Patents

Literature

57results about How to "Tighten up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

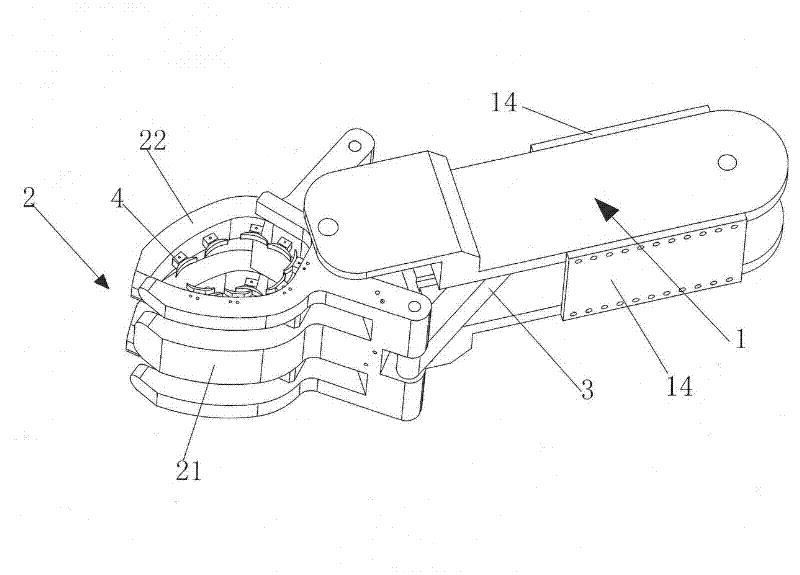

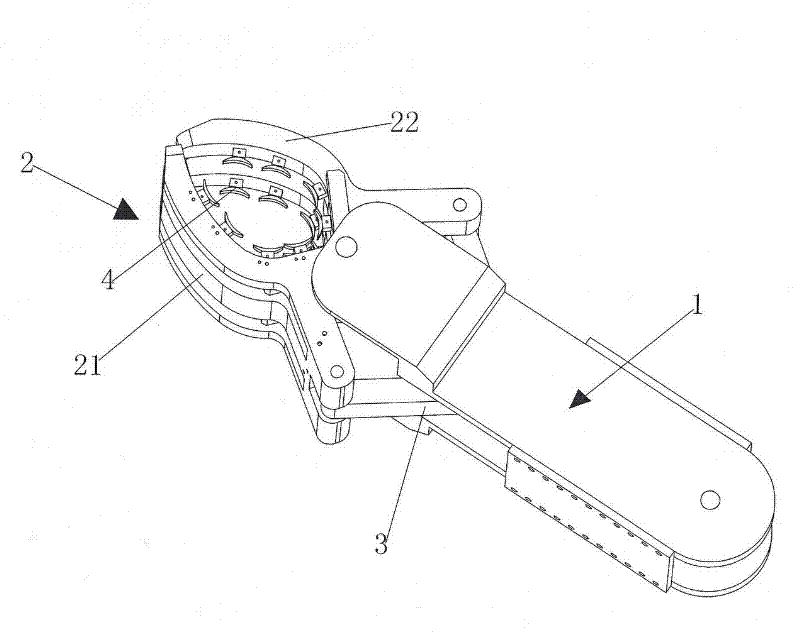

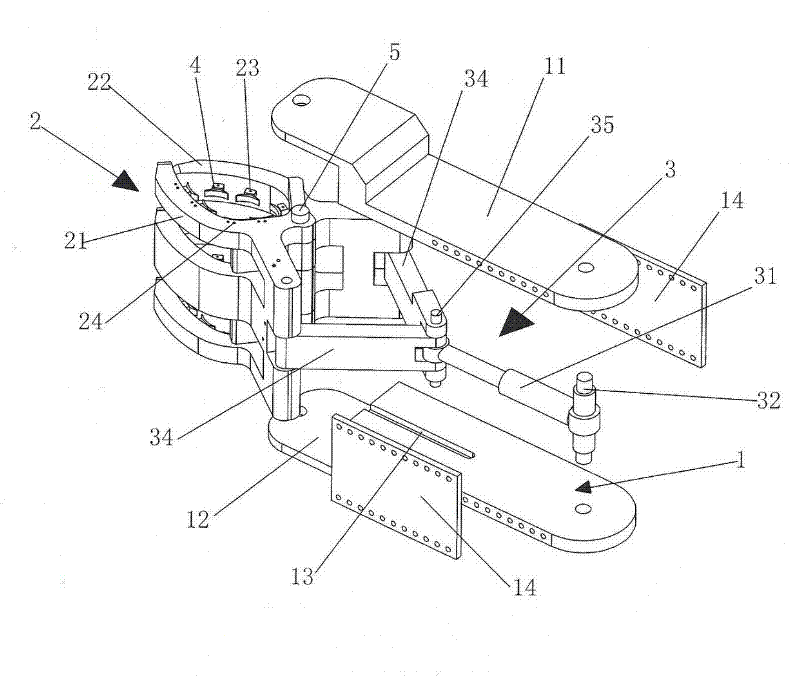

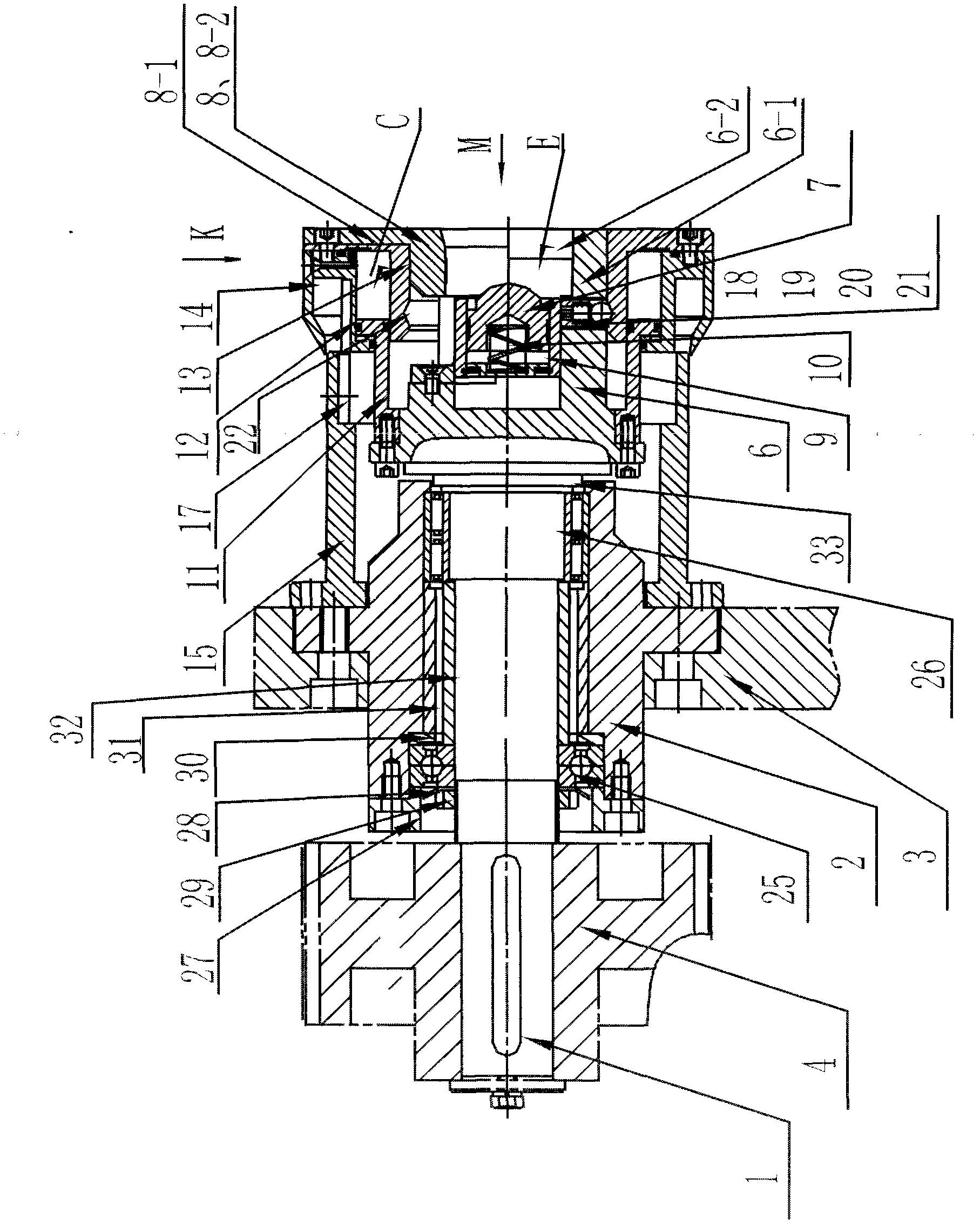

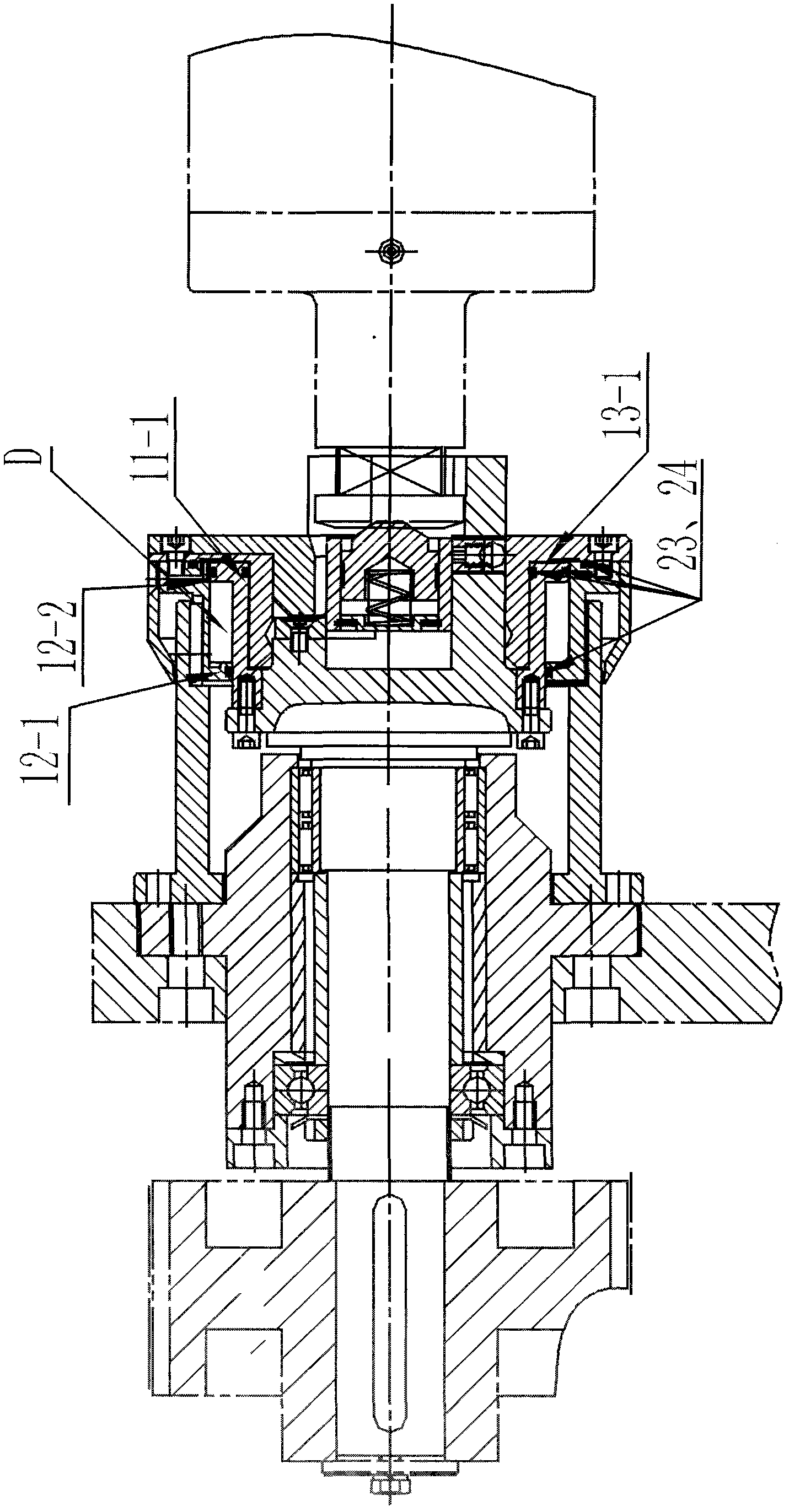

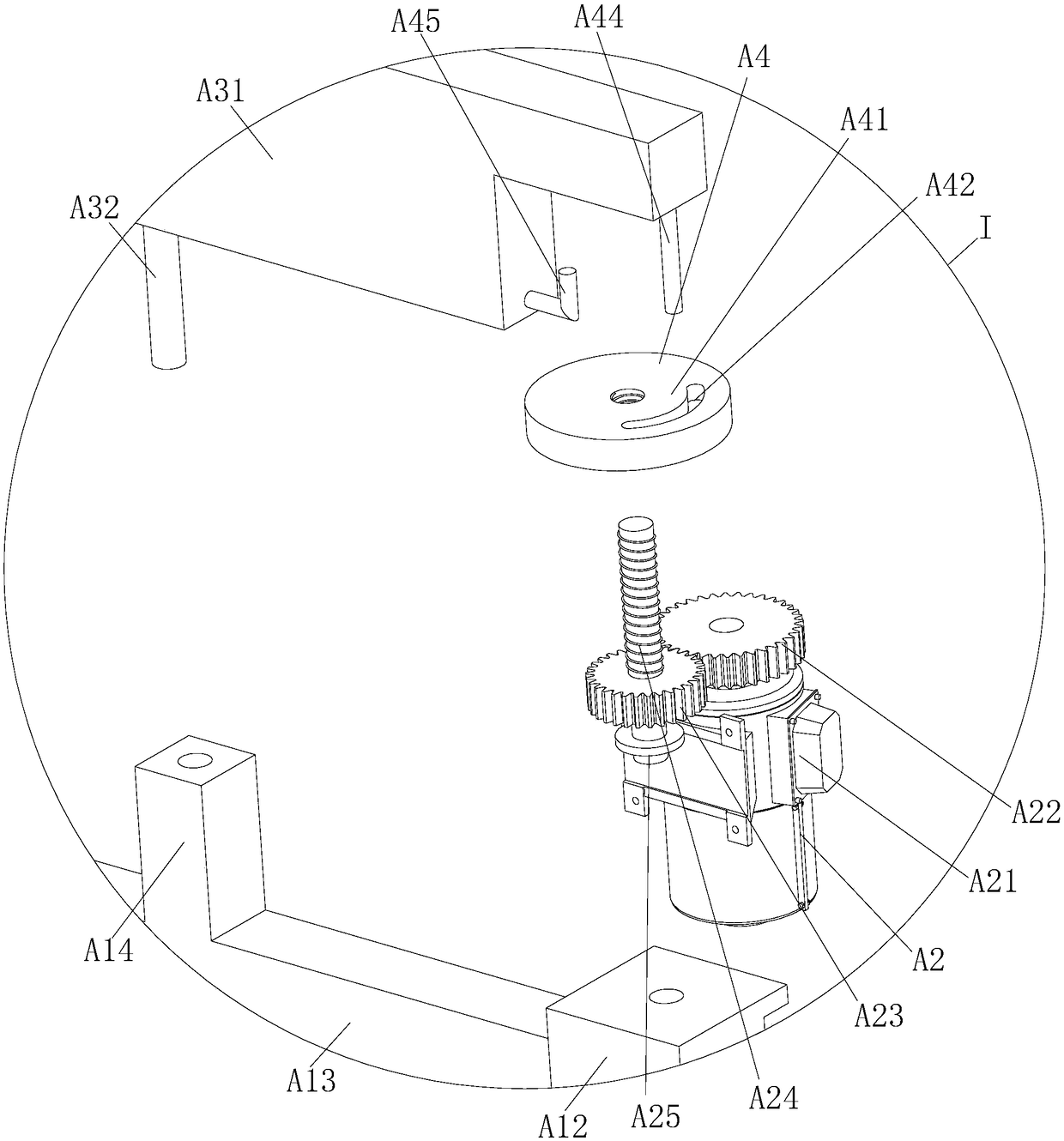

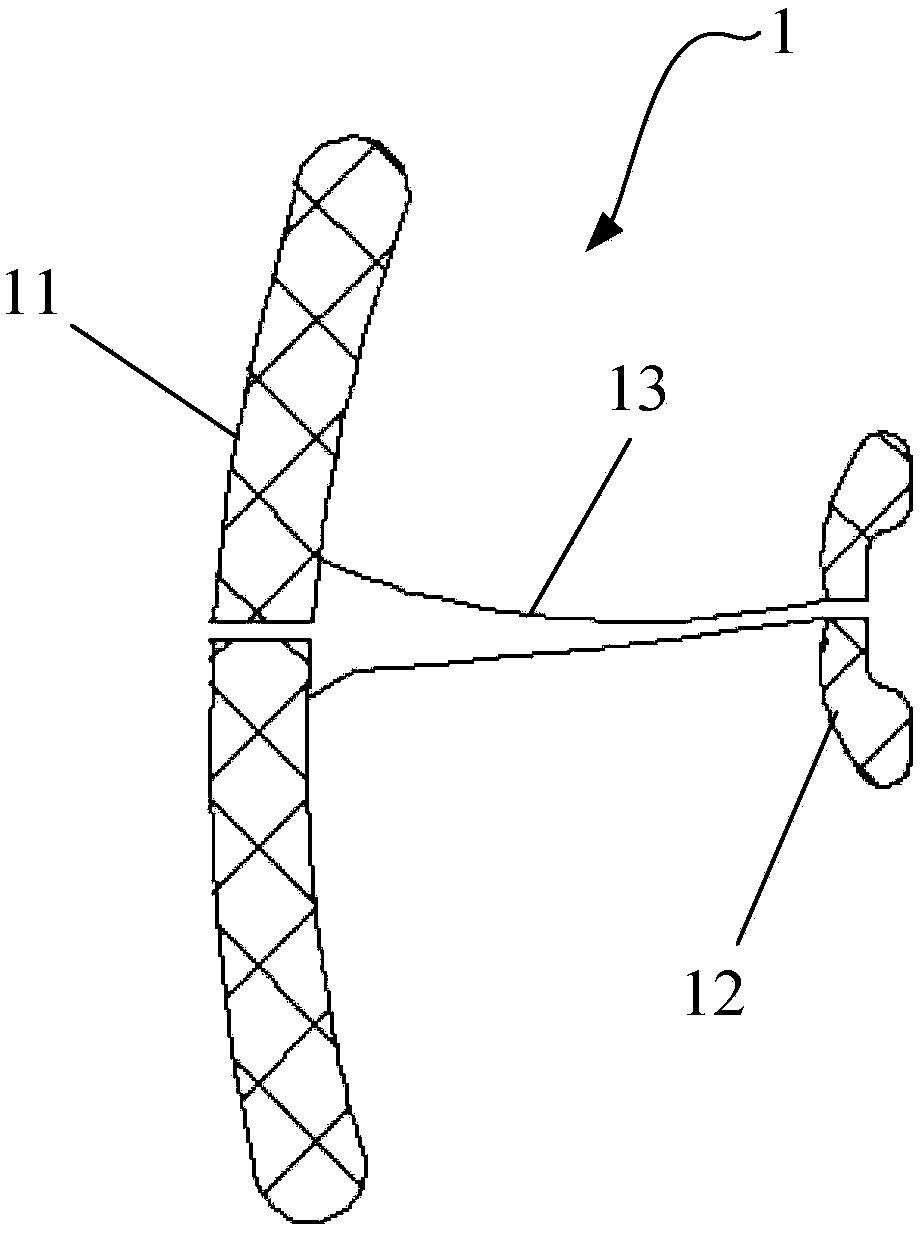

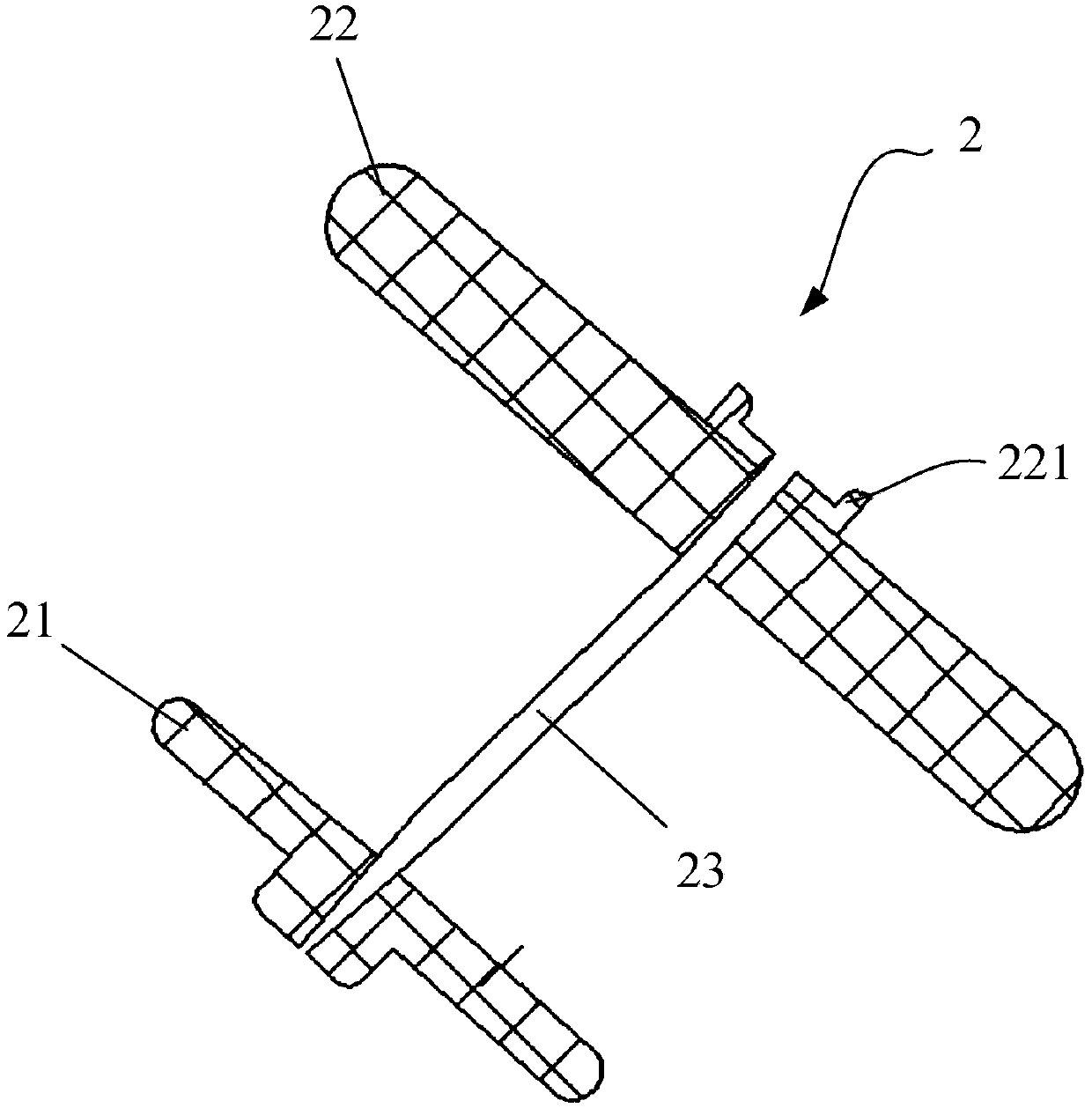

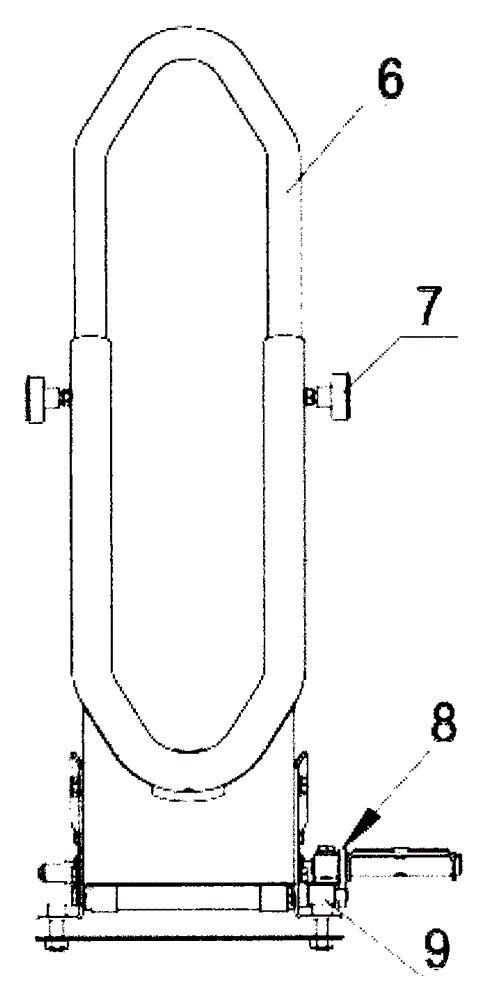

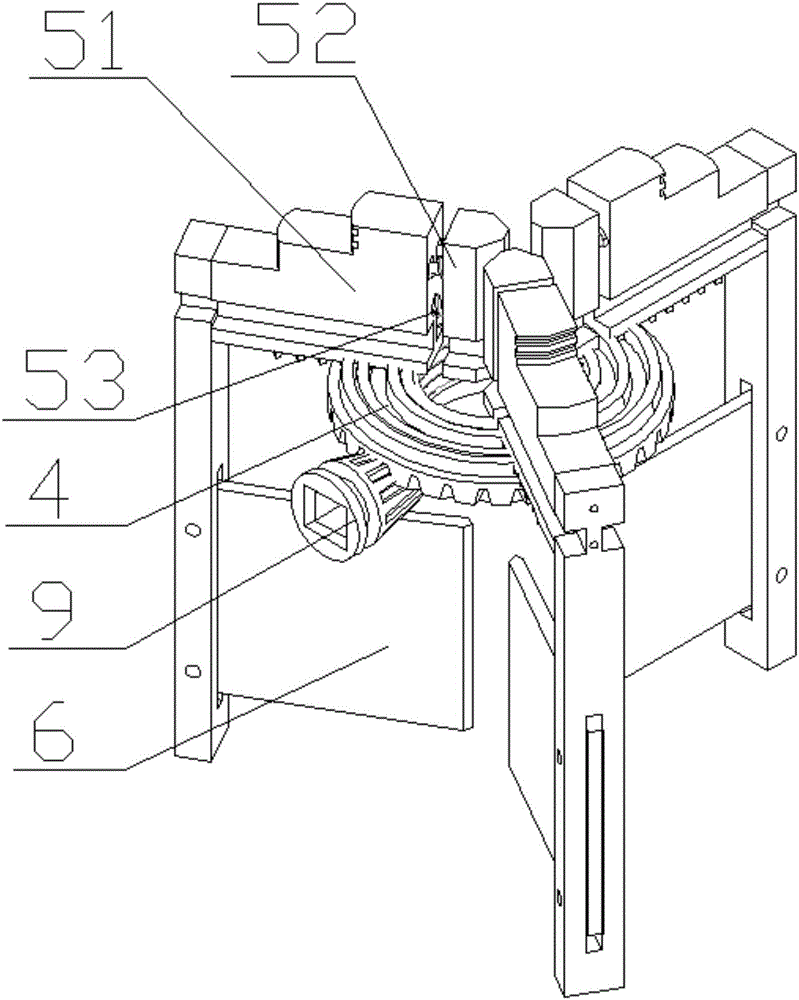

Multipoint mechanical hand for myriametre well drill

The invention discloses a multipoint mechanical hand for a myriametre well drill, which comprises an arm, a crossed hand, a hand driving mechanism and an elastic floating friction mechanism. The hand driving mechanism drives the crossed hand to open or close to clamp or release a tubular column, and the elastic floating friction mechanism is arranged on the inner side of the crossed hand. The crossed handle can be crossed to achieve grab of well casings with different pipe diameters, and one well drilling equipment only needs one handle. The elastic floating friction mechanism can automatically and slightly adjust angles to achieve a multipoint and force-equipotent clamping mode, and clamping points are evenly distributed around the well casing, so that too much clamping force is not required, and deformation of the well casing is avoided. An elastic friction sheet of the elastic floating friction mechanism is in a floating mode, so that friction area can be enlarged, the clamping force can be further reduced, and clamping can be reliable and safe.

Owner:JILIN UNIV

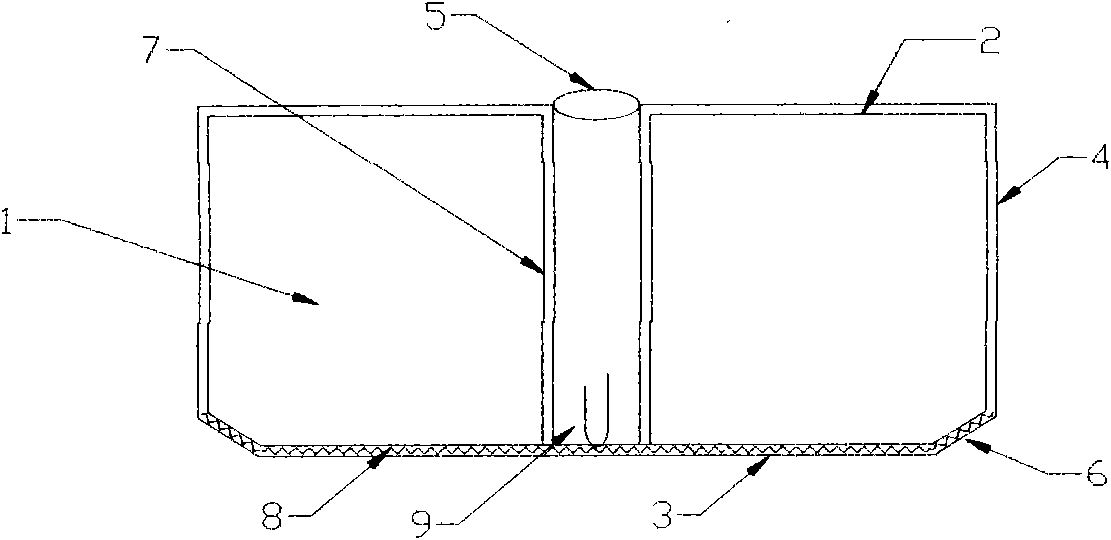

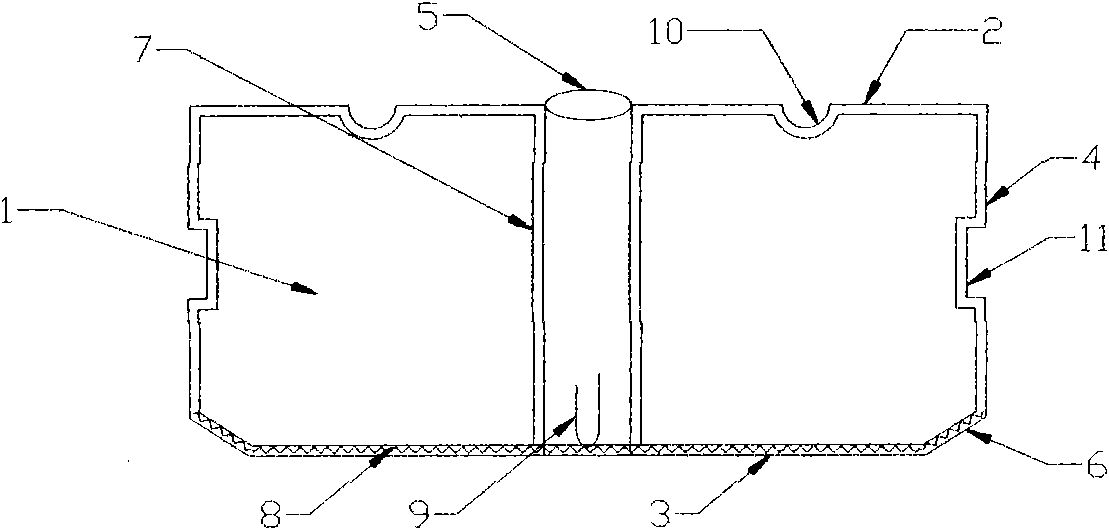

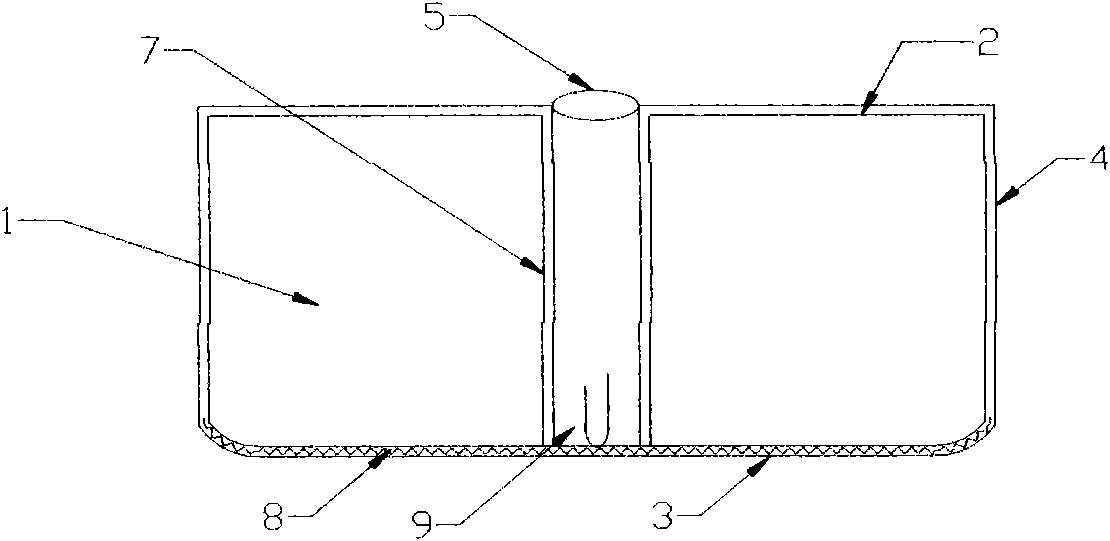

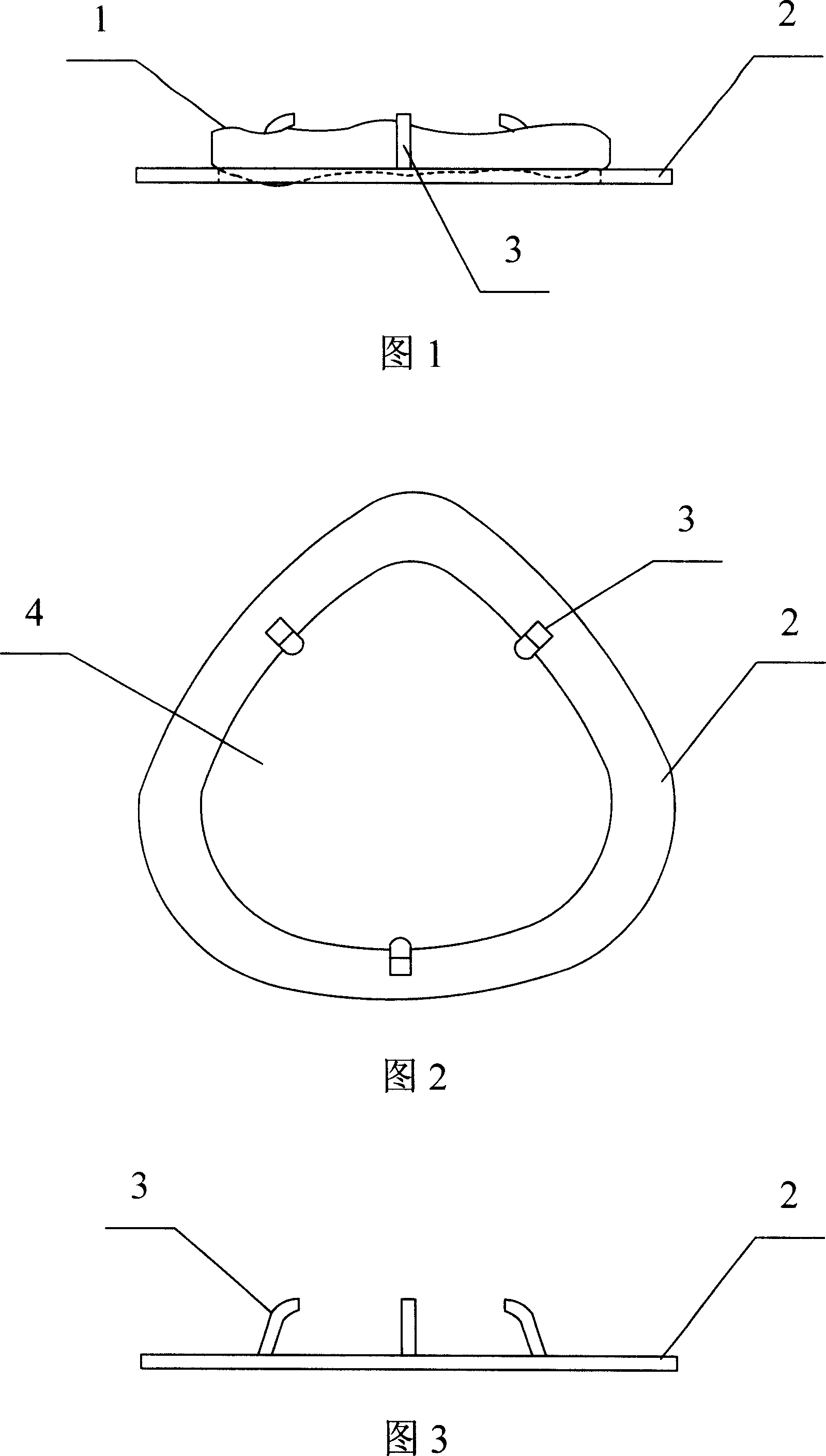

Energy-saving cast-in-place hollow floor

InactiveCN102003010AMaintain integrityMaintain aestheticsFloorsForms/shuttering/falseworksCrack resistanceEngineering

The invention relates to an energy-saving cast-in-place hollow floor, which comprises thin-wall box bodies, a rib beam between the box bodies and an upper flange plate, wherein the upper flange plate contains an electric heating tube, and an electric heater and heat retention liquid are arranged in the electric heating tube; the top surface of the thin-wall box body is provided with at least one groove, the lateral surface of the thin-wall box body is provided with a closed hole, the closed holes of the adjacent box bodies are connected through a junction pipe, the lower end of the hole wall is connected with the bottom surface and closed, and the upper end of the hole wall is communicated with the top surface to form a hole; and the inclined plane and the bottom surface of the box bodies form an included angle of 100 to 165 degrees, and the side length of the inclined plane is more than 20 millimeters. Sunken closed holes are reserved on the lateral surfaces of the box bodies, the closed holes are opened before casting and the junction pipe can pass through the open closed holes to form an interconnected through heat energy blowing passage, and grooves for laying heating pipes are reserved on the top surfaces of the thin-wall box bodies to form a floor energy supply system. The floor adopting the thin-wall box bodies has the advantages of light weight, high hardness, reasonable structure, energy conservation, environment friendliness, cracking resistance and seismic resistance, and also can solve the heating problem by using the box bodies to transfer the heat energy.

Owner:王本淼

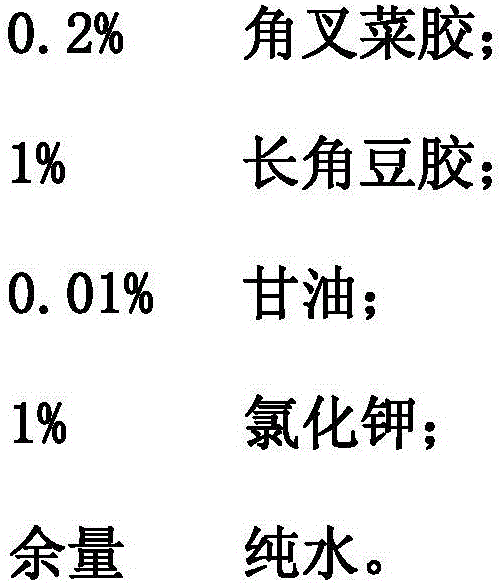

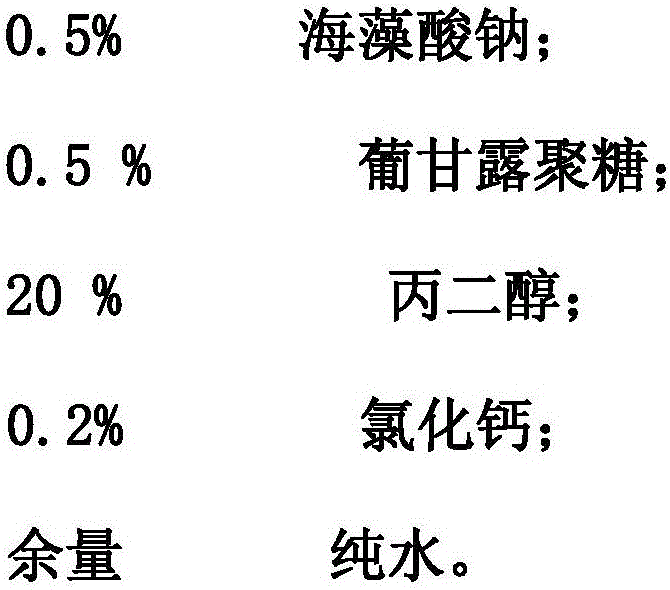

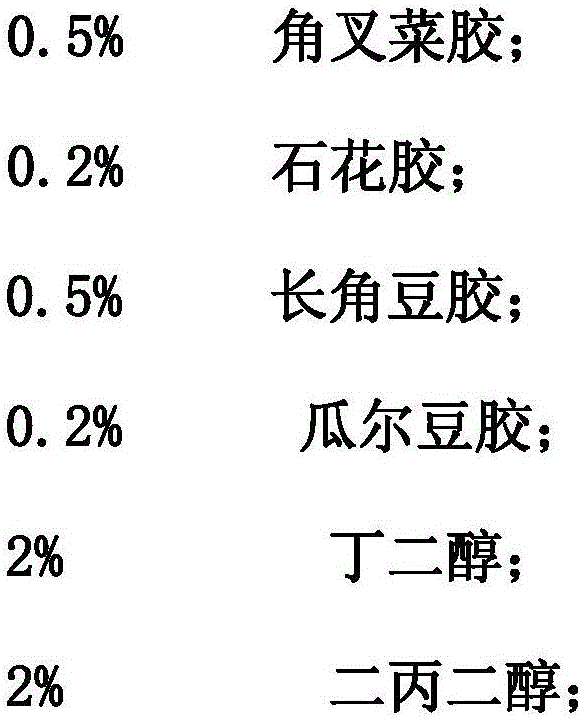

Mask cloth containing multiple kinds of natural hydrophilic gel

InactiveCN105816335AMoisturizeTighten upCosmetic preparationsToilet preparationsMedicineNonwoven fabric

The invention relates to mask cloth containing multiple kinds of natural hydrophilic gel. The mask cloth comprises a non-woven body and multiple kinds of natural hydrophilic gel. The multiple kinds of natural hydrophilic gel and non-woven cloth are combined, the mask cloth has the following advantages that a high-molecular polymer forming the gel has the characteristics of swelling but not dissolving and can bear more mask essence, and being extracted from natural algas or plants, the gel has excellent skin care effects of moisturizing, tightening, whitening and the like.

Owner:NOX BELLCOW COSMETICS CO LTD

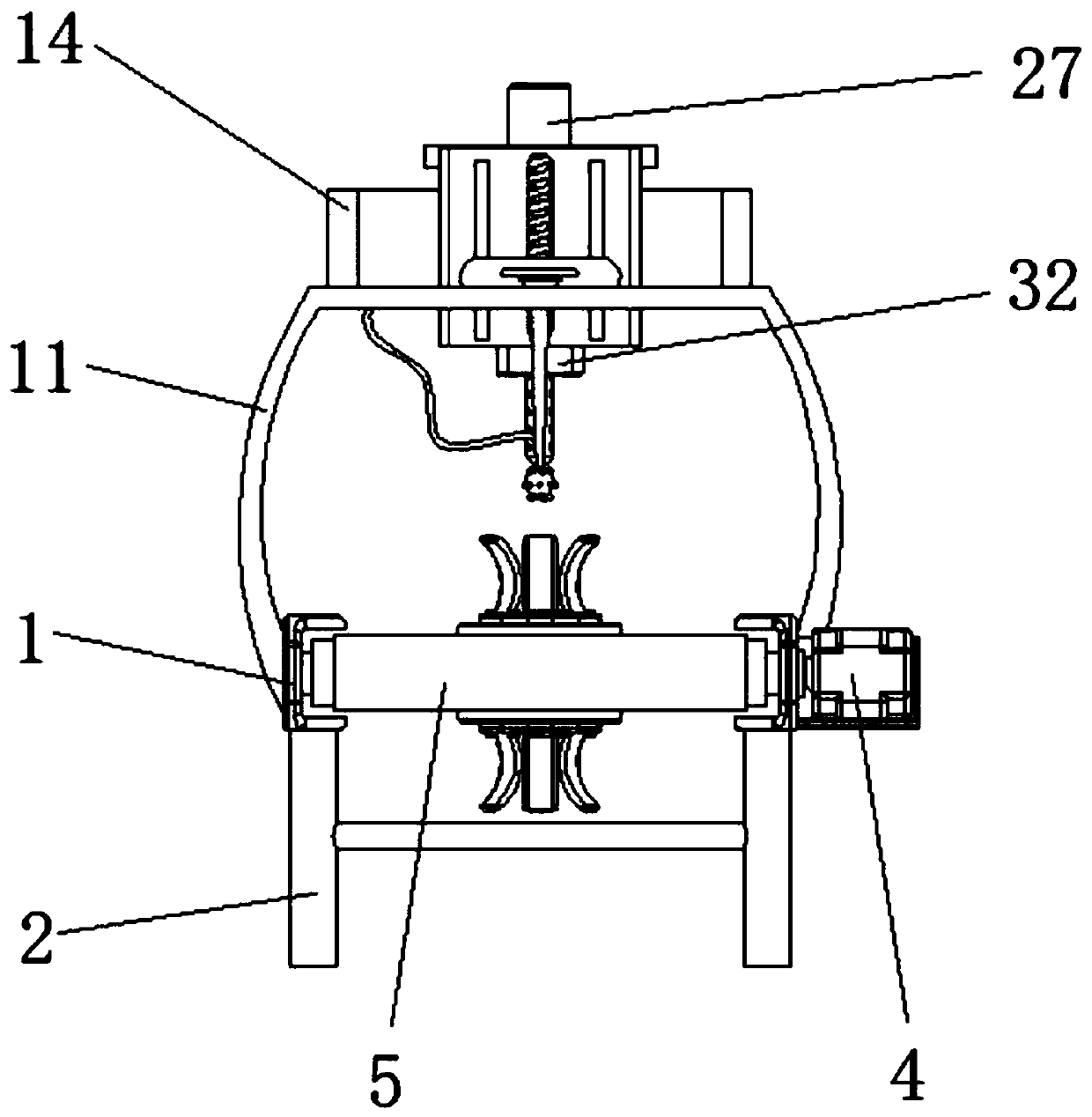

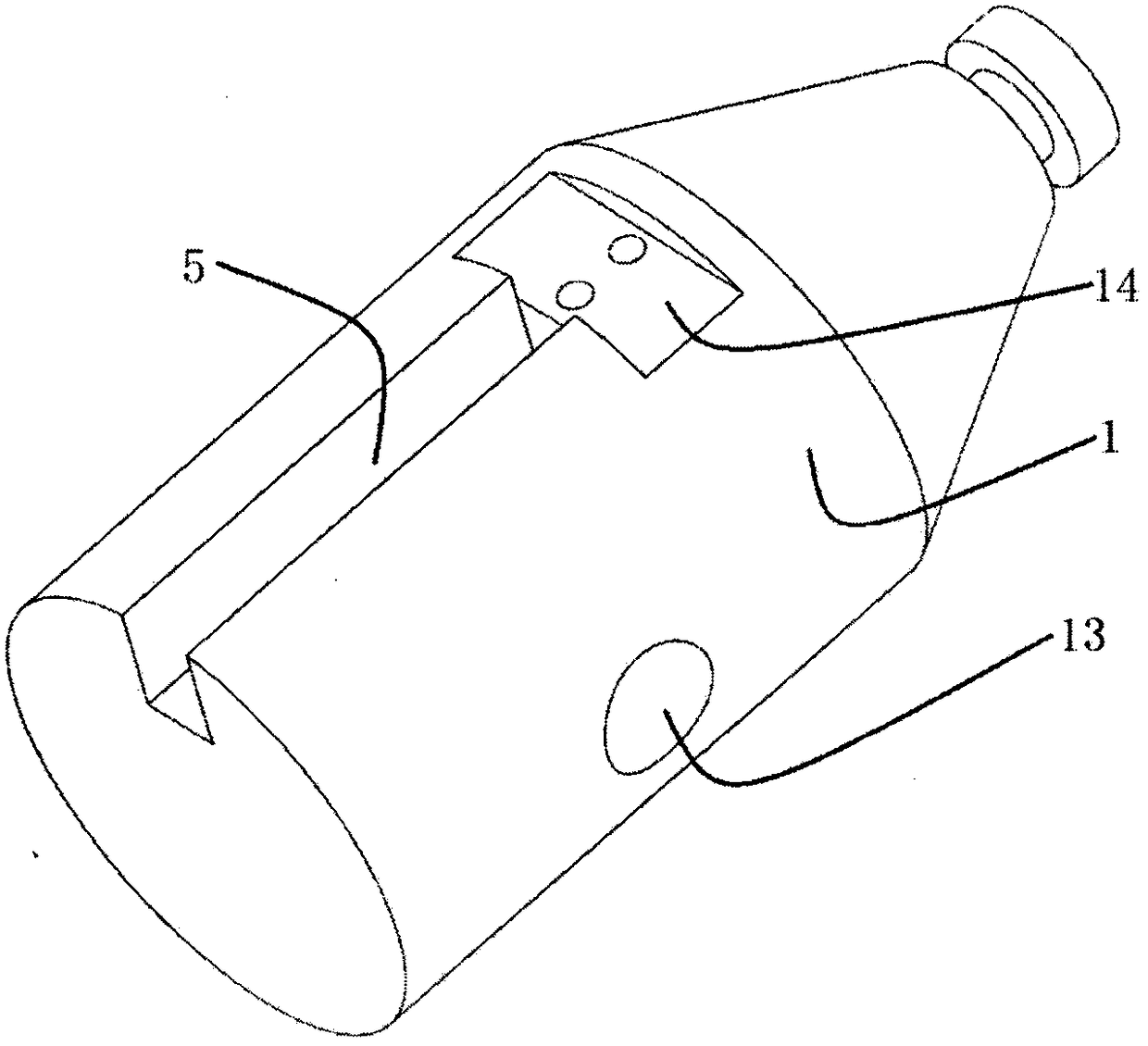

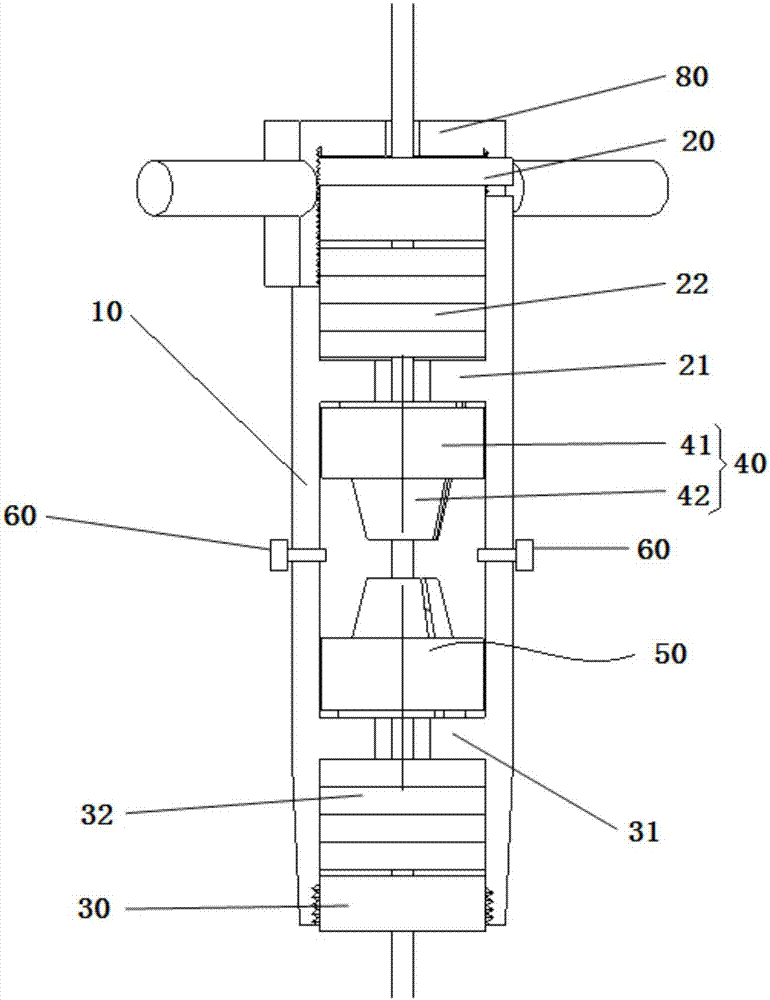

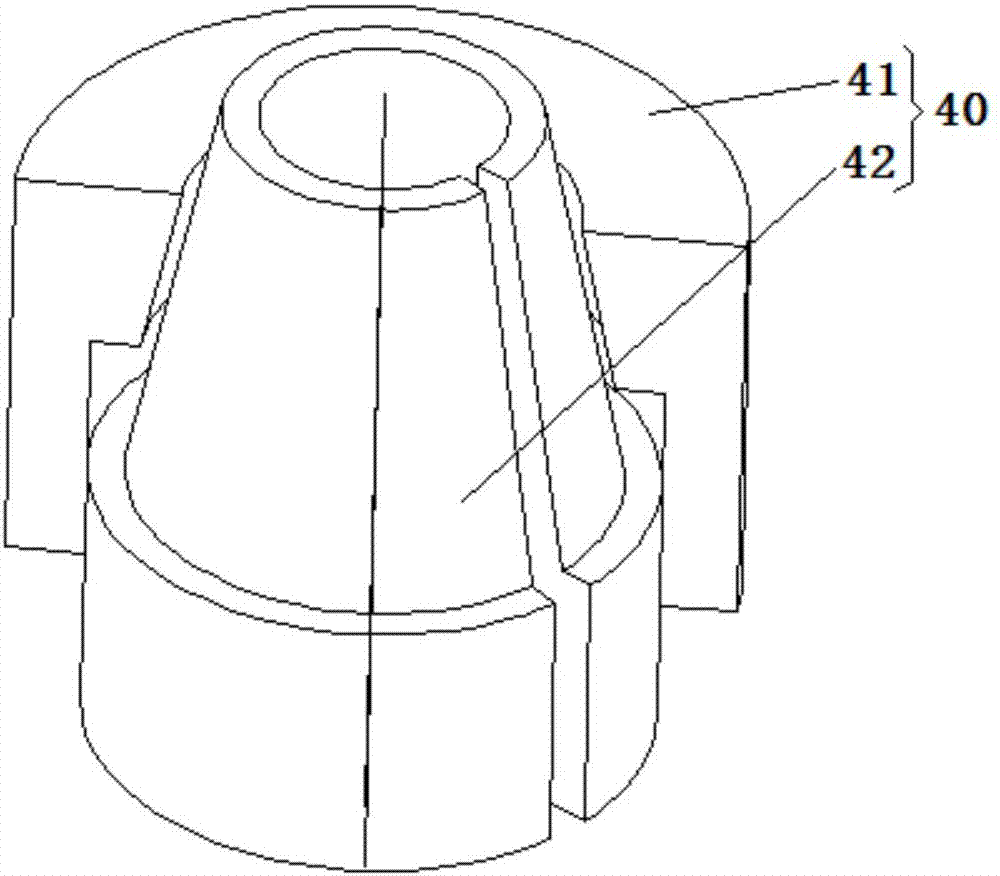

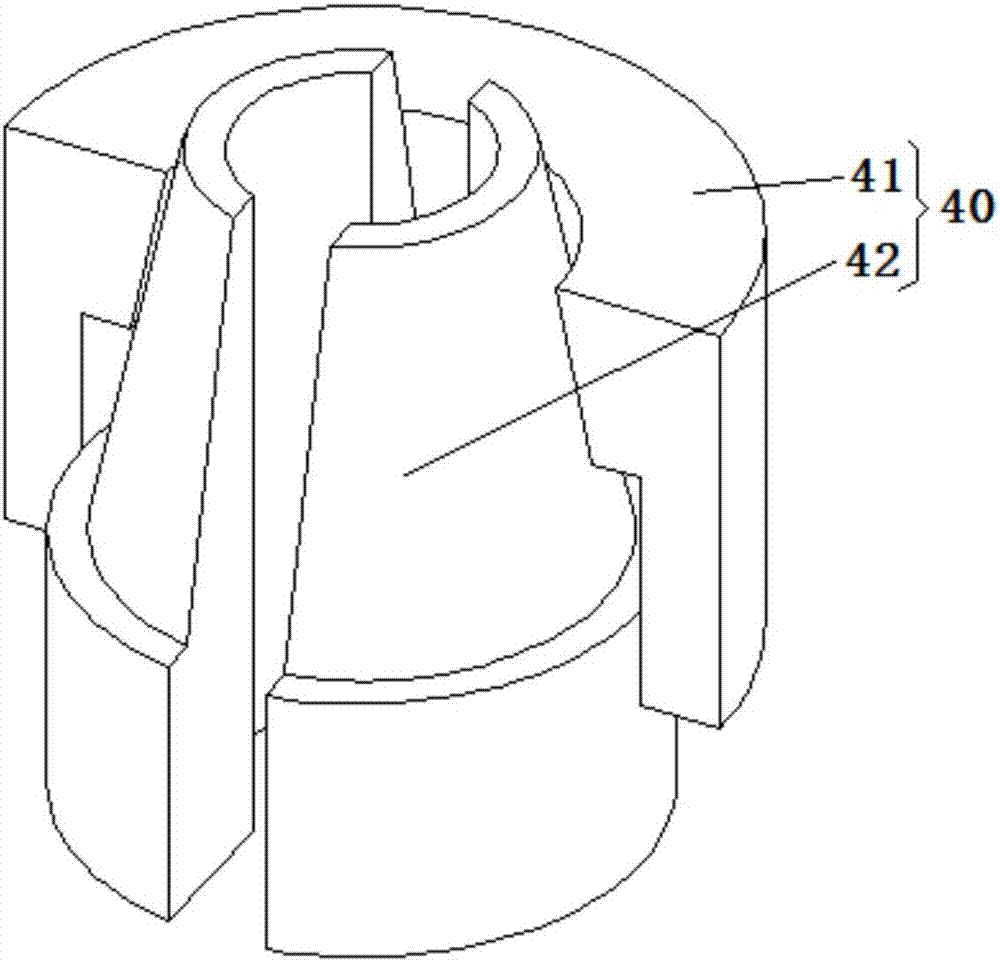

Ceramic bottle internal glaze spraying equipment for process ceramic production

ActiveCN111113649AAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

The invention belongs to the technical field of glaze spraying equipment, in particular to ceramic bottle internal glaze spraying equipment for process ceramic production. The ceramic bottle internalglaze spraying equipment comprises a protection support plate, wherein supporting legs are arranged at the bottom of the protection support plate, and an L-shaped supporting plate is arranged on one side of the protection support plate; a first motor is arranged at the top of the L-shaped supporting plate, and the output end of the first motor penetrates through the protection support plate. A ceramic bottle internal glaze spraying mechanism is arranged, on the one hand, storage and placement of glaze for glazing the surface of a ceramic bottle can be achieved through a material storage box, paint can be conveniently provided for glazing and spraying on the internal surface of the ceramic bottle, and meanwhile, the material storage box is used for storing the glaze so that the working amount of repeated adding of the glaze by an operator can be relieved; and on the other hand, a guide supporting cylinder can be conveniently inserted into the interior of the ceramic bottle through the mode that a transmission screw is adopted to move up and down for adjustment, and uniform glaze spraying treatment is carried out on the inner wall of the ceramic bottle by using a spherical glaze spraying joint.

Owner:广东金润源陶瓷股份有限公司

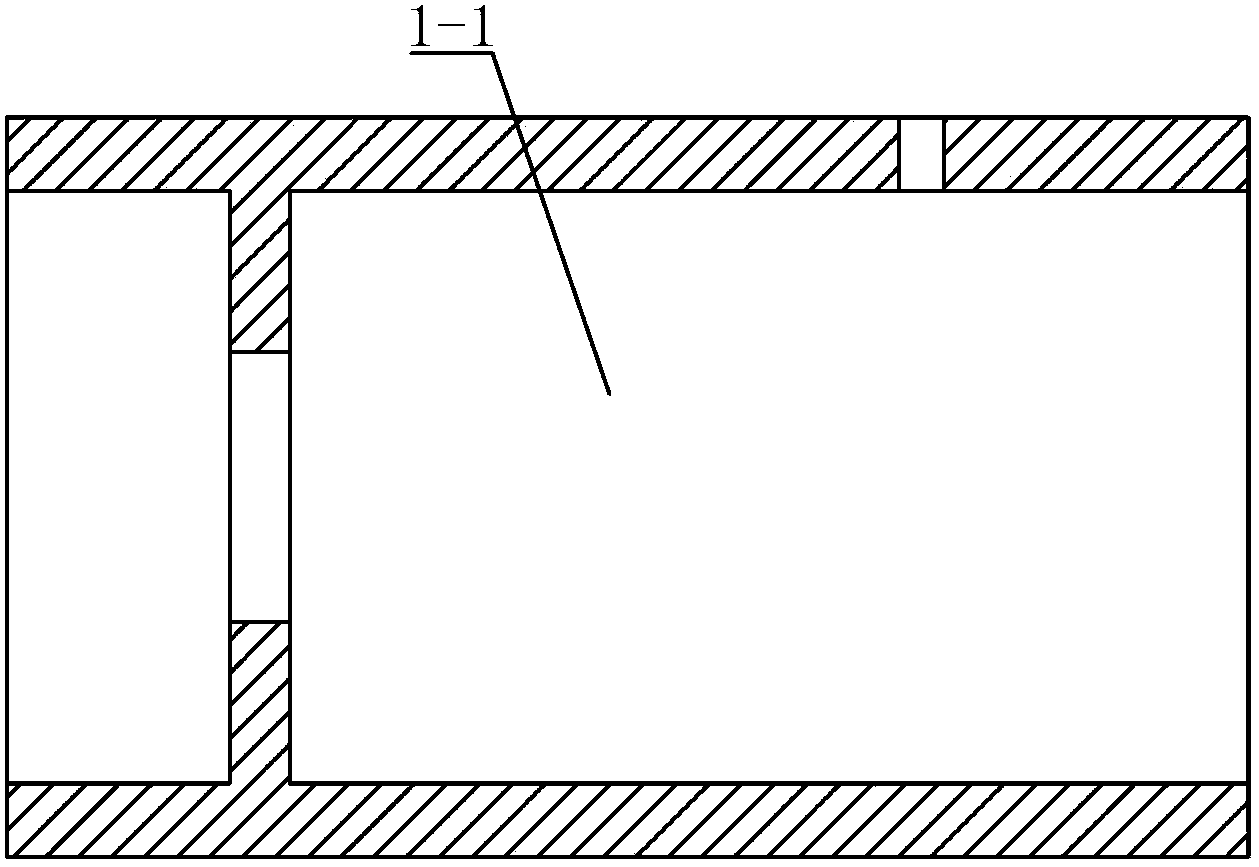

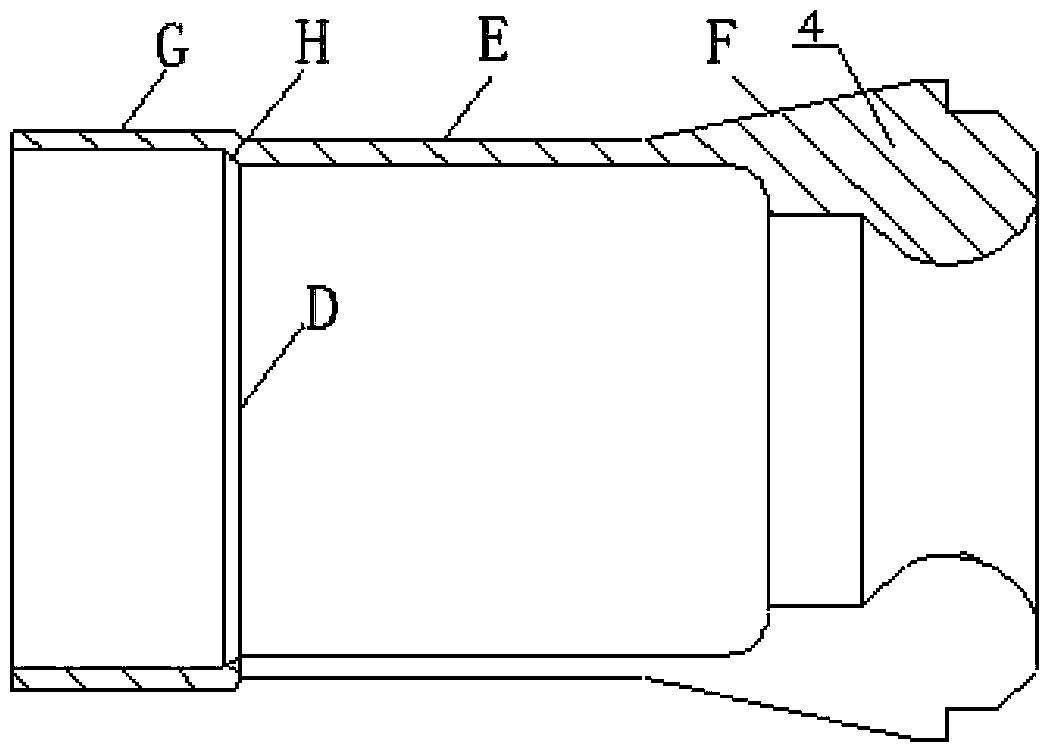

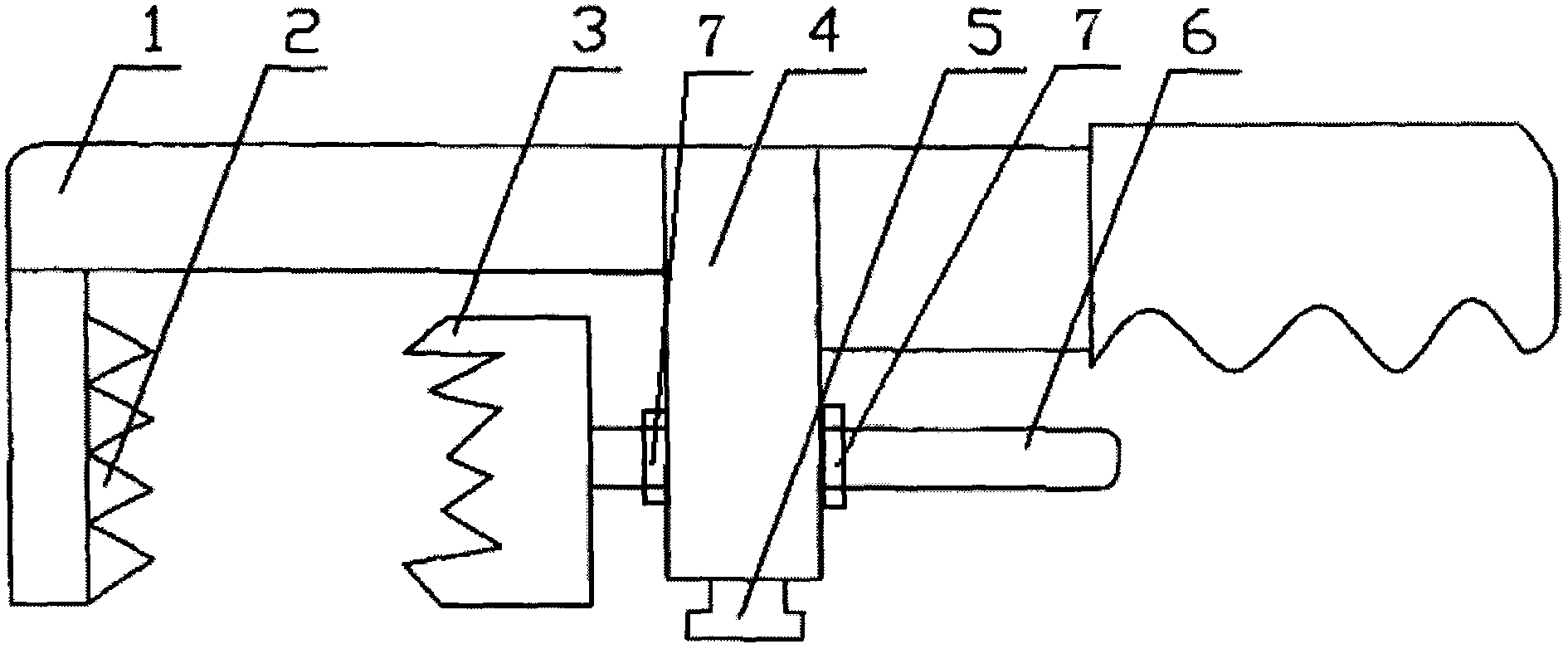

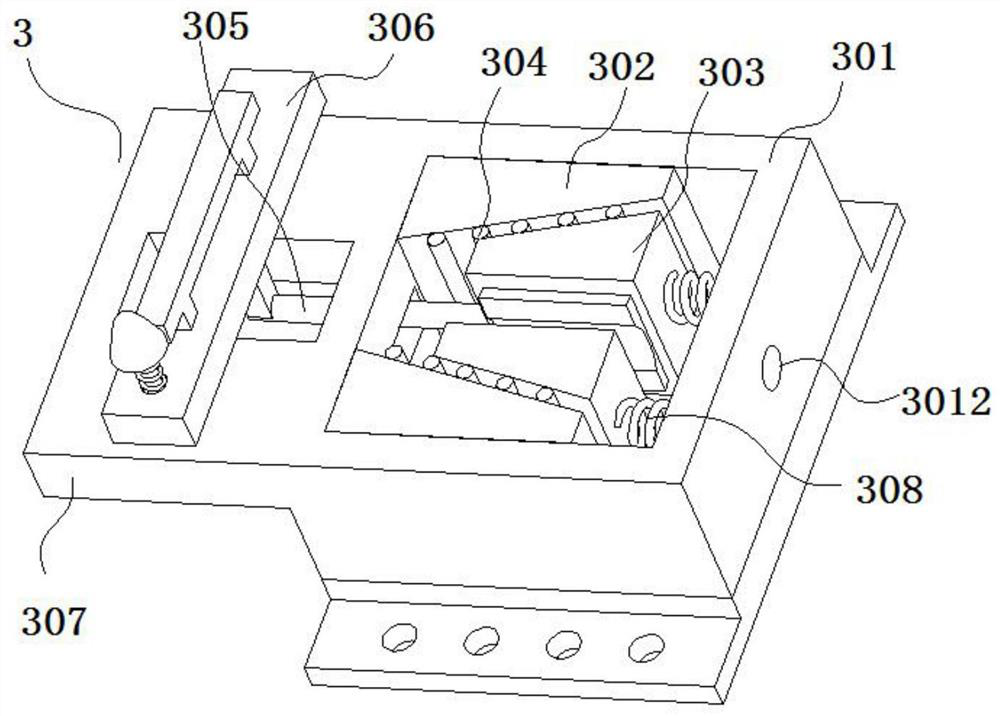

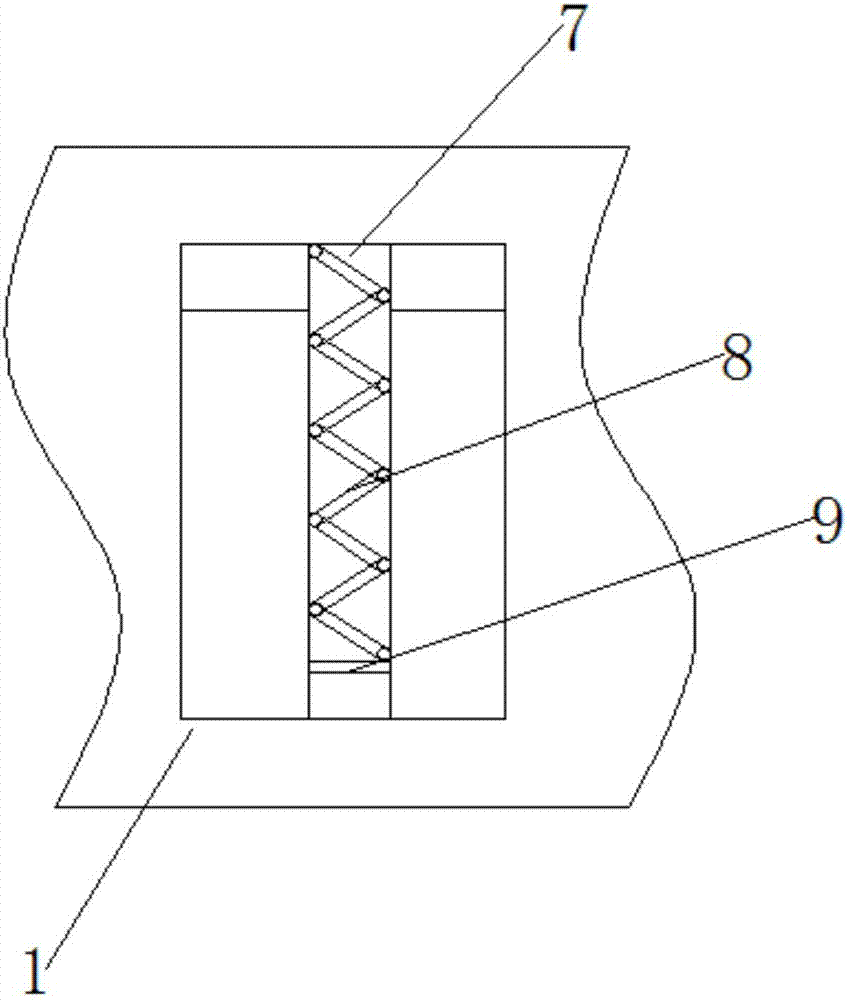

Inward contracting type spring sleeve clamp

The invention discloses an inward contracting type spring sleeve clamp which comprises a shell body with a cavity. A fixed sleeve is arranged in the cavity of the shell body, a conical surface is arranged at the tail end of the fixed sleeve, an elastic sleeve is arranged in the fixed sleeve, the elastic sleeve comprises a sleeve seat, the sleeve seat is connected with a plurality of elastic sections, guide seats matched with the conical surface are arranged at the tails of the elastic sections, and the sleeve seat of the elastic sleeve is connected with a pull rod. The inward contracting type spring sleeve clamp has the advantages of being reasonable in design, simple in structure, convenient to operate, high in centring precision and reliable in clamping, saving time and labor in the workpiece dismounting process, and being low in labor intensity of an operator, high in production efficiency, low in production cost and convenient to popularize and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Safe releasing mechanism

InactiveCN103466042AReliable disengagementProtect life safetyTowing/pushing equipmentEngineeringWinch

The invention discloses a safe releasing mechanism which comprises a connecting shell, a retaining ring, a movable spring seat, a flexible chuck, a spring, an inner sleeve, an outer sleeve, a breakable pin, a fixing ring, a tow rope, a tapered slider, a compression sleeve and the like. The safe releasing mechanism is mounted on a winch of a navigation body in high-speed navigation, and absorbs certain impact energy to reduce influences of internal impact to a take-up towing system when an underwater carrier connected with the navigation body encounters accidents and then towing tension of the tow rope is increased. When the towing tension is increased to certain value, the breakable pin in the mechanism is broken off under the action of the towing force, so that the towing rope can be reliably separated from the winch, the high-speed navigation body can navigate normally, overturning accidents are avoided, and injuries of operators due to breakage of cables can also be avoided.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

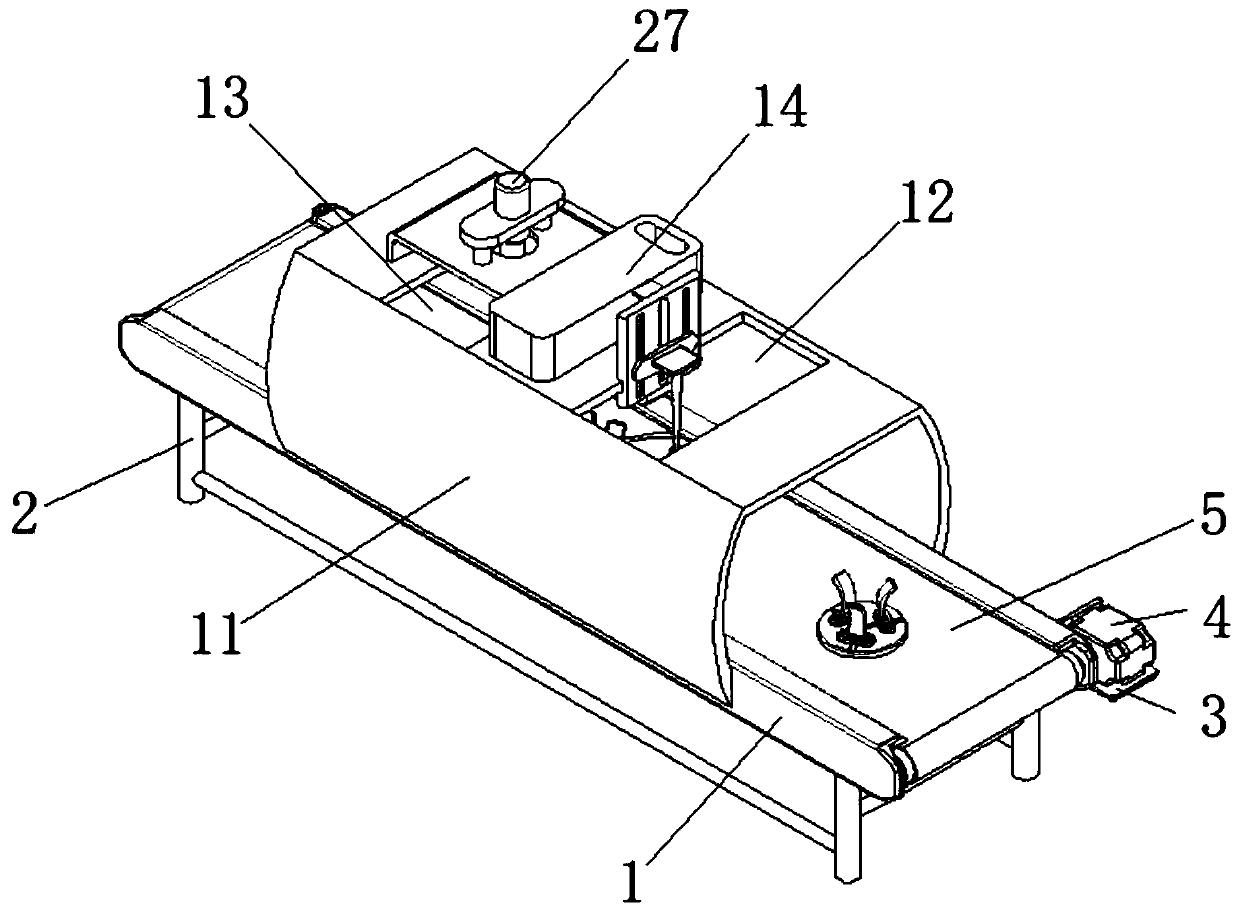

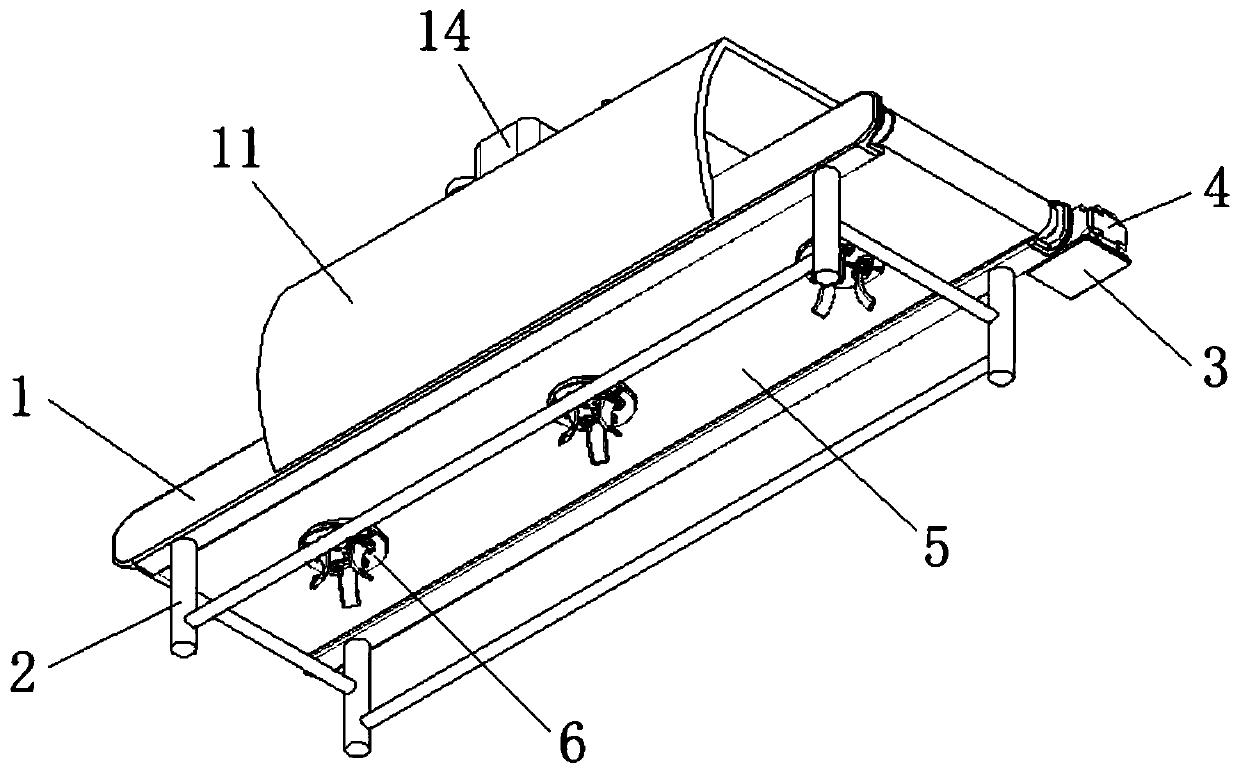

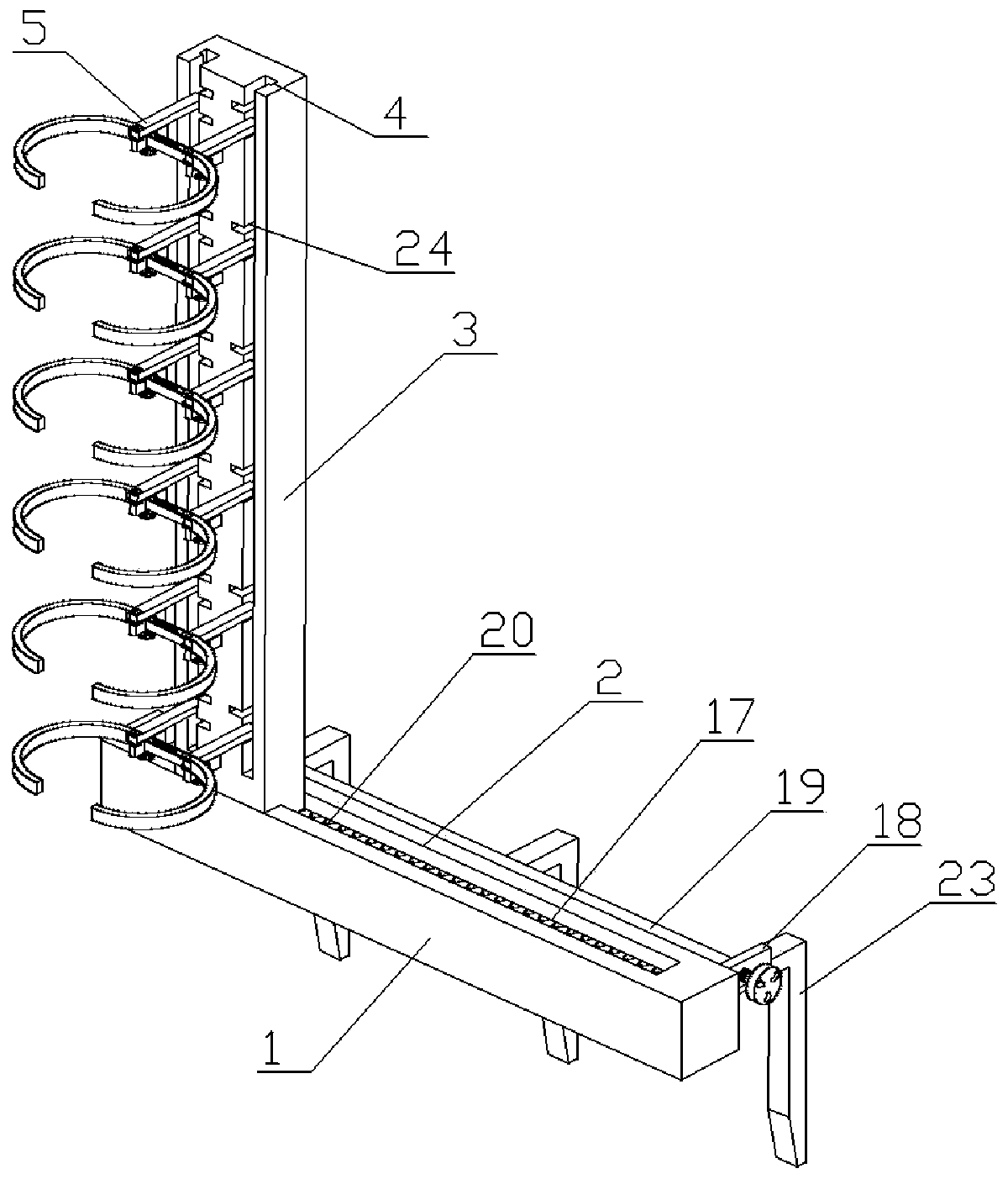

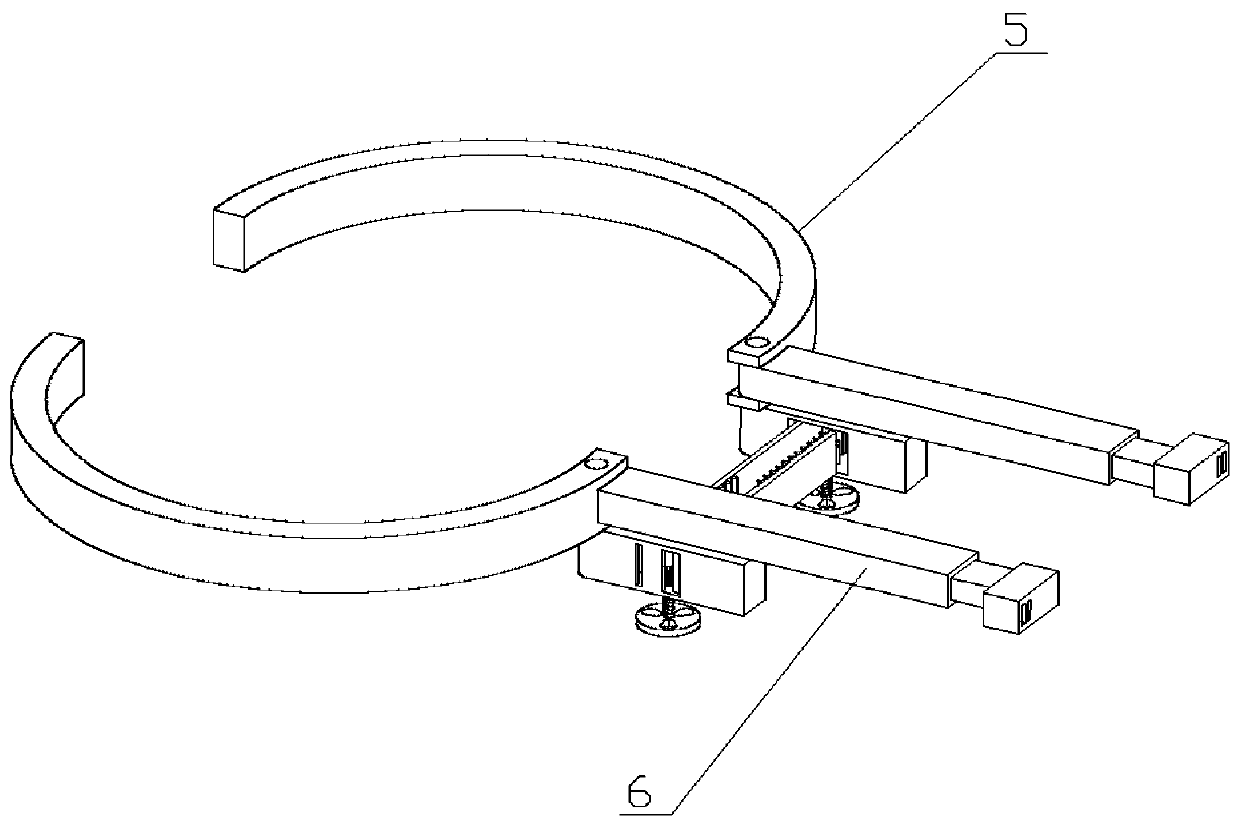

Heat-supply pipe network segmented regulation fixing bracket

ActiveCN111561607AFixed position in timeEasy centralized clampingPipe supportsPipe laying and repairStructural engineeringMechanical engineering

The invention discloses a heat-supply pipe network segmented regulation fixing bracket. The heat-supply pipe network segmented regulation fixing bracket comprises a bracket base and a sliding rail. The bracket base is provided with a sliding groove I. A bracket vertical arm is arranged on the upper side of the bracket base. The lower end of the bracket vertical arm is slidably clamped in the sliding groove I. The rear side face of the bracket vertical arm is provided with a plurality of tooth holes. The bracket vertical arm is provided with a pair of sliding grooves II. A plurality of clampingdevices used for clamping and fixing a heat-supply pipe are slidably arranged in the sliding grooves II. Each clamping device comprises a pair of clamping mechanisms arranged oppositely. The heat-supply pipe network segmented regulation fixing bracket has the beneficial effects of clamping, regulating and fixing the heat-supply pipe in a segmented mode, and improving the abutting accuracy and theabutting mounting efficiency in the abutting mounting process of the heat-supply pipe in the vertical direction.

Owner:陈小辉

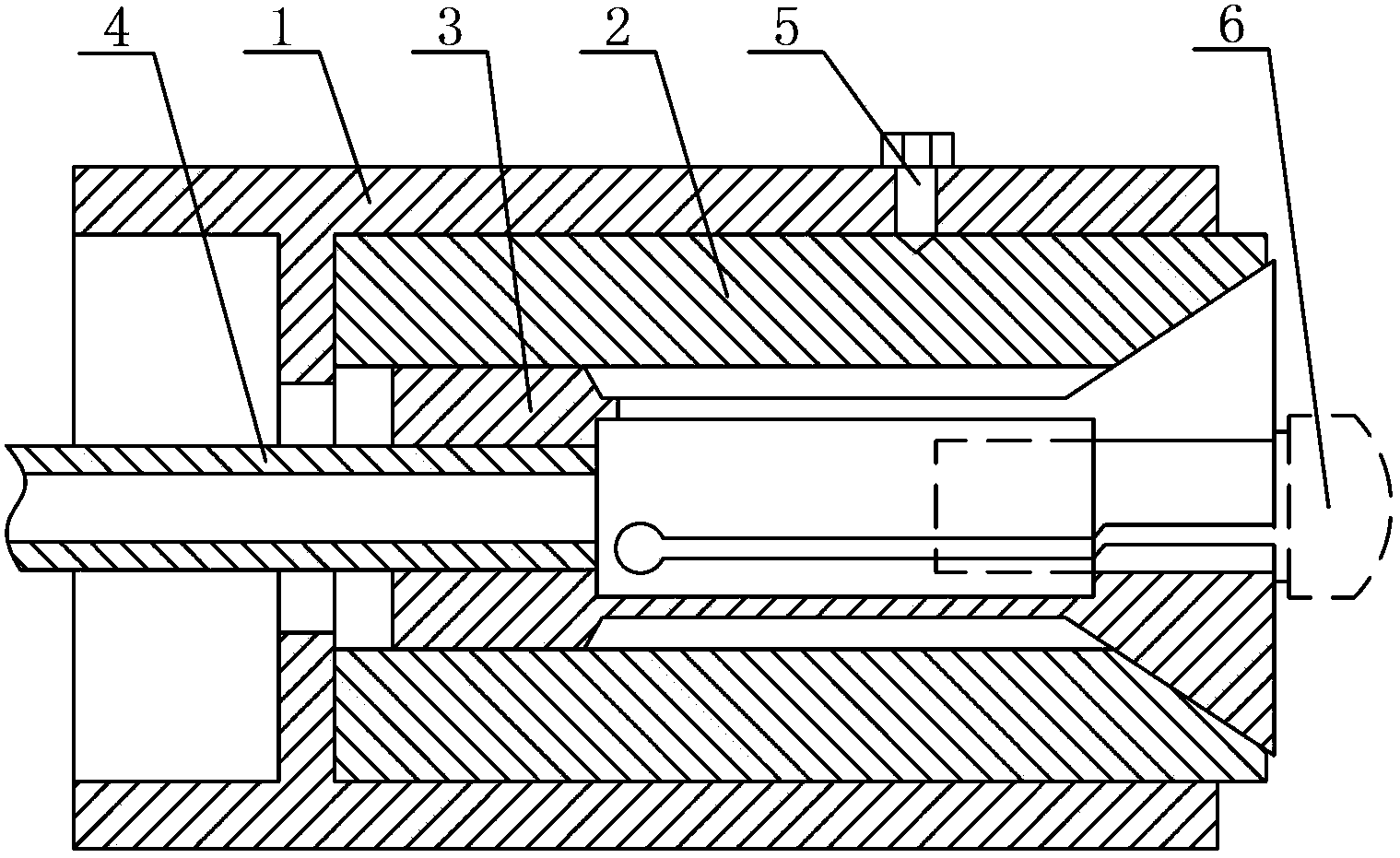

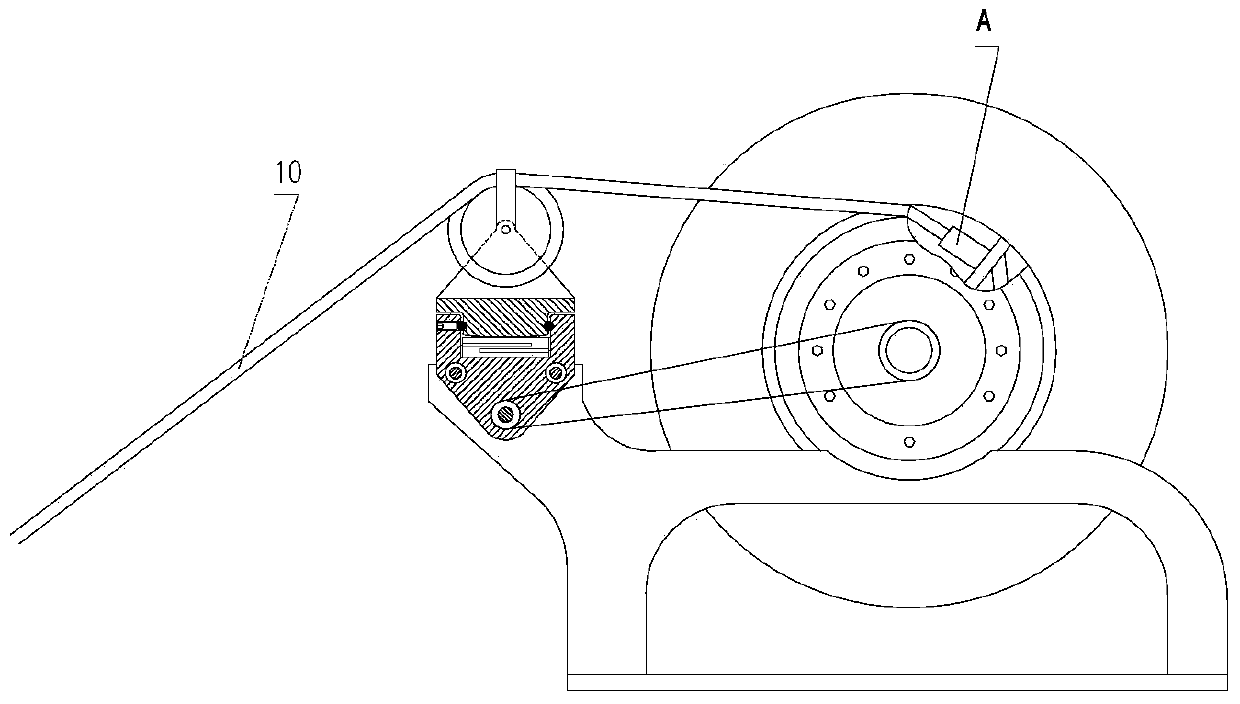

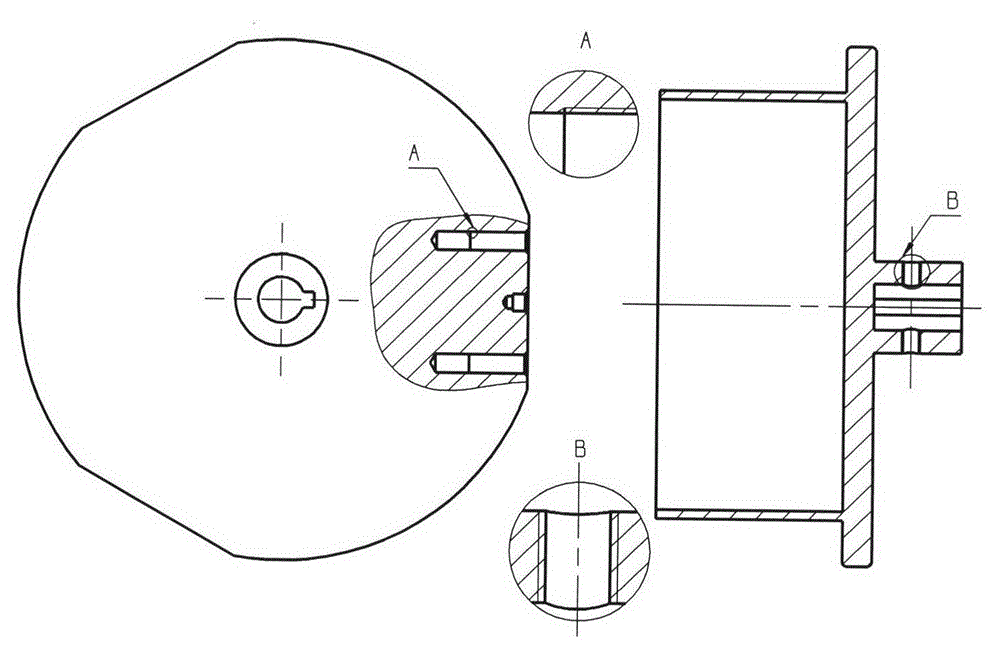

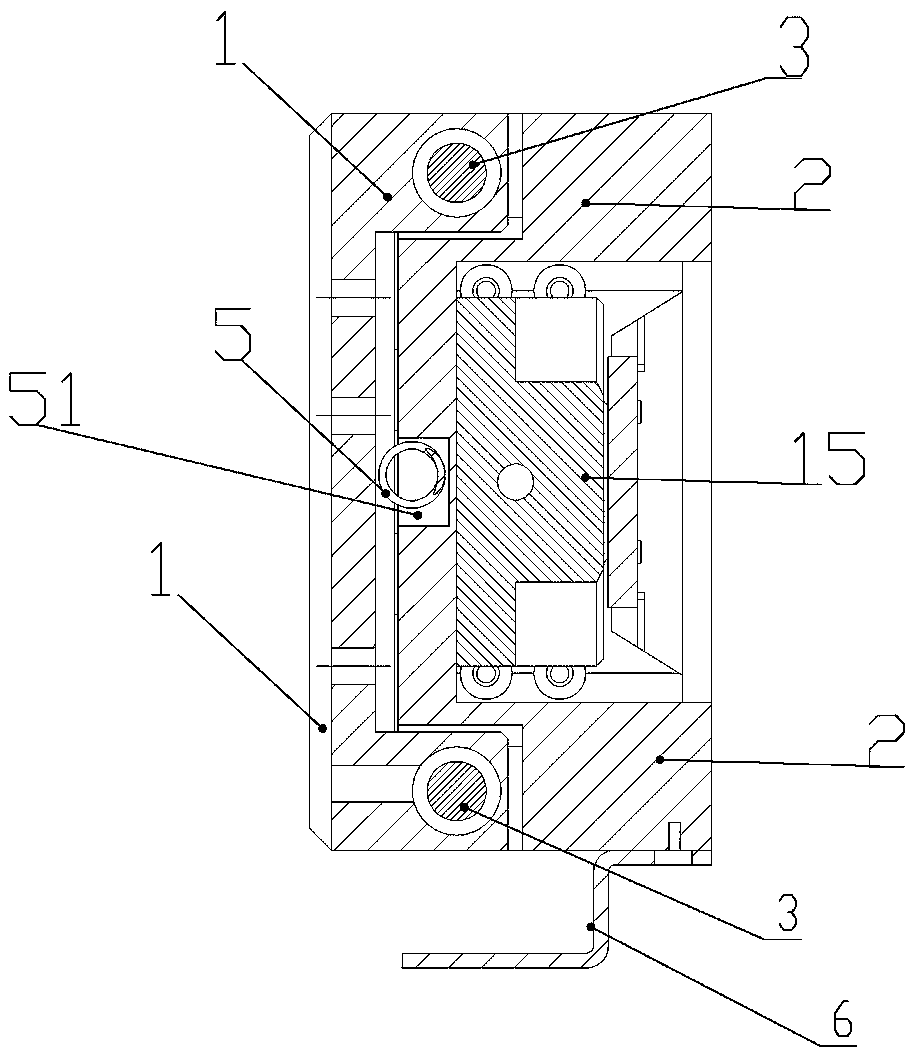

Safe chuck

The invention discloses a safe chuck. The safe chuck comprises a transmission shaft and a pneumatic clamping mechanism, wherein the transmission shaft is supported on a rack through a bearing sleeve; a belt wheel is arranged at one end of the transmission shaft, and a positioning component for clamping an air expansion shaft is arranged at the other end of the transmission shaft; the pneumatic clamping mechanism is used for clamping the air expansion shaft; the positioning component comprises a fixed positioning block for positioning the air expansion shaft axially and a sliding ejection head for positioning the air expansion shaft axially; the pneumatic clamping mechanism comprises a clamping air chamber for clamping the air expansion shaft, a loosening air chamber for loosening the air expansion shaft and a clamping positioning block for clamping and positioning the air expansion shaft in the radial direction. The safe chuck has the characteristics of simple structure, flexibility in operation, convenience for mounting and dismounting the air expansion shaft, firmness in clamping, and safety and reliability; the safe chuck is provided with a protection structure for preventing incorrect operation; and meanwhile, the safe chuck further has the characteristics of high power transmission efficiency and the like.

Owner:JIANGYIN LIDA PRINTING & PACKAGING MACHINERY

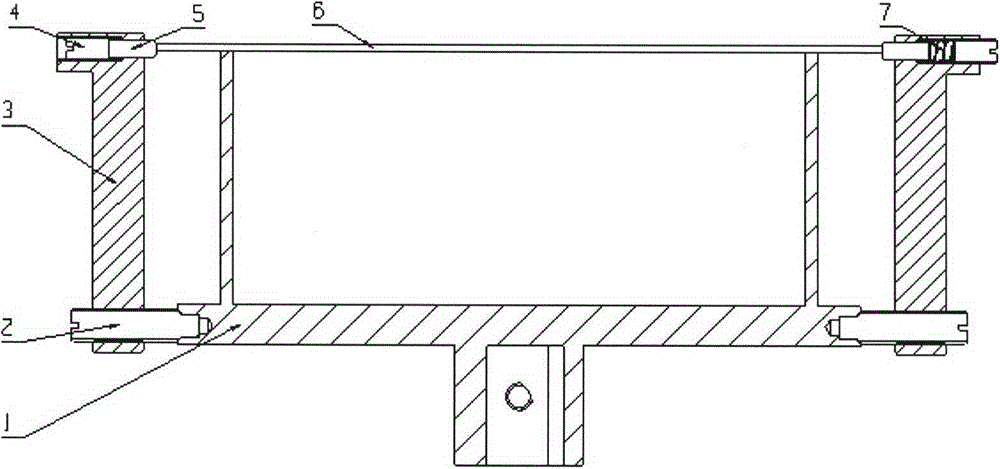

Auxiliary apparatus for plate part thermal spraying technology

InactiveCN104894504AEfficient recyclingReduce wasteMolten spray coatingThermal sprayingThermal deformation

The invention relates to an auxiliary apparatus for a plate part thermal spraying technology. The auxiliary apparatus comprises a powder collecting pot, a T-shaped rack, a bulb lifting pin, a small spring, a fastening screw, a setting-up screw and an installation screw; one end of the powder collecting pot is a cavity with the wall thickness of 2mm, and the cavity is filled with a proper amount of water to effectively recover metal powder; and the T-shaped rack is connected with the powder collecting pot through the setting-up screw and the installation screw, and can clamp plate parts with different sizes as needed. The auxiliary apparatus can realize accurate positioning and reliable clamping of the parts to be sprayed, and also can effectively prevent arching of the middle parts of the plate parts due to high temperature thermal deformation in the spraying process.

Owner:ZHENJIANG BULL MECHANICAL & ELECTRICAL TECH

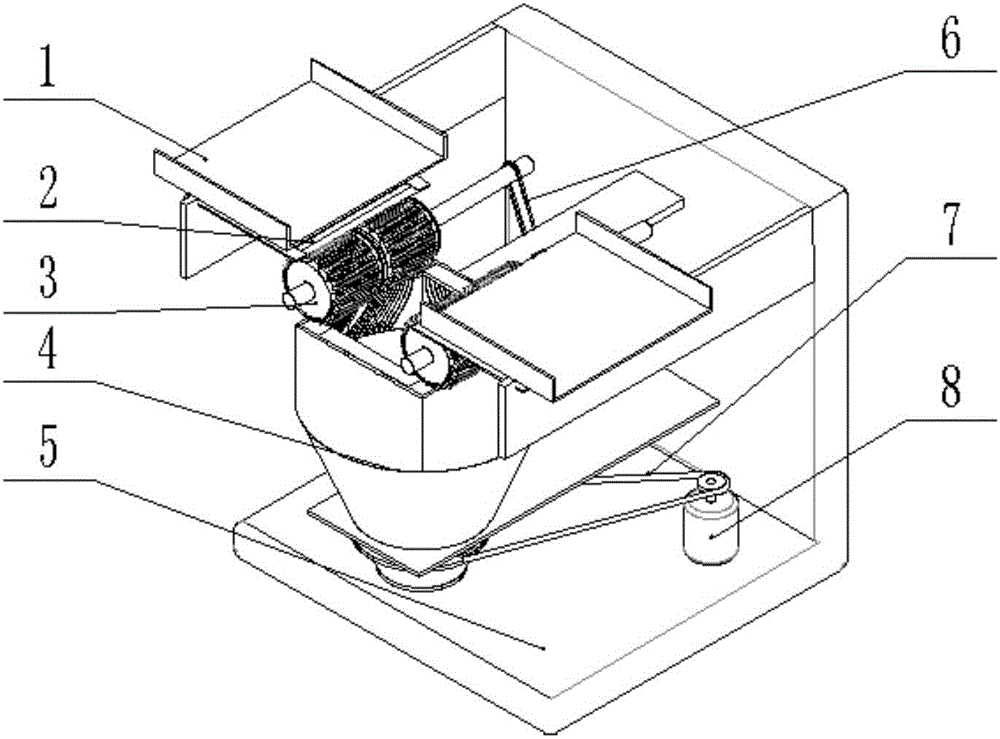

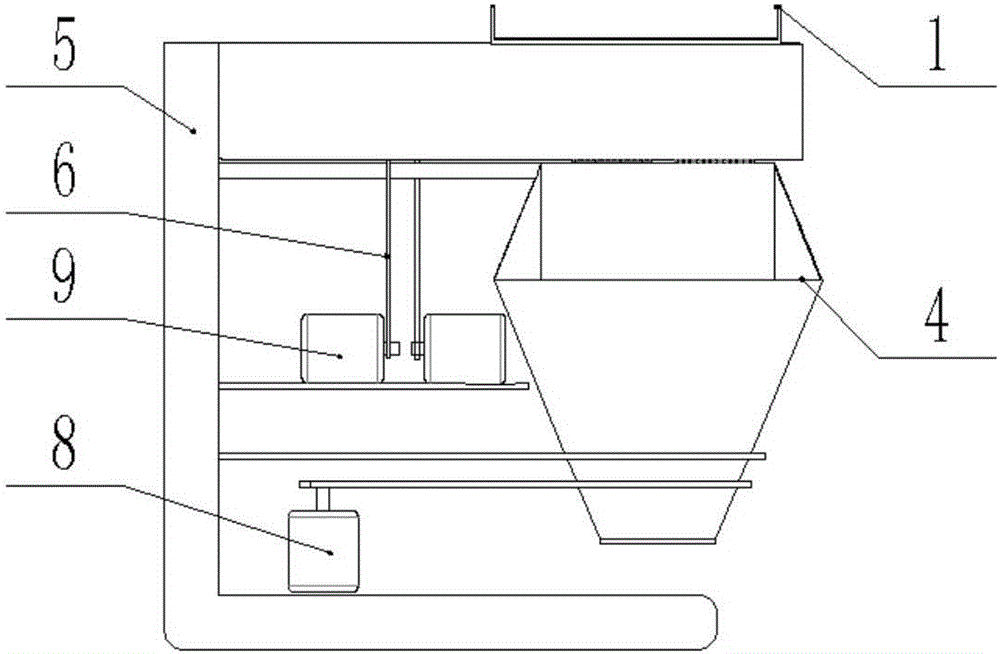

Vertical chili bundle remover

ActiveCN106723203AStep up accuratelyTighten upFood treatmentAgricultural engineeringCentrifugal force

The invention discloses a vertical chili bundle remover and belongs to the field of agricultural machinery. The vertical chili bundle remover is composed of discharging plates, a knife, a rotating clamp, a charging bucket, a rack, a belt, a chain, a first motor and two second motors, the discharging plates are symmetrically mounted on the rack, the charging bucket is mounted on the rack, the rotating clamp is mounted on the rack, the knife is mounted on the rack, the first motor is mounted on the rack, the chain is connected with the first motor and the charging bucket, the two second motors are oppositely mounted on the rack, and the belt is connected with the rotating clamp and the second motors. The vertical chili bundle remover has the advantages that a vertical rotating mode is utilized to enable chilies to be uniform in orientation; a lower bucket body retaining plate can enhance effect of centrifugal force on the chilies; an upper bucket body ribbed plate sequentially feeds the chilies to the top end; a clamping piece strip can control when a Y-shaped clamping portion thereon clamps and releases during high-speed rotating; the inside of the Y-shaped clamping portion is wavy, so that chili bundles are clamped more stably; the outer end of a compression column is spherical, so that friction resistance during movement is reduced.

Owner:丰城市老实人食品有限公司

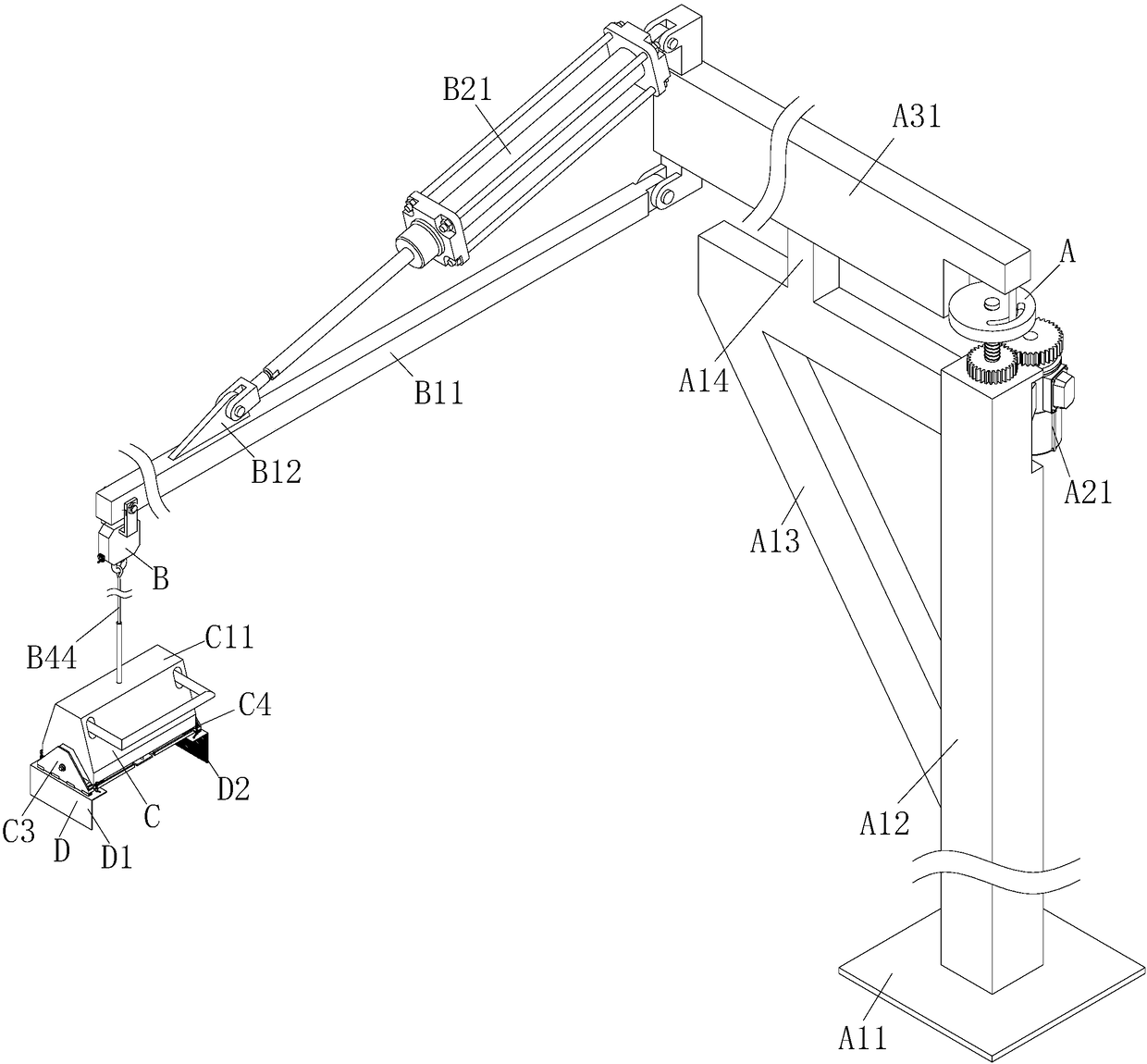

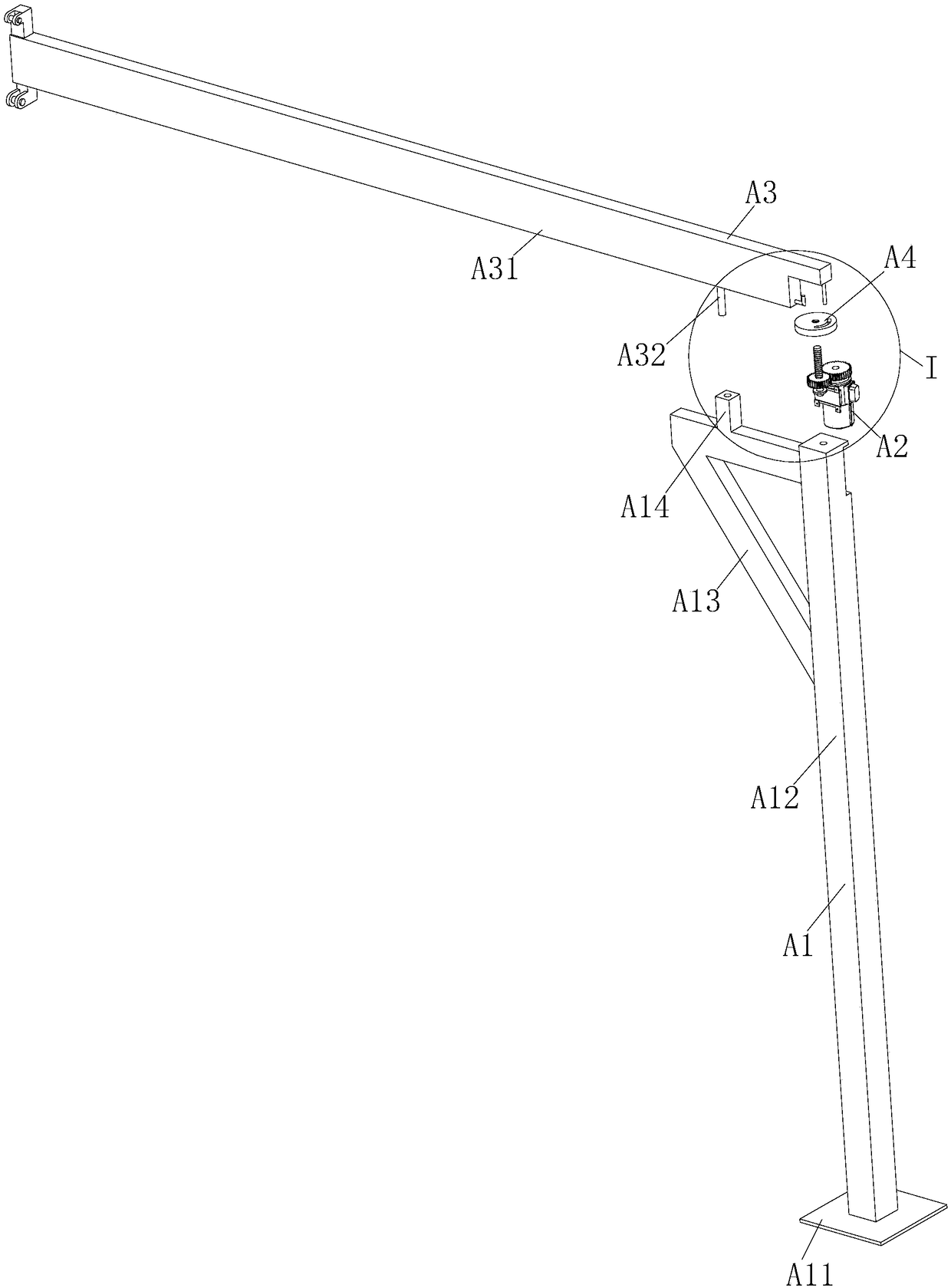

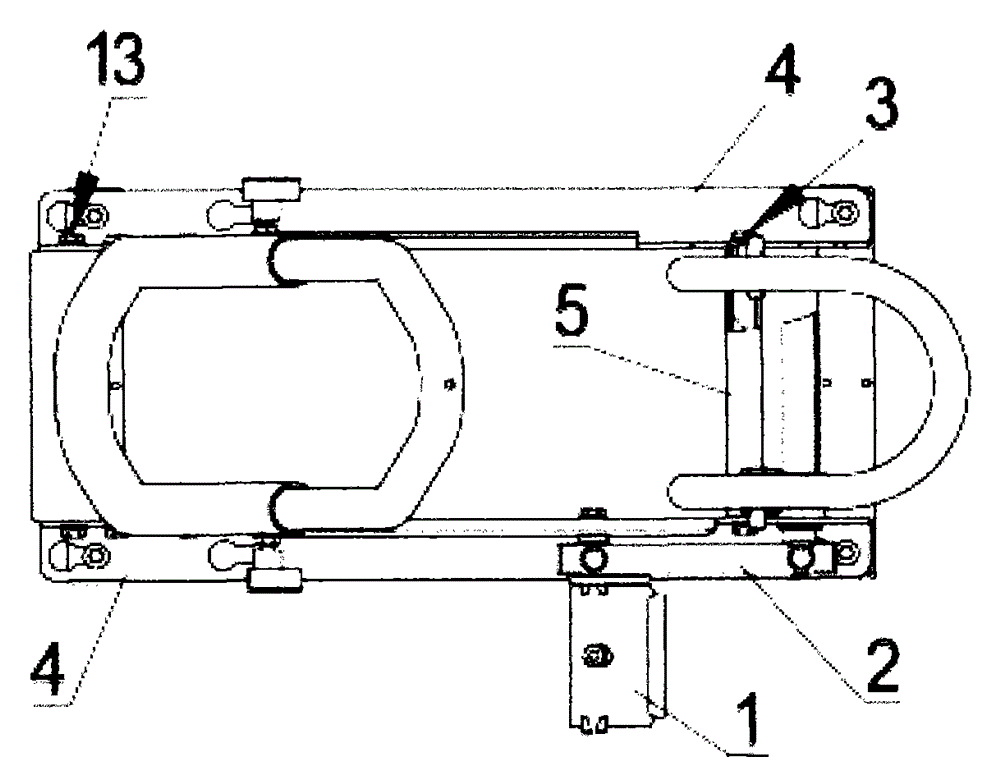

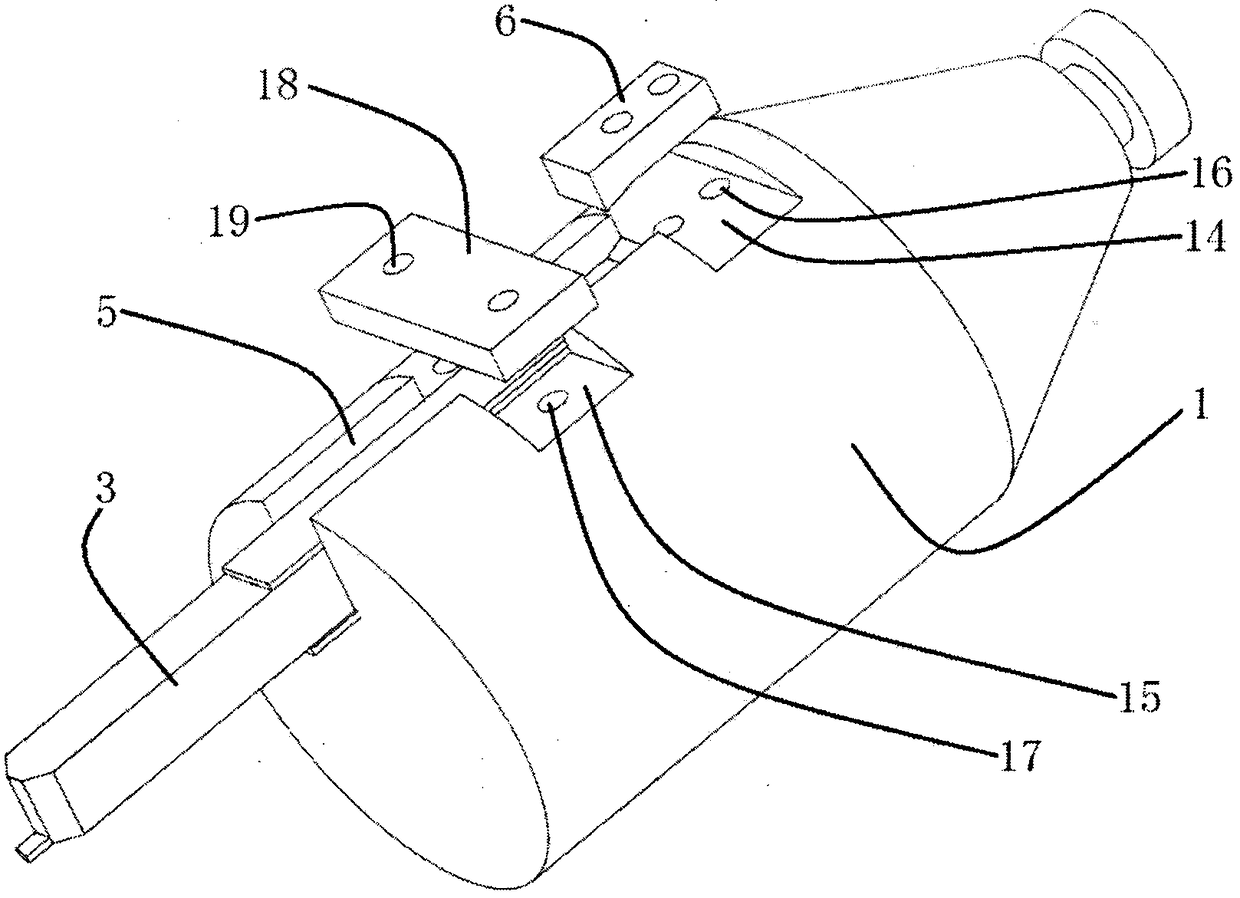

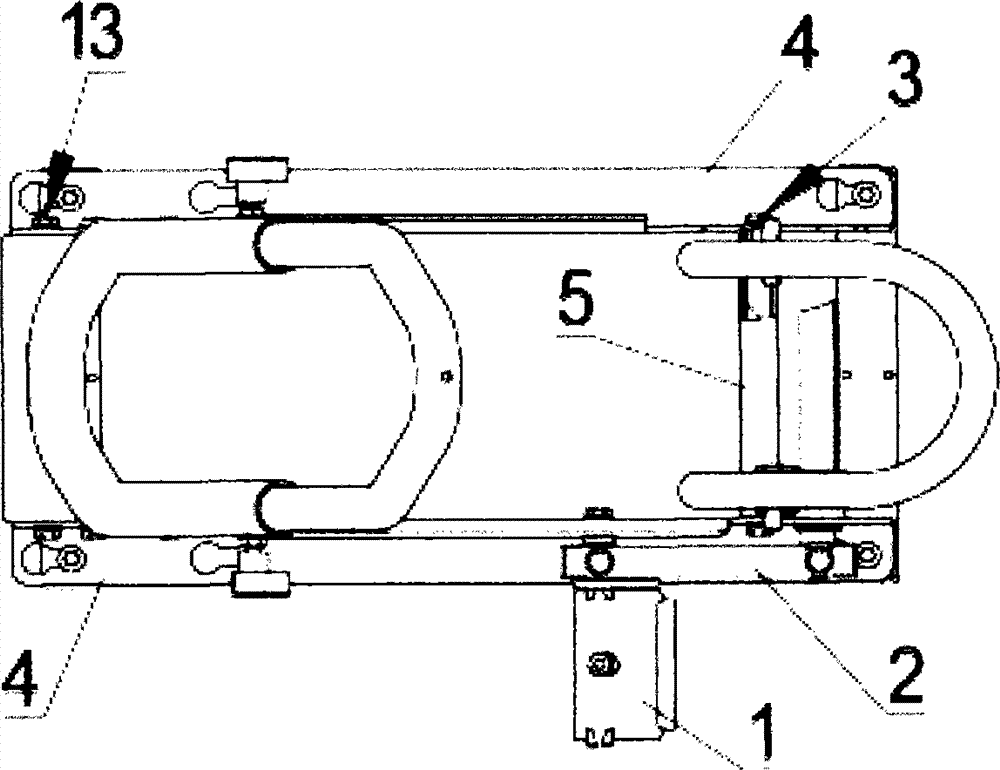

Water tank hoisting device and method

ActiveCN108584727AEnsure safetyRealize fixed angle rotationCranesLoad-engaging elementsMechanical engineeringQuartz

The invention relates to a water tank hoisting device and method, and belongs to the field of water tank production equipment. The water tank hoisting device and method aim at solving the problems that a quartz sand water tank is heavy and is carried with amount of force, and the quartz sand water tank is fallen off during being carried out, causing extremely high potential risk to workers, and meanwhile, the working efficiency is hardly ensured. The water tank hoisting device comprises a reciprocating swinging arm device, a hoisting tool locking device, a telescoping clamping device and an angle adjusting device, wherein the hoisting tool locking device is mounted on the reciprocating swinging arm device; the telescoping clamping device is mounted on the hoisting tool locking device; andthe angle adjusting device is mounted on the telescoping clamping device. With the adoption of the water tank hoisting device, the working efficiency is improved; the workers can safely operate; and the input of labor cost can be decreased.

Owner:嘉兴九腾科技咨询有限公司

Medical device

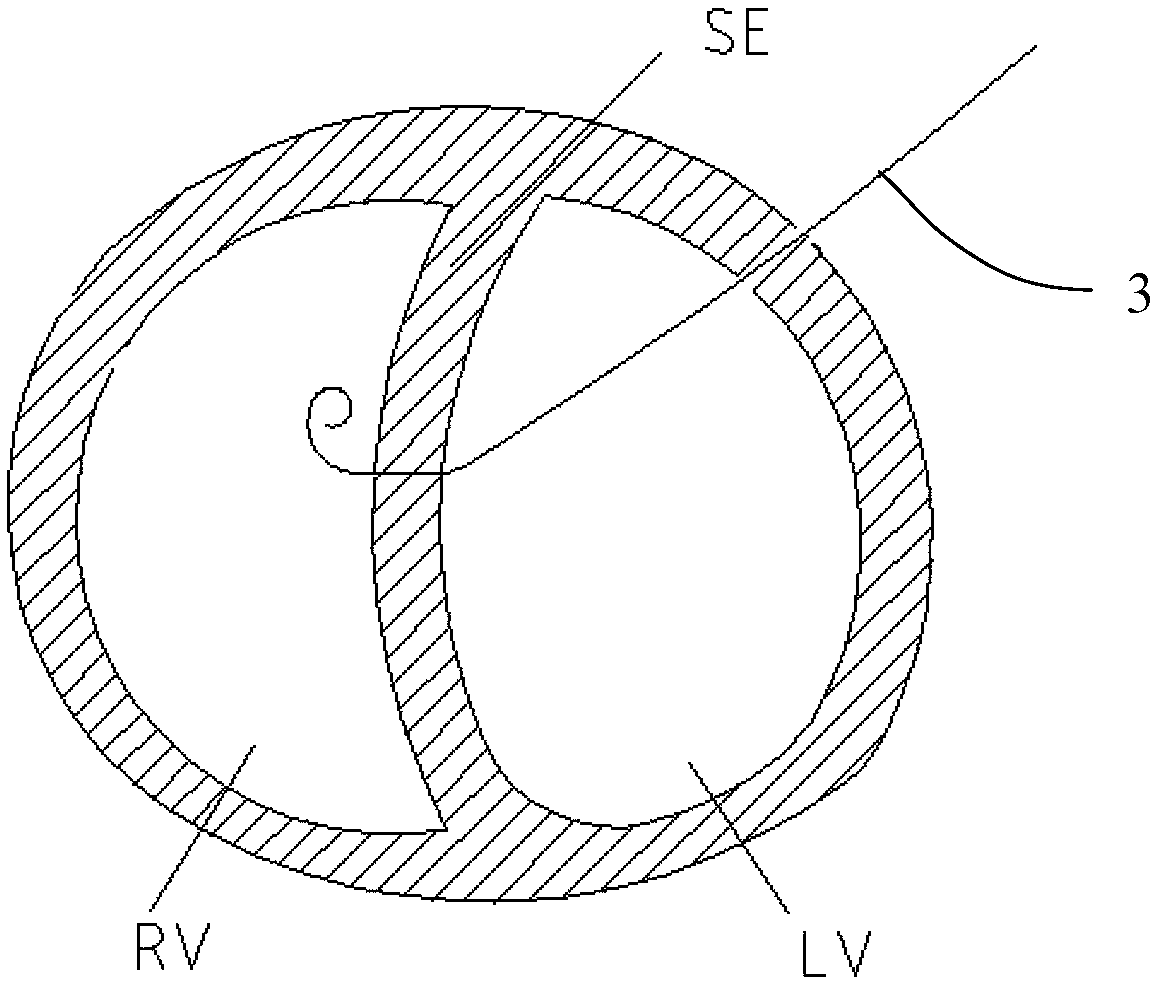

The invention provides a medical device which does not need an additional tightening structure and a separation structure for cutting the tightening structure. The easiness for doctors to operate likeinstruments is improved, and the operation time is shortened. The medical device includes a first fixing piece including a first portion and a second portion which are connected, the first portion isused for contacting with a first wall of an implanted object, the second fixing piece comprises a third portion and a fourth portion which are connected, the third portion is used for connection withthe second portion, and the fourth portion is used for contacting with a third wall of the implanted object; when the third portion is separated from the second portion, the implanted subject is in afirst state, and the implanted subject is in a second state when the third portion is connected to the second portion.

Owner:MICROPORT SINICA CO LTD

Electric control metal machining and fixing device

InactiveCN108177133AEasy to changeEffective coolingWork benchesPositioning apparatusLiquid-crystal displayMetal machining

An electric control metal machining and fixing device comprises a base, a first connecting base and a second connecting base. The first connecting base and the second connecting base are fixedly connected to the two ends of the base correspondingly. The upper end of the first connecting base is fixedly connected with an electric cylinder. The output end of the electric cylinder is fixedly connected with a clamping block, and a first shaft disc is fixedly connected into the other end of the clamping block. The other end of the first shaft disc is fixedly connected with a first fixing block, anda pressure sensor is fixed to the first fixing block. The upper end of the second connecting base is fixedly connected with a fixing cavity, and the fixing cavity is right opposite to the first shaftdisc. The pressure sensor sends data to a liquid crystal display control panel through a control chip, the liquid crystal display control panel displays pressure data, and the liquid crystal displaycontrol panel sends work or stop instructions to the electric cylinder through the control chip. By means of the electric control metal machining and fixing device, the degree of force for fixing metal products can be monitored in real time, the liquid crystal display control panel is used for fixing the metal products, and the problem of too large fixing force or too small fixing force is effectively solved.

Owner:重庆精高金属结构制造有限公司

Self-locking motorcycle frame

The invention relates to a self-locking motorcycle frame which comprises a lateral fixing support, a front fixing support, a fixing spindle, a blocking pipe, foot rests and adjustable supports of foot rests. The self-locking motorcycle frame has the advantages that (1) adjustable pipes can adjust heights and fix wheels of the motorcycle; (2) the self-locking motorcycle frame is simple in structure, reliable in fastening and convenient in cooperation due to the facts that foot rests are heightened, accordingly a self-locking hook rotates and breaks away from an axis pin thereby driving a small wheel on adjustable supports of foot rests to swing back and forth to change rotating directions of the blocking pipe and the clasping fixing and loosening breaking away of the motorcycle wheels are achieved; (3) the self-locking motorcycle frame is skillful in design, novel and practical due to the fact that foot rests can drive the self-locking hook to rotate and combined with the axis pin by gravity of the foot rests so that self-locking is achieved.

Owner:青岛东陆科技有限公司

Pipe wrench

The invention discloses a pipe wrench, which comprises a fixed jaw end and a movable jaw end, wherein the fixed jaw end is fixedly arranged on a wrench body, the movable jaw end is arranged on a regulating frame through a screw nut and a threaded structure, the regulating frame is arranged on the wrench body through a macro adjusting screw nut structure, the movable jaw end is arranged on the regulating frame through a fine adjusting screw thread structure, the fine adjusting screw thread structure comprises a fine adjusting screw rod and a screw rod knob used for controlling the fine adjustable screw rod to move, and the movable jaw end is fixedly arranged on the fine adjusting screw rod. The pipe wrench provided by the invention has the advantages that the structure is simple, the use is convenient, a round pipe can be firmly and reliably clamped in the jaw, in addition, the manufacturing is simple, and the production cost is low.

Owner:吕桂年

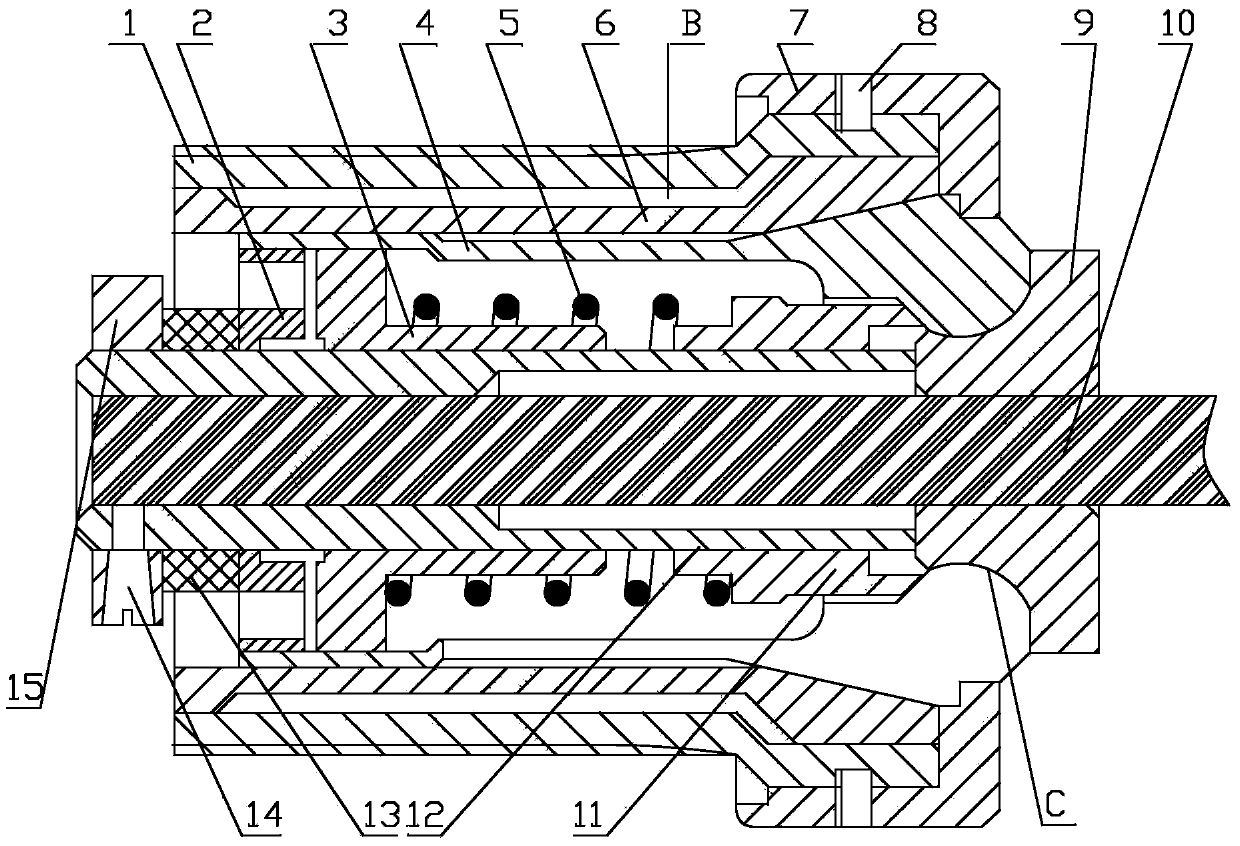

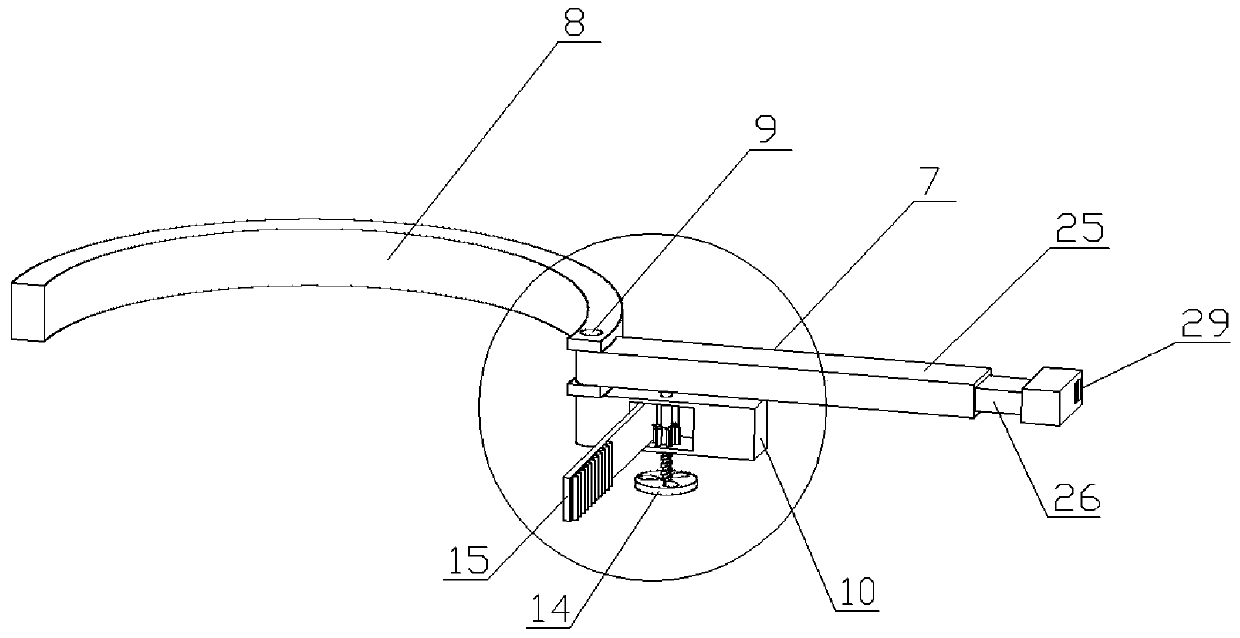

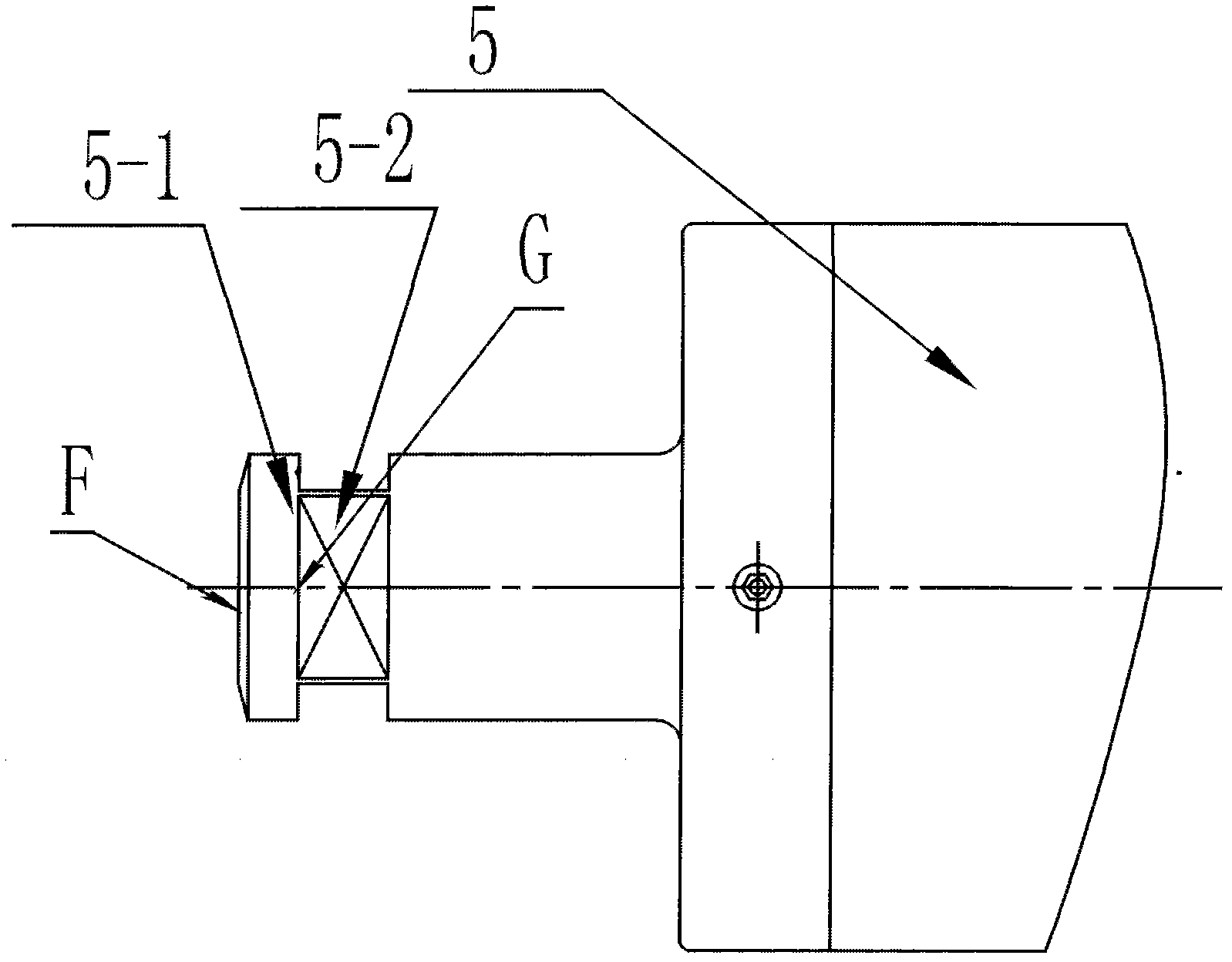

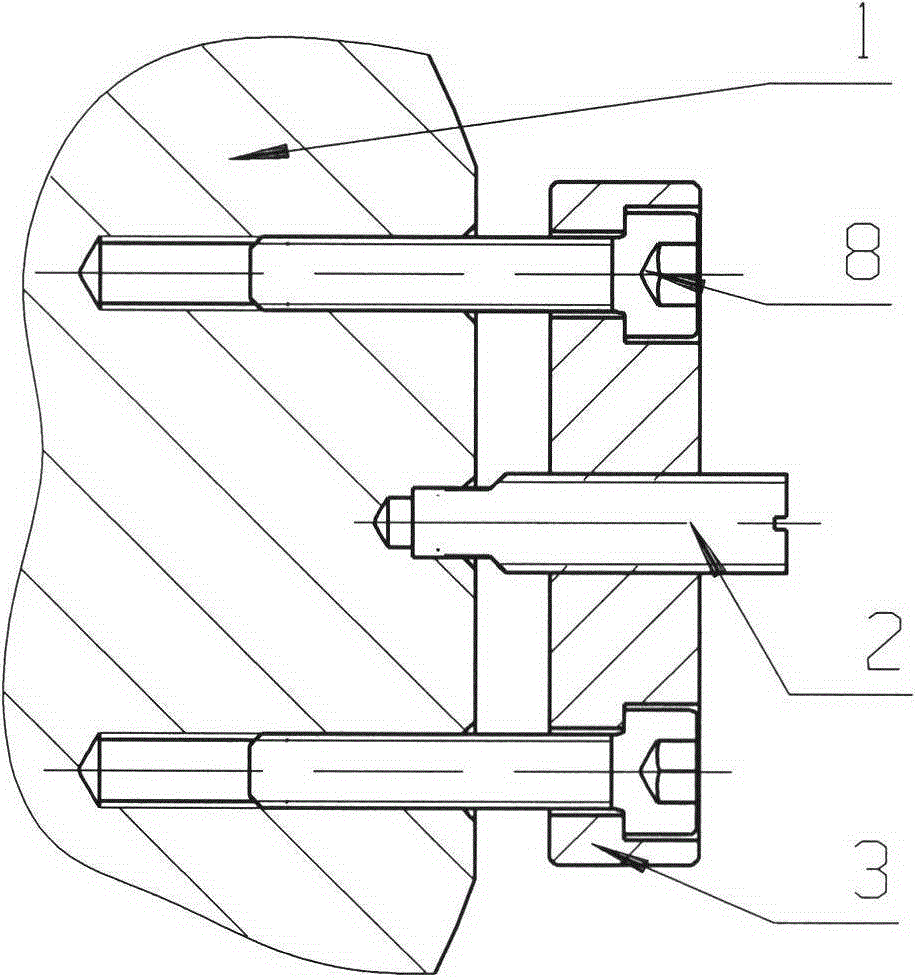

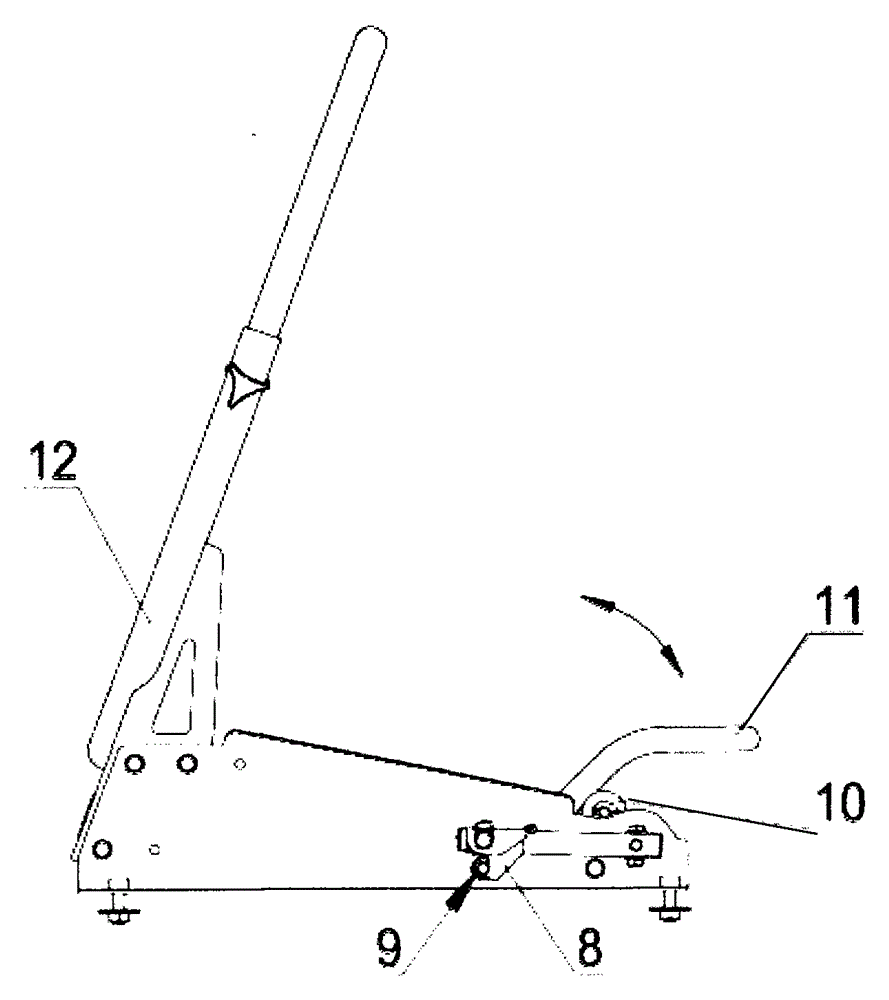

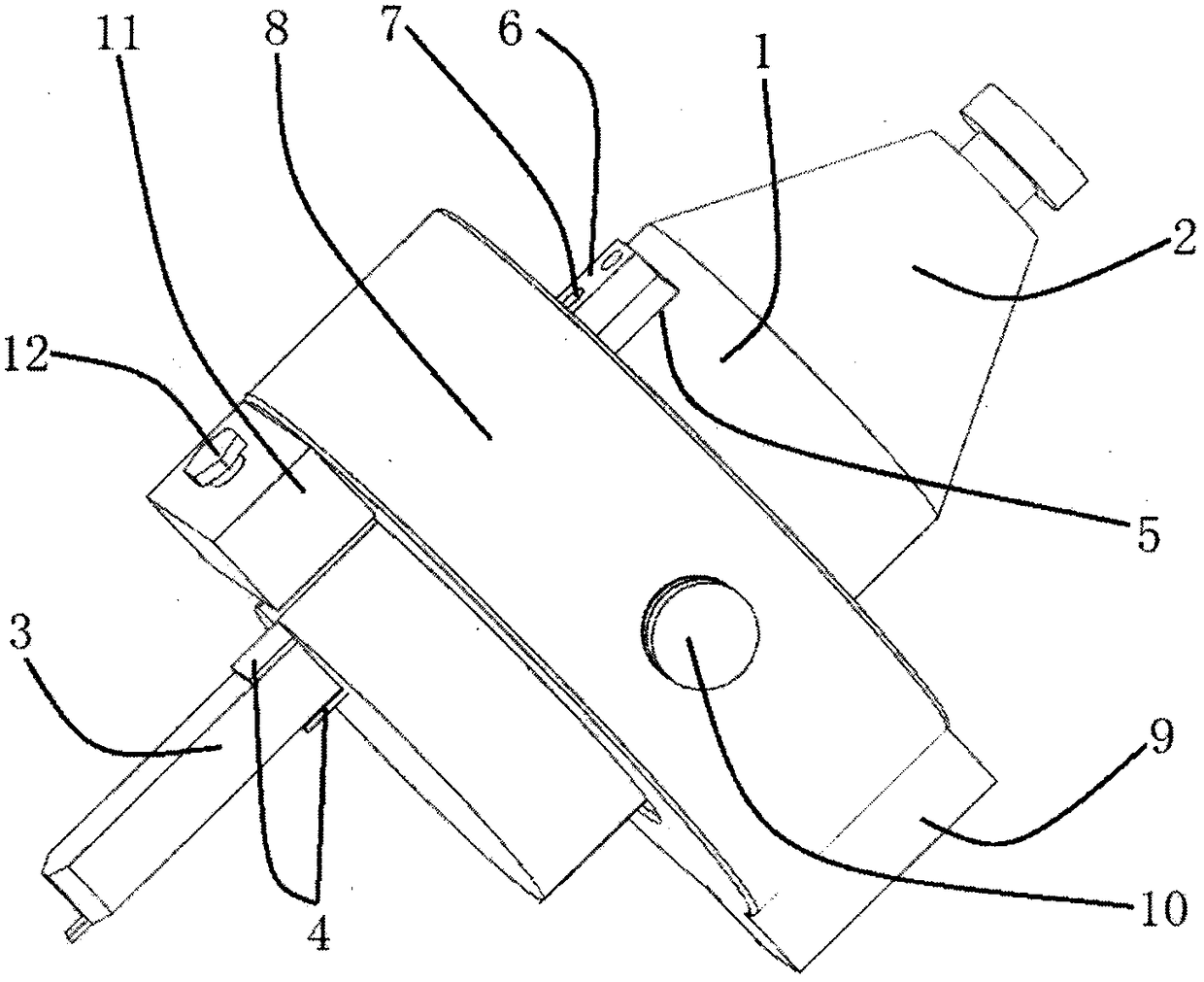

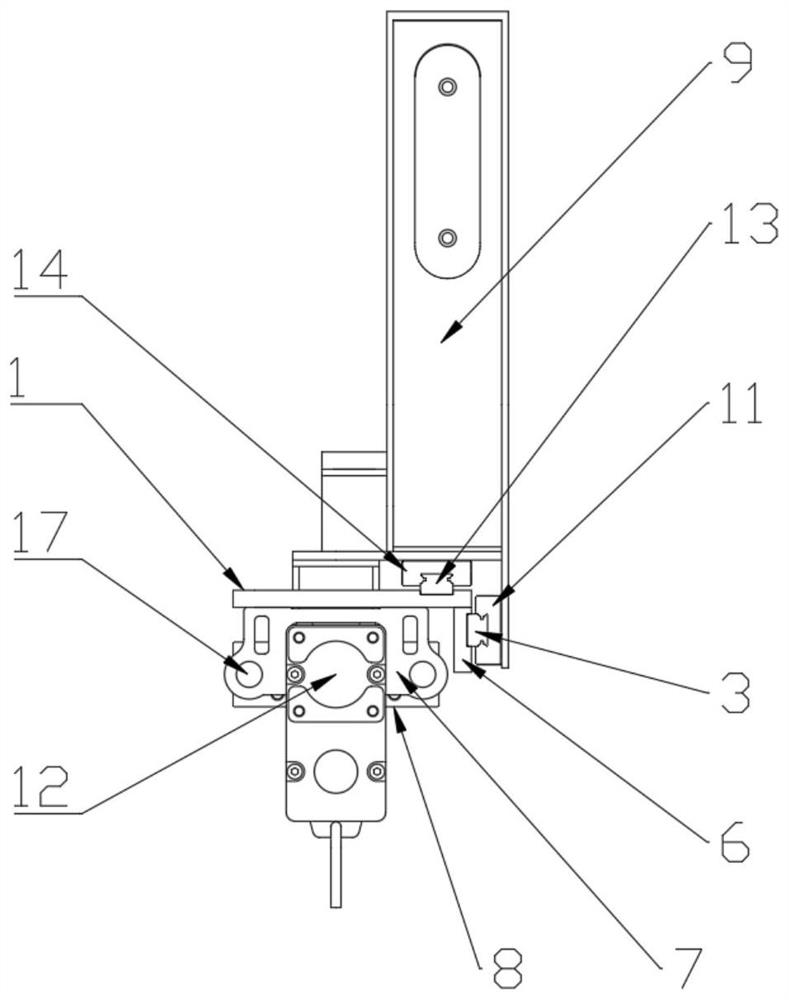

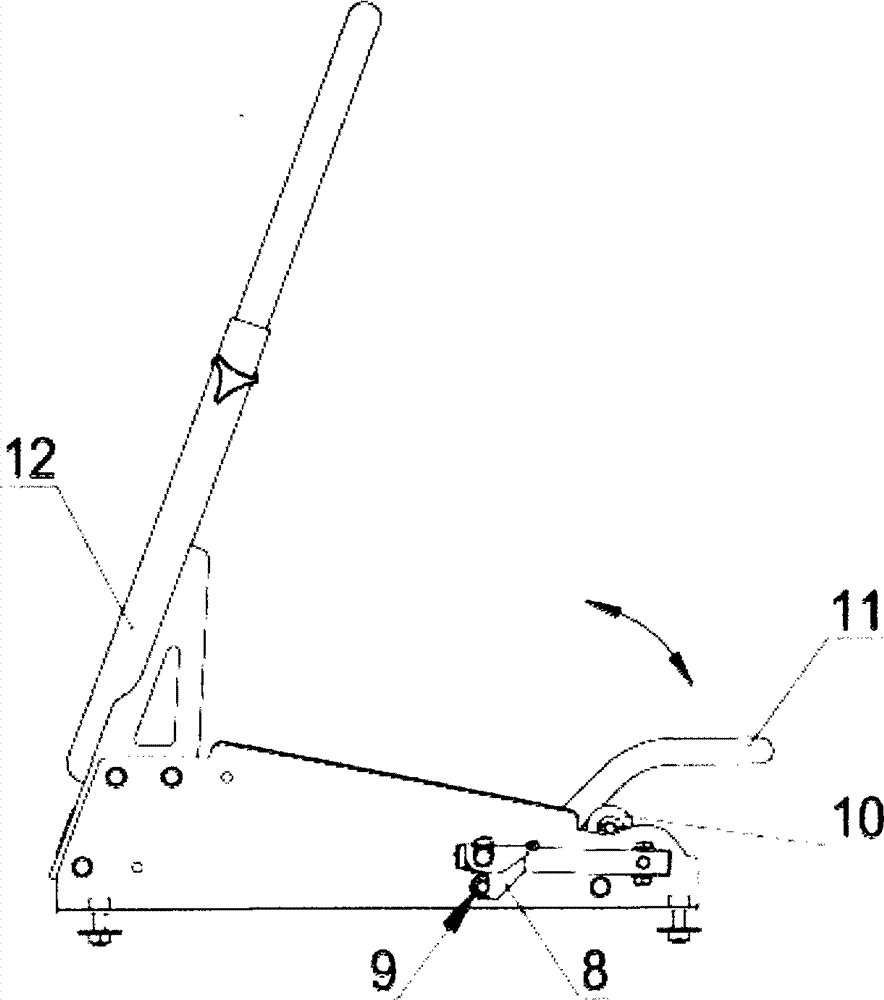

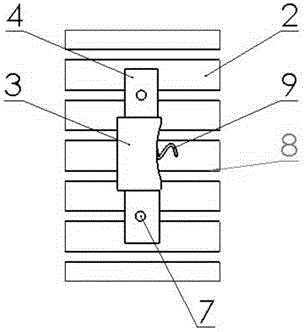

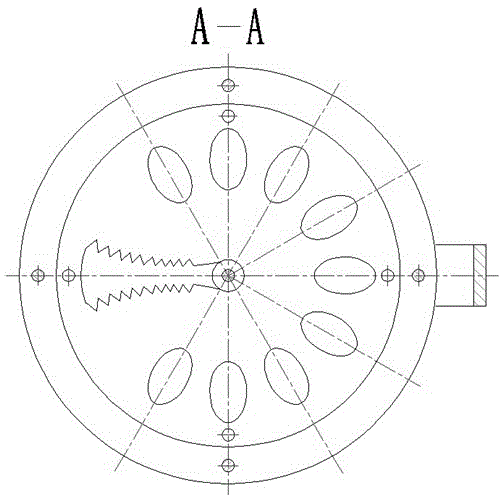

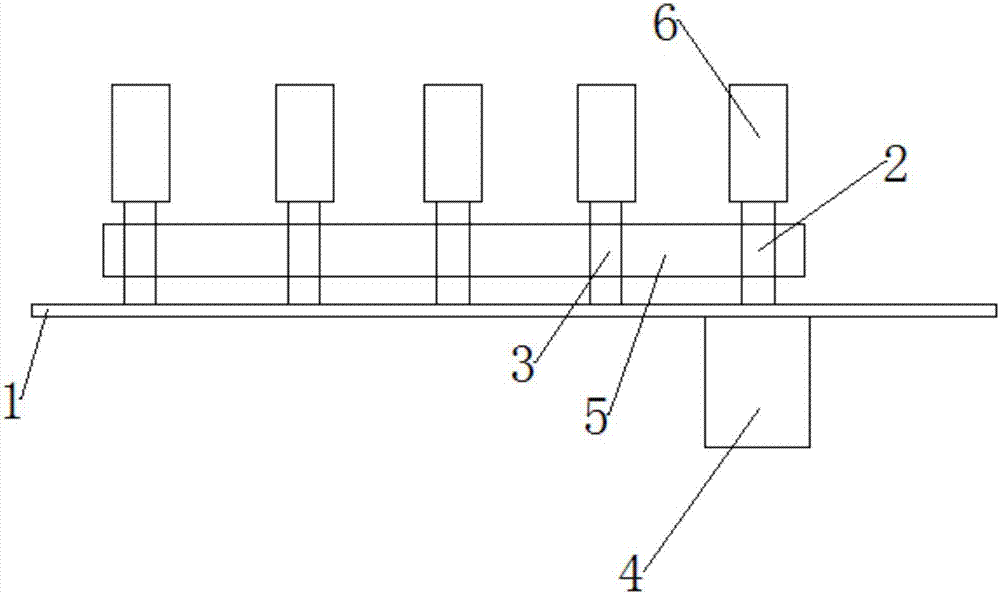

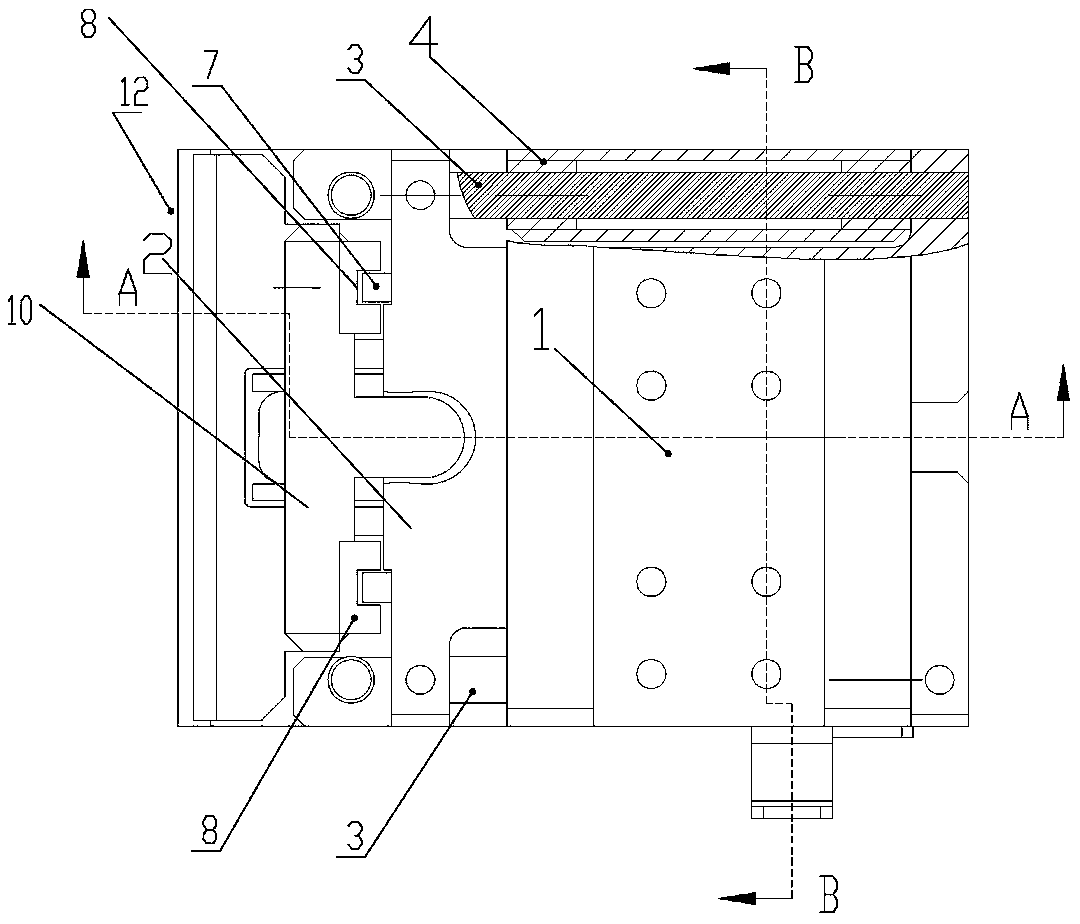

Fine blanking flange parallel multiple circular groove processing center posttreatment knife handle cutter combination

ActiveCN109202148AHigh strengthImprove efficiencyMilling equipment detailsPositioning apparatusPunchingEngineering

The invention relates to a fine blanking flange parallel multiple circular groove processing center posttreatment knife handle cutter combination, which is applicable to the installing, clamping and processing of a plurality of circular grooves on a processing center once, and is particularly applicable to the efficient processing of a plurality of parallel circular grooves with higher precision requirements on a precision punching stainless steel thick flange. The concrete structure consists of a knife handle 1 with a groove, an end surface groove knife 3, an annular press ring 8 with an eccentric mass block, a support shaft 10 with a groove, a pressing screw 12 and a regulating pad knife blade 4, wherein the end surface groove knife is eccentrically arranged in the knife handle with thegroove, and is fixed by a press plate and screws; the cutter position can be precisely controlled by the processing center; a plurality of parallel or concentric circular grooves can be processed on aworkpiece.

Owner:江苏鹏德工业科技有限公司

Wellhead sealing device for downhole heating cable

ActiveCN106930717ATighten upImprove stress resistanceConstructionsSealing/packingEngineeringMechanical engineering

The invention provides a wellhead sealing device for a downhole heating cable. A sealing main pipe is fixed to a wellhead and used for penetrating of the cable, an upper gland is arranged inside the upper end of the sealing main pipe, a lower gland is arranged inside the lower end of the sealing main pipe, and the upper gland and the lower gland are each provided with a port which the cable can penetrate through. The wellhead sealing device further comprises an upper squeezing sealing member and a lower squeezing sealing member, wherein the upper squeezing sealing member is positioned in the sealing main pipe, located at the lower side of the upper gland and matched with the upper gland, and the lower squeezing sealing member is positioned in the sealing main pipe, located at the upper side of the lower gland and matched with the lower gland. A colloid injecting valve is arranged on the position, between the upper squeezing sealing member and the lower squeezing sealing member, of the sealing main pipe. The technical scheme of the wellhead sealing device for the downhole heating cable can effectively solve the problem that the airtightness of the downhole heating cable at a wellhead is poor.

Owner:PETROCHINA CO LTD

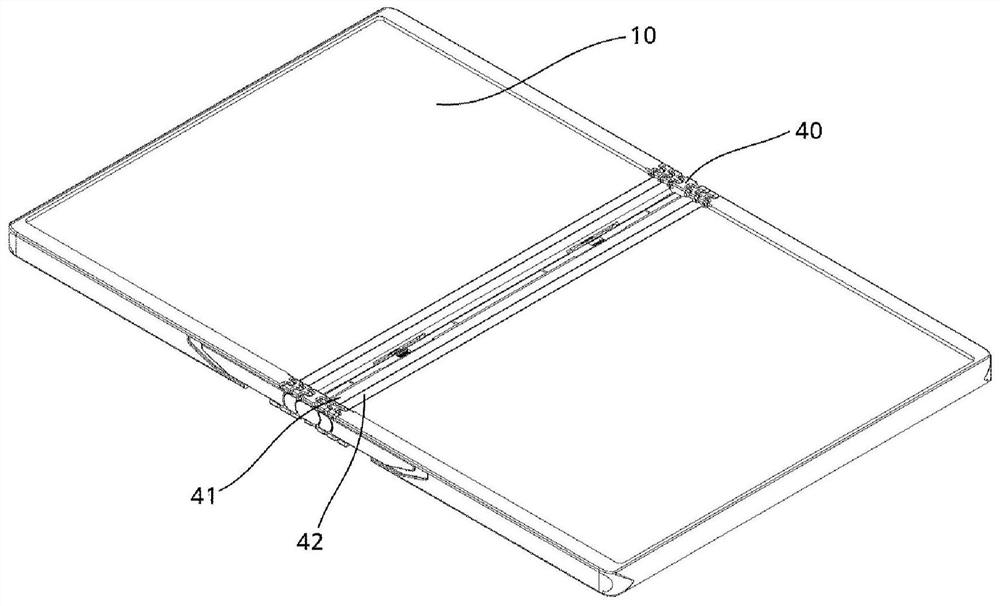

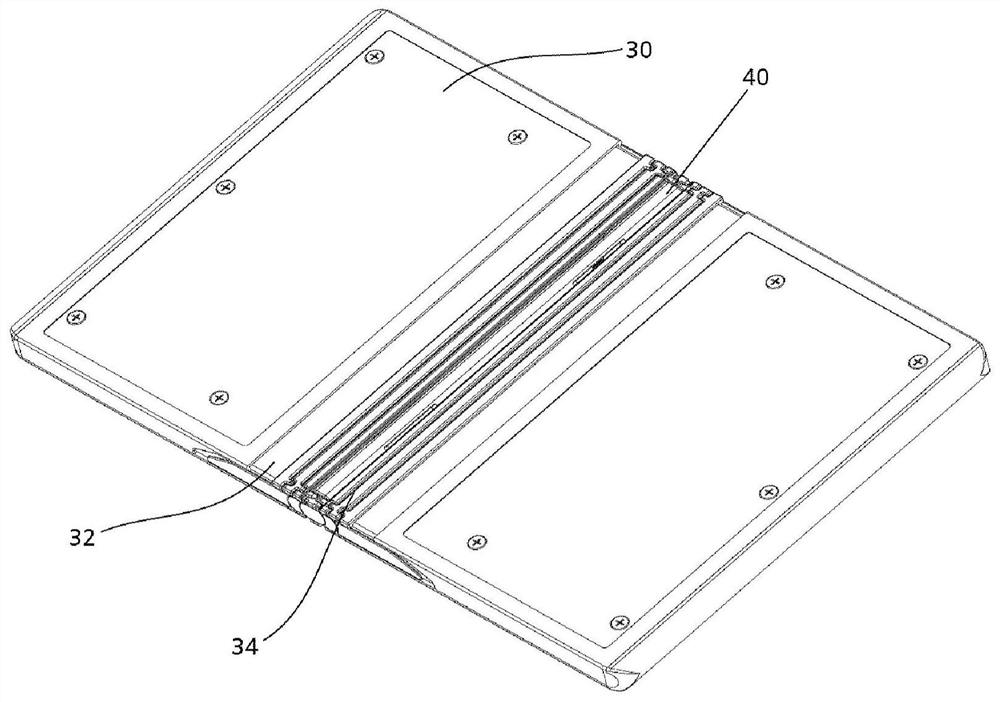

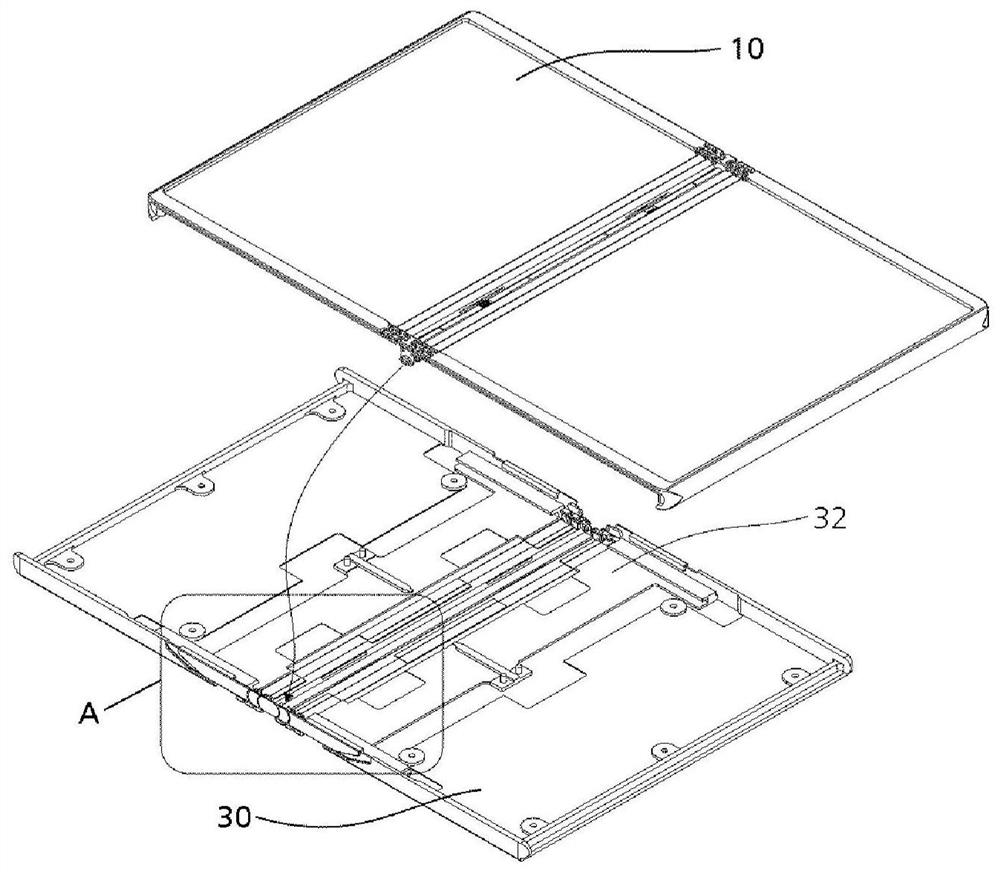

Hinge structure for terminal folded in two opposing directions

PendingCN112384876AAvoid damageTighten upDetails for portable computersSubstation equipmentEngineeringStructural engineering

The present invention relates to a hinge structure for a terminal folded in two opposing directions, characterized in that a smart phone having a flexible display panel can be folded, from a completely unfolded state, in both the inward direction in which the flexible display panel is positioned on the folded inner side and the outward direction in which the flexible display panel is positioned onthe outer surface, such that a screen displaying an image such as a video can be hidden inside or can be seen from the outside in a state in which the foldable smart phone is folded, thereby allowingthe display panel to be seen in two opposing directions.

Owner:奥福雷株式会社

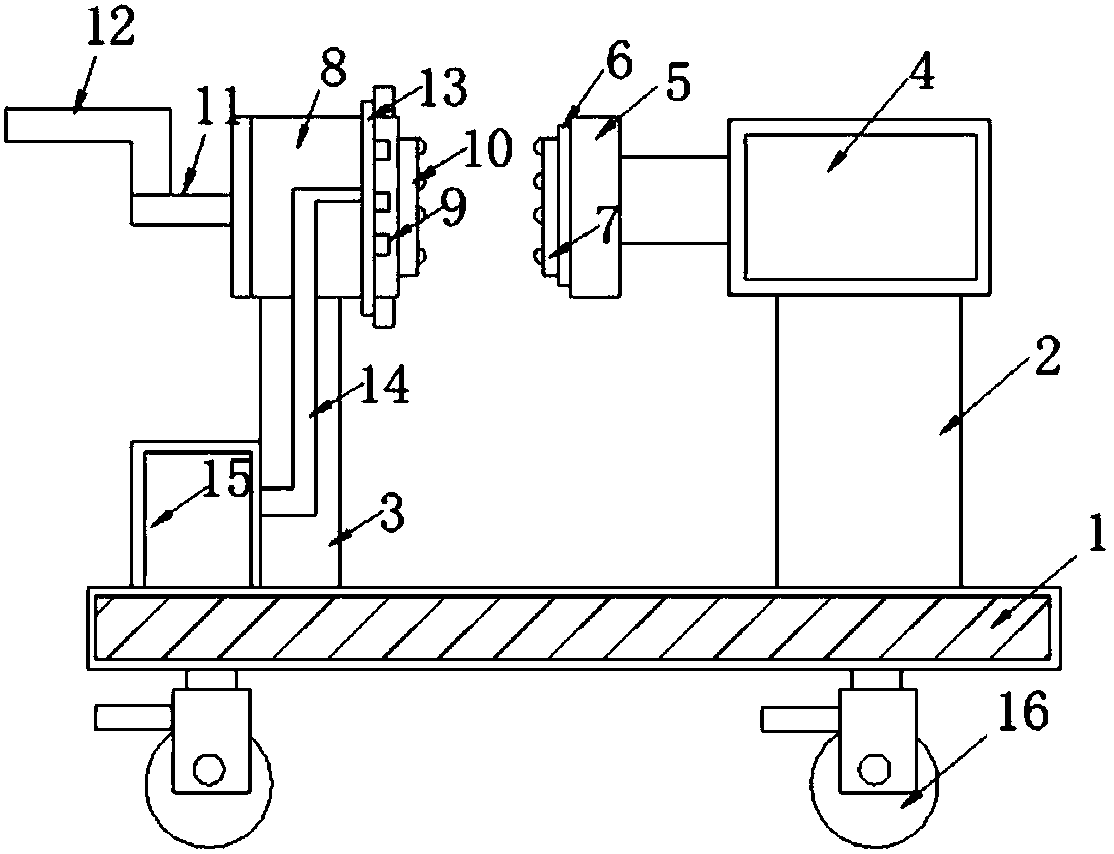

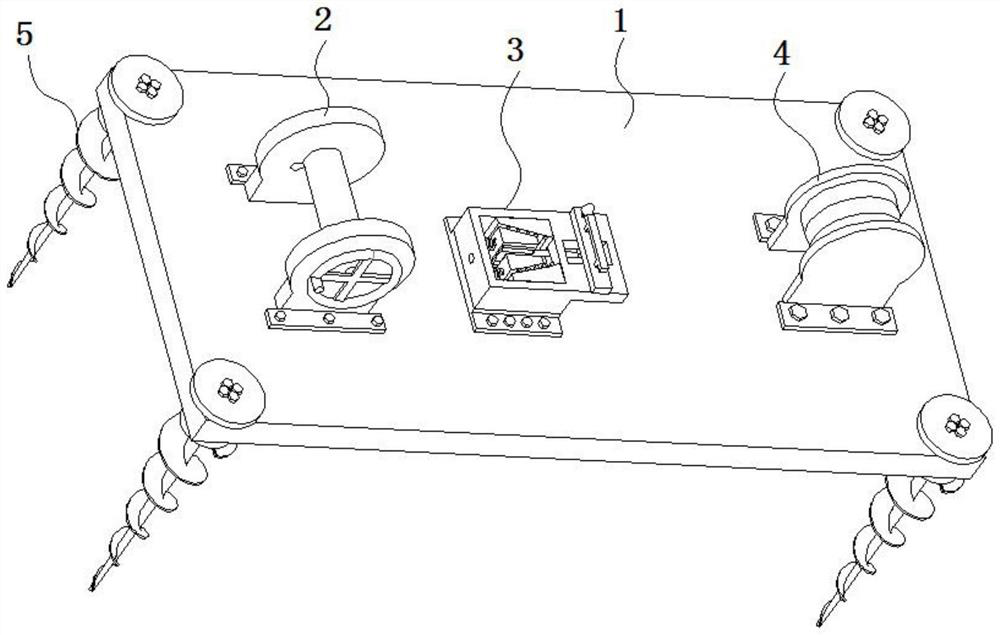

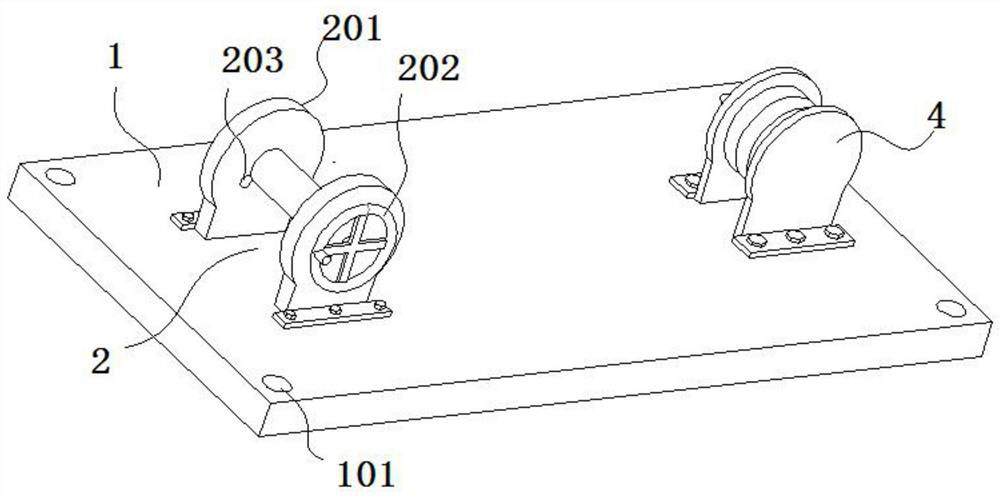

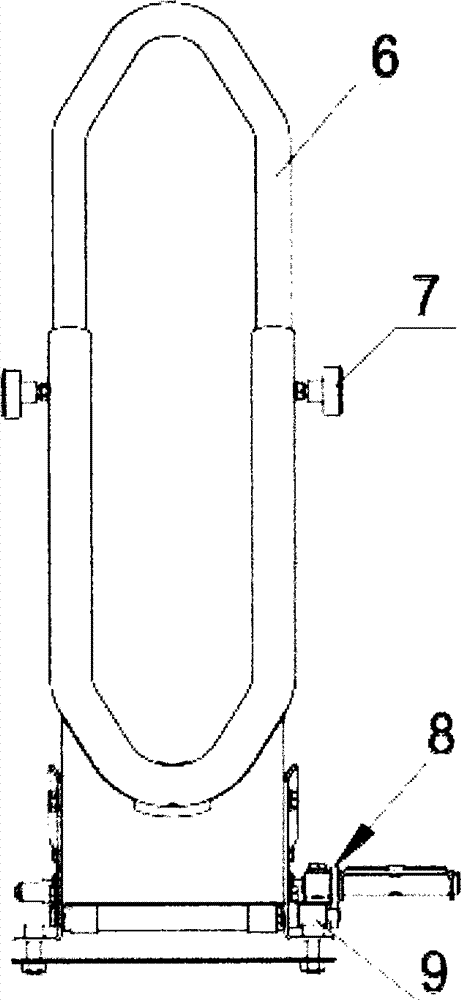

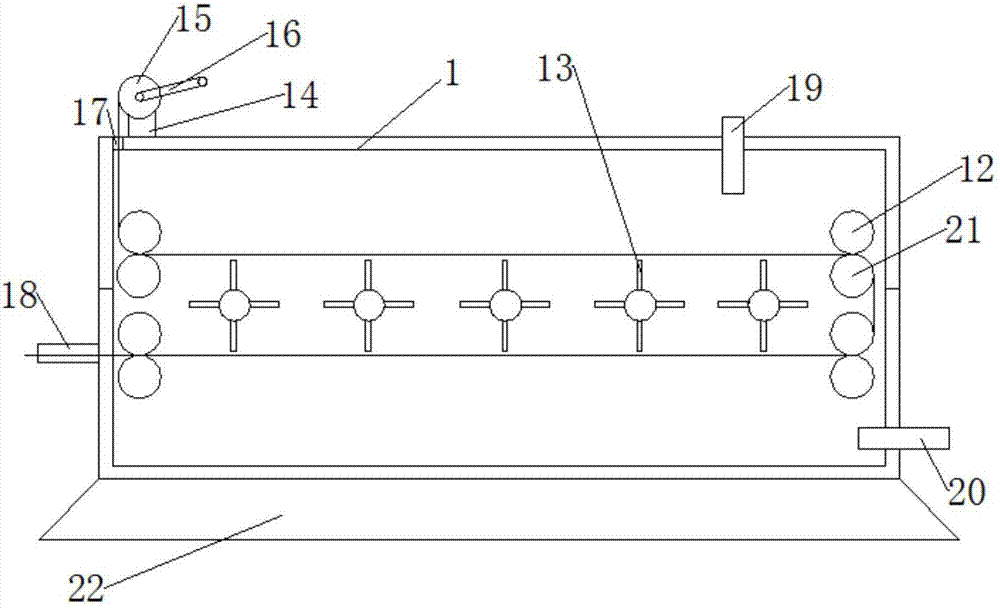

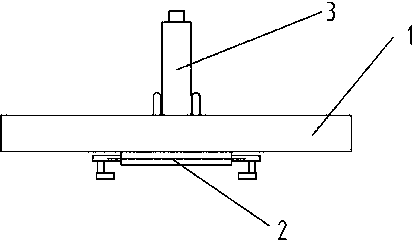

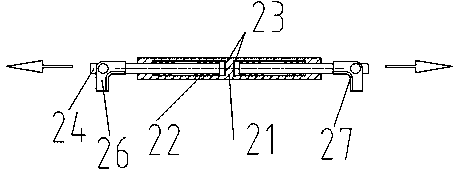

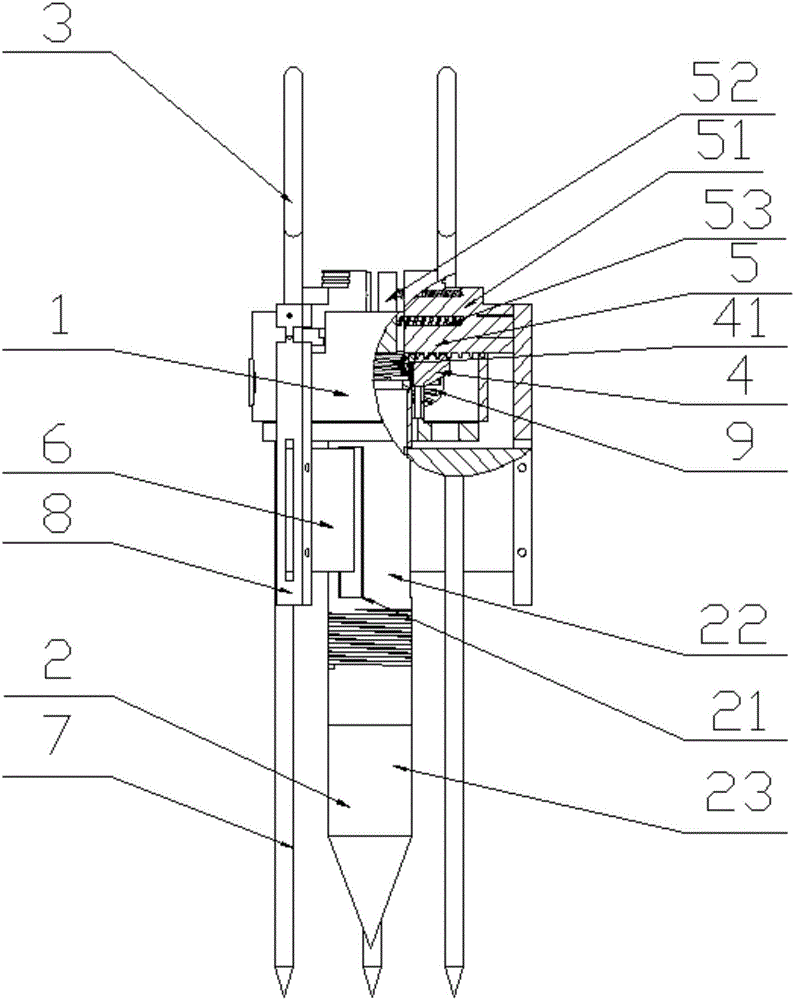

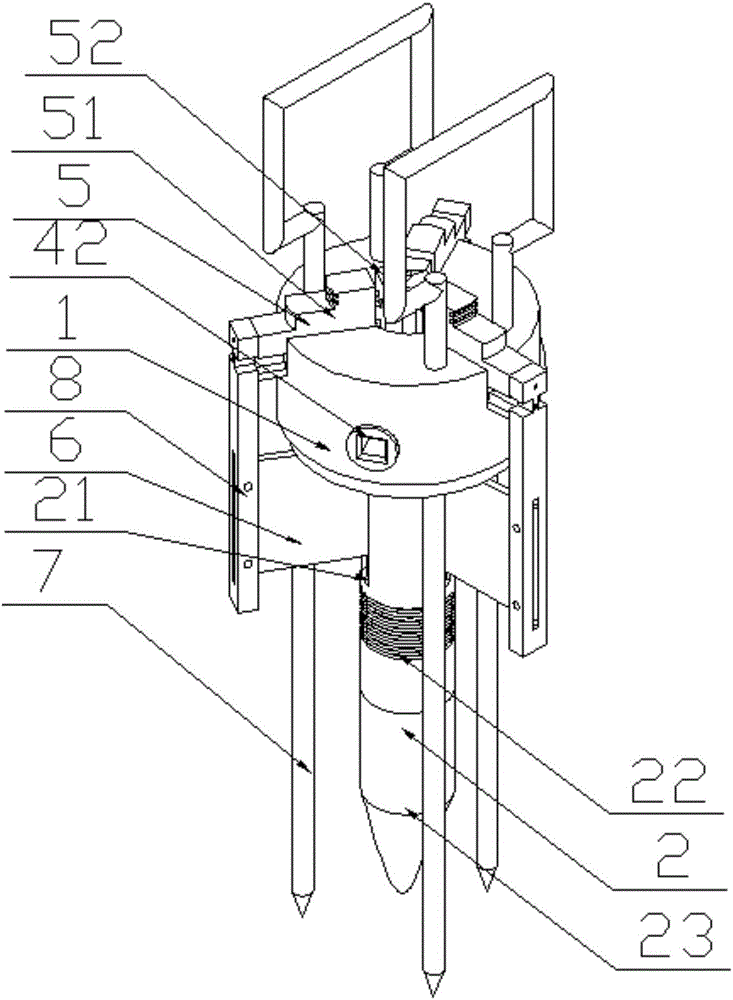

Steel wire rope clamping device for drilling crane

InactiveCN112158750ATighten upStep up and be effectiveWinding mechanismsMarine engineeringRight trapezoid

The invention discloses a steel wire rope clamping device for a drilling crane, and relates to the technical field of drilling and workover equipment in the petroleum industry. The steel wire rope clamping device comprises a base, an adjusting assembly, a fastening assembly, a guide wheel and ground anchor assemblies arranged at the four corners of the base in a sleeving mode; the adjusting assembly is fixedly installed on the upper surface of the base; the adjusting assembly comprises a wire spool fixedly installed on the upper surface of the base; a wire winding handle is fixedly installed on one side surface of the wire spool; the fastening assembly is fixedly installed on the upper surface of the base and located on one side of the adjusting assembly; and the guide wheel is fixedly installed on the upper surface of the base and located on the side, away from the adjusting assembly, of the fastening assembly. According to the steel wire rope clamping device for the drilling crane, after the length of a guy rope is adjusted through the adjusting assembly, a main clamp block and an auxiliary clamp block of a right trapezoid structure in the fastening assembly are matched with eachother, so that a brake pad of an arc-shaped structure can stably tighten the guy rope, the structure is simple, it can be guaranteed that gaps between the two sides of a main clamp and the two sidesof an auxiliary clamp are uniform, meanwhile the guy rope can be effectively tightened in the fixing assembly, and the stability of a derrick is improved.

Owner:合肥星研科技有限公司

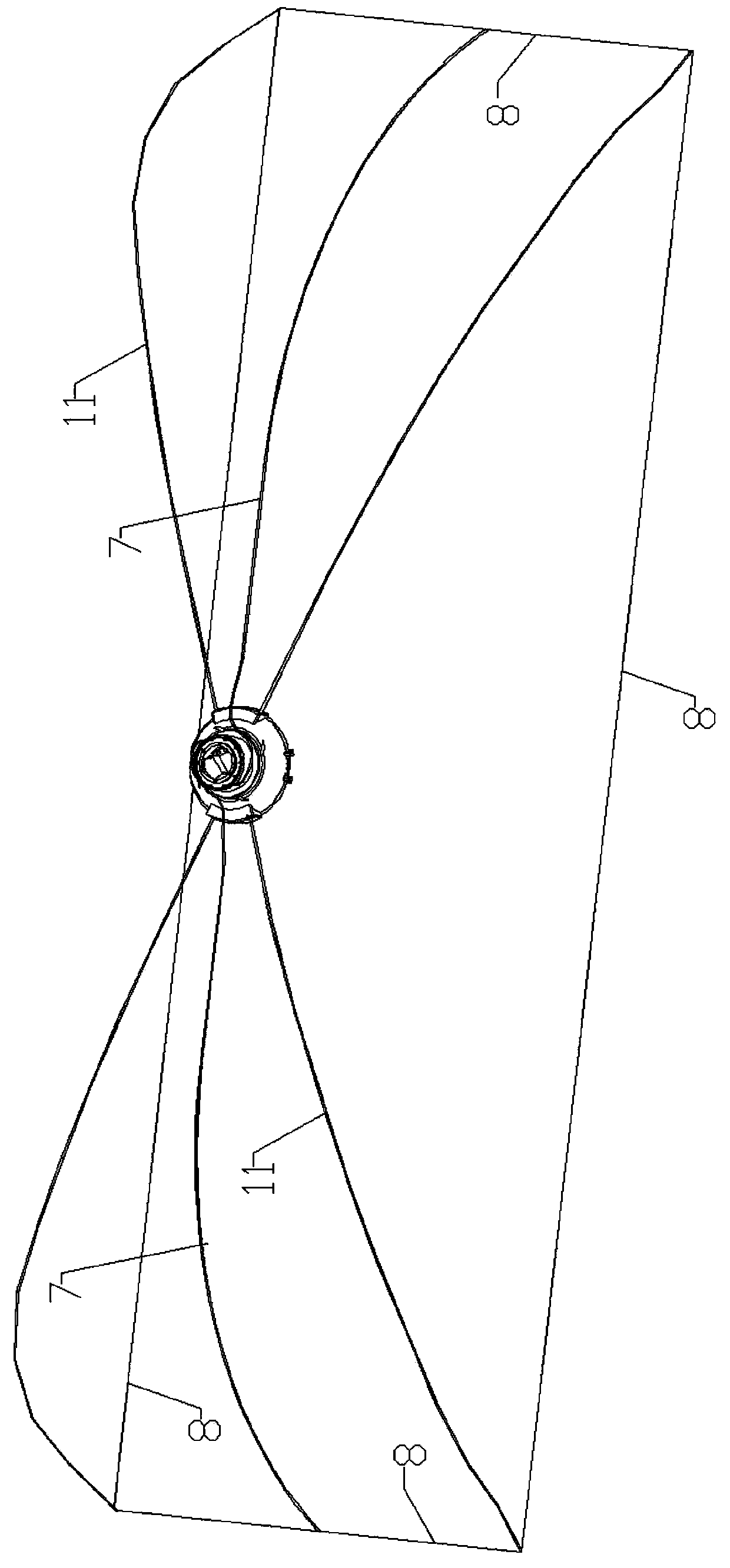

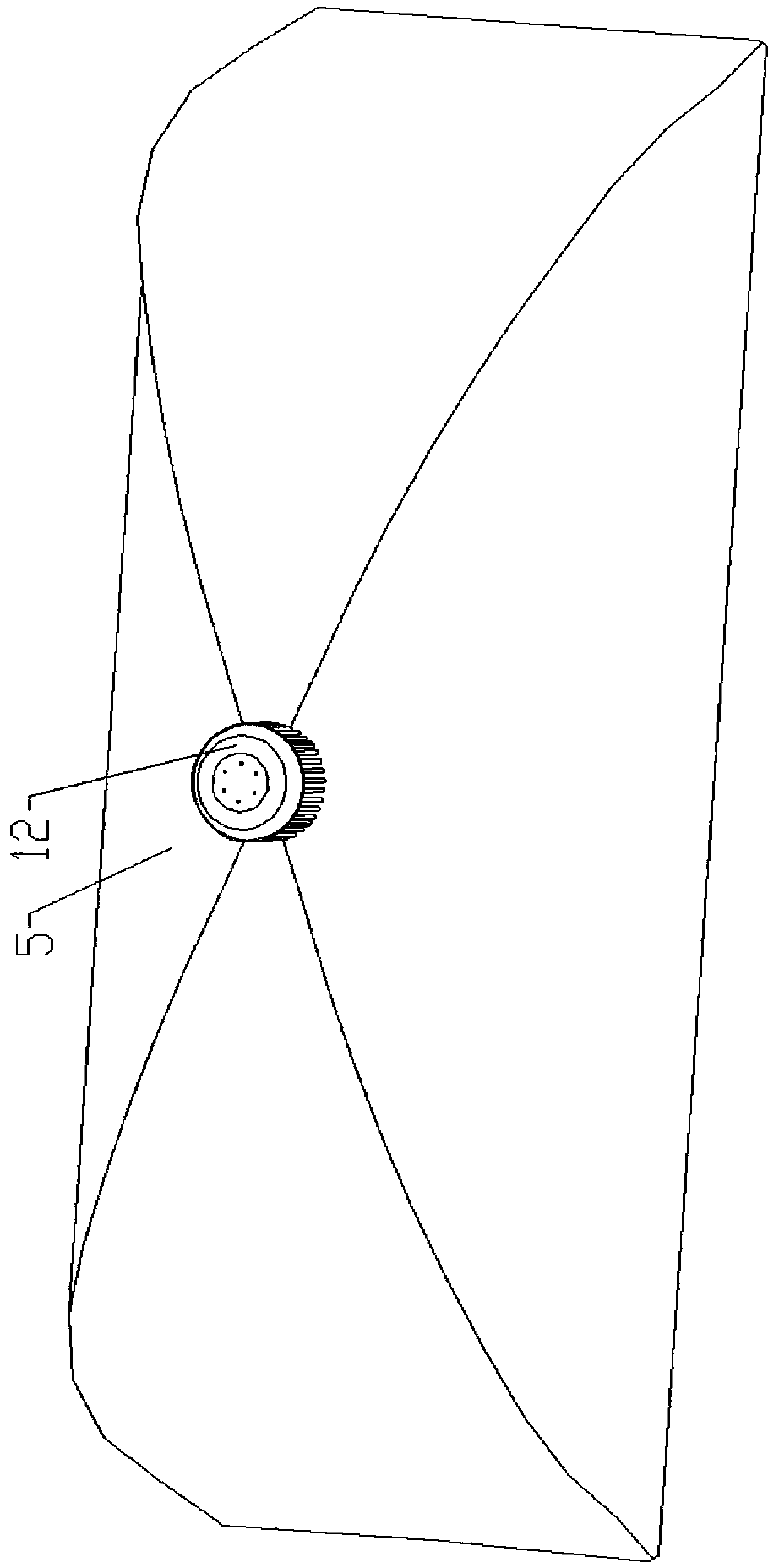

Cloth cover tightening mechanism of full automatic automobile cover

A cloth cover tightening mechanism of a full automatic automobile cover comprises a fixing seat (2), an adjusting ring (3) arranged on the fixing seat (2) through threads in a screwed and sleeved mode, a transmission ring (4) circumferentially fixed and axially and movably clamped to the adjusting ring (3) in a sleeved mode, at least one hose (7) connected with a cloth cover (5) and a tightening rope (8), wherein the end of the hose (7) is fixed to a closing rotating disc (6) of an automobile cover opening mechanism, and the tightening rope (8) is arranged along the circle of a cover opening in the lower end of the cloth cover (5). The fixing seat (2) is provided with a baffle (2.1) for limiting the excessive rotation of the adjusting ring (3), the tightening rope (8) stretches out of the cover opening in the lower end of the cloth cover (5), sequentially penetrates through the hose (7) and the closing rotating disc (6) and then is fixed to the transmission ring (4), and the number of turns of the spread cloth cover (5) and the spread tightening rope (8) is larger than the number of turns of the one-direction screwing of the adjusting ring (3) along the fixing seat (2). The tightening mechanism can automatically tighten the cover opening when the cloth cover is blown by wind, and the cloth cover is prevented from bulging and even being blown away by the wind.

Owner:胡建明

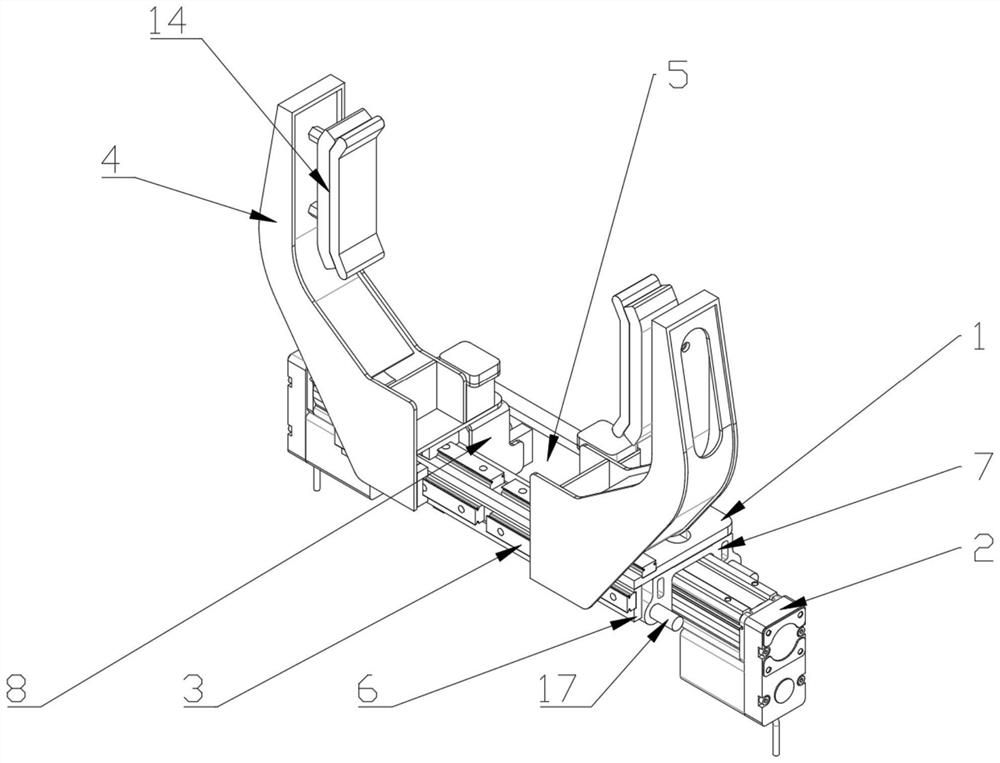

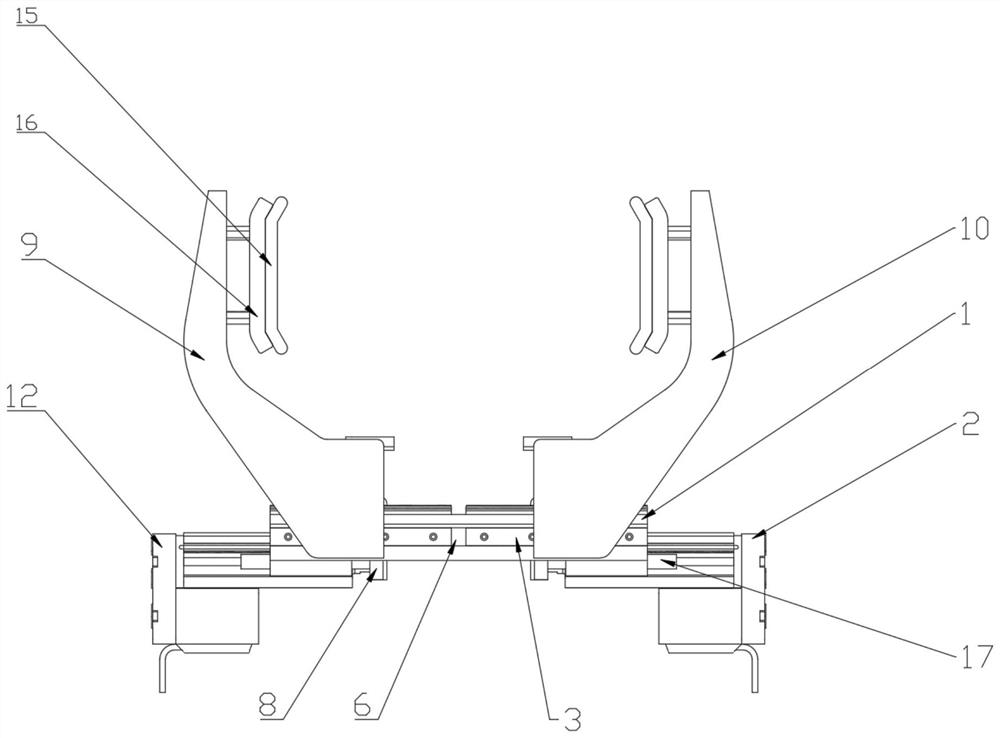

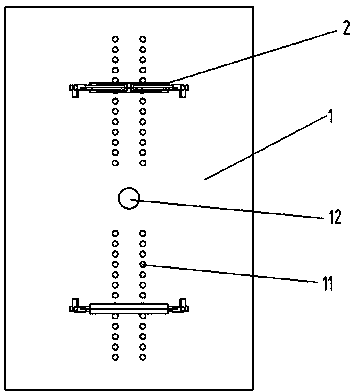

Cement pole electric holder capable of self-adapting to pole diameter

PendingCN111702771AEffectively step upSimple mechanical structureOverhead installationManipulatorMechanical engineeringClimbing robots

The invention discloses a cement pole electric holder capable of self-adapting to a pole diameter. The cement pole electric holder comprises a main bracket, an electric cylinder, a linear guide rail and a grip, wherein a waist-shaped through hole is formed in the main bracket, and one side of the lower surface of the main bracket is fixedly connected to a guide rail connecting plate; the linear guide rail is fixedly arranged on the guide rail connecting plate; the electric cylinder is arranged at one end of the lower surface of the main bracket; a telescopic lead screw of the electric cylinderis fixedly connected to a T-shaped plate; the T-shaped plate can horizontally move in the waist-shaped through hole of the main bracket through the telescopic lead screw; the grip is composed of a left grip and a right grip; the lower end of the right grip is connected to the linear guide rail in a sliding mode through a slide block; the position, close to one side of the left grip, of the lowerend of the right grip is fixedly connected to the T-shaped plate; and the telescopic lead screw of the electric cylinder drives the right grip to horizontally move towards the left grip in the waist-shaped through hole of the main bracket, so that the left grip and the right grip hold a cement pole. The cement pole electric holder can be matched with a climbing robot to perform power distributionoverhead line operation, and is also suitable for the pole with taper.

Owner:DALI POWER SUPPLY BUREAU YUNNAN POWER GRID

Self-locking motorcycle frame

The invention relates to a self-locking motorcycle frame which comprises a lateral fixing support, a front fixing support, a fixing spindle, a blocking pipe, foot rests and adjustable supports of foot rests. The self-locking motorcycle frame has the advantages that (1) adjustable pipes can adjust heights and fix wheels of the motorcycle; (2) the self-locking motorcycle frame is simple in structure, reliable in fastening and convenient in cooperation due to the facts that foot rests are heightened, accordingly a self-locking hook rotates and breaks away from an axis pin thereby driving a small wheel on adjustable supports of foot rests to swing back and forth to change rotating directions of the blocking pipe and the clasping fixing and loosening breaking away of the motorcycle wheels are achieved; (3) the self-locking motorcycle frame is skillful in design, novel and practical due to the fact that foot rests can drive the self-locking hook to rotate and combined with the axis pin by gravity of the foot rests so that self-locking is achieved.

Owner:青岛东陆科技有限公司

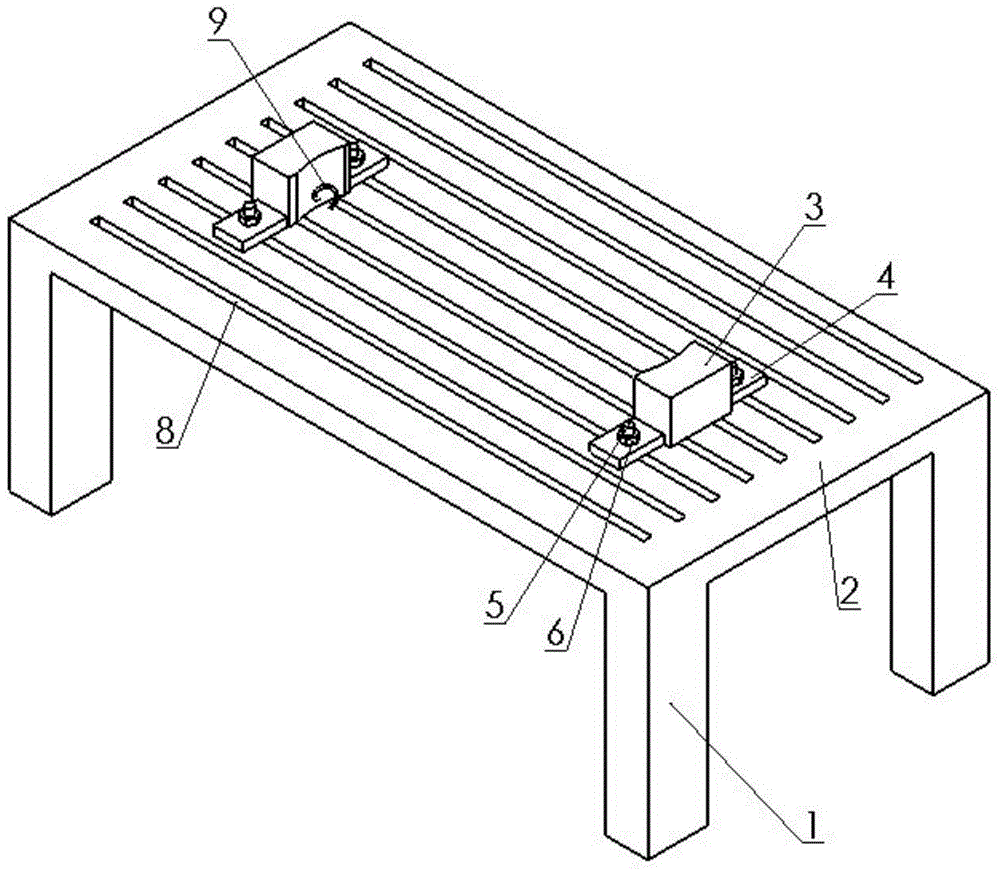

Clamping tooling for pipe

InactiveCN105750953ASimple structureEasy to manufacturePositioning apparatusMetal-working holdersEngineeringDesk

The invention provides a clamping tooling for a pipe. The clamping tooling comprises a plurality of supporting columns, an operation desk and two clamping elements, wherein the operation desk is fixedly connected onto the supporting columns; a plurality of slideways are arranged on the operation desk; the plurality of slideways are parallel to one another on the operation desk; the two clamping elements are respectively connected with the operation desk through the slideways in a sliding way; a circular arc surface is arranged in the middle of one side face of each clamping element; the circular arc surfaces of the two clamping elements are opposite to each other; a plurality of springs are arranged on each circular arc surface. The clamping tooling for the pipe has the advantages of simple structure, easiness in manufacturing, convenience in operation and high operation efficiency; a clamping space between the two clamping elements is adjusted by sliding of the two clamping elements on the slideways, and the clamping operation of the pipes of different sizes can be adapted, so that the generality of the tooling is high; by arranging the springs on the clamping elements, workpieces can be tightened more firmly by using opposite action forces of the springs.

Owner:天津右岸牵伊网络科技有限公司

Method for manufacturing ornament accessory and obtained ornament accessory and finished product the ornament accessory

InactiveCN101147632ATighten upSet off beautifulOrnamental structuresFoundry mouldsNatural stoneMetal

The present invention relates to a manufacture method of metal ornament attachment, in particular, it relates to a metal ornament attachment which has natural stone-block form and whose surface possesses concave-convex lines and its manufacture method. Said method includes the following steps: (a), selecting and using natural stone-block as sample; (b), using said sample to make silicone rubber mould and forming a sample-like cavity in the silicone rubber mould; and (c), pouring high-temperature metal into the silicone rubber mould interior; the described high-temperature metal can be tin-lead alloy or zinc-aluminium alloy; and cooling so as to obtain the invented metal ornament attachment with natural stone-block form and concave-convex lines.

Owner:ZHEJIANG NEOGLORY JEWELRY CO LTD

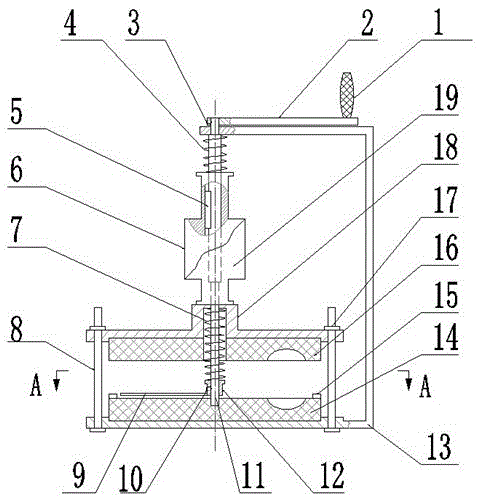

Rapid hand-cranking egg cutting device

A rapid hand-cranking egg cutting device comprises a handle, a connecting rod, a transmission shaft, an upper cylindrical cam, a lower cylindrical cam, a tool rest, a guiding flat key, a fastening screw, a sawtooth-shaped cutter, an upper base, an upper egg base, a lower base, a lower egg base, guide columns, nuts, limiting blocks, a small spring and a big spring. The rapid hand-cranking egg cutting device is novel in structure, high in egg cutting efficiency and good in safety; different kinds of eggs can be cut by replacing different upper egg bases and lower egg bases and debugging other parameters, and the application range is wide; the sawtooth-shaped cutter is adopted, and thus edge cutting is more effortless; and the damage to the edge of an eggshell is minimized after an egg is cut, and the separation faces of the egg are flat and attractive.

Owner:HARBIN UNIV OF SCI & TECH

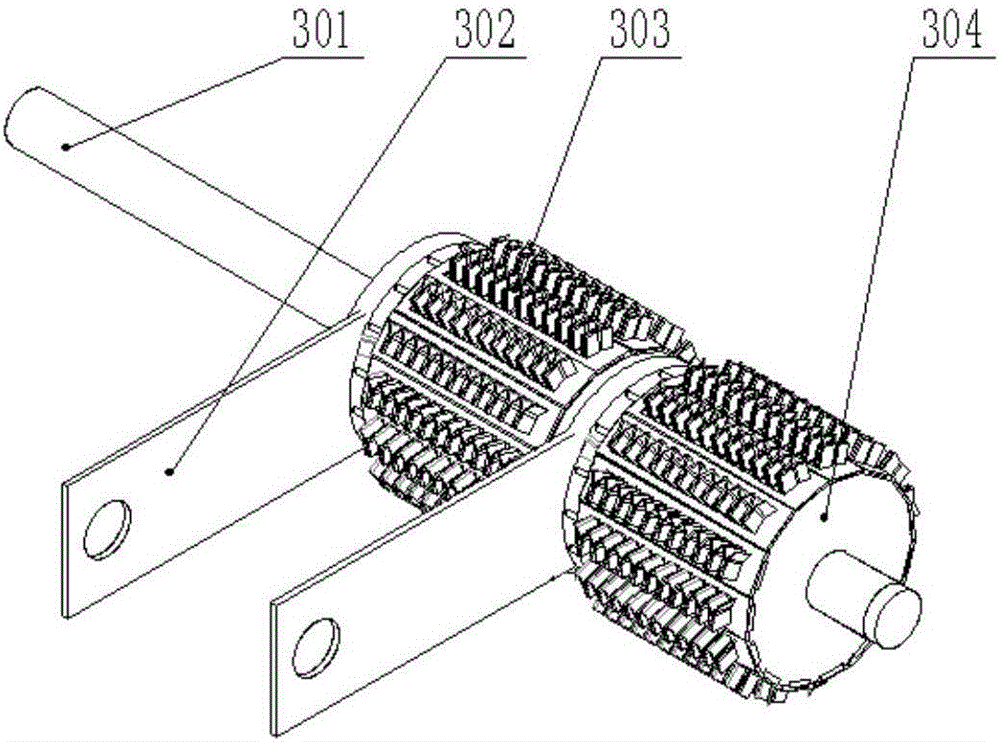

Cleaning device for textile fabric

InactiveCN107956068AAchieve deep cleaningTighten upMechanical cleaningPressure cleaningDrive shaftEngineering

The invention discloses a cleaning device for textile fabrics. A driving shaft runs through the right side of the middle part of the rear side wall of the housing inner cavity, the output end of the motor is fixedly connected to the driving shaft, and the outer side wall of the driving shaft is closely attached to the right end of the conveyor belt. The conveyor belt is closely attached to the outer wall of the driven shaft, the front end of the driving shaft and the driven shaft are fixedly connected with cleaning rollers, and the front and rear side walls of the inner cavity of the housing are provided with four T-shaped slots. The cleaning roller is installed to realize the deep cleaning of the front and back of the cloth. There is also a manual rewinding device, which can manually control the speed of rewinding, that is, the cleaning time of the cloth can be manually controlled, and the invention also uses the T-shaped slot The movable connection with the first roller, the T-shaped groove is equipped with a spring, which can tighten the cloth more stably and transport it in the device, and the invention has a simple structure and is easy to operate.

Owner:SUZHOU LEMIFUN ELECTRICAL TECH CO LTD

Bedside mobile phone support

InactiveCN104052842AEasy to installTighten upTelephone set constructionsMechanical engineeringBiomedical engineering

The invention discloses a bedside mobile phone support which comprises a flat plate, clamping devices and a rotation device. The flat plate is provided with insert holes and a rotation hole. Each clamping device is provided with a cylindrical pipe, compression springs, a spring compression container, sliding rods, connection columns, right-angle clamping plates, sponge mats, insert rods and rubber sleeve pipes. The rotation device is provided with a rotation main rod, a round fixed clamping plate and a hose connector. The bedside mobile phone support is convenient to use, two hands can be released, a user of a mobile phone has a comfortable and labor-saving watching process, the mobile phone is convenient to install and firm in fastening, the view angle of the mobile phone can be rotated according to the angle of the user, and the whole watching process is relaxed.

Owner:蒋杰

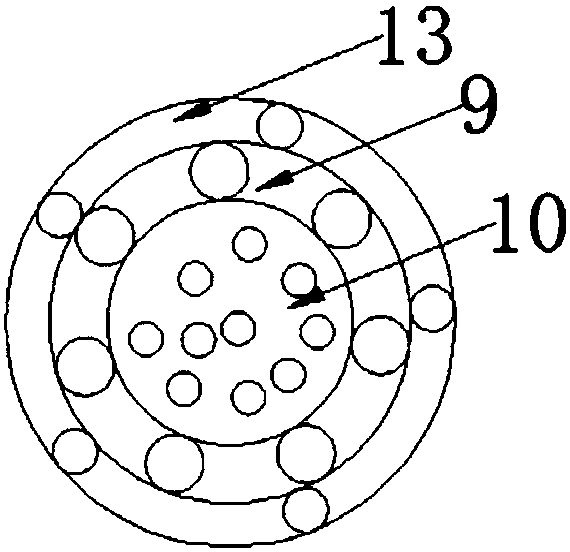

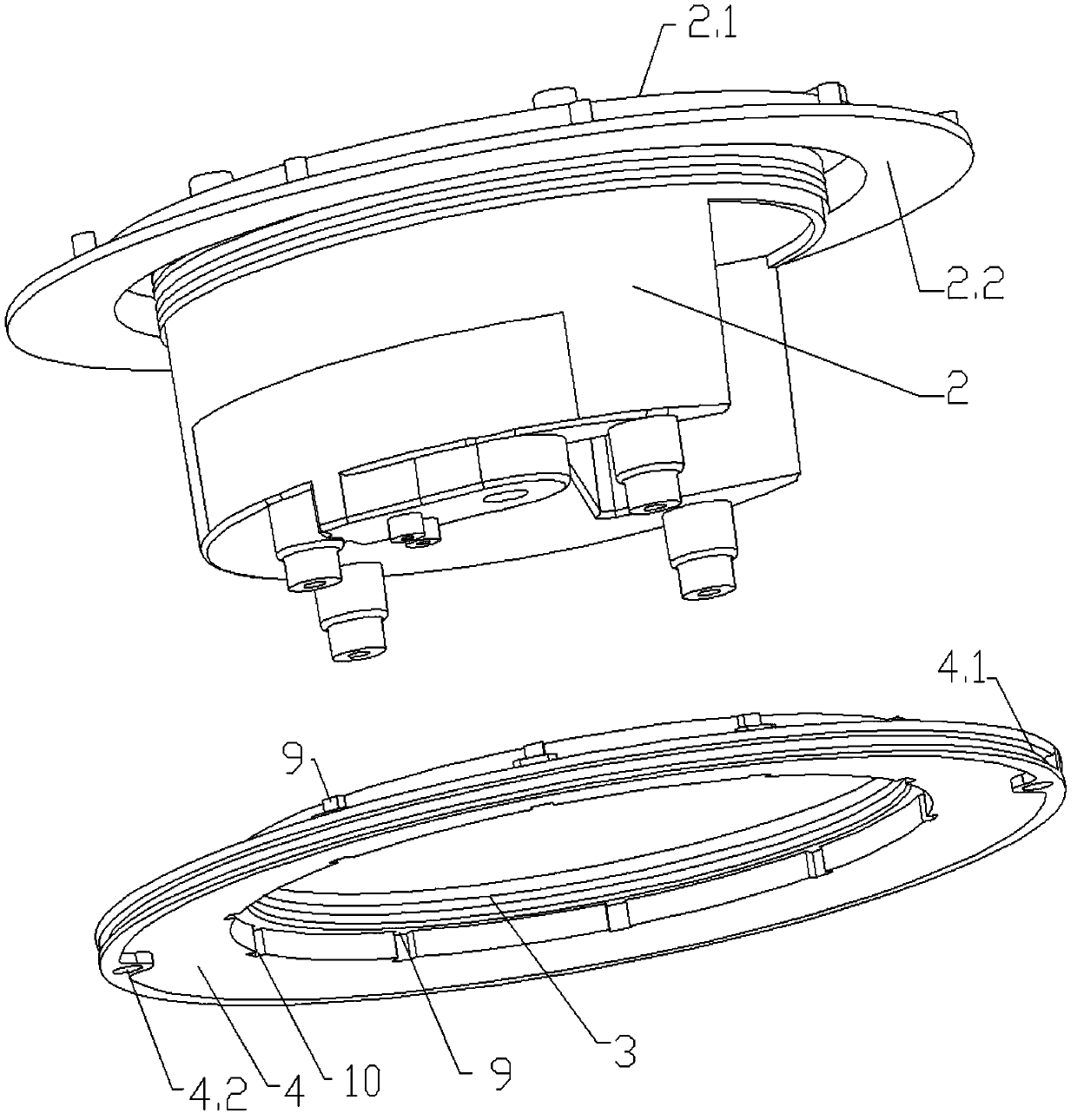

Movable plant clamping and fixing device with automatically-separable clamping jaws

The invention relates to a movable plant clamping and fixing device with automatically-separable clamping jaws. The movable plant clamping and fixing device comprises a base, a multi-jaw chuck clamping device, a sleeve, auxiliary fixing legs and handles. The multi-jaw chuck clamping device comprises an annular chuck wire coil and a plurality of elastic clamping jaw devices. The sleeve consists of a hollow cylinder and conical barrel at the lower end of the hollow cylinder, the multi-jaw chuck clamping device is mounted on the base, the center of the base is provided with a first through hole identical to the sleeve in internal diameter, and the elastic clamping jaw devices are capable of simultaneously moving towards or away from the axis of the first through hole to tightly clamp or release crop stalks in the sleeve. The movable plant clamping and fixing device is simple in structure, small in size, portable and capable of clamping stalks different in thickness and freely moving by a fixed distance according to requirements to adjust row spacing and line spacing, and simulation of various field planting modes such as broadcast sowing, transplanting and mechanical sowing of crops can be realized.

Owner:HUAZHONG AGRI UNIV

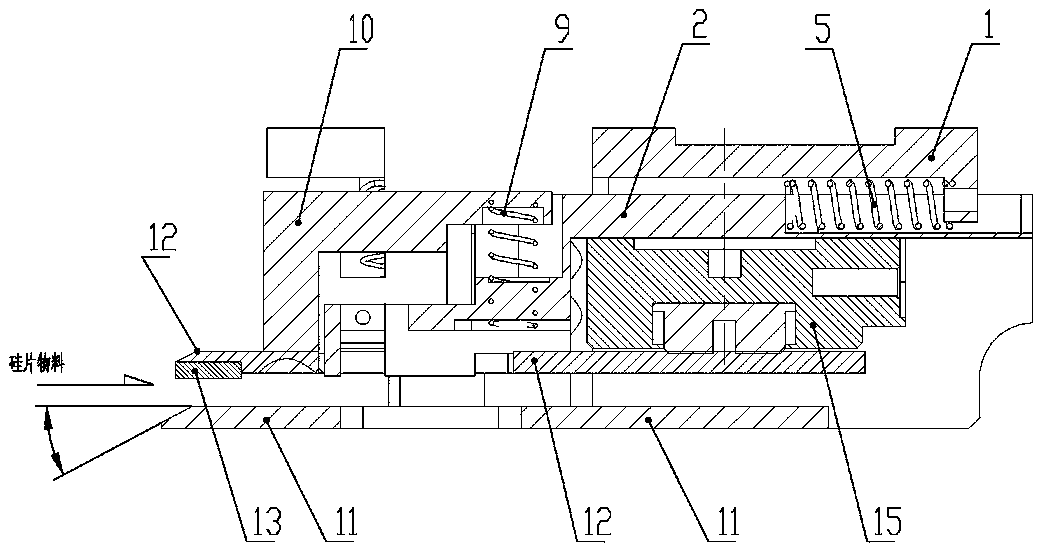

Silicon-wafer manipulator chuck for LED wafer automation sorting machine

PendingCN109985826ANot easy to damageImprove gripping efficiencyGripping headsSortingRobotic armManipulator

The invention relates to a silicon-wafer manipulator chuck for an LED wafer automation sorting machine. The silicon-wafer manipulator chuck comprises a sensor bracket, wherein the sensor bracket is connected with a manipulator arm and grabs wafers according to the position of the manipulator arm; a clamp body is arranged on the sensor bracket; the clamp body is connected with the sensor bracket through a guiding shaft; a reset spring is arranged on the guiding shaft; and the two ends of the reset spring are separately connected with a sensor-diaphragm clamping air cylinder bracket and the clamp body so that the silicon-wafer manipulator chuck for the whole LED wafer automation sorting machine can elastically contact the wafers without damaging the wafers.

Owner:山东泓瑞光电科技有限公司

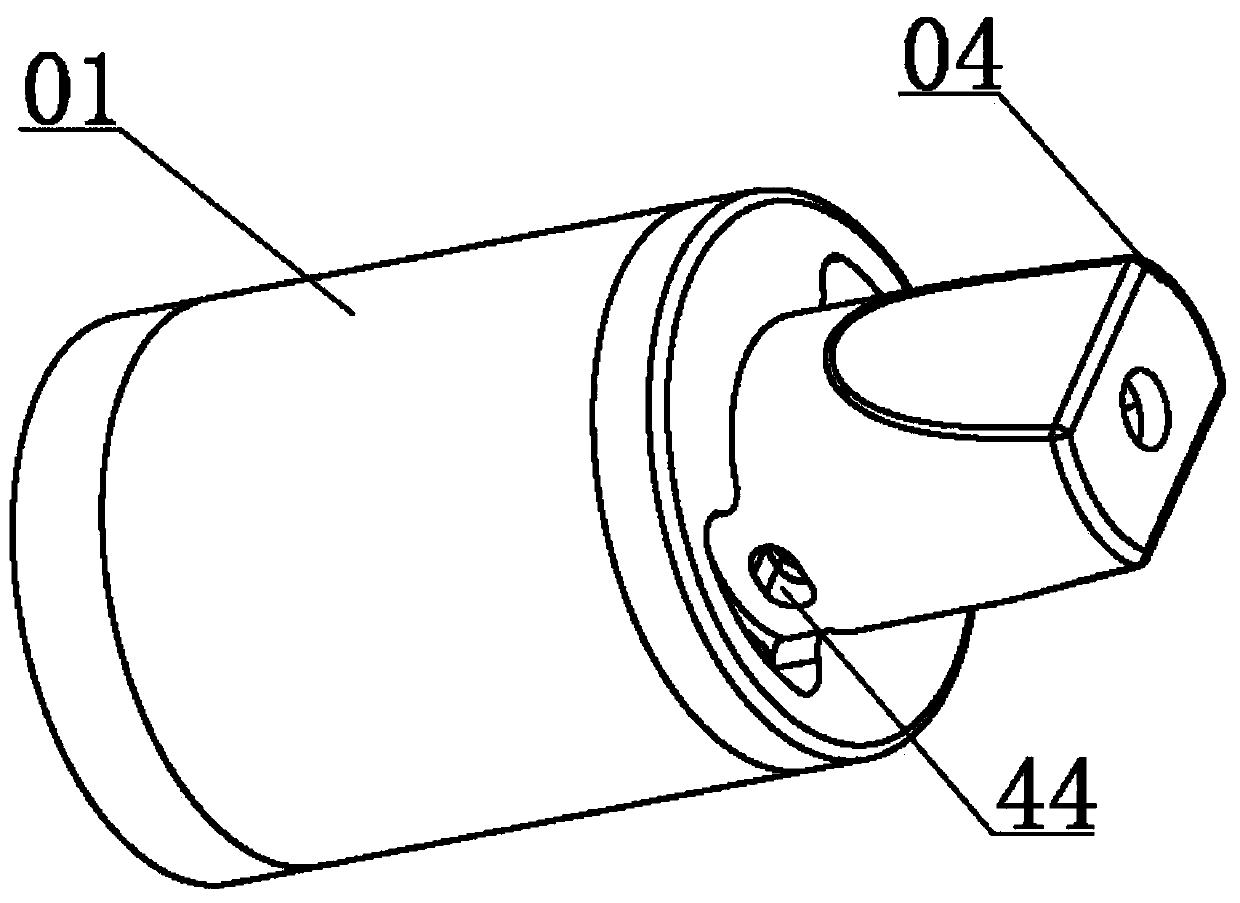

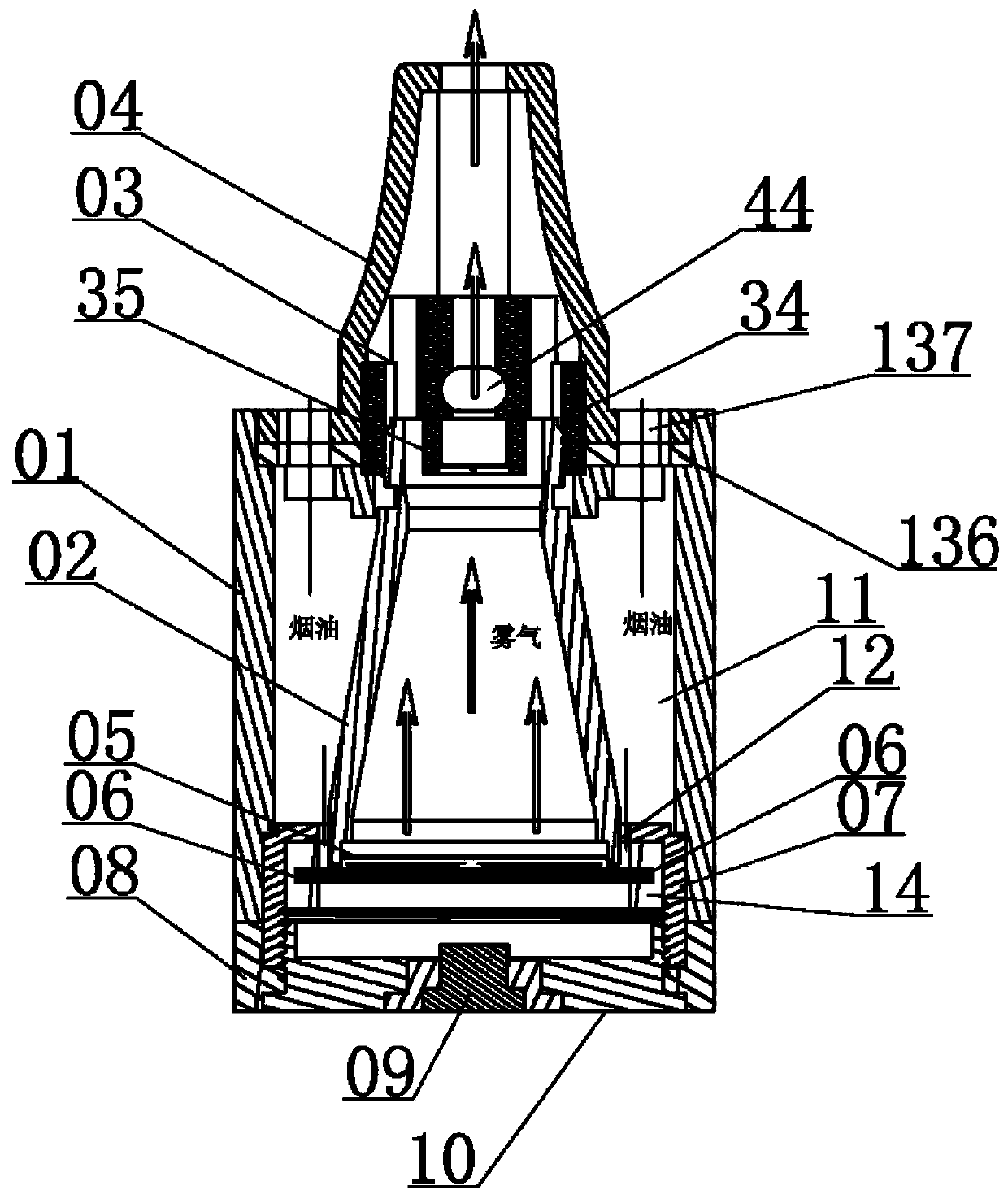

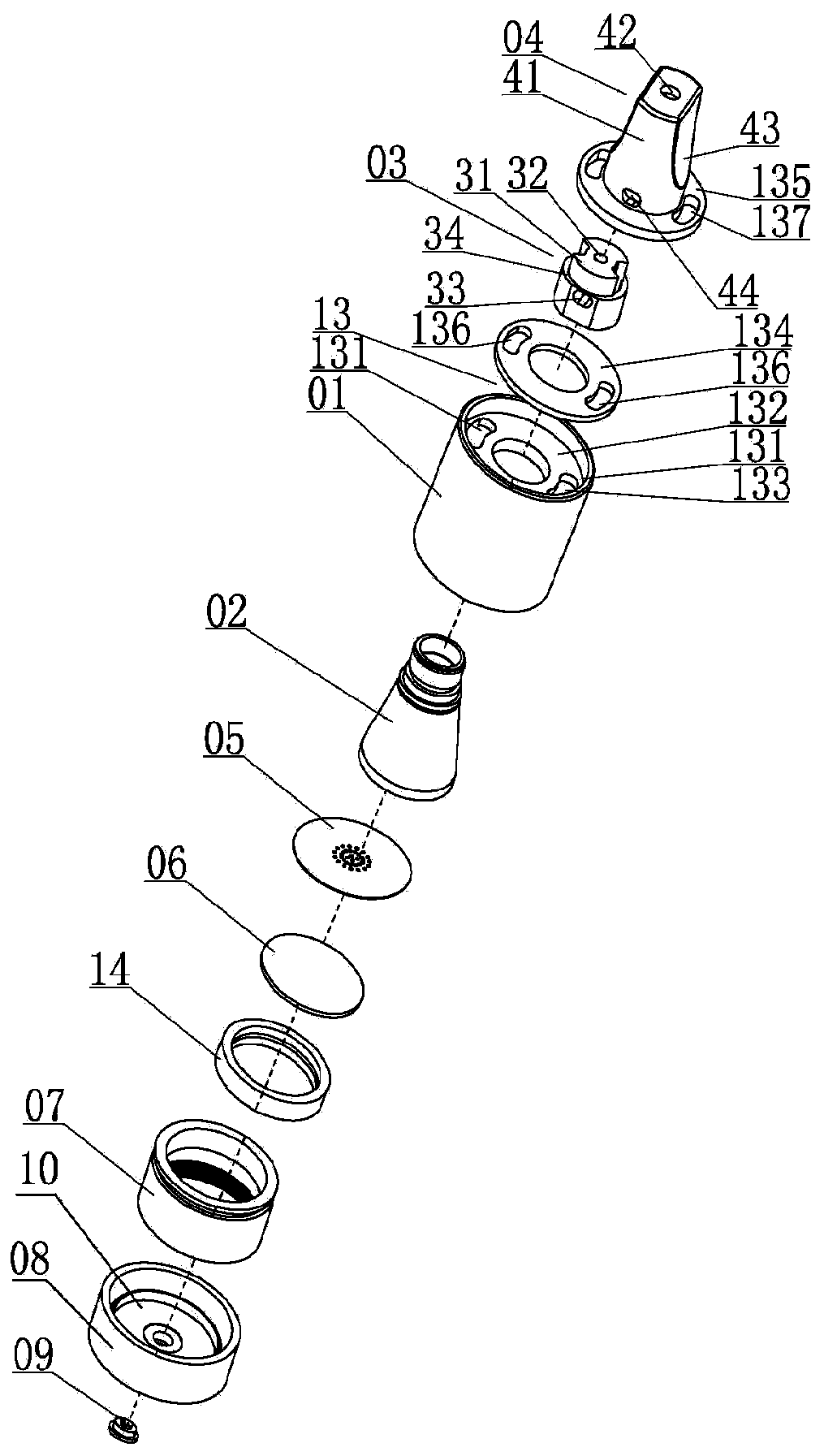

Energy concentrating ultrasonic atomizing device

PendingCN109892705ASolve the problem of overheatingSolving Recycling ProblemsTobacco devicesElectricityEngineering

The invention discloses an energy concentrating ultrasonic atomizing device which comprises an outer shell, a conical cavity arranged on the outer shell and extending upwards to the outer upper portion of the outer shell, a connecting piece connected to the upper end of the conical cavity in a sleeved manner, an upper cover connected to the connecting piece, a metal substrate and a piezoelectric ceramic piece which are sequentially arranged at the bottom of the conical cavity, a fixing seat accommodating the metal substrate, the piezoelectric ceramic piece and the conical cavity is arranged under the piezoelectric ceramic piece and a bottom cover accommodating the fixing seat and connected with the outer housing is connected onto the fixing seat in a sleeving manner. A first electrode anda second electrode which are respectively connected with the piezoelectric ceramic piece are arranged on the bottom cover. By the non-heating working mode, the problem of overheating of fuselage is solved; liquid is atomized easily, and energy exchange efficiency is improved; meanwhile, metal substrates, piezoelectric ceramics and other parts can be easily recycled assuredly, and daily maintenanceis facilitated.

Owner:华健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com