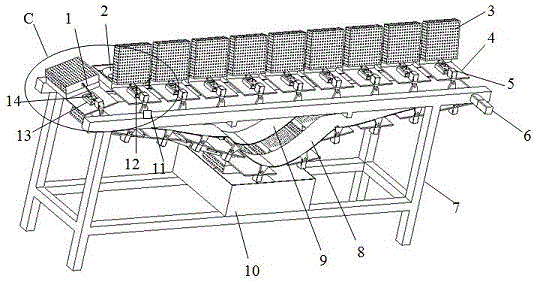

Conveyor-type box-shaped glaze dipping device

The technology of conveyor belt and conveyor belt two is applied in the field of automatic glazing devices, which can solve the problems of low efficiency, poor glazing quality, complex structure and the like, and achieve the effects of simple structure, guaranteed glazing quality and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

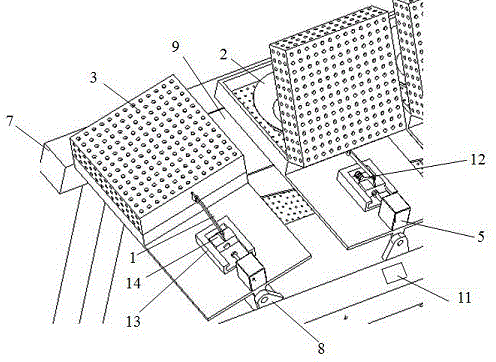

[0028] Such as figure 2 , 3 As shown, the first is the clamping process of the bowl blank 2, the bowl blank 2 holding mechanism moves to the B station, at this time the electromagnet 5 is in the energized state, the slider 14 absorbs and moves along the chute 13 and drives the pull rod 1 Bowl base cover 3 swings, and bowl base cover 3 is opened, and the operator puts bowl base 2 into rocking plate 4, and electromagnet 5 loses power subsequently. Slide block 14 moves along chute 13 under the effect of tension spring 12, and then bowl blank cover 3 is closed, and bowl blank 2 is limited in a certain area, finishes the position limiting process of bowl blank 2.

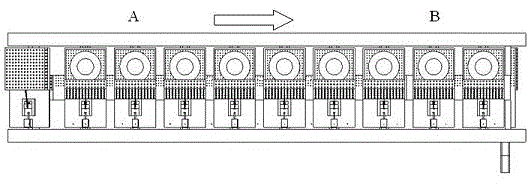

[0029] control figure 1 After the position of bowl blank 2 is defined, low-speed motor 6 rotates, low-speed motor 6 drives conveyor belt one 8 and conveyor belt two 9 to rotate on the integral support 7, and the bowl blank holding mechanism is connected to the hinged boss on conveyor belt one 8 and conveyor belt two 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com