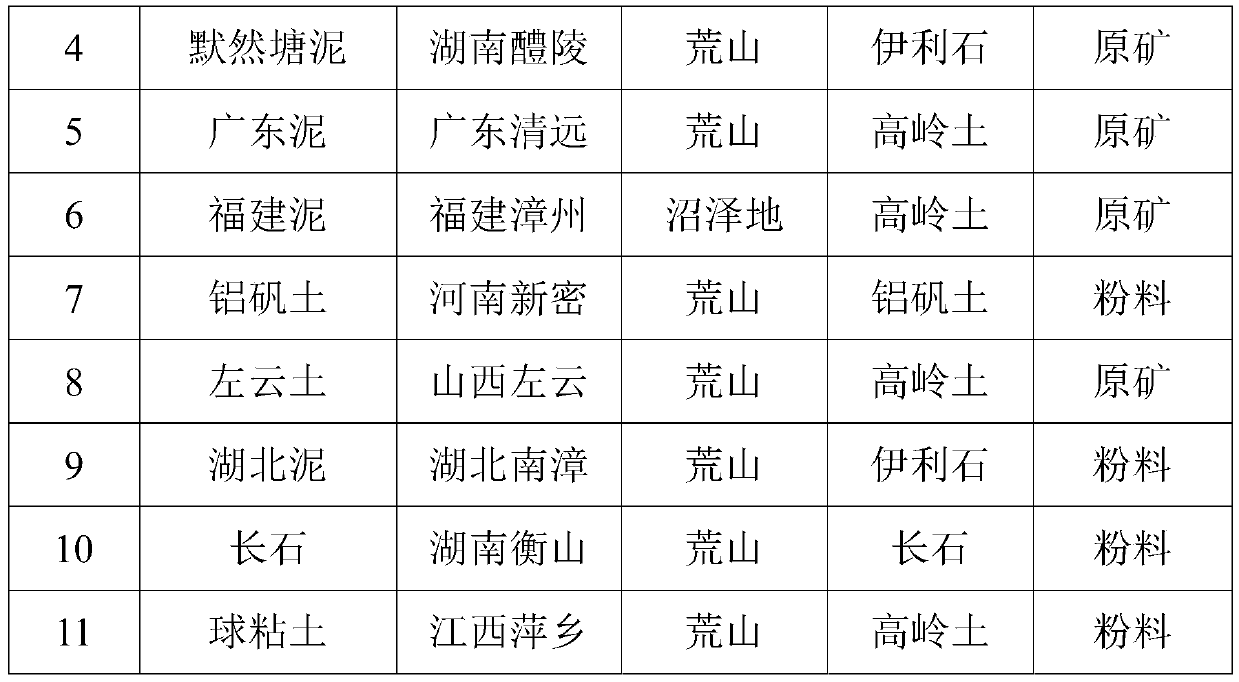

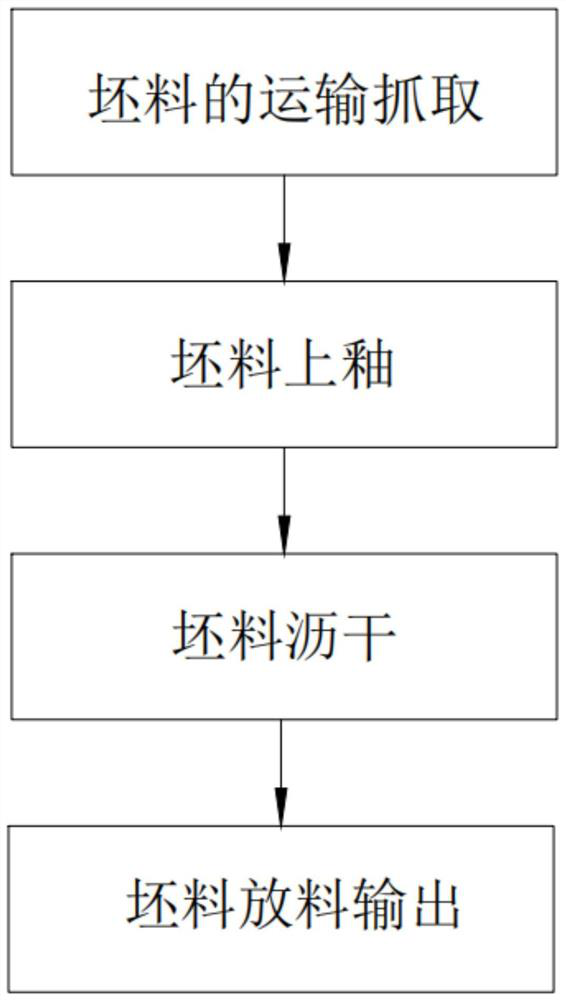

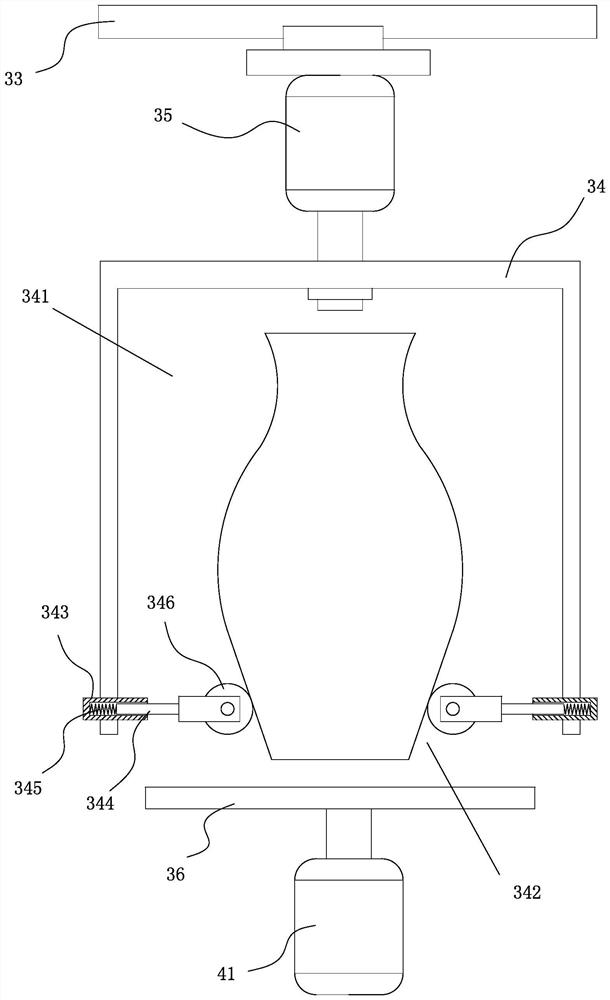

Ceramic glazing process

ActiveCN111331717AUniform adhesionImprove qualityCeramic shaping apparatusClaywaresGear wheelRubber sheet

The invention provides a ceramic glazing process. The ceramic glazing process comprises the following steps that a blank is transported and grabbed; the blank is glazed; the blank is drained off; andthe blank is discharged and output. A guiding wheel outwards moves to support the blank, the blank is grabbed through cooperation of a rubber plate, then the blank is immersed in a glaze pool under the effects of a guiding rod and a limiting ring, in the glaze pool, a gear is matched with a rack a and a rack b successively to drive the blank to rotate forwards and reversely in the glaze pool, andthe technical problem that in the prior art, the ceramic blank is glazed in a smearing mode, the glaze thickness is difficult to keep consistent, and consequently the ceramic firing effect is affectedis solved.

Owner:佛山市大境陶瓷科技有限公司

Glaze spraying equipment for sanitary appliances

The invention relates to the field of ceramic processing, in particular to glaze spraying equipment for sanitary appliances. The glaze spraying equipment comprises a conveying abutting mechanism, a processing mechanism and a guide mechanism, wherein the processing mechanism comprises a flexible processing pipe and a plurality of spring rods, one end of the processing pipe is fixedly connected to one end of a moving block, the other end of the processing pipe is fixedly connected to the other end of the moving block, the lower ends of the spring rods are fixedly connected to the side surface ofthe processing pipe, the spring rods and the processing pipe are located on the same vertical plane, a flexible dividing strip is vertically and fixedly arranged in the processing pipe, one side of the dividing strip and the inner wall of the processing pipe define a glaze spraying cavity, the other side of the dividing strip and the inner wall of the processing pipe define a dust collection andwatering cleaning cavity, a first through hole communicating with the glaze spraying cavity is formed in the processing pipe, and a second through hole communicating with the cleaning cavity is formedin the processing pipe. According to the scheme of the glaze spraying equipment, the consistency of floating material removing operation, water spraying operation on the surfaces of blanks and glazing operation can be improved, and the processing efficiency of the ceramic sanitary appliances can be improved.

Owner:CHONGQING CONCAST SANITARY WARE

Bowl support type automatic glaze dipping device

The invention provides a bowl support type automatic glaze coating device which comprises a support, a slide block and a sucker, wherein a bowl blank is put in a groove formed in a bowl support, a transverse moving motor is used for driving a transverse moving mechanism to move a longitudinal moving mechanism to be above the bowl support, a longitudinal moving motor is used for enabling the slide block to move downward, the transverse moving mechanism and the longitudinal moving mechanism cooperate to act to allow the bowl blank to enter a glaze pool to be glazed, then the longitudinal moving mechanism allows the bowl support and bowl blank to leave the glaze water surface after glazing is finished, and the longitudinal moving mechanism and the transverse moving mechanism cooperate again to send the bowl support and the bowl blank to a transmission rack, so that the whole glazing process is finished. The bowl support type automatic glaze coating device is used for automatic glazing in production of domestic ceramics, and can be used for solving the problems that the existing glazing devices used in factories have complicated driving mechanisms, low glazing efficiency and dead angle in glazing.

Owner:睢宁宝源新能源发电有限公司

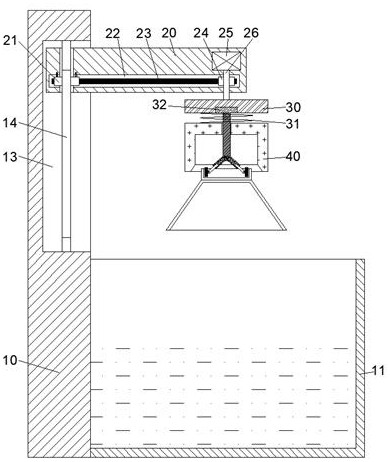

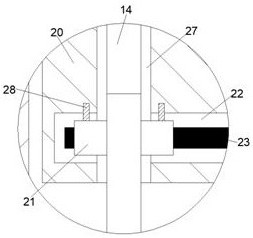

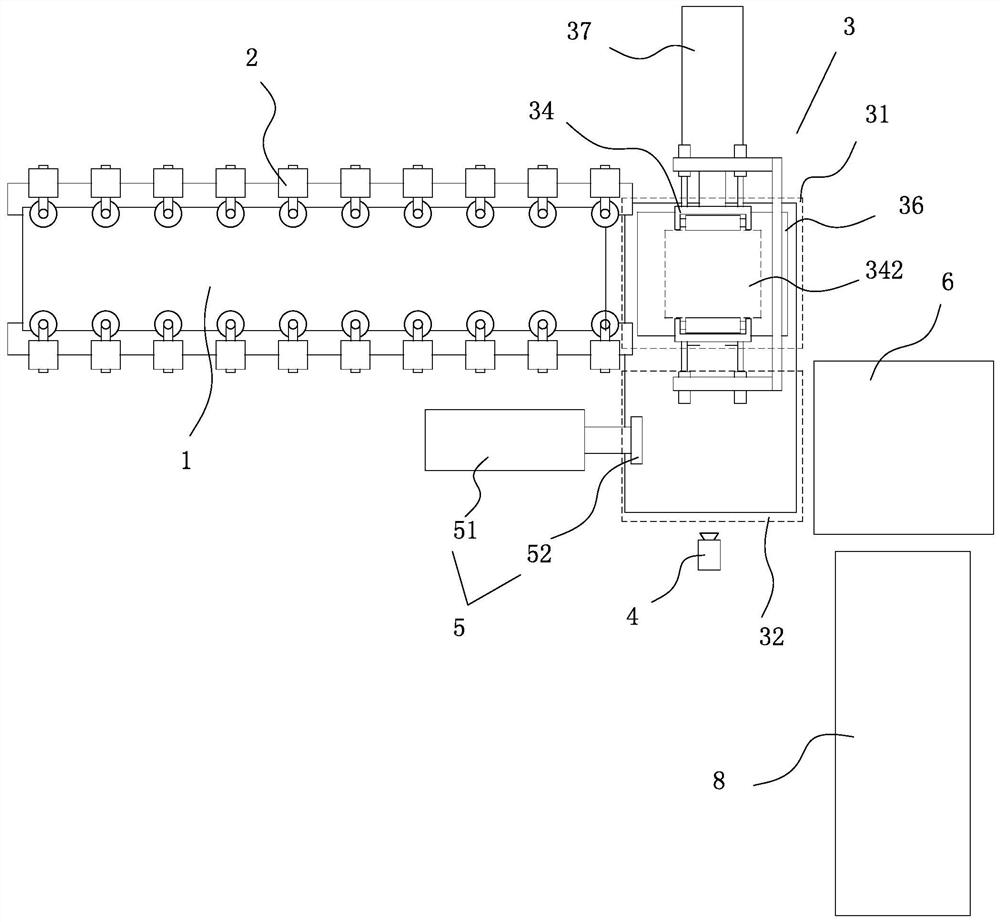

Human-simulating automatic ceramic glazing equipment and method

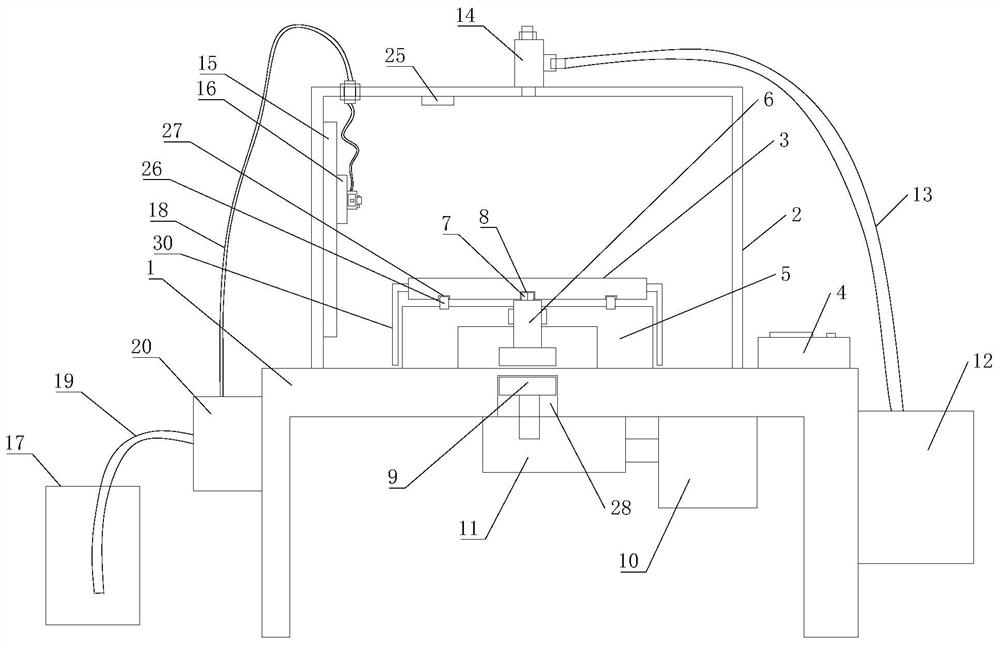

ActiveCN112776149ARealize the production of glazing processImprove glazing efficiencyCeramic shaping apparatusElectric machineryCeramic glaze

The invention relates to the technical field of ceramic production, in particular to human-simulating automatic ceramic glazing equipment and method. The equipment comprises a workbench, a glazing box, a rotary disc, a controller, a driving device, a vacuumizing device, a glaze spraying device and a detection device; the driving device comprises a motor, a speed reducer, a magnetic coupler and a mounting frame; the vacuumizing device comprises a vacuum pump, a connecting pipe and an electromagnetic valve; the glaze spraying device comprises a vertical track, a synchronous belt motor, a glaze barrel, a first glaze pipe, a second glaze pipe, a high-pressure pump, an electromagnetic regulating valve and a spray gun; the detection device comprises a flow velocity detection sensor, a distance detection sensor and an air pressure detection sensor; the signal output ends of the flow velocity detection sensor, the distance detection sensor and the air pressure detection sensor are connected with the input end of the controller; and the output end of the controller is connected with the control ends of the motor, the vacuum pump, the electromagnetic valve, the synchronous belt motor, the high-pressure pump and the electromagnetic regulating valve. The human-simulating ceramic glaze spraying effect can be achieved.

Owner:龙泉市九龙青瓷有限公司

Manufacturing process of comprehensively-glazed ceramic

ActiveCN112339088AFull GlazingNo manual deliveryAuxillary shaping apparatusGlazeMechanical engineering

The invention discloses a manufacturing process of comprehensively-glazed ceramic. The ceramic is comprehensively glazed through an overturning type comprehensive glazing device in the ceramic manufacturing process. The overturning type comprehensive glazing device comprises a limiting and fixing base plate and a bearing frame assembly for containing the ceramic. A lifting and overturning mechanism and a positioning assembly used in cooperation with the lifting and overturning mechanism are installed on one side of the surface of the limiting and fixing base plate, and an adjusting and fixingglazing mechanism is installed on the lifting and overturning mechanism. By means of the overturning type comprehensive glazing device, the ceramic can be overturned after being glazed by dipping, then glaze in the ceramic with grooves is poured out in the overturning process; and then glazing by dipping is conducted, and therefore a contact part of the ceramic can also be dipped with the glaze.

Owner:广东顺辉新型材料科技有限公司

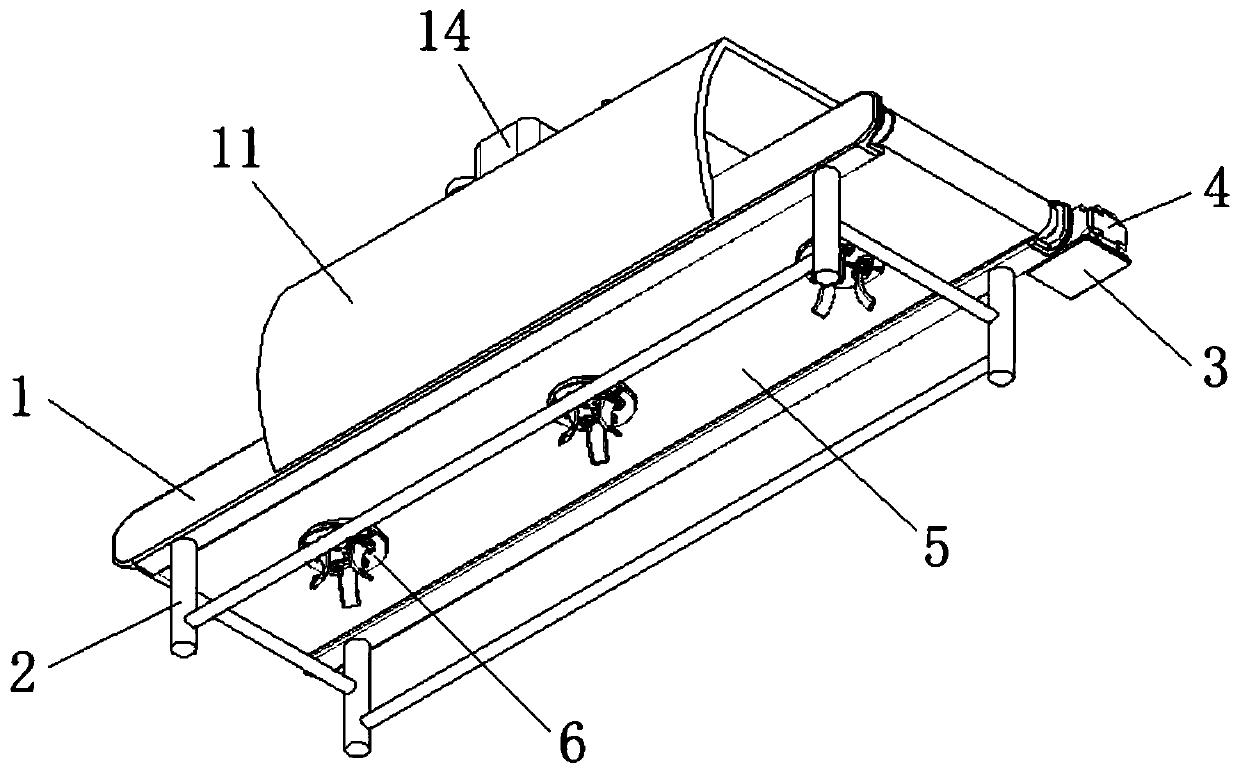

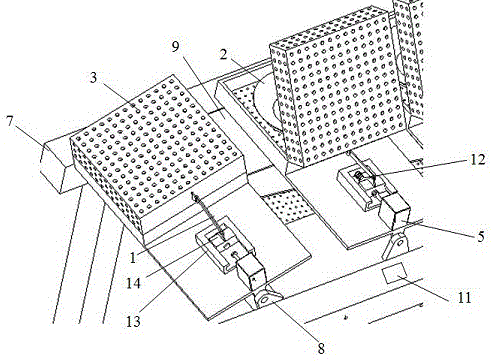

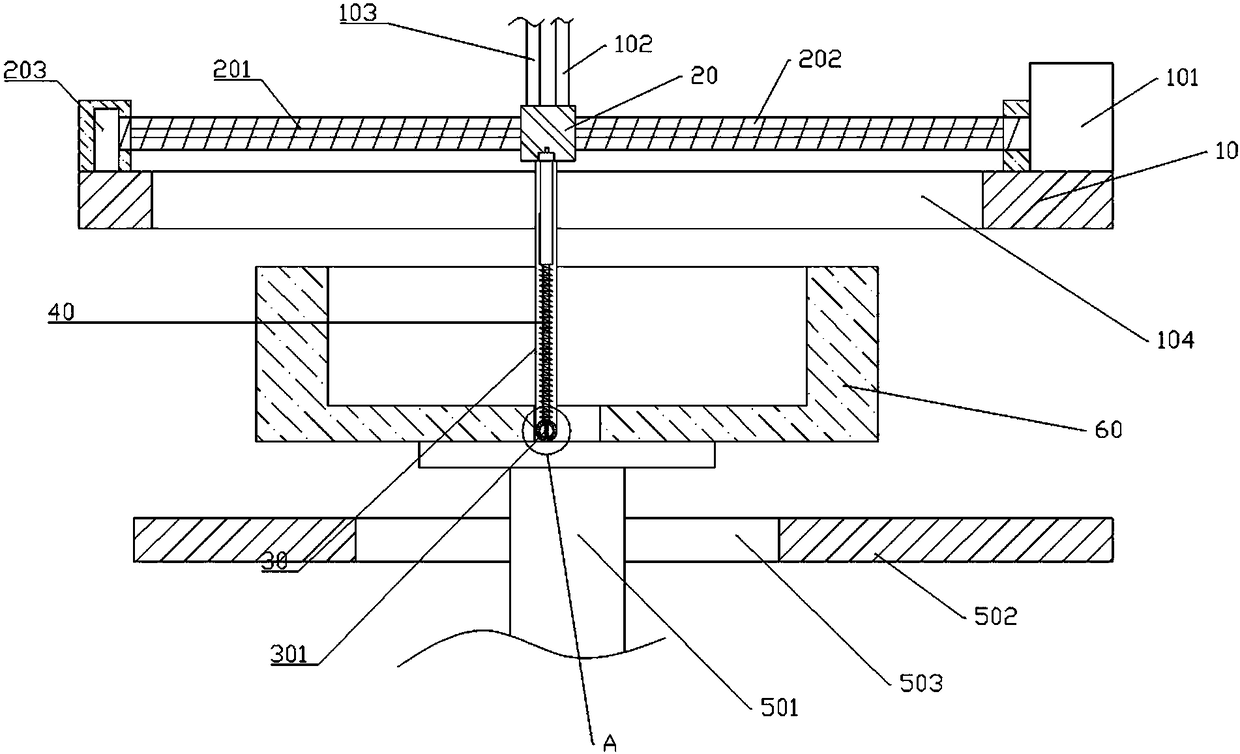

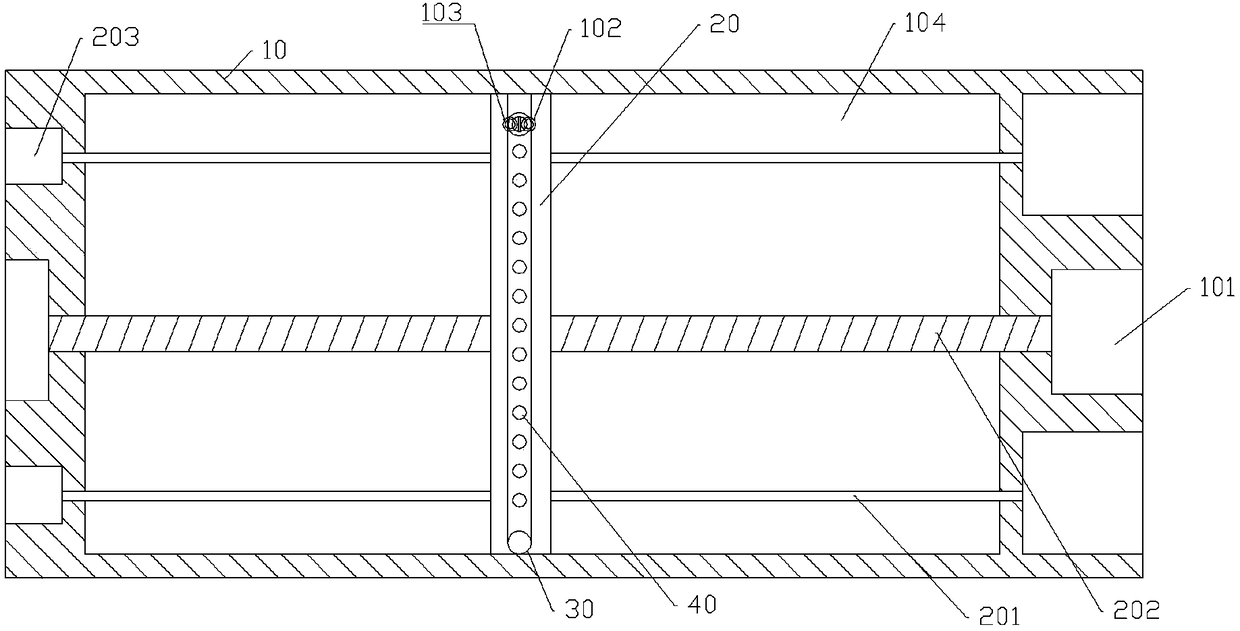

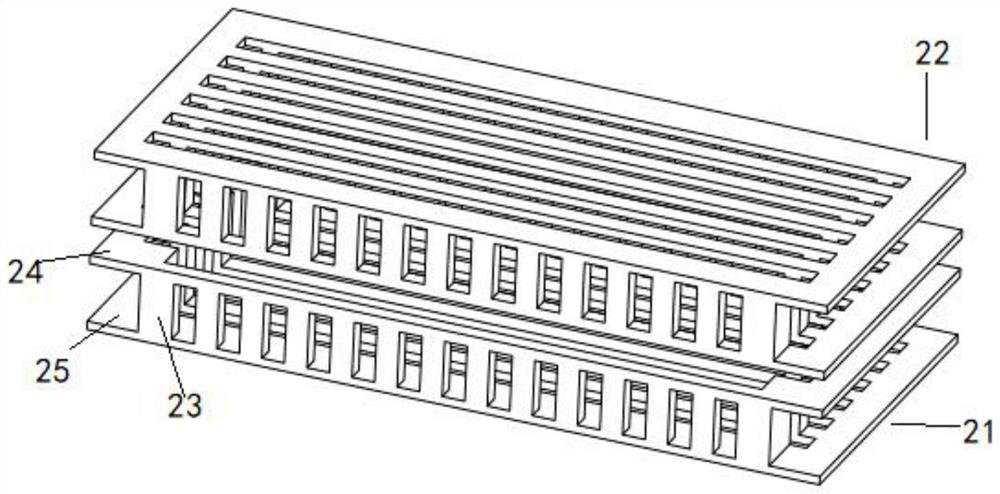

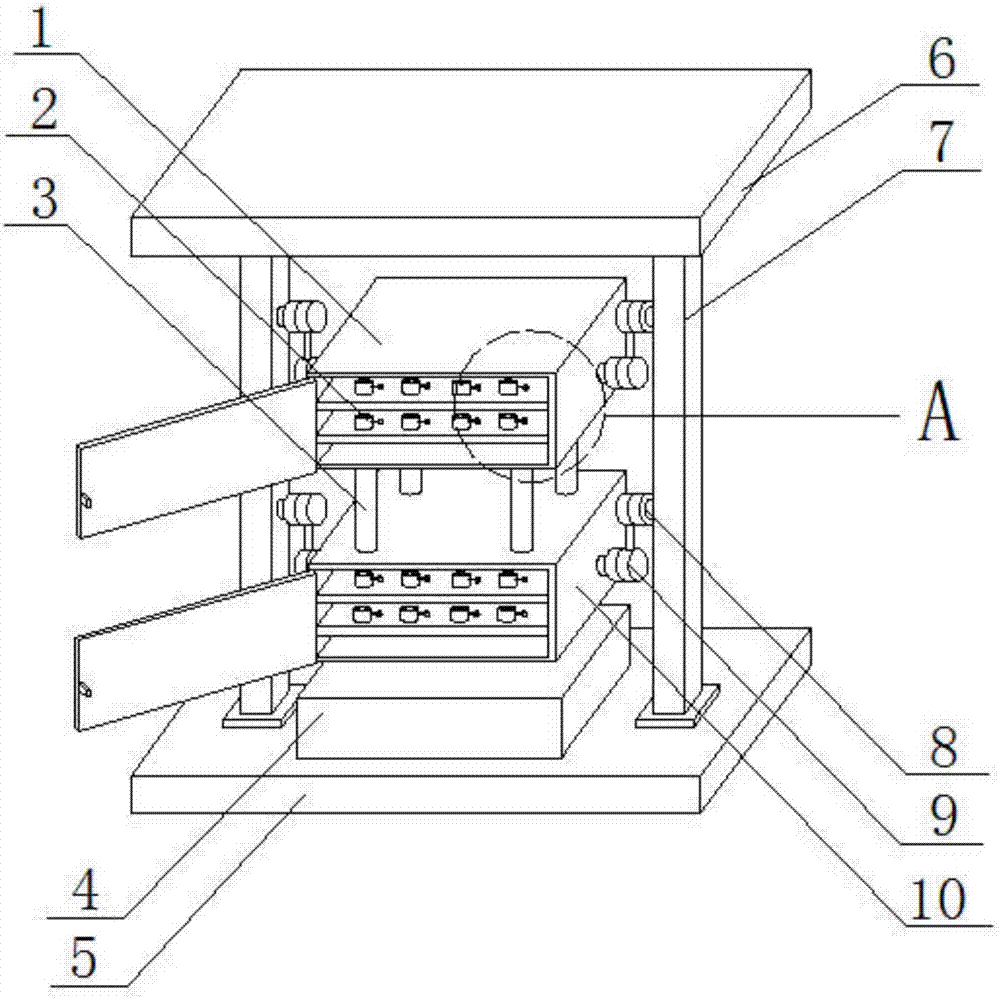

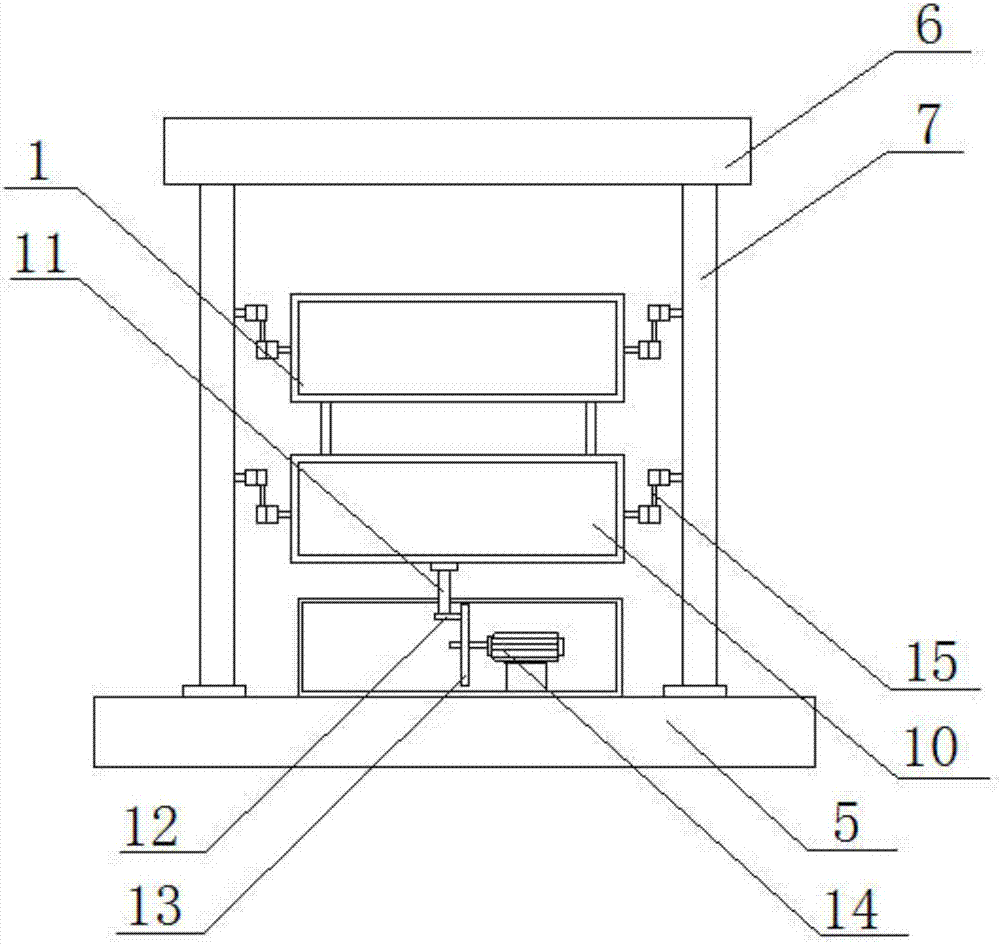

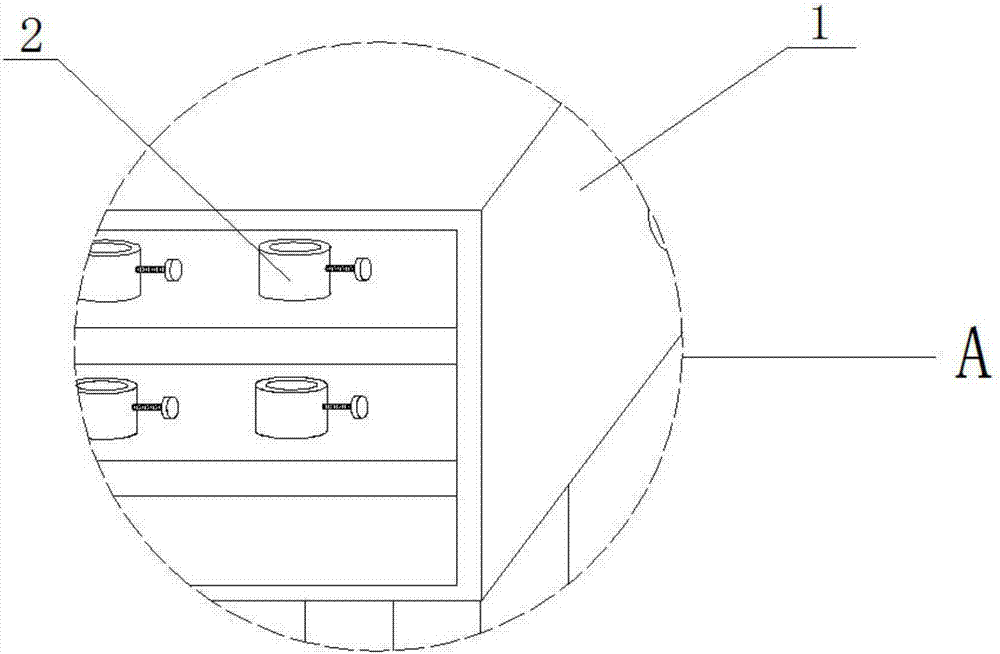

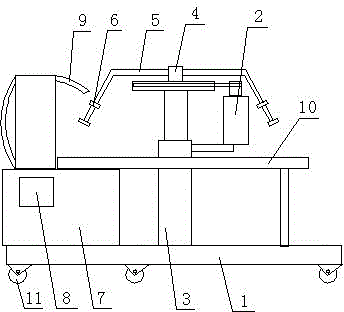

Auxiliary glaze shaking device used for ceramic glazing

InactiveCN107225659AEnables automated shaker mixingEasy to placeCeramic shaping apparatusCentrifugationEngineering

The invention discloses an auxiliary glaze-sloshing device for ceramic glazing, which comprises a base, a protection box is arranged in the middle of the upper end of the base, a driving device is arranged in the protection box, and the driving device is fixed in the protection box through a fixing device , the output shaft of the driving device is provided with a centrifugal wheel, the centrifugal wheel is fixed with a centrifugal rod, the centrifugal rod is connected with a pull rod for rotation, the upper end of the protection box is provided with an opening, and the pull rod passes through the opening and Extending to the upper end of the protection box, both sides of the protection box are provided with support columns, and the support columns are fixed on the base through the fixing block, and the opposite side of the two support columns is provided with a plurality of first a connecting rod. The present invention realizes the automatic vibration mixing of the glaze material in the ceramic bottle through the combination of the centrifugal wheel, the centrifugal rod and the driving device, and increases the placement amount of the ceramic bottle through the arrangement of multiple placing boxes and placing plates, thereby improving the glaze application efficiency. Efficiency, suitable for promotion.

Owner:CHONGQING YAYU CERAMICS CO LTD

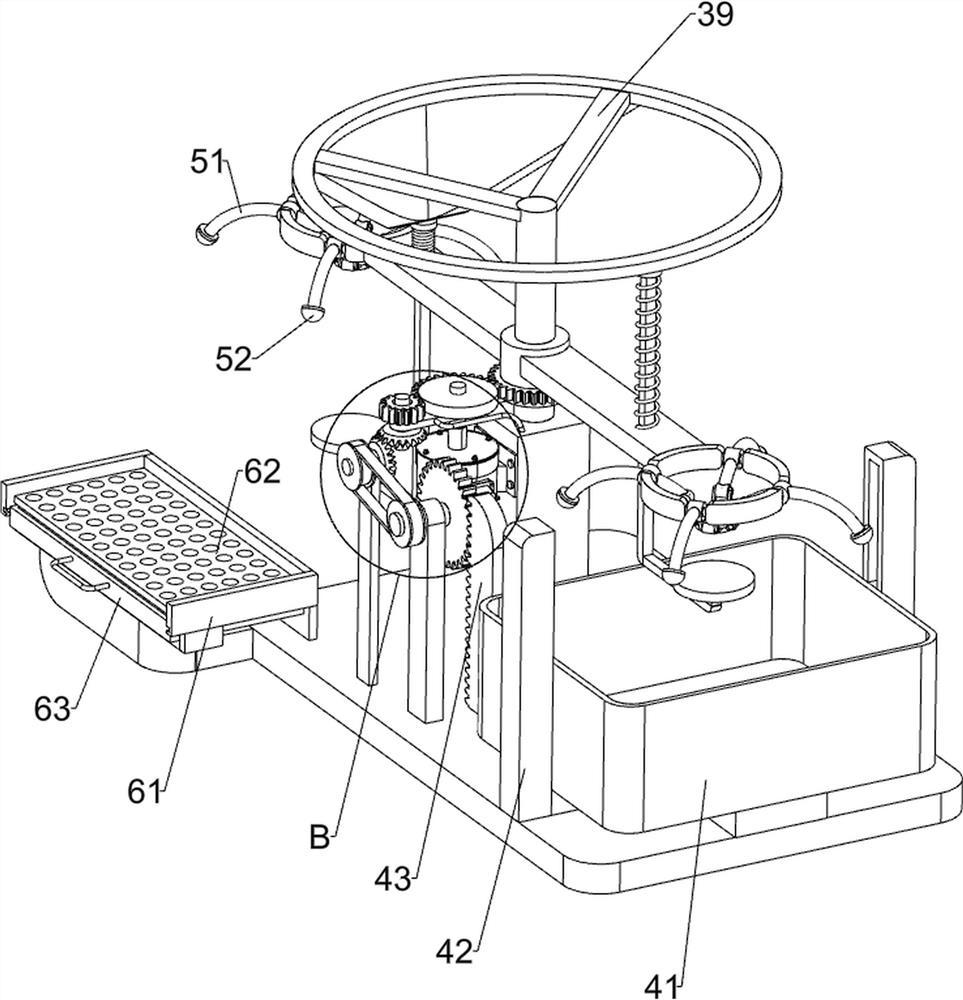

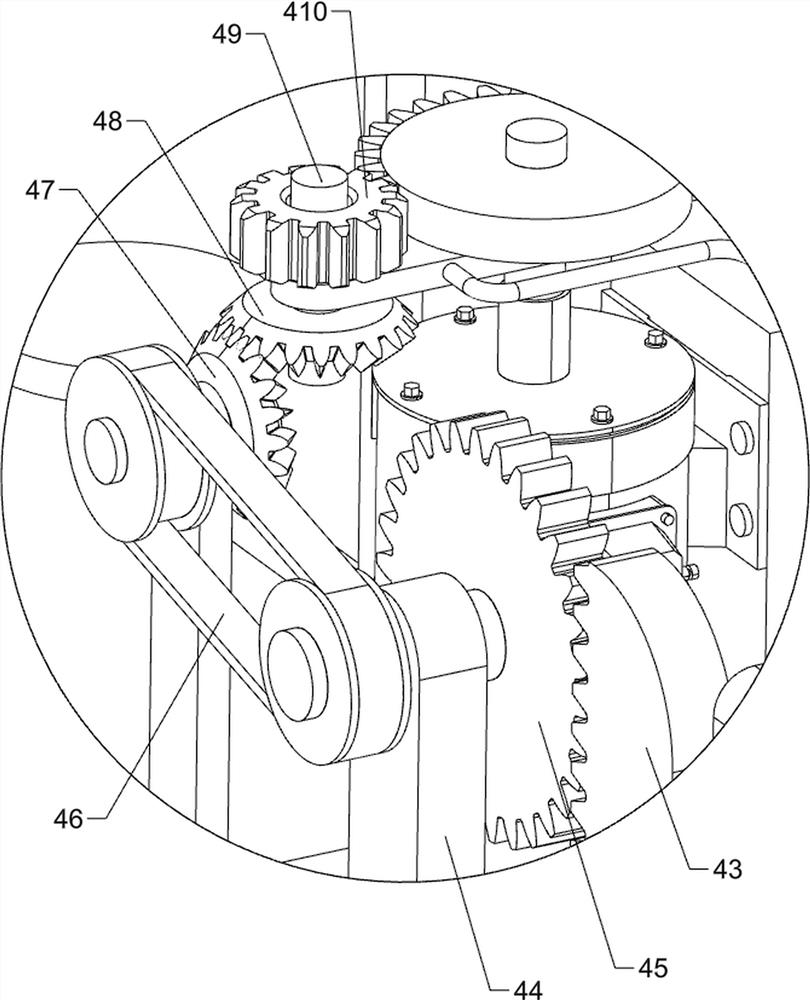

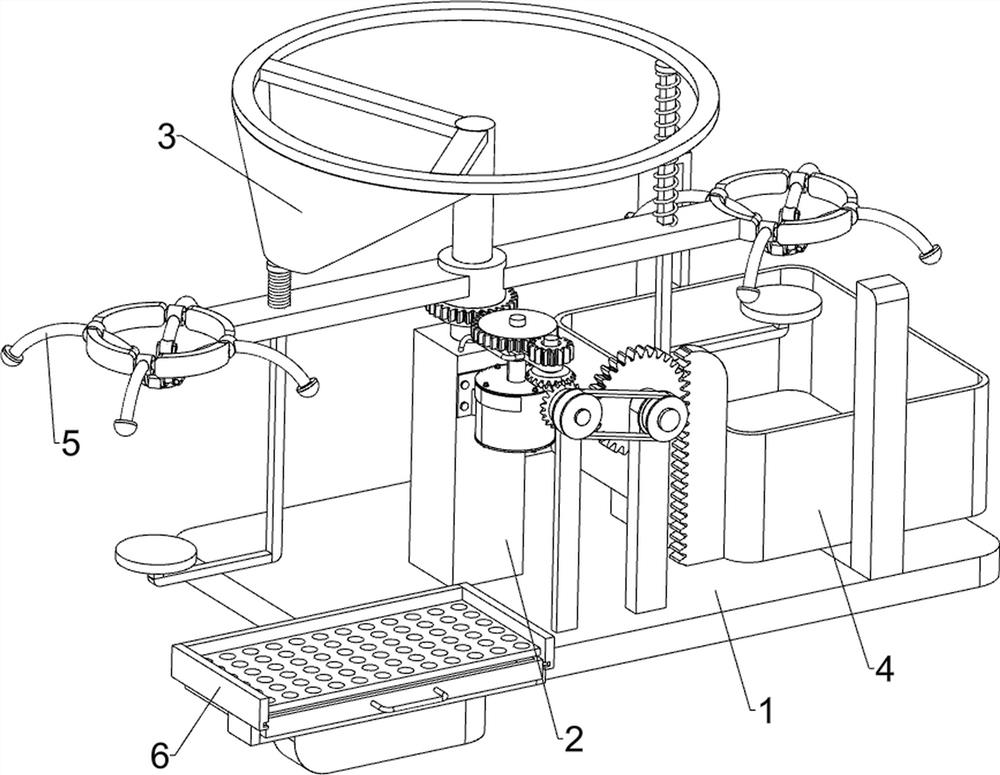

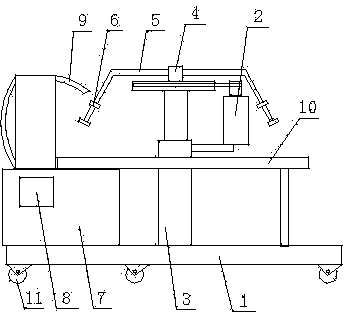

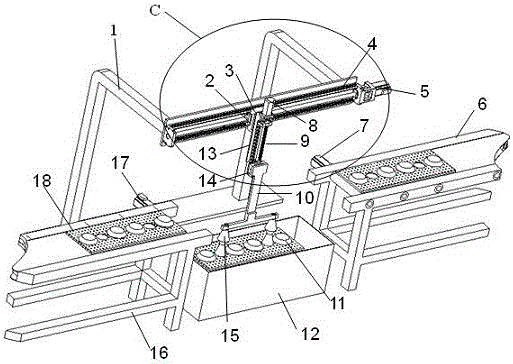

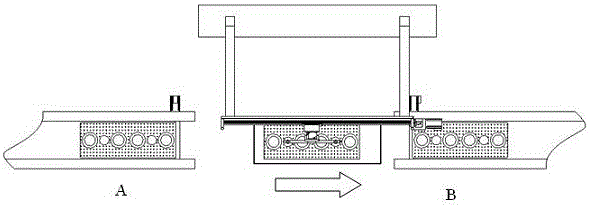

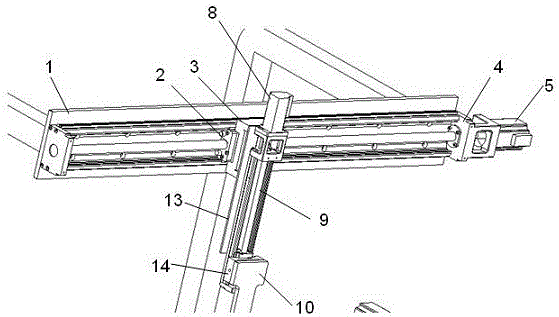

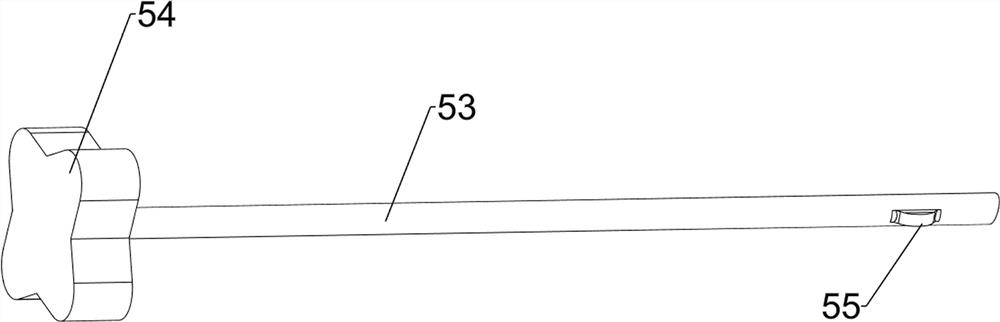

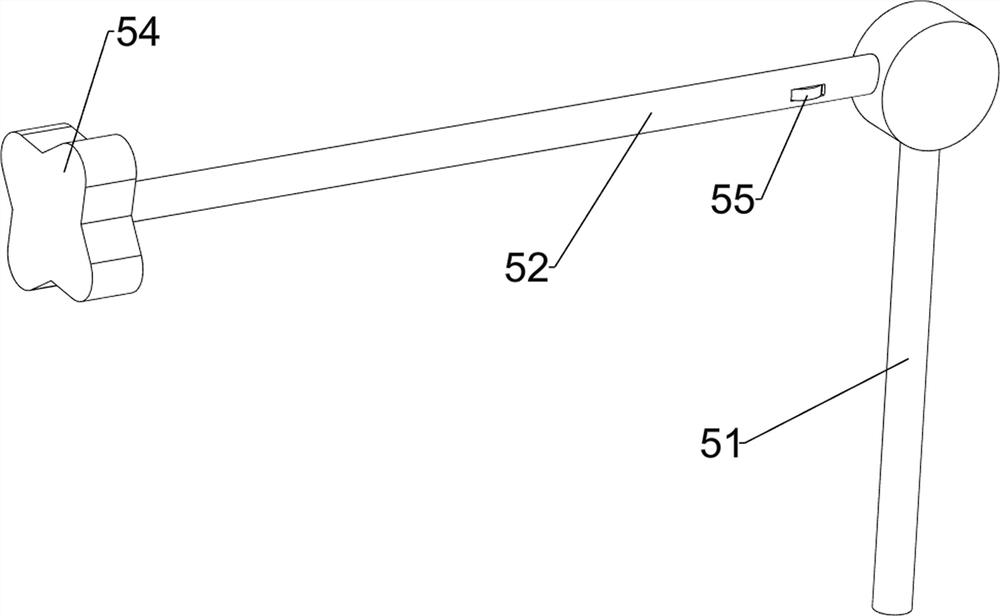

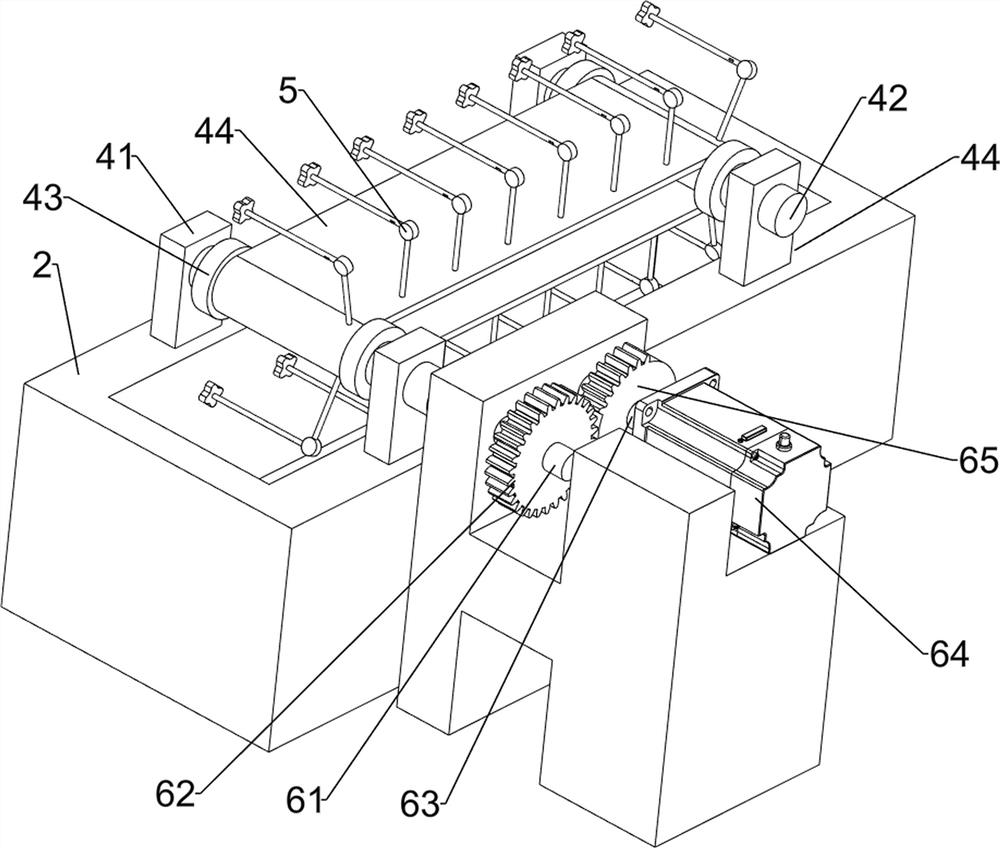

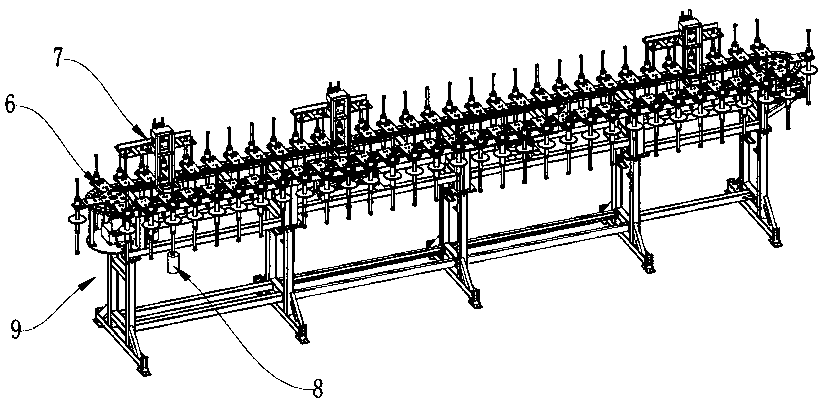

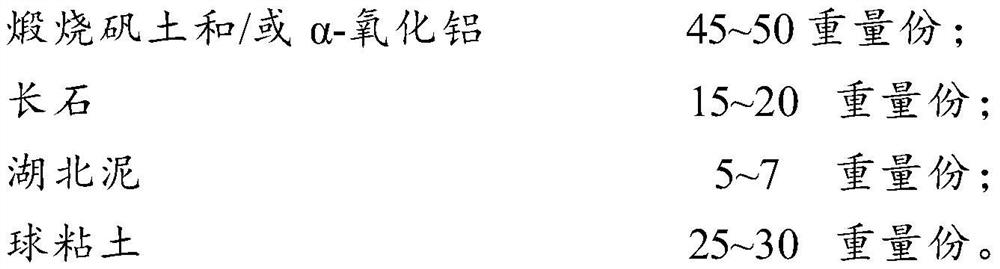

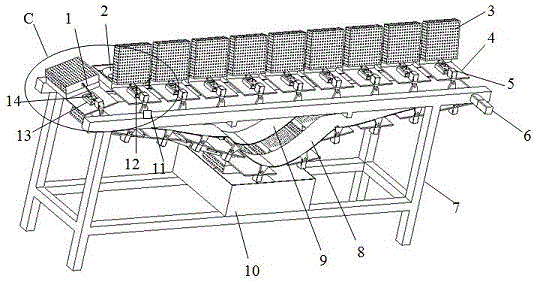

Soup spoon glazing device for ceramic soup spoon production

PendingCN113146811AGlazing automaticImprove glazing efficiencyCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to a glazing device, in particular to a soup spoon glazing device for ceramic soup spoon production. The soup spoon glazing device which can automatically conduct soup spoon glazing, conduct glazing on soup spoons in batches and improve the glazing efficiency and is used for ceramic soup spoon production is provided. The soup spoon glazing device for ceramic soup spoon production comprises a bottom plate, a support, a conveying mechanism and a driving mechanism, and one side of the bottom plate is connected with a glaze containing box. The support is installed on the other side of the bottom plate. The conveying mechanism is installed on the glaze containing box, and a hanging mechanism is installed on the conveying mechanism. The driving mechanism is installed on the support, and the driving mechanism is in transmission connection with the conveying mechanism. The soup spoons can be hung in batches through the hanging mechanism, the conveying mechanism can be driven to work through the driving mechanism, and by means of the conveying mechanism, the soup spoons can be conveyed into the glaze containing box in batches to be glazed, and the glazed soup spoons can be conveyed out of the glaze containing box.

Owner:谢斌

A kind of high-gloss anti-friction varnish and its preparation method

Owner:ZHEJIANG KEXIN INK

A kind of equipment for spraying glaze inside the porcelain bottle used in the production of craft ceramics

ActiveCN111113649BAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

Owner:广东金润源陶瓷股份有限公司

A ceramic glazing process

ActiveCN111331717BUniform adhesionImprove qualityCeramic shaping apparatusClaywaresGear wheelEngineering

The invention provides a ceramic glazing process, which includes the following steps: transportation and grabbing of blanks, glazing of blanks, draining of blanks, and discharge of blanks. The board grabs the blank, and then the blank is immersed in the glaze pool under the action of the guide rod and the limit ring. In the glaze pool, the gear cooperates with the rack a and the rack b to drive the blank in the forward and reverse directions in the glaze pool. In the prior art, ceramic blanks are glazed by smearing, but the thickness of the glaze is difficult to keep consistent, which affects the technical problem of ceramic firing effect.

Owner:佛山市大境陶瓷科技有限公司

Porcelain bowl glazing equipment

InactiveCN113733321AImprove readinessImprove glazing efficiencyCeramic shaping apparatusStructural engineeringMechanical engineering

The invention discloses porcelain bowl glazing equipment. The porcelain bowl glazing equipment comprises a main box body, a lifting base is arranged in the main box body, an electromagnet base is arranged on the lower side of the lifting base, a magnetic anti-glaze cover is arranged on the lower side of the electromagnet base, an anti-glaze cover sliding rod is arranged in the magnetic anti-glaze cover, and a porcelain bowl supporting mechanism and a locking mechanism are arranged in the anti-glaze cover sliding rod. According to the porcelain bowl glazing equipment, through cooperation of the porcelain bowl supporting mechanism and the locking mechanism, the porcelain bowl bottom can be rapidly supported and fixed, the preparation work of porcelain bowl glazing is accelerated, the porcelain bowl glazing efficiency is improved, meanwhile, through the magnetic anti-glaze cover capable of moving up and down, the porcelain bowl bottom can be covered, glaze slip is prevented from making contact with the porcelain bowl bottom, workers can conveniently take bowls and are prevented from making contact with the glaze slip when taking the bowls, it is guaranteed that glaze layers of porcelain bowls are uniform, and meanwhile the influence of the glaze slip on the health of the workers is reduced.

Owner:陈小凤

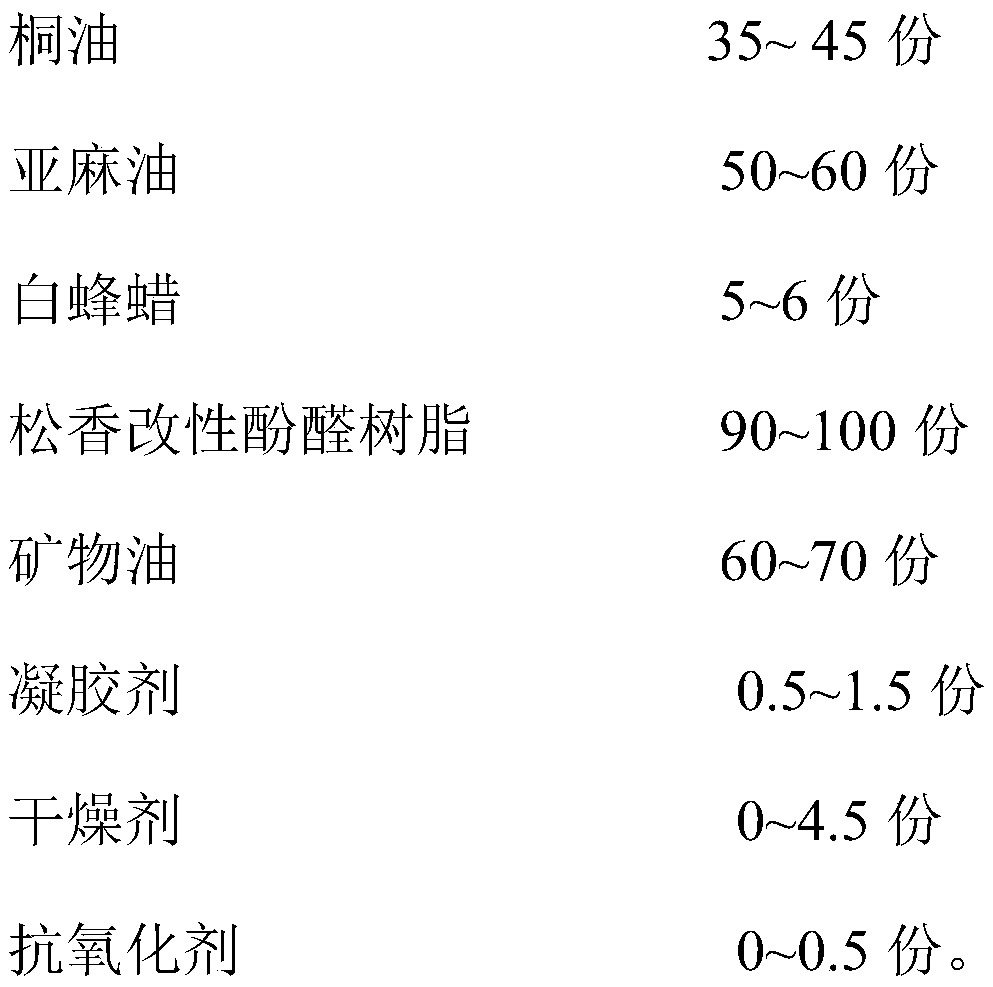

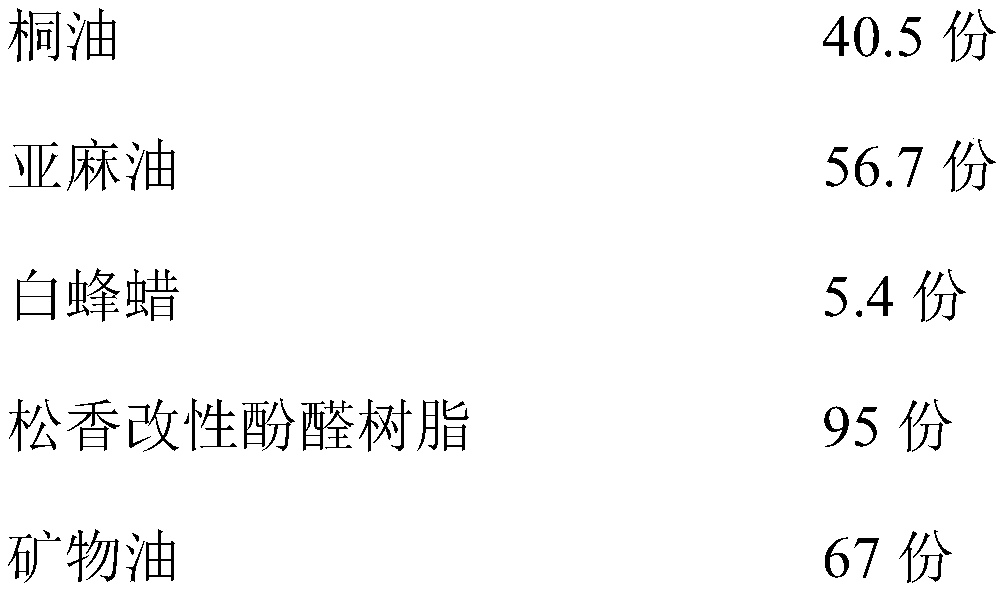

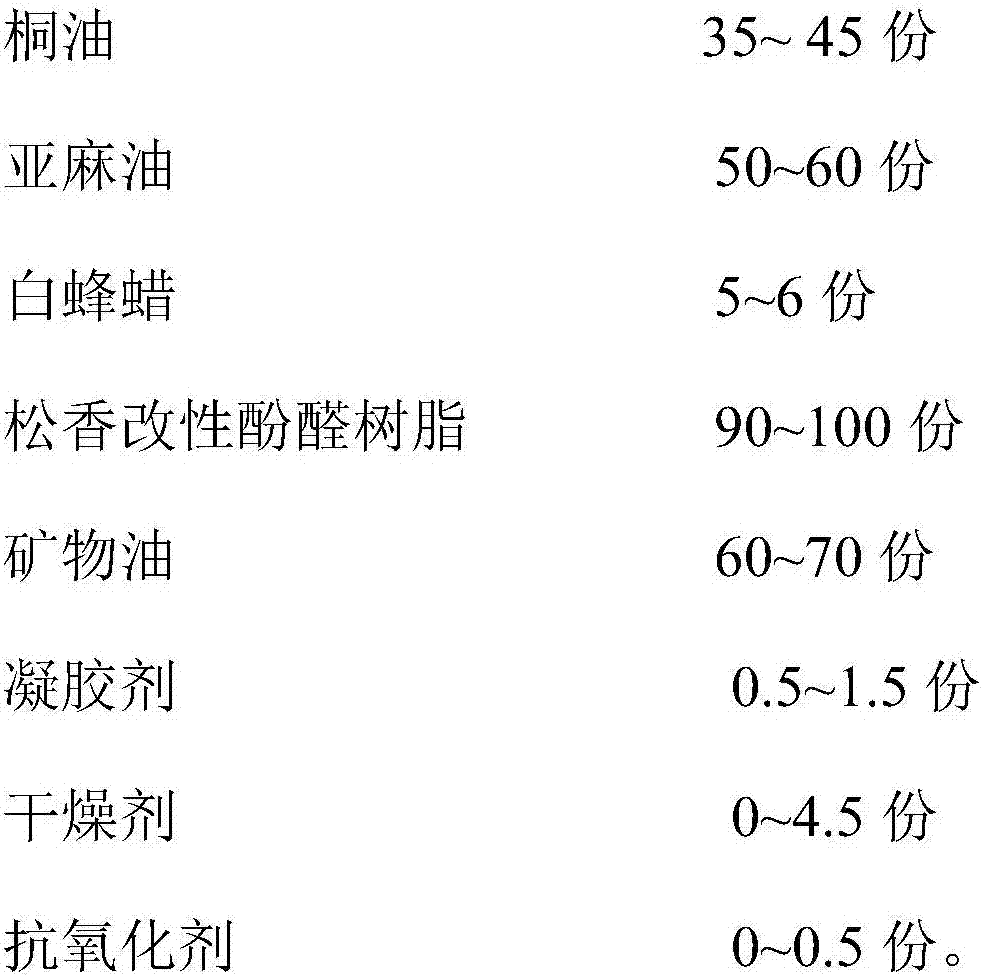

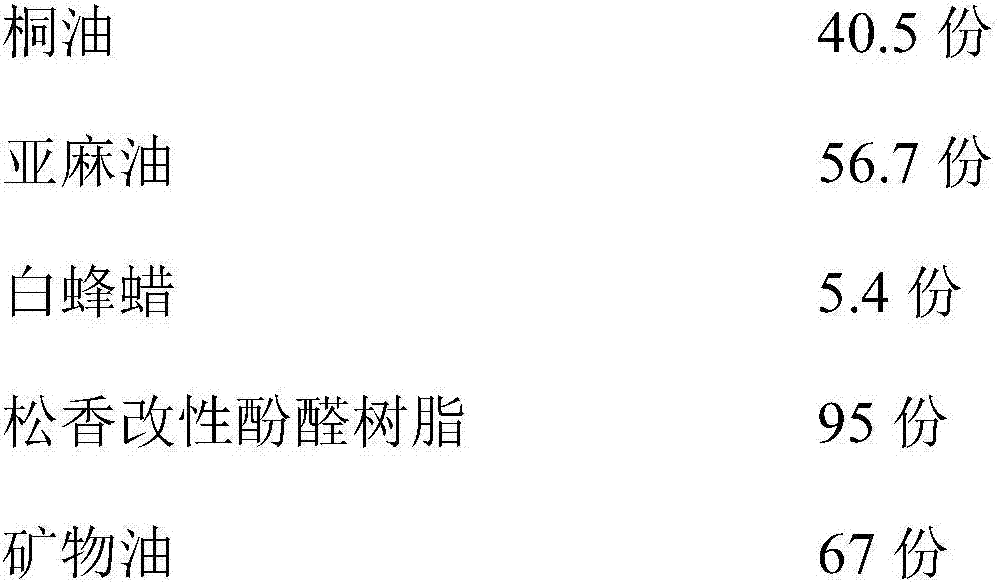

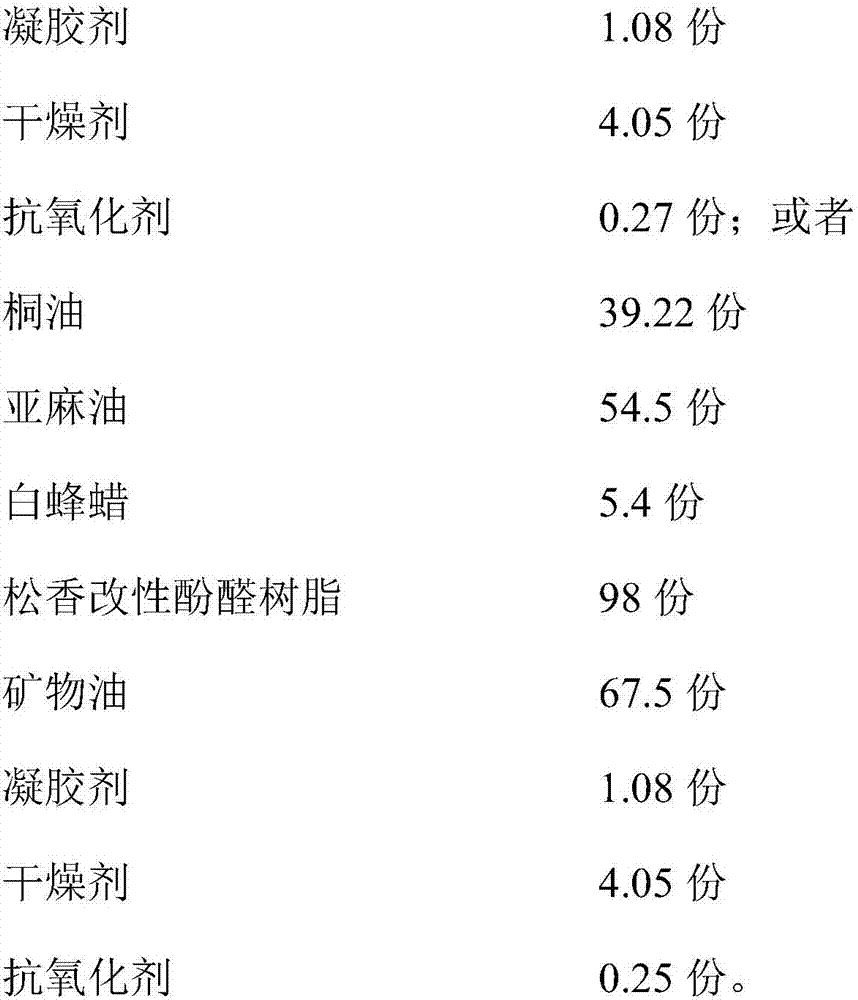

High-gloss and friction-resistant varnish and preparation method thereof

The invention belongs to the technical field of coatings and discloses high-gloss and friction-resistant varnish and a preparation method thereof. The varnish is prepared from raw materials as follows: tung oil, linseed oil, cera alba, rosin modified phenolic resin, mineral oil, gel, a drying agent and an antioxidant. The varnish has the characteristics of good friction resistance, high gloss and proneness to drying, and the preparation process of the varnish has the advantages of being convenient to operate, low in cost and suitable for large-scale industrial production.

Owner:ZHEJIANG KEXIN INK

Ceramic pot glazing device for porcelain production

PendingCN113997395AImprove glazing efficiencyIncreased rate of glazing operationsAuxillary shaping apparatusWater storage tankCeramic

The invention relates to a glazing device, in particular to a ceramic pot glazing device for porcelain production. According to the ceramic pot glazing device for porcelain production, the stability of ceramics is good in a glazing process, and the ceramics can be quickly pushed to designated positions for glazing. The ceramic pot glazing device for porcelain production comprises: a first movable plate, which is arranged on a first supporting frame in a sliding mode; first compression springs, which are arranged between and connected with the two sides of the first movable plate and the first supporting frame, and are wound on the first movable plate; and a water storage tank, which is arranged at the upper middle part of the first supporting frame. According to the ceramic pot glazing device, a limiting mechanism is arranged and matched with a suction mechanism, the suction mechanism controls a ceramic pot to move, the limiting mechanism can be matched with the ceramic pot to move, and meanwhile, oil can be dried, so ceramic pot glazing efficiency can be improved.

Owner:台州骏隆印刷包装有限公司

A circular glazing line

ActiveCN111055374BImprove glazing efficiencyEffective connectionCeramic shaping plantsGlazeEngineering

An annular glazing line, comprising an annular conveying line, a cup edge grinding device, a roller type glaze device, a turning device and a glaze stirring device, the cup edge grinding device, the roller edge glaze device, the turning device and the glaze The material stirring devices are distributed along the annular conveying line. According to the above content, the present invention proposes an annular glazing line, which can effectively connect the functions realized by each station, thereby effectively improving the glazing efficiency of the ceramic cup.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

Ceramic automatic mechanical equipment based on vector control

PendingCN114789503ABuild a three-dimensional structureAchieve orientationAuxillary shaping apparatusControl vectorControl system

The invention relates to the field of ceramic production equipment, in particular to ceramic automatic mechanical equipment based on vector control, and mainly solves the problems that in the prior art, ceramic glaze spraying efficiency is low, and the surface is prone to overflow. Comprising a rack, a control system arranged on the rack, an input conveying belt, guide assemblies, a transfer assembly, a surface pretreatment assembly, a material pushing assembly, a glaze spraying box, a glaze spraying assembly and an output conveying belt, the guide assemblies are arranged on the two transverse sides of the input conveying belt, and the transfer assembly is arranged at the output end of the input conveying belt 1; the transferring assembly is provided with a temporary storage station and an identification station, the pushing assembly is arranged at the output end of the transferring assembly, the glaze spraying box is arranged at the output end of the pushing assembly, a second supporting platform and a third driving motor connected with the second supporting platform are arranged in the glaze spraying box, and the glaze spraying assembly is arranged in the glaze spraying box and located on the upper side of the second supporting platform; the output conveying belt is arranged at the output end of the glaze spraying box.

Owner:晋江捷兴机械有限公司

A kind of electric porcelain insulator and preparation method thereof

Owner:湖南阳东电瓷电气股份有限公司

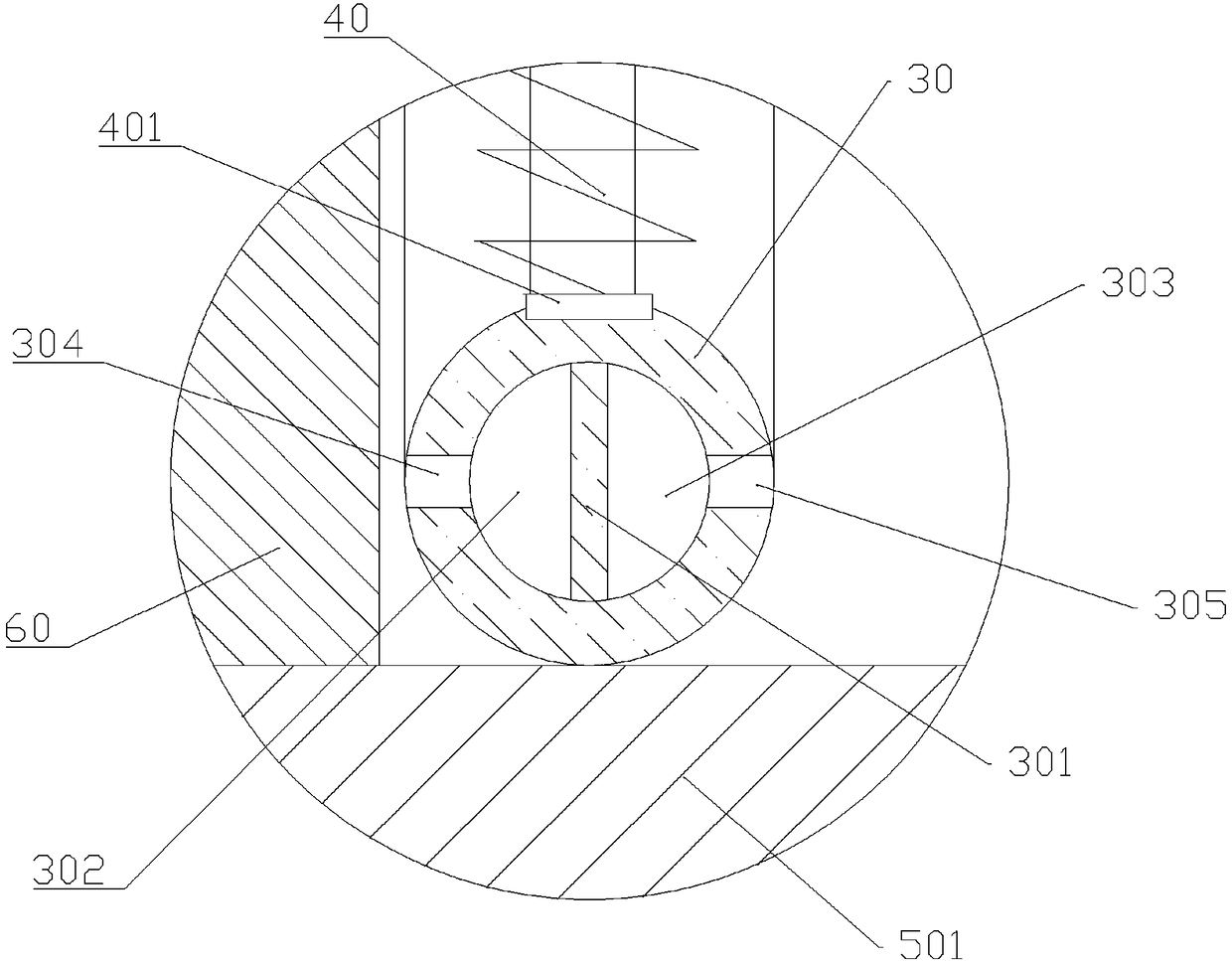

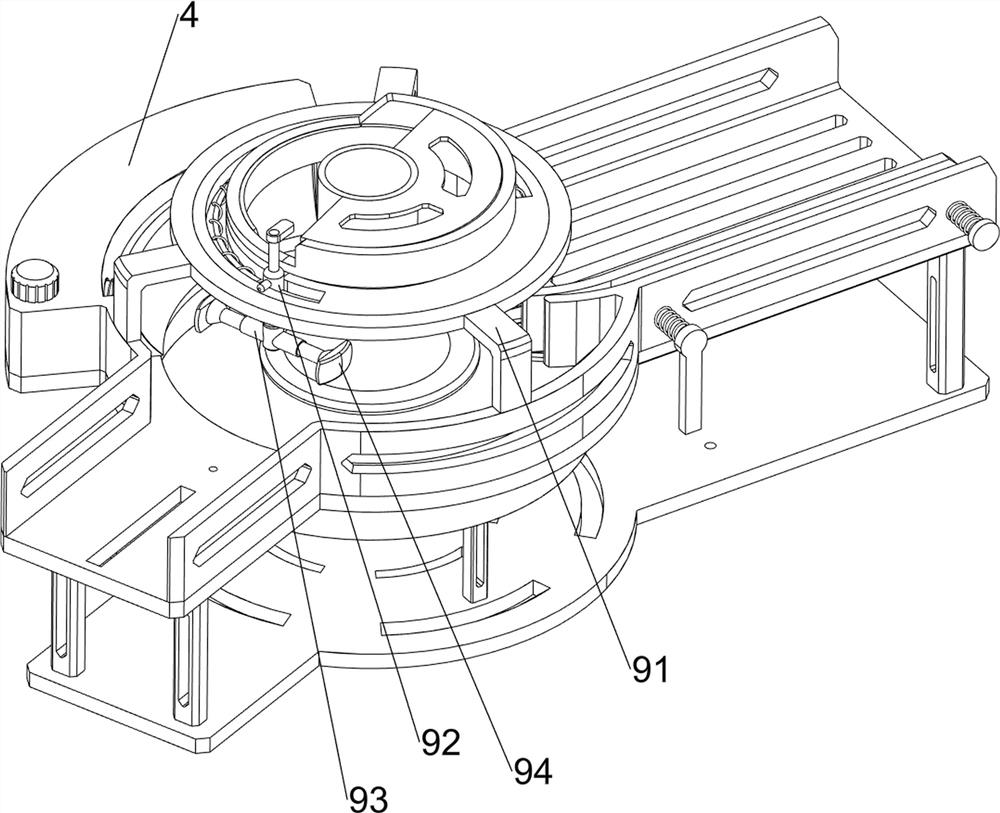

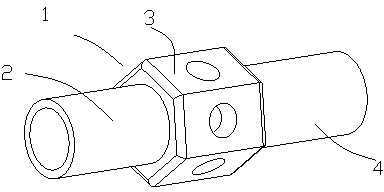

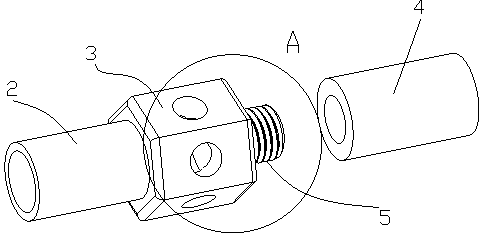

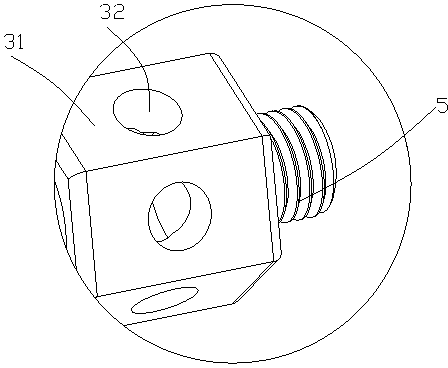

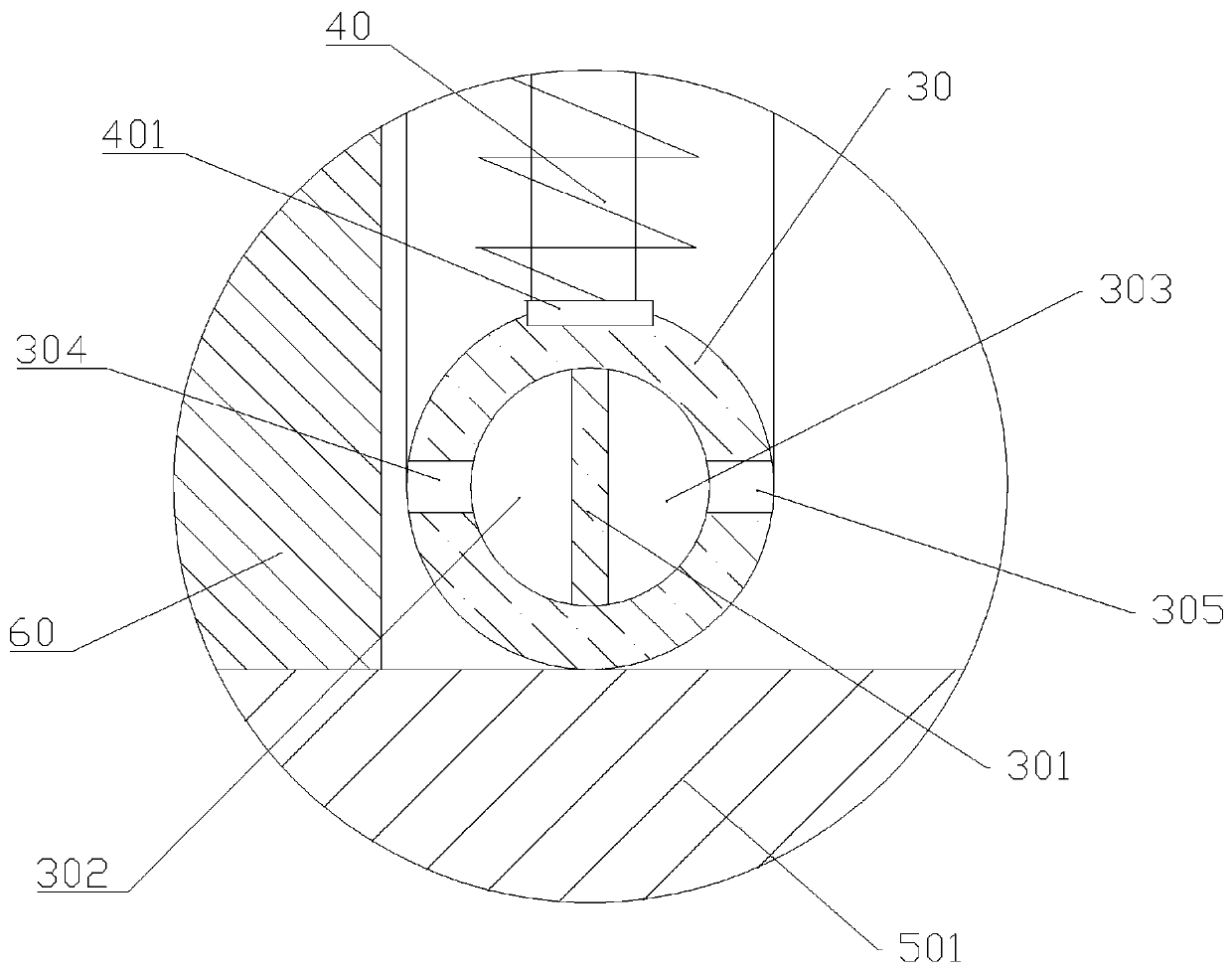

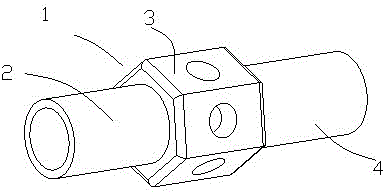

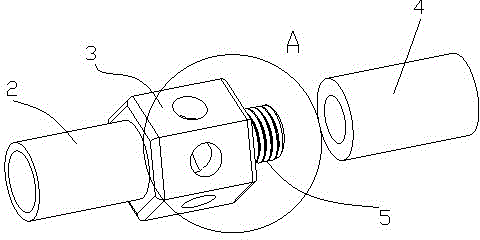

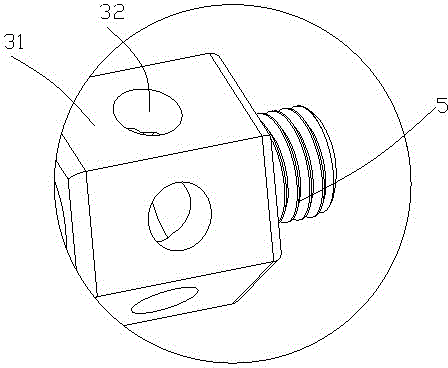

Rubber covered roller mounting machine head for glazing machine

ActiveCN103722879AImprove usabilityImprove glazing efficiencyPrinting press partsAgricultural engineering

The invention discloses a rubber covered roller mounting machine head for a glazing machine. The rubber covered roller mounting machine head for the glazing machine comprises a driving sleeve, and the head of the driving sleeve is provided with a detachable mounting boss in a hexagonal prism shape and a connecting bolt. A detachable driven sleeve is arranged on the connecting bolt, and a mounting through hole is formed in each lateral wall of the mounting boss. The detachable mounting boss in the hexagonal prism shape is adopted in the rubber covered roller mounting machine head for the glazing machine, a user can mount six rubber covered rollers at the same time, and meanwhile can select the mounting bosses of different sizes according to the sizes of the rubber covered rollers, so that usability of the glazing machine is greatly improved, and glazing efficiency is improved. The rubber covered roller mounting machine head for the glazing machine is simple in structure and high in practicality.

Owner:中山市格能电子科技有限公司

Rotary Automatic Glazing Machine

Owner:简厚诚

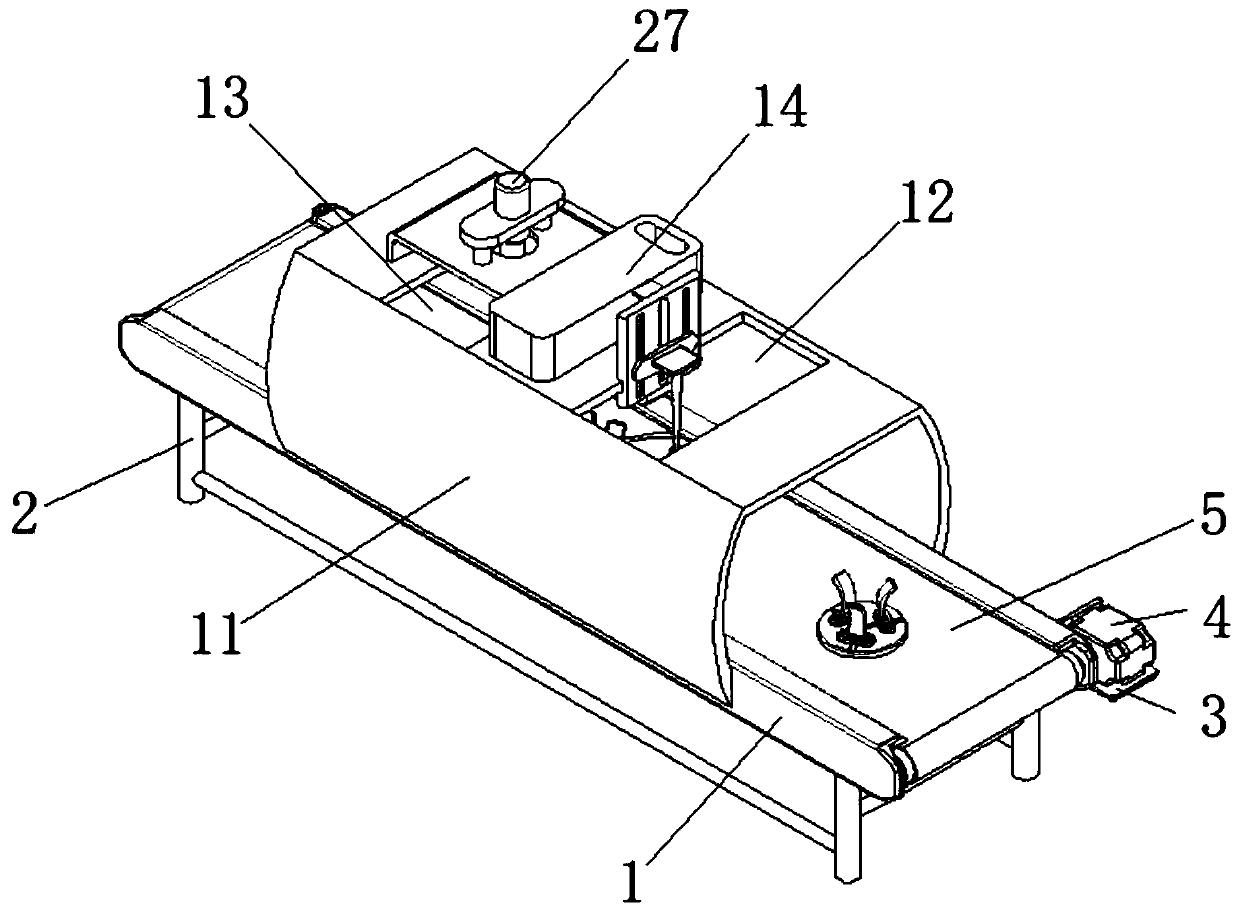

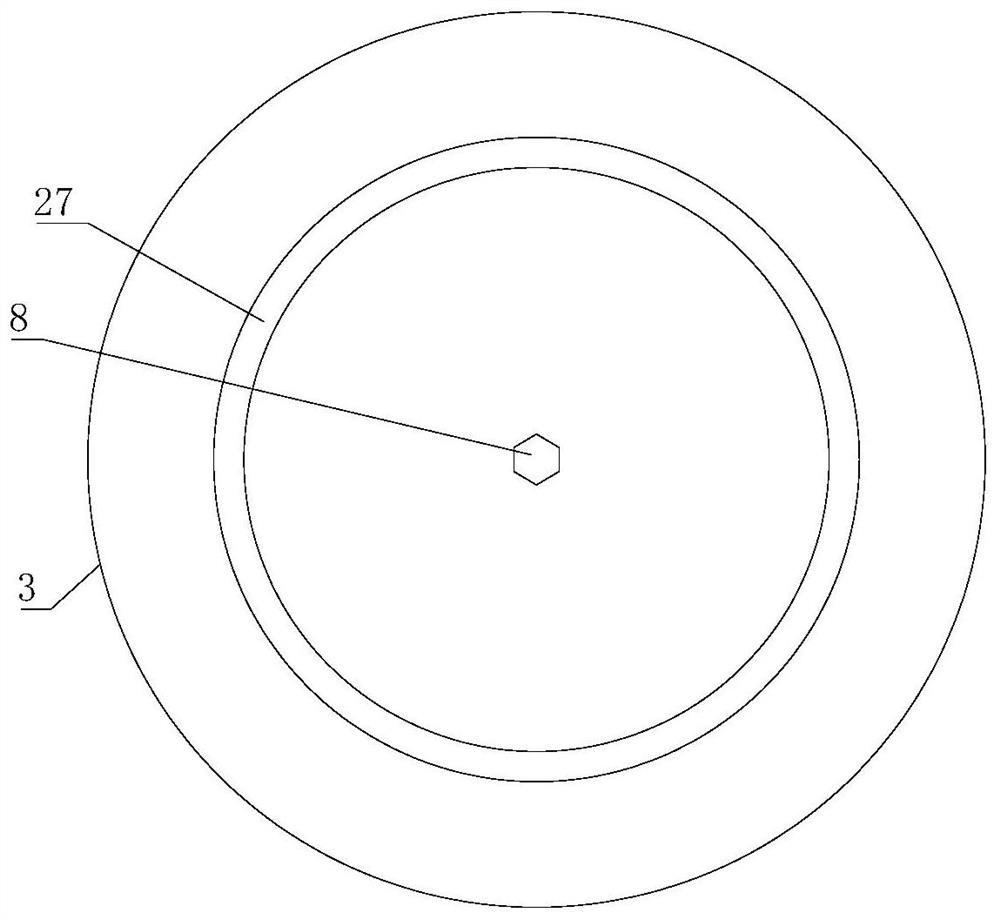

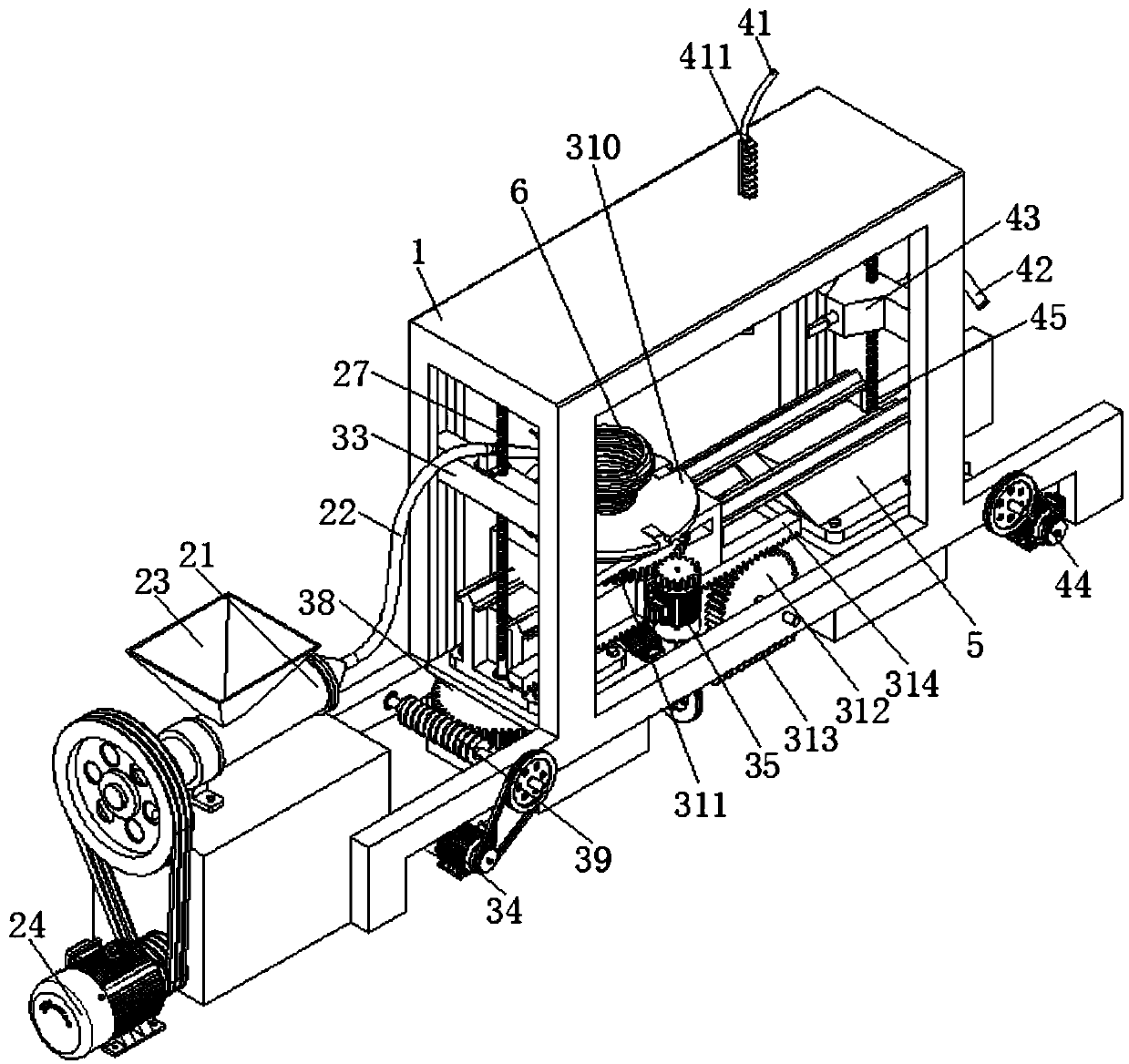

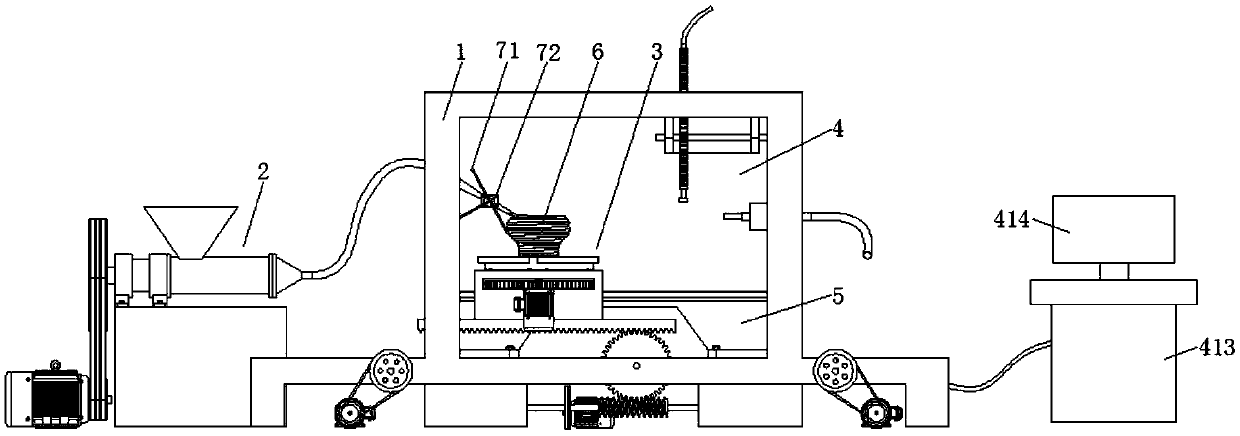

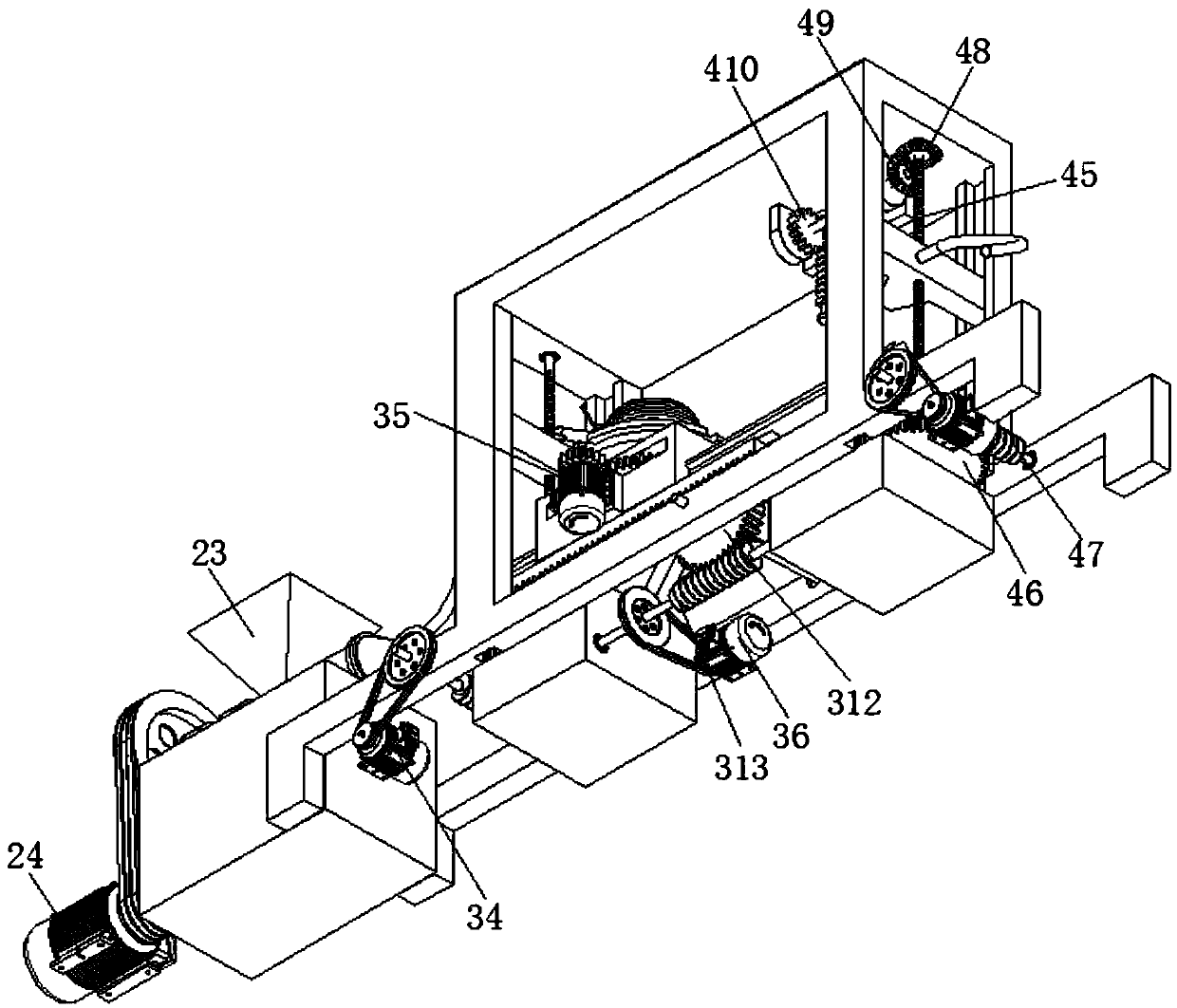

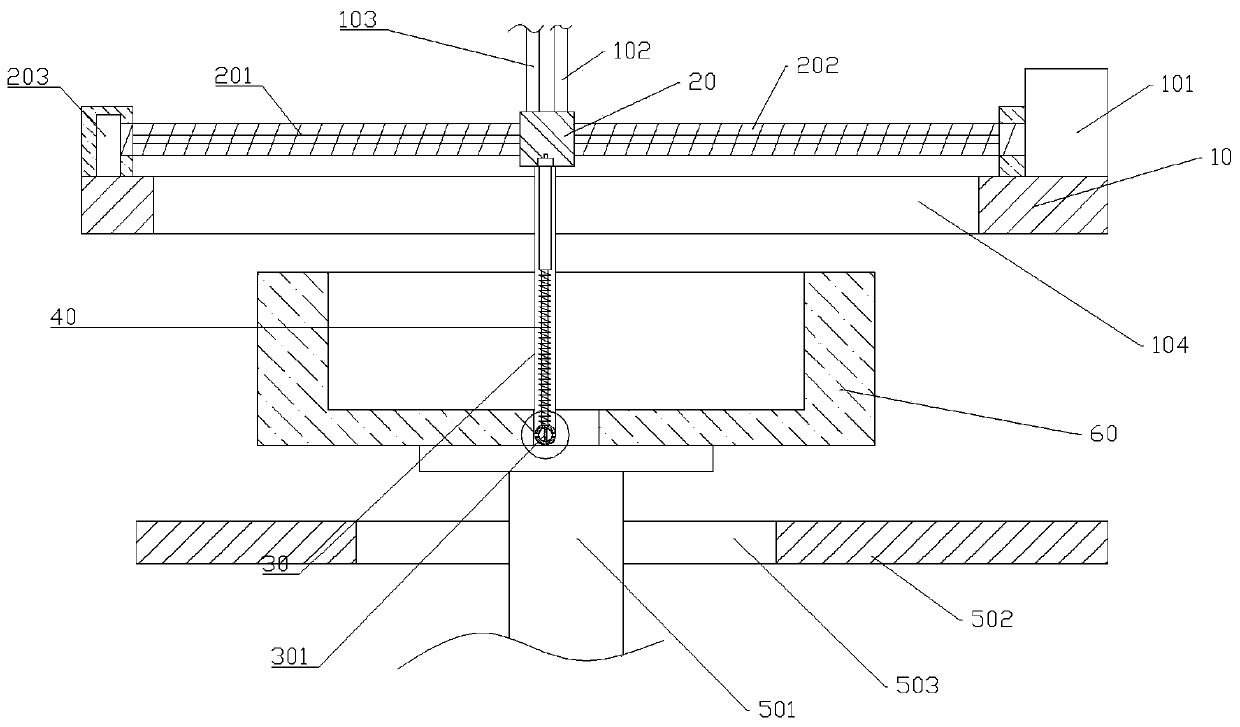

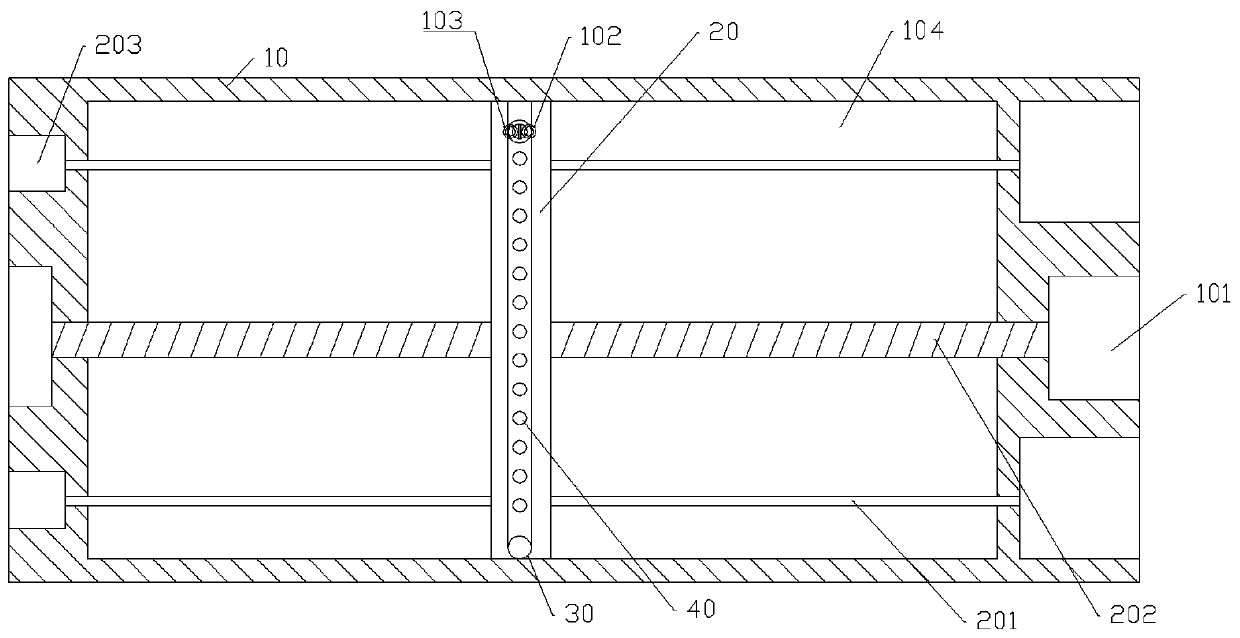

Fully-automatic ceramic green body processing technology and device

InactiveCN108673721APrecise size controlWill not deformCeramic shaping apparatusClaywaresCompression PumpWork in process

The invention provides a fully-automatic ceramic green body processing technology and relates to the field of ceramic product processing. The fully-automatic ceramic green body processing technology comprises the following steps that a clay strip is formed, wherein clay is extruded and conveyed through a compression pump, and the clay is extruded into a strip-shaped structure; and the clay strip is wound to form a green body, wherein 1, the produced clay strip is continuously extruded out of a nozzle of a conveying pipe through the conveying pipe and falls onto a rotating disc; and 2, at the moment, the rotating disc rotates at the uniform speed and moves horizontally back and forth, the nozzle of the conveying pipe ascends continuously, and furthermore, the nozzle of the conveying pipe and the rotating disc are in the positional relation with different time, so that the clay strip produced in step 1 is wound to form the green body on the rotating disc to form a semi-finished ceramic green body. According to the fully-automatic ceramic green body processing technology, the ceramic green body is processed in a manner that the clay strip is wound to form the green body, and the shapeand size of the ceramic green body can be controlled precisely; even if the size of the ceramic green body is excessively large, the ceramic green body cannot deform; the effect that manual processing is shifted to intelligentized automatic process is achieved; and product quality is improved, and processing efficacy is improved.

Owner:SHAOXING UNIVERSITY

Glazing equipment for sanitary ware

ActiveCN108527624BEasy to sendEasy to processCeramic shaping apparatusVertical planeMechanical engineering

The invention relates to the field of ceramic processing, in particular to glaze spraying equipment for sanitary appliances. The glaze spraying equipment comprises a conveying abutting mechanism, a processing mechanism and a guide mechanism, wherein the processing mechanism comprises a flexible processing pipe and a plurality of spring rods, one end of the processing pipe is fixedly connected to one end of a moving block, the other end of the processing pipe is fixedly connected to the other end of the moving block, the lower ends of the spring rods are fixedly connected to the side surface ofthe processing pipe, the spring rods and the processing pipe are located on the same vertical plane, a flexible dividing strip is vertically and fixedly arranged in the processing pipe, one side of the dividing strip and the inner wall of the processing pipe define a glaze spraying cavity, the other side of the dividing strip and the inner wall of the processing pipe define a dust collection andwatering cleaning cavity, a first through hole communicating with the glaze spraying cavity is formed in the processing pipe, and a second through hole communicating with the cleaning cavity is formedin the processing pipe. According to the scheme of the glaze spraying equipment, the consistency of floating material removing operation, water spraying operation on the surfaces of blanks and glazing operation can be improved, and the processing efficiency of the ceramic sanitary appliances can be improved.

Owner:CHONGQING CONCAST SANITARY WARE

A rubber roller installation head of a glazing machine

ActiveCN103722879BImprove usabilityImprove glazing efficiencyPrinting press partsEngineeringMechanical engineering

The invention discloses a rubber covered roller mounting machine head for a glazing machine. The rubber covered roller mounting machine head for the glazing machine comprises a driving sleeve, and the head of the driving sleeve is provided with a detachable mounting boss in a hexagonal prism shape and a connecting bolt. A detachable driven sleeve is arranged on the connecting bolt, and a mounting through hole is formed in each lateral wall of the mounting boss. The detachable mounting boss in the hexagonal prism shape is adopted in the rubber covered roller mounting machine head for the glazing machine, a user can mount six rubber covered rollers at the same time, and meanwhile can select the mounting bosses of different sizes according to the sizes of the rubber covered rollers, so that usability of the glazing machine is greatly improved, and glazing efficiency is improved. The rubber covered roller mounting machine head for the glazing machine is simple in structure and high in practicality.

Owner:中山市格能电子科技有限公司

A post insulator glazing and polishing device and its working principle

ActiveCN111993554BReduce lossEasy to collectCeramic shaping apparatusDisplay deviceMechanical engineering

Owner:湖南太阳电力电瓷电器制造有限公司

Conveyor-type box-shaped glaze dipping device

The invention provides a conveying belt type box-shaped glaze dipping device which comprises a pull rod and a bowl blank, wherein a low-speed motor drives a conveying belt I and a low-speed motor II to simultaneously move, a bowl blank containing mechanism articulated with the conveying belt I and the conveying belt II limits the position of the bowl blank within a certain region, the bowl blank is glazed when the bowl blank containing mechanism is dipped in a glaze pool positioned at the bottom of an integral support frame, then the conveying belt I and the conveying belt II can take the bowl blank containing mechanism out of the glaze pool, a position sensor detects the bowl blank containing mechanism when the bowl blank containing mechanism moves to the station A, an electromagnet attracts a slide block, the slide block drives the pull rod to open a bowl cover, and a worker takes out the bowl blank, so that the integral glazing process is completed. The conveying belt type box-shaped glaze dipping device disclosed by the invention can be used for an automatic glazing procedure of a domestic ceramic production process and overcomes such defects of certain glazing devices used in a plant at present as complicated driving mechanism, low glazing efficiency and glazing dead angle.

Owner:徐州兴梁农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com