Forming filling machine for ham production

A technology of filling machine and ham, which is applied in the field of forming and filling machines for ham production, and can solve the problems of external dust and other impurities entering the lower hopper, ham quality degradation, and no protective measures for the lower hopper port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

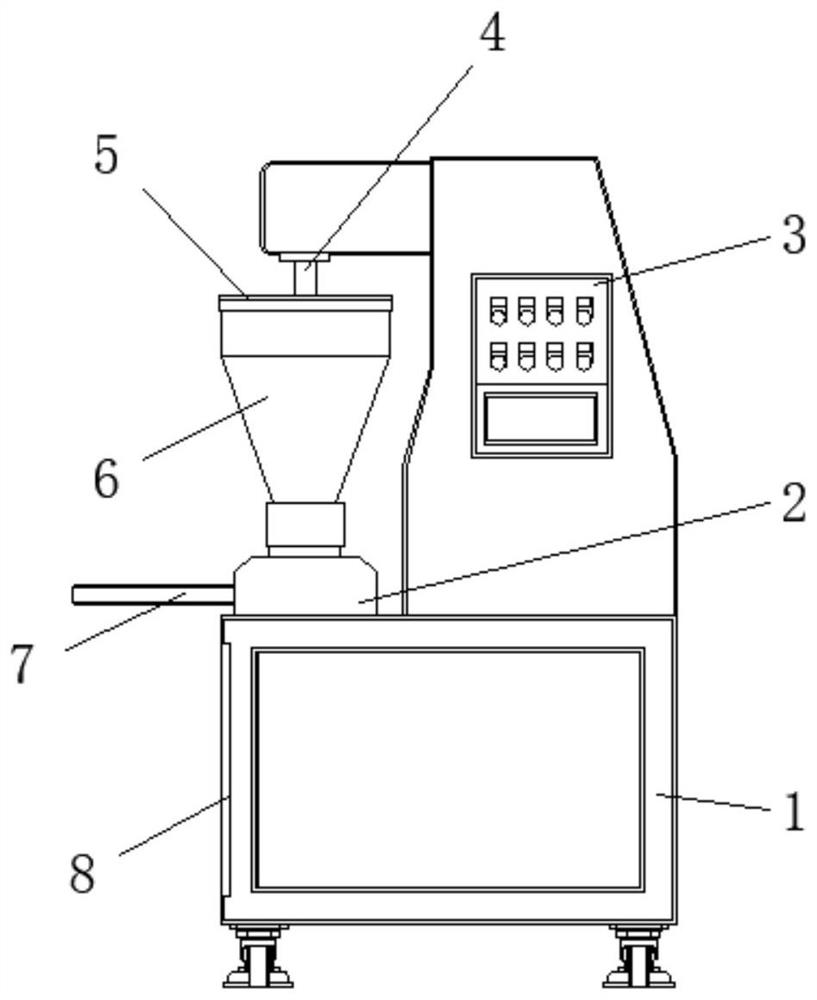

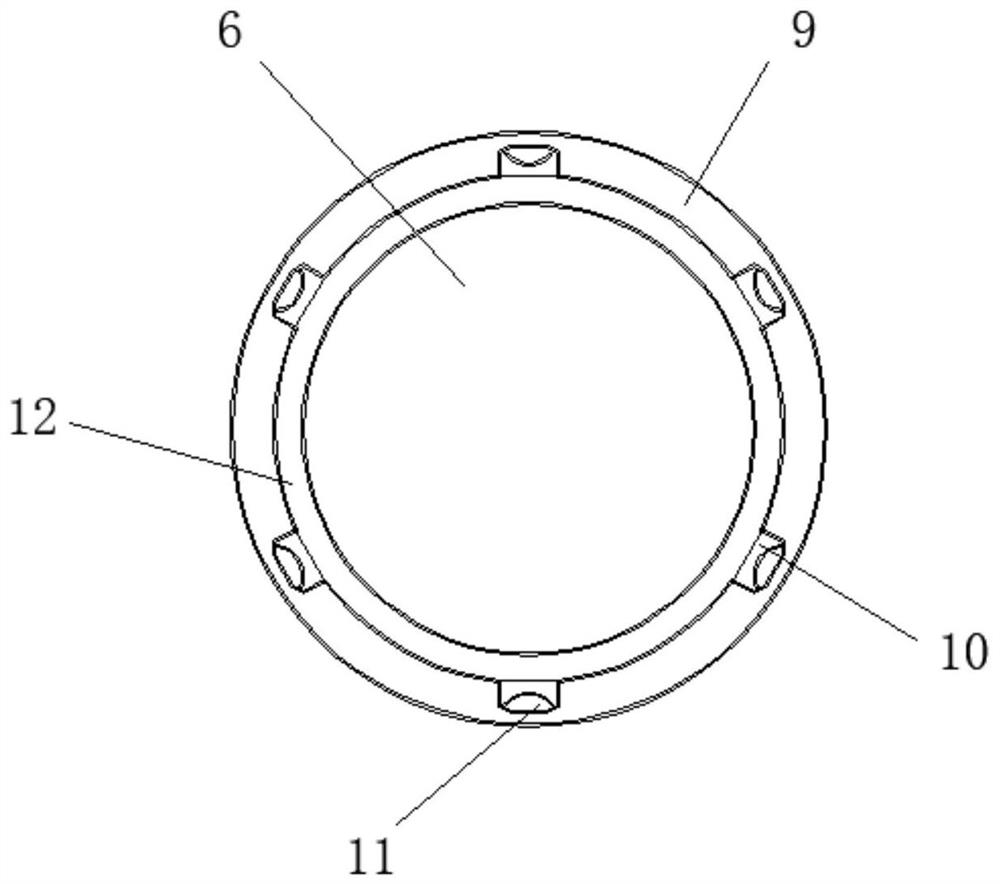

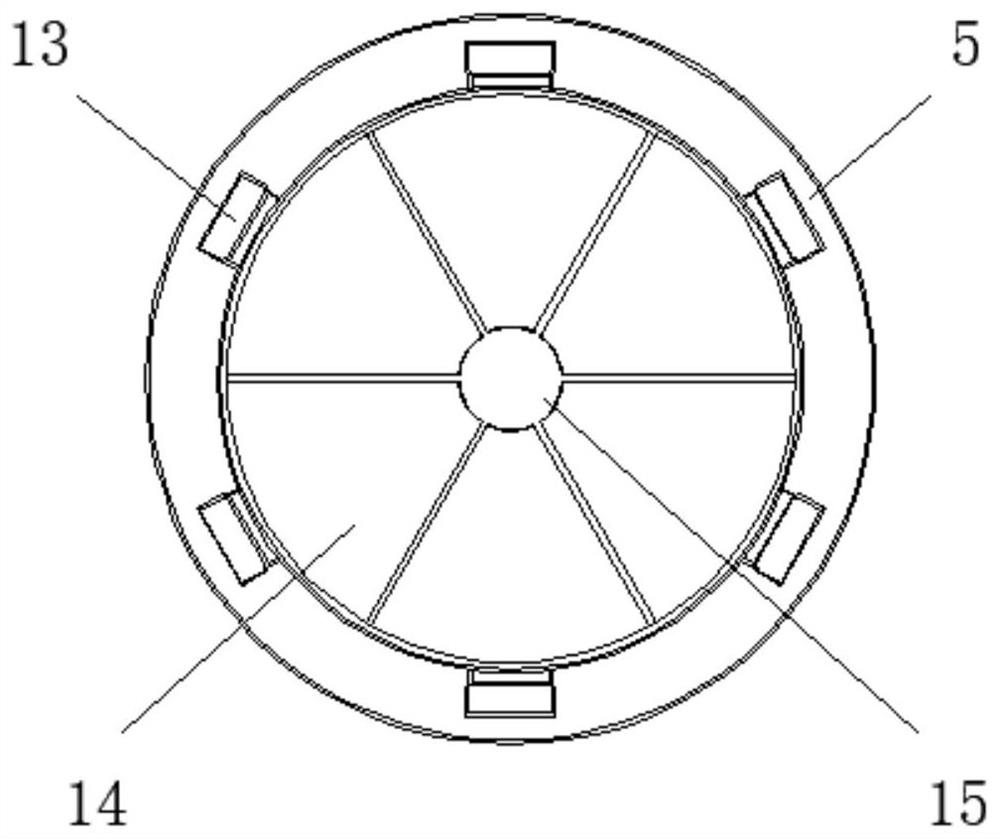

[0031] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a forming and filling machine for ham production, a forming and filling machine for ham production, comprising a body 1, an enema main body 2 is fixedly connected to the inner bottom of the working port of the machine body 1, and the front end of the enema main body 2 An enema tube 7 is fixedly connected, the top of the enema main body 2 is fixedly connected with a lower hopper 6, the top surface of the lower hopper 6 is provided with a fixed sleeve 5, and the outer wall of the port of the lower hopper 6 is fixedly connected with a wrapping 9, and the top surface of the wrapping 9 An annular groove 12 is provided, and the inner wall of the port of the annular groove 12 is provided with a bayonet socket 10, and the port of the bayonet socket 10 is fixed on the top surface of the wrapping 9, and the inner wall of the bayonet socket 10 is fixedly connected ...

Embodiment 2

[0034] Please refer to figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, the present invention provides a forming and filling machine for ham production, a forming and filling machine for ham production, comprising a body 1, an enema main body 2 is fixedly connected to the inner bottom of the working port of the machine body 1, and the front end of the enema main body 2 The enema tube 7 is fixedly connected, the side of the body 1 is fixedly connected with the electric control box 3, both ends of the bottom of the body 1 are fixedly connected with casters, the bottoms of both sides of the body 1 are fixedly connected with foot supports, and the front surface of the body 1 is in the The bottom of the enema pipe 7 is provided with a square groove 8, and the inside of the square groove 8 is provided with a storage board 22, and both sides of the storage board 22 are fixedly connected with ribs 24, and the bottom inner wall of the square groove 8 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com