Spinning cake string holding clamp

A wire cake and jig technology, which is applied in the direction of conveying filamentous materials, conveyor objects, conveyors, etc., can solve the problems of reducing work efficiency and the impact of wire cake classification and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

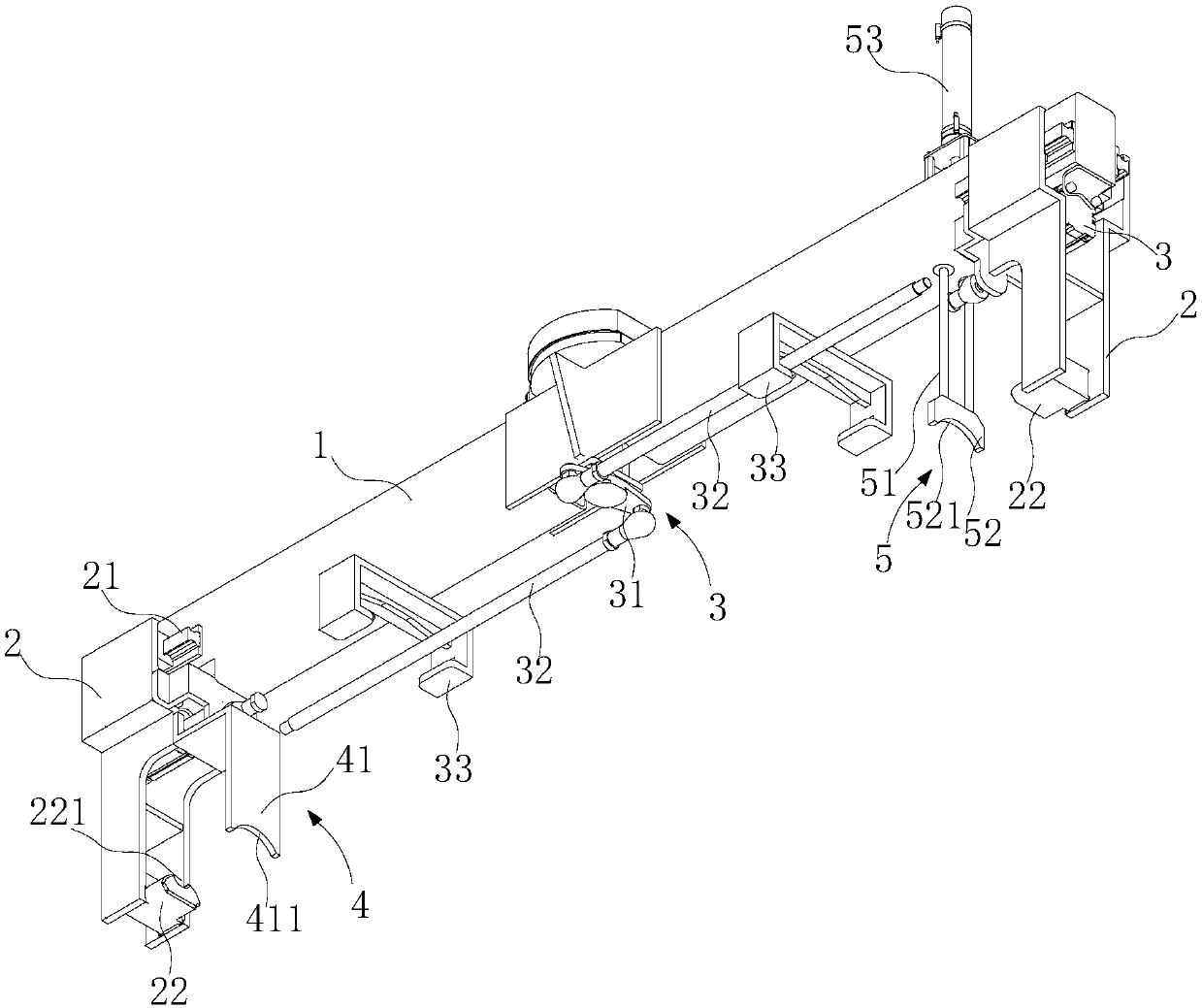

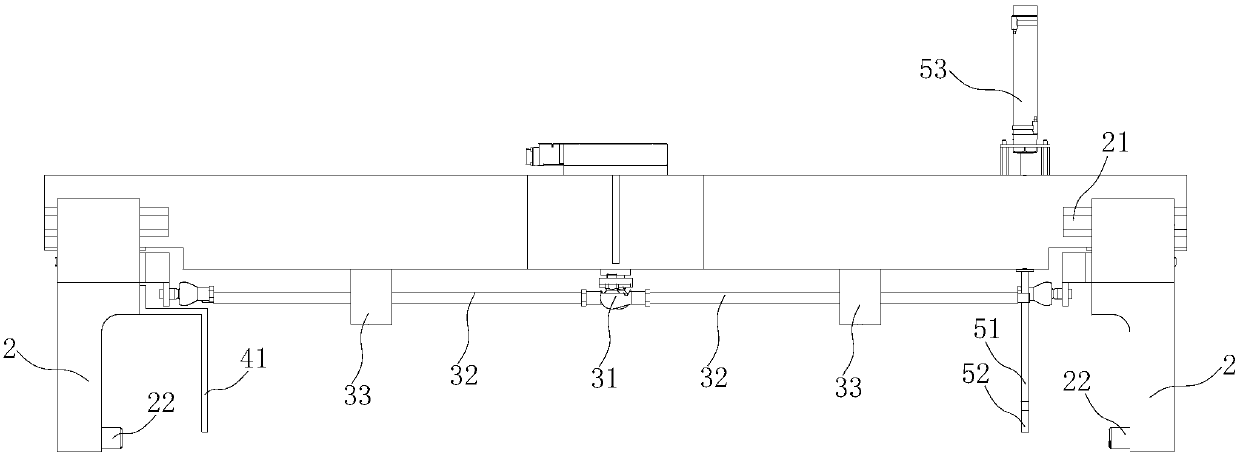

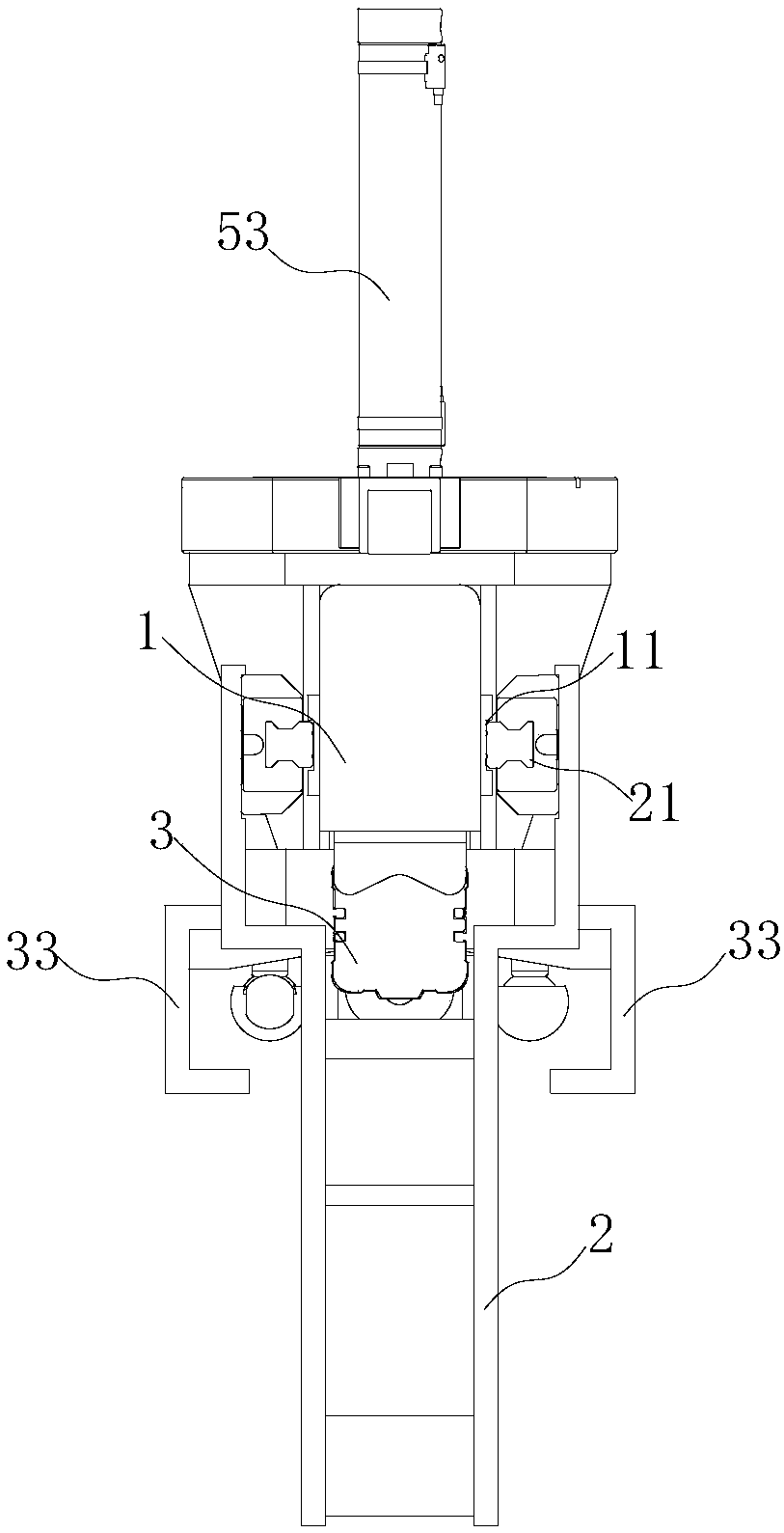

[0034] Such as Figure 1 ~ Figure 3 As shown, the present invention includes: a horizontal bracket 1; two vertical brackets 2, the two vertical brackets 2 respectively slidably fit with the two ends of the horizontal bracket 1, and the two vertical brackets 2 are arranged at the same level and can penetrate Positioning insert 22 inside the cake tube; two first driving mechanisms 3, respectively used to drive two vertical supports 2 to slide on the horizontal support 1. An avoiding groove 221 is provided on the positioning insert 22.

[0035] After the doffing car transports the cakes wound by the winder to the cake receiving table, the reclaiming robot is replaced with the string holding fixture of the present invention, and the whole series of other types of cakes on the cake receiving table are held to the storage rack After the doffing of other models is completely transported, the reclaiming robot will hold the cake from the storage rack to the cake receiving table, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com