Silicon-wafer manipulator chuck for LED wafer automation sorting machine

A manipulator and sorter technology, applied in manipulators, chucks, sorting and other directions, can solve the problems of low production efficiency and high chip breakage rate, and achieve reliable tightening and loosening, not easy to damage, and convenient clamping efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

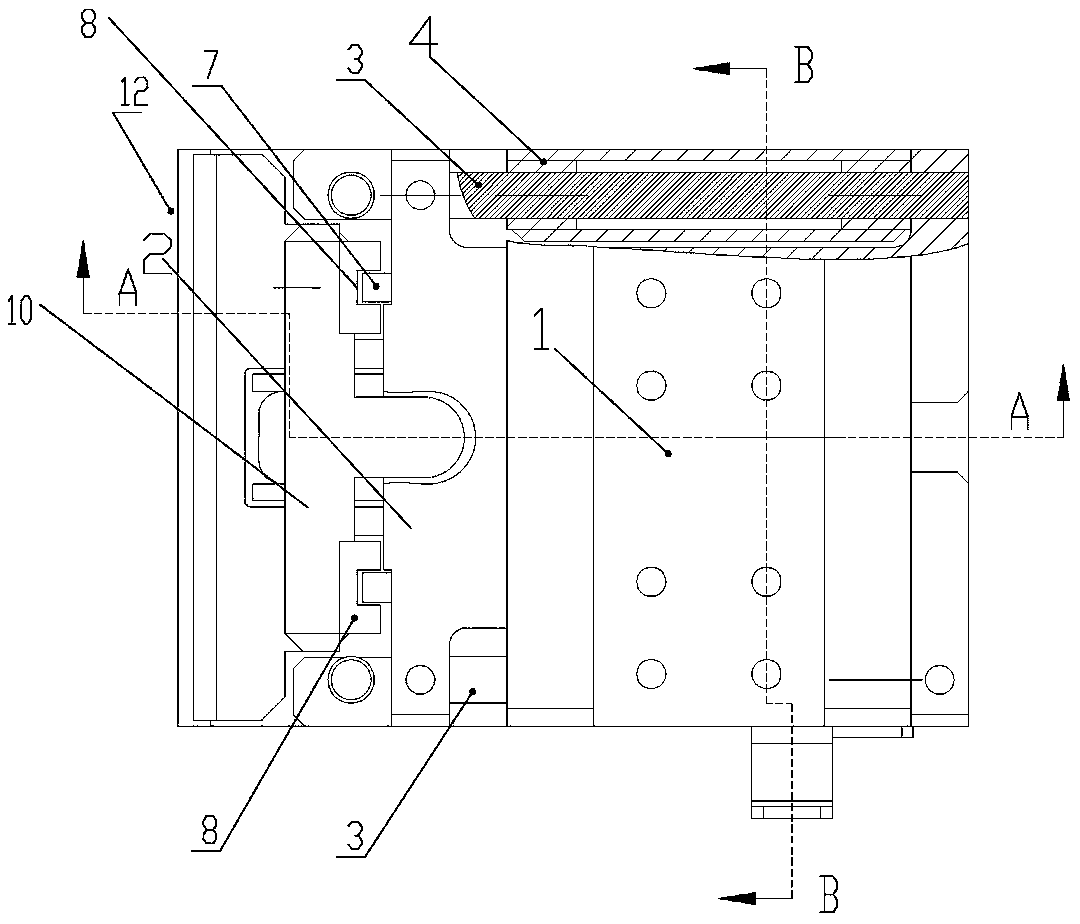

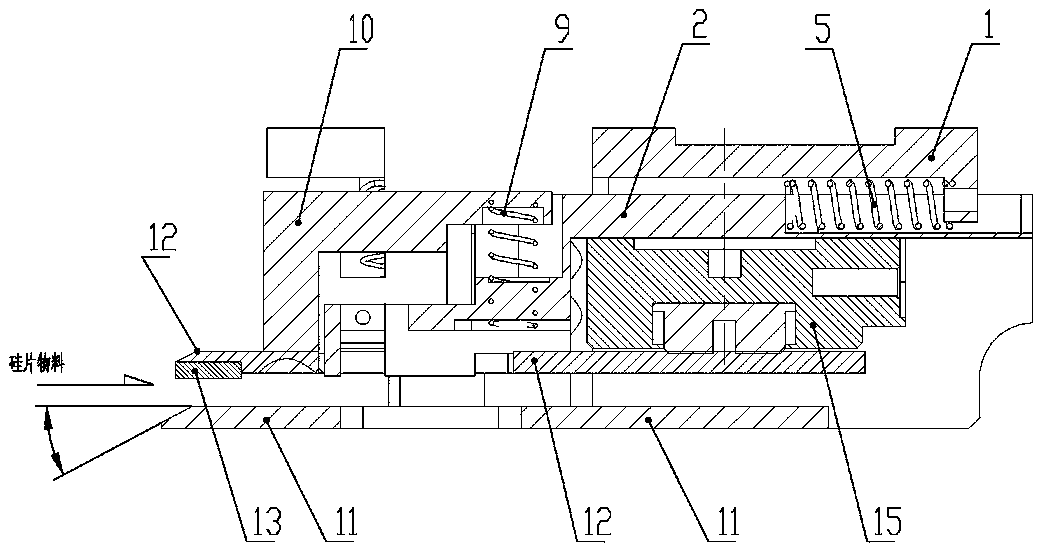

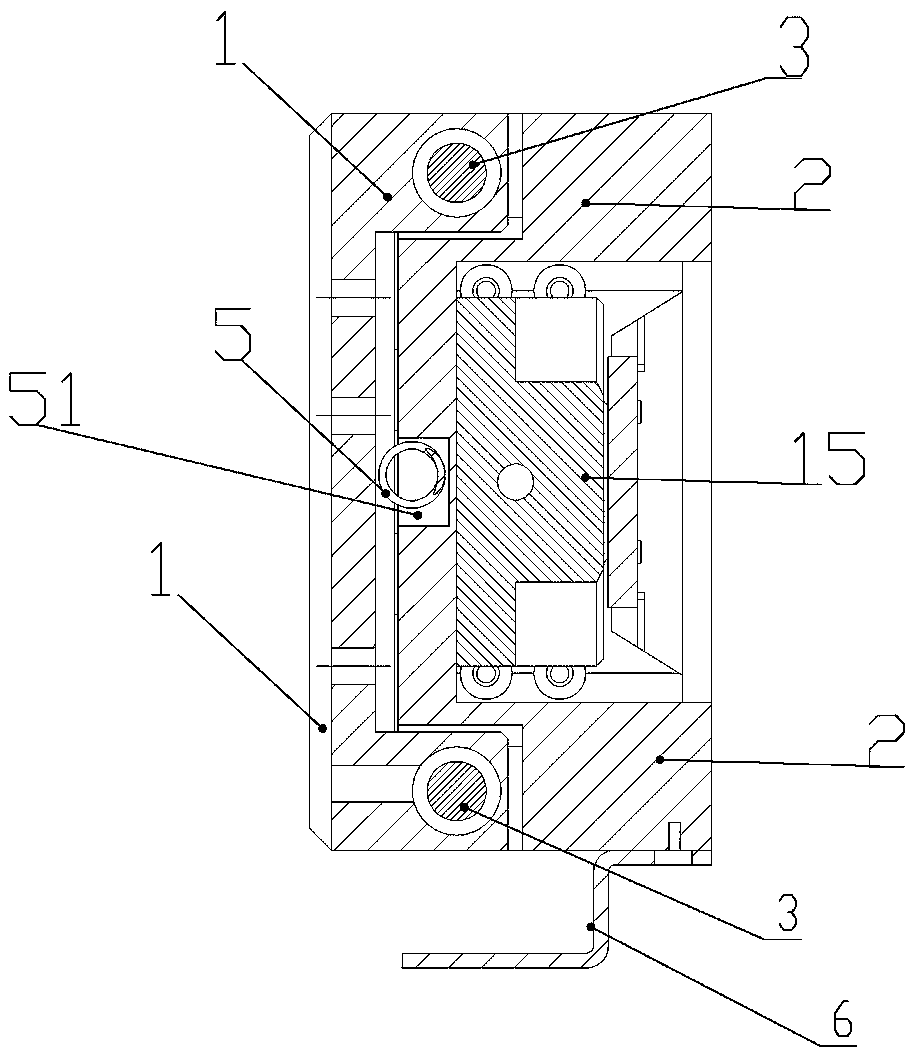

[0019] Examples, as attached figure 1 , Attached figure 2 , Attached image 3 And Figure 4 As shown, a silicon wafer manipulator chuck for an automatic LED wafer sorting machine includes a sensor bracket 1, which is connected with a robot arm, and picks up wafers according to the position of the robot arm.

[0020] The sensor bracket 1 is provided with a clamp body 2, which is connected to the sensor bracket 1 by a guide shaft 3. A guide shaft groove 31 is provided on the clamp body 2, and the guide shaft 3 is arranged in the guide shaft groove 31. The guide shaft 3 is provided with a bushing 4, the upper surface of the clamp body 2 is provided with a return spring groove 51, the return spring groove 51 is provided with a return spring 5, the two ends of the return spring 5 are respectively connected to the sensor diaphragm clamping The cylinder bracket 1 and the clamping body 2 enable the entire silicon wafer manipulator chuck to elastically contact the wafer without damaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com