Patents

Literature

85results about How to "Improve gripping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loading method and device of intelligent logistics environment robot

ActiveCN108942946ASimple structureEasy to operateProgramme-controlled manipulatorMachine visionLogistics management

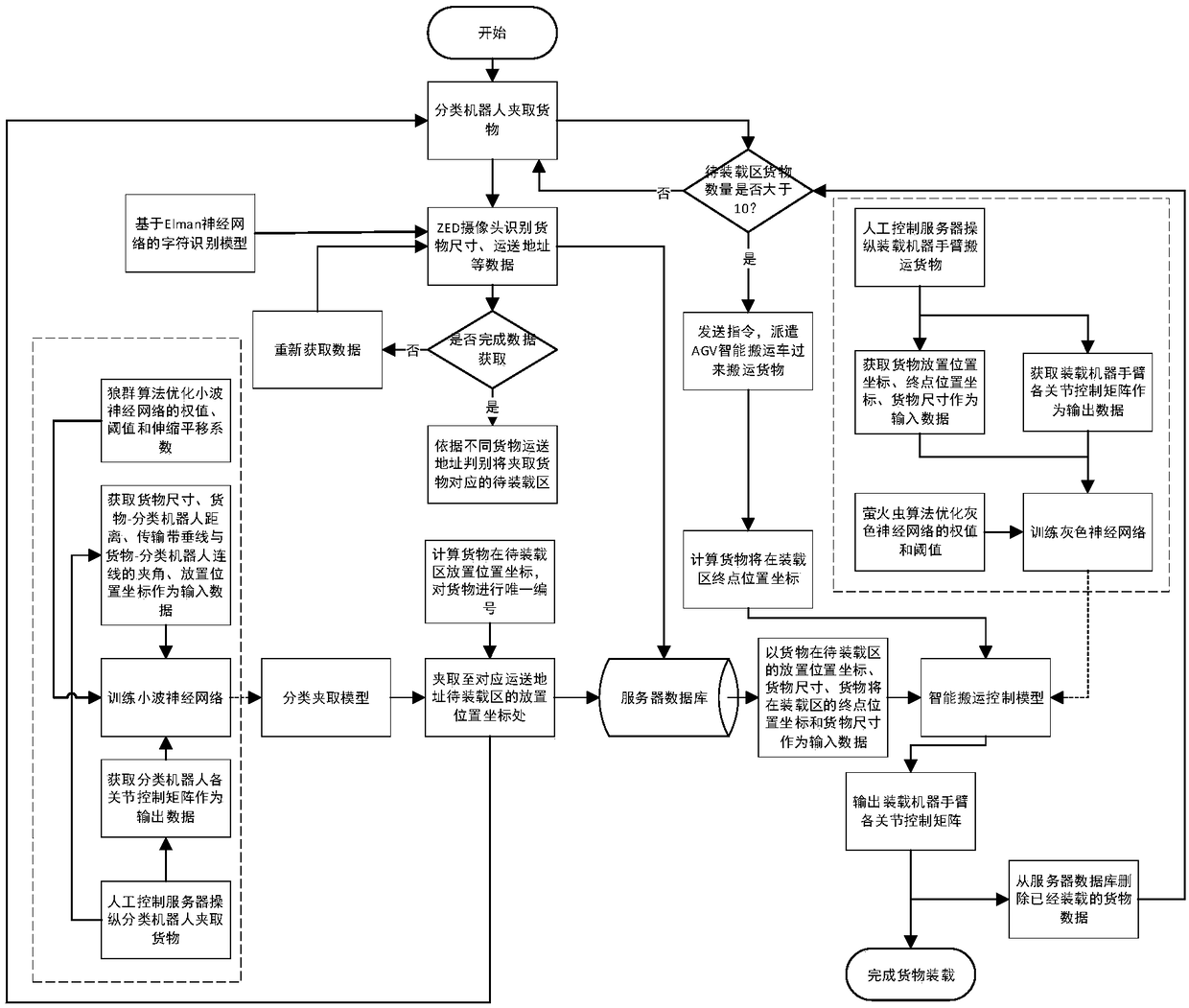

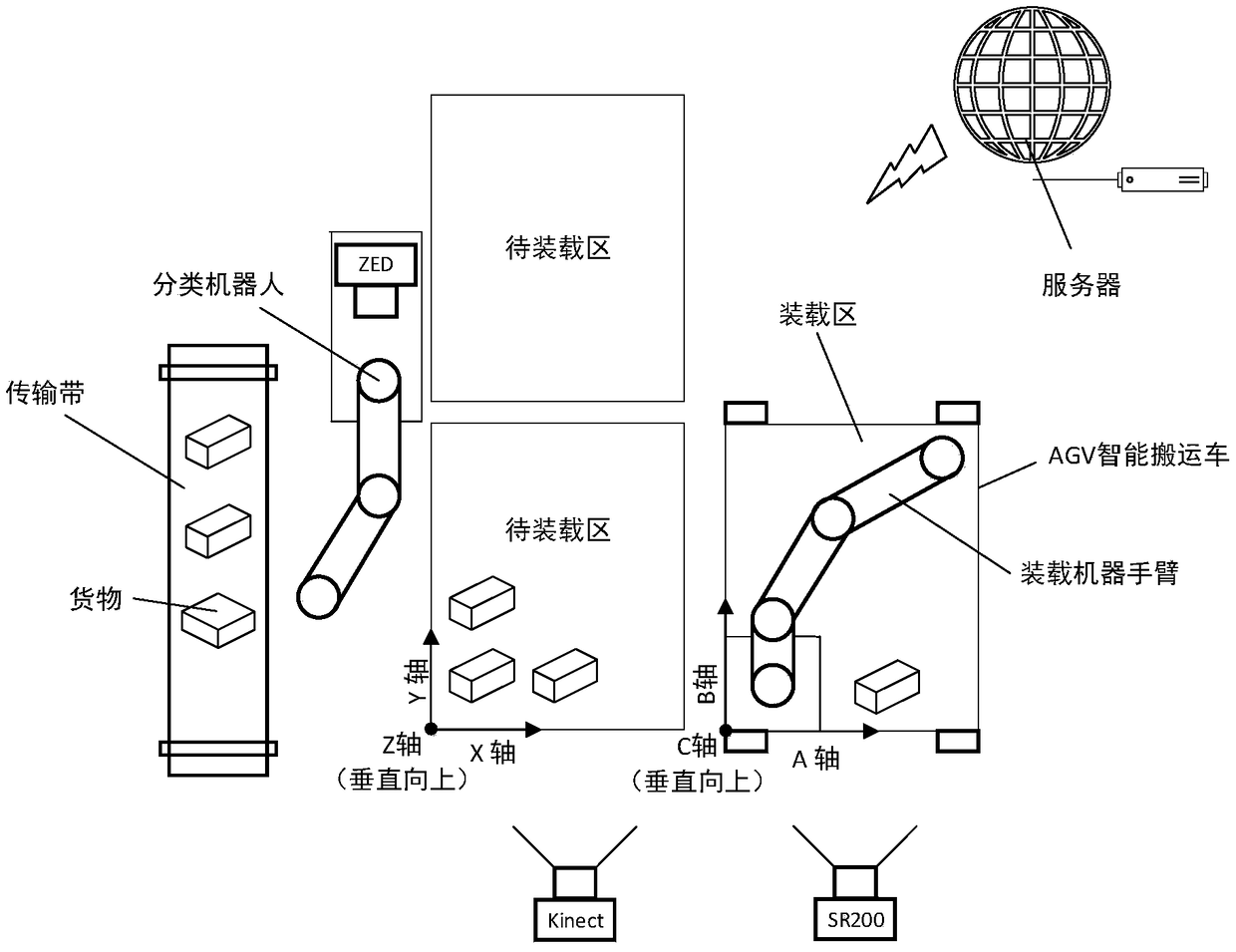

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

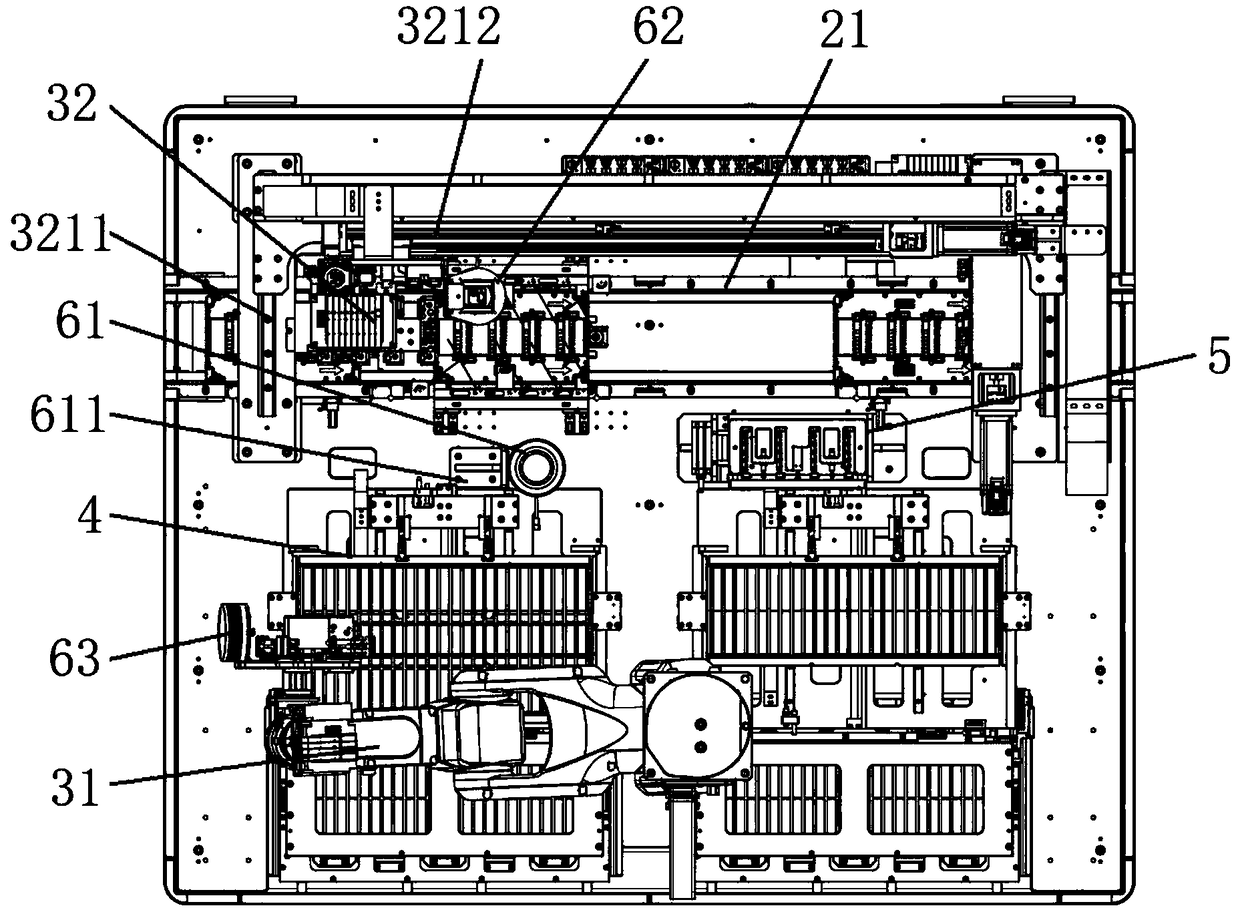

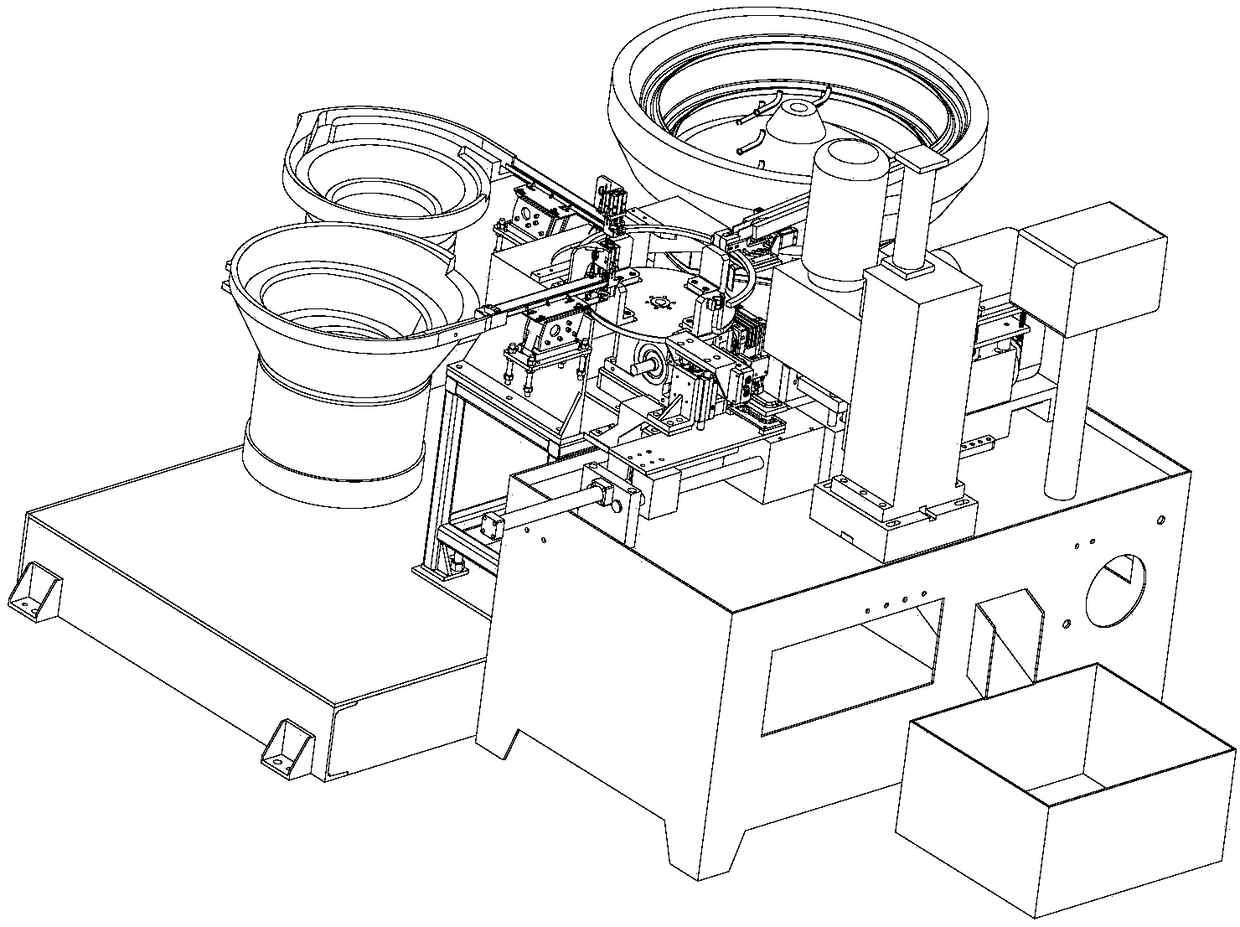

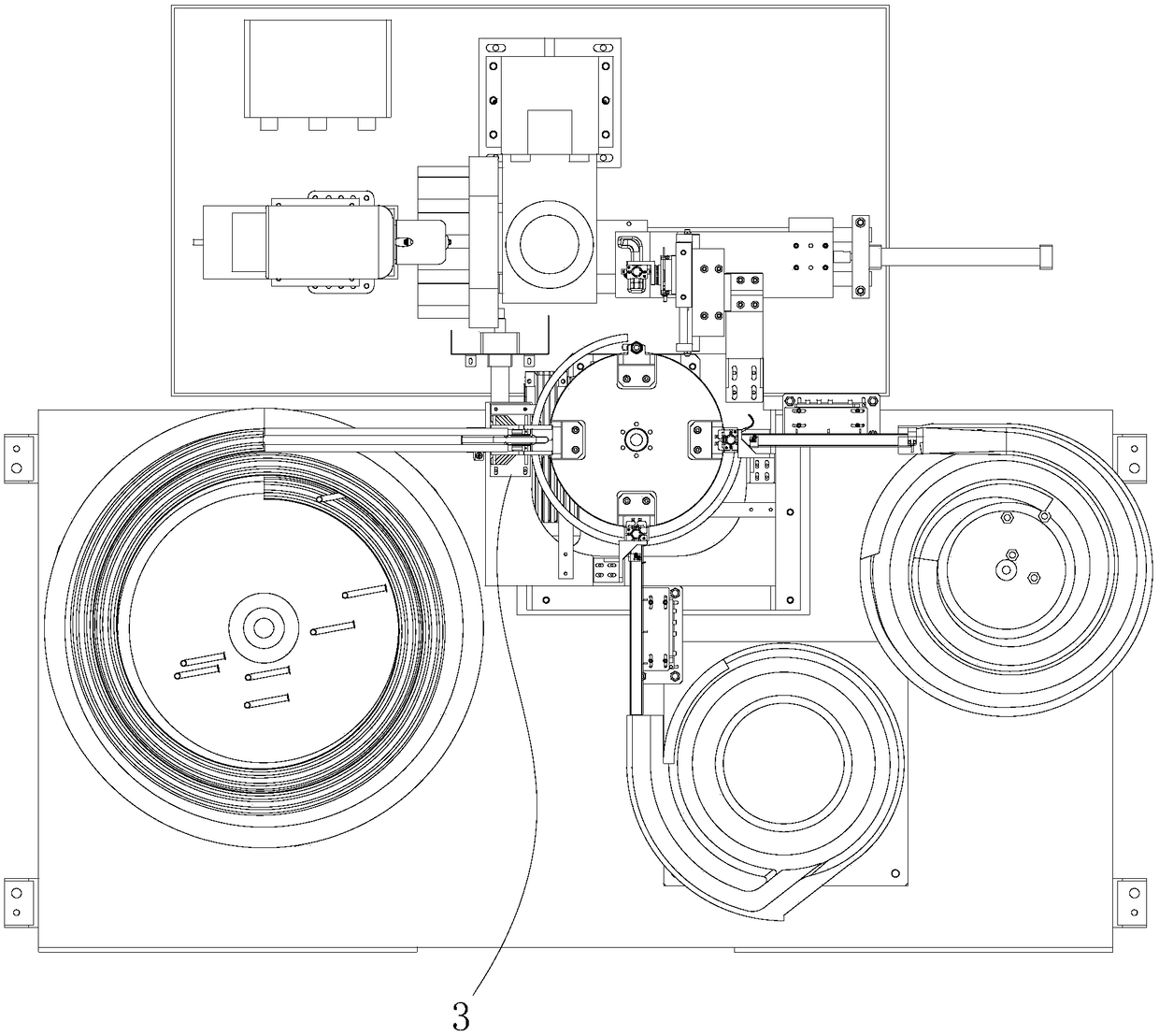

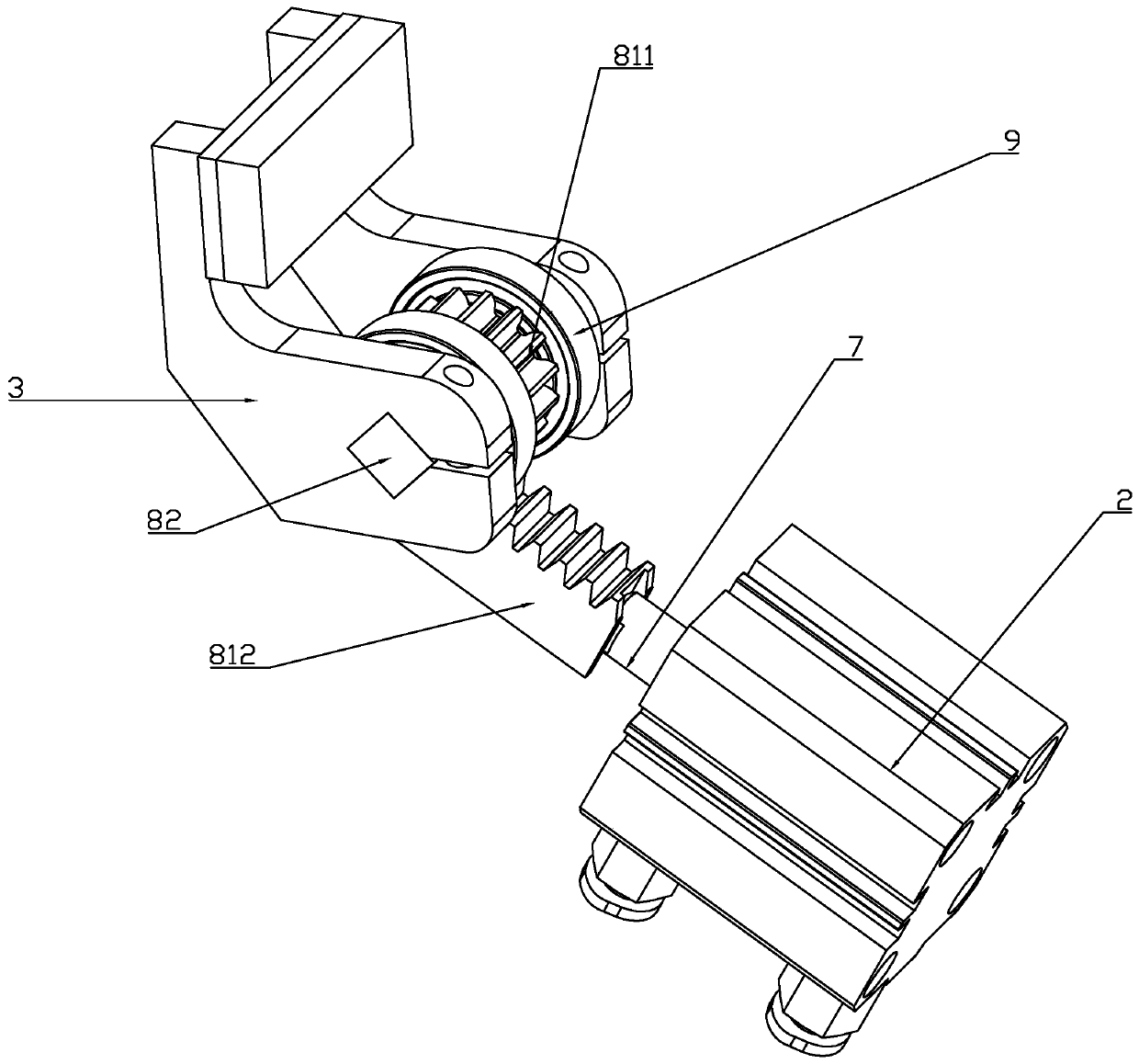

Material picking device

PendingCN109132523AAccurate grippingAccurate placementConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:SUZHOU RS TECH

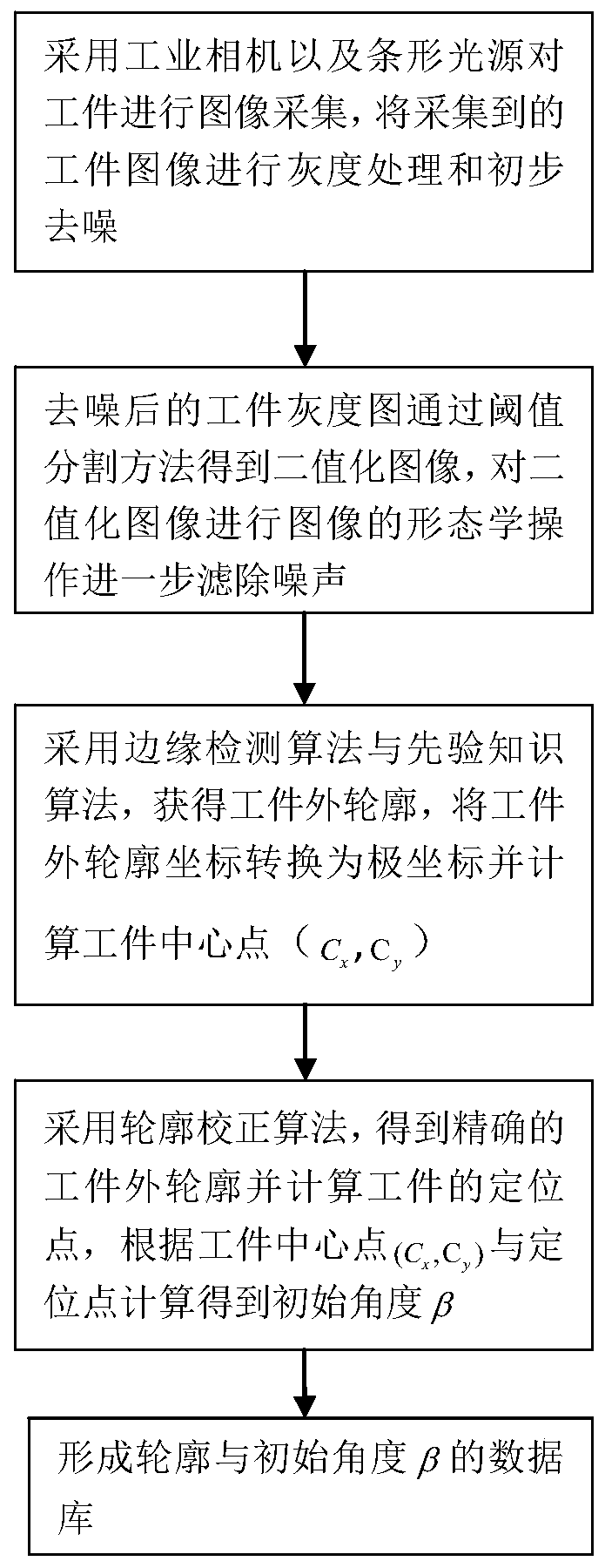

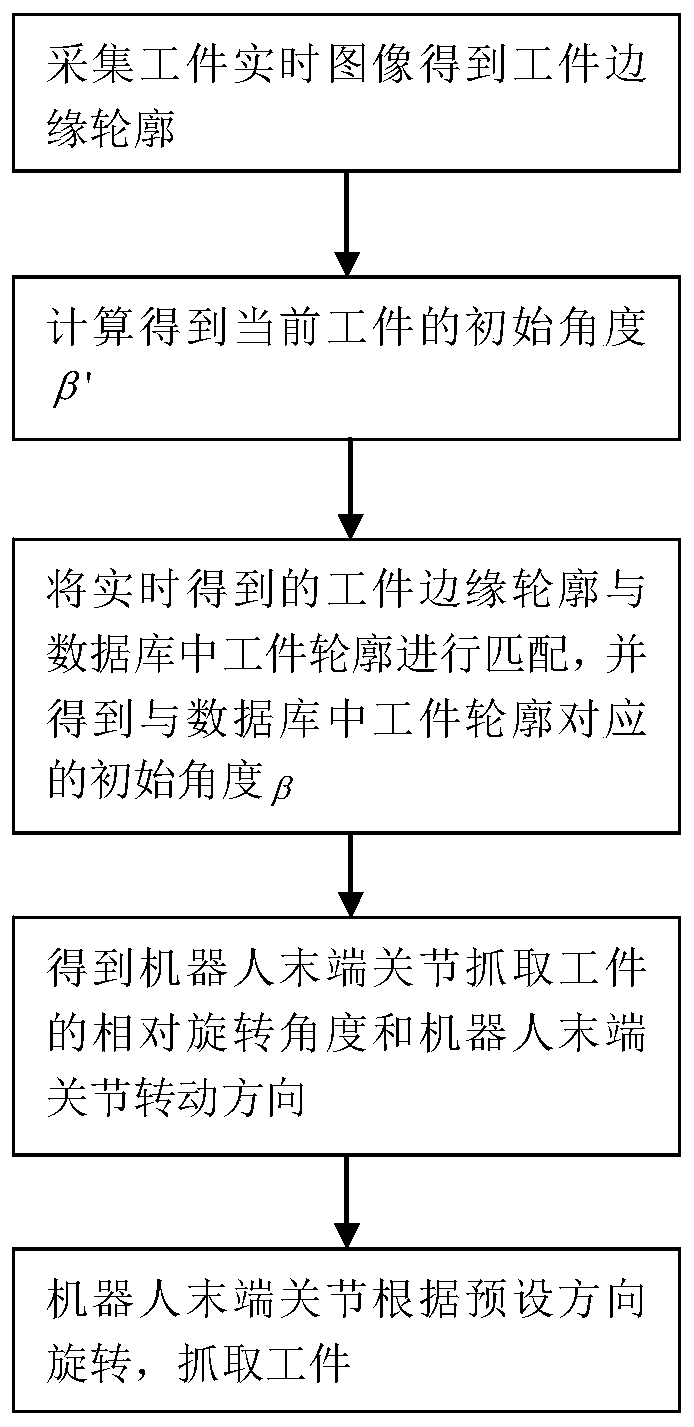

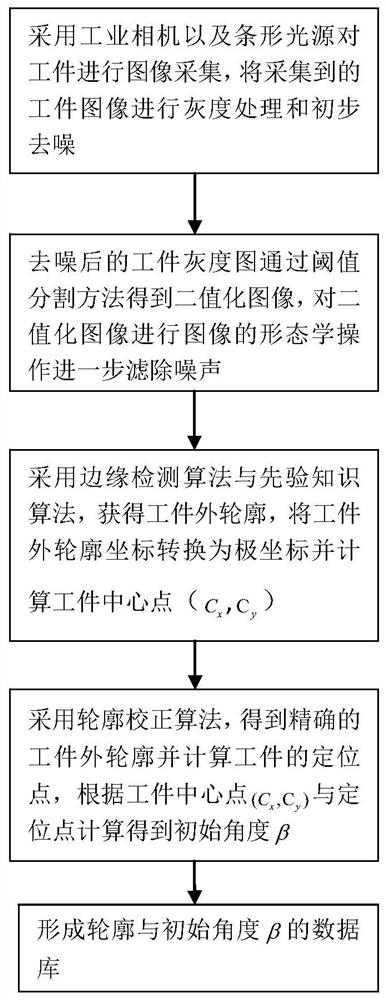

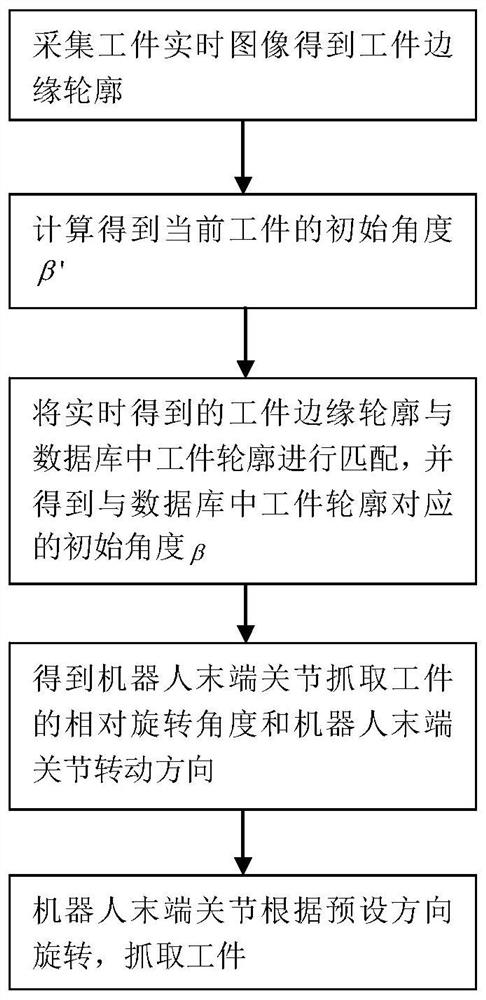

Workpiece grasping method based on machine vision

ActiveCN110625644AImprove gripping efficiencyAccurate and stable angle informationImage enhancementProgramme-controlled manipulatorMachine visionVisual perception

The invention discloses a workpiece grasping method based on machine vision, and belongs to the technical field of industrial robot grasping, comprising offline operation steps and real-time online operation steps. The offline operation steps comprise: collecting a workpiece image to obtain a workpiece edge contour, calculating a workpiece center point, optimizing to obtain an accurate workpiece outer contour, and calculating a positioning point and an initial angle beta of the workpiece. A database is formed according to the workpiece edge contour and the corresponding initial angle beta thereof. The online operation steps comprise: collecting a workpiece real-time image to obtain a workpiece edge contour and meanwhile calculating an initial angle beta' of the current workpiece. The workpiece edge contour obtained in real time is matched with the workpiece contour in the database to obtain a relative rotation angle of a robot tail end joint gripping the workpiece and a rotation direction of the robot tail end joint. The invention provides the workpiece grasping method based on machine vision, which enables a robot to accurately position the workpiece and perform effective grasping.

Owner:HOHAI UNIV CHANGZHOU

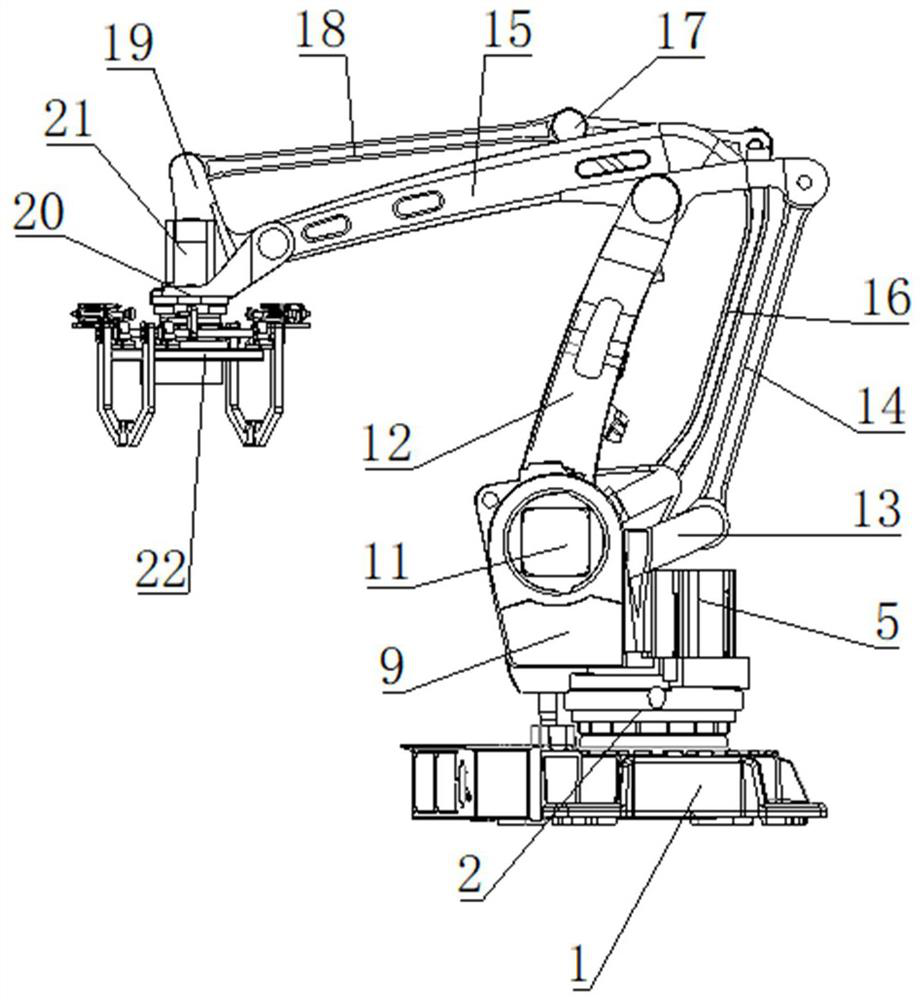

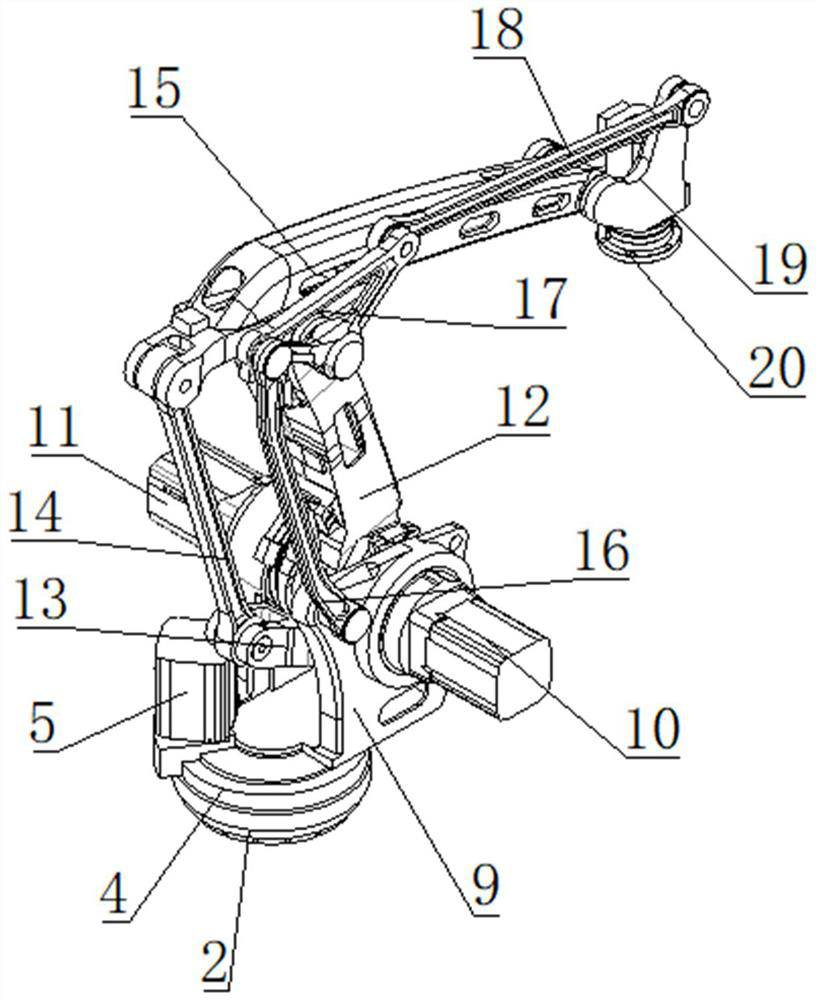

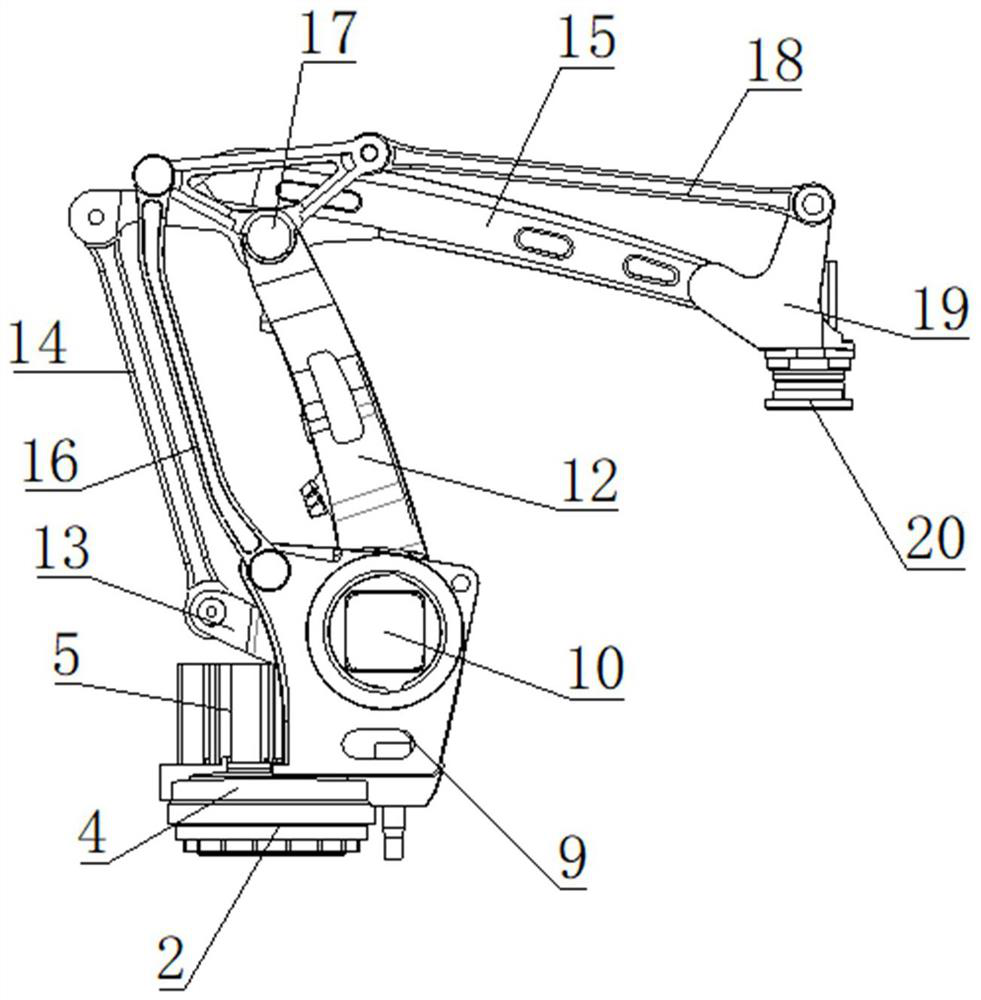

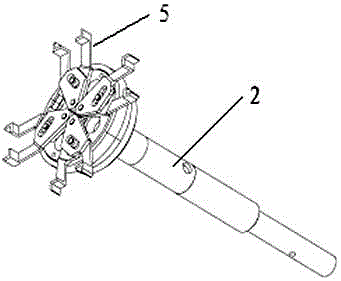

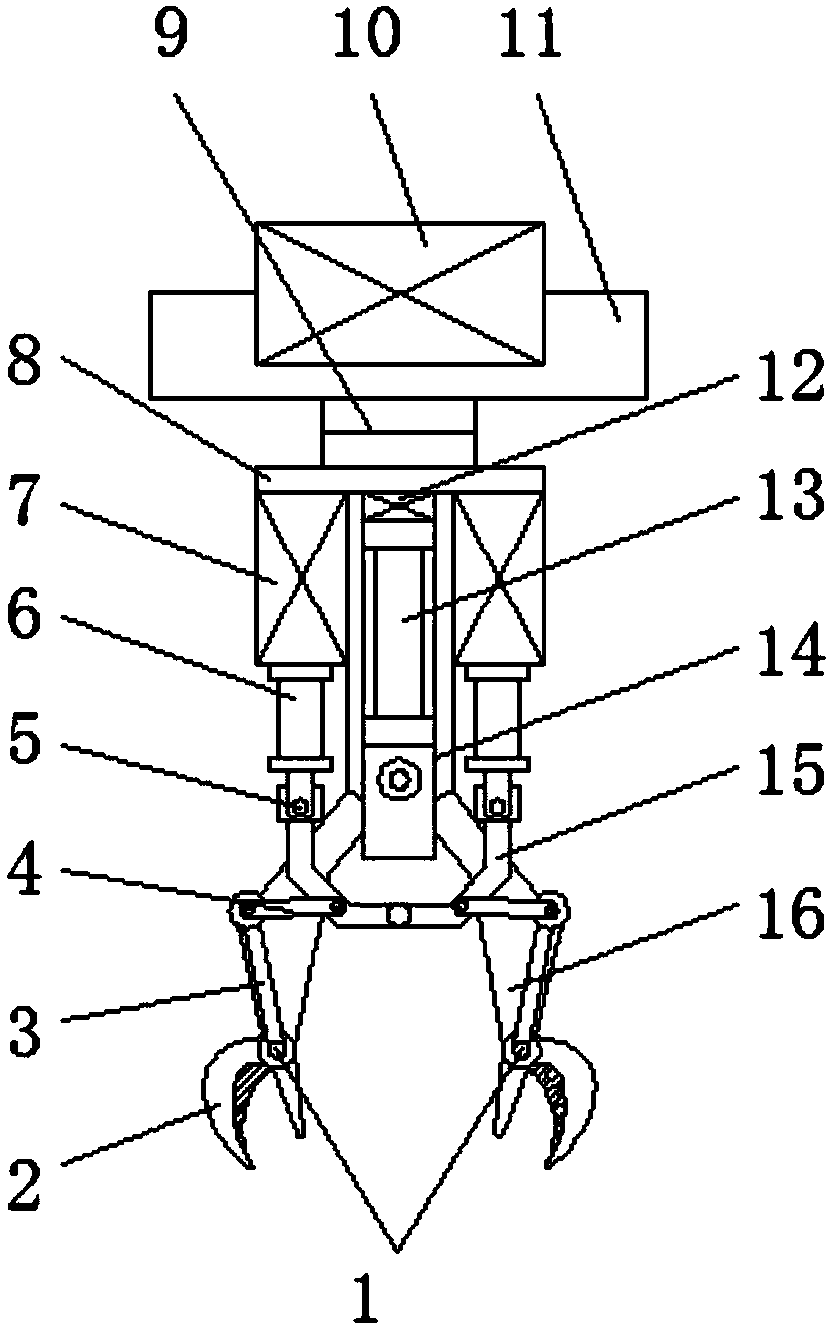

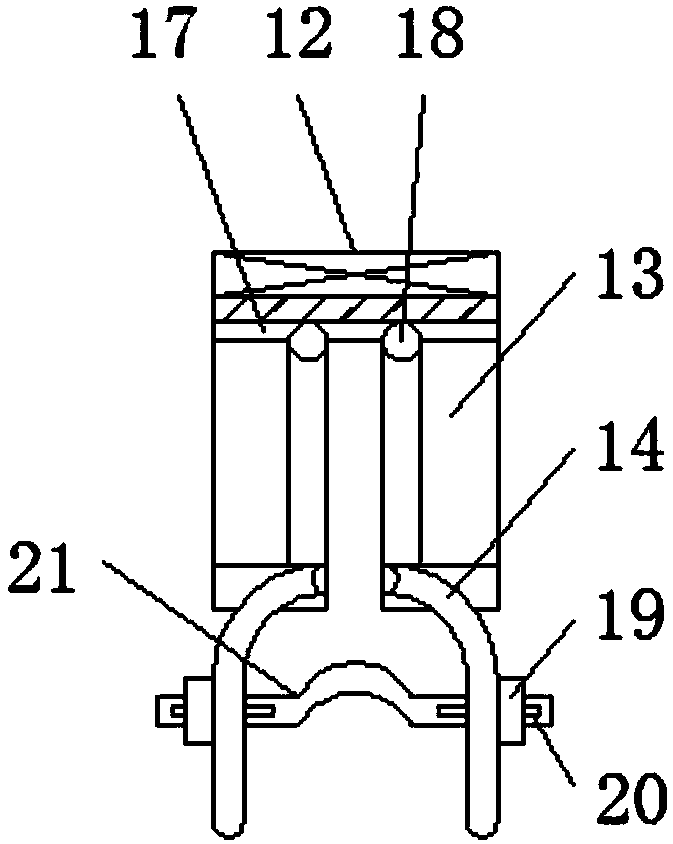

Grabbing equipment of industrial intelligent robot and grabbing method thereof

InactiveCN111993405AImplement the crawl rangeQuick grabProgramme-controlled manipulatorGripping headsControl engineeringElectric machinery

The invention discloses grabbing equipment of an industrial intelligent robot. The grabbing equipment comprises an installation base, a fixing seat, a supporting column, a grabbing arm support and a grabbing assembly; the installation base is fixedly installed with the industrial intelligent robot, the fixing seat is fixedly installed at the center position of the upper end of the installation base, the supporting column is fixedly connected to the center position of the upper end of the fixing seat, a rotating cover is rotatably installed on the supporting column, the grabbing arm support isfixedly installed on the rotating cover, and a second motor and a third motor are fixedly installed on the grabbing arm support. According to the grabbing equipment, a grabbing assembly and a clampingassembly are arranged to grab and clamp objects, thus the different functions of the industrial intelligent robot are achieved, the using range of the industrial intelligent robot is increased, the fast and stable operation of the object grabbing and clamping is achieved, the range of grabbing and clamping is wide, the position adjustment is large, and it is effectively guaranteed that the objects with different shapes are stably grabbed and clamped.

Owner:马鞍山贺辉信息科技有限公司

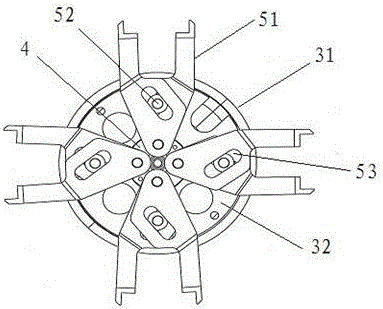

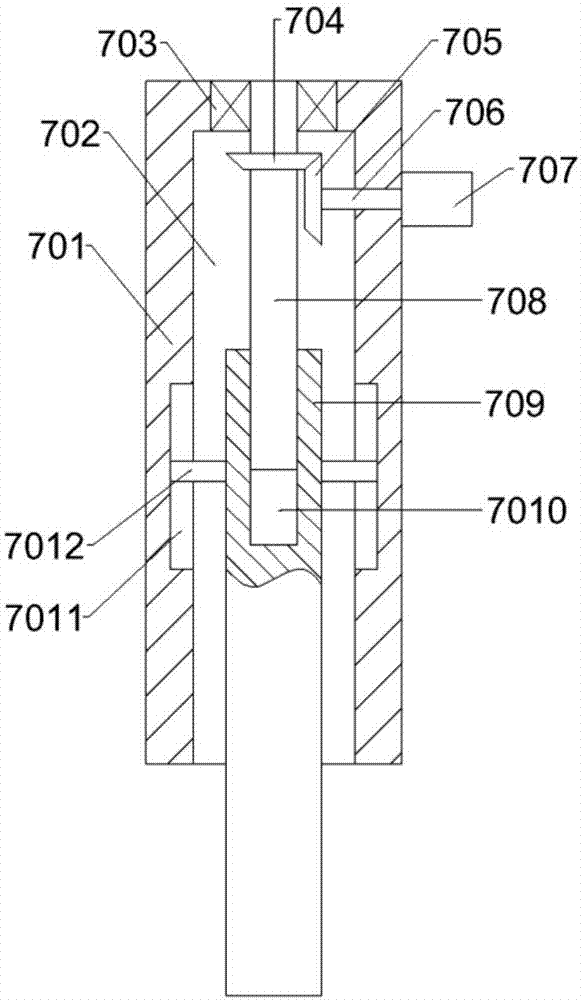

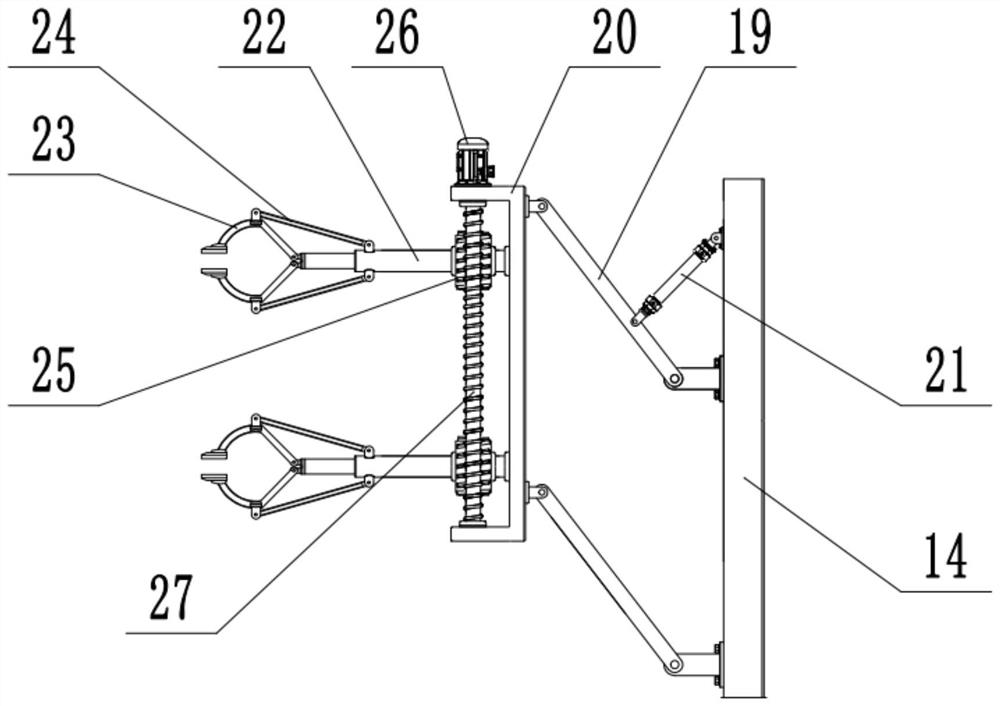

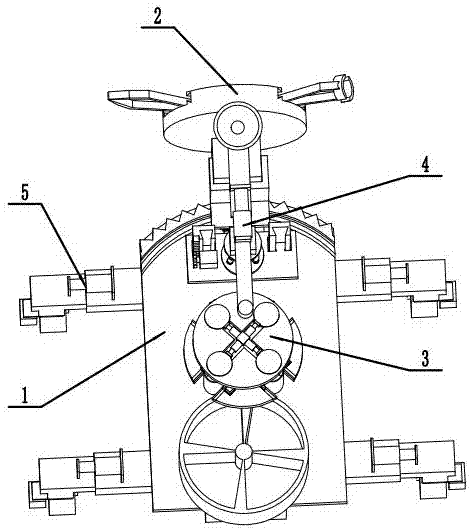

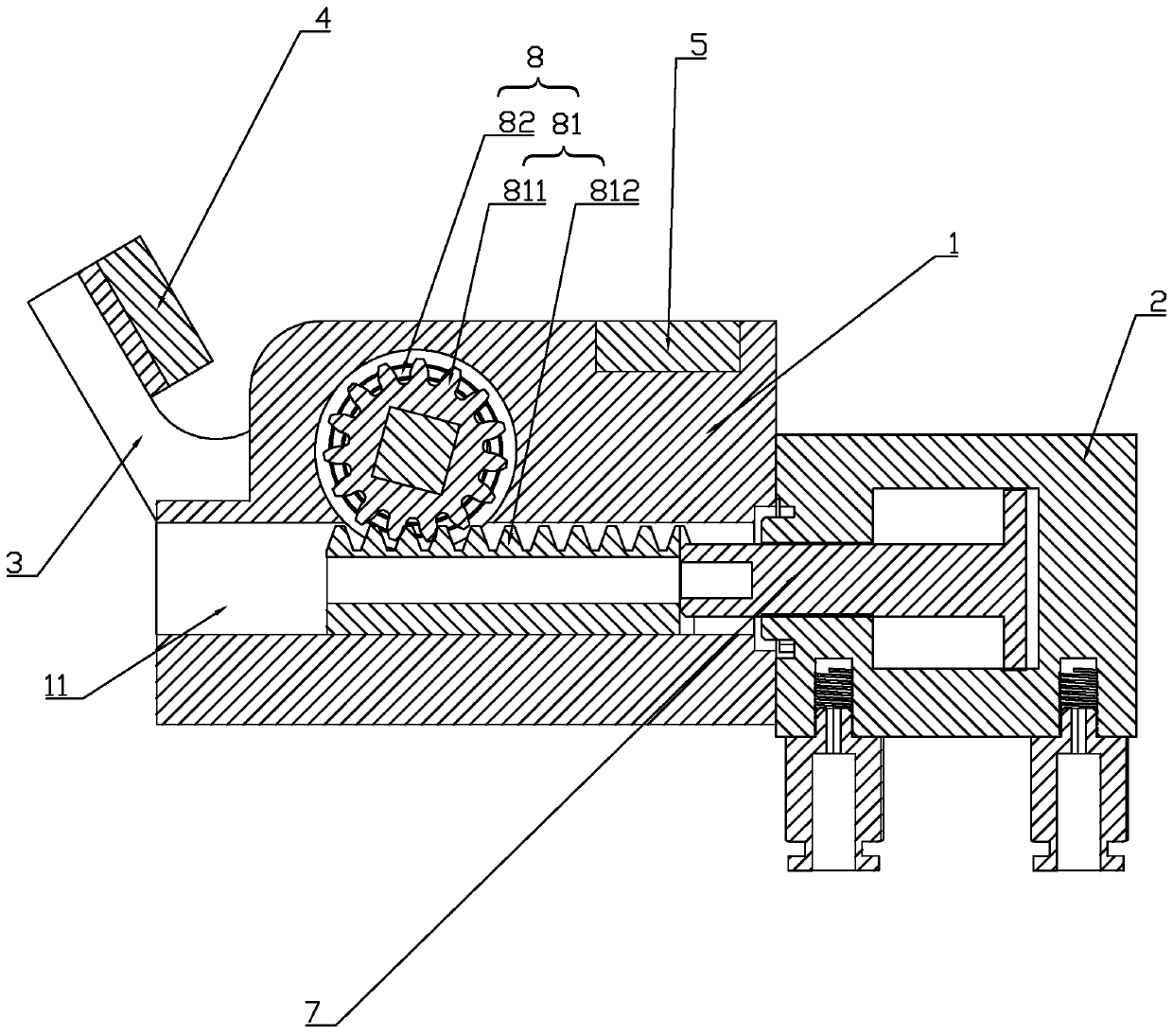

Rotary multi-station candy clamping mechanism

The invention relates to a rotary multi-station candy clamping mechanism. The rotary multi-station candy clamping mechanism is characterized by comprising a rotating body, a body shaft sleeve, a candy clamping claw guiding disc, a candy clamping claw positioning plate and candy clamping claws; a guiding inner disc is driven by the rotating body to rotate, and the candy clamping claws arranged on the candy clamping claw positioning plate are driven to rotate through transmission of the candy clamping claw positioning plate; connecting pins in connecting pin guiding grooves in the guiding inner disc are closely attached to concave-convex outlines of the inner wall of a guiding outer sleeve under the action of pressure springs in the rotating process, the moving track of the connecting pins in the radial direction is the track of the concave-convex outlines of the inner wall of the guiding outer sleeve, through the displacement of the connecting pins in the radial direction, the clamping claws are driven by the parts, located in candy clamping claw guiding grooves, of the connecting pins to be opened and closed, automatic candy packaging and clamping are achieved, the clamping efficiency is improved, and the production rate is increased.

Owner:NANTONG WEALTH MASCH TECH CO LTD

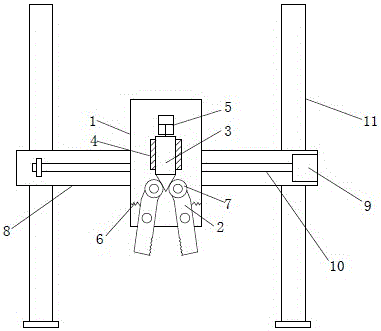

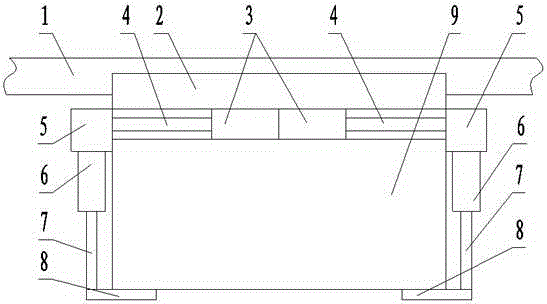

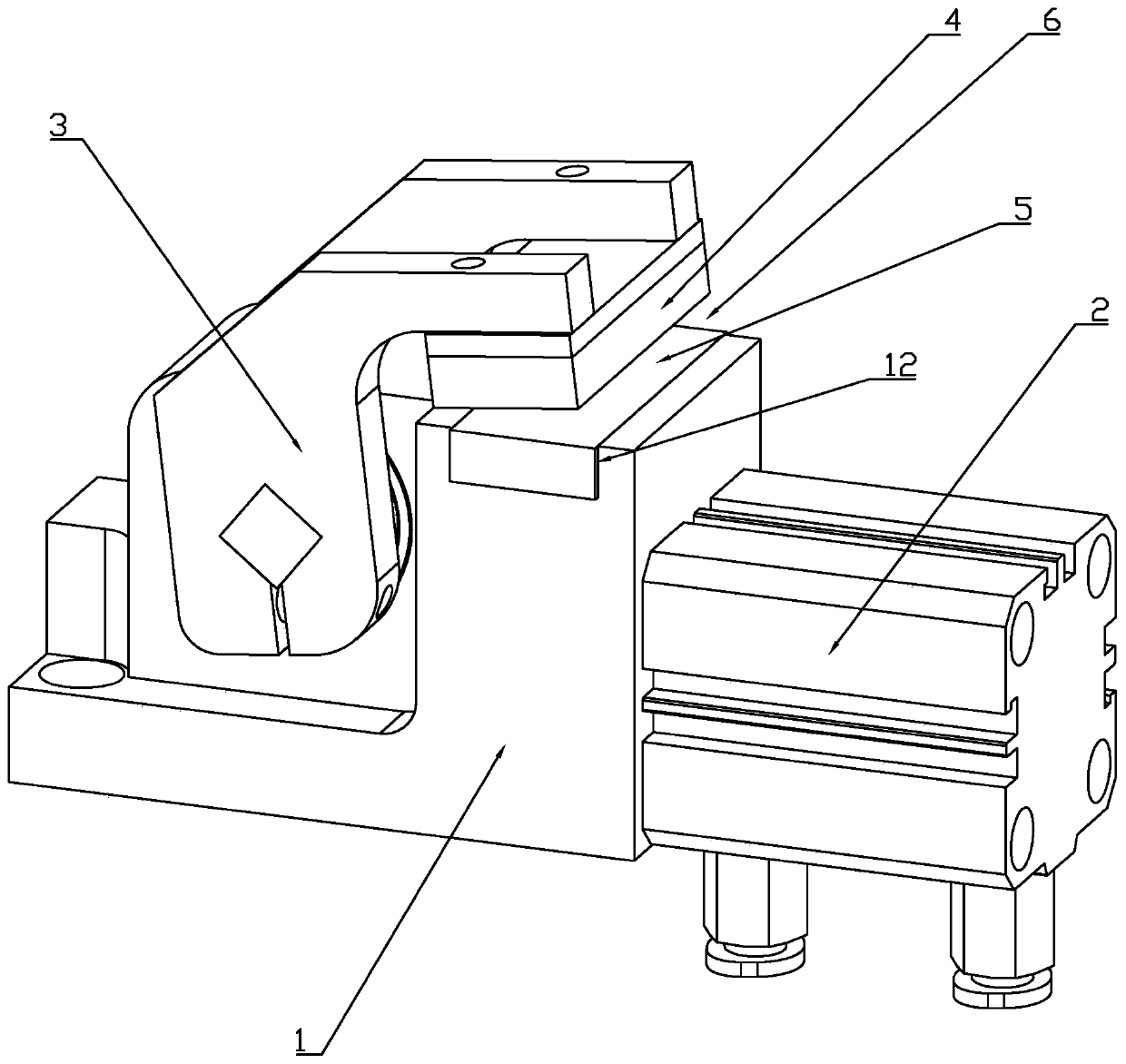

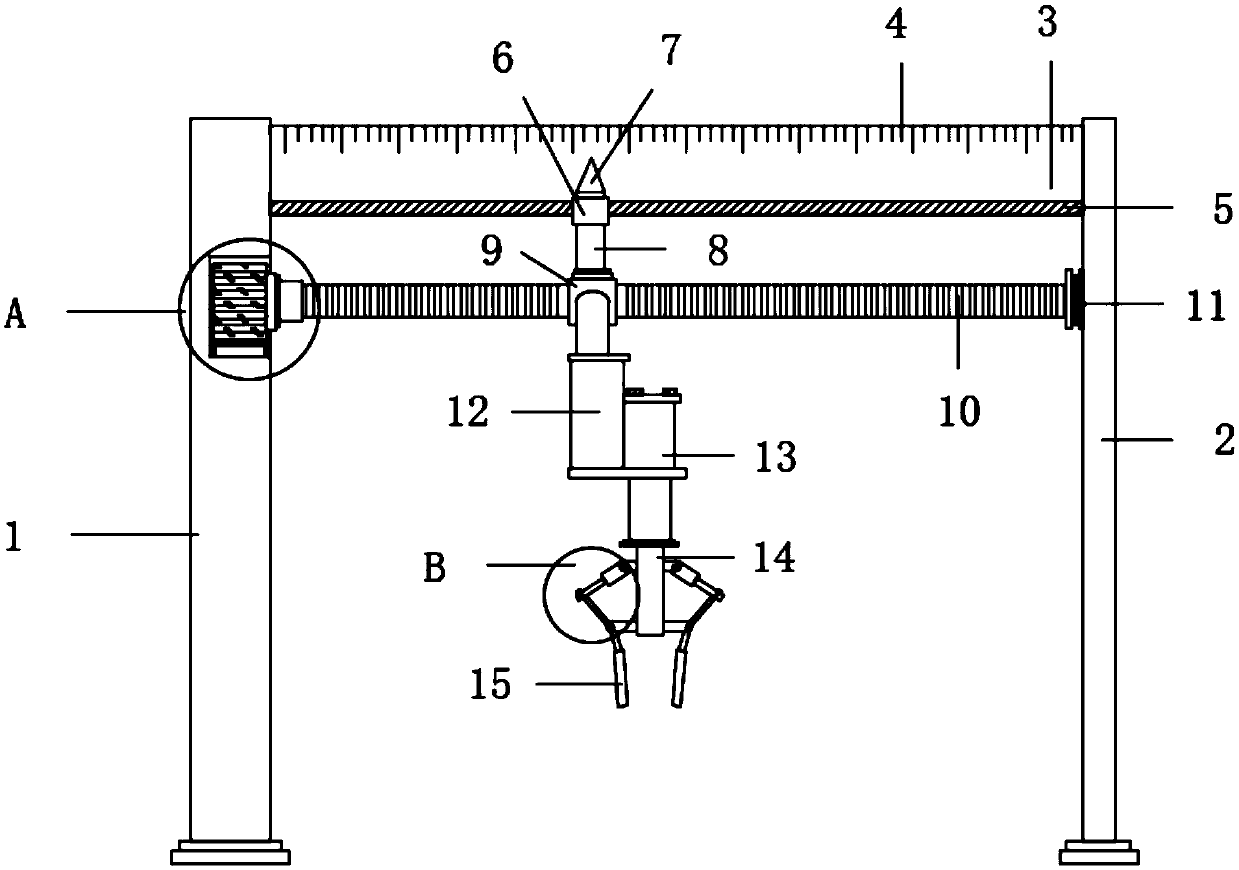

Feeding clamping device

InactiveCN106182055AIncrease frictionImprove wear resistanceProgramme-controlled manipulatorGripping headsEngineeringIdler-wheel

The invention discloses a feeding clamping device and belongs to the field of automation equipment. The feeding clamping device comprises two stand columns, a cross beam mounted on the two stand columns, and a clamping mechanism mounted on the cross beam. The clamping mechanism comprises a vertical plate, two oppositely arranged clamping arms mounted on the lower portion of the vertical plate, and a drive block mounted on the upper portion of the vertical plate. The drive block can slide up and down along the vertical plate. Guide plates located on the two sides of the drive block correspondingly are arranged on the vertical plate. An air cylinder is connected to the upper end of the drive block. The middles of the two clamping arms are hinged to the vertical plate. The sides, away from each other, of the two clamping arms are connected with two sides of the vertical plate through springs correspondingly. Idler wheels are hinged to the upper ends of the two clamping arms correspondingly. The opposite faces of the lower ends of the two clamping arms are clamping faces. The clamping faces are each in a serrated shape. The lower end of the drive block stretches into the space between the idler wheels of the two clamping arms. The two sides of the lower end of the drive block are provided with wedge-shaped faces making contact with the corresponding idler wheels. The clamping mechanism can slide along the cross beam. The structure is simple, the clamping efficiency is high, and the cost is lowered.

Owner:吴道华

Mechanical arm device

The embodiment of the invention provides a mechanical arm device. The mechanical arm device includes an installation base, a drive mechanism a support and two clamping mechanisms; the drive mechanism is arranged on the installation base; the support is connected to the drive mechanism; the two clamping mechanisms are symmetrically arranged two sides of the support; the drive mechanism includes a motor, an over-current protector and an output shaft, wherein the over-current protector is electrically connected to the motor and is used for turning off power of the motor when the motor is overloaded, a surface of the output shaft is provided with threads; a threaded hole is formed in the center of the support, the output shaft passes through the threaded hole, and the threaded hole can be in fit connection with the threads of the output shaft; the motor is connected to the output shaft and is used for driving the output shaft to rotate around the axis of the output shaft to drive the support to do straight reciprocating motion and then drive the two clamping mechanisms to rotate relative to the installation base to hold articles. According to the mechanical arm device, the motor is turned off when articles are clamped, and then burnout due to locked rotor can be avoided; the clamping force can be kept during power off, and the clamped articles cannot fall down; and the mechanical arm device is simple in structure and is easy to control.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

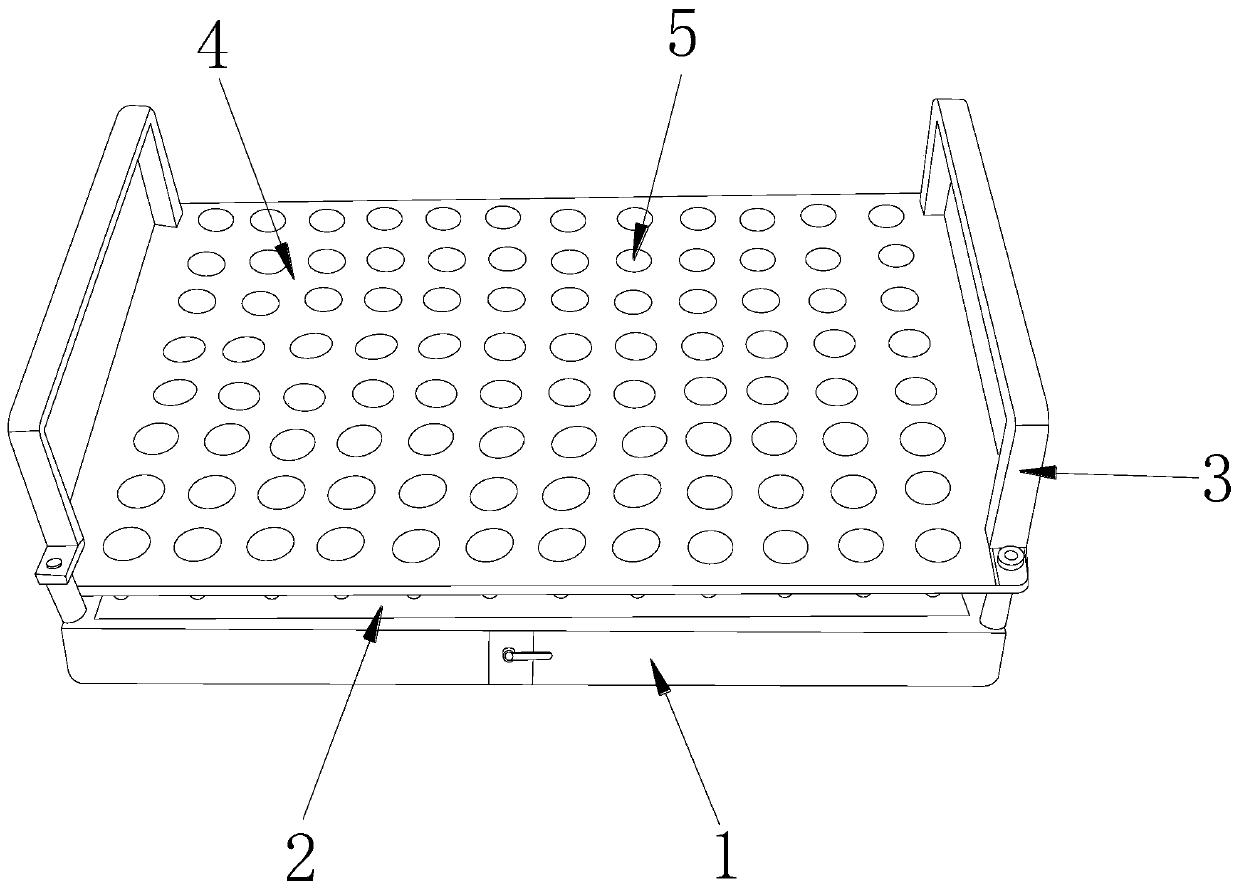

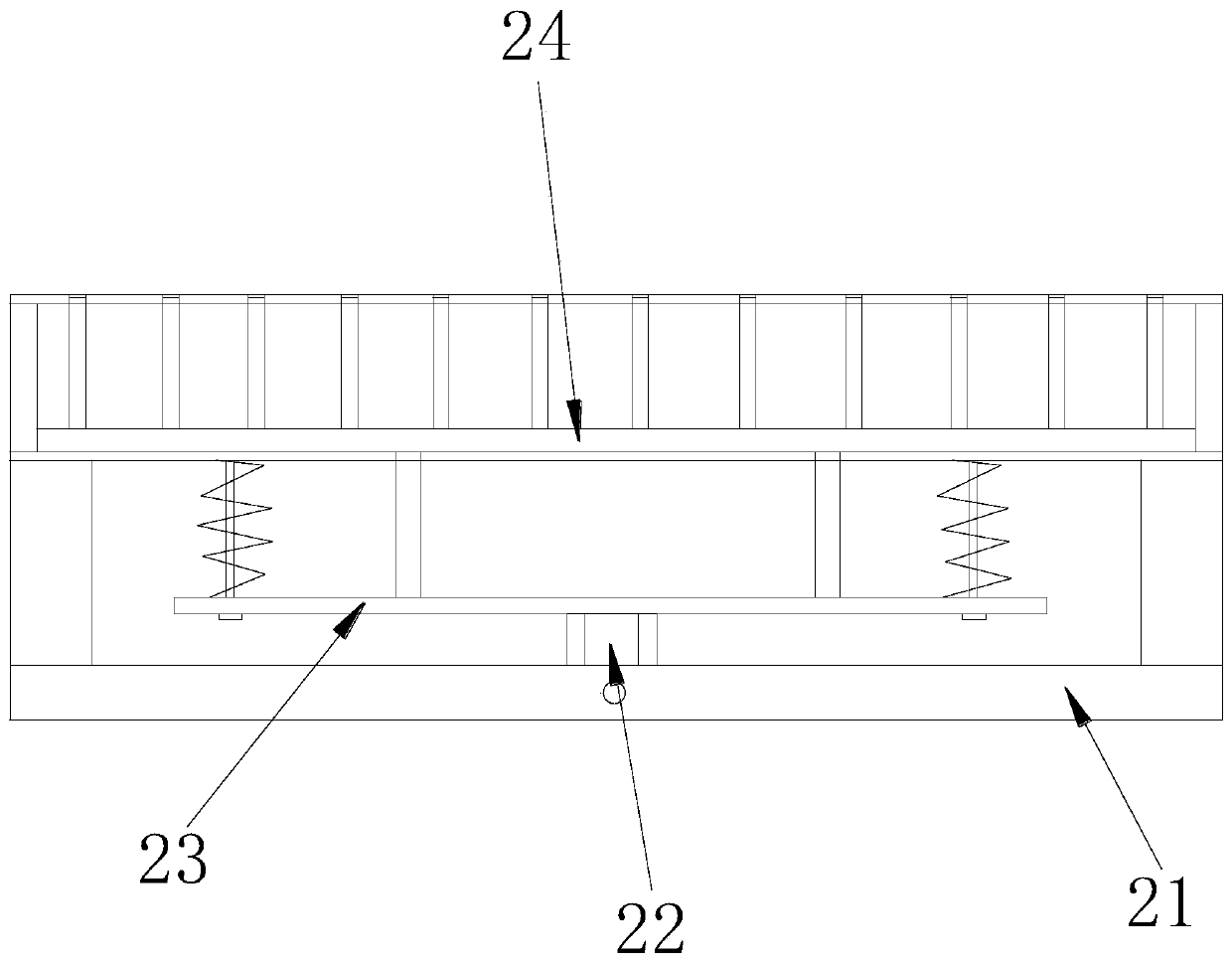

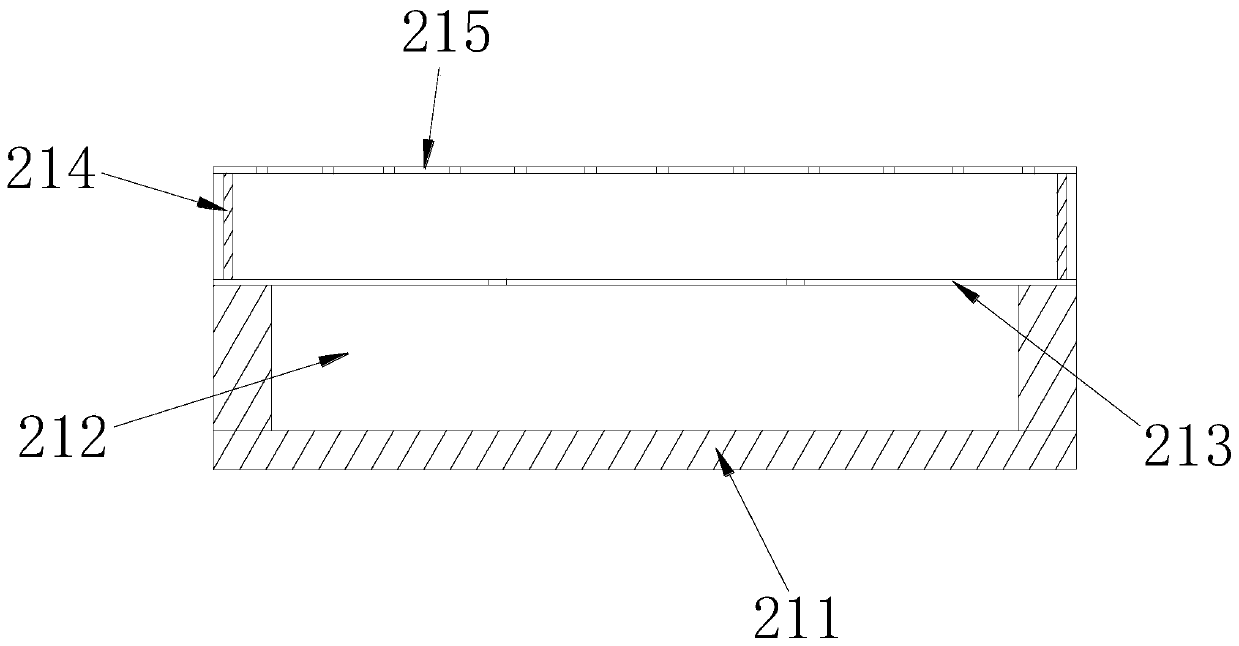

Lifting ejector type optical lens ultrasonic cleaning jig

ActiveCN110000154AQuick breakEasy to removeFlexible article cleaningCleaning using liquidsEngineeringLens plate

The invention discloses a lifting ejector type optical lens ultrasonic cleaning jig. The lifting ejector type optical lens ultrasonic cleaning jig structurally comprises a base, a lifting ejector device, handle frames, a placement table and lens grooves. According to the lifting ejector type optical lens ultrasonic cleaning jig, after cleaning, the jig is taken out, then, a hand-operated lifting mechanism is rotated so that a screw can cooperate a connection slide block to drive a lifting supporting rod to ascend, upward force is applied to a thrust plate ejecting mechanism, thus, a pressing plate on the thrust plate ejecting mechanism move upwards along an I-shaped slide frame so that upward force can be applied to a material ejecting plate, ejecting rods on the material ejecting plate simultaneously move upwards from a sealing cover plate at the top of an installation box till lenses are ejected out from the lens grooves, and accordingly, the situation that the lenses can be quicklyseparated from the lens grooves is achieved; and the cleaned lens can be taken down more quickly, the lens clamping efficiency is improved, the time and labor are saved during lens clamping, the clamping difficulty is lowered, the whole clamping process is more efficient, and the practicality of the jig is indirectly improved.

Owner:日照福瑞德科技有限公司

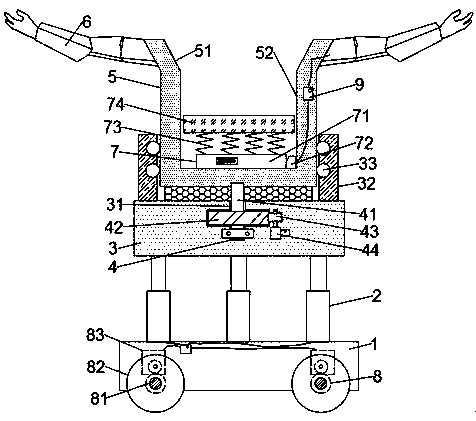

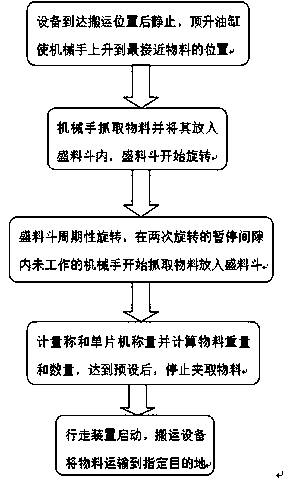

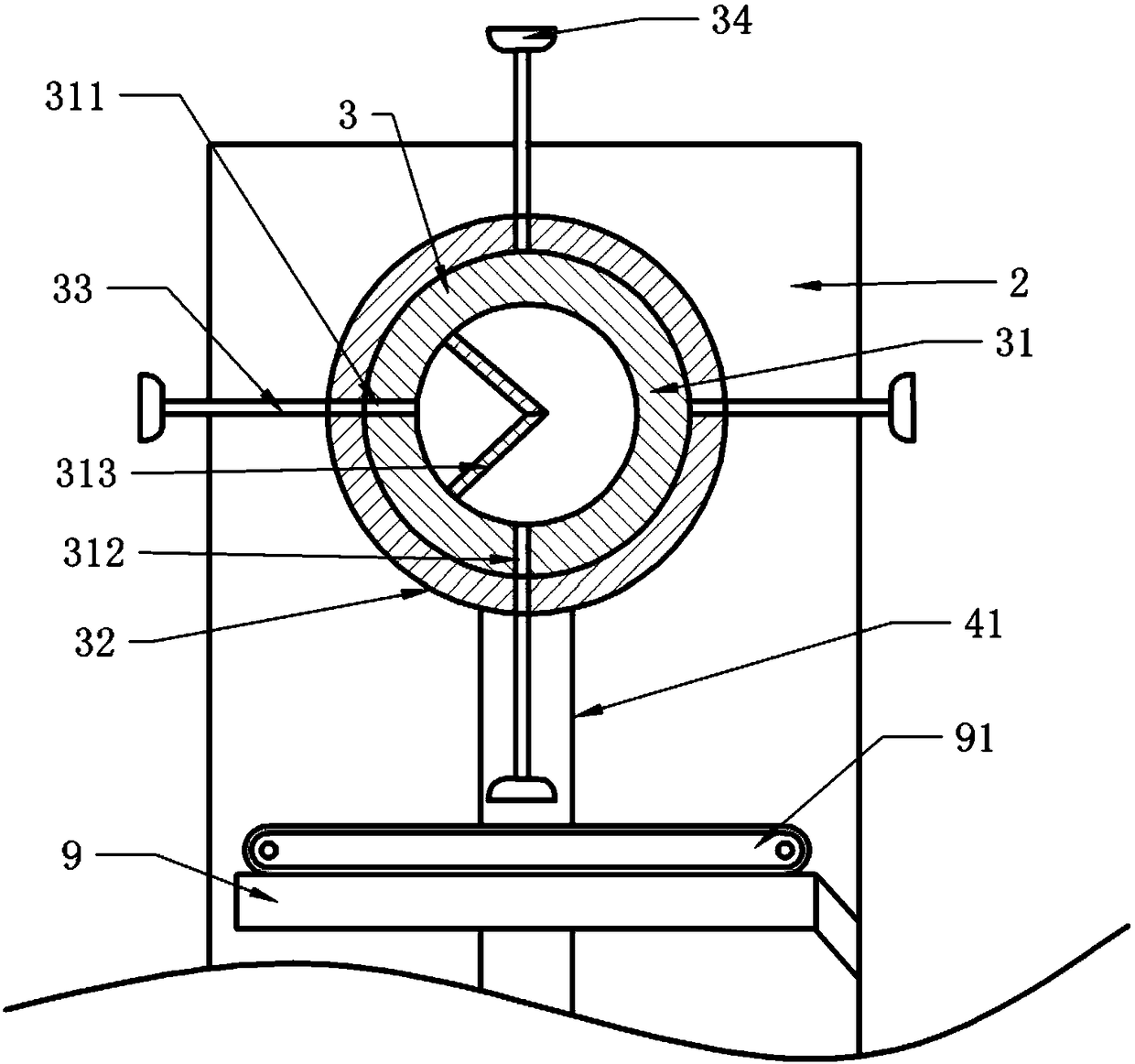

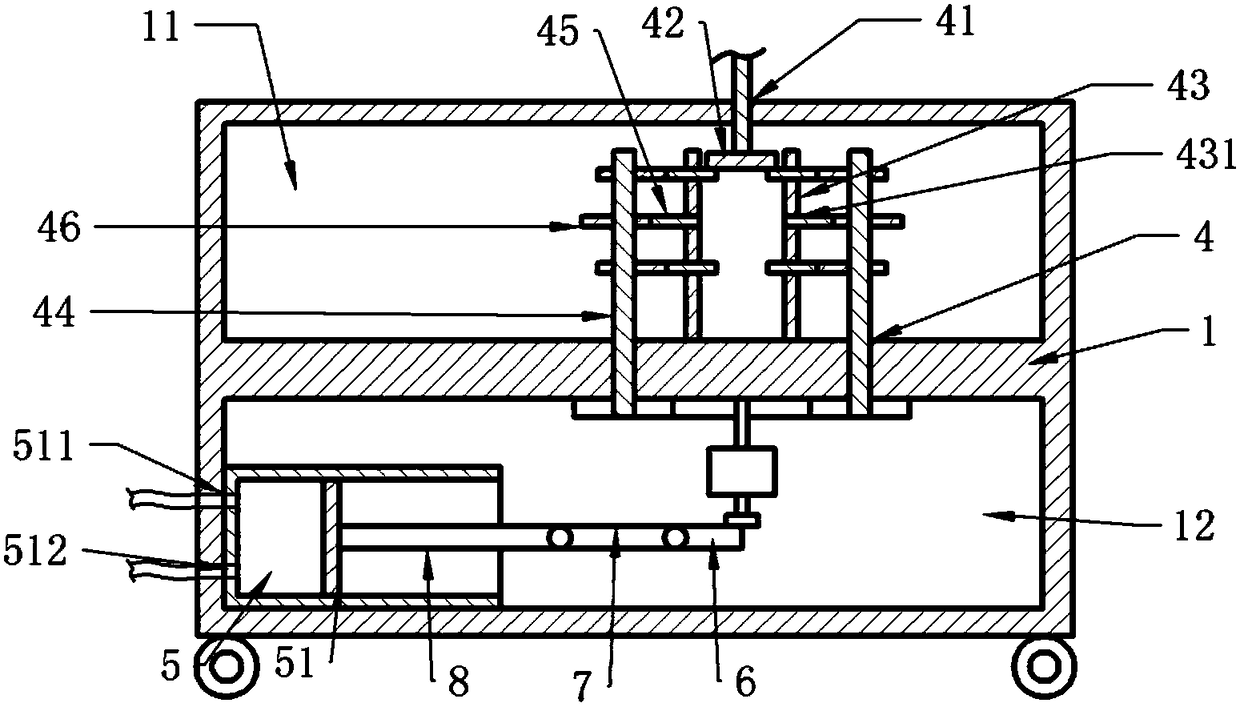

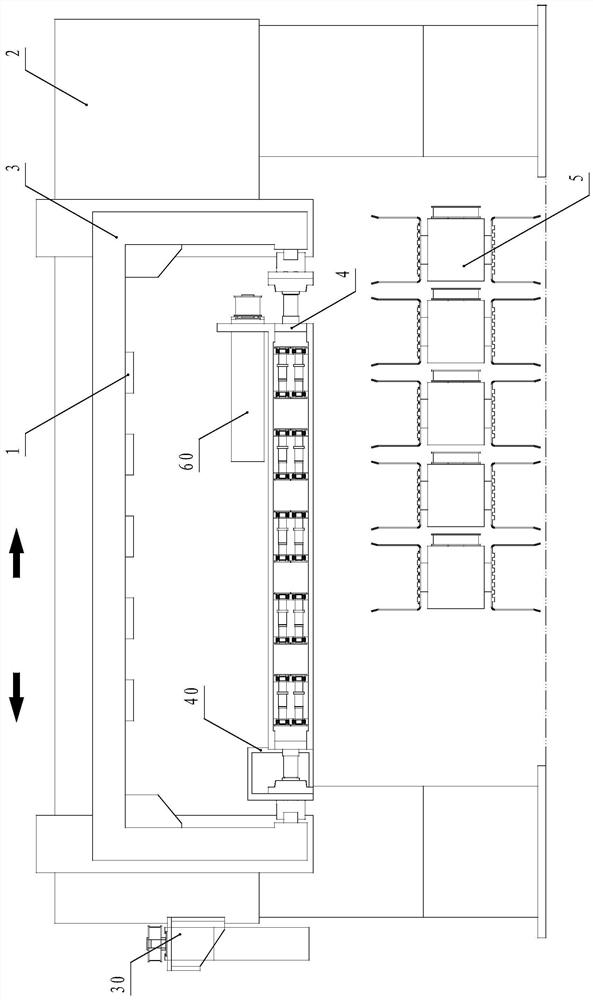

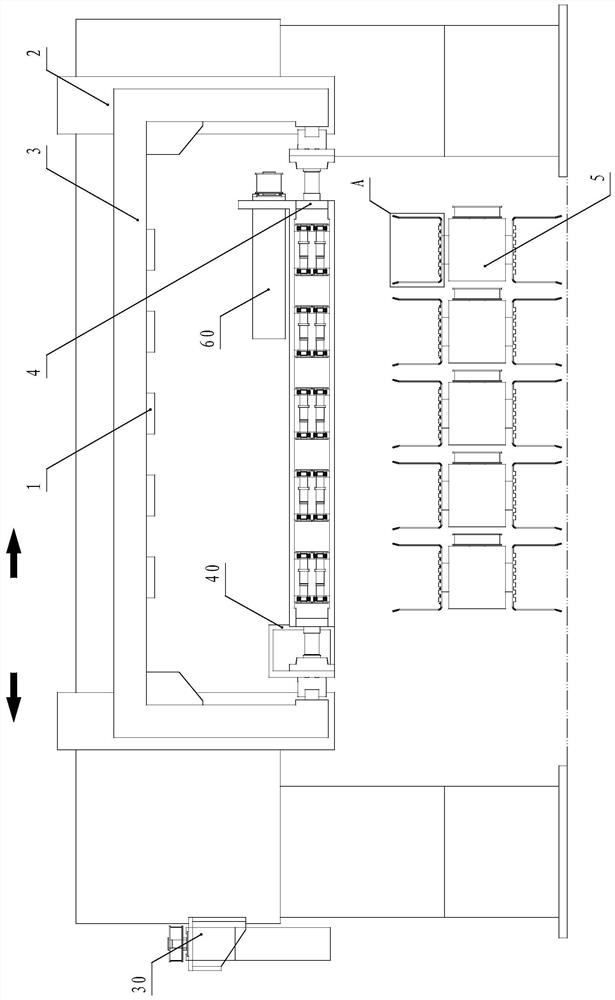

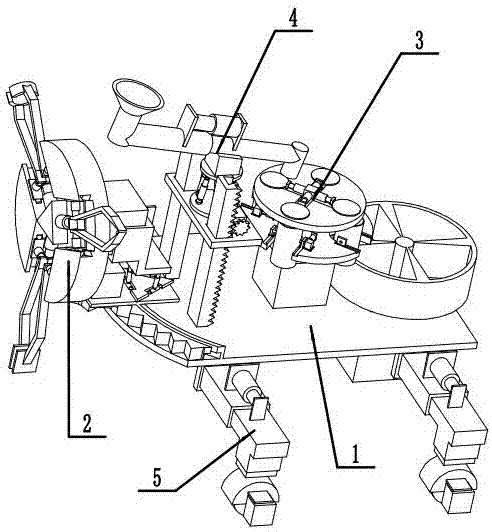

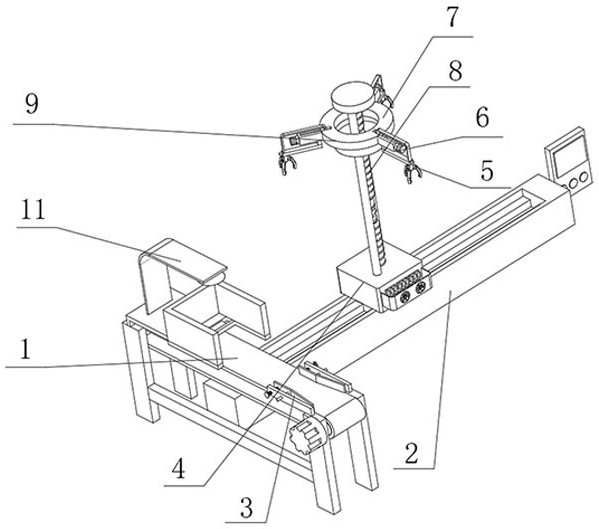

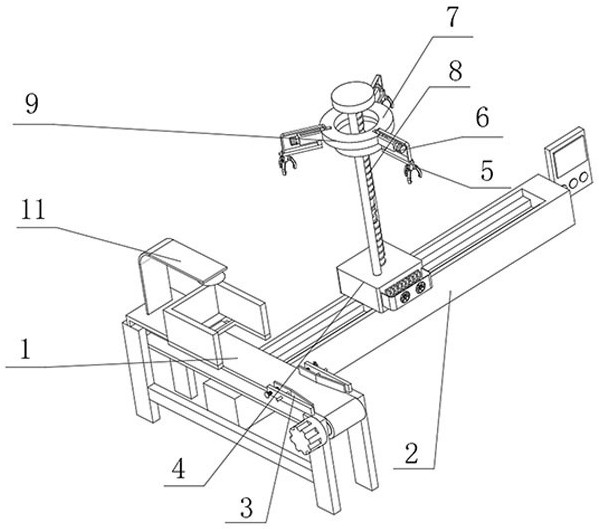

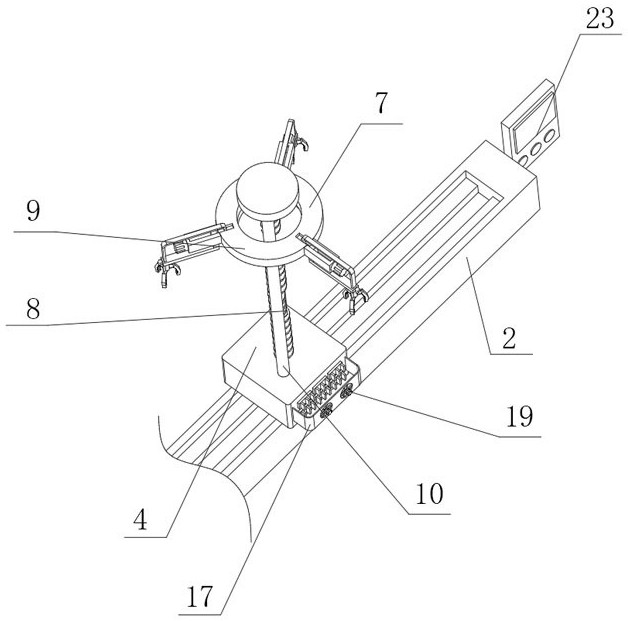

Omnibearing intelligent material handling equipment and recording method

InactiveCN109573589AAvoid the danger of dumping the hopperImprove securityConveyorsControl devices for conveyorsMicrocomputerMicrocontroller

The invention discloses an omnibearing intelligent material handling equipment and recording method. The omnibearing intelligent material handling equipment comprises a force-bearing base, walking devices are mounted at the bottom end of the force-bearing base, a lifting table is connected to the top end of the force-bearing base through jacking oil cylinders, a rotary material receiving hopper ismounted at the top end of the lifting table through a circumferential rotation mechanism, and manipulators and a weighing and counting device are separately mounted on the outer side and the inner side of the rotary material receiving hopper. The omnibearing intelligent material handling recording method comprises the steps that the manipulators clamp materials into the rotary material receivinghopper after the handling equipment travels to an appointed position for handing materials, the weighing and counting device records the weight of the materials, the number of the materials is calculated through a singlechip microcomputer, the singlechip microcomputer transmits a signal to a controller to control the equipment to perform corresponding action, the efficiency of clamping the materials is high, the safety of material handling is high, the handling efficiency of the materials is improved, the materials with multiple heights, multiple orientation and multiple angles can be clamped,springs play buffering and damping roles on the materials, the weight and number of the materials can be calculated, and accurate delivery from storage or processing of the materials can be guaranteed.

Owner:盐城汇金科技信息咨询服务有限公司

Stone clamping device for excavating robot

The invention belongs to the technical field of excavating aids, and discloses a stone clamping device for an excavating robot. The stone clamping device comprises a base and a support plate as well as a clamping mechanism and an adjusting mechanism; the clamping mechanism comprises a mounting shaft and a rotating roller which are hollow; the mounting shaft is slidably connected to the support plate, and provided with a first through hole and a second through hole; the mounting shaft is provided with two baffles, and divided into a negative pressure chamber and a pressure relief chamber by thetwo baffles; the rotating roller is connected to four connecting rods which are provided with industrial vacuum chucks; the base is internally provided with a cavity which is internally provided witha motor, a piston barrel and a piston, and the stone clamping device further comprises a first support rod, a second support rod and a third support rod which are hinged in sequence; the motor is connected to a rotating disk, and the first support rod is fixed to the rotating disk; the third support rod is hinged to the piston; and the piston barrel is provided with an air inlet and an air outlet. According to the stone clamping device disclosed by the invention, the problem that the stone clamping efficiency is low since stones can be clamped one by one only in the prior art is solved.

Owner:CHONGQING UNIV OF ARTS & SCI

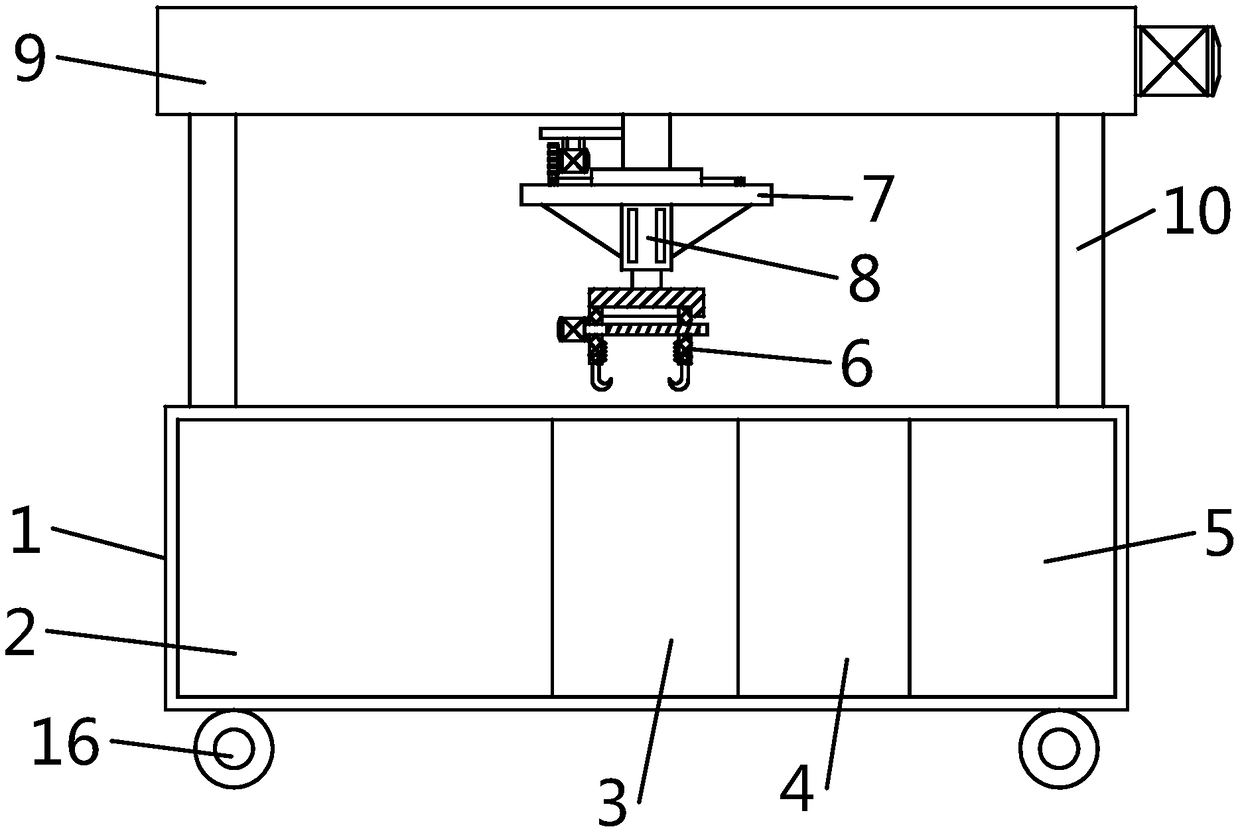

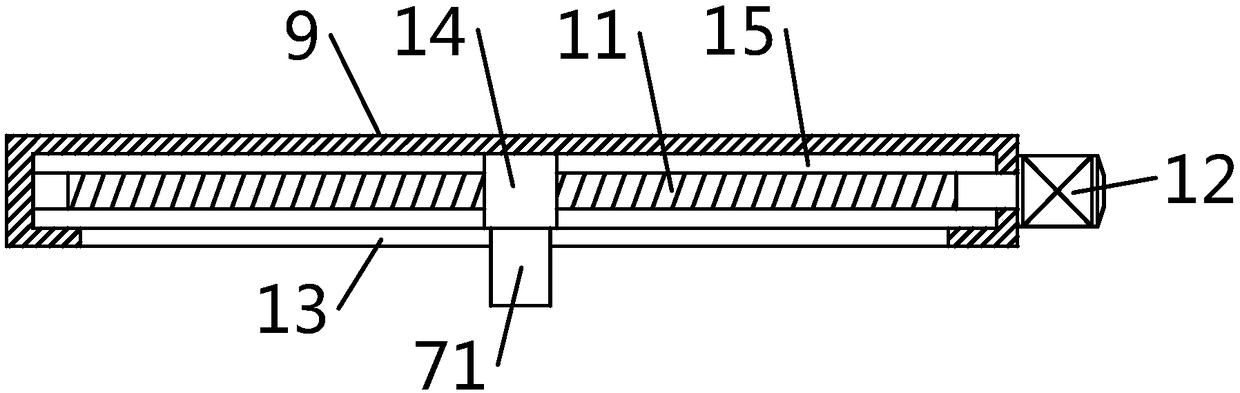

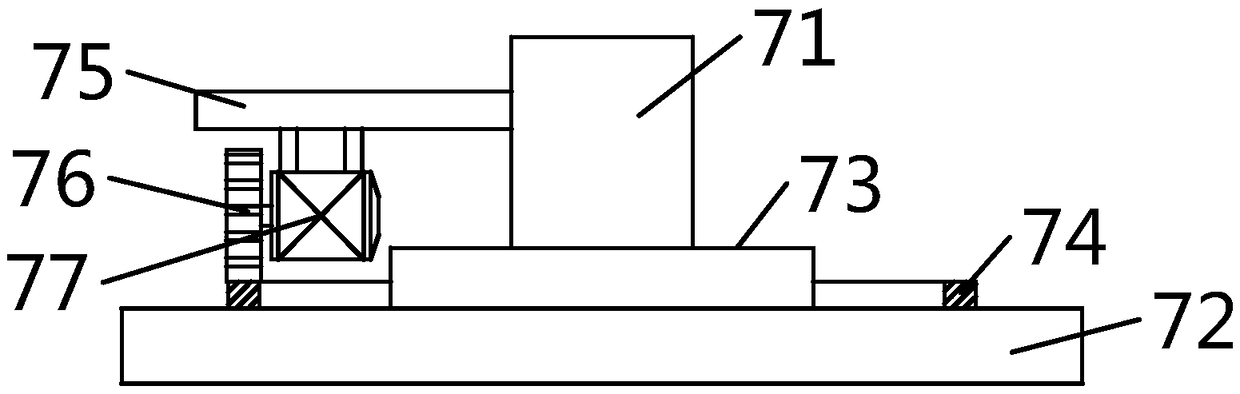

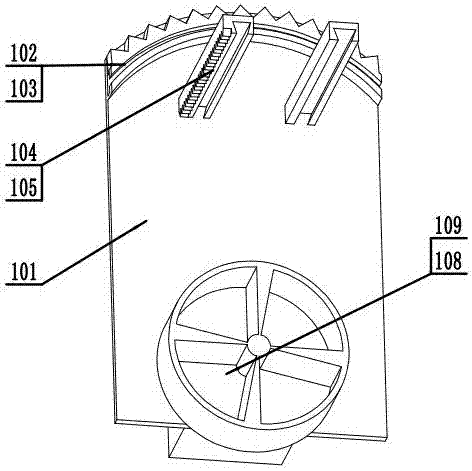

Moving type construction site waste classifying and screening device

InactiveCN108636983AEasy accessImprove gripping efficiencyConstruction waste recoverySolid waste disposalElectric machineryArchitectural engineering

The invention discloses a moving type construction site waste classifying and screening device comprising a box, a clamping mechanism, a rotating mechanism, a telescopic cylinder, a supporting cross beam and trundles. The box is provided with a mixture containing groove, a metal containing groove, a plastic containing groove and a residue soil and impurity groove. The tops of the two ends of the box are both fixedly connected with supporting stand columns in a welded manner. The supporting cross beam is fixedly erected at the top ends of the supporting stand columns. A rectangular sliding cavity is formed in the supporting cross beam. A lead screw is rotationally erected in the rectangular sliding cavity. The rectangular sliding block is arranged on the lead screw in a threaded connectionmanner. The rotating mechanism comprises a connection stand column, a supporting plate, a supporting seat, an annular rack, a gear and a third drive motor. A telescopic cylinder used for driving the clamping mechanism to ascend and descend in the vertical direction is fixedly installed at the bottom end of the middle part of the supporting plate on the rotating mechanism. The moving type construction site waste classifying and screening device can achieve classifying and screening of construction waste, mechanical operation is adopted, the construction waste classifying treatment efficiency and safety are improved, and the moving type construction site waste classifying and screening device is convenient to use and easy to popularize.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

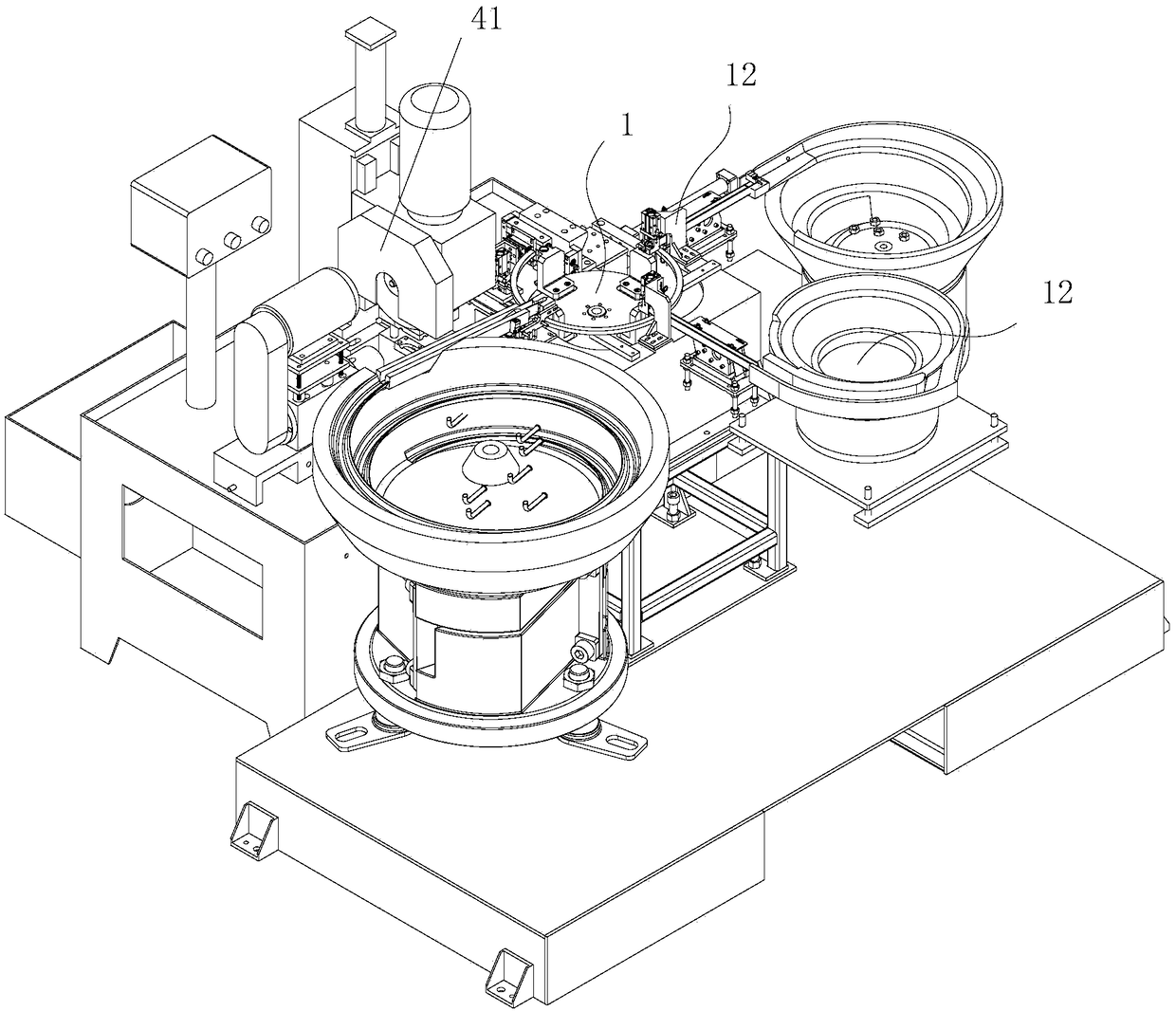

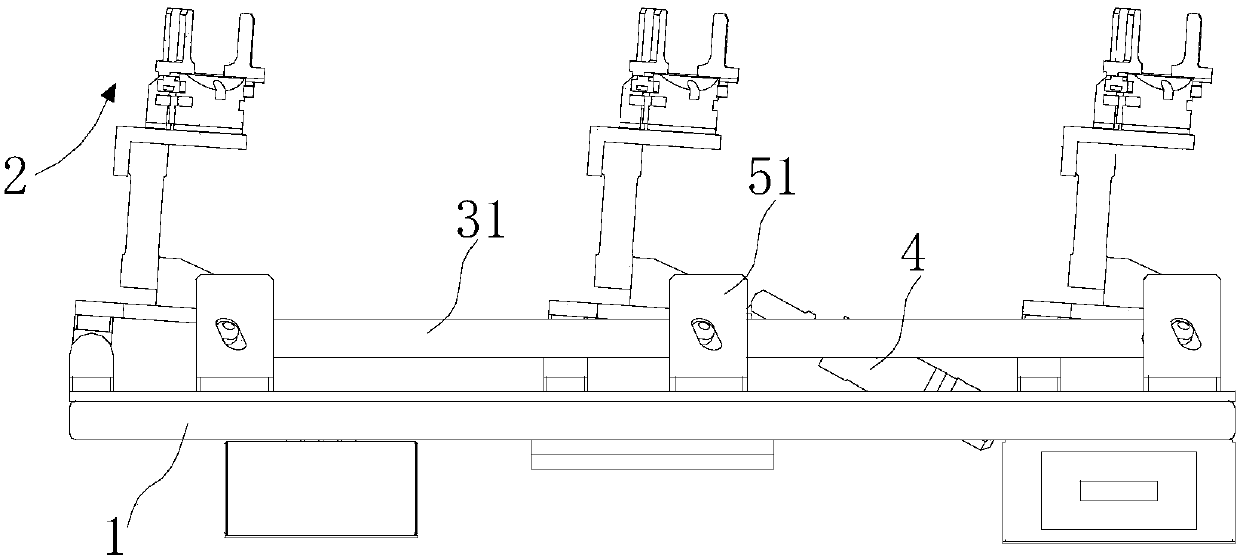

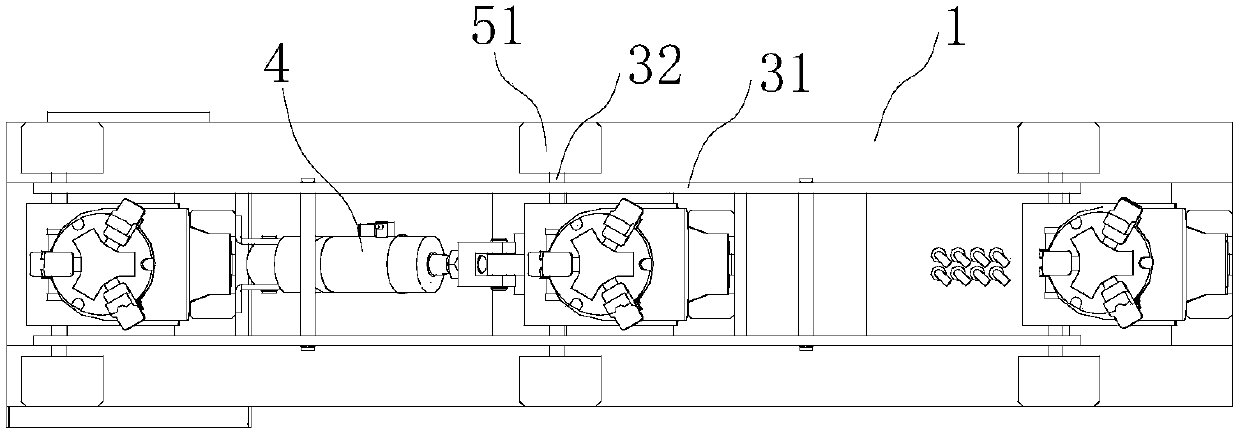

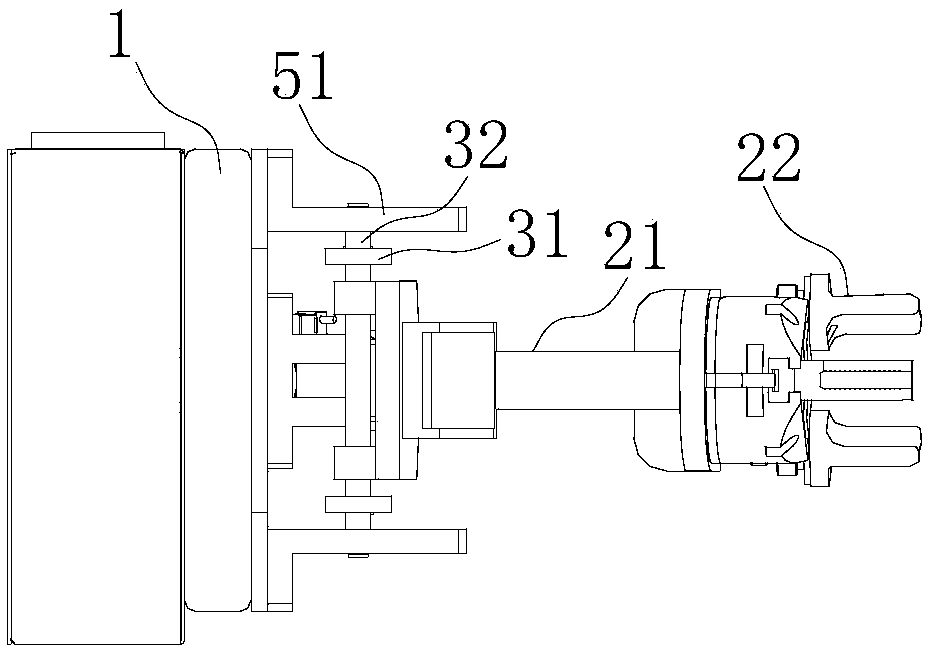

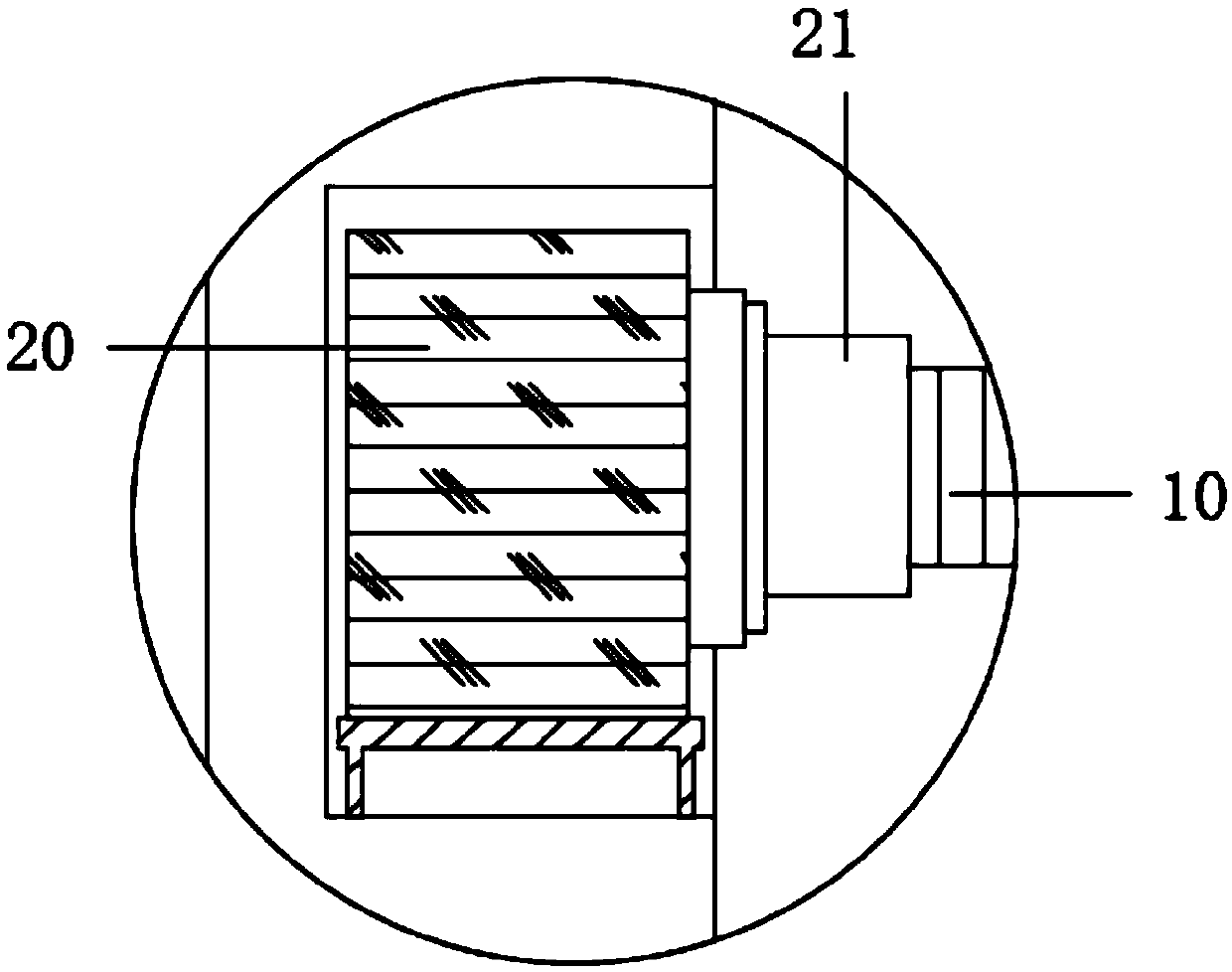

Automatic feeding equipment

PendingCN109434444ALow costAchieve positioningAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses automatic feeding equipment. The equipment comprises a feeding rack, a driving device, positioning and placing devices, a positioning and turning device, and a clamping and conveying device. During feeding, the positioning and placing device located at the first station places a first hexagon nut in a tool clamp in an opening facing downwards mode; then a rotary disc is driven to turn to the next station, the positioning and placing device located at the second station places a second hexagon nut in the tool clamp in the opening facing downwards mode to enable the second hexagon nut to be stacked on the first hexagon nut; then the rotary disc is driven to turn to the next station, the positioning and turning device located at the third station conveys a bent pipe onto a lifting plate, and the lifting plate is driven by a material turning air cylinder to upwards turn over to enable the bent pipe to penetrate into the two hexagonal nuts in the tool clamp along a curve; and finally the rotary disc is driven to turn to the next station, the clamping and conveying device located at the fourth station integrally clamps materials which are connected in series, places the materials into a conveying plate for temporary storage, and conveys the materials one by one to machining stations for machining through conveying hydraulic cylinders.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Novel hackle clamp device

InactiveCN107447259AEasy to operateAvoid entanglementHackling machinesEngineeringMechanical engineering

The invention relates to a novel hackle clamp device. The novel hackle clamp device comprises an upper clamp plate, a lower clamp plate, two screw assemblies and a drive assembly, wherein the upper clamp plate and the lower clamp plate are oppositely parallelly arranged at interval, the two screw assemblies penetrate the upper clamp plate and the lower clamp plate and are located at two opposite ends of the upper clamp plate and the lower clamp plate, the upper end of each screw assembly is provided with an adjusting end, and the drive assembly is arranged above the upper clamp plate and can move upwards and downwards. The novel hackle clamp device has the advantages that the two screw assemblies are arranged at two ends of the upper clamp plate and the lower clamp plate, hemp is fed through an area between the two screw assemblies, hemp bundle intertwining caused by the fact that hemp bundles are mistakenly placed on the screws, and carding quality and hackled line producing rate are increased; operation of a hemp feeding operator is facilitated, quality and yield can be increased favorably, and the work efficiency of bundle separation can be multiplied.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

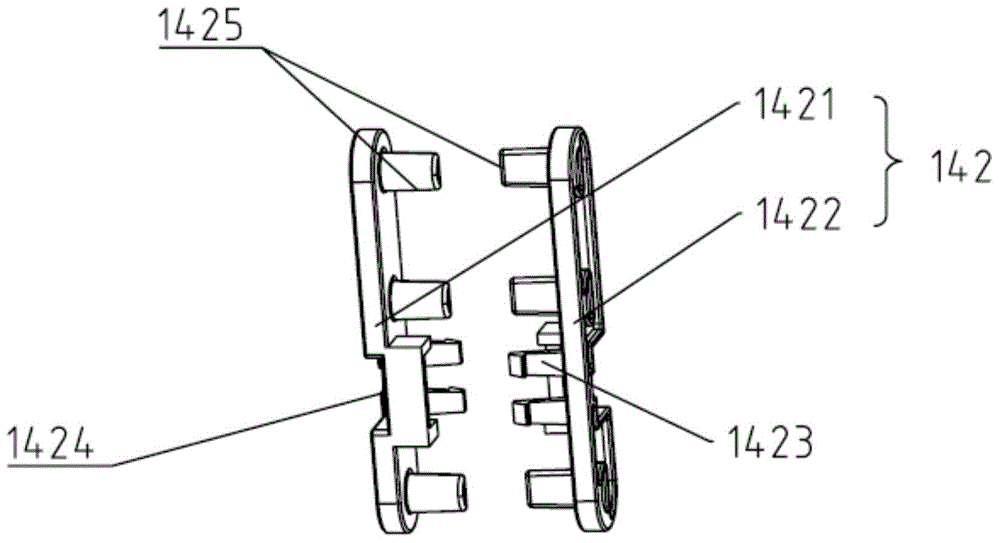

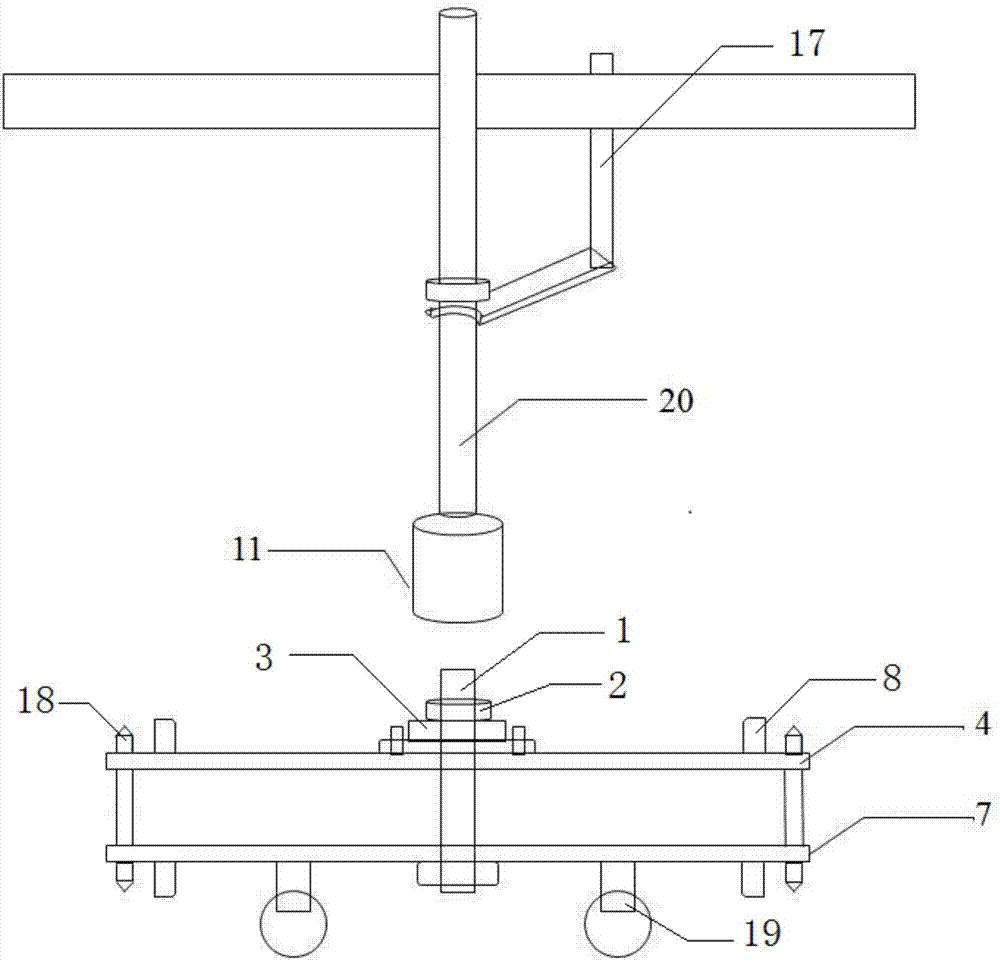

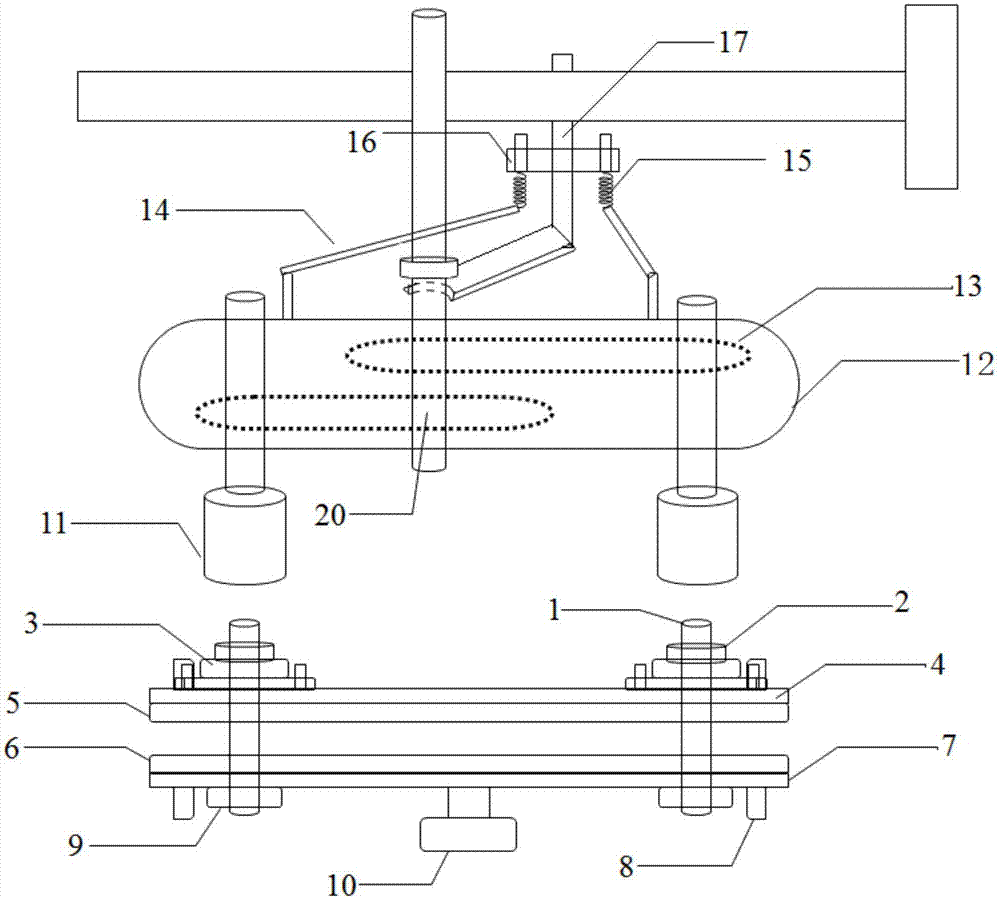

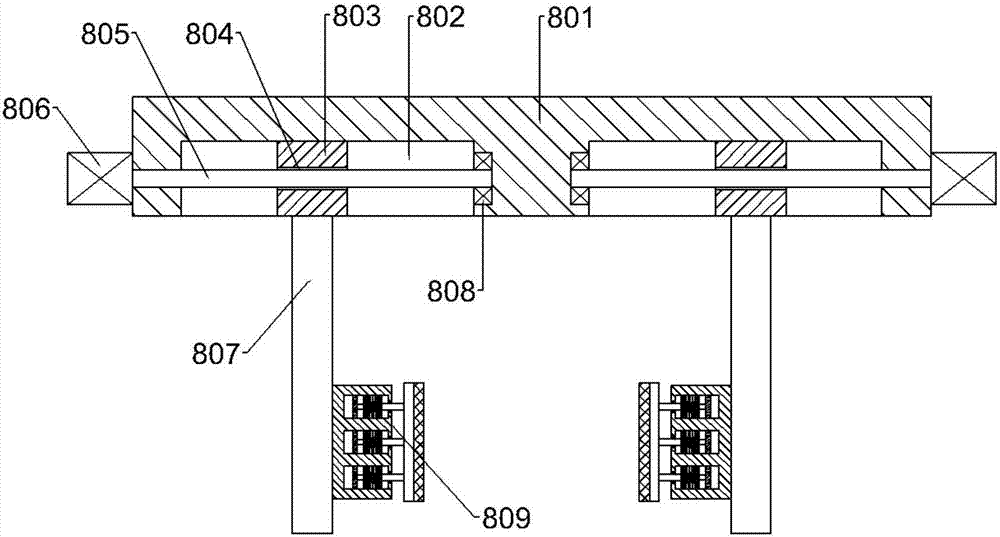

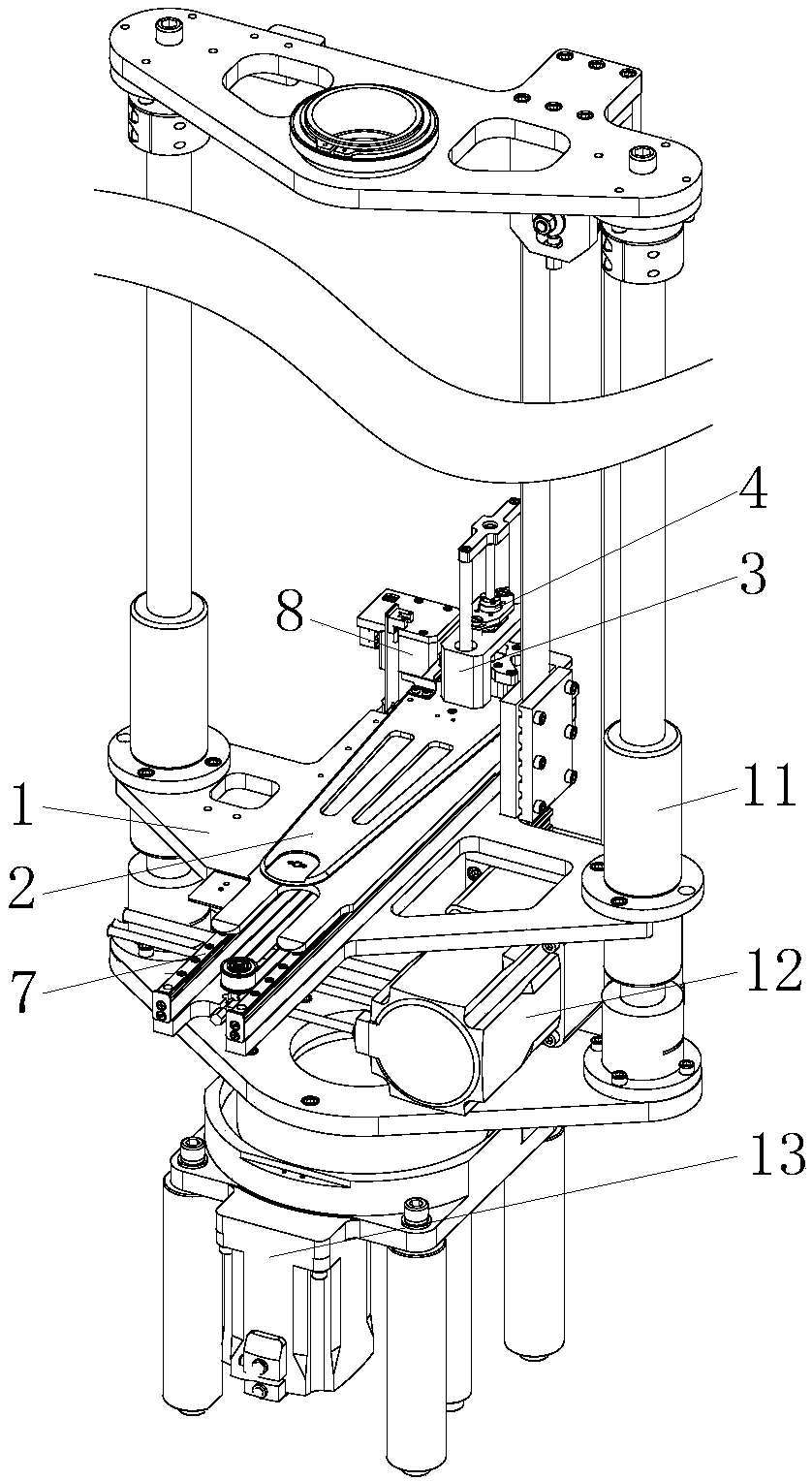

Spinning cake clamp

PendingCN107720247AImprove gripping efficiencyReduced parts countConveyor partsStructural engineeringManufacturing engineering

The invention discloses a spinning cake clamp. The spinning cake clamp comprises an installing plate, a plurality of clamping jaws, a linkage mechanism and a driving mechanism; the installing plate isprovided with a plurality of installing positions arranged in the same direction, the multiple clamping jaws are hinged to the installing positions, the linkage mechanism is used for achieving linkedconnection of the multiple clamping jaws, and the driving mechanism is used for driving linkage of the multiple clamping jaws; the linkage mechanism comprises linkage rods arranged in the direction of the installing position and a plurality of driving rods correspondingly and fixedly penetrating the clamping jaws; and the ends, corresponding to the linkage rods, of the driving rods fixedly penetrate the linkage rods. The multiple clamping jaws on the spinning cake clamp achieves synchronized linkage matching, the multiple clamping jaws clamp different spinning cakes at the same time, and thespinning cake clamping efficiency is greatly improved; and in addition, only one driving mechanism for driving the clamping jaws to move needs to be arranged to achieve driving on the multiple clamping jaws, the number of components is greatly reduced, and the manufacturing cost is reduced.

Owner:HANGZHOU RUIGUAN TECH

Protection device provided clamping device for electronic device machining

InactiveCN107351092AEffective protectionReasonable structural designGripping headsEngineeringThreaded rod

A clamping device for electronic device processing with a protection device, comprising a base, four support legs are fixedly connected to the lower side of the base, two mounting plates are symmetrically fixedly connected to the upper side of the base, and a conveyor belt is arranged between the mounting plates. A support plate is fixedly connected between the tops of the mounting plates, and several vertical movement devices are evenly arranged on the support plate, and the vertical movement devices include a support column, which is fixedly connected with the support plate, and the support column A groove with the opening facing downwards is opened on the top, and a first threaded rod is arranged in the groove. The beneficial effect of the present invention is that the vertical movement device is used to drive the clamping hand to move downward, and the mutual cooperation between the second threaded rod and the moving block is used to realize the encirclement of the two splints to clamp the electronic device. The invention has the advantages of reasonable structural design, high clamping efficiency, good clamping stability, etc., and has certain popularization and application value in the field of electronic device manufacturing.

Owner:牛峰

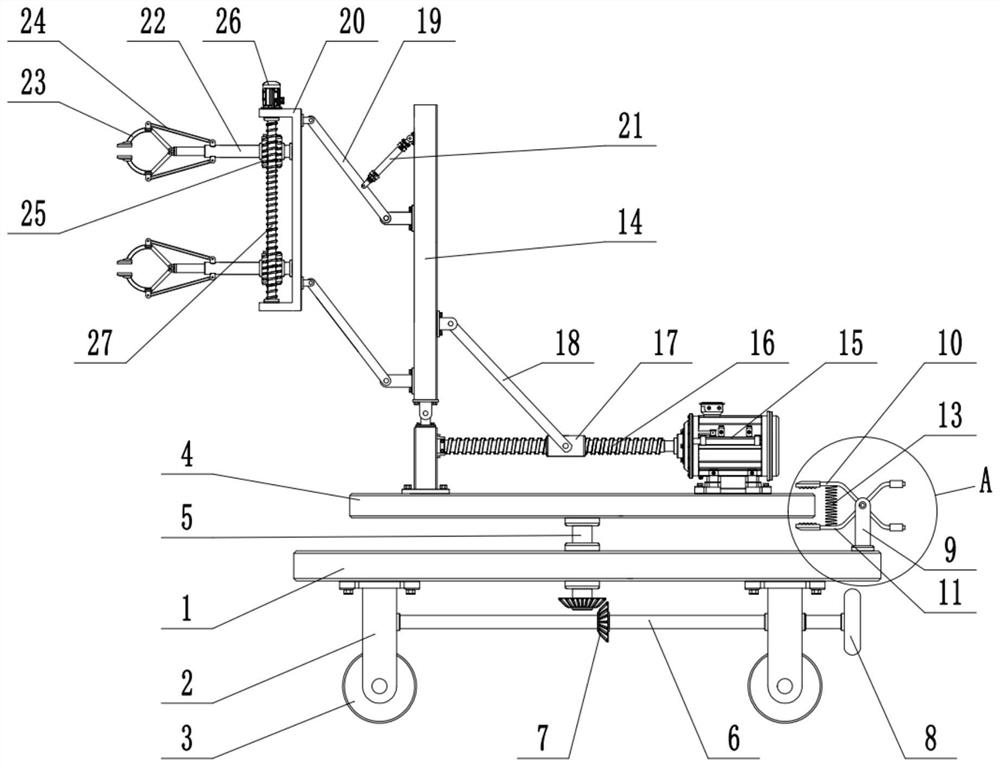

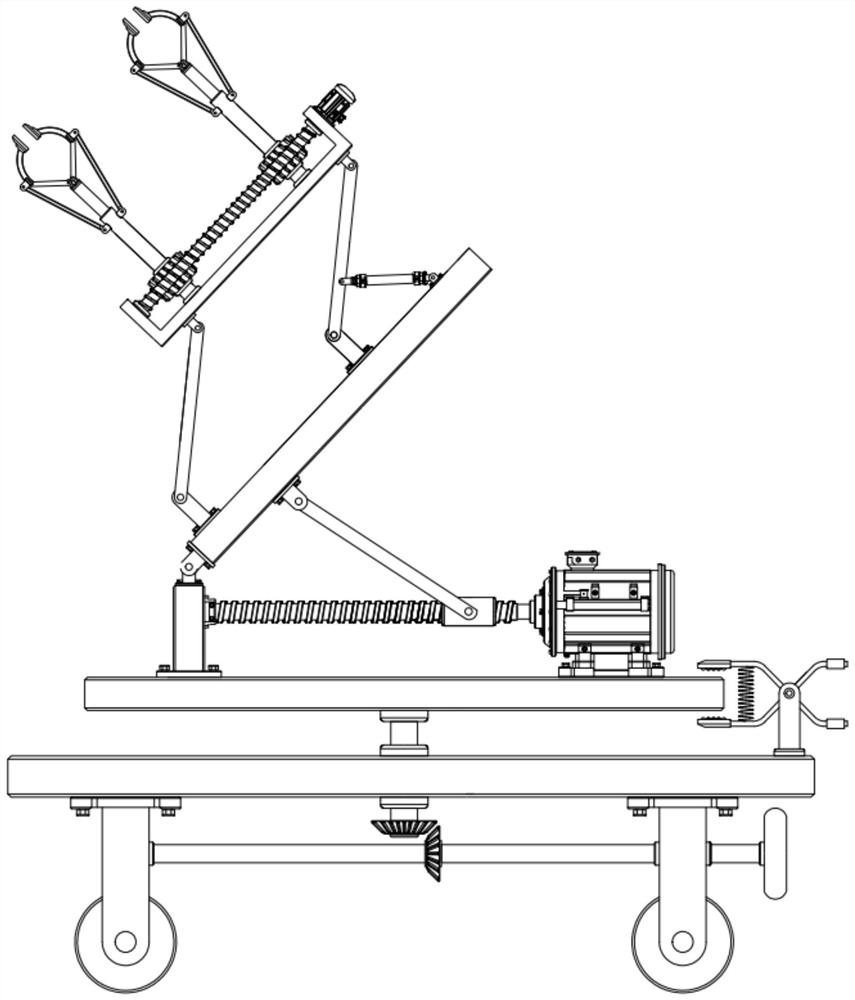

Clamping device used for intelligent manufacturing and convenient to adjust

InactiveCN113120600AHeight adjustableAdjust the clamping angleConveyorsCastorsRotary stageEngineering

The invention relates to the technical field of intelligent manufacturing, in particular to a clamping device used for intelligent manufacturing and convenient to adjust. The clamping device comprises a worktable, a rotating shaft penetrates through the worktable, a rotating table is mounted at the top end of the rotating shaft, a movable plate is hinged to the rotating table, a driving assembly is mounted on the rotating table, and the driving assembly is connected with the movable plate. Two parallel movable rods are hinged to the side wall of the movable plate, a clamping frame is hinged to the ends of the movable rods, a clamping assembly is mounted on the clamping frame, a rotating assembly is mounted on the clamping frame, and the rotating assembly is connected with the clamping assembly. The movable plate is driven by the driving assembly to rotate, so that the movable plate rotates to a proper angle, the rotating table can be driven to rotate through a power assembly, and the orientation of the movable plate is adjusted; and the clamping device is further provided with the rotating assembly, the clamping position can be adjusted according to the appearance of a workpiece, the clamping height, the clamping angle and the clamping position can be conveniently adjusted by the clamping device, and operation is quite flexible and convenient.

Owner:苏州斯睿研智能科技有限公司

Material quickly-grabbing device

Owner:ROBOTECHN INTELLIGENT TECH CO LTD

Demolding and counting machine as well as demolding and arranging device therein

PendingCN112026084AHigh speedIncrease speed to increase productivityDomestic articlesCoatingsEngineeringStructural engineering

The invention discloses a demolding and arranging device. The demolding and arranging device is arranged in a demolding and counting machine, is capable of simultaneously clamping a plurality of gloves as well as arranging, flattening and tidying the gloves, and comprises a base, wherein a following moving frame and a following driving mechanism are arranged on the base; the following driving mechanism is used for driving the following moving frame to move; a glove arranging sliding frame and a sliding driving mechanism are arranged on the following moving frame; the glove arranging sliding frame is capable of moving in the direction perpendicular to the sliding direction of the following moving frame; the sliding driving mechanism is used for driving the glove arranging sliding frame to slide; at least one line of clamping assemblies are arranged on the glove arranging sliding frame; each line of clamping assemblies comprise rotating clamping seats and rotating driving mechanisms; therotating clamping seats are arranged on the glove arranging sliding frame; the rotating driving mechanisms are used for driving the rotating clamping seats to rotate; clamping devices are arranged inthe rotating clamping seats; each clamping device comprises a pair of clamping jaws and a clamping jaw opening-closing driving mechanism used for driving the pair of clamping jaws to perform opening-closing motion. The demolding and counting machine is cooperatively used with a semi-demolding-type glove demolding machine, and the online clamping of the gloves is achieved.

Owner:ZHANGJIAGANG PIONEER AUTOMATION MACHINERY EQUIP

Automatic road garbage cleaning vehicle

ActiveCN107326841AIncreased trash pick-up efficiencyImprove work efficiencyRoad cleaningMotor driveEngineering

An automatic road garbage cleaning vehicle comprises a base, a garbage picking part, a garbage sorting part, a garbage transporting part and four travelling parts. The automatic road garbage cleaning vehicle is characterized in that an arc-shaped sliding block of the garbage picking part is slidably installed in an arc guiding rail, and a gear of the garbage picking part is engaged with an arc rack; a second stepping motor drives the gear to drive the garbage picking part to rotate by a certain angle, then the heights of picking tools are adjusted through three third hydraulic cylinders to enable the picking tools to be located above garbage, later on, a base plate of the garbage picking part is driven through a first steering engine of the garbage picking part to rotate to enable one of the appropriate first picking tool, second picking tool and third picking tool to be downward, and through coordinate work of a second hydraulic cylinder and two first hydraulic cylinders, the picking tools are made to clamp the garbage, so that the automatic road garbage cleaning vehicle selects the different clamping tools according to the different shapes of the garbage; and the garbage clamping efficiency is improved, and the working efficiency is improved.

Owner:FEIXIANG YUANDA AUTOMOBILE MANUFACTORY

Textile bobbin clamping device with locking function

InactiveCN108545463AAchieve grippingRealize the locking functionConveyorsFilament handlingBobbinTextile

The invention discloses a textile bobbin clamping device with a locking function. The textile bobbin clamping device comprises telescopic connecting shafts, a balanced fixing plate, a machine frame body, a sliding connecting rod, movable clamping claws and a clamping frame limiting rod. The textile bobbin clamping device is characterized in that the balanced fixing plate is movably connected withthe bottom end of the machine frame body through a rotating connecting frame, and a driving device is mounted below the middle portion of the balanced fixing plate; an arc-shaped clamping frame is movably connected with the bottom end of the sliding connecting rod, and second sliding blocks are arranged on the outer side, near the arc-shaped clamping frame, of the clamping frame limiting rod; anda U-shaped frame is movably connected with the other ends of the telescopic connecting shafts through movable support lugs, and movable locking brackets are movably connected with the lower ends of the movable clamping claws through movable connecting shafts. The textile bobbin clamping device with the locking function realizes the functions of clamping and locking through the structures such as the movable locking brackets, the movable clamping claws and the arc-shaped clamping frame, the stability of textile bobbins is improved, and the clamping flexibility and the clamping efficiency are improved through matching of the structures such as the rotating connecting frame.

Owner:XIANGSHUI COUNTY XINHONG TEXTILE CO LTD

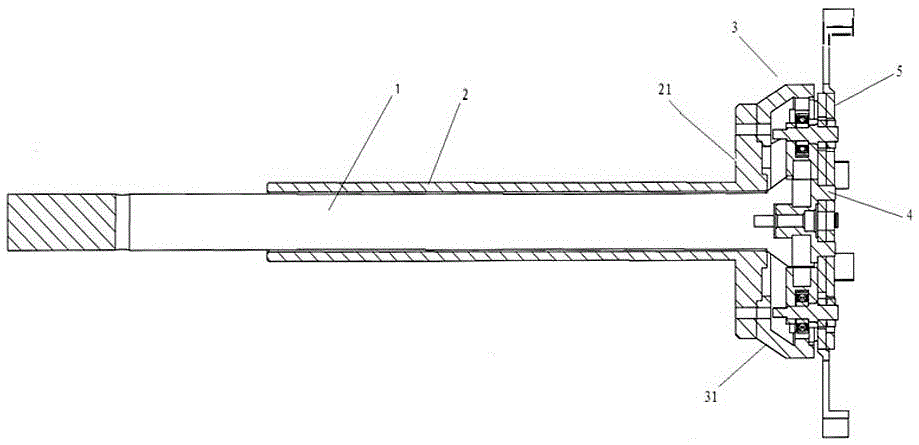

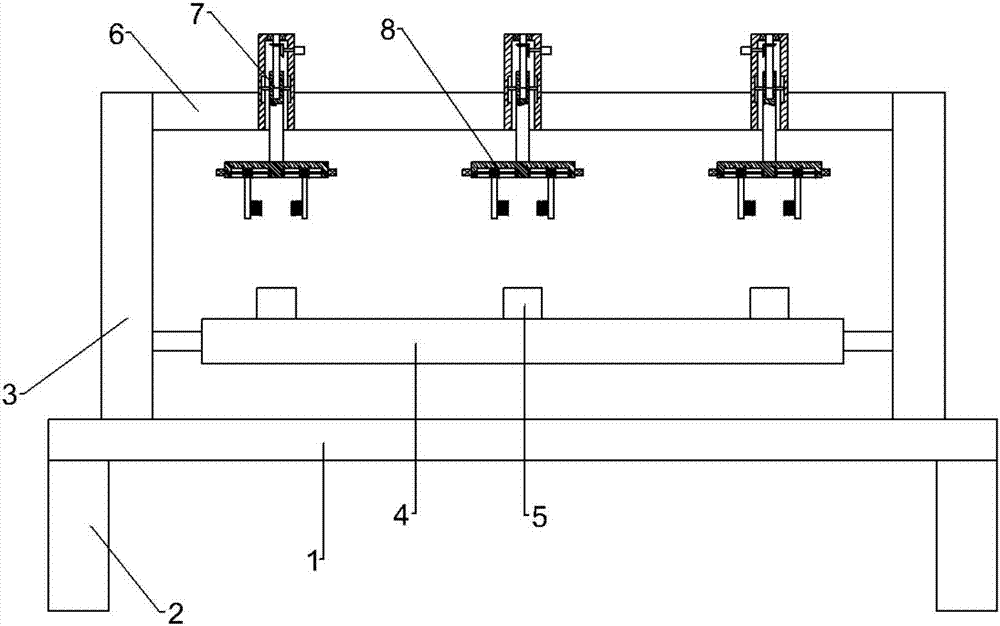

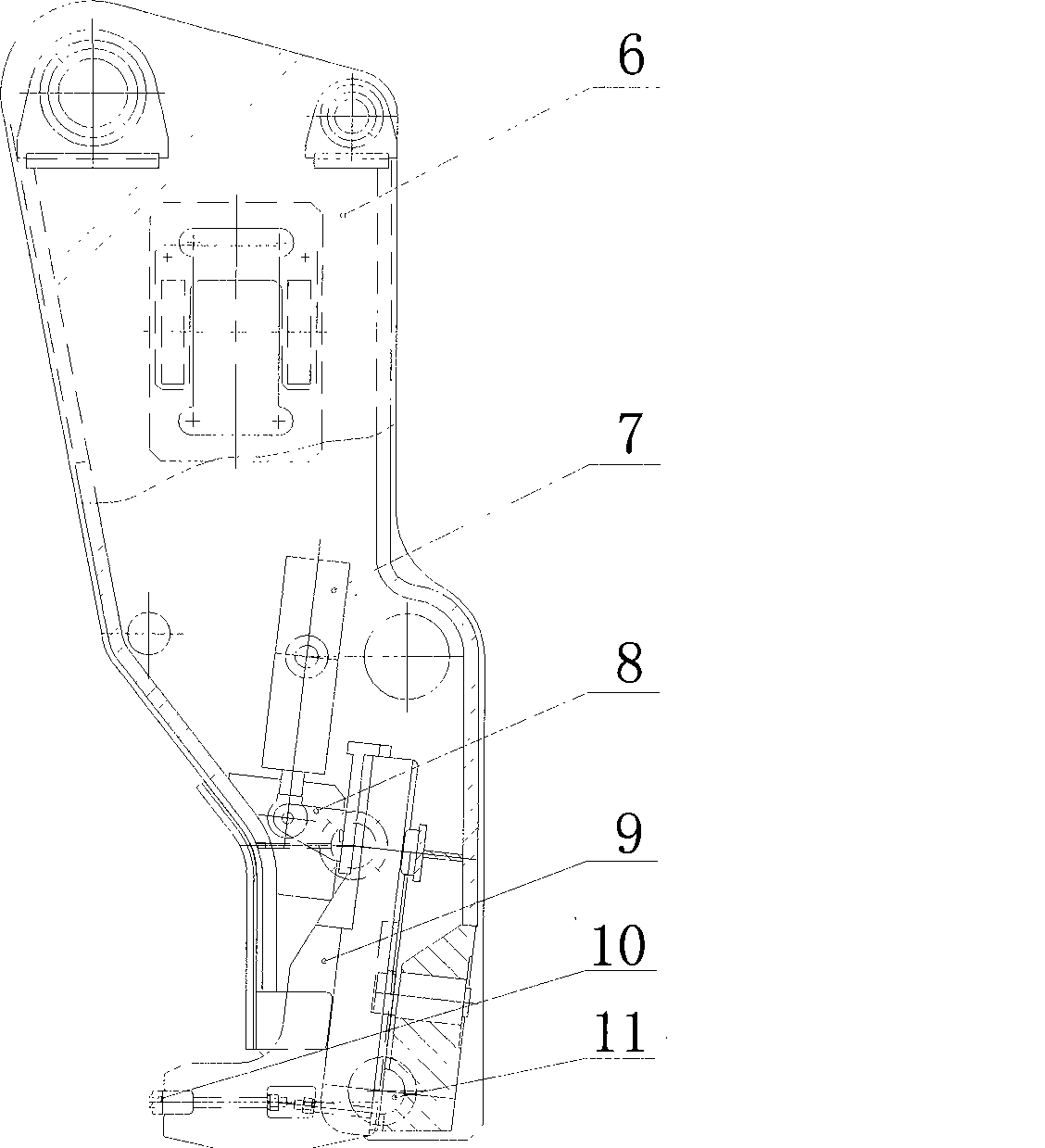

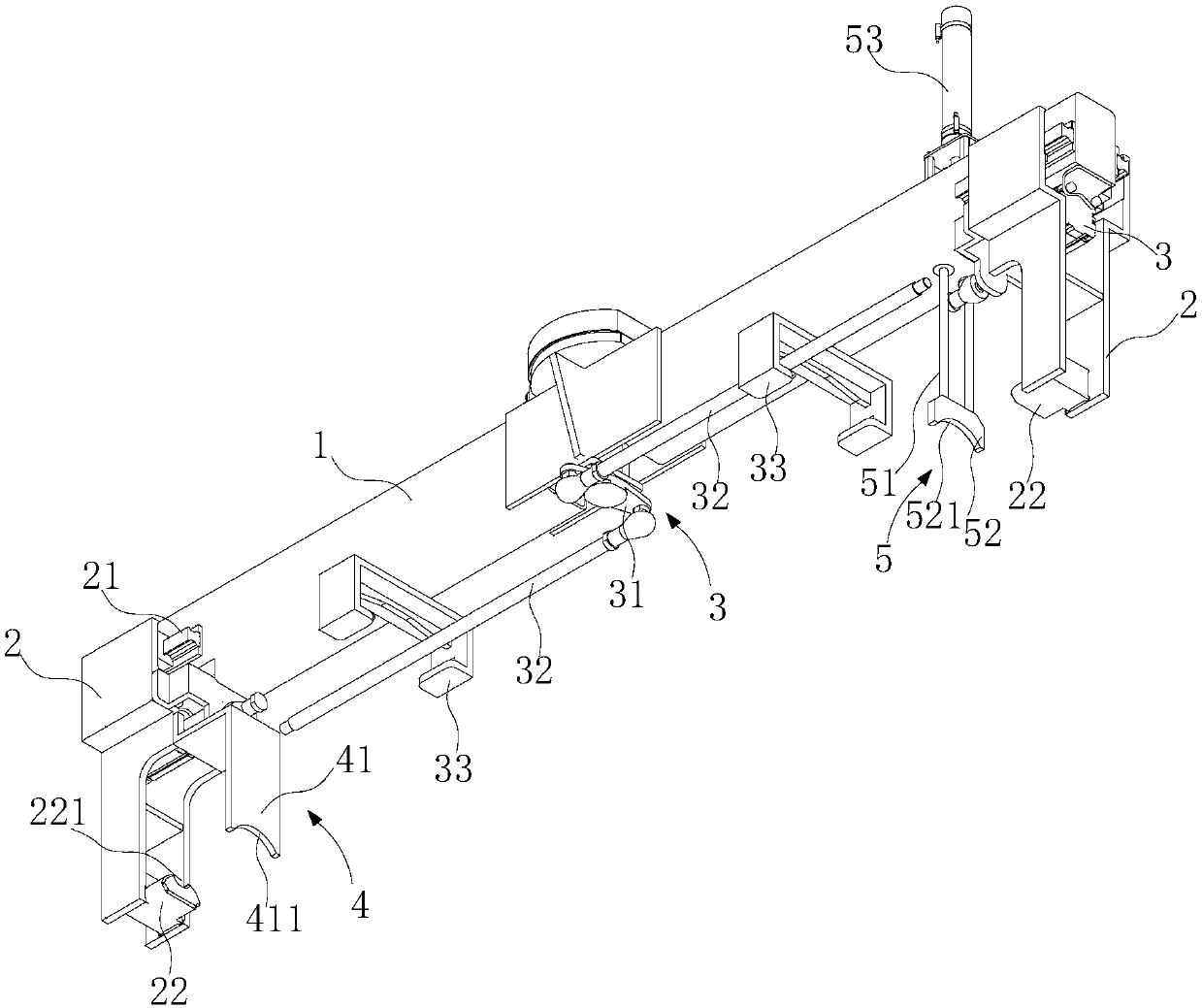

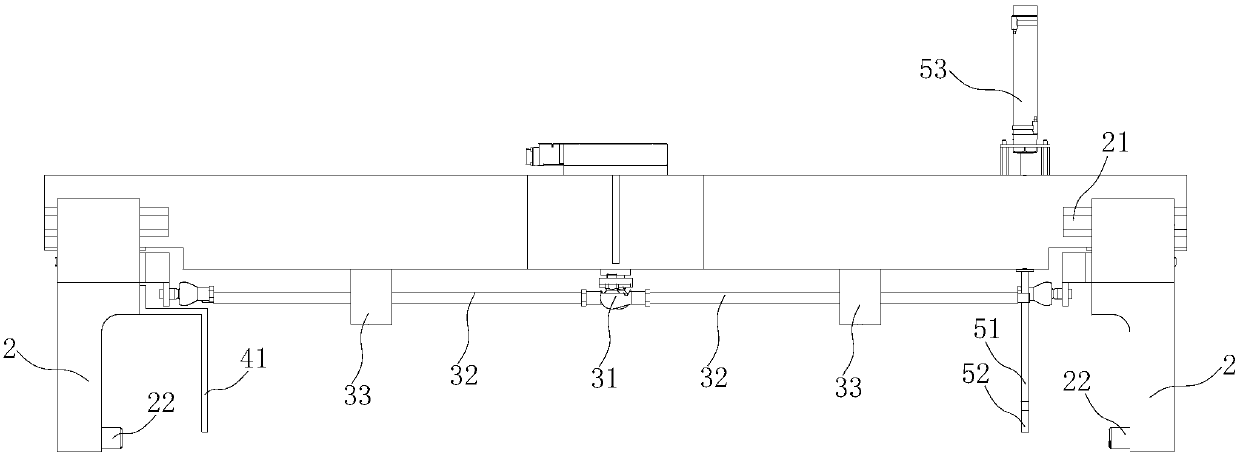

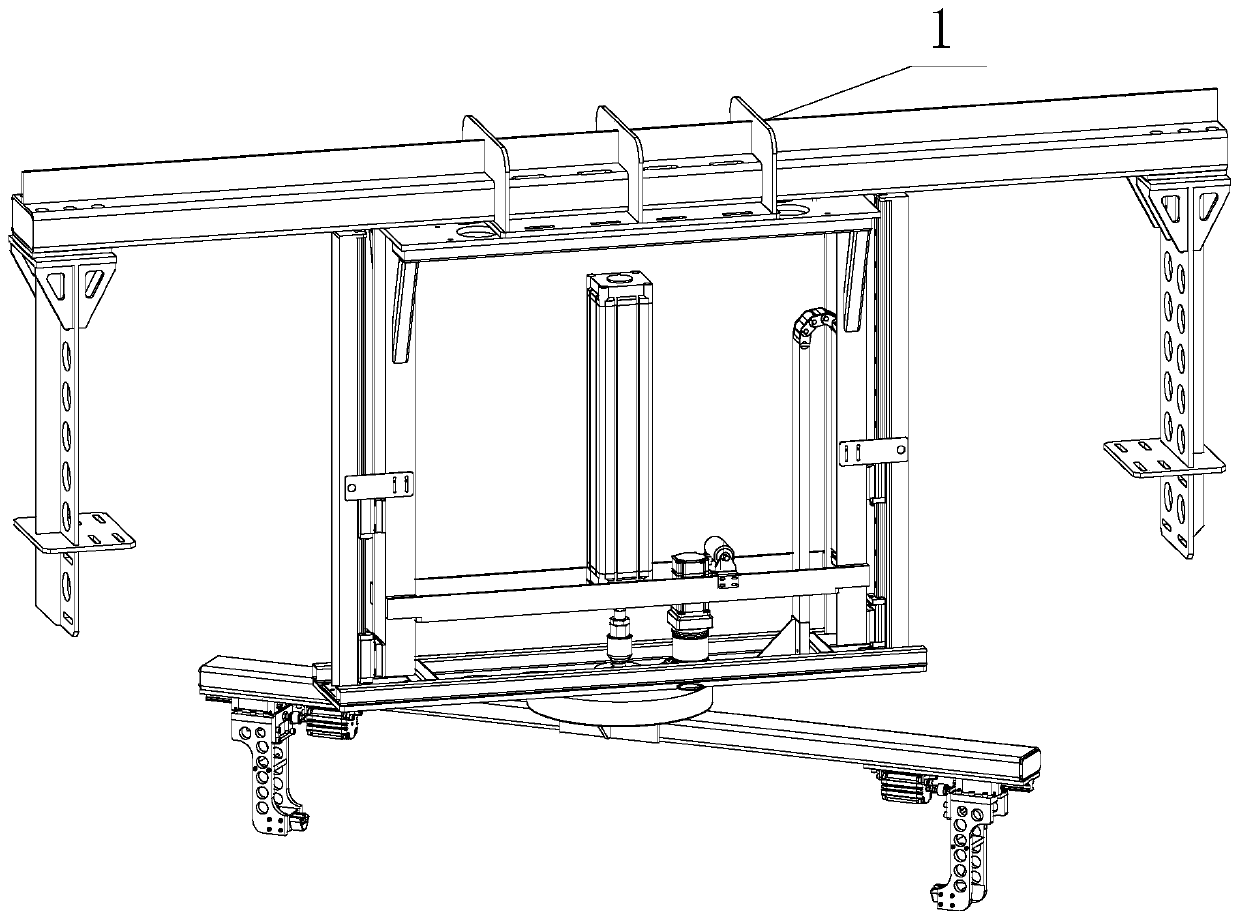

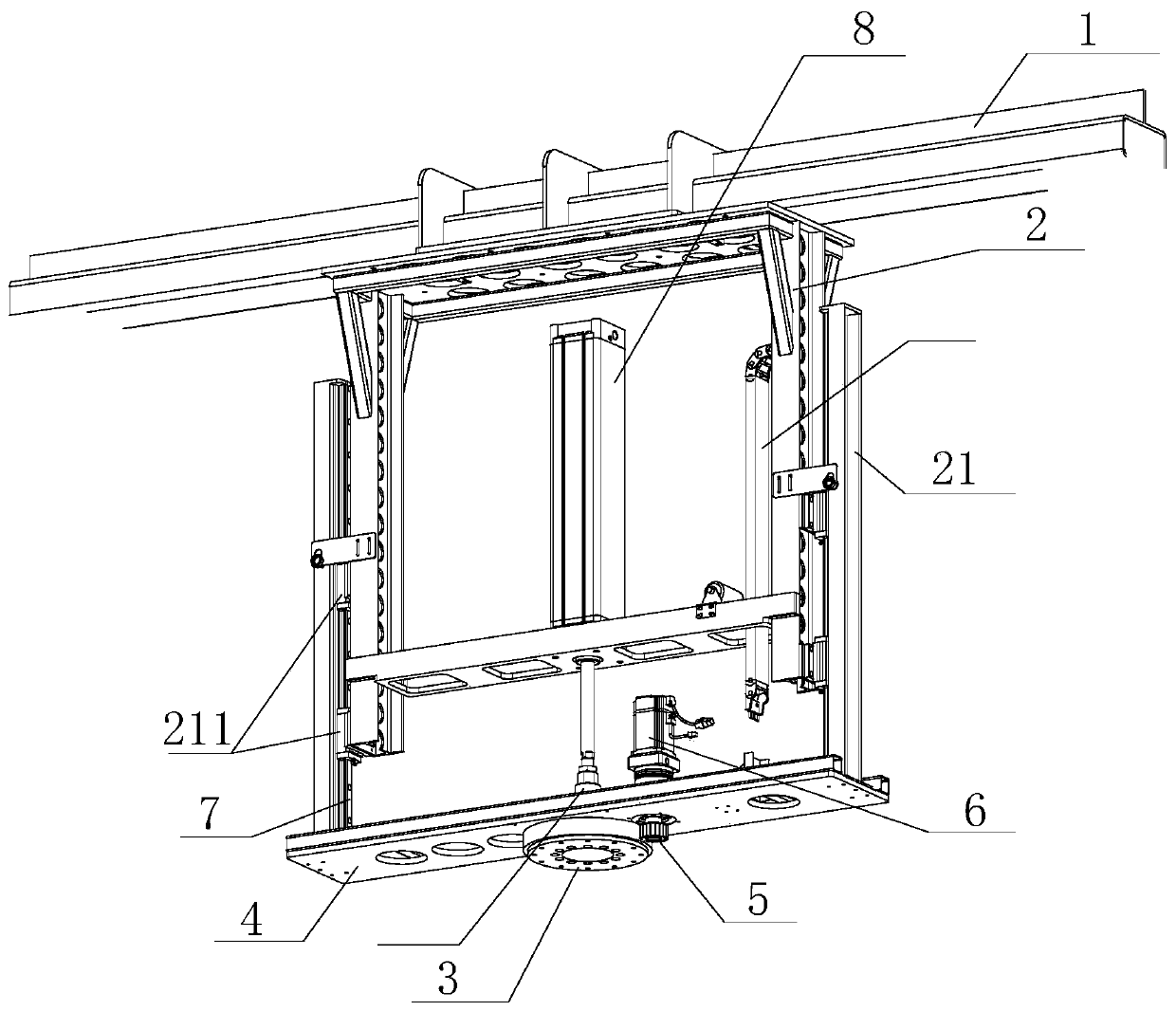

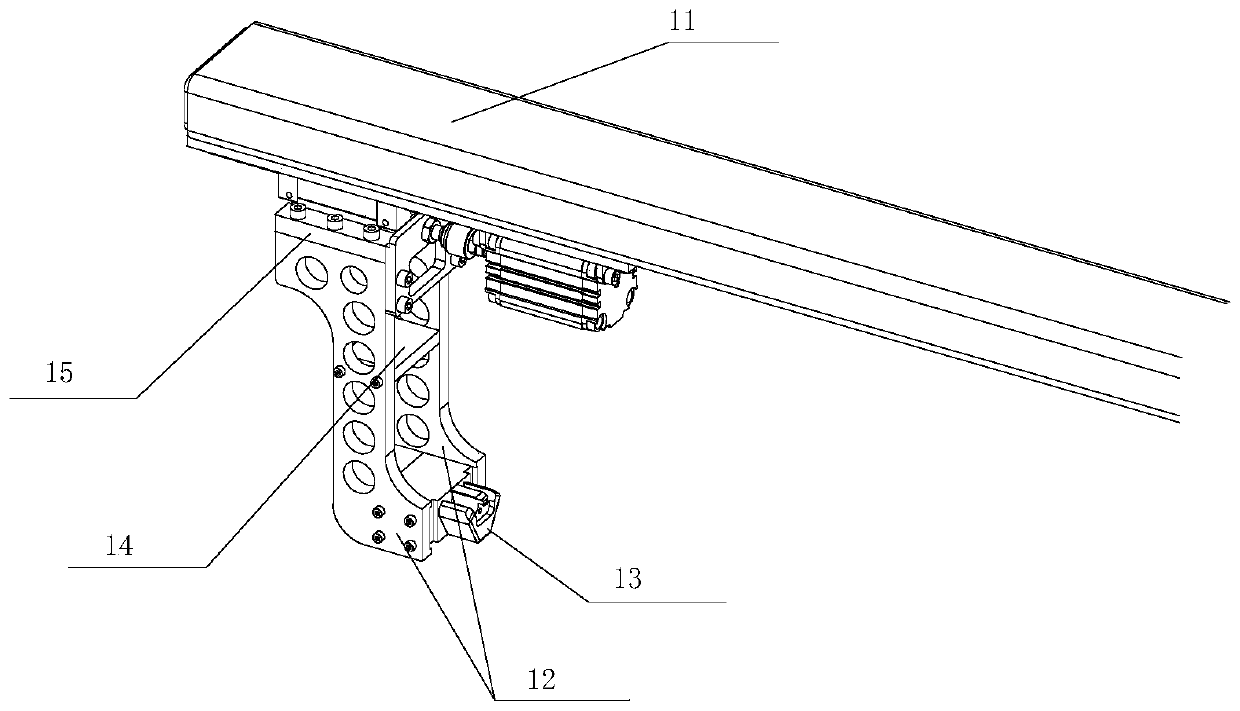

Suspension type clamping device used for wooden door polishing

ActiveCN105196175ARealize fully automatic positioningReduce labor intensityGrinding work supportsHydraulic cylinderStructural engineering

The invention discloses a suspension type clamping device used for wooden door polishing. The clamping device includes a track (1), wherein the track (1) is connected with a sliding block (2); two horizontal retractable hydraulic cylinders (3) are connected with the lower part of the sliding block (2); one horizontal push rod (4) is connected with the left side of one horizontal retractable hydraulic cylinder (3)and another horizontal push rod (4) is connected with the right side of the other horizontal retractable hydraulic cylinder (3); a positioning block (5) is connected with one end of each horizontal push rod (4); a vertical retractable hydraulic cylinder (6) is connected with the lower part of each positioning block (5); the lower part of each vertical retractable hydraulic cylinder (6) is connected with a clamping plate (8) through a vertical push rod (7). The suspension type clamping device used for wooden door polishing, provided by the invention, not only can reduce the labor intensity, but also has the advantages of being high in catching efficiency, tight-clamping efficiency and positioning accuracy, and capable of facilitating polishing.

Owner:临沂佳画电子商务有限公司

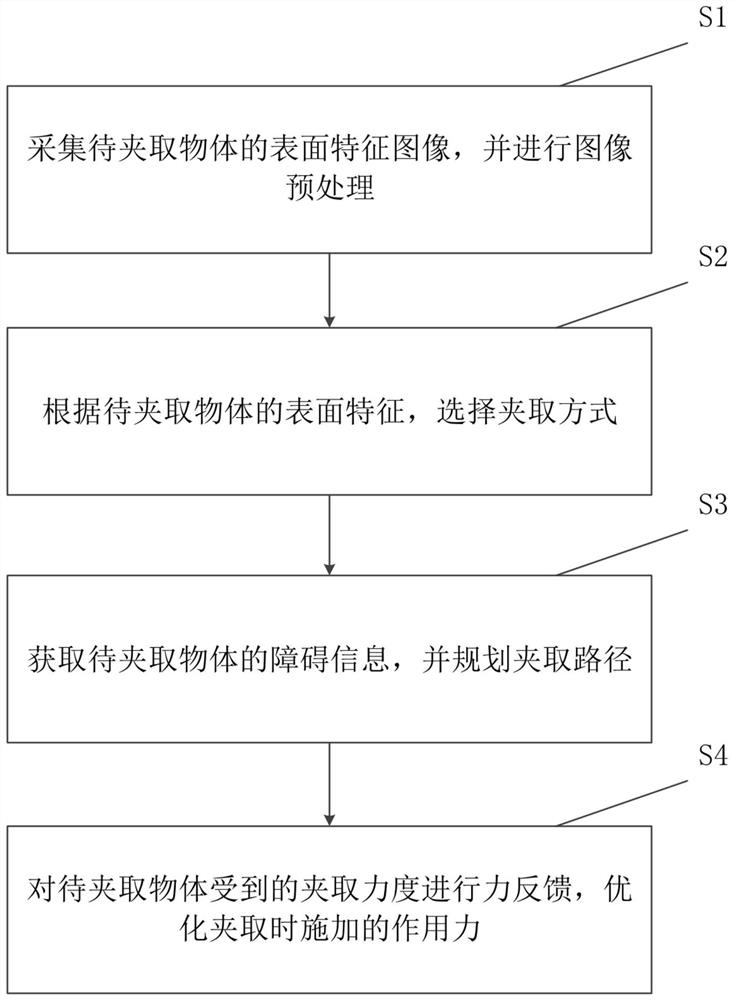

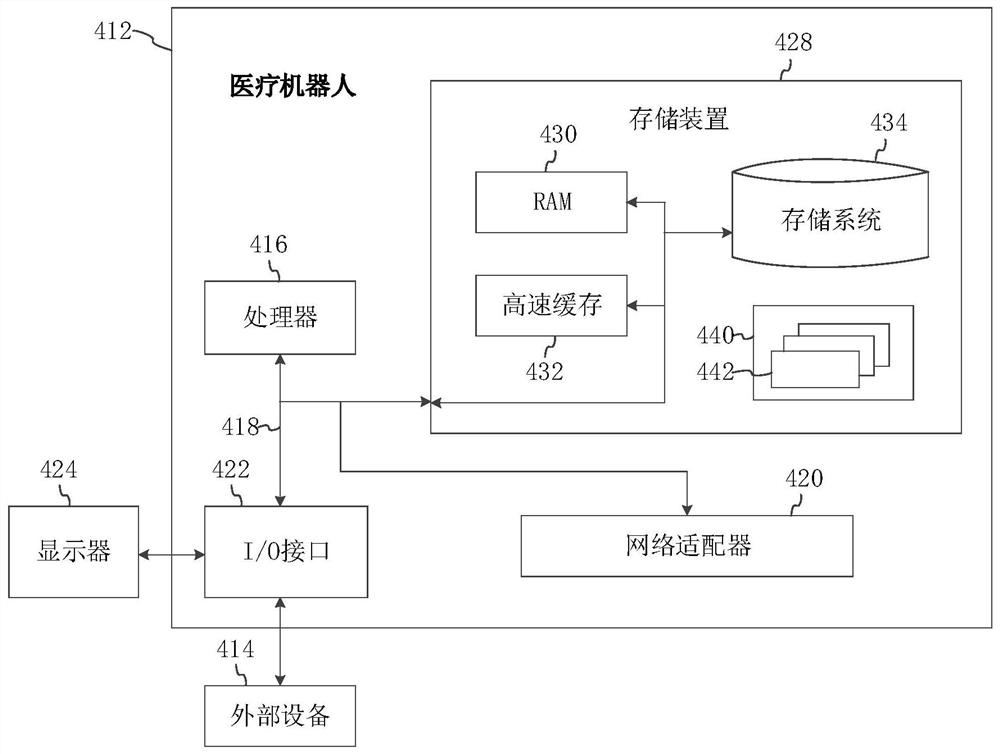

Medical clamping method and system, medical robot and storage medium

PendingCN112967265AFully automatedIncrease forceImage enhancementImage analysisPhysical medicine and rehabilitationMedical robot

The invention discloses a medical clamping method and system, a medical robot and a storage medium, and belongs to the field of medical instruments. The method comprises the steps of collecting a surface feature image of an object to be clamped, and performing image preprocessing; selecting a clamping mode according to the surface characteristics of the to-be-clamped object; acquiring obstacle information of an object to be clamped, and planning a clamping path; feeding the clamping force applied to the object to be clamped back, and optimizing the acting force applied during clamping. According to the invention, the to-be-clamped object can be automatically clamped so as to assist smooth completion of an operation, the automation degree is high, the controllability is high, the clamping efficiency and accuracy are improved, and the labor cost is reduced.

Owner:联仁健康医疗大数据科技股份有限公司

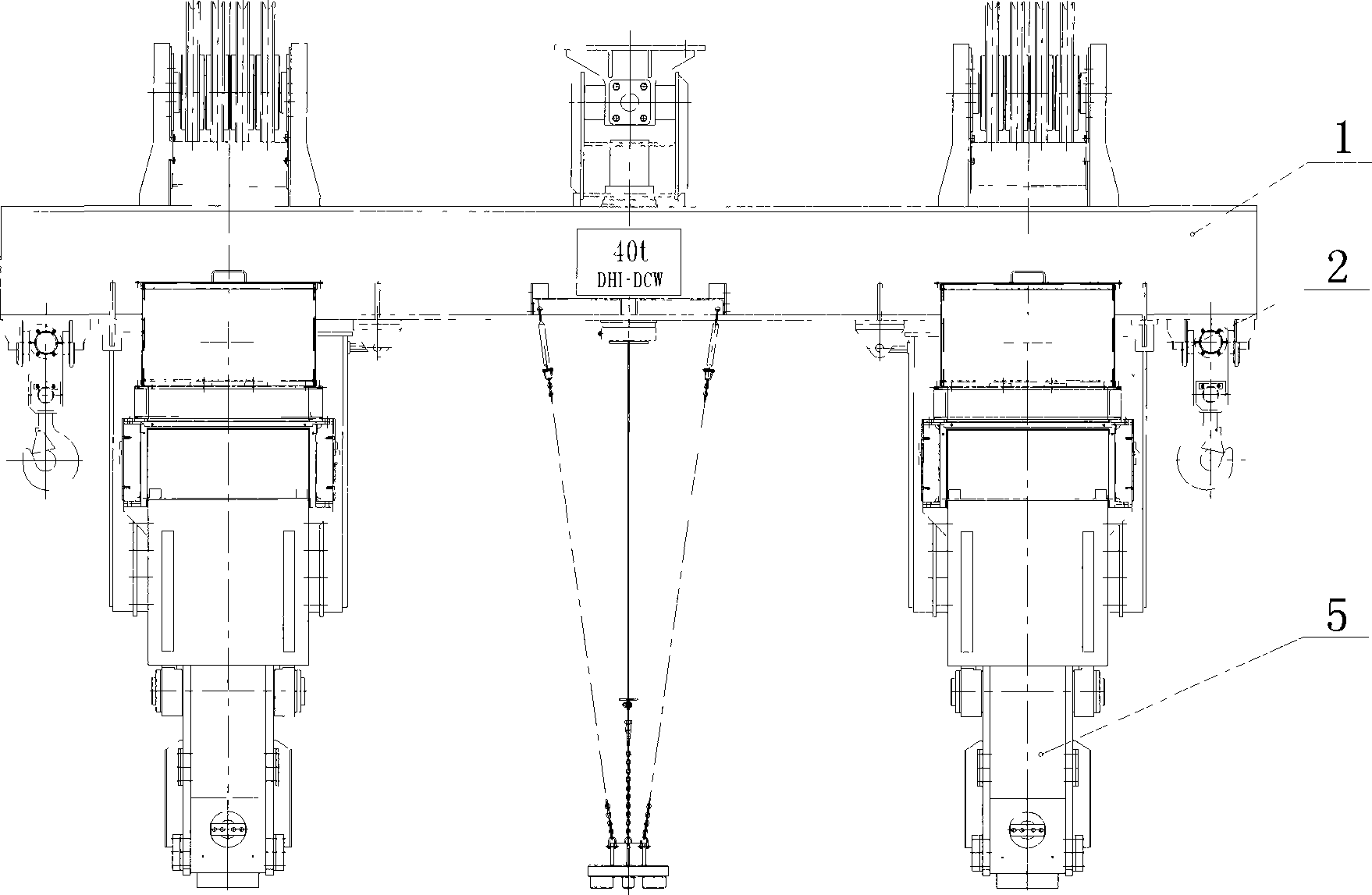

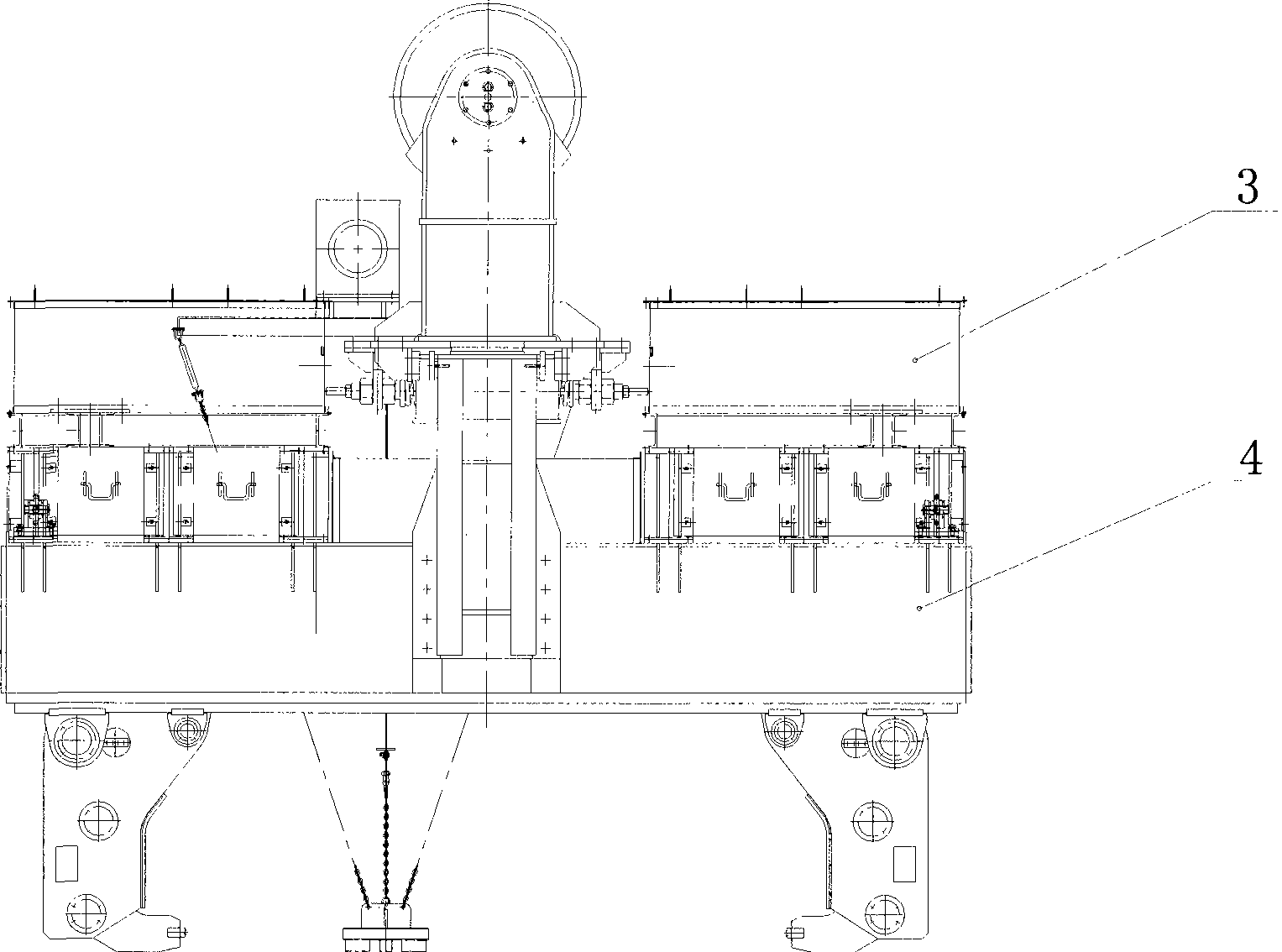

Electric translational type slab clamp with slide compensation mechanism

InactiveCN101434368AImprove safety and reliabilityImprove gripping efficiencyLoad-engaging elementsEngineeringMechanical engineering

The invention discloses an electric translation slab clamp provided with a sliding compensation mechanism, wherein, the sliding compensation mechanism consists of an integrated return spring inside a hydrocylinder, which not only retains the original reset function, but also has the function of actively pushing a guide sliding block to slide backward in place. The invention changes the situations that set teeth skid relative to the slab and slab dropping happen, which are caused by that the guide sliding block does not slide backward in place in an inclined slideway and the clamping force is not enough due to the influence of temperature, lubrication ad the like on the electric translation slab clamp, and solves the slab dropping problem of the clamp.

Owner:DALIAN HUARUI CO LTD

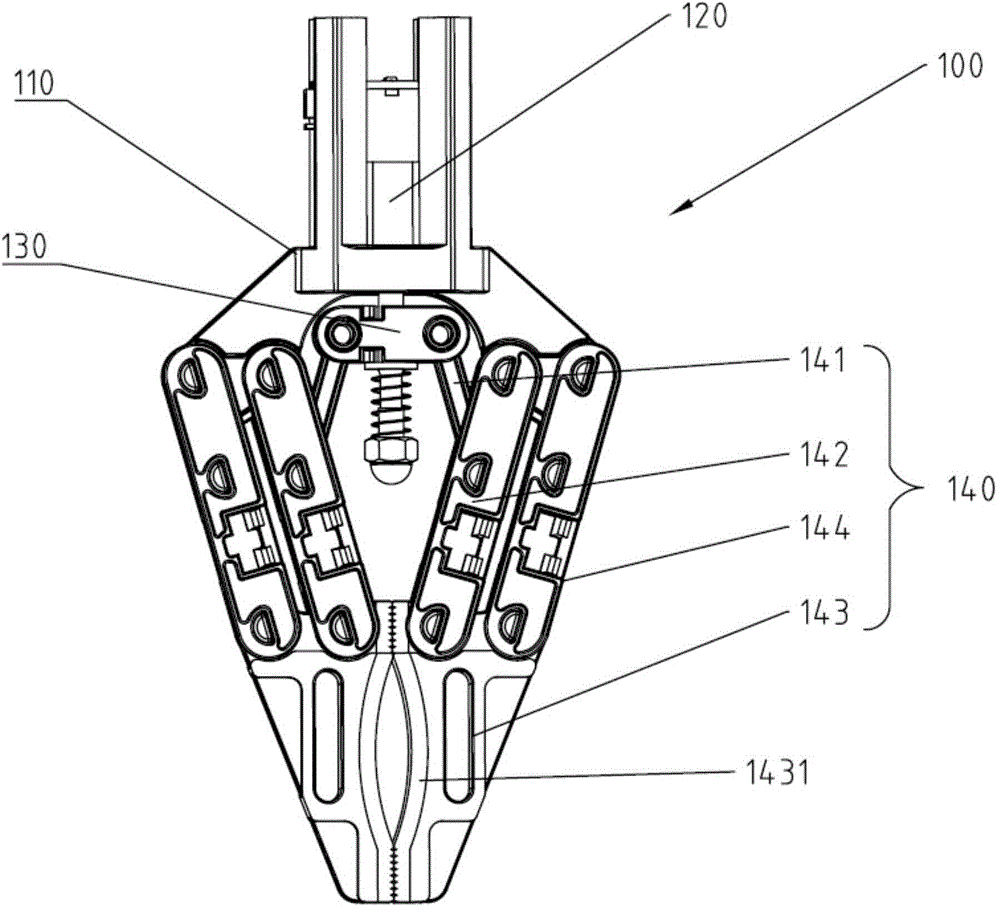

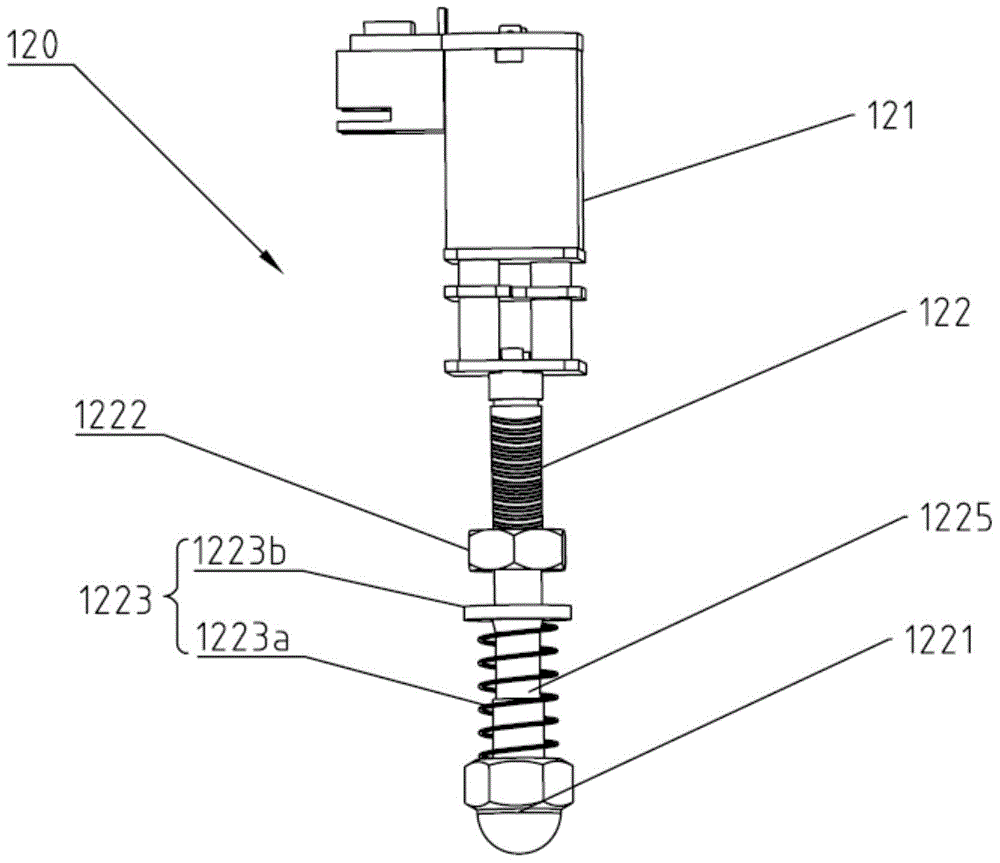

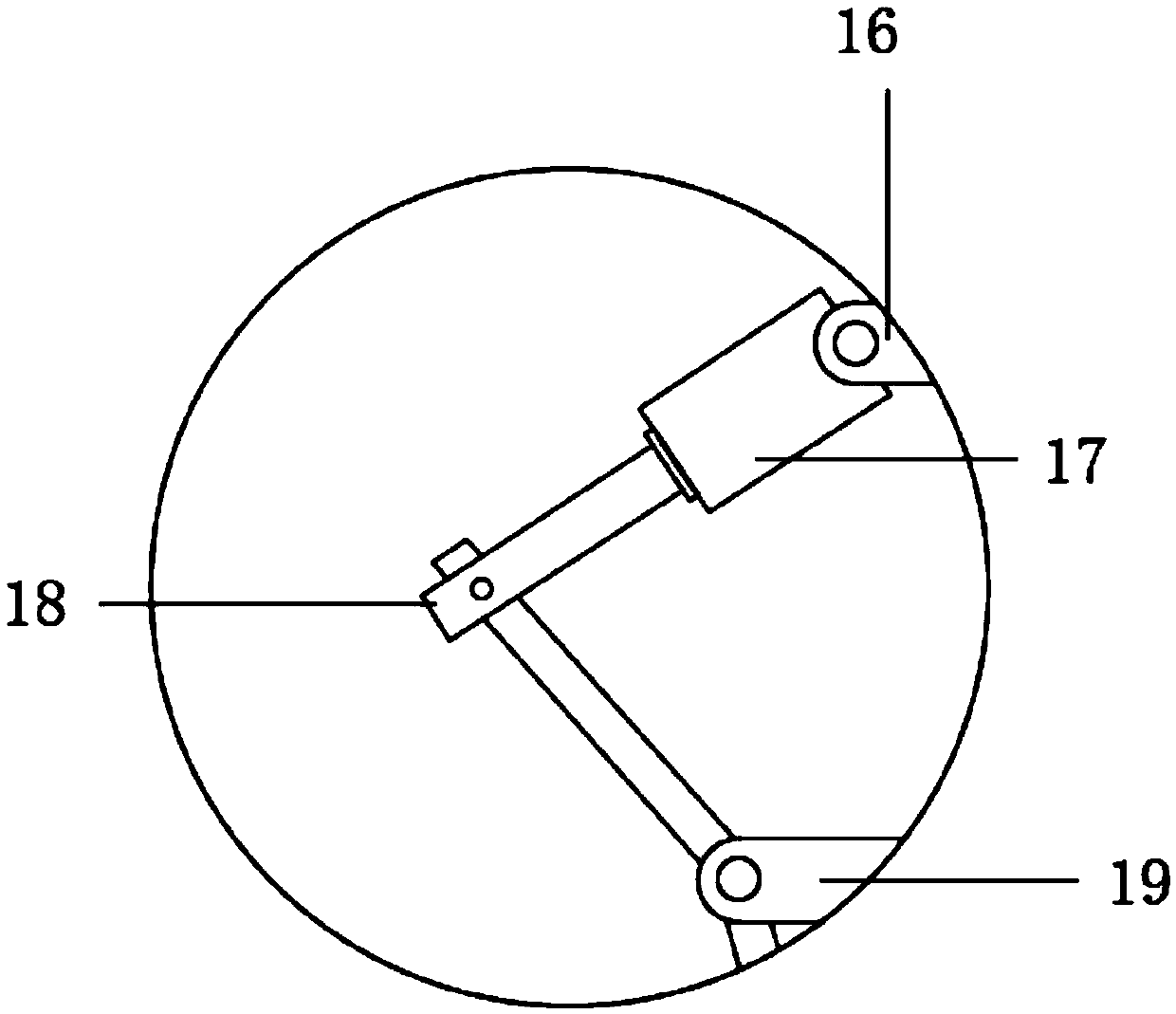

Mechanical gripper

PendingCN111136675AImprove gripping efficiencyStrong gripping stabilityGripping headsEngineeringMechanical engineering

Owner:WENZHOU KEWANG MACHINERY

A method of workpiece grasping based on machine vision

ActiveCN110625644BSolve the problem of contour deformationImprove gripping efficiencyProgramme-controlled manipulatorImage enhancementMachine visionEngineering

The invention discloses a workpiece grasping method based on machine vision, belongs to the technical field of industrial robot grasping, and includes offline operation steps and real-time online operation steps. The off-line operation steps include: collecting the image of the workpiece to obtain the edge profile of the workpiece and calculating the center point of the workpiece, obtaining an accurate edge profile of the workpiece through optimization, and calculating the positioning point and the initial angle β of the workpiece. A database is formed according to the workpiece edge profile and its corresponding initial angle β. The online operation steps include: collecting the real-time image of the workpiece to obtain the edge profile of the workpiece and simultaneously calculating the initial angle β' of the current workpiece. Match the edge profile of the workpiece obtained in real time with the edge profile of the workpiece in the database to obtain the relative rotation angle of the robot's end joint to grab the workpiece and the rotation direction of the robot's end joint, and the robot uses this to grab the workpiece. The invention provides a workpiece grasping method based on machine vision, which can enable a robot to accurately locate the position of the workpiece and effectively grasp it.

Owner:HOHAI UNIV CHANGZHOU

Blank stacking device for autoclaved lime-sand bricks

InactiveCN110626808AImprove code blank efficiencyAchieve lateral movementProgramme-controlled manipulatorGripping headsHydraulic cylinderBrick

The invention provides a blank stacking device for autoclaved lime-sand bricks. The blank stacking device comprises a first bracket, a second bracket and a lead screw, one side of the upper end of thefirst bracket is connected with a guiding rod, the second bracket is connected to the side, opposite to the first bracket, of the guiding rod, the guiding rod is connected between the upper end of the first bracket and the upper end of the second bracket, a guiding rail is arranged at the lower end of the guiding rod, and the guiding rail is connected with a sliding block. By arranging the lead screw and a lead screw motor and arranging scale identification accurate to centimeters on the guiding rod, when a metal clamping arm transversely moves, transverse moving of the metal clamping arm canbe accurately achieved, and accuracy of blank stacking of the metal clamping arm is improved; by arranging a hydraulic cylinder and a hydraulic rod, up-down moving of the metal clamping arm can be controlled, the clamping efficiency of the metal clamping arm is improved, the production efficiency of a factory is improved, and the production cost of a brickyard can further be reduced while manpower and material resources are reduced; and the blank stacking device is simple and compact in structure and convenient to operate, and the blank stacking efficiency of the autoclaved lime-sand bricks is greatly improved.

Owner:钟祥三和建材有限公司

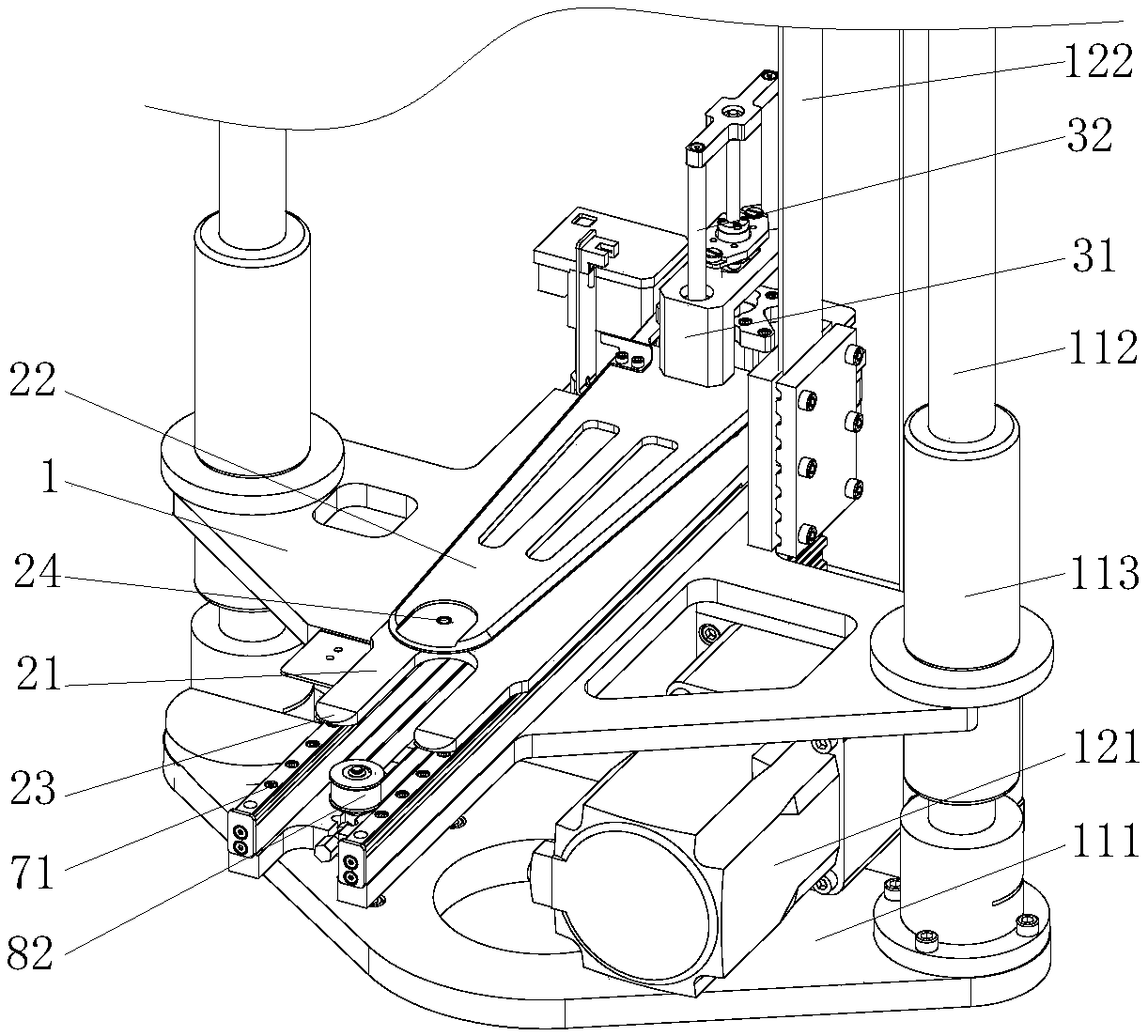

Spinning cake string holding clamp

PendingCN107826897AFor temporary storageImprove gripping efficiencyConveyorsFilament handlingClassical mechanicsEngineering

The invention discloses a spinning cake string holding clamp. The spinning cake string holding clamp comprises a horizontal supporting frame, two vertical supporting frames and two first driving mechanisms, wherein the two vertical supporting frames are in sliding fit with the two ends of the horizontal supporting frame correspondingly; positioning inserting blocks capable of penetrating into spinning cake tubes are arranged on the same horizontal height of the two vertical supporting frames; and the two first driving mechanisms are used for driving the two vertical supporting frames to slideon the horizontal supporting frame. The spinning cake string holding clamp is used for clamping spinning cake strings by a material taking robot so that the material taking robot can clamp spinning cake strings of other specifications to temporarily store the spinning cake strings on a storage frame. The spinning cake string holding clamp is convenient to use, and greatly improves the clamping efficiency of the spinning cake strings.

Owner:HANGZHOU RUIGUAN TECH

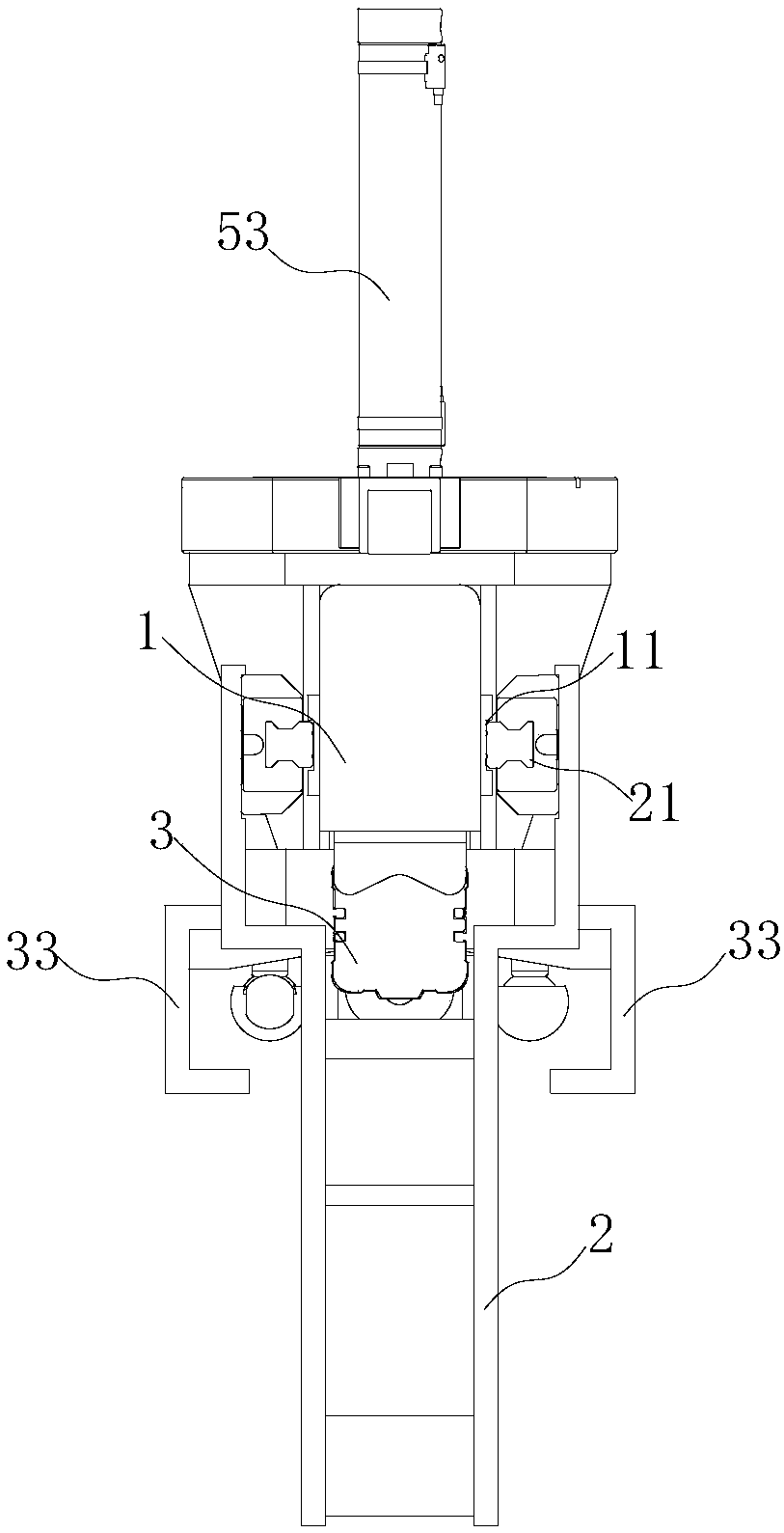

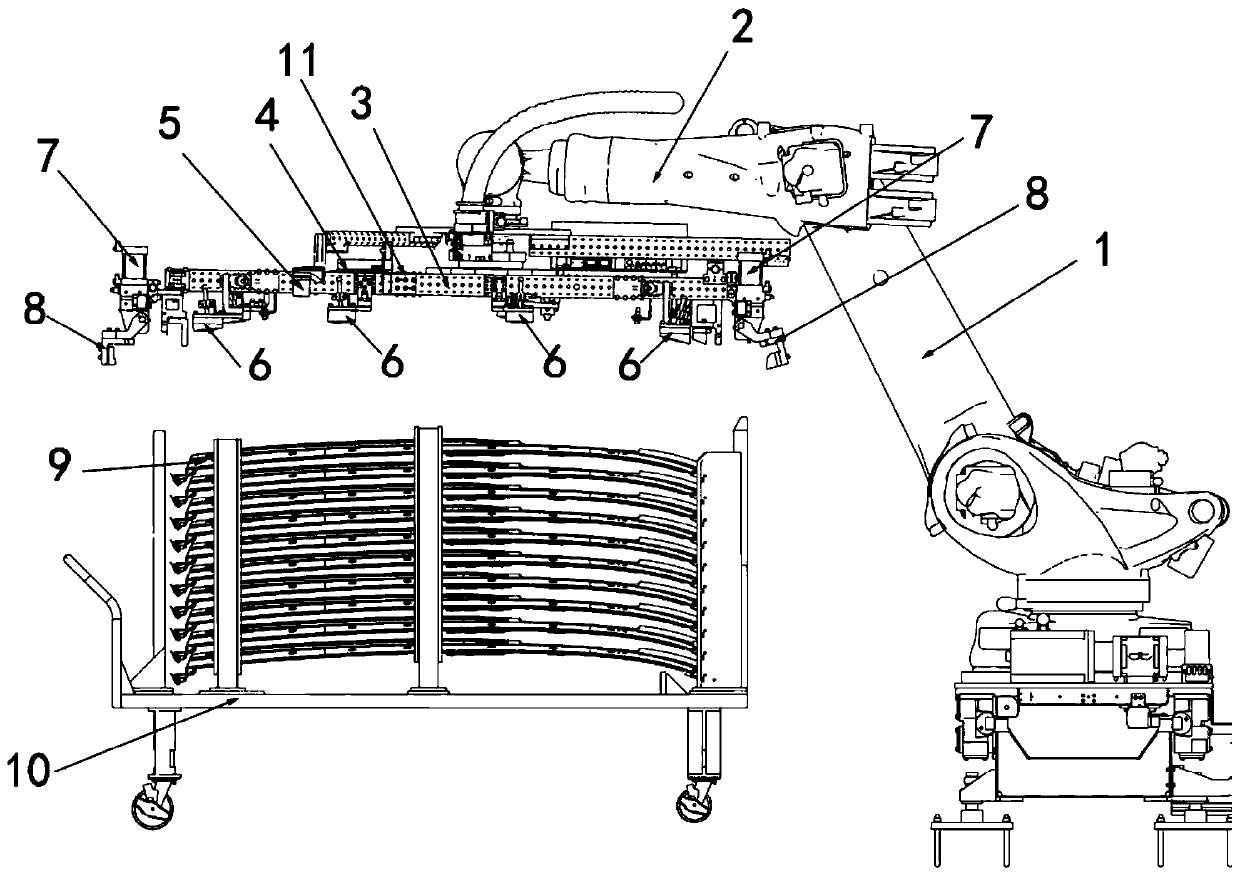

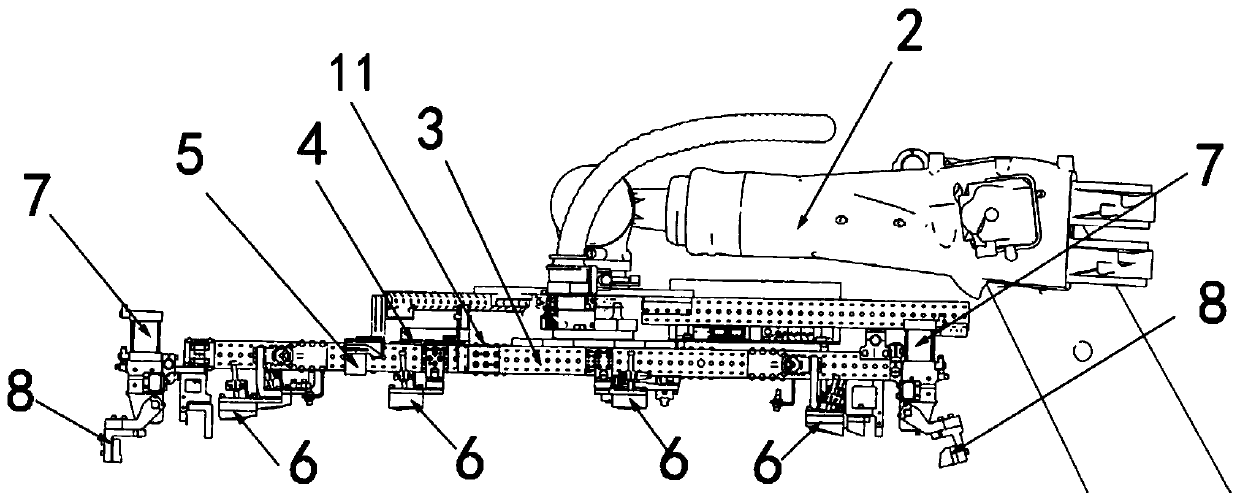

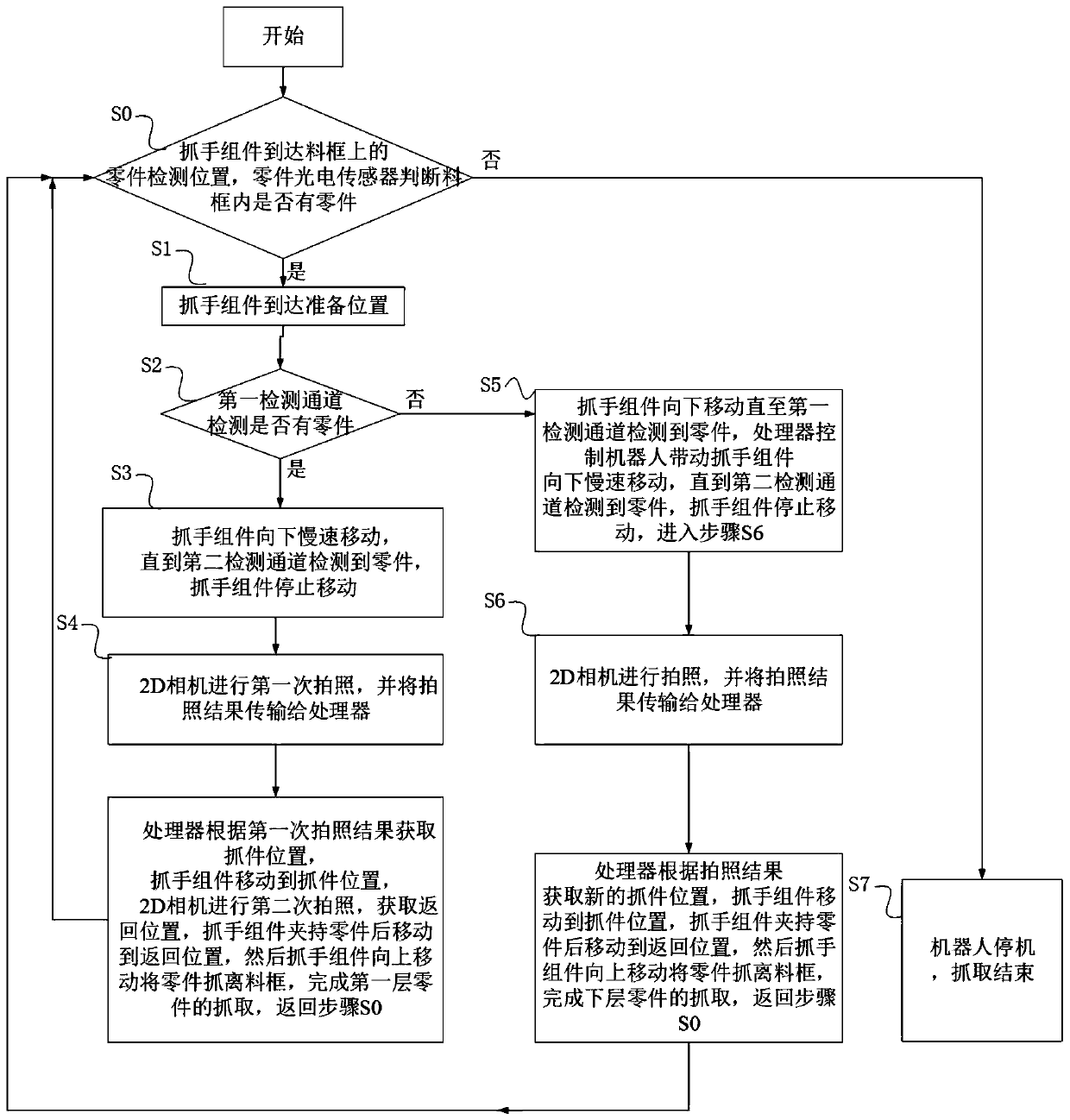

System for grabbing part from material frame under visual guidance of robot and control method

ActiveCN110802599ALow costImprove accuracyProgramme-controlled manipulatorGripping headsEngineeringVisually guided

The invention relates to a system for grabbing a part from a material frame under visual guidance of a robot and a control method. The system comprises the robot, a processor and a grabber assembly. The grabber assembly comprises a main beam, and a part position sensing module and a clamping module which are arranged on the main beam. The part position sensing module comprises a part photoelectricsensor, a dual-channel photoelectric sensor and a 2D camera. The control method includes the steps that the part position sensing module confirms whether there is a part in the material frame or not,obtains the position information of the part and the material frame and obtains the part grabbing position and the returning position according to the position information, and the grabber assembly moves to the part grabbing position to grab the part and then moves to the returning position to move up so as to complete the grabbing of the part. Compared with the prior art, the horizontal positioninformation of the part and the material frame is obtained through the single 2D camera, the robot is guided to move on the basis of the horizontal position information obtained by the 2D camera, thepart is clamped through a telescopic suction cup and a claw, the device cost is low, maintenance is convenience, and the grabbing accuracy and stability are high.

Owner:FFT PRODION SYST SHANGHAI

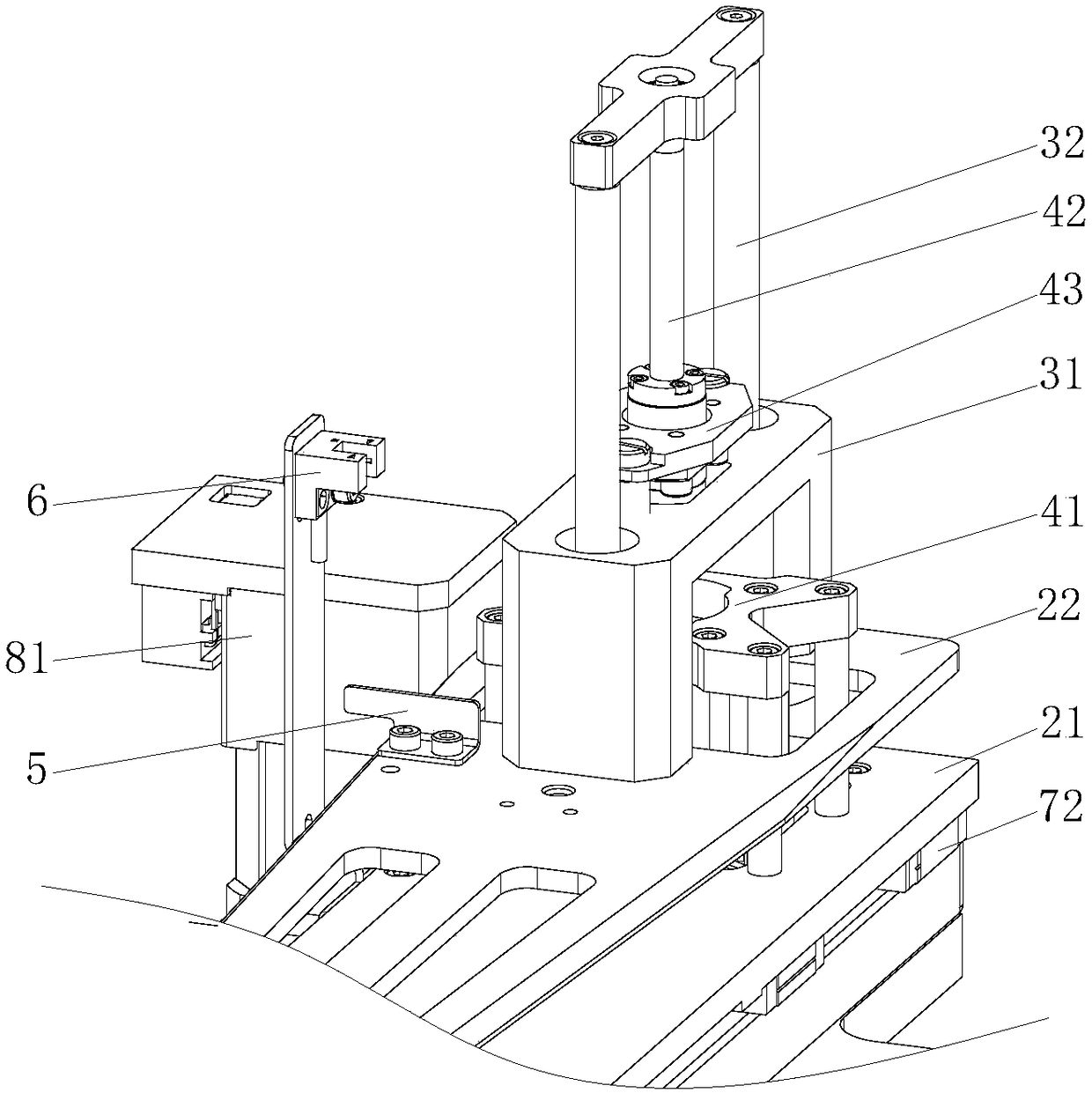

Cross beam-mounted whole string direction changing device and spinning cake string holding device

PendingCN110745642AFor temporary storageImprove gripping efficiencyFilament handlingMechanical engineeringPhysics

The invention discloses a cross beam-mounted whole string direction changing device and a spinning cake string holding device. The spinning cake string holding device comprises a clamp used for clamping spinning cake strings and the cross beam-mounted whole string direction changing device; the cross beam-mounted whole string direction changing device comprises a bearing cross beam and a mountingunit arranged on the bearing cross beam and used for mounting the clamp; and the mounting unit comprises a direction changing base fixedly connected with the bearing cross beam, a rotating support fixedly connected with the clamp, a fixing bottom plate slidably connected with the direction changing base and used for mounting the rotating support, a rotating driving mechanism used for driving the rotating support to rotate relative to the fixing bottom plate, and a sliding driving mechanism used for driving the fixing bottom plate to slide relative to the direction changing base. According to the devices, the spinning cake strings can be clamped through a material taking robot, different directions can be changed for clamping so that the material taking robot can conveniently clamps other types of spinning cake strings to a storage frame for temporary storage, the use is convenient, and the pinning cake string clamping efficiency is greatly improved.

Owner:HANGZHOU RUIGUAN TECH

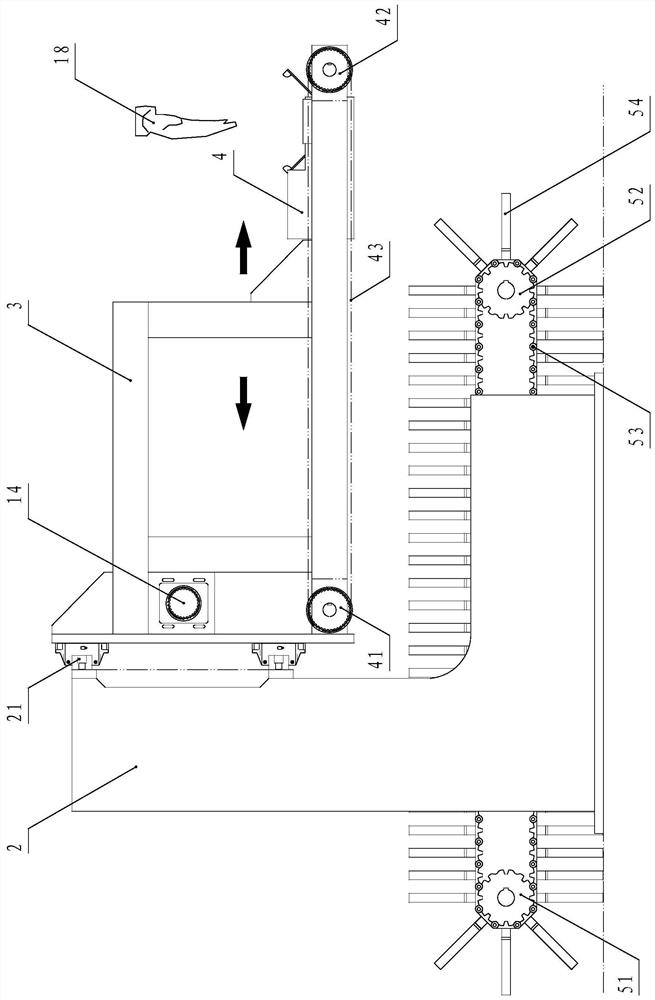

Automatic goods sorting and storing device for stereoscopic warehouse

InactiveCN114803245AGuaranteed accuracyCompact structureConveyorsControl devices for conveyorsEngineeringStructural engineering

The invention discloses a stereoscopic warehouse goods automatic sorting and storage device which comprises an electric guide rail, a conveying mechanism, a lifting mechanism and a control mechanism, the outer wall of the top of the electric guide rail is slidably connected with a limiting mechanism, and the control mechanism comprises a first fixed shell fixed to the outer wall of the top of the limiting mechanism; the lifting mechanism comprises a lead screw rotationally arranged on the inner wall of the bottom of the first fixing shell, the top of the lead screw extends to the position above the first fixing shell, the circumferential outer wall of the lead screw is rotationally connected with a round block through threads, through holes are formed in the two sides of the outer wall of the top of the round block, and the lifting mechanism comprises two limiting round rods slidably arranged on the inner walls of the through holes. According to the invention, through the arrangement of the fixed bracket and the draft fan, the semiconductor chilling plate in work can be blown and cooled, long-time normal work of the semiconductor chilling plate is ensured, the semiconductor chilling plate can dissipate heat and cool an internal electric appliance, normal work of the electric appliance is ensured, and the device becomes more perfect and reasonable.

Owner:深圳云瑾电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com