High-gloss and friction-resistant varnish and preparation method thereof

A mineral oil, part of the technology, applied in high-gloss, friction-resistant varnish and its preparation field, can solve the problems that hinder the development of water-based varnish, poor surface adhesion of printed matter, not easy to dry, etc., to reduce cleaning and maintenance costs , Enhance friction resistance and gloss, easy to dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

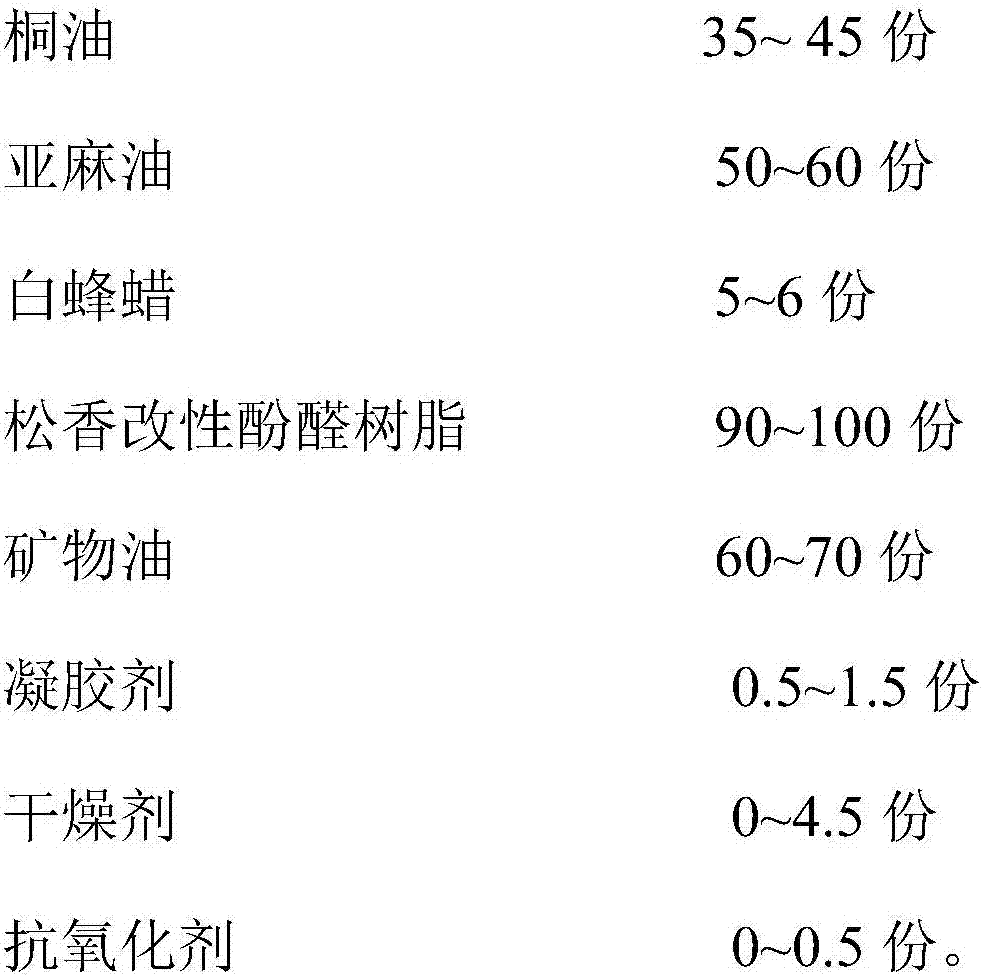

[0032] A kind of glazing oil, it is made up of the raw material of following weight part:

[0033]

[0034] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 400g, 550g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccants are cobalt dry liquid and manganese dry liquid, the weights of which are respectively: 13.5g and 27g.

[0035] Above-mentioned glazing oil is prepared by following steps:

[0036] S1. Mix 405g tung oil and 135g linseed oil, heat up to 90-110°C, add 54g beeswax, and stir to obtain a wax paste;

[0037] S2, heat up the wax paste in step S1 to 160-170°C, keep it warm, add 400g8376# resin and 550g8102# resin in 5 times under constant stirring; then heat up to 230-240°C, add 432g linseed oil, 500g mineral oil; Then lower the temperature to 155-165°C, add 10.8g of liquid aluminum and 27g of mineral oil;

[0038] S3. The temperature of the mixture obtaine...

Embodiment 2

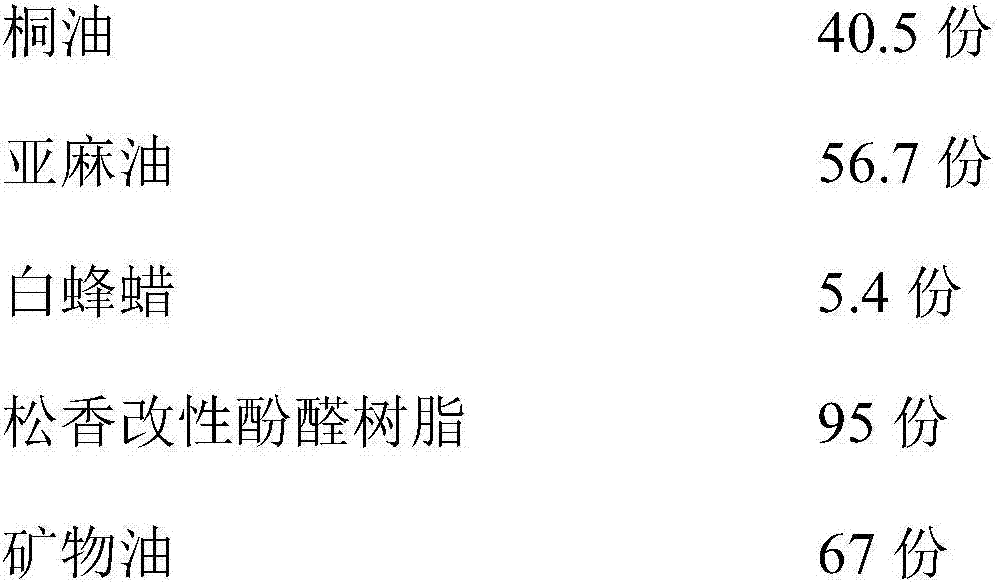

[0042] A kind of glazing oil, it is made up of the raw material of following weight part:

[0043]

[0044] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 380g and 570g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccant is cobalt dry liquid and manganese dry liquid, the weight of both is: 12.0g, 28.5g.

[0045] Above-mentioned glazing oil is prepared by following steps:

[0046] S1. Mix 392.2g tung oil and 109g linseed oil, heat up to 90-110°C, add 54g beeswax, and stir to obtain a wax paste;

[0047] S2, heat up the wax paste in step S1 to 160-170°C, keep warm, add 380g8376# resin and 570g 8102# resin in 5 times under constant stirring; then heat up to 230-240°C, add 436g linseed oil, 513g mineral oil ;Then lower the temperature to 155~165℃, add 10.8g liquid aluminum and 27g mineral oil;

[0048] S3. The temperature of the mixture obtained in step S2 is raised ...

Embodiment 3

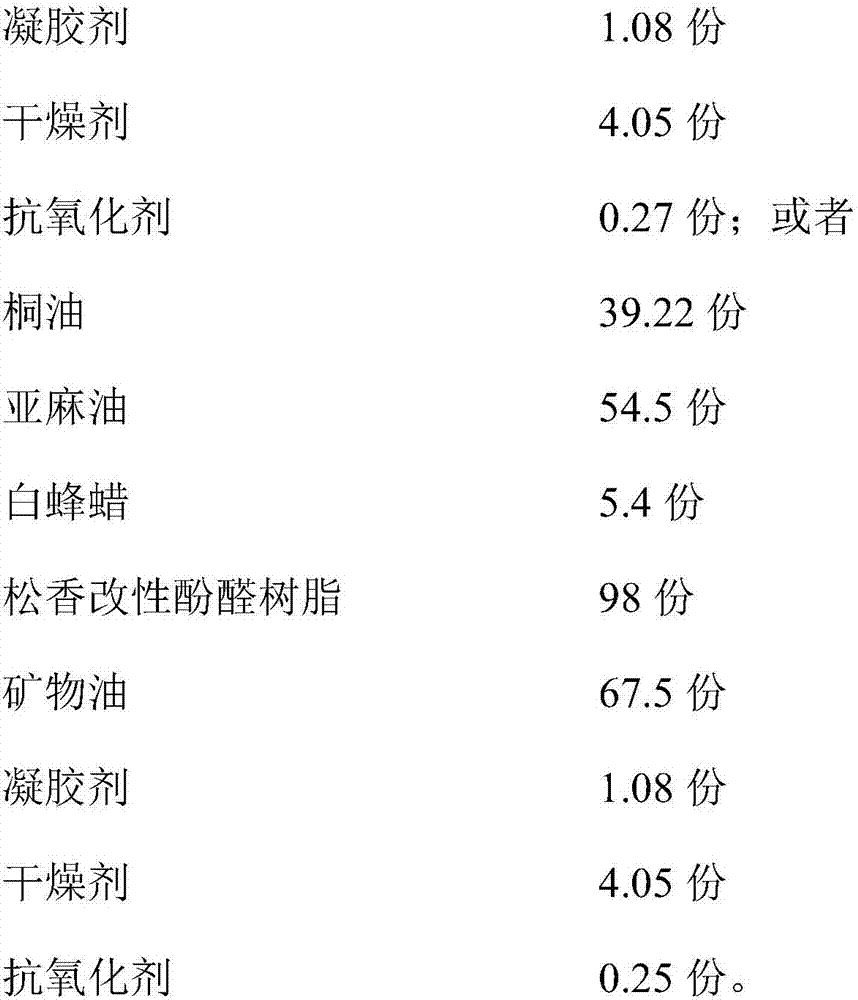

[0052] A kind of glazing oil, it is made up of the raw material of following weight part:

[0053]

[0054]

[0055] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 500g and 500g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccants are cobalt dry liquid and manganese dry liquid, the weights of which are respectively: 15g and 30g.

[0056] Above-mentioned glazing oil is prepared by following steps:

[0057] S1. Mix 450g tung oil and 143g linseed oil, heat up to 90-110°C, add 50g beeswax, and stir to obtain a wax paste;

[0058] S2, heat up the wax paste in step S1 to 160-170°C, keep it warm, add 500g8376# resin and 500g8102# resin in 7 times under constant stirring; then heat up to 230-240°C, add 357g linseed oil, 522g mineral oil; Then lower the temperature to 155-165°C, add 15g of liquid aluminum and 27.45g of mineral oil;

[0059] S3. The temperature of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com