Patents

Literature

115results about How to "Achieve outflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

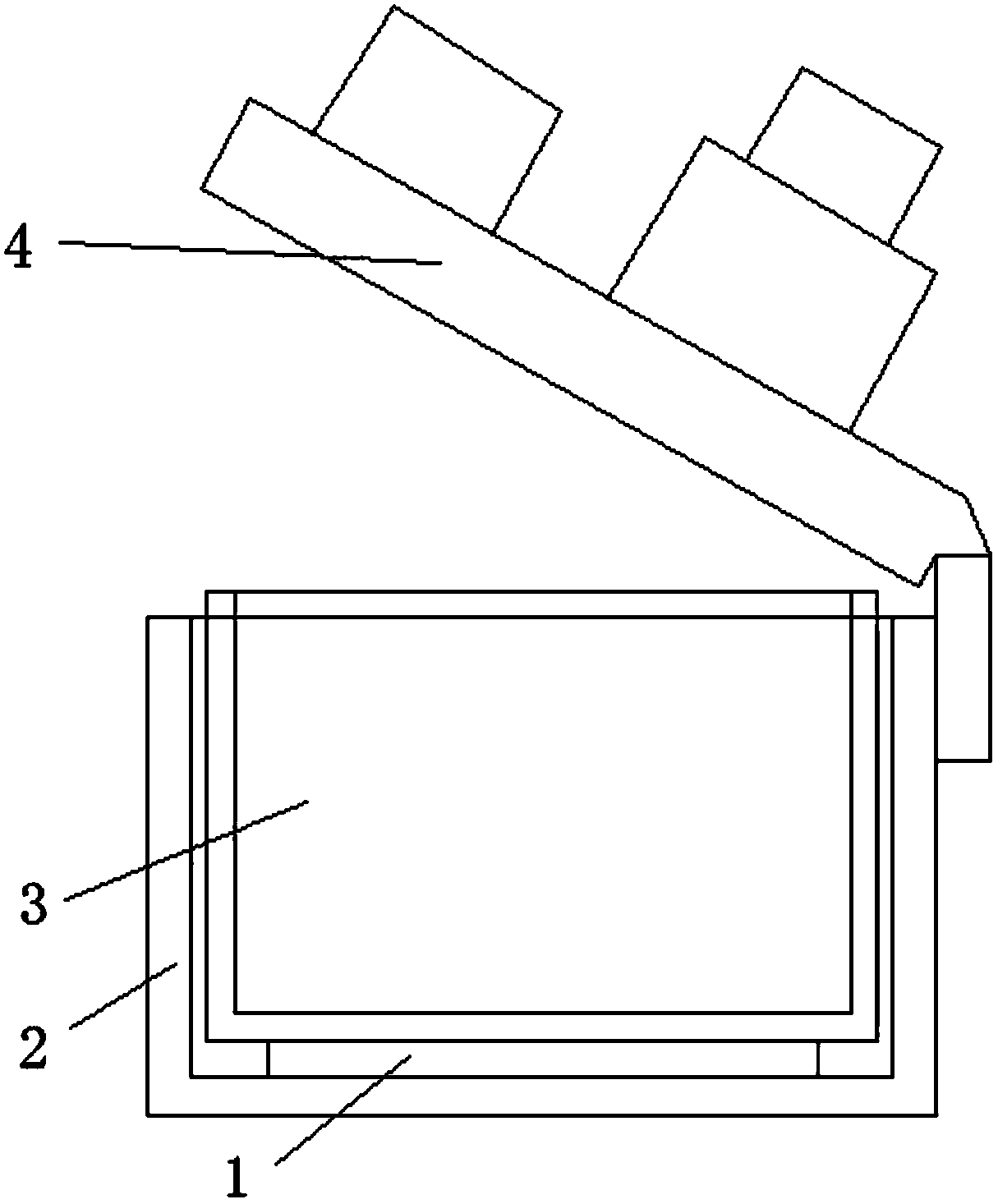

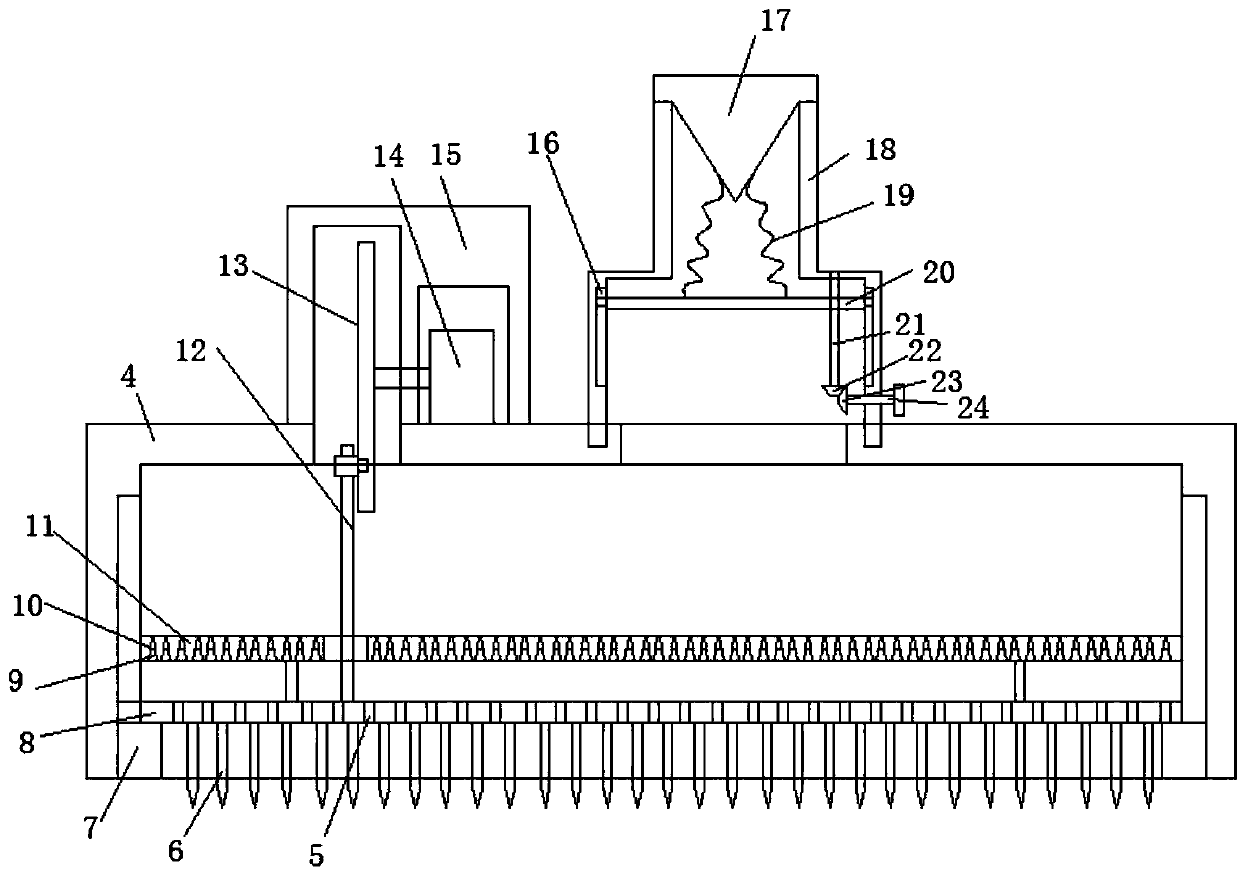

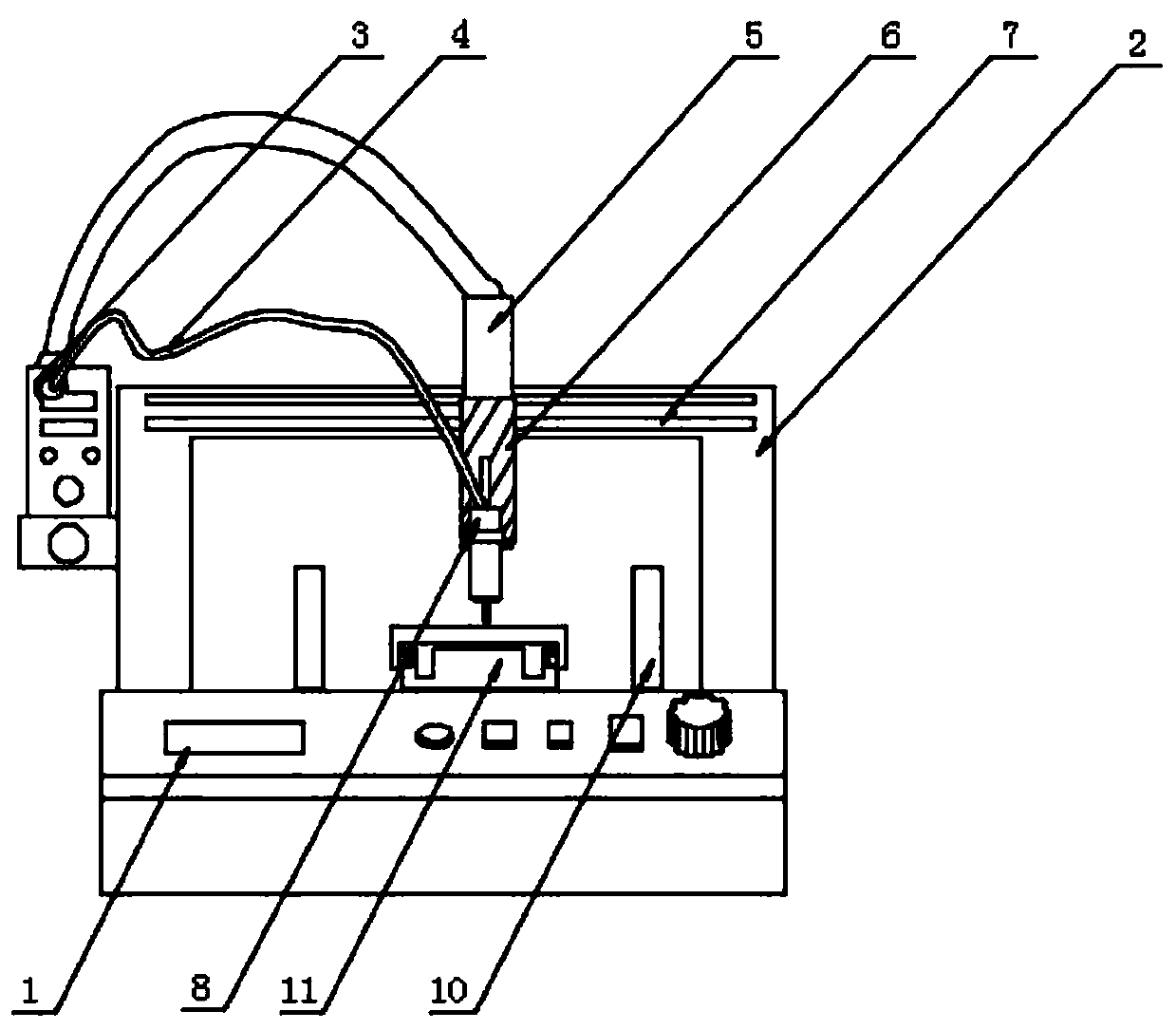

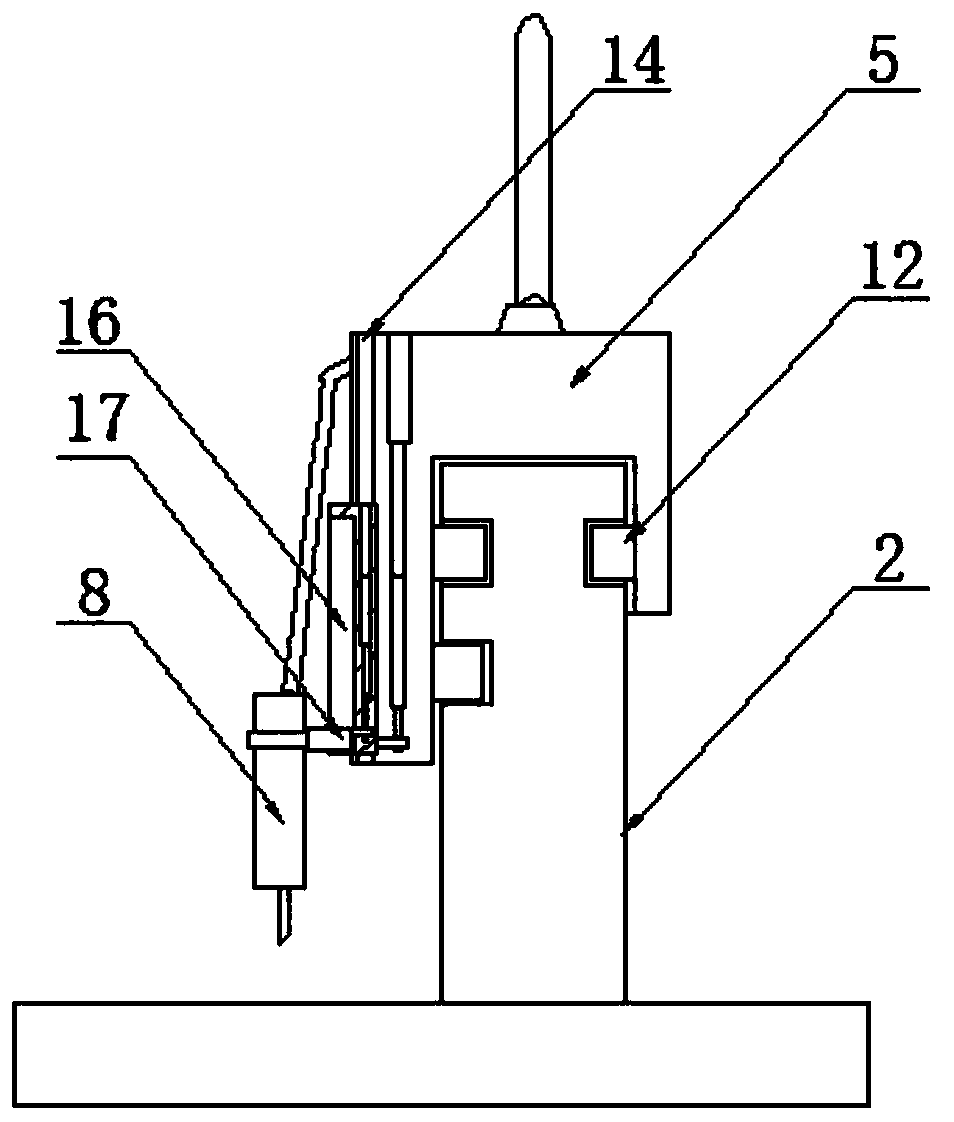

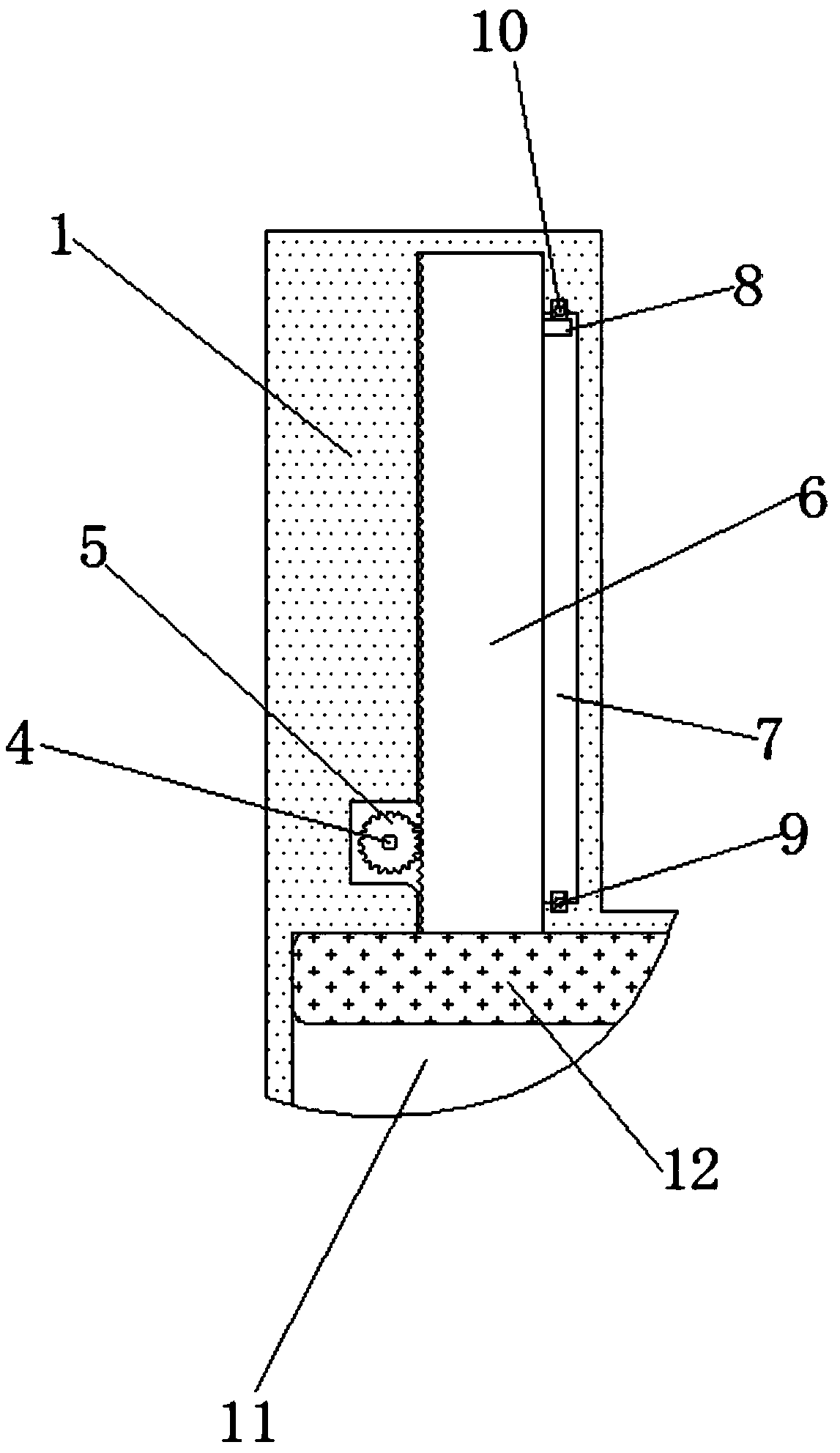

Electric cooker capable of preventing water overflow

The invention discloses an electric cooker capable of preventing water overflow. The electric cooker includes an electric cooker body, the inner wall of the bottom of the electric cooker body is provided with a heating element, the inside of the electric cooker body is movably provided with an inner pot, the inner pot is located on the heat element, one side of the top of the electric cooker bodyis hinged to a top cover, the top of the top cover is provided with a fixing shell and an air outlet cylinder, one side of the fixing shell is provided with the air outlet cylinder, a cavity is formedin the fixing shell, a driving motor is fixed in the cavity, an output shaft of the driving motor is connected with a vertically arranged rotating disk, the rotating disk is located in the fixing shell, the edge of the side wall of the rotating disk is rotatably connected with a connection block, the bottom of the connection block is connected with a connection rod through welding, the bottom ofthe connection rod is rotatably connected with a horizontally arranged movable plate, and the movable plate is provided with first defoaming holes arranged in an array. The electric cooker can eliminate steam bubbles generated the cooking process of the electric cooker for many times, meanwhile, adjustment of pressure of a steam valve can be achieved, and liquid in the electric cooker is preventedfrom overflowing in the cooking process.

Owner:唐文剑

LED ceiling illuminating lamp

InactiveCN113669663AAchieve circulationImprove cooling effectLighting heating/cooling arrangementsLighting elementsLight equipmentEngineering

The invention relates to the technical field of lighting equipment and discloses an LED ceiling lighting lamp. The LED ceiling lighting lamp comprises a base, wherein a lampshade is fixedly installed on a front face of the base, a circle of air inlet holes are formed in the side wall of the base, an LED lamp is fixedly installed at the center axis of the bottom side of the base, and a plurality of air outlet holes are formed in the end, away from the lampshade, of the base; a circle of sliding groove is formed in the side wall of the base, and a heat induction deformation ball is fixedly installed at the position of a center shaft in the base. According to the LED ceiling illuminating lamp, when the internal temperature reaches a certain value, the temperature rises to drive a heat induction deformation ball to deform, and then a semi-arc stop block is driven to move under the action of a moving rod, so an air inlet hole is exposed, and air enters the interior of a base; and meanwhile, air enters to drive an airflow plate to rotate under the action of an arc-shaped flow guide plate, so an impact rod impacts a collision rod to achieve air circulation, and heat dissipation of the interior of the lampshade is facilitated.

Owner:莫银琪

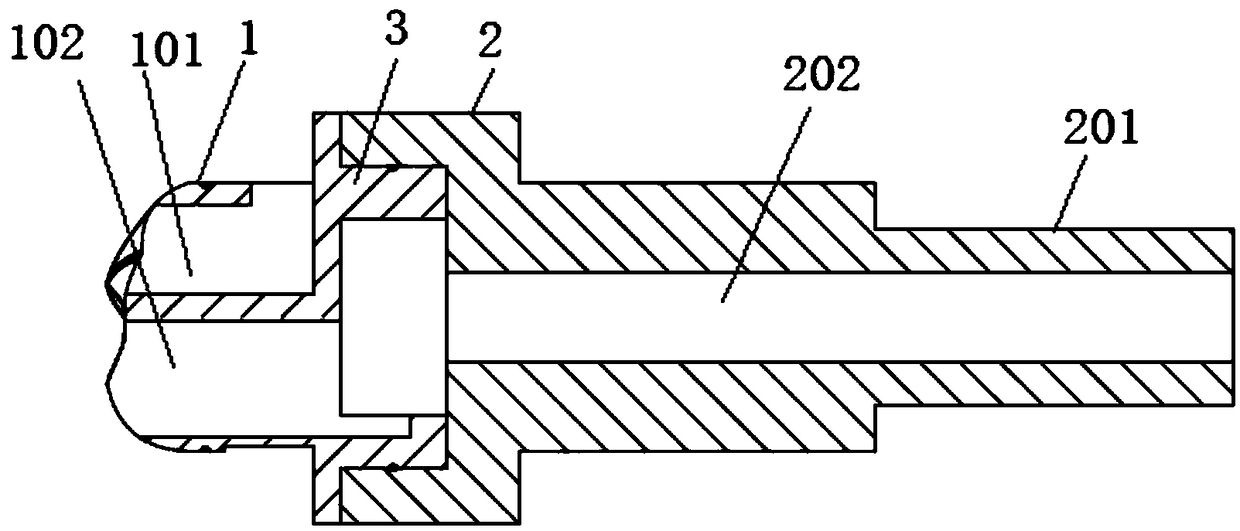

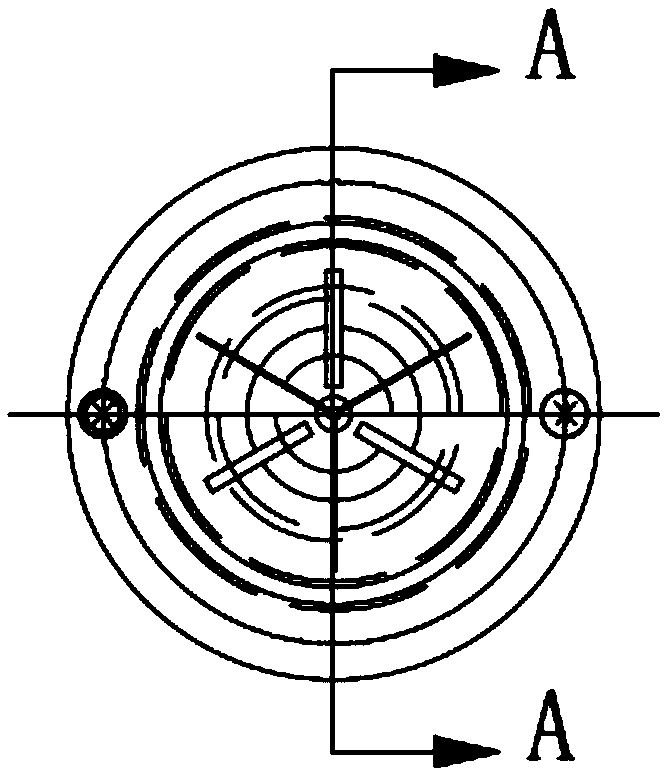

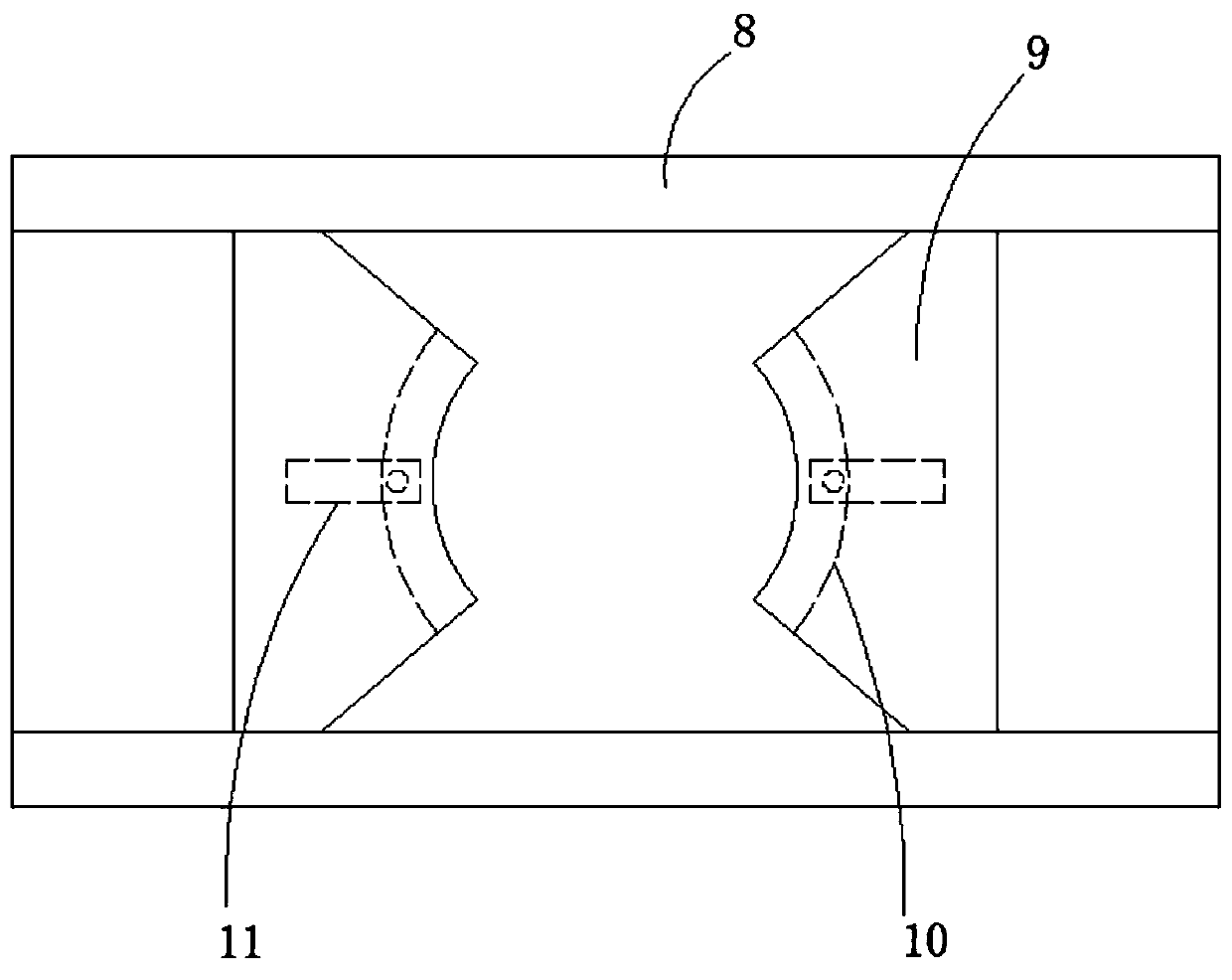

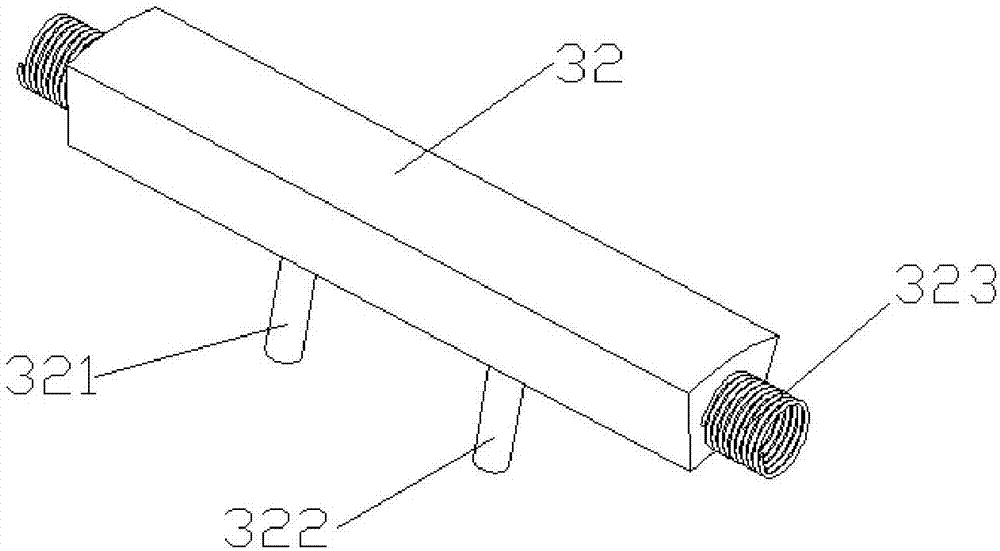

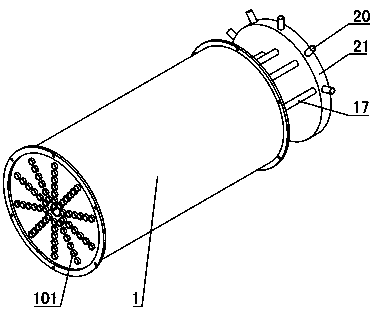

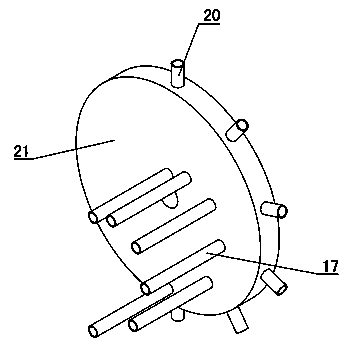

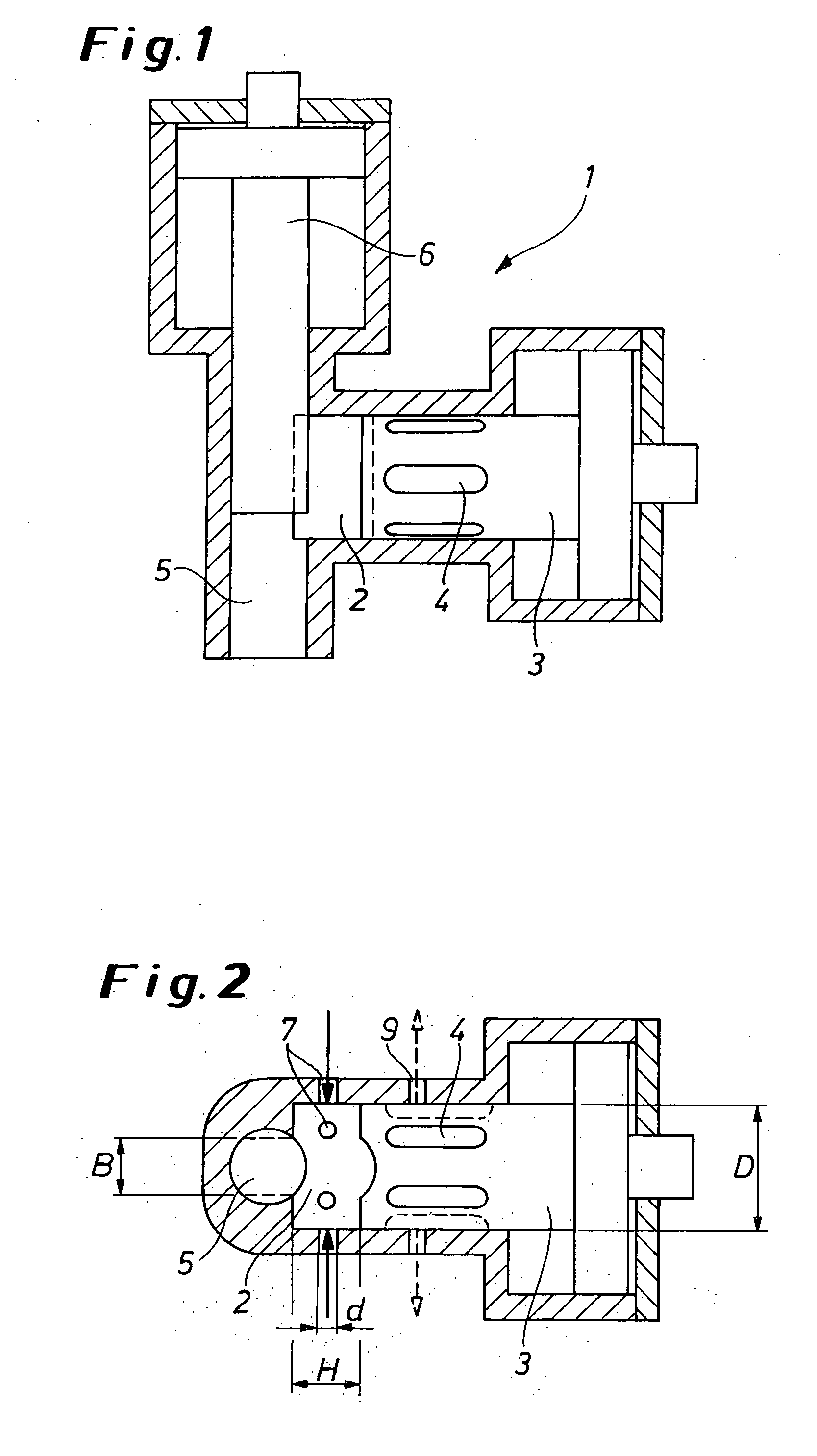

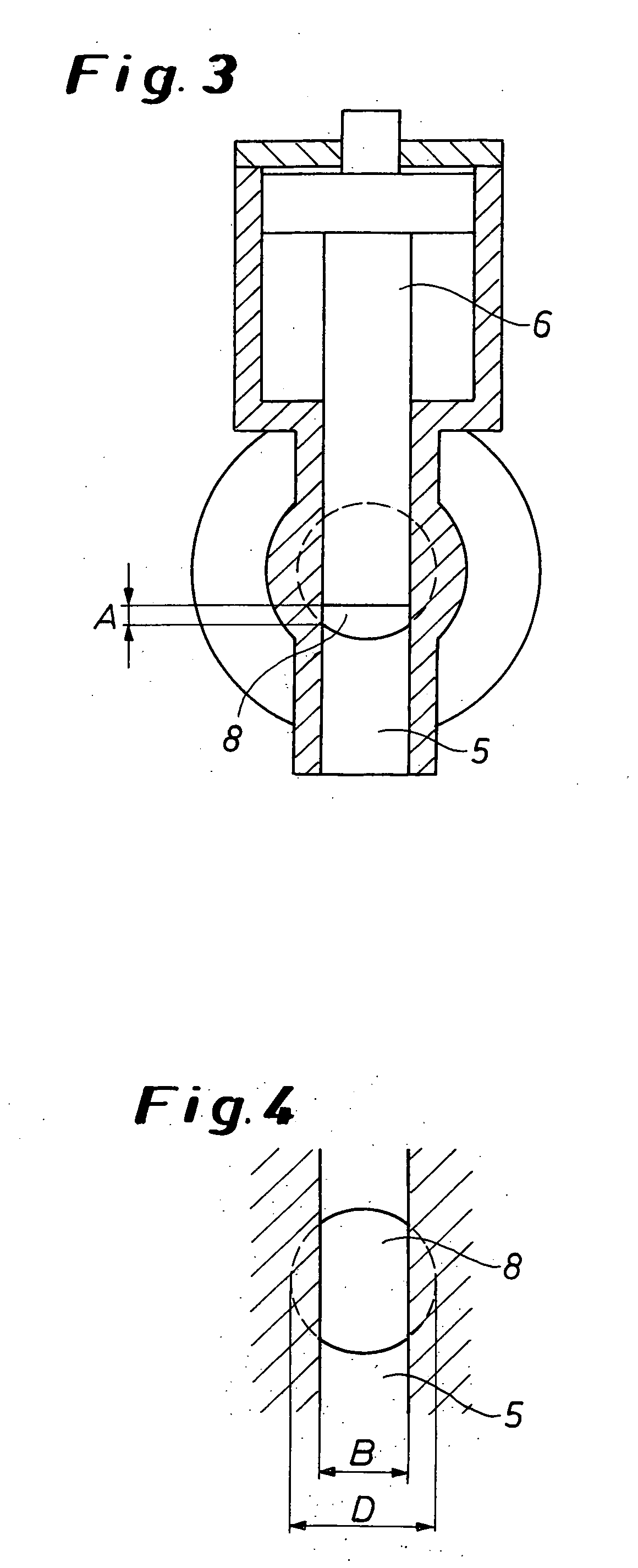

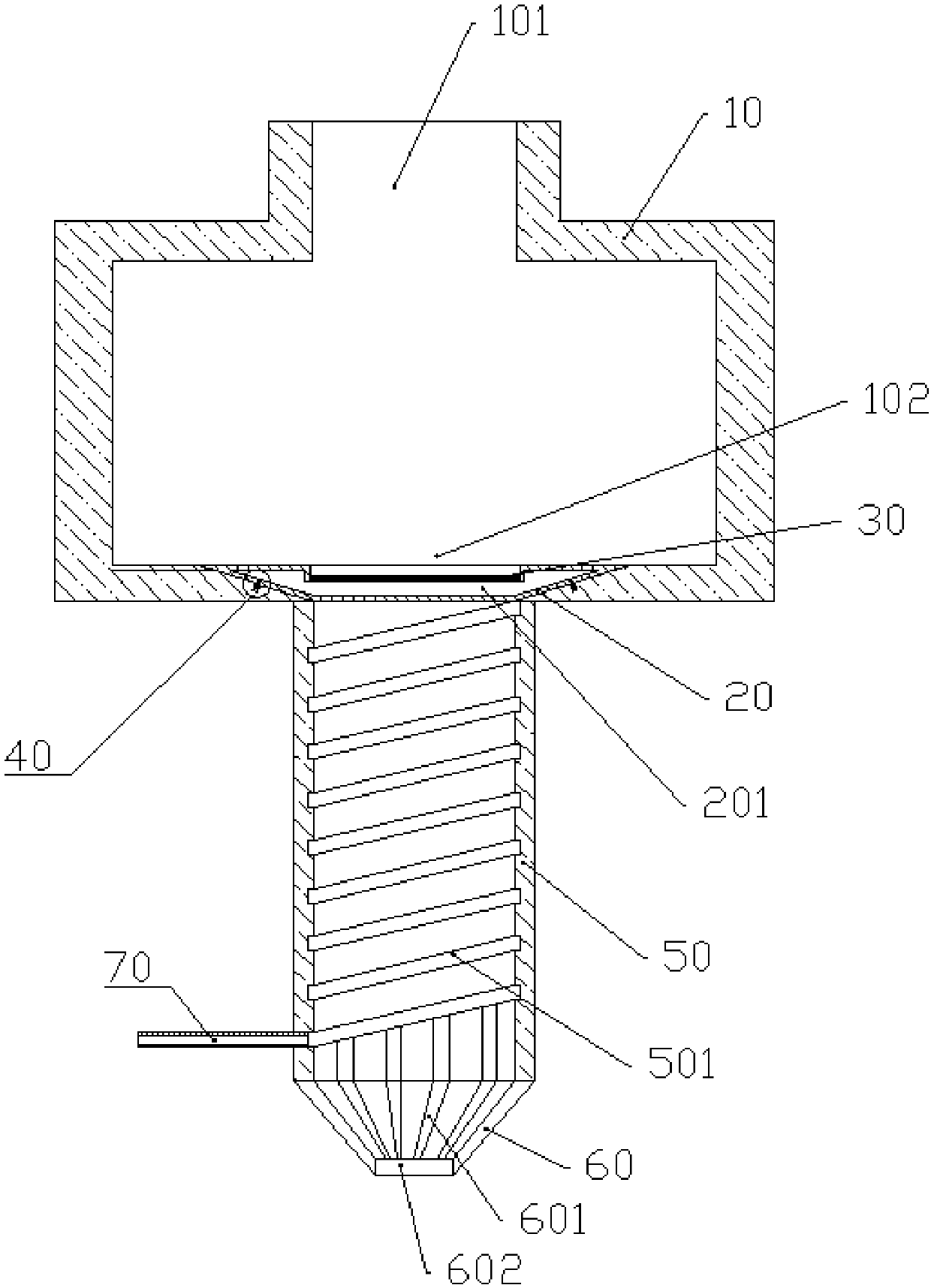

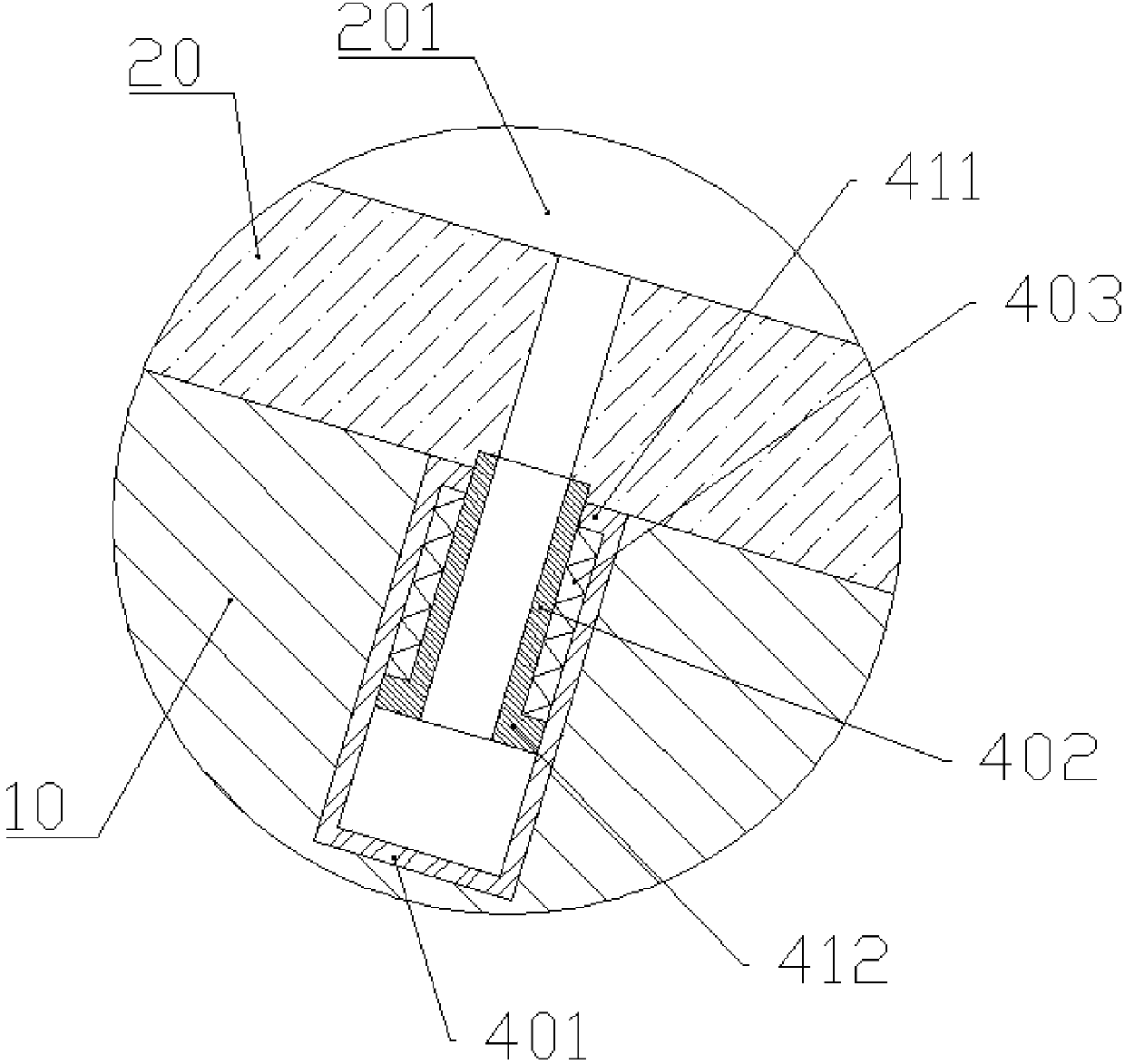

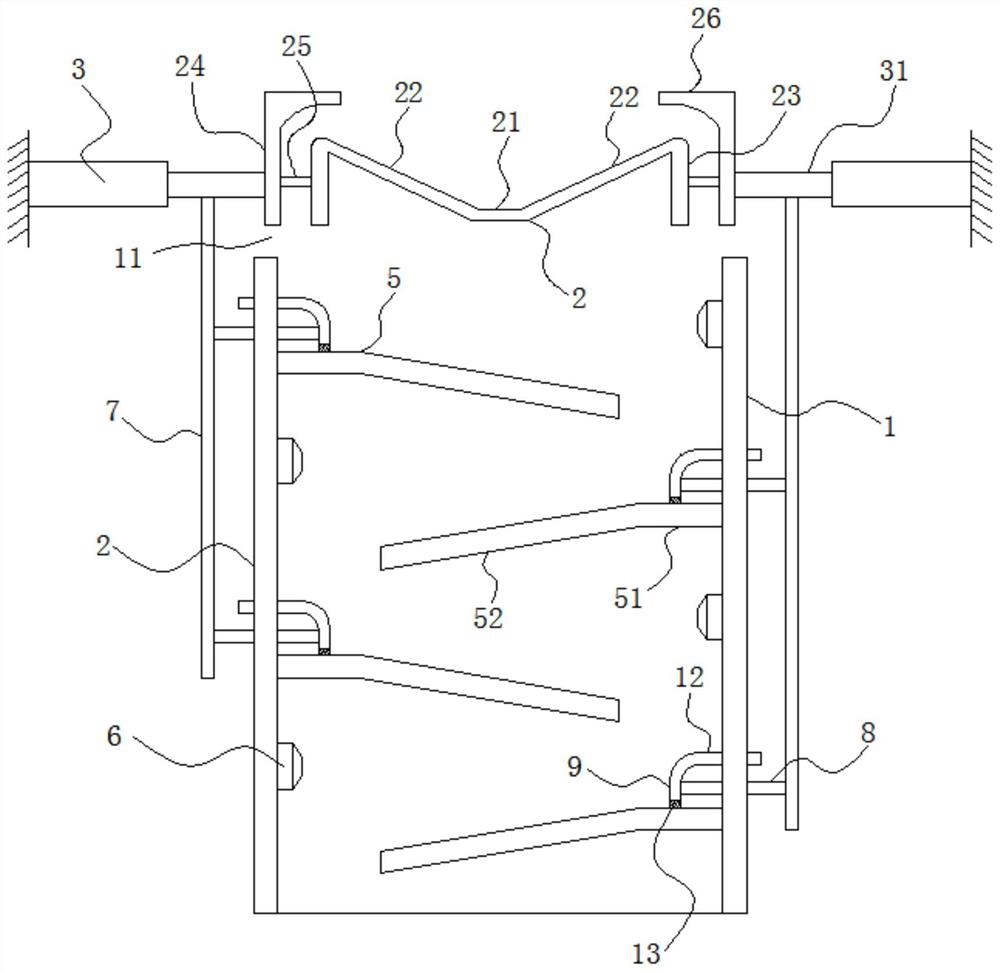

Cathode for free-form-surface-cavity electrochemical machining

ActiveCN109226914AAchieve inflowAchieve outflowMachining electrodesElectrical-based machining electrodesElectrolysisFree form

The invention discloses a cathode for free-form-surface-cavity electrochemical machining. The cathode comprises a cathode body and a cathode head, wherein an electrolyte inflowing channel is formed inthe cathode body, a liquid-inlet inflowing channel and a liquid-outlet outflowing channel are formed in the cathode head, one end of the liquid-inlet inflowing channel is communicated with the electrolyte inflowing channel, the other end of the liquid-inlet inflowing channel leads to a workpiece, one end of the liquid-outlet outflowing channel leads to the workpiece, and the other end of the liquid-outlet outflowing channel is leaded out of the side face of the cathode head at the upper portion of the workpiece. A free-form surface comprises a protruding part and a concave part, the liquid-inlet inflowing channel is formed in the protruding part of the free-form surface, and the liquid-outlet outflowing channel is formed in the concave part of the free-form surface. According to the cathode for free-form-surface-cavity electrochemical machining, inflowing and outflowing of electrolyte can be simultaneously achieved, the integrity of a flow field is guaranteed, dead water zones in machining gaps can be effectively eliminated, and the short circuit phenomenon caused by a unsmooth flow field is prevented.

Owner:CHANGZHOU INST OF TECH

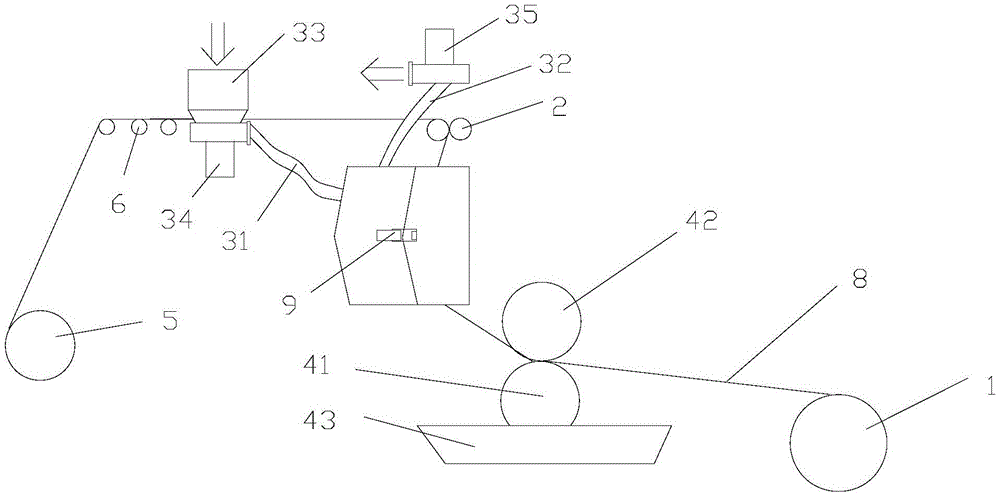

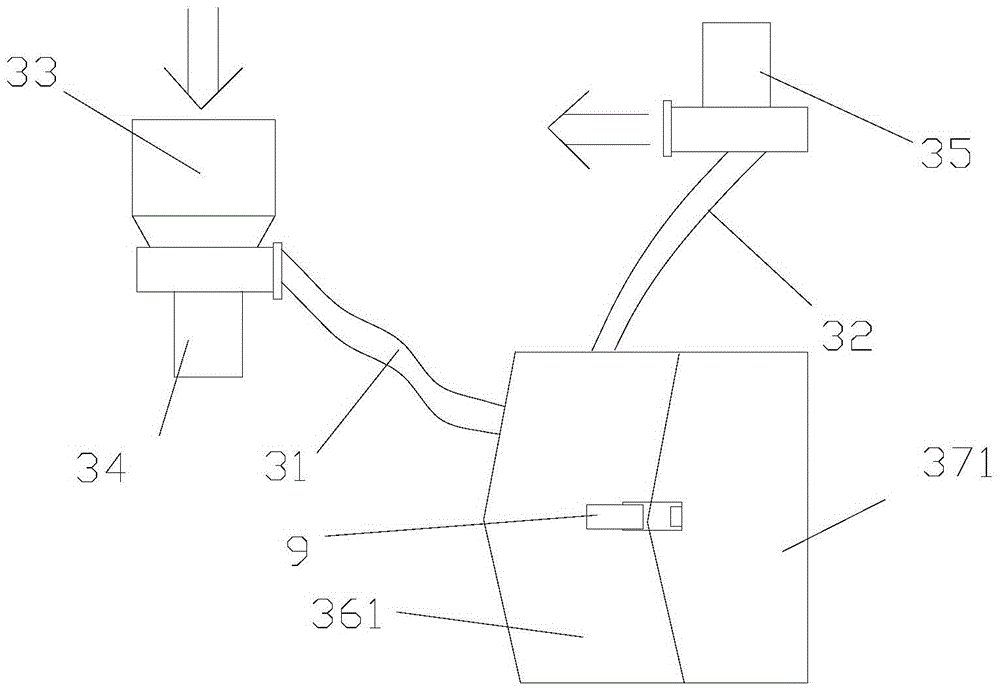

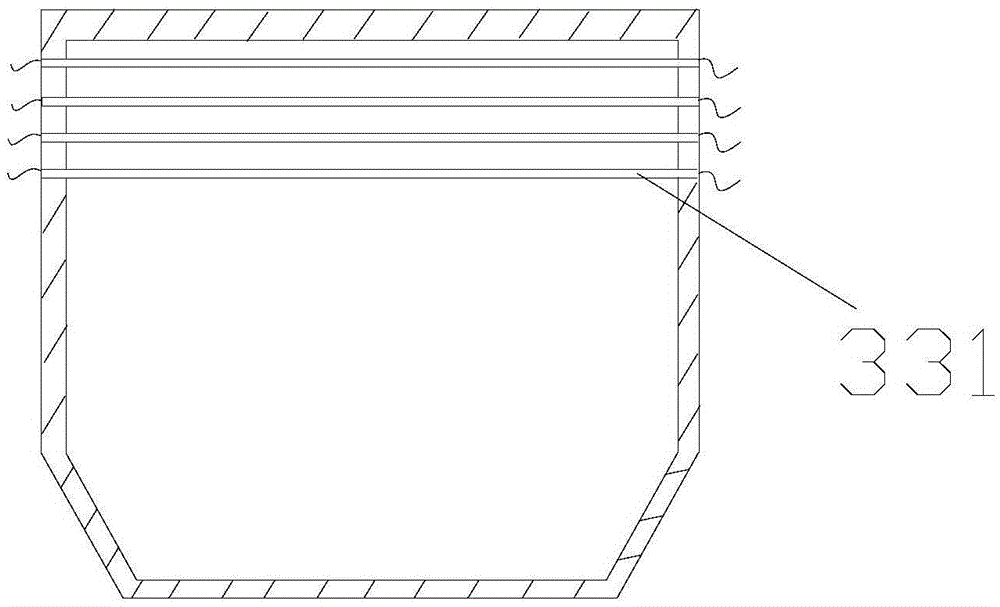

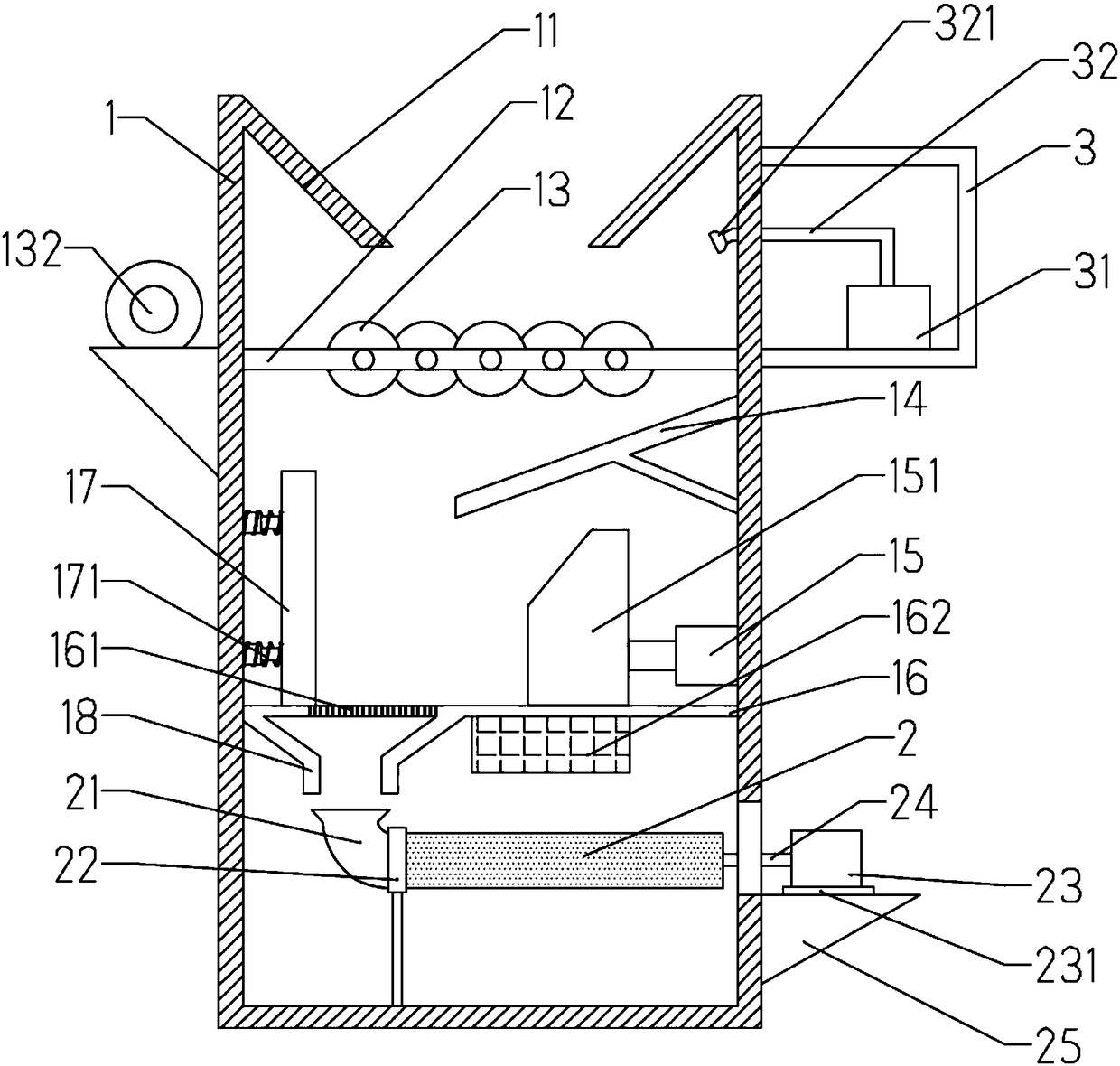

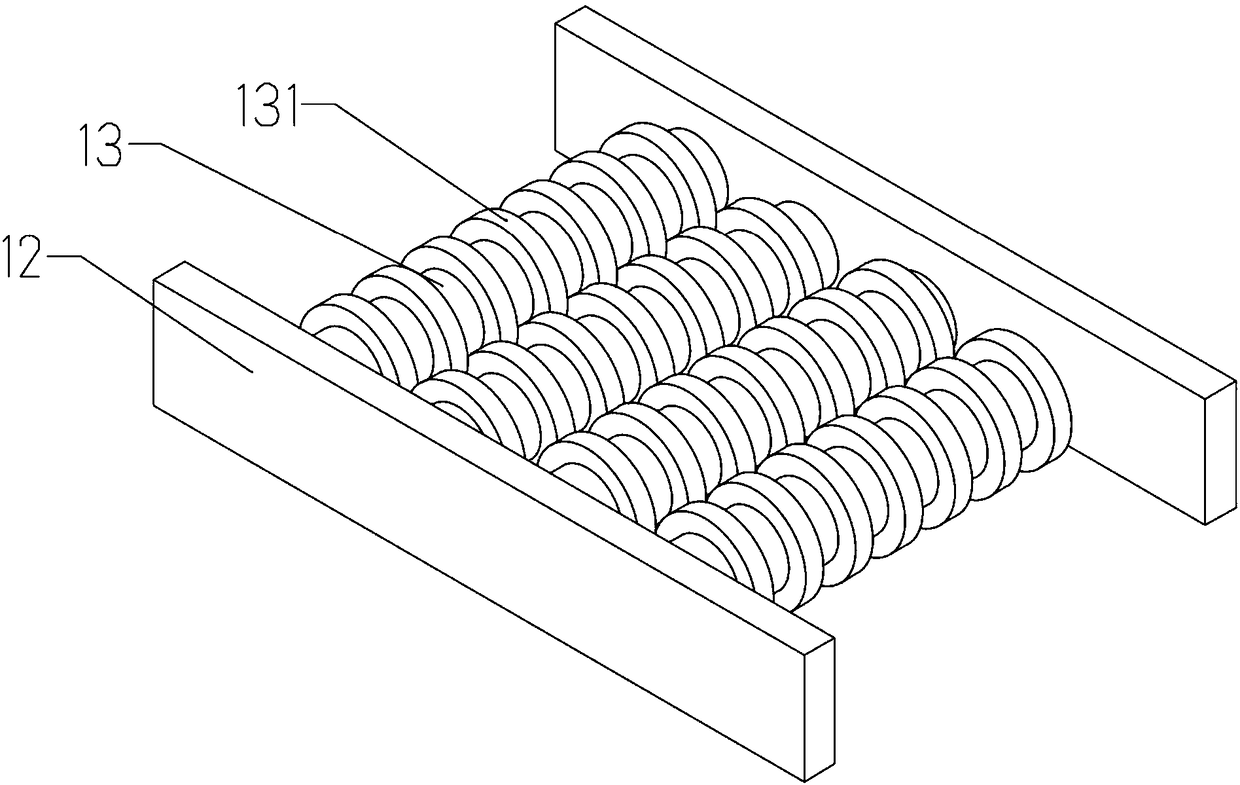

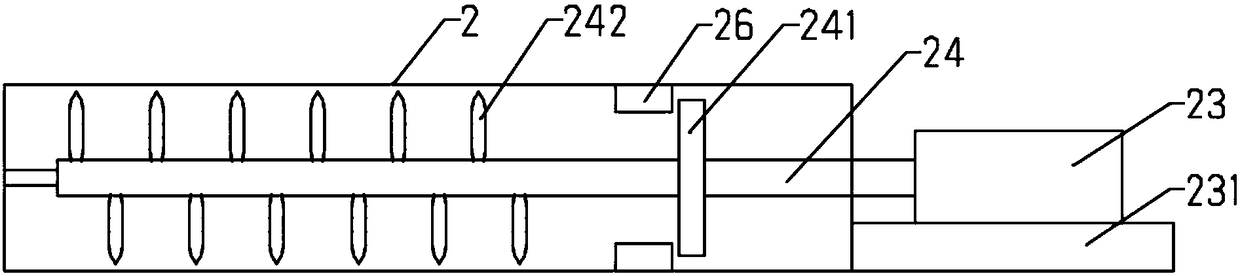

Beverage cup loading machine

ActiveCN106214002AShorten working timeReduce splashBeverage vesselsEngineeringMechanical engineering

The invention relates to a beverage cup loading machine which comprises a water conveying device and a transition container. The water conveying device is used for allowing the transition container obtain a beverage from the water conveying device. The transition container is provided with a liquid circulating opening. The liquid circulating opening is used for being controlled to be opened or closed so as to discharge liquid and transferring the beverage in the transition container into a water cup. By means of the beverage cup loading machine, the beverage cup loading speed can be increased, and the beverage can not be easily splashed out when poured.

Owner:李永刚

Rapid glue dispenser

ActiveCN110918391AAchieve outflowRealize the discharge of rubber material and realize the outflowLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the technical field of glue dispensers, and particularly relates to a rapid glue dispenser. According to the rapid glue dispenser, glue can be discharged to achieve glue dispensing operation only by controlling lifting of a glue containing inner barrel. When the glue containing inner barrel drives an inner glue dispensing head to move downwards, the inner glue dispensing head is extruded by a conical hole and can deform, and therefore glue can flow out, and glue dispensing operation is achieved. A glue discharging cavity comprises a shrinkage conical cavity, a middle cylindrical cavity and a diffusion conical cavity which communicate in sequence, and therefore glue can effectively flow downwards when the inner glue dispensing head deforms. Meanwhile, glue soaking cotton is arranged, glue can be effectively adsorbed, glue is prevented from being left due to gravity, the glue discharging amount during glue discharging is stabilized, and the glue dispensing accuracy is improved.

Owner:陈伦权

Convenient waist training device for free combat

The invention discloses a convenient waist training device for free combat, which comprises a base plate, a fixed shell, a stepping motor, a rotating shaft, a gear, a rack board, a chute, a trigger plate, a first travel switch, a second travel switch, a water storage chamber, a piston, a guide rod, a buffer pad and a water storage box, a first avoiding hole, a fixed ring, a second avoiding hole, asupport frame, a first auxiliary roller, a second auxiliary roller, a third auxiliary roller, a pull rope, a belt, a support seat, a hanger, chains, and a sandbag. First, through the adjustable waistload-bearing design, the convenient waist training device for free combat cannot only improve the training staff's waist training, but also according to different training level or physical conditionachieve the waist load intensity adjustment, and expand the practicality of the training. Then through the sandbag cooperation effect, the convenient waist training device for free combat can achievethe waist load-bearing training of the training staff, and also be convenient for the training staff to carry out boxing training, and finally achieve good popularization and application.

Owner:国武时代国际文化传媒(北京)有限公司

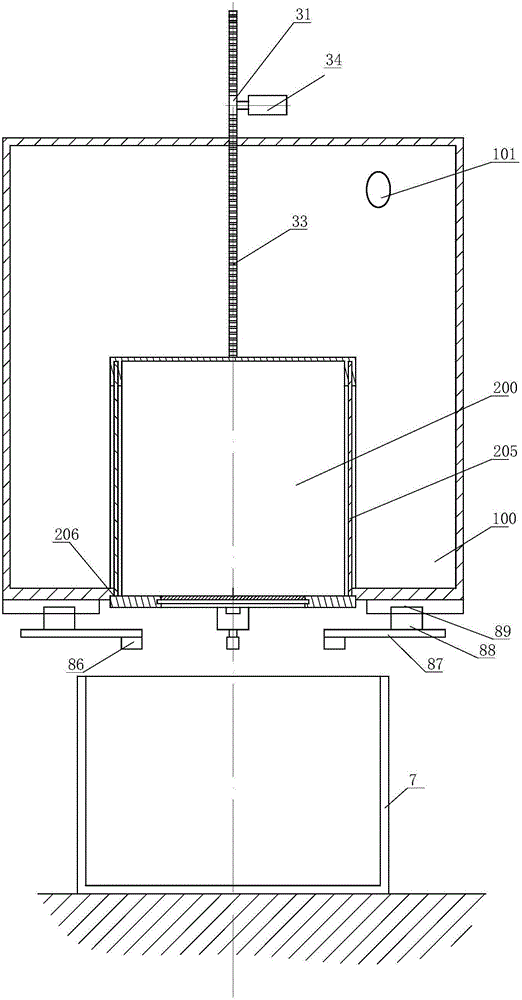

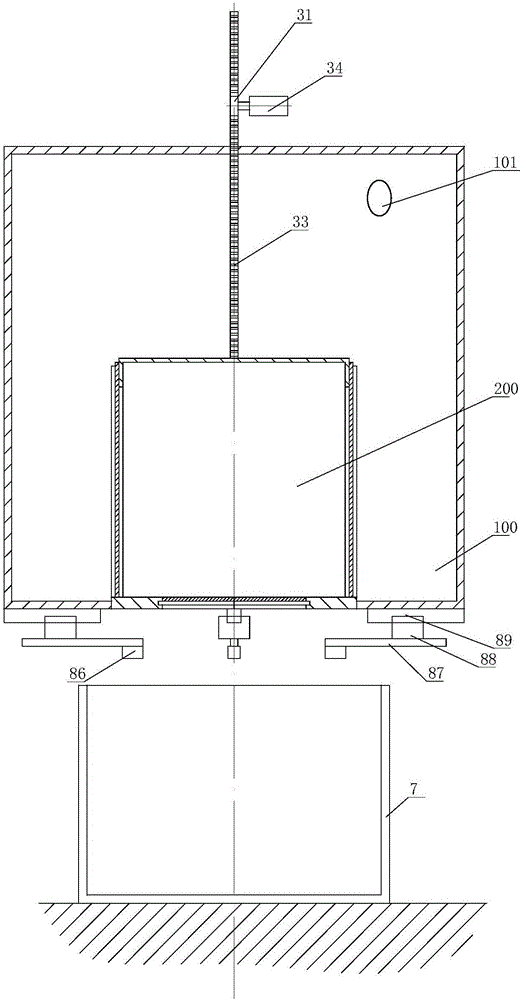

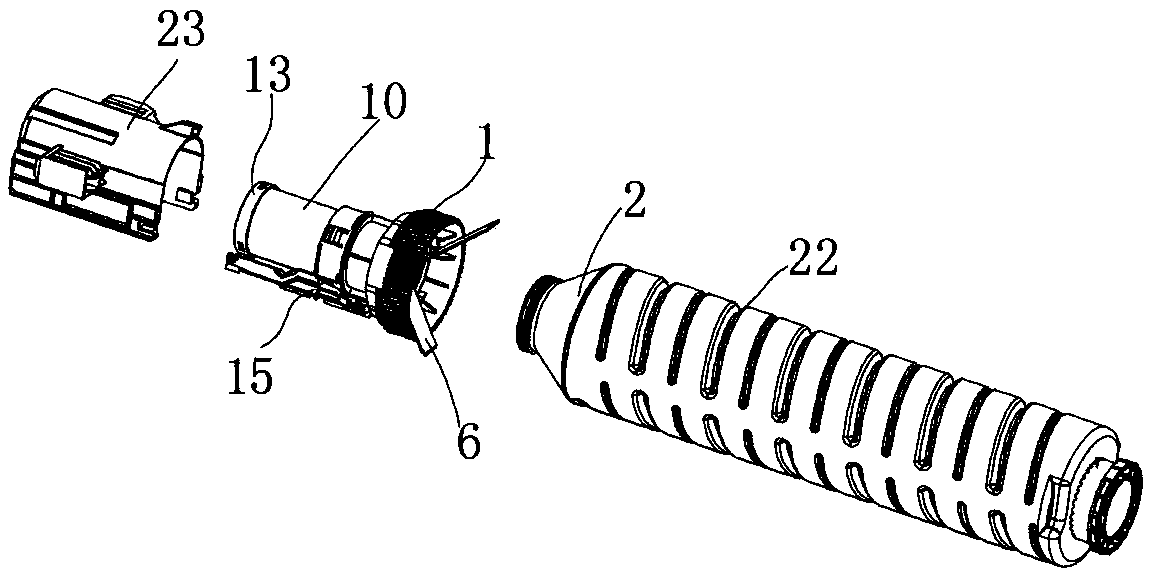

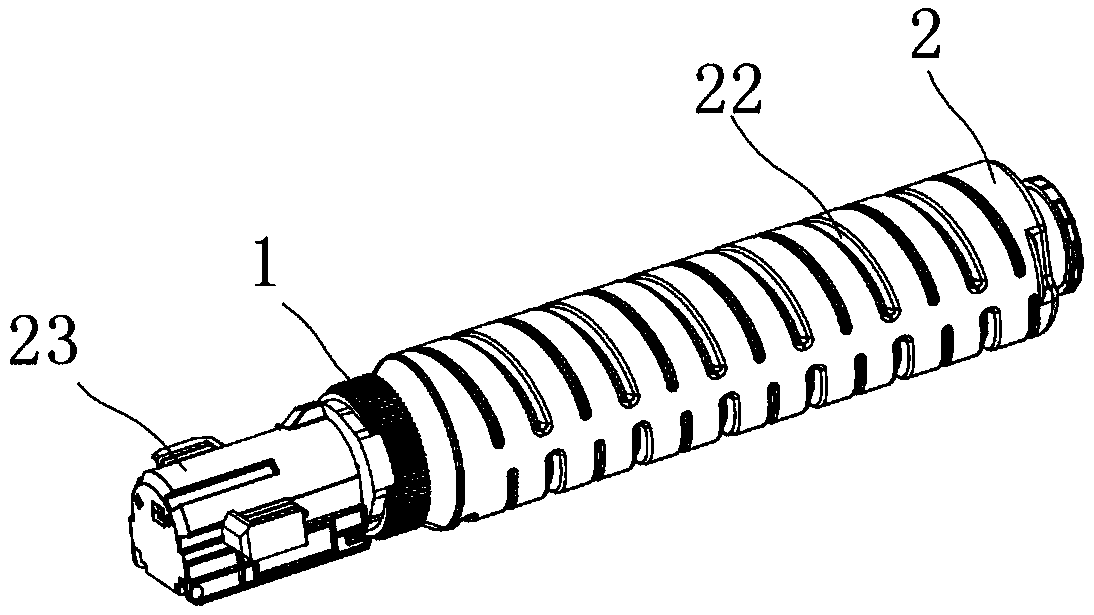

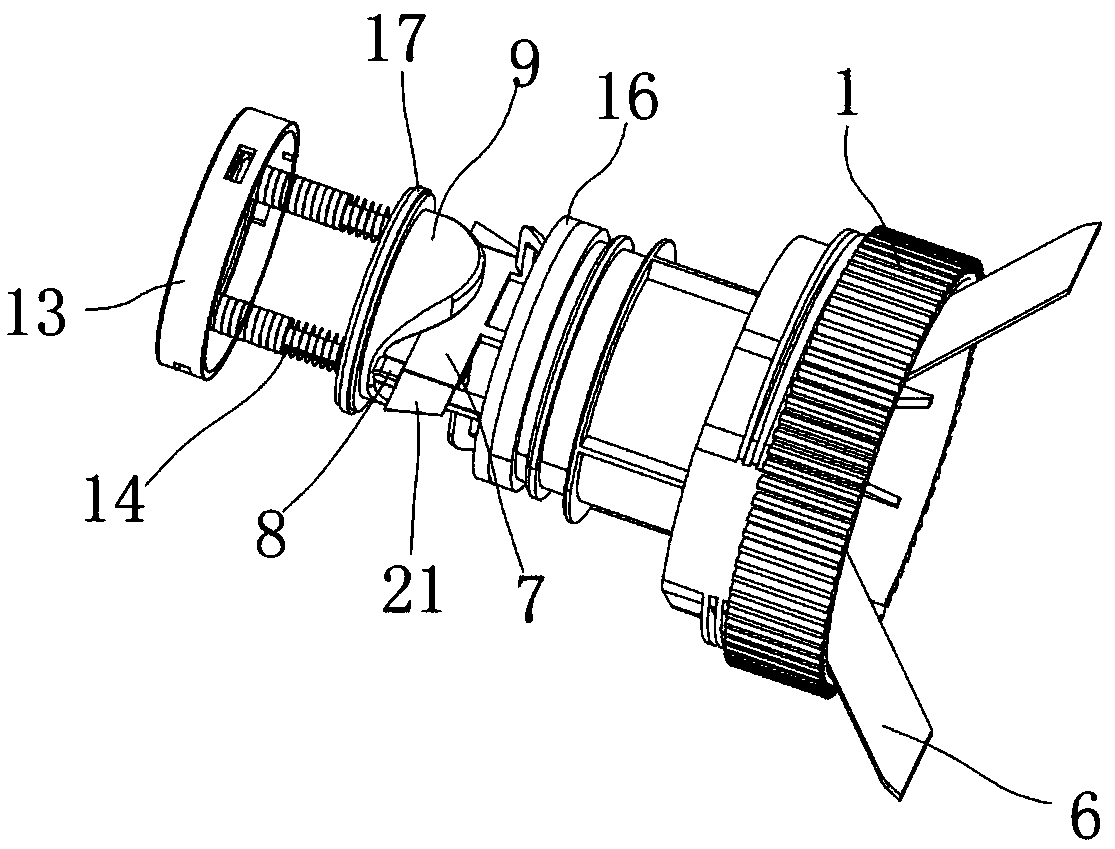

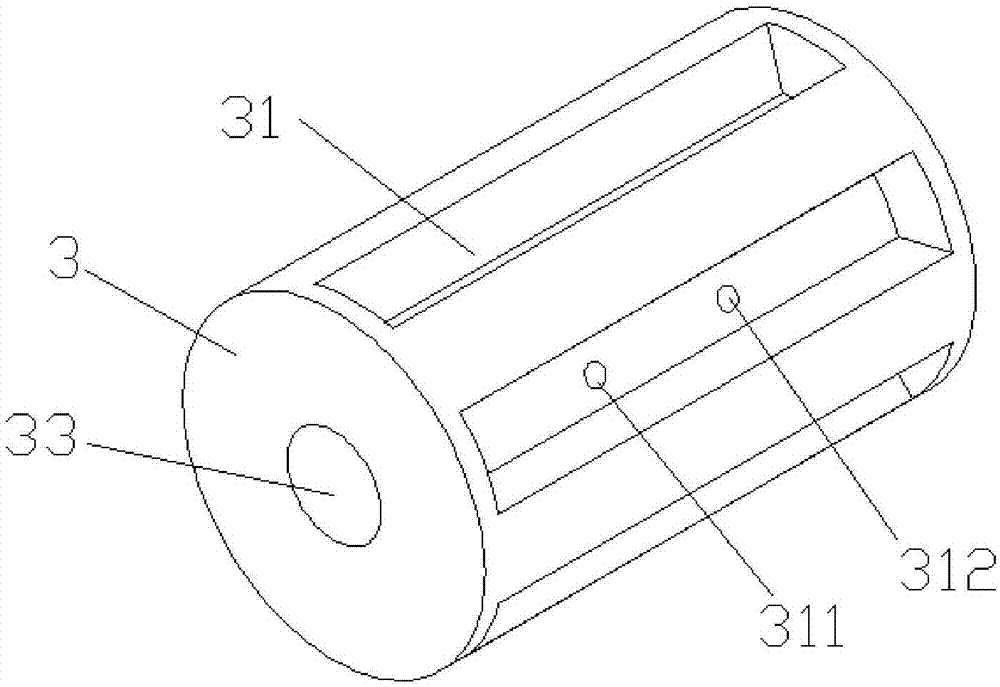

Developer supplying container and device

InactiveCN109634081AAchieve sealingSmooth dischargeElectrographic process apparatusEngineeringMechanical engineering

The invention discloses a developer supplying container and device. The developer supplying container and device includes a gear cover; the end part of the gear cover is connected to a barrel body, and the internal on the other end is provided with a slide rail; a inserting block is inserted in the slide rail; a spiral stirring plate is fixed on the inserting block; a first stirring plate is fixedat the end part of the spiral stirring plate, and a second stirring plate is fixed at the end part on the other end; driving blocks are fixed on the second stirring plate; the end faces of the driving blocks are in tight contact with the end face of a piston; the piston is located at the internal of a power outlet box; the power outlet box is clamped at the end part of the gear cover; guide columns are fixed on one end of the piston and slide in guide sleeves; the guide sleeves are fixed on a piston cover; the outer sides of the guide columns and guide sleeves are sleeved by springs; and themiddle part on the sidewall of the power outlet box is provided with a discharging mechanism. Thus, the feeding of a developer can be realized; and the developer supplying container and device is highin working efficiency, stable and good in equipment sealing, so that raw material leakage can be avoided.

Owner:JIANGXI KAILIDE TECH CO LTD

Double-arc irregular shaped inner-cooling type efficient titanium alloy milling tool

The invention relates to a double-arc irregular shaped inner-cooling type efficient titanium alloy milling tool. High processing difficulty, low cutting efficiency and short service life of a tool are caused by the mutual influence of physical, chemical and mechanical properties of titanium alloy, so that the titanium alloy becomes a typical difficultly processed material. The double-arc irregular shaped inner-cooling type efficient titanium alloy milling tool comprises a tool handle (1), wherein the tool handle (1) is transited to a milling tool bit with a double-arc shape at the front end through a cone (2); a pair of chip pockets (6) with front angle structures are arranged on one side of the tool bit; a cooling liquid channel (5) is arranged at the center of the tool; an outlet of the cooling liquid channel is located on the end part of the tool; and a negative chamfered edge (7) is arranged on the tail part of the tool. The invention is applied to the milling tool.

Owner:HARBIN UNIV OF SCI & TECH

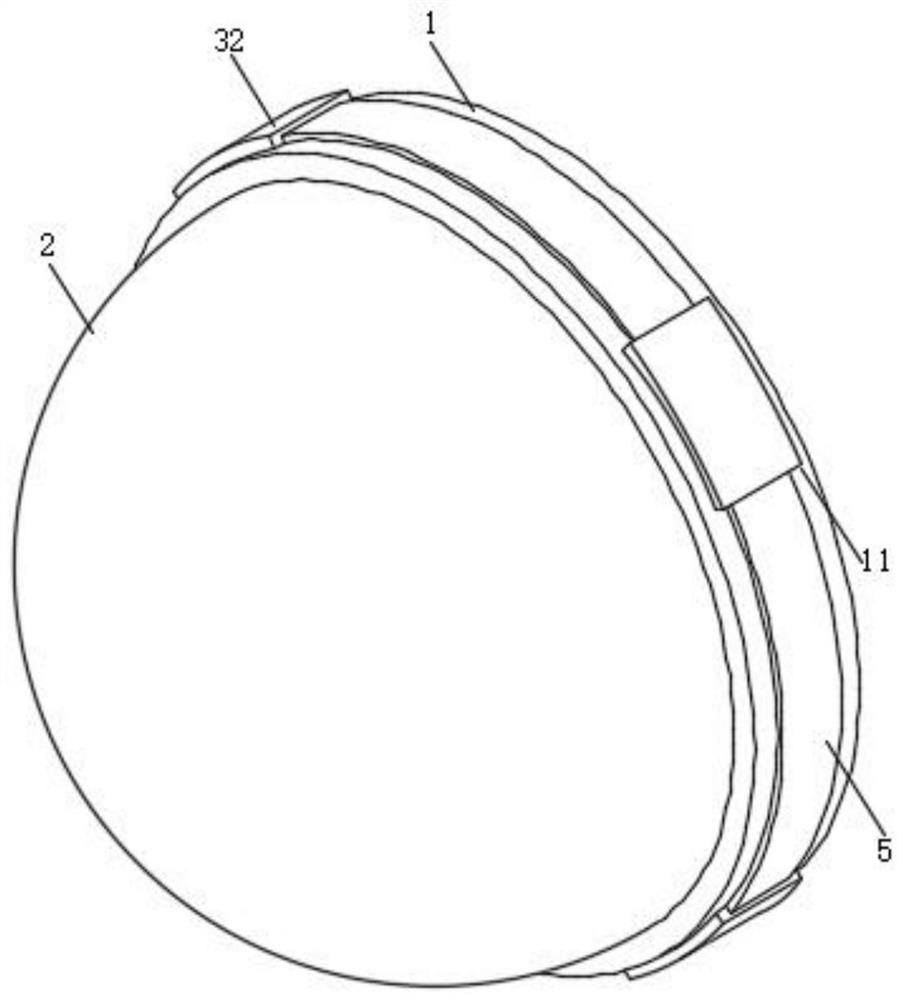

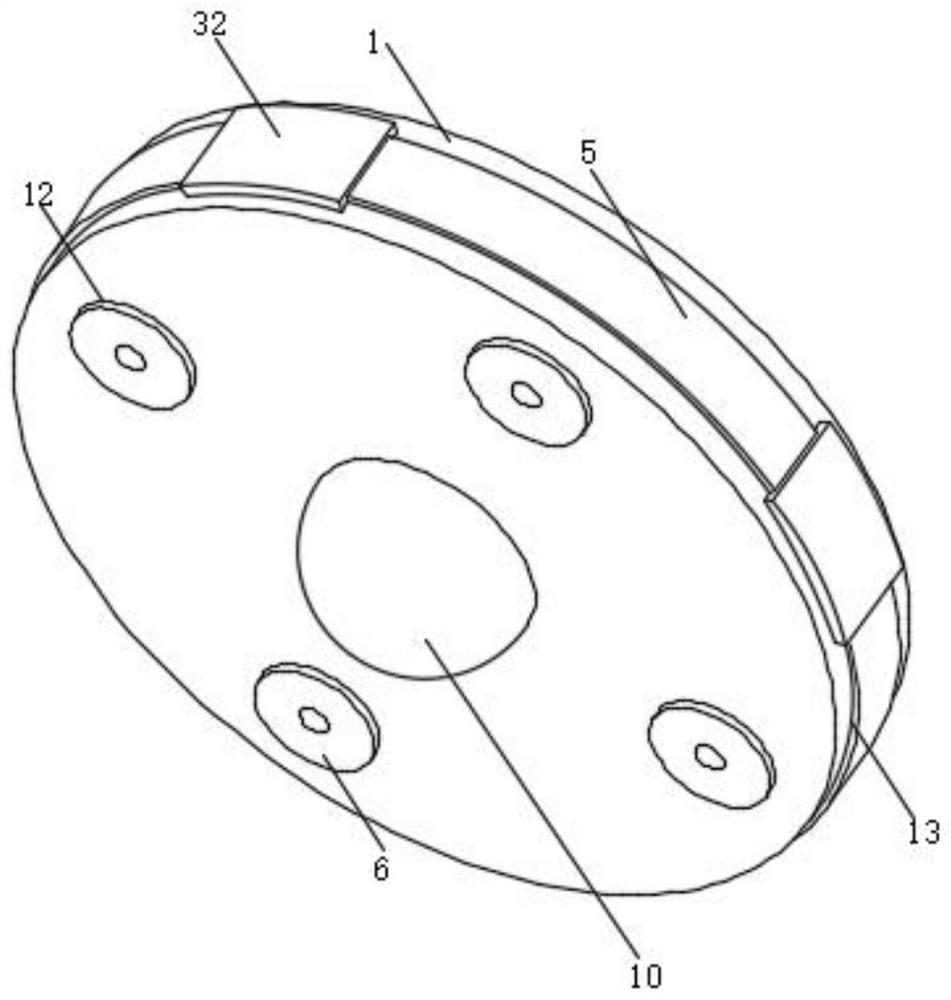

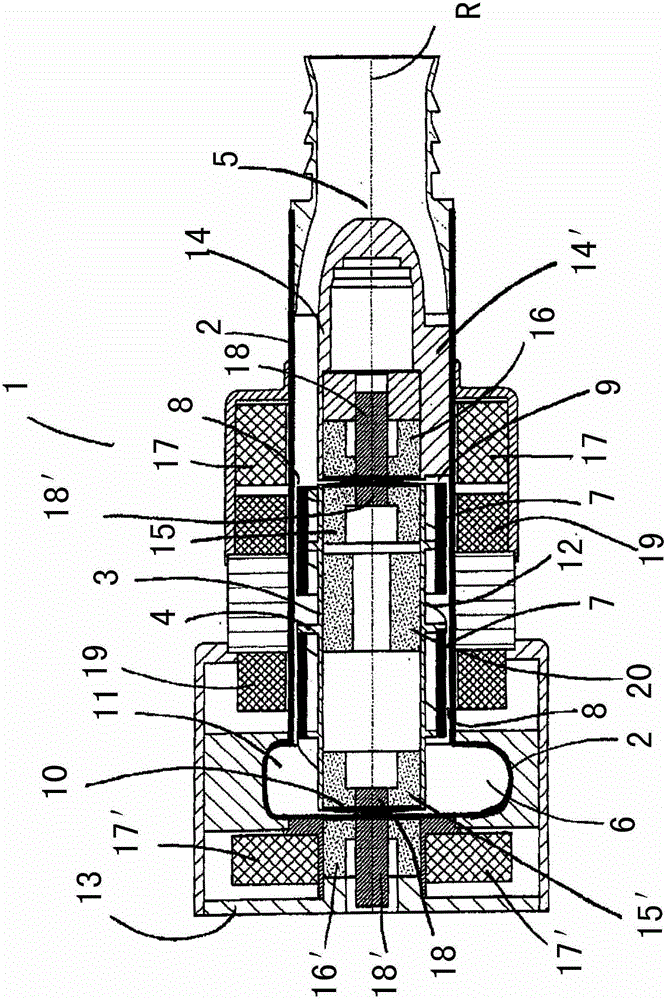

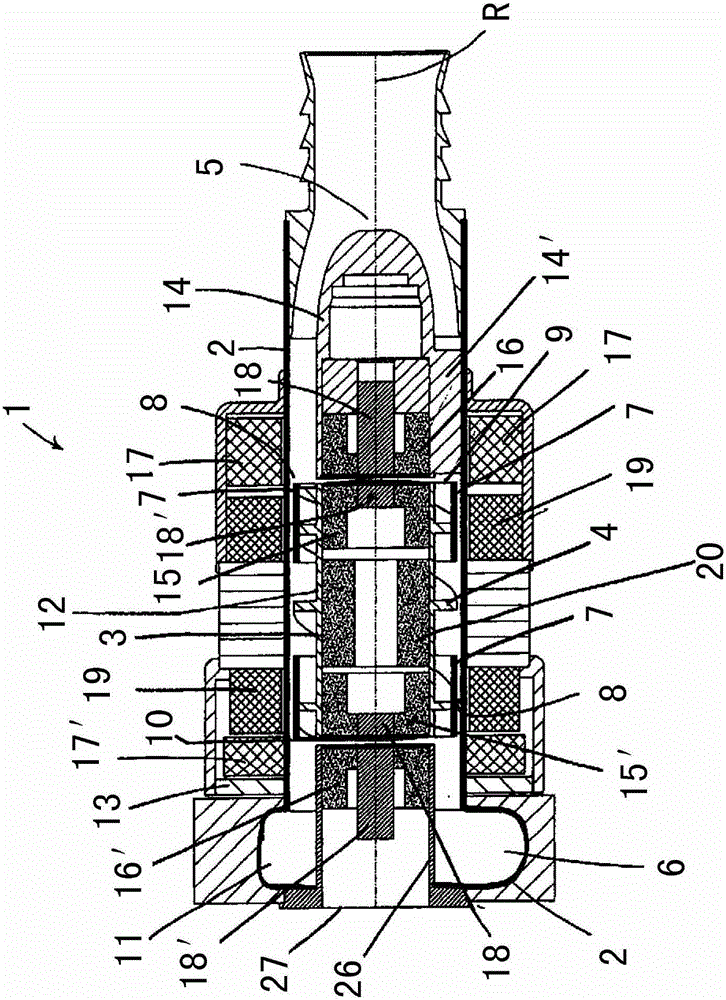

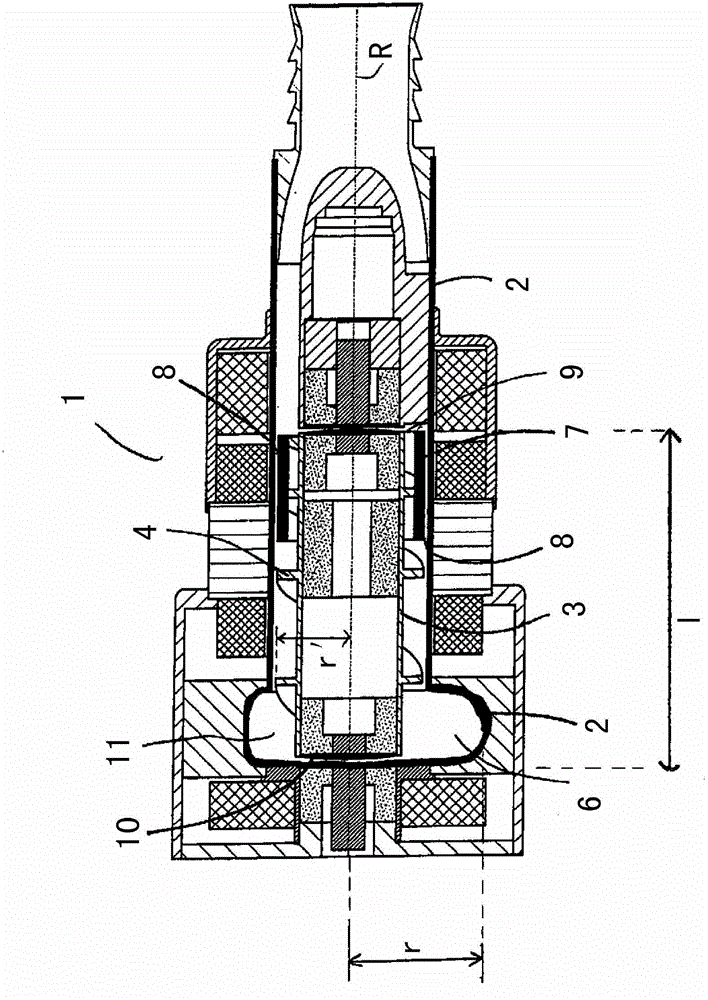

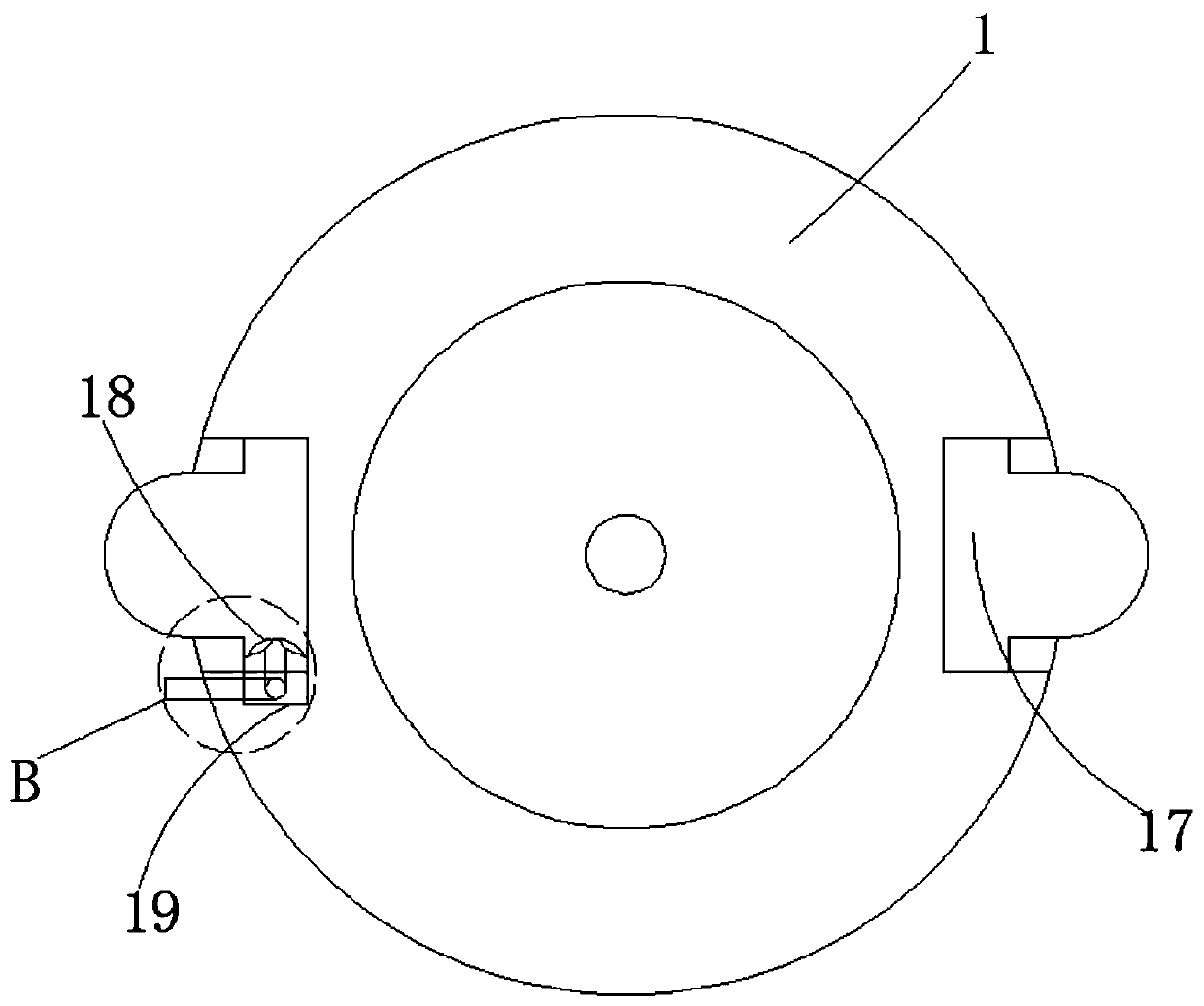

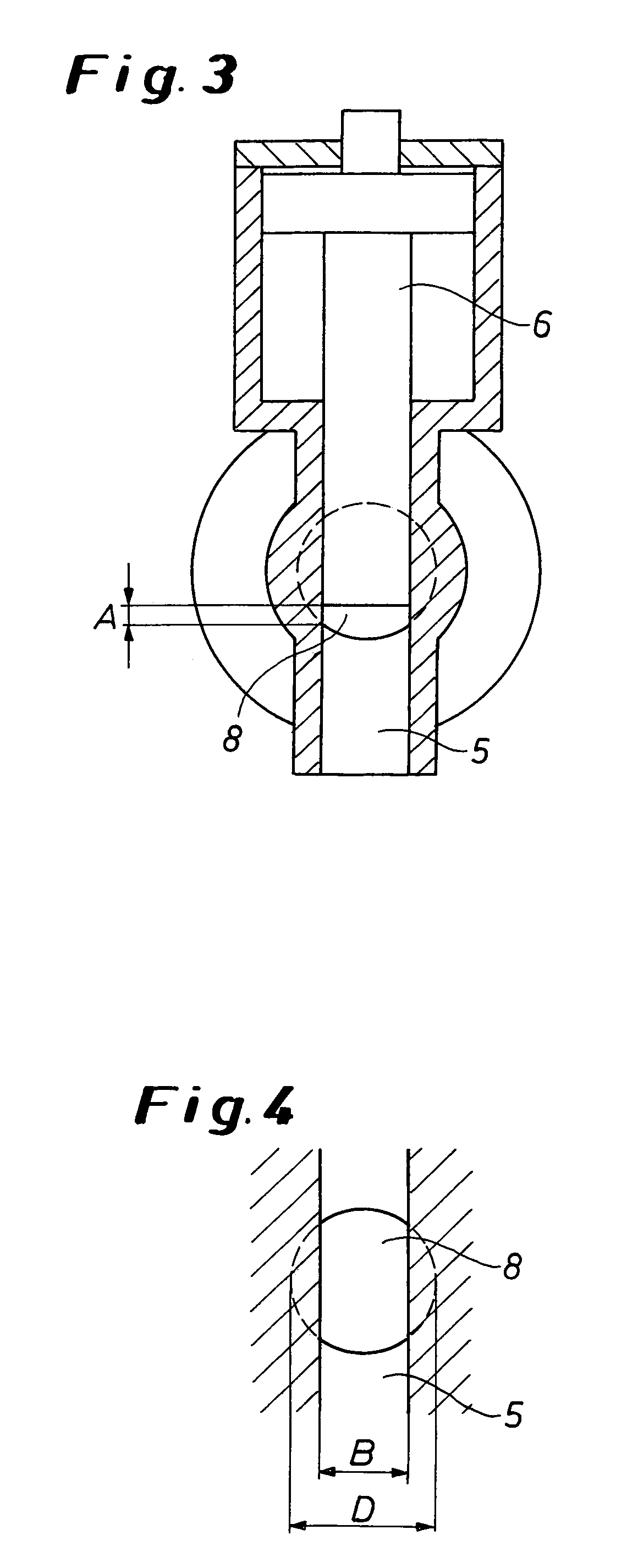

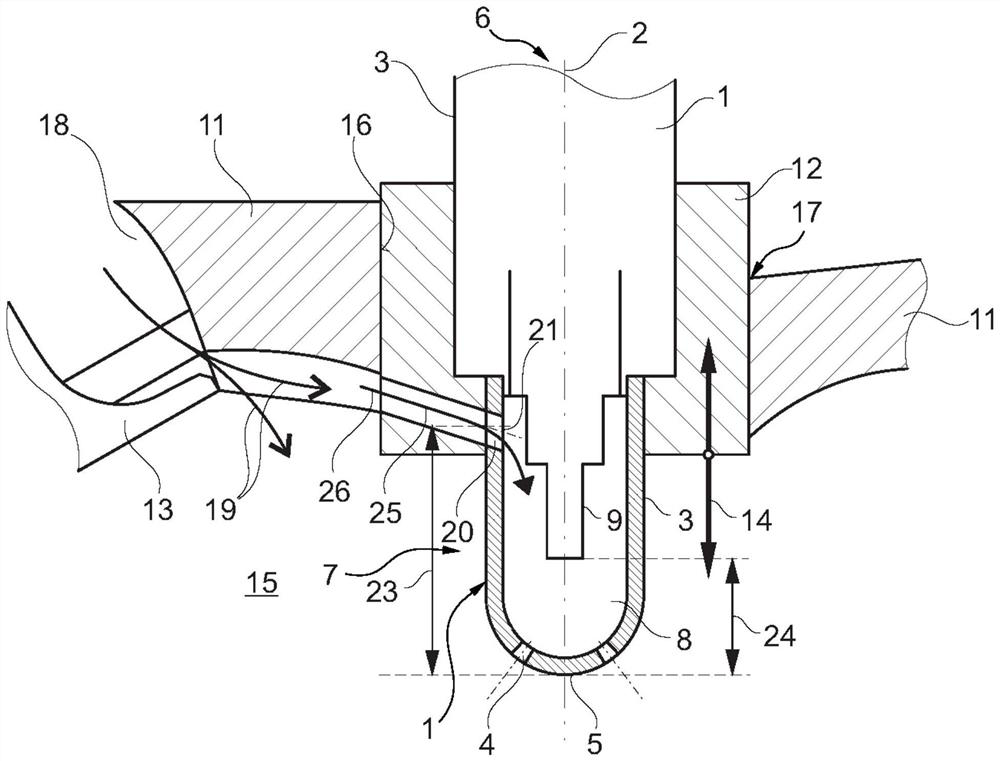

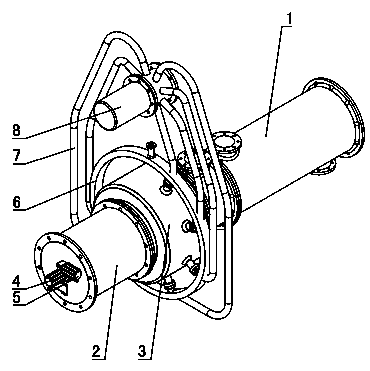

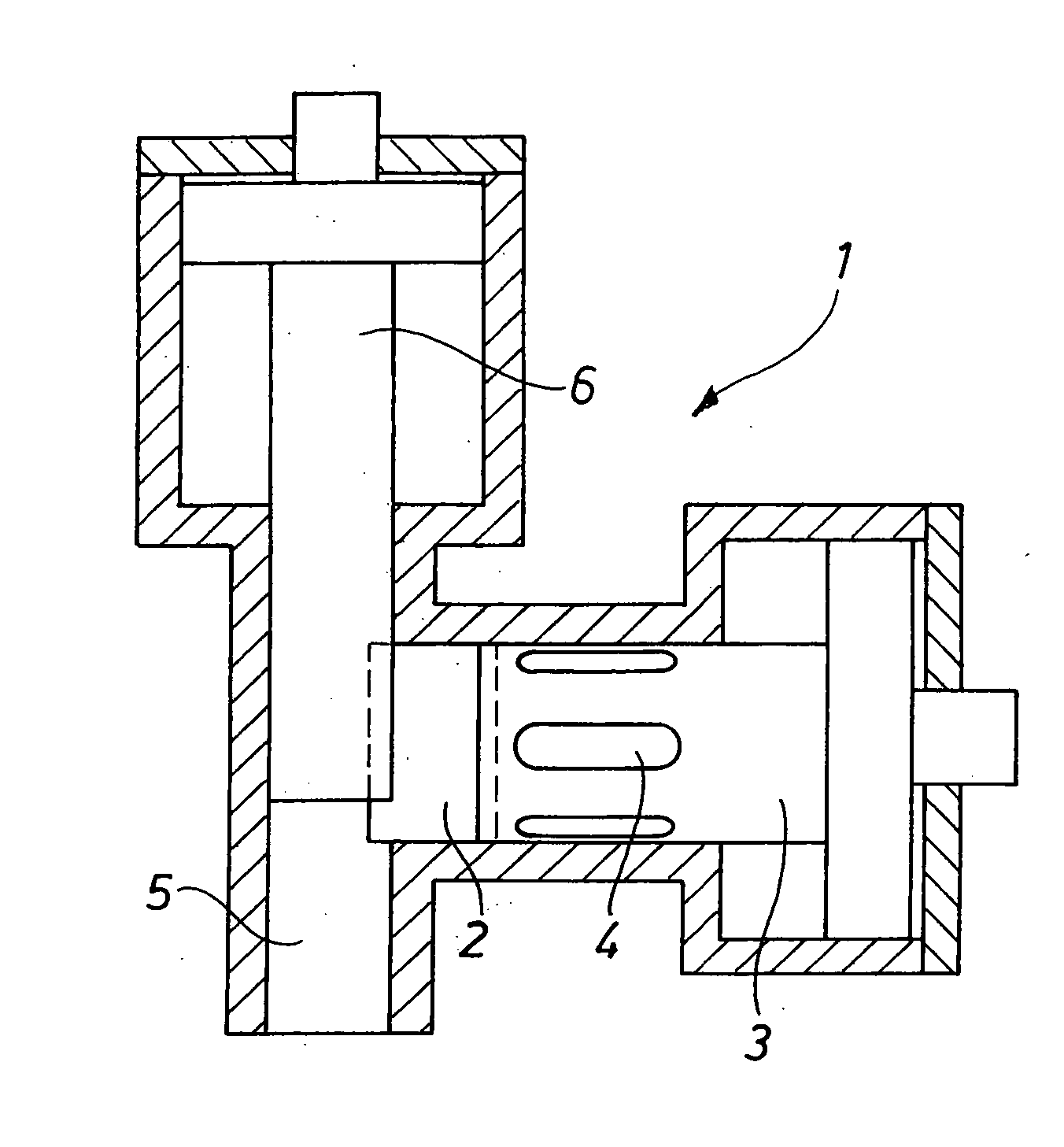

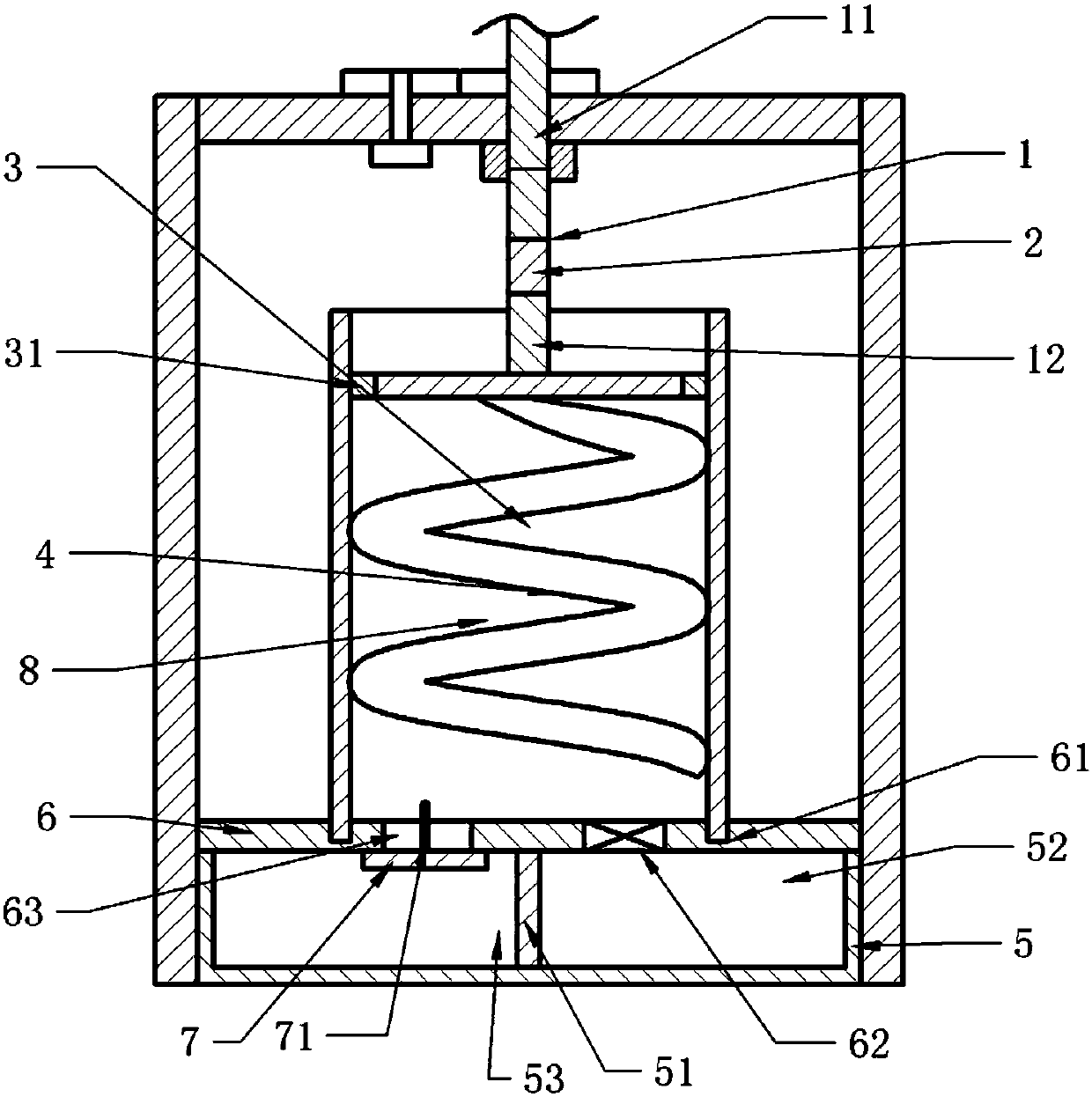

blood pump

InactiveCN102711862BAchieve outflowQuick connectionControl devicesBlood pumpsRotational axisImpeller

The invention relates to a blood pump (1) comprising a hollow body (2) in which is arranged an impeller (3) with blade means (4) for generating blood along said impeller ( 3) and said blood pump further comprising an at least partially actively stabilized magnetic bearing arrangement (15, 15', 16, 16', 17, 17', 18, 18' for said impeller ) and a hydrodynamic bearing device (7), wherein the impeller (3) can be set to rotate around its axis of rotation (R) by means of a motor stator (19) positioned outside the hollow body, and the hollow body ( 2) comprising an inlet (5) for allowing blood to flow into the hollow body (2) in an inflow direction (E) substantially parallel to the axis of rotation (R), and an outlet (6), the outlet For making blood flow out of the hollow body (2) along the outflow direction (A), the outlet (6) is set to be offset from the rotation axis (R) of the impeller (3), for An outflow angle (α) results between the inflow direction (E) and the outflow direction (A), which angle is not equal to zero, and the blading ( 4 ) is designed as a spiral. The invention also relates to a total artificial heart comprising two blood pumps of the type proposed herein.

Owner:BERLIN HEART GMBH

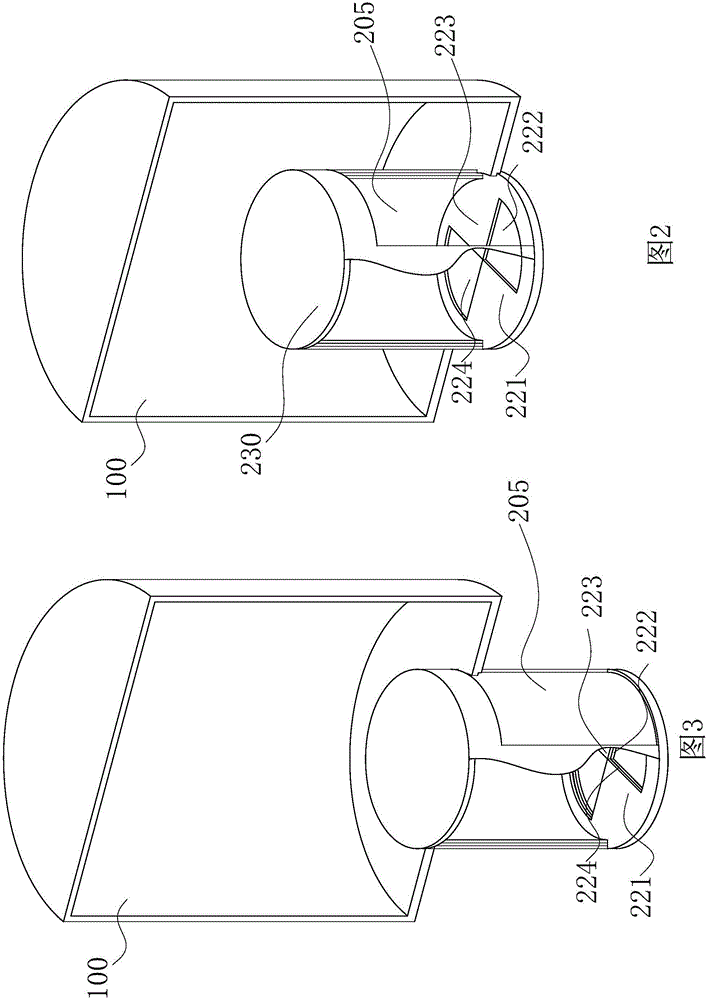

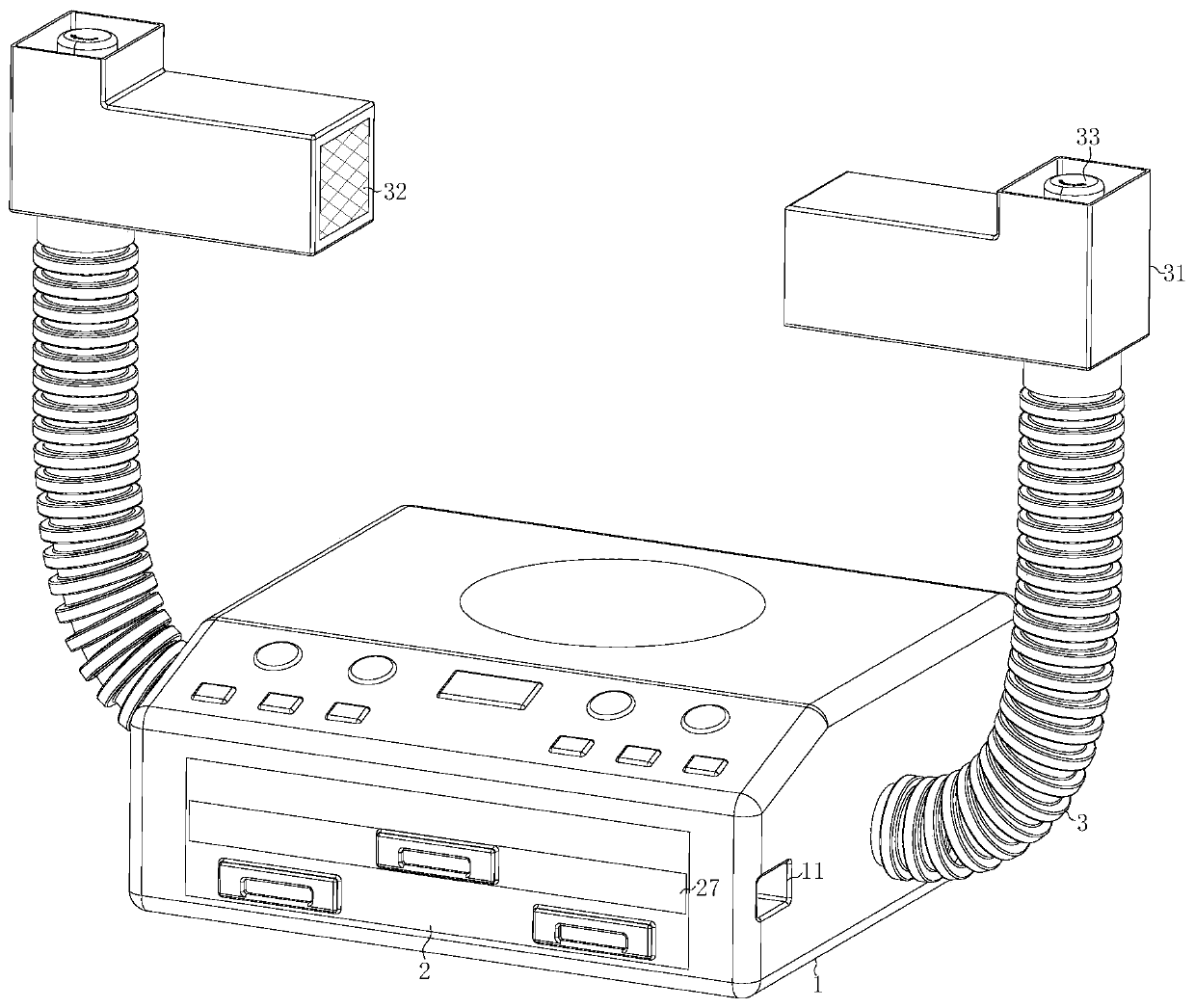

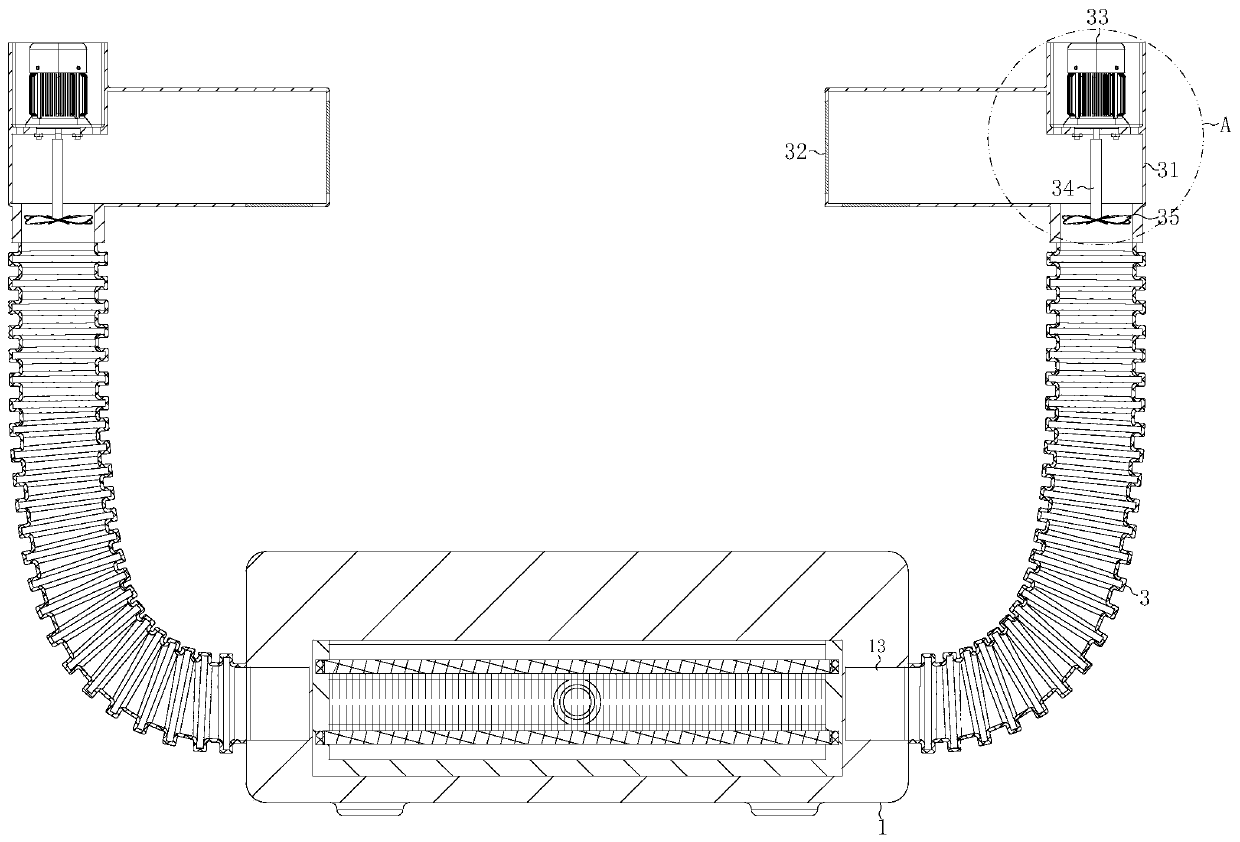

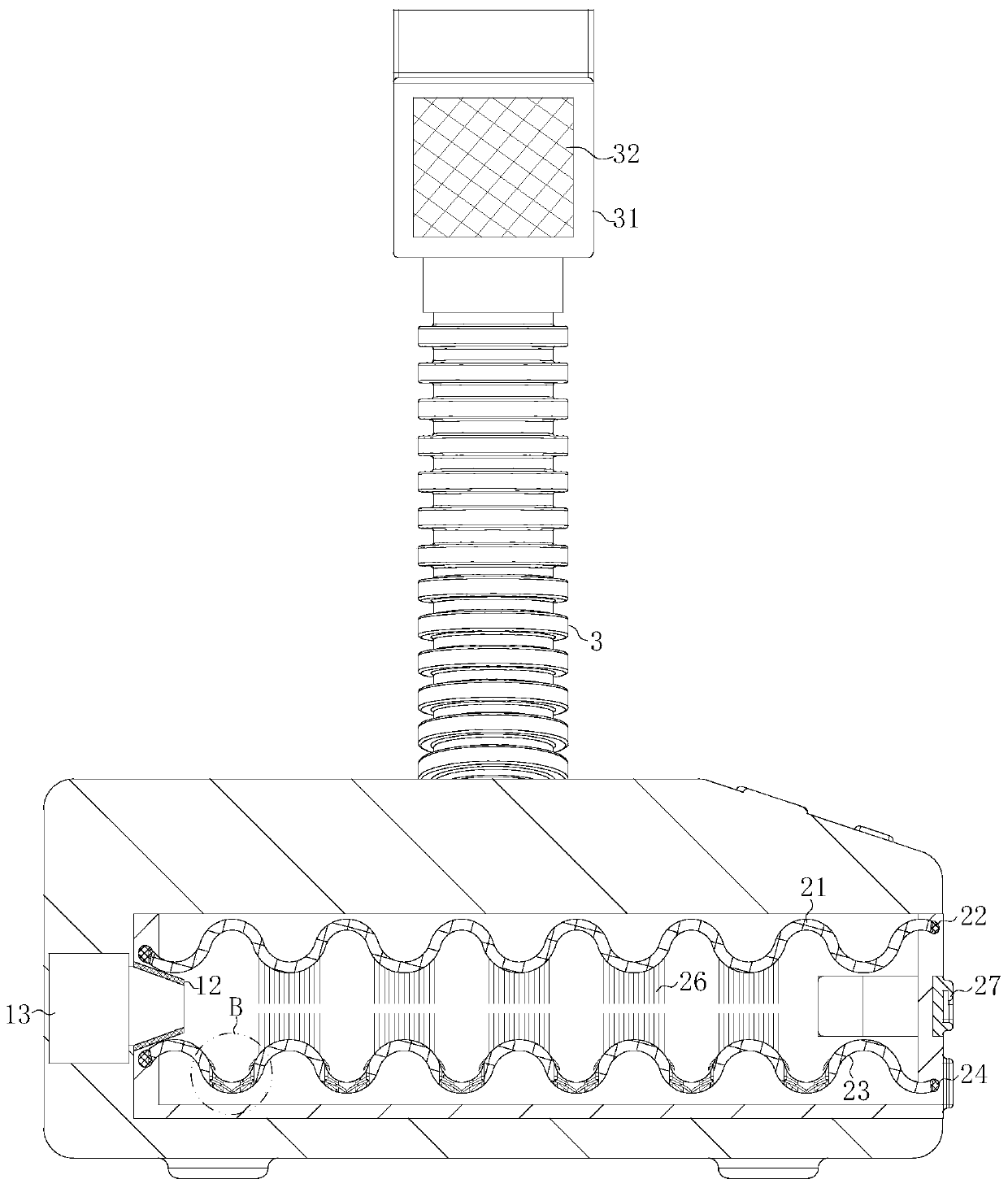

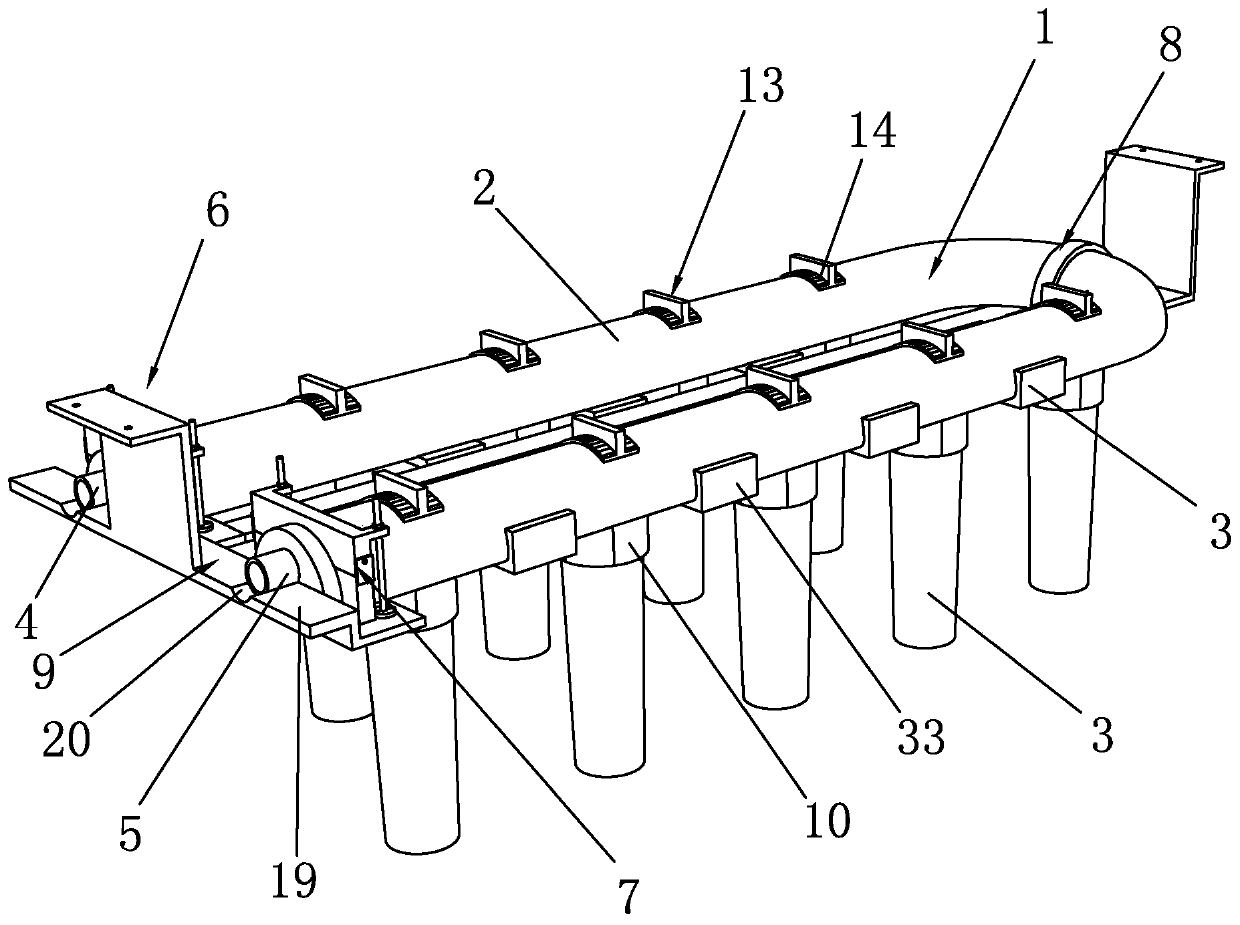

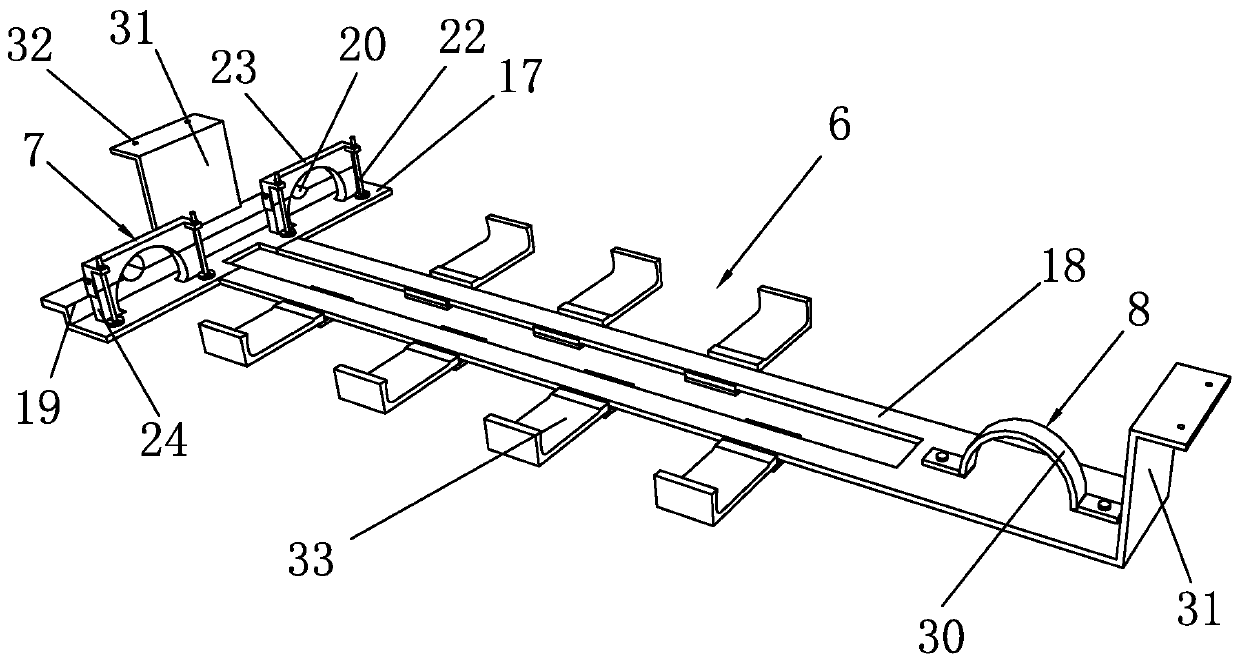

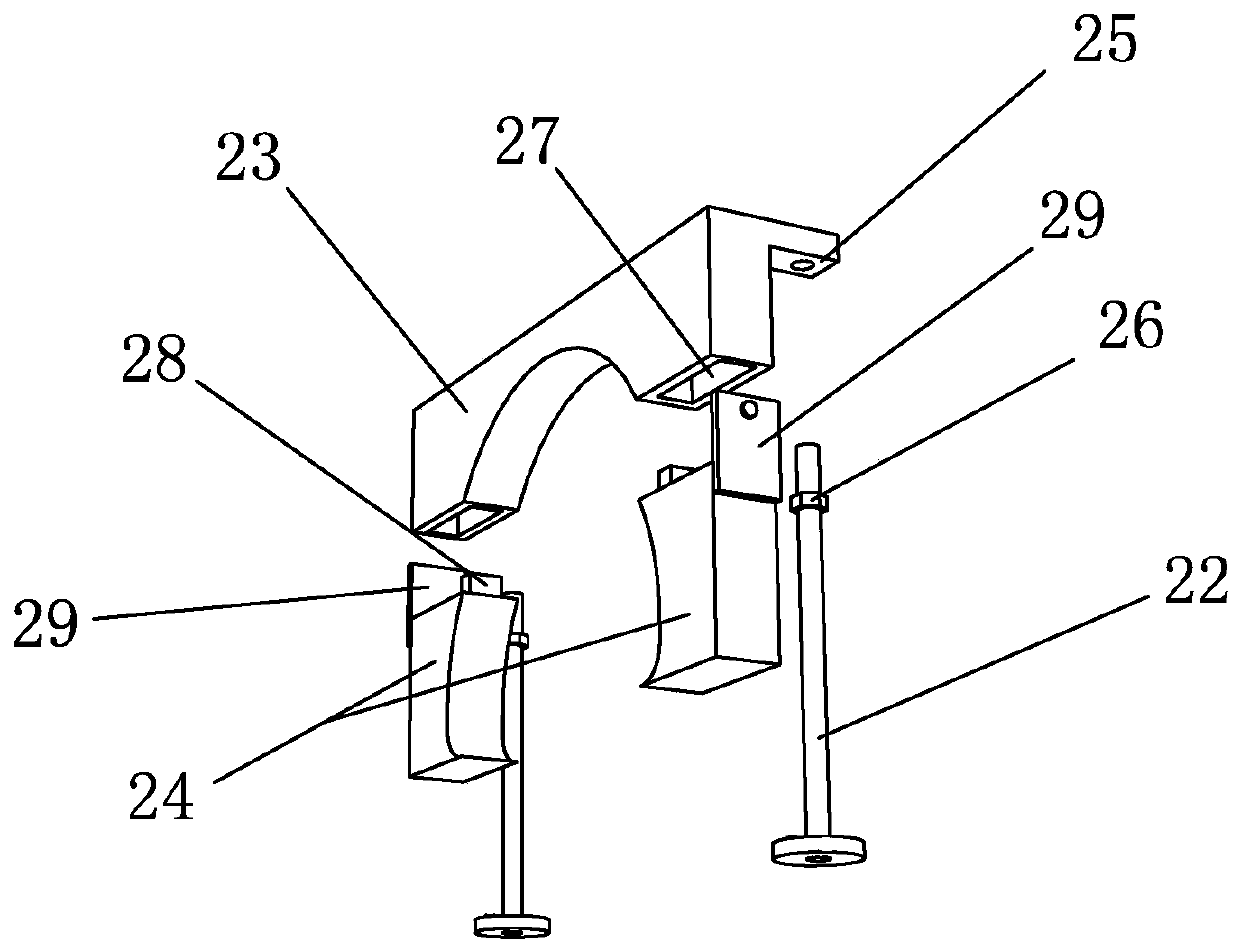

Household induction cooker

ActiveCN110529885AImplement filter collectionImprove the use environmentDomestic stoves or rangesLighting and heating apparatusEngineeringFan blade

The invention belongs to the technical field of kitchen household appliances, and particularly relates to a household induction cooker which comprises an induction cooker main body, a filter box and acorrugated adjusting pipe. The filter box is connected into the induction cooker main body in a sliding manner, a first wavy panel and a second wavy panel are inserted into the filter box, and the corrugated adjusting pipes are fixedly connected to the two side faces of the induction cooker body. The tops of the corrugated adjusting pipes are fixedly connected with the air inlet pipe heads, a motor is fixedly connected to the tops of the air inlet pipe heads, and the fan blades are arranged in the air inlet pipe heads. According to the present invention, the oil gas particles in the oil smokecan be filtered and collected, and the clean gas is finally exhausted, the requirements of the people for oil smoke treatment is met, the use environment of the users is improved, and the serious influence of the oil smoke on the health of the users is reduced.

Owner:中山市艾利普电器有限公司

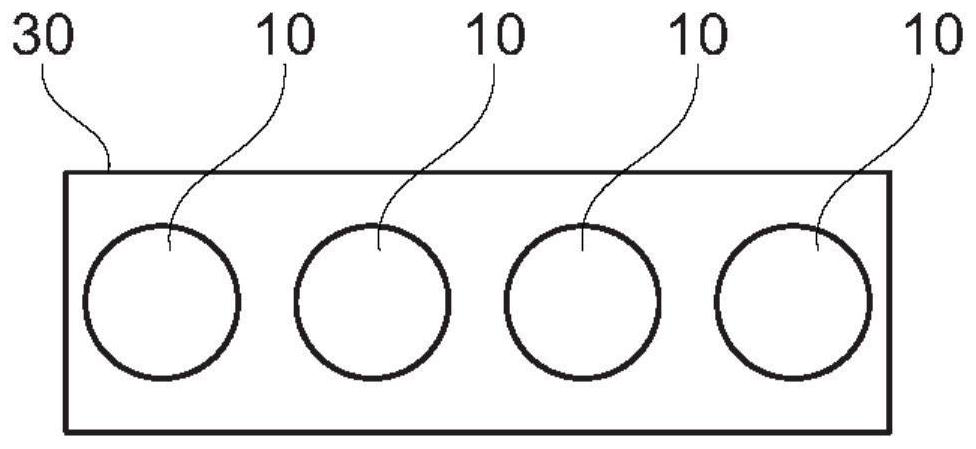

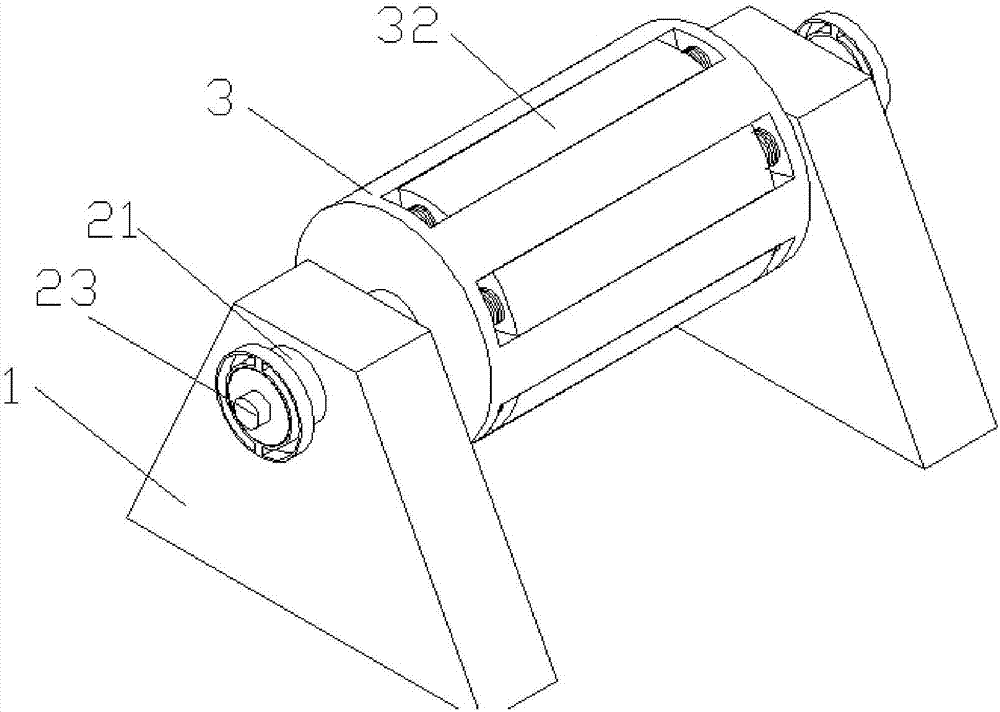

Energy-saving type ice-making evaporator and installation method thereof

PendingCN109959191AImprove structural stabilityNot easy to shake and deformIce productionFood processingPulp and paper industryRefrigerant

The invention discloses an energy-saving type ice-making evaporator, which includes an evaporator body and a supporting assembly. The supporting assembly includes end positioning parts, a middle positioning part and a bottom support plate, the end positioning parts and the middle positioning part are all located on the bottom support plate, the end positioning parts are located at the two ends ofa U-shaped pipe correspondingly, and the middle positioning part is located on the bent section of the U-shaped pipe. An installation method includes the following steps that (1) the evaporator body is assembled; (2) the bottom support plate is installed; (3) the end positioning parts are installed; (4) the middle positioning part is installed; and (5) the evaporator is installed. According to theenergy-saving type ice-making evaporator and the installation method thereof, a detachable installation mode is adopted between ice-making columns and the U-shaped pipe, deformed ice-making columns can be replaced regularly, meanwhile, through design of the supporting assembly, the overall structure of the evaporator is firmer, installation and positioning between the evaporator and an ice machine are more convenient, the structure stability performance of the evaporator during use can be guaranteed effectively, and thus circulation of a refrigerant is more stable and smoother.

Owner:新昌县长城空调部件股份有限公司

Packaging film printing mechanism

InactiveCN105620025AIncrease temperatureTo achieve the purpose of secondary heatingRotary pressesPrinting press partsEngineeringMechanical engineering

The invention discloses a packaging film printing mechanism. The packaging film printing mechanism sequentially comprises a packaging film feeding roller, a printing mechanism body, a packaging film printing drying device, a pair of traction rollers and a winding roller from front to back according to the technological process. The packaging film printing drying device comprises an air inlet pipe, an air outlet pipe and a drying device body, wherein the drying device body comprises a heating unit and a packaging film conveying unit. The heating unit is used for drying ink on the surface of a packaging film conveyed through the packaging film conveying unit. The air inlet pipe and the air outlet pipe both communicate with the heating unit, the heating unit further comprises a heating box, an air inlet is formed in the top of the heating box, and the heating box communicates with the air inlet pipe. The packaging film printing mechanism has the advantages that the drying effect is good, and material pouring is convenient.

Owner:ANQING BOMEI PLASTIC CO LTD

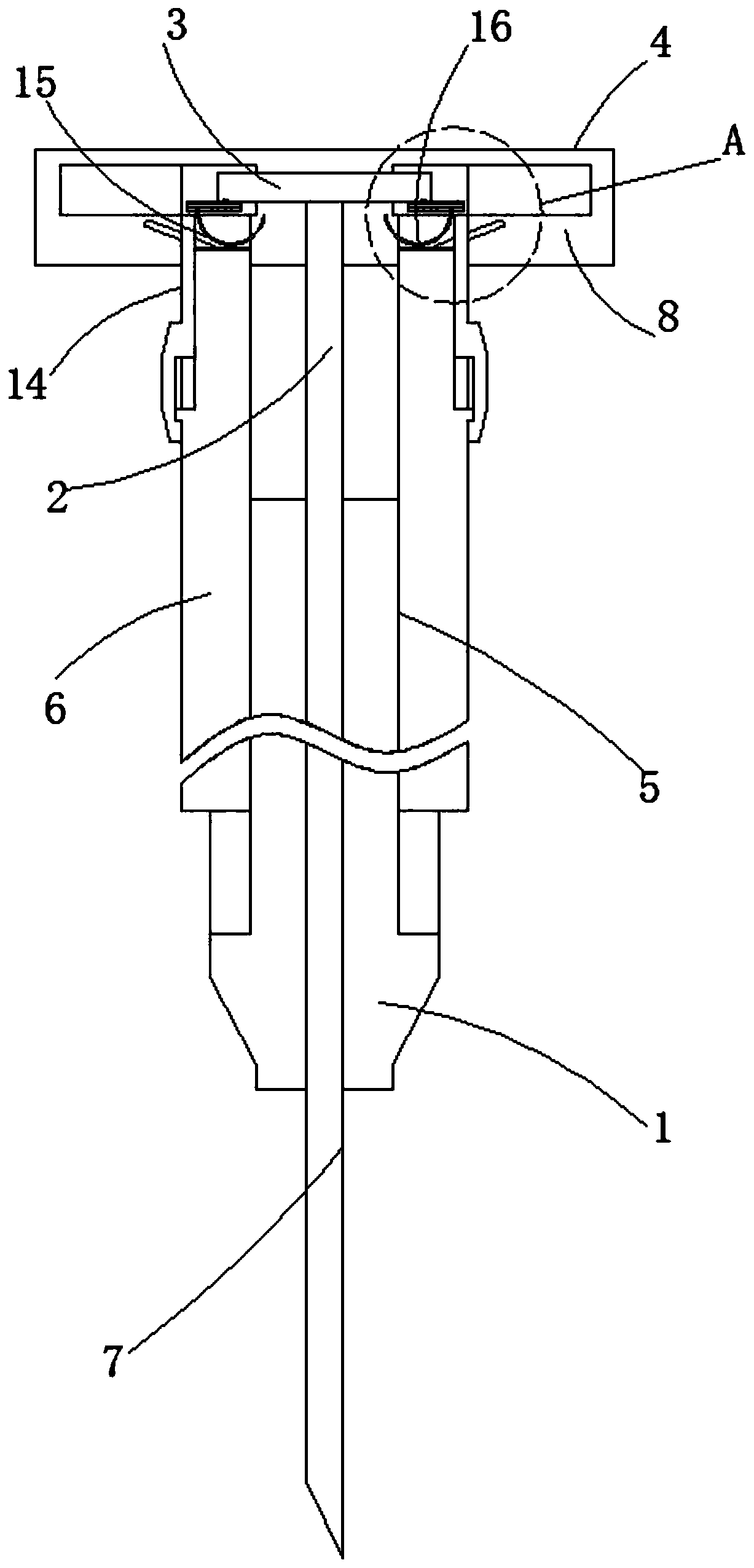

Micro-scale syringe

The invention belongs to the field of gas chromatographic sample injector, in particular to a micro-scale syringe. According to the scheme, the micro-scale syringe includes a work drum and a piston rod is arranged at the top end of the work drum. One end, extending out of the work drum, of the piston rod is fixedly connected with a pushing button which is provided with a butt joint assembly. A pair of retention grooves are symmetrically formed along two sides of one end, near the pushing button, of the work drum. A guidance assembly, connected with the butt joint assembly, is in a sliding connection with the internal part of the retention grooves. According to the micro-scale syringe, the combination with and separation from a syringe is conducted to realize reuse. When using the micro-scale syringe, the pushing button of the syringe is guided to avoid the deflection of the pushing button and the piston rod connected with the pushing button and protect the safety of the syringe. When the micro-scale syringe injecting, by buffering the force of the piston rod, over much injection volume and over fast injection is avoided when pushing force is over strong. Relative motion between thework drum and the pushing button is avoided to realize quantitative injection, and the outflow of liquid in the syringe, under the action of external forces, when do not use the micro-scale syringe,is avoided.

Owner:WEST ANHUI UNIV

Multiple component mixing head

The invention relates to a mixing head and to a method of mixing at least one polyol component and at least one isocyanate component and where appropriate additives, to form a polyurethane reaction mixture.

Owner:HENNECKE

Milling device for monosodium glutamate production

InactiveCN108212472AEasy to processSimple structureGrain treatmentsMonosodium glutamateFood processing

The invention relates to the technical field of food processing, in particular to a milling device for monosodium glutamate production. The milling device comprises a shell, wherein a feeding inlet isformed in the top part of the shell; two fixed plates are horizontally arranged in the shell; a plurality of milling bars are arranged between the two fixed plates; a baffle plate is arranged under the milling bars; a milling plate is horizontally arranged under the baffle plate; an air cylinder is also arranged under the baffle plate; one side of the air cylinder is connected with an impact block; a vertical plate is arranged at one side, which is far away from the air cylinder, in the shell; a discharging outlet is also formed in the bottom part of the milling plate; a feeding pipe is arranged under the feeding inlet; a horizontal end of the feeding pipe is connected with a filter barrel; the filter barrel is rotationally connected with the feeding pipe; a rotating motor is arranged atone side of the shell; an output end of the rotating motor is connected with a rotating shaft. The milling device disclosed by the invention is simple in structure, the milling sufficiency of raw materials is effectively ensured, the problem that powdery raw materials are caked is also avoided, and the milling device is convenient to popularize and use.

Owner:重庆真渝食品有限公司

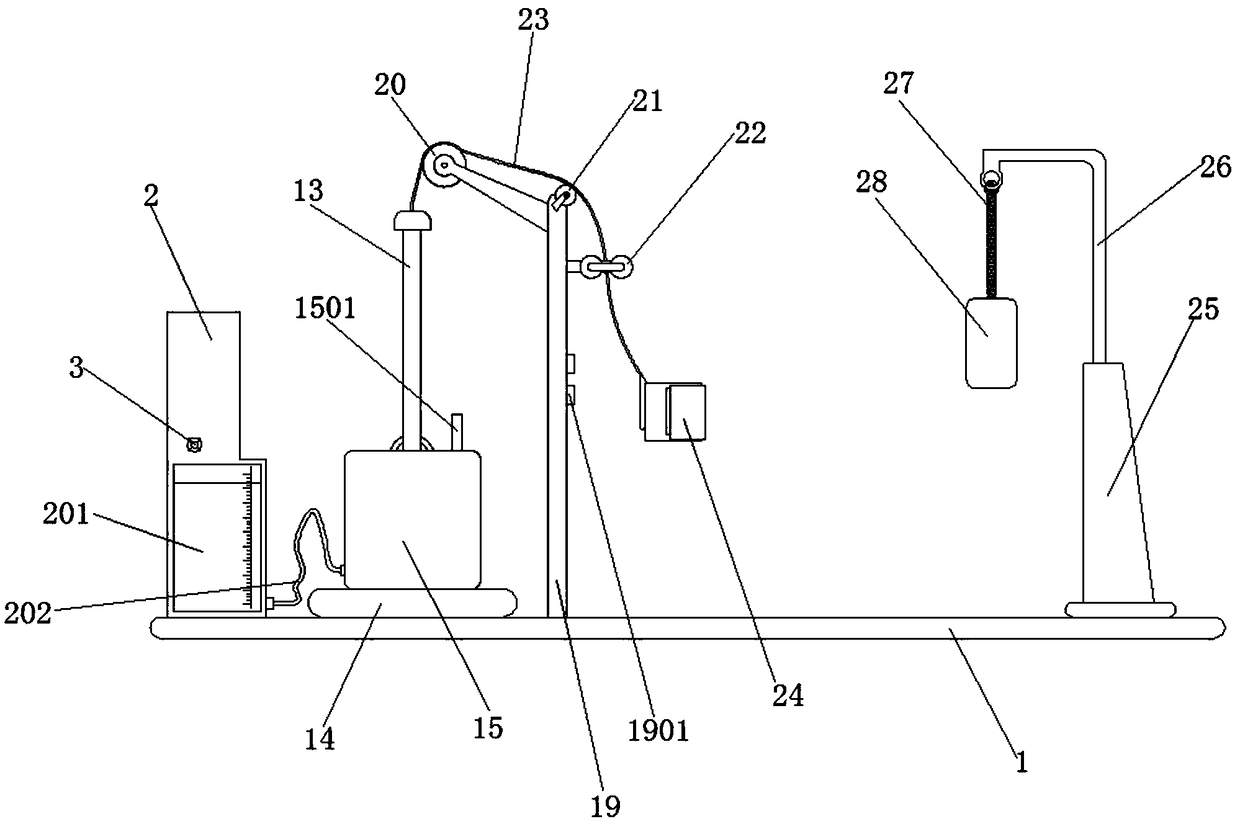

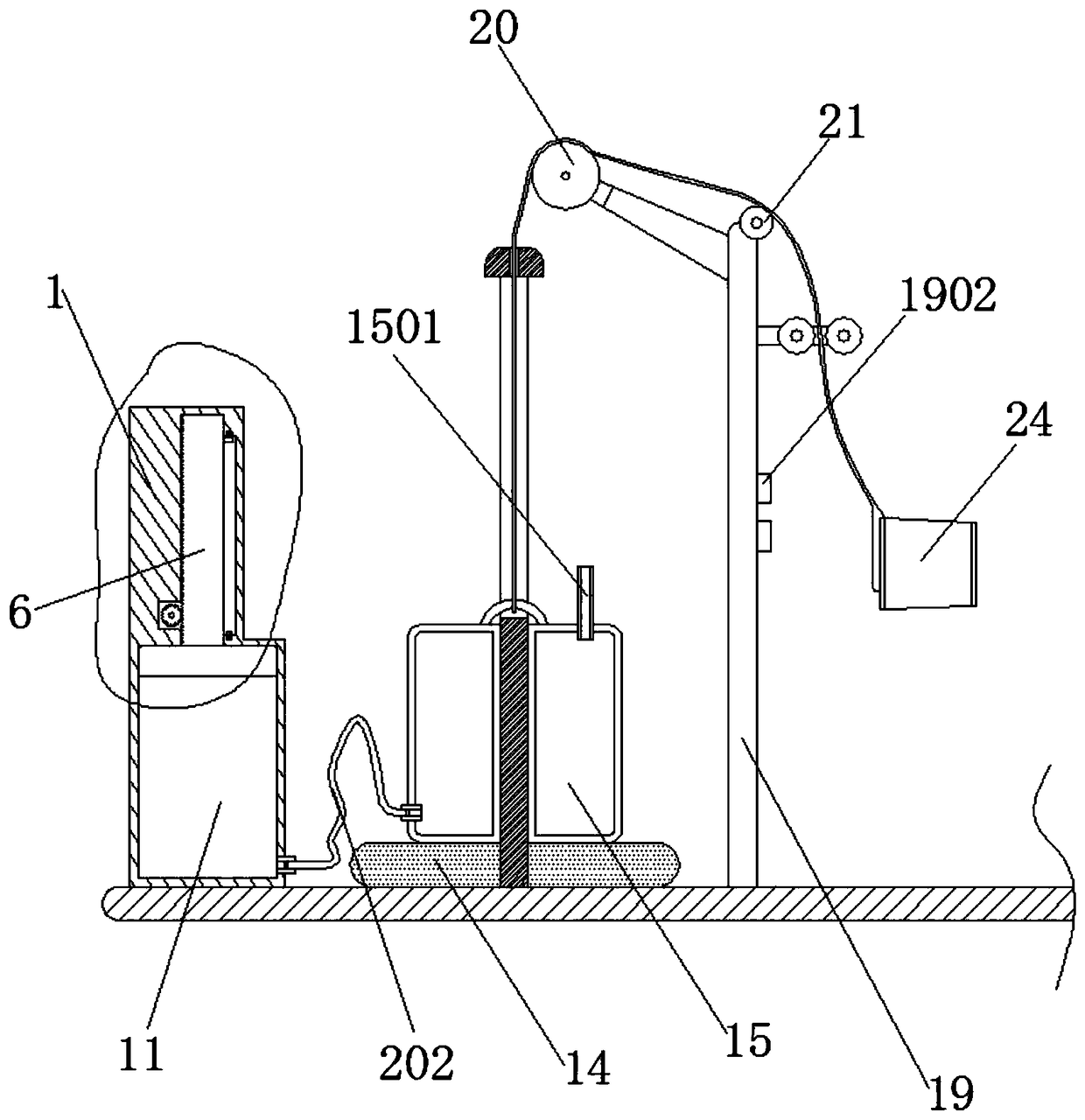

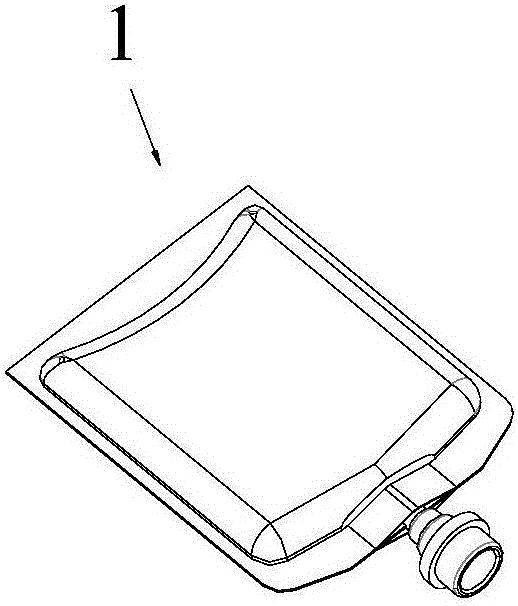

Pharmaceutical dispensing device and dispensing method for penicillin bottle

InactiveCN106038292ASimple structureEasy to usePharmaceutical containersMedical packagingBiomedical engineeringExtrusion

The invention discloses a pharmaceutical dispensing device and a dispensing method for a penicillin bottle. The pharmaceutical dispensing device comprises a base plate, an infusion bag and a penicillin bottle are arranged on the base plate, the infusion bag communicates with the penicillin bottle through an infusion tube part, an elevating part is connected above the installation station of the infusion bag , the elevating part comprises a bracket, the bracket can be elevated and lowered relative to the infusion bag to realize the contact extrusion of the infusion bag, and the base plate is also provided with a rotating part capable of driving the base plate to rotate in a vertical plane. The dispensing method thereof includes preparation, extrusion of the infusion bag, rotation of the base plate, second extrusion of the infusion bag, and completion of dispensing. According to the dispensing device, the structure is simple, the usage is convenient, there is no need to adopt a transfer container to make the infusion bag communicate with the penicillin bottle to realize direct infusion or outflow of liquid of the infusion bag and the penicillin bottle, the structure is optimized, and mutual infection is avoided. Compared with manual extrusion of the infusion bag, the dispensing method can achieve automatic extrusion or loose pressure on the infusion bag, improve the dispensing efficiency, and save the dispensing time.

Owner:CHENGDU JIESHIDE SCIENCE AND TECHNOLOGY CO LTD

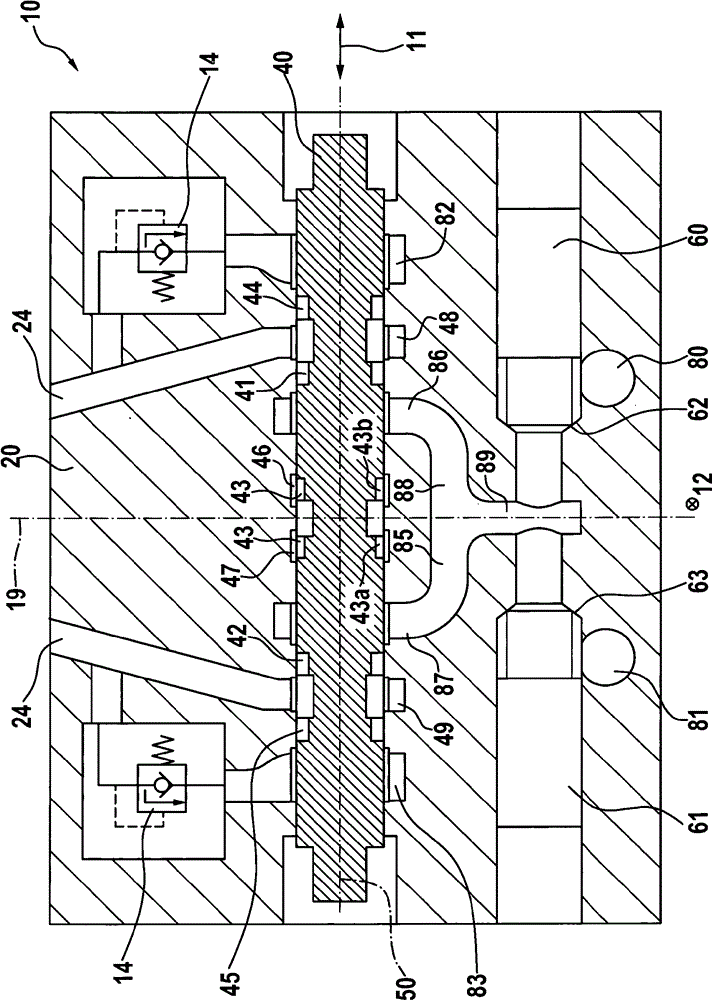

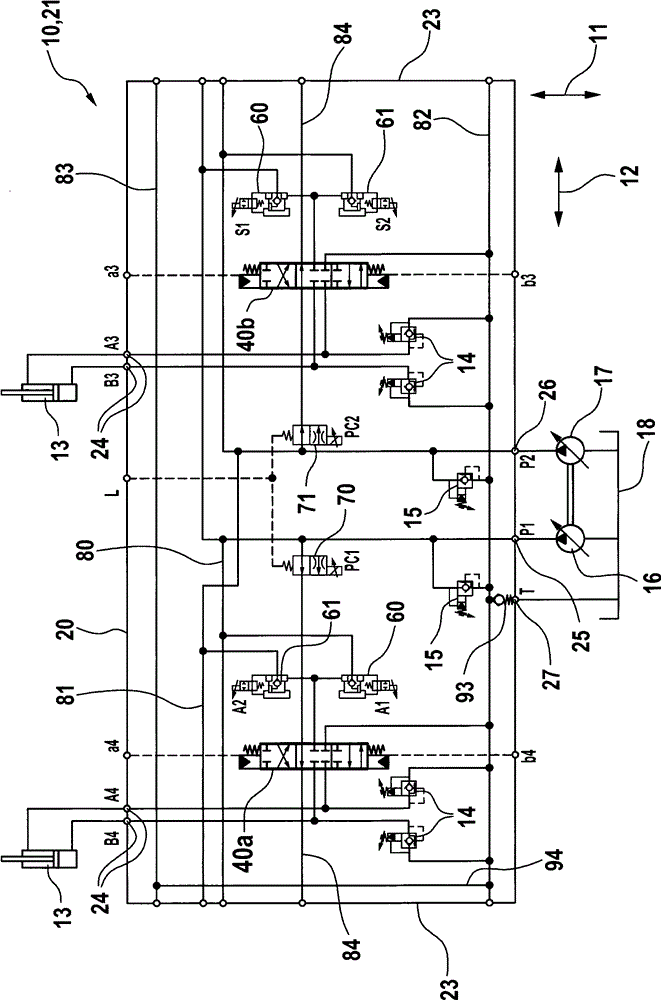

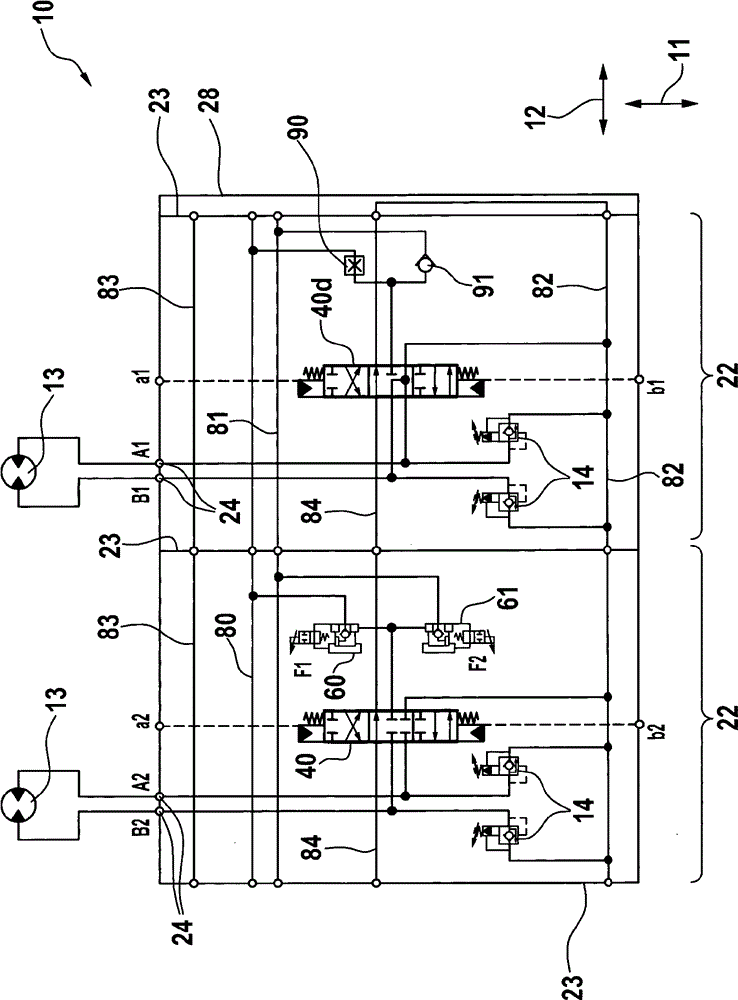

Open-centre valve block with two pump connections and associated auxiliary sliders on the main sliders

ActiveCN104704174AAvoid formingLow costServomotor componentsServomotorsEngineeringElectrical and Electronics engineering

The invention relates to a valve block (10) comprising a plurality of main sliders (40), which are supplied in parallel with pressure fluid via a first and a second pump conduit (80; 81), the fluid stream, which flows in from the respective pump conduits (80; 81), being controllable by means of an associated first and second auxiliary slider (60; 61). All main sliders (40) are surrounded by a first and a second annular groove (46; 47) in the housing (20) so as to form an adjustable third main aperture (43) that connects the first annular groove to the second annular groove (46; 47), the first annular groove (46) of a first main slider being connected to the first pump connection, the first annular groove (46) of a second main slider being connected to the second pump connection, the second annular groove (47) of a third and of a fourth main slider being connected to a tank connection on the housing (20), furthermore, the first annular groove (46) of a main slider (40) being connected to the second annular groove (47) of an adjacent main slider (40), the third main aperture (43) becoming smaller when the first or the second main aperture (41; 42) of the same main slider (40) becomes larger.

Owner:ROBERT BOSCH GMBH

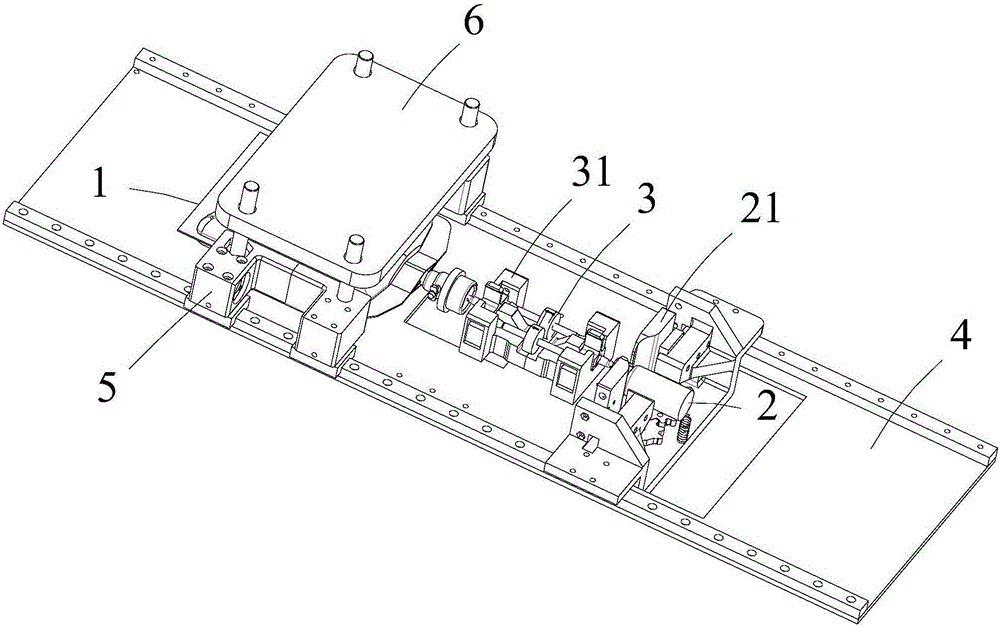

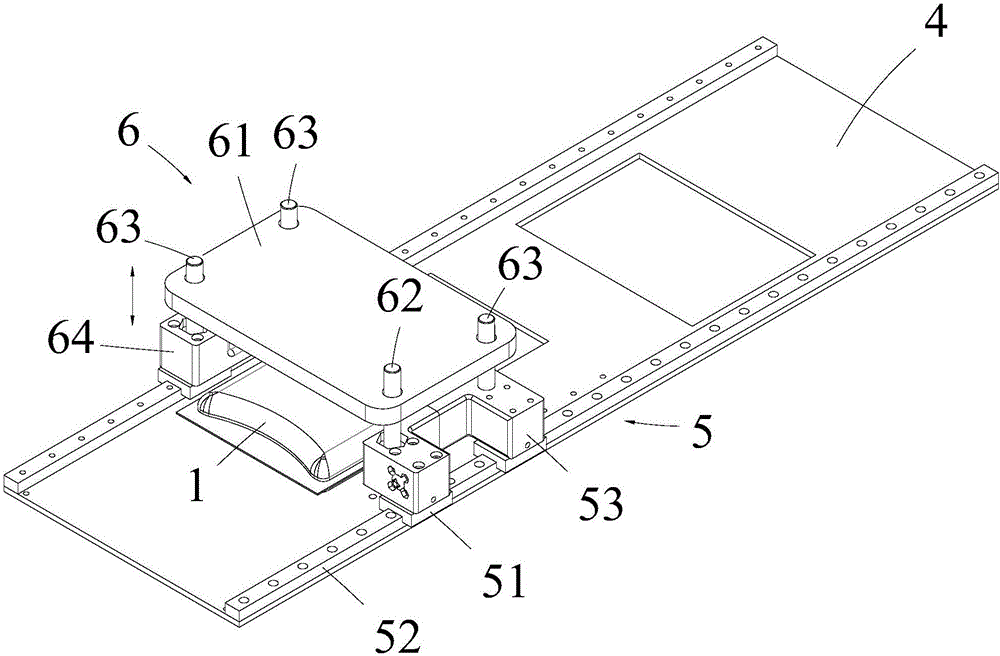

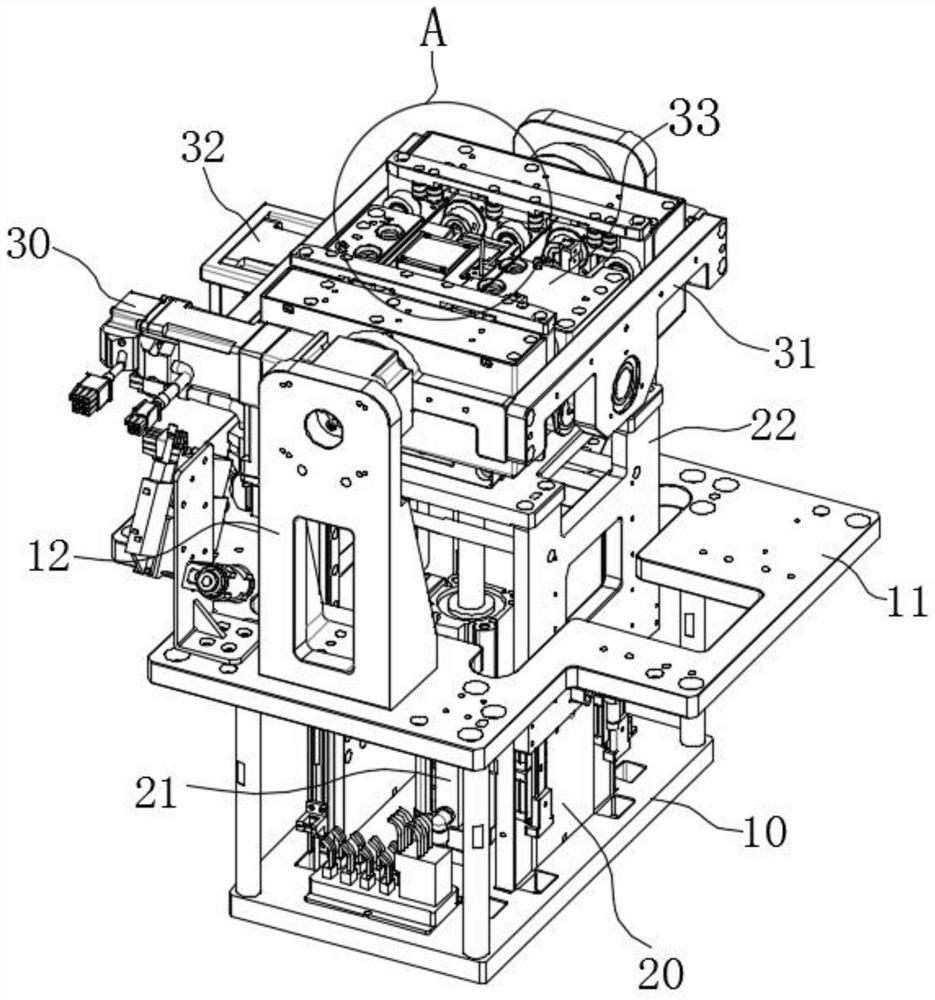

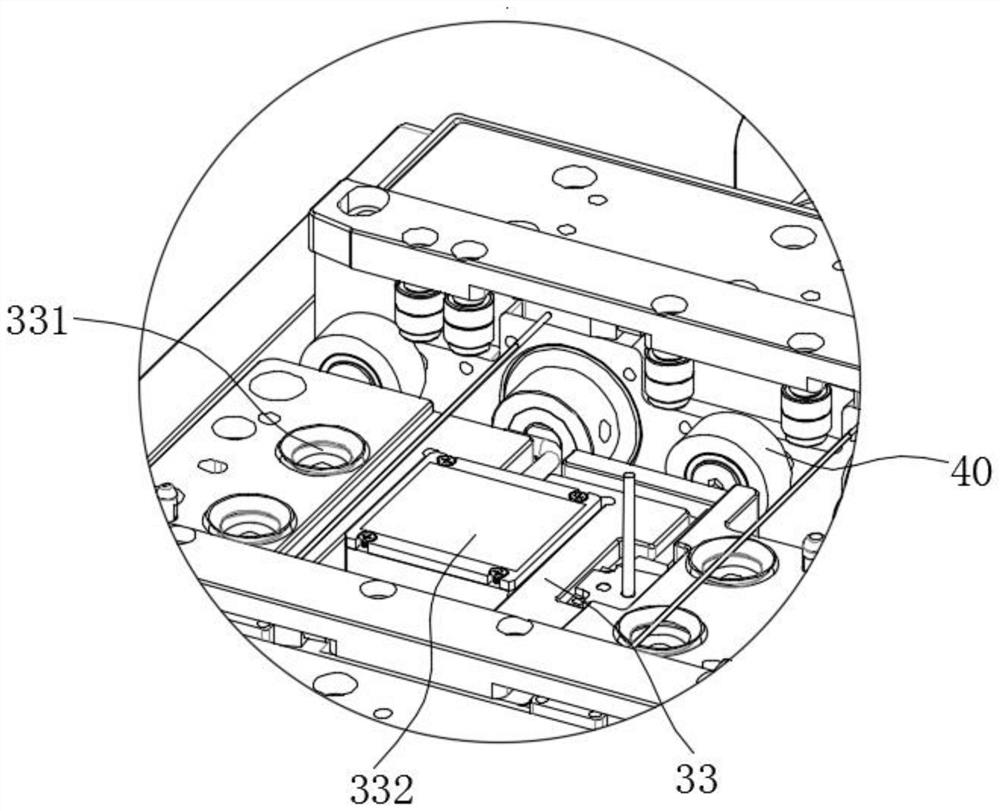

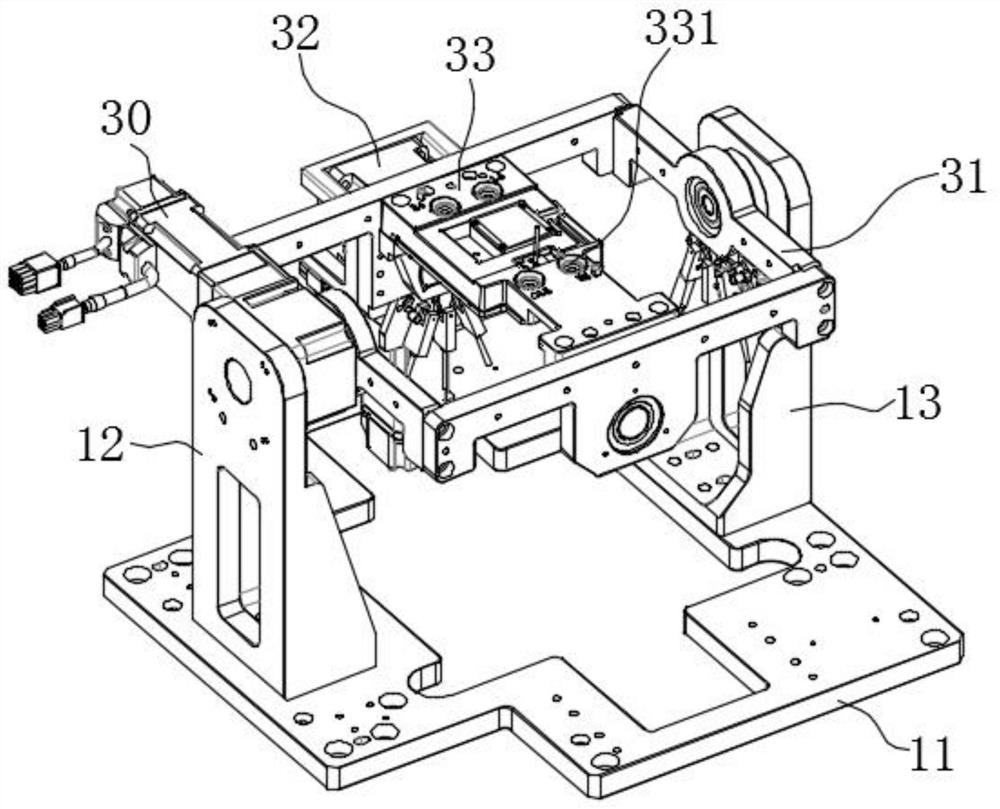

Multi-degree-of-freedom adjusting device and transmission mechanism

PendingCN112378927AImprove work efficiencyCompact structureOptically investigating flaws/contaminationConveyor partsTransmission lineMulti degree of freedom

The invention discloses a multi-degree-of-freedom adjusting device which comprises: an overturning assembly, wherein the overturning assembly comprises a first overturning driving source, a first overturning piece, a second overturning driving source and a second overturning piece, and the first overturning driving source is connected with the first overturning piece to drive the first overturningpiece to overturn, the second overturning driving source is arranged on the first overturning piece, and the second overturning driving source is connected with the second overturning piece to drivethe second overturning piece to overturn; a conveying assembly which is in butt joint with the transmission line so as to input or output products; and a lifting assembly, wherein the lifting assemblyis located on the lower side of the conveying assembly and drives the conveying assembly to do lifting action, the conveying assembly descends so that the products can fall on the second overturningpiece, and the conveying assembly ascends so that the products on the second overturning piece can be jacked. Machining, assembling, detecting and conveying of curved surface products are facilitated,the working precision is improved, the size is small, and the structure is compact.

Owner:BOZHON PRECISION IND TECH CO LTD

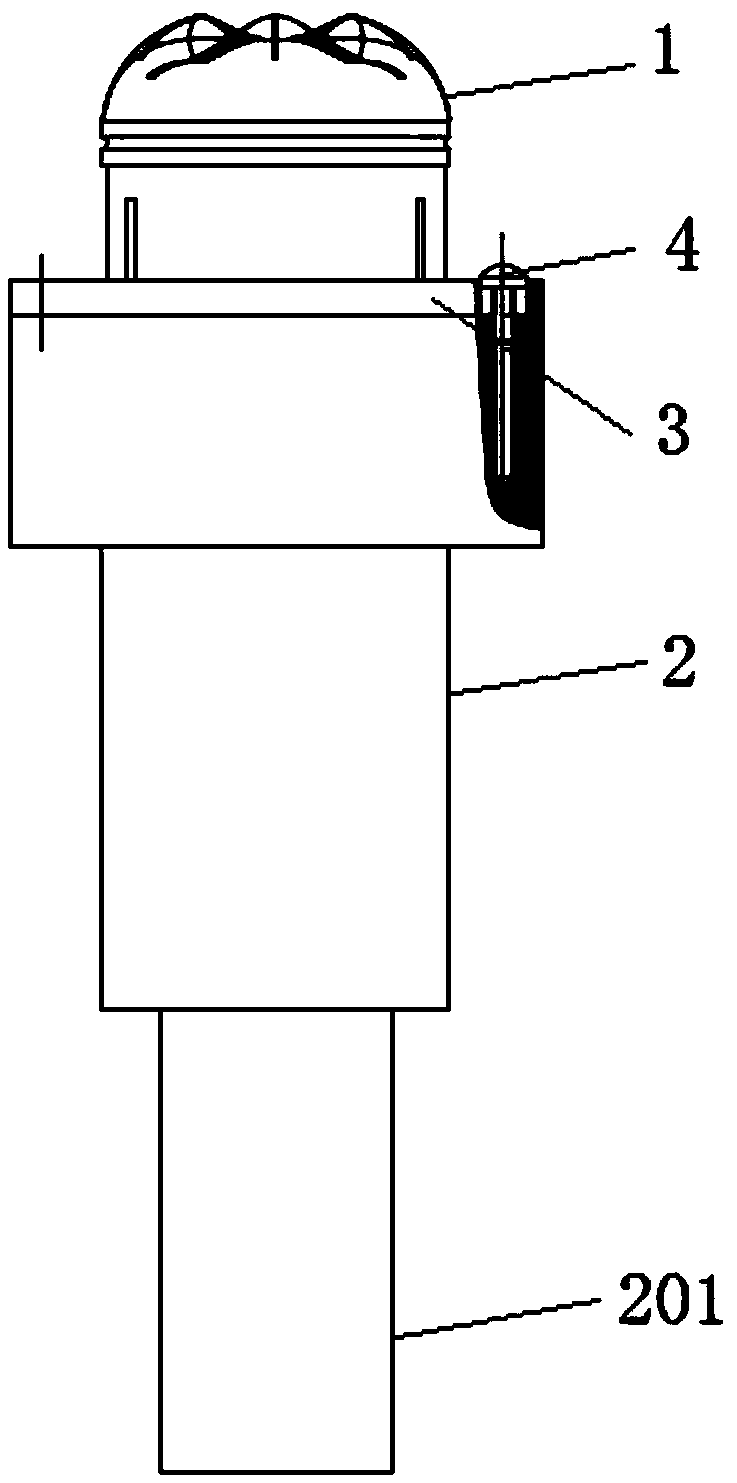

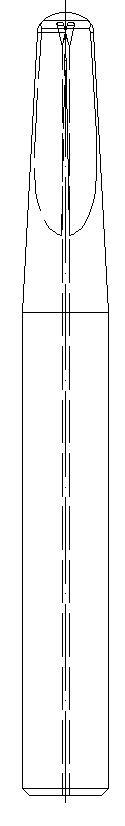

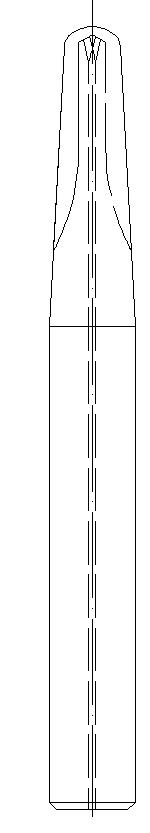

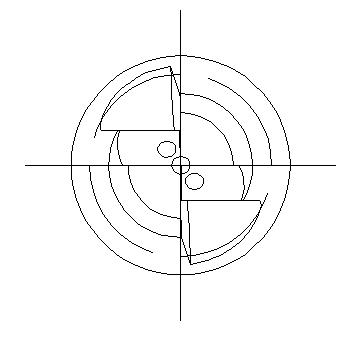

Ignition plug with pre-chamber and device for flushing pre-chamber

PendingCN112177765AReadyAchieve outflowSparking plugsInternal combustion piston enginesThermodynamicsCombustion chamber

Described is an ignition plug (1) comprising an outer wall (3) comprising a combustion chamber-side region (7) configured to be arranged in a combustion chamber (15), a longitudinal axis (2), a combustion chamber-side end (5) in the longitudinal direction and a combustion chamber counter-end (6), at least one pre-combustion chamber (8) being arranged at the combustion chamber-side end (5), and thepre-combustion chamber (8) has at least one combustion chamber-side opening (4) for conducting the mixture that has been ignited in the pre-combustion chamber into the combustion chamber (15). The outer wall (3) is at least partially surrounded in the circumferential direction by a support (12), at least one flow channel (20, 25) for flushing the pre-chamber extends through the support (12) and the outer wall (8) in the region of the pre-chamber (8), the at least one flow channel fluidically connecting the pre-chamber (8) to the combustion chamber-side region (7), wherein the flow channel (20, 25) for flushing the pre-chamber is configured to be opened and closed by means of a displacement of the bracket (12) relative to the cylinder head (11) in an installed state within the cylinder head (11).

Owner:FORD GLOBAL TECH LLC

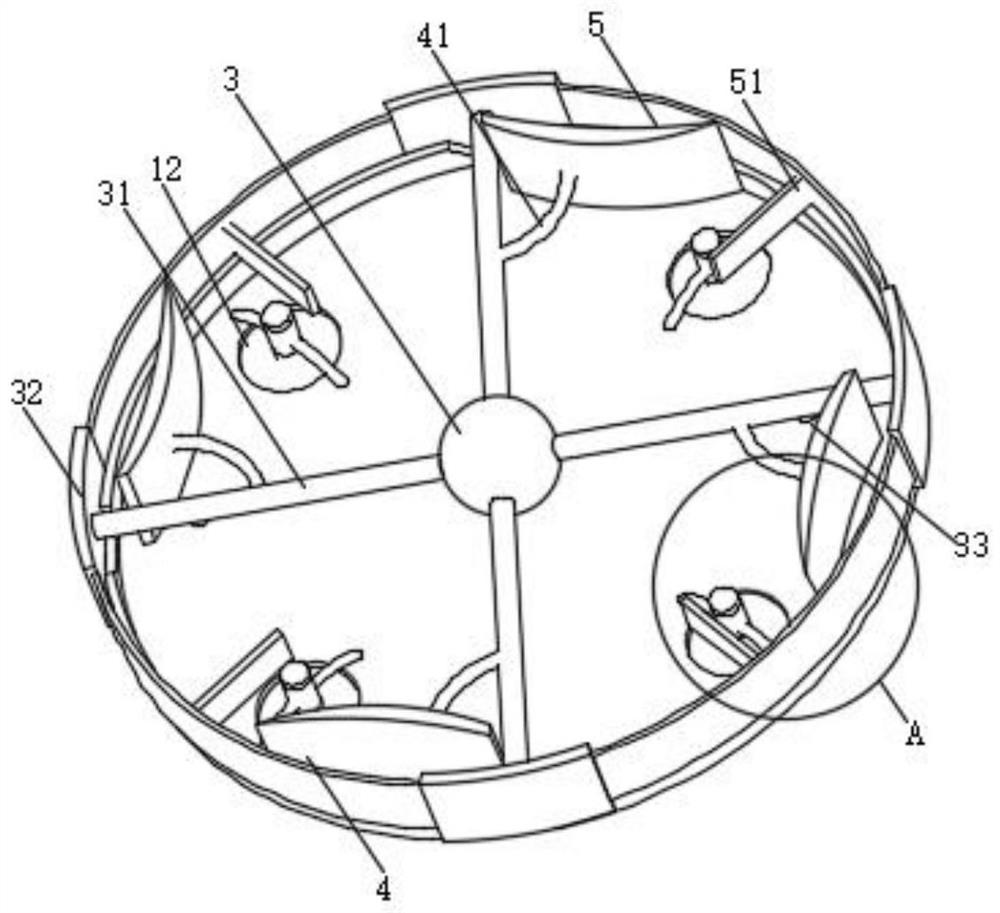

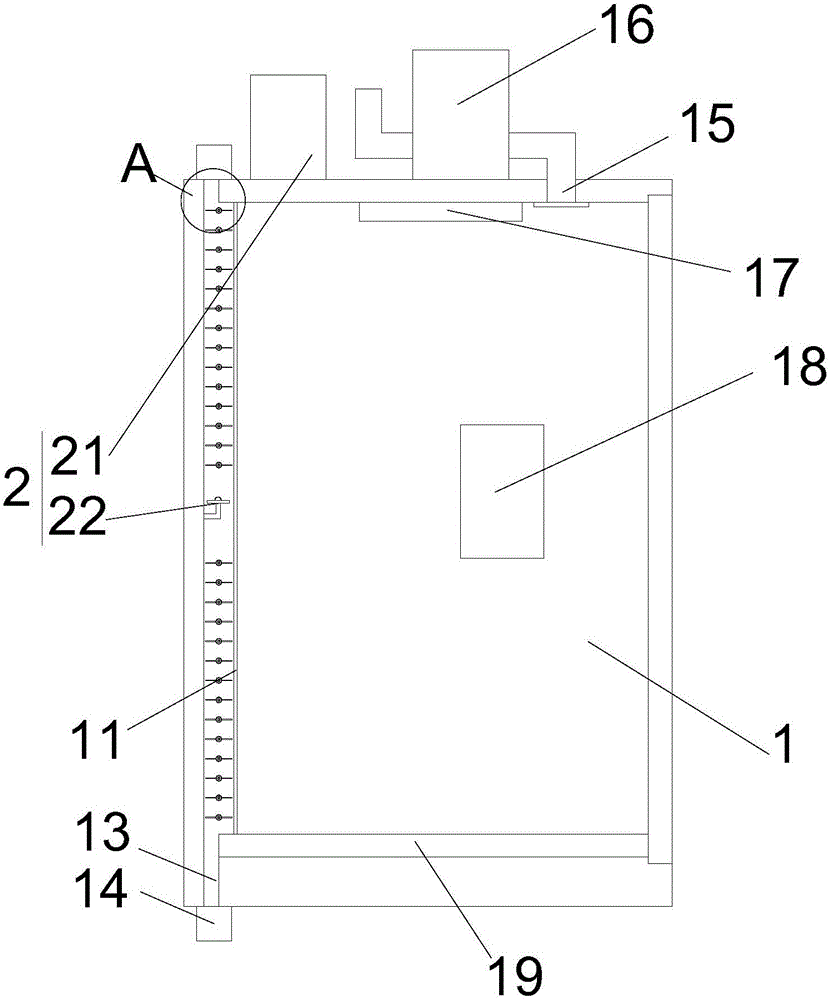

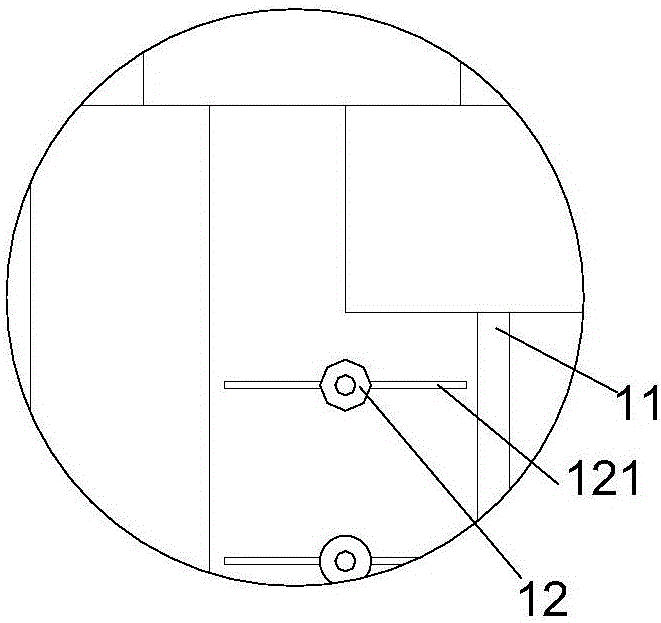

Integrated algae culture apparatus

InactiveCN107881083APrevent sticking phenomenonAvoid shortness of breathBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeEngineering

The integrated algae cultivating device includes a rotatable cultivation tank; the cultivation tank is a cylindrical structure, and an installation through groove is arranged in the middle, and several grooves are uniformly arranged on the outer wall of the cultivation tank, each The bottoms of the grooves are provided with a set of flow holes; each of the grooves is provided with a culture tube, the culture tube is a hollow structure, and a set of flow channels are arranged at the bottom of the culture tubes. The flow pipes communicate with the flow holes respectively, so that the culture tubes can be arranged in the grooves. The beneficial effects created by the present invention are: the design of the rotatable cultivation device keeps the algae liquid in a state of motion all the time during the cultivation process, preventing the occurrence of dead algae; Integration of inflow and outflow.

Owner:新昌县熠凡花木专业合作社

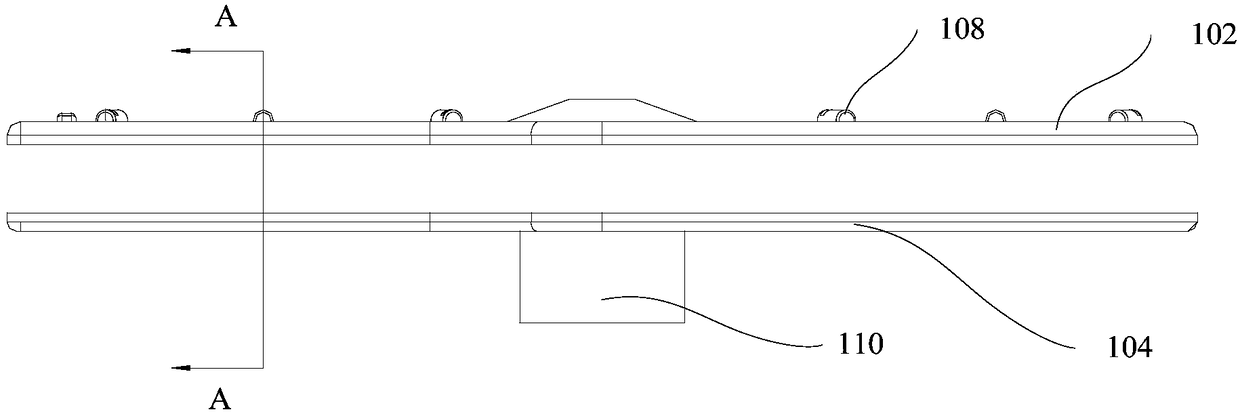

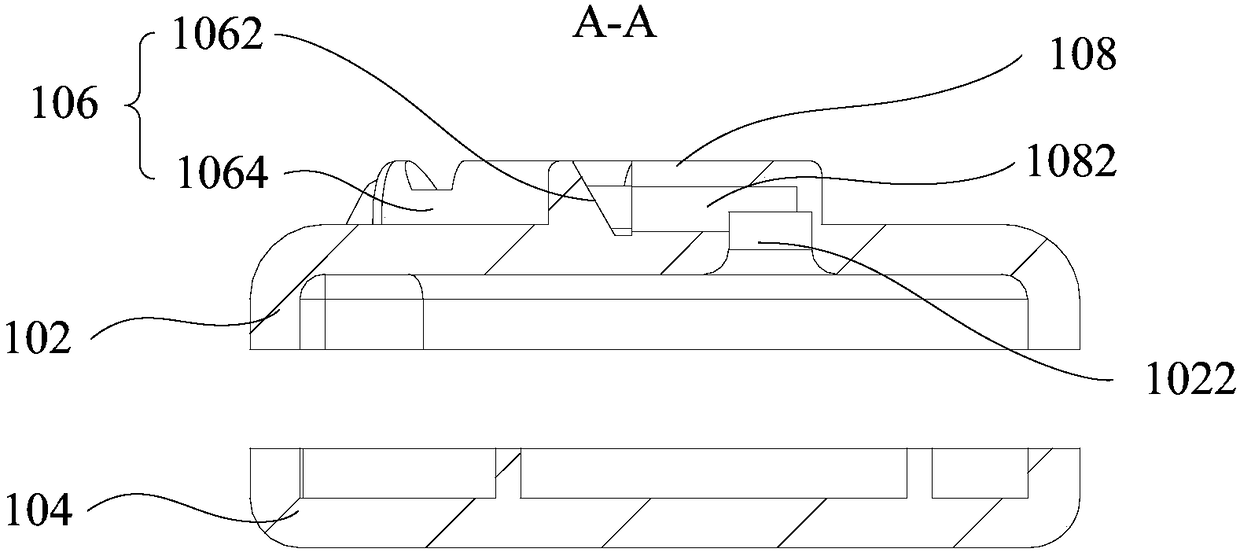

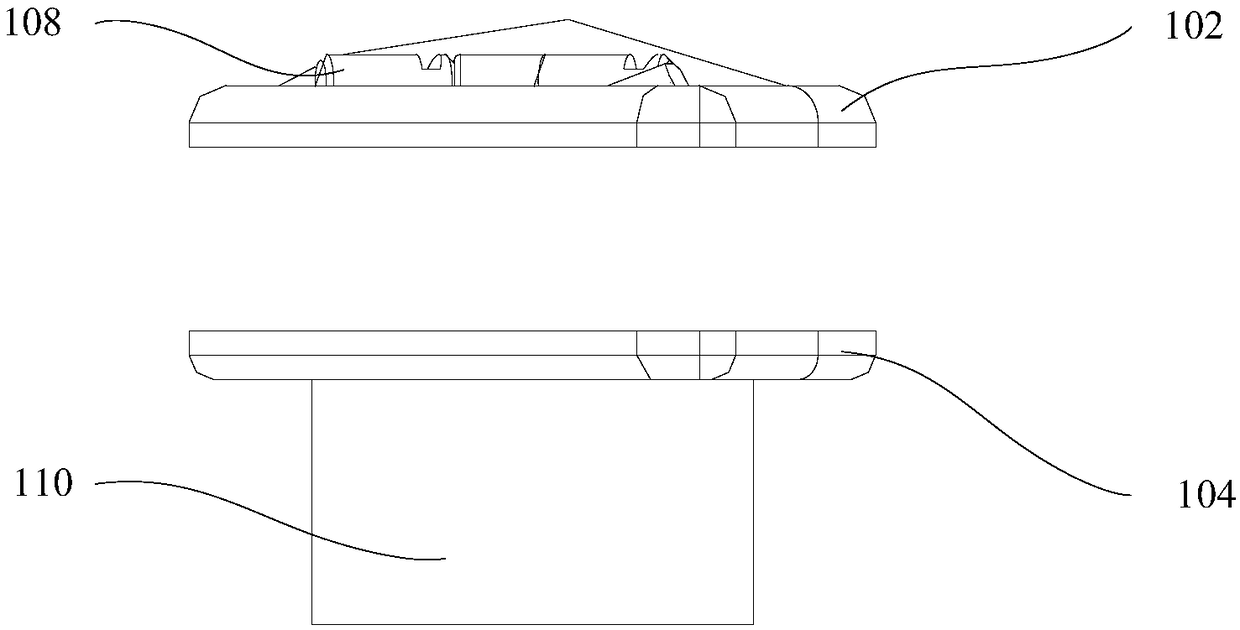

Heat exchanger with brushing function and convenient-to-replace cleaning ball

InactiveCN109269342AEasy to replaceEasy to washFlush cleaningNon-rotary device cleaningButt jointEngineering

The invention discloses a heat exchanger with a brushing function and a convenient-to-replace cleaning ball, and belongs to the technical field of heat exchangers. The heat exchanger is characterizedthat multiple columns of heat exchange pipes (101) are arranged in the radial direction of the heat exchanger (1), multiple brushing pipes (17) are arranged at the end, close to a water inlet tube, ofa distributing plate (21), the range of each brushing pipe (17) to the center of the distributing plate (21) is the same as the range from the heat exchange pipe (101) in the corresponding position of the brush pipe to the heat exchanger (1), and the brushing pipes (17) are allowed to in butt joint with the heat exchange pipes (101) one by one; a transparent pipe (27) is arranged between a cleaning ball flow returning pipeline and a water outlet end of the heat exchange pipe (101), a return ball valve (28) is arranged between the transparent pipe (27) and the cleaning ball returning pipeline,and a discharging valve (29) is connected with a water outlet end of the transmission pipe (29). The heat exchanger has the advantages that online cleaning of the heat exchanger is achieved by the heat exchanger with the brushing function and the convenient-to-replace cleaning ball, and the replacement of the cleaning ball is convenient.

Owner:SHANDONG UNIV OF TECH

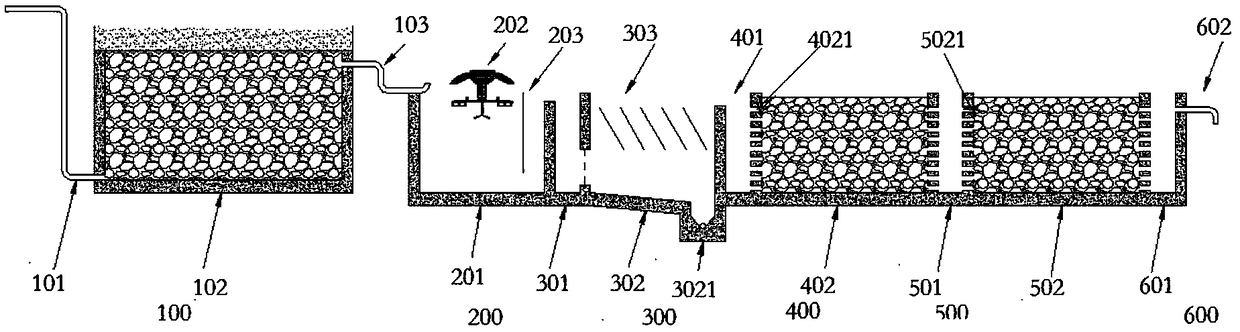

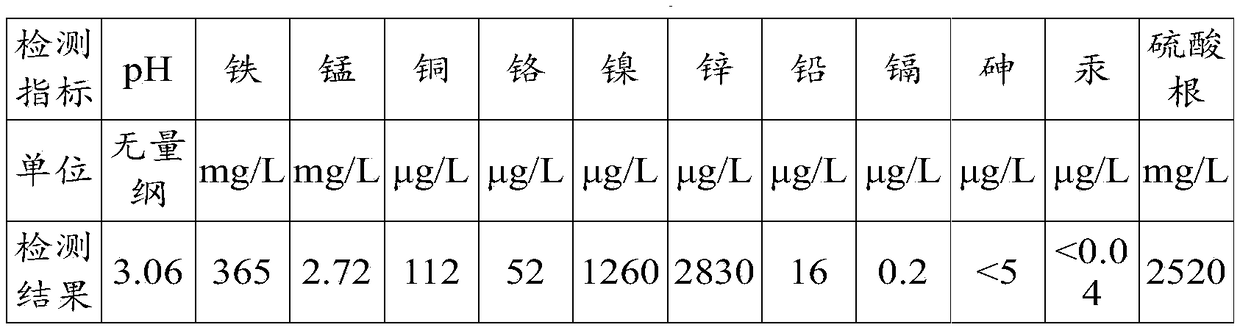

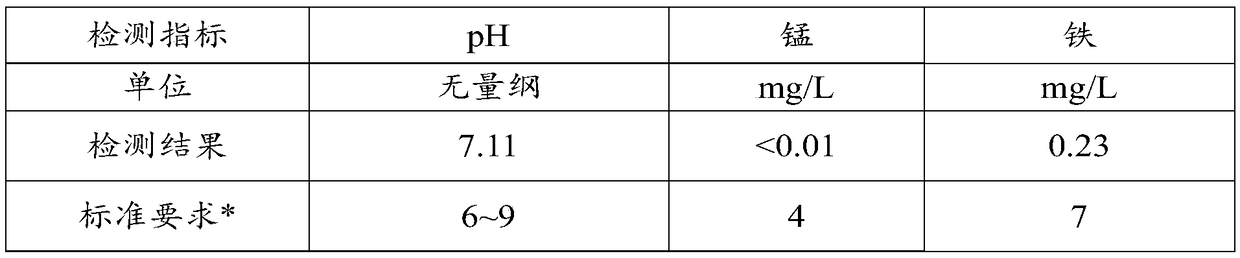

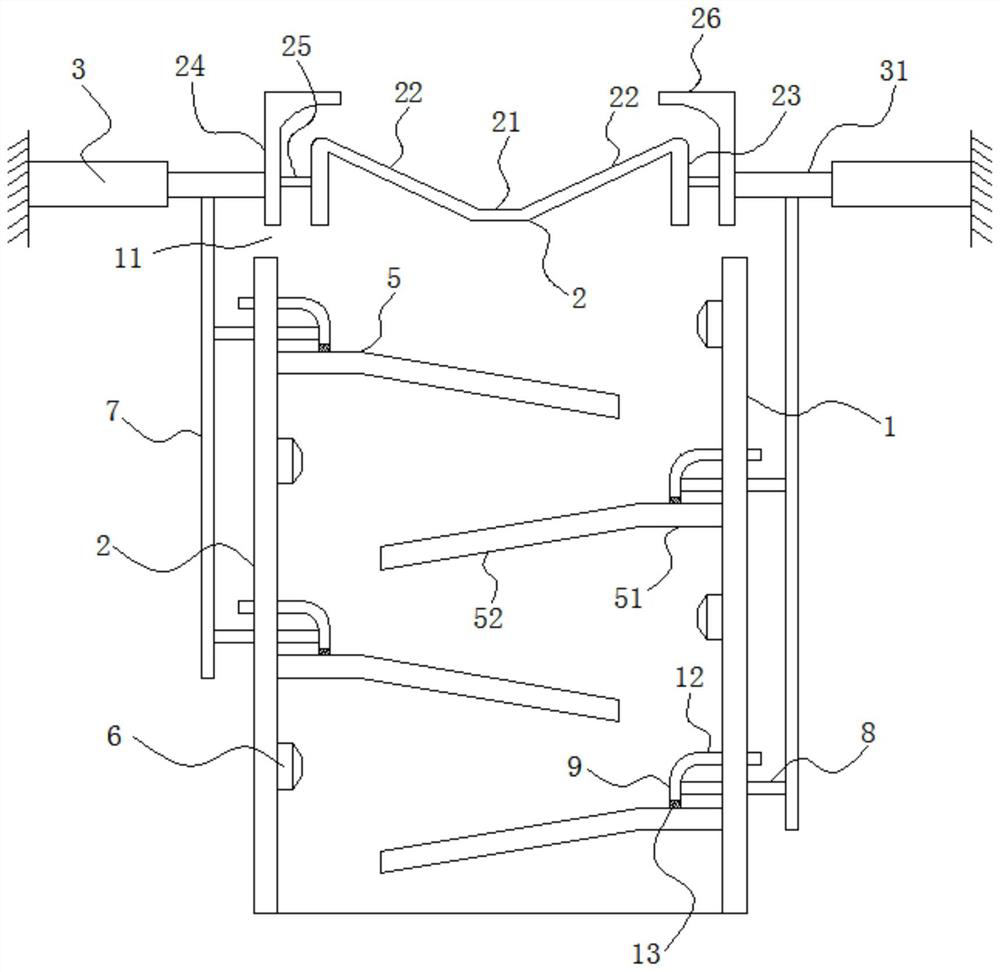

Acid mine drainage treatment system

InactiveCN108975564AAchieve outflowFully processedWaste water treatment from quariesWater aerationMedicineWastewater

The invention provides an acid mine drainage treatment system, and relates to the technical field of the water treatment. The acid mine drainage treatment system comprises a neutralizing treatment unit for performing a neutralization reaction on wastewater, an aerating treatment unit for aerating the wastewater, a precipitate treatment unit for performing precipitation on the wastewater, a first-level deep-treatment unit for performing first-level deep-treatment on the wastewater, a second-level deep-treatment unit for performing second-level deep-treatment on the wastewater and a water outletunit which are successively communicated. The neutralizing treatment unit is internally provided with an alkaline material. The first-level deep-treatment unit is internally filled with a first deep-treatment agent. The second-level deep-treatment unit is internally filled with a second deep-treatment agent. A water outlet end of the water outlet unit is provided with a water outlet channel. A technical problem in the prior art that required cost is higher while the wastewater in a waste mine pit is treated is solved. The acid mine drainage treatment system is capable of, through the neutralizing treatment unit, the aerating treatment unit, the precipitate treatment unit, the first-level and second-level deep-treatment units and the water outlet unit, realizing the adequate treatment to the wastewater.

Owner:爱土工程环境科技有限公司 +1

Lift car energy-saving device

The invention provides a lift car energy-saving device which comprises a lift car and a control mechanism. A mesh plate is installed in the lift car and is parallel to the car wall on the side, opposite to a car door, of the lift car. Multiple rotary shafts are installed between the mesh plate and the car wall on the side, opposite to the car door, of the lift car. The rotary shafts are parallel to the length direction of the mesh plate and are distributed in the height direction of the mesh plate. The two ends of each rotary shaft are rotationally installed on two adjacent car walls of the car door of the lift car. Ventilation holes are formed in a car bottom and a car top of the lift car and located in the sides, away from the mesh plate, of the rotary shafts. Air filter devices are installed at the positions, corresponding to the ventilation holes, on the lift car. Air baffles are arranged on the two opposite sides of each rotary shaft. An air guide hole is further formed in the car top of the lift car. A draught fan is installed on the lift car. A draught fan air inlet communicates with the air guide hole. A lighting lamp is installed in the lift car. The control mechanism comprises a control device, a pressure induction device and an air speed sensor. By the adoption of the lift car energy-saving device, the quality of air in the lift car can be effectively improved, and energy losses can be effectively reduced.

Owner:ANHUI REGON ELEVATOR SERVICES CO LTD

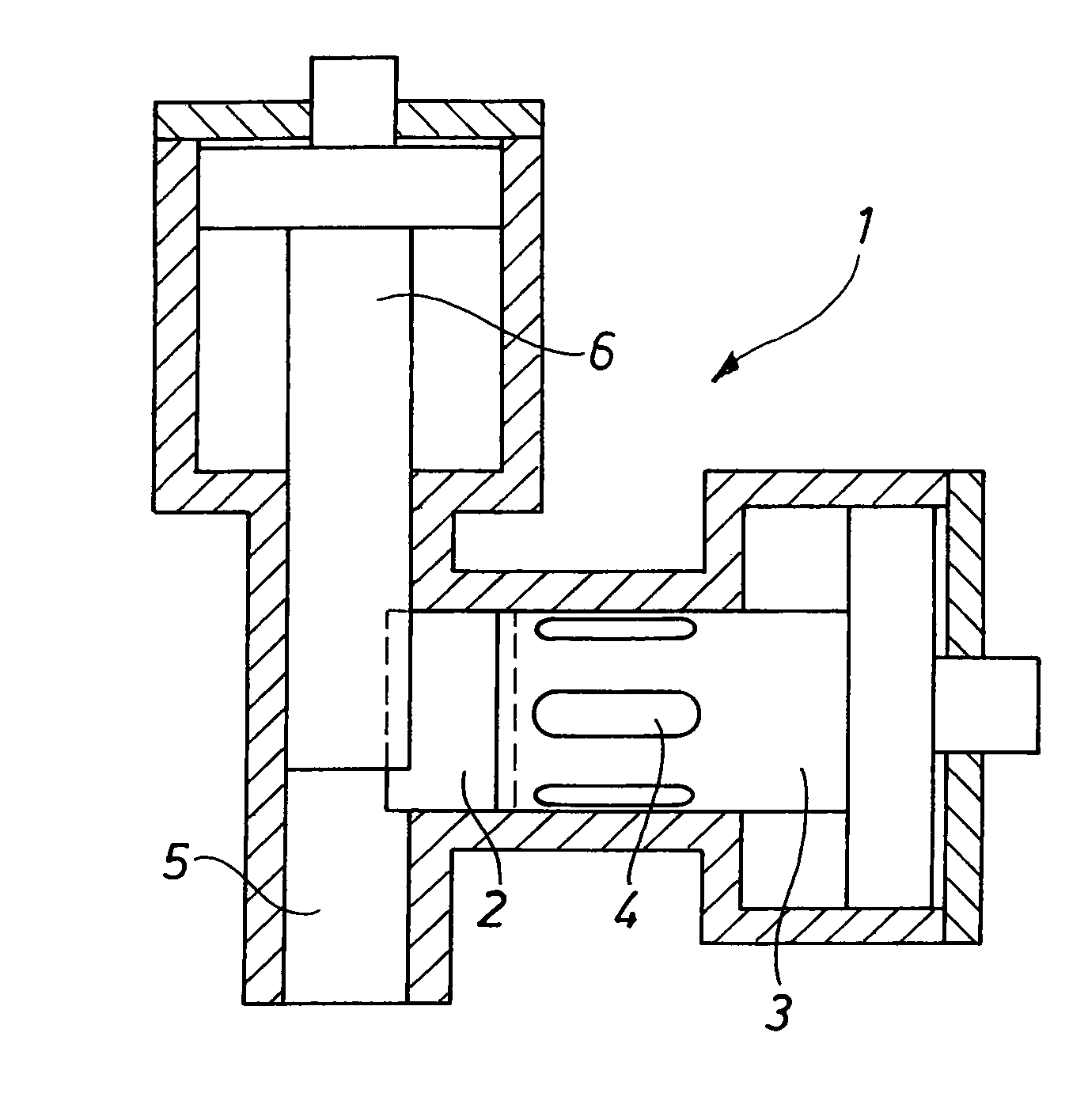

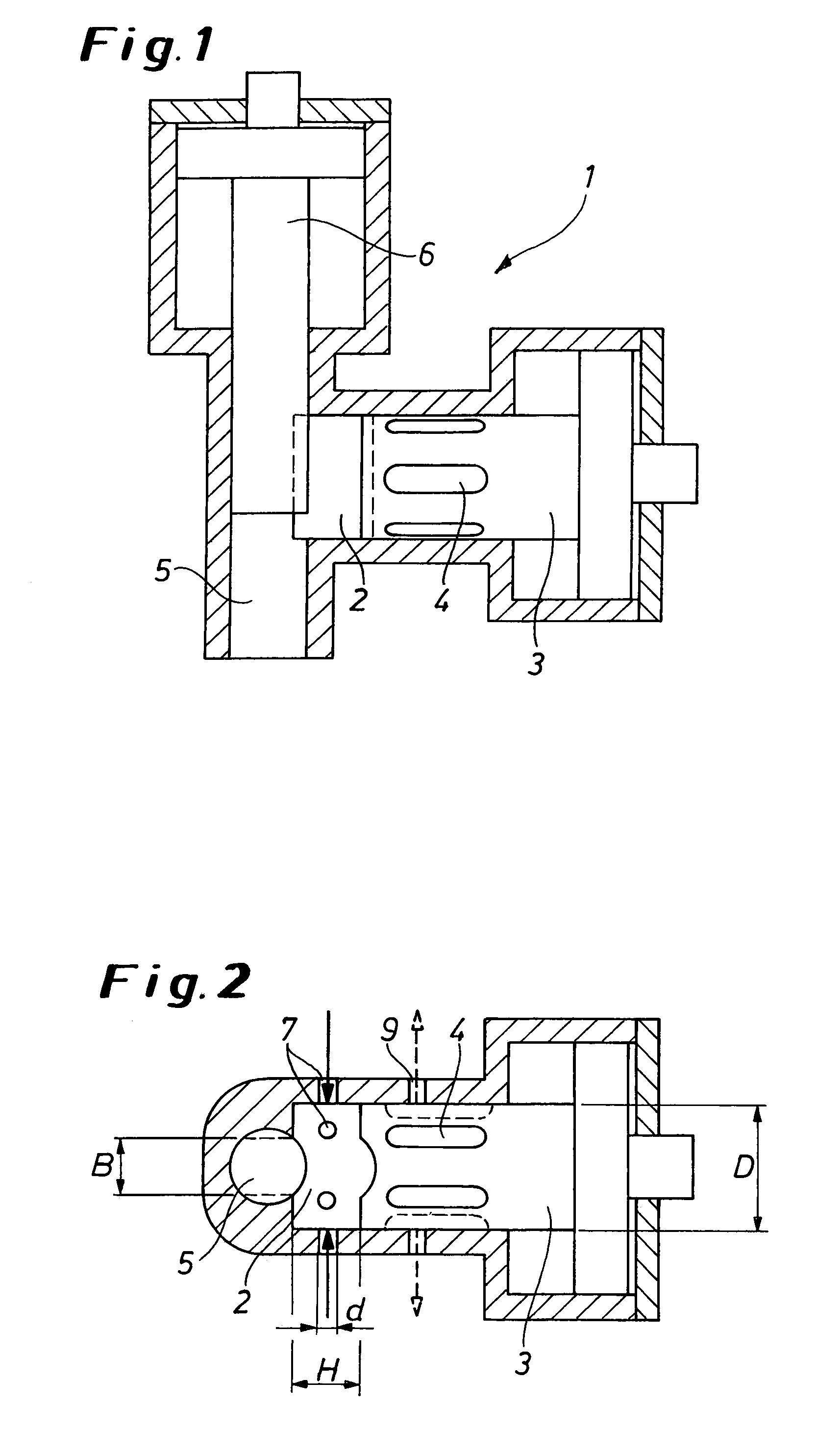

Multiple component mixing head

InactiveUS20050241708A1Low pressure lossAchieve outflowPlug valvesFlow mixersMultiple componentChemistry

The invention relates to a mixing head and to a method of mixing at least one polyol component and at least one isocyanate component and where appropriate additives, to form a polyurethane reaction mixture.

Owner:HENNECKE

Pipeline cleaning device

The invention belongs to the technical field devices or equipment for cleaning and discloses a pipeline cleaning device. The pipeline cleaning device comprises a rack and a cleaning mechanism installed on the rack; the cleaning mechanism comprises a rotating shaft, a sealed plate, a stirring shaft and a water storing box, and the rotating shaft is in threaded connection with the rack; a driven gear is connected to the rotating shaft in a spline manner; the rack is provided with a driving gear engaged with the driven gear and a motor driving the driving gear to rotate; the sealed plate is located on the lower portion of the rotating shaft; the stirring shaft is spiral and is fixed to the bottom of the rotating shaft; the water storing box comprises a clean water part and a sewage part; thewater storing box is fixed to the bottom of the rack, and is provided with a supporting plate which is provided with a clean water port and a sewage port communicated with the clean water part and thesewage part correspondingly; the clean water port is provided with a reflux valve; a baffle sealing the sewage port is hinged to the lower surface of the supporting plate, and is provided with a first magnet; and a second magnet is arranged on the supporting plate. The pipeline cleaning device solves the problem that a pipeline in the prior art is damaged when the inner wall is cleaned.

Owner:宁波江北清纬环保科技有限公司

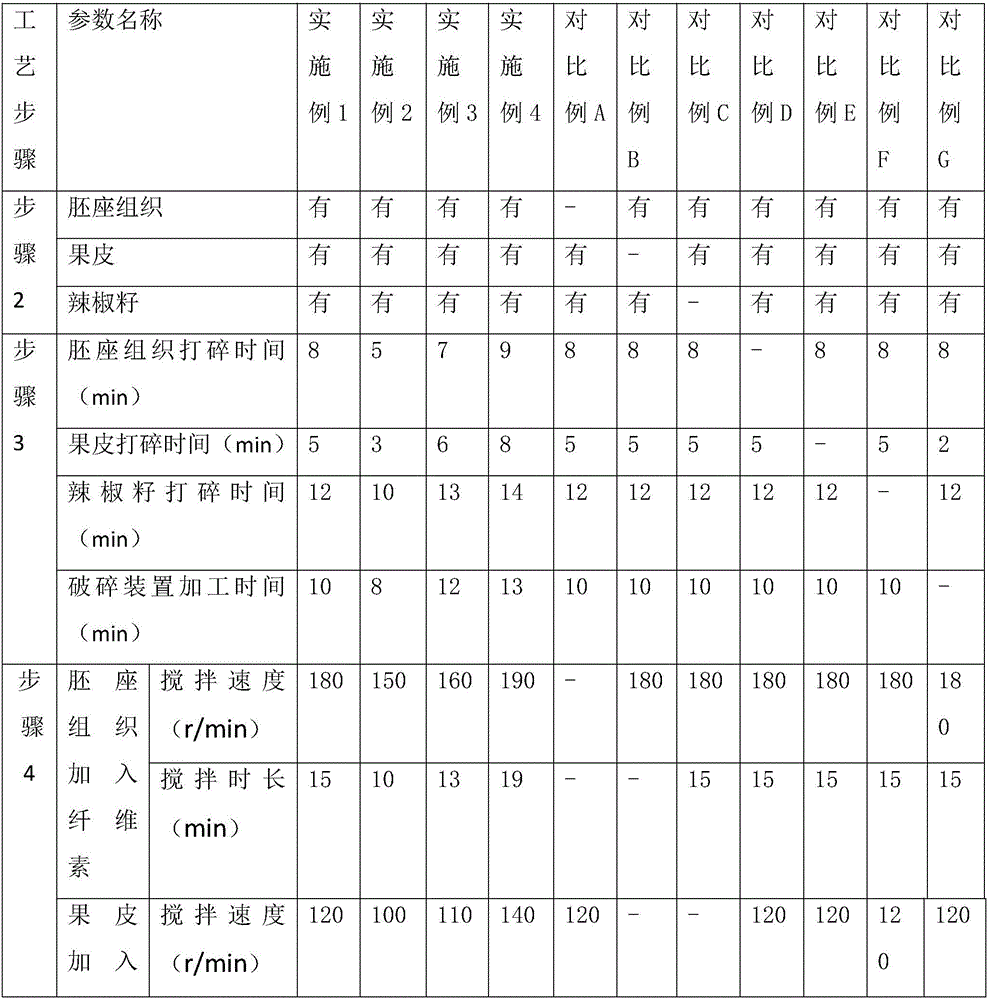

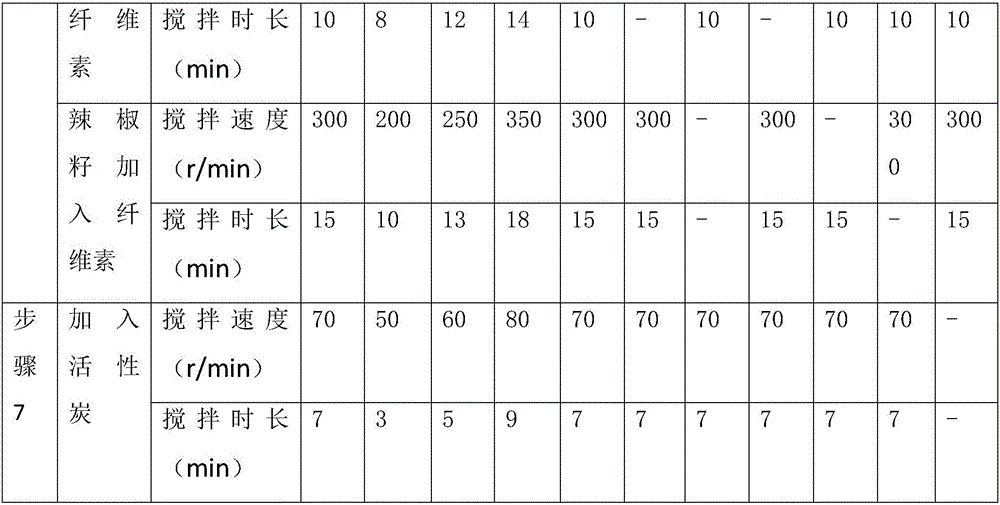

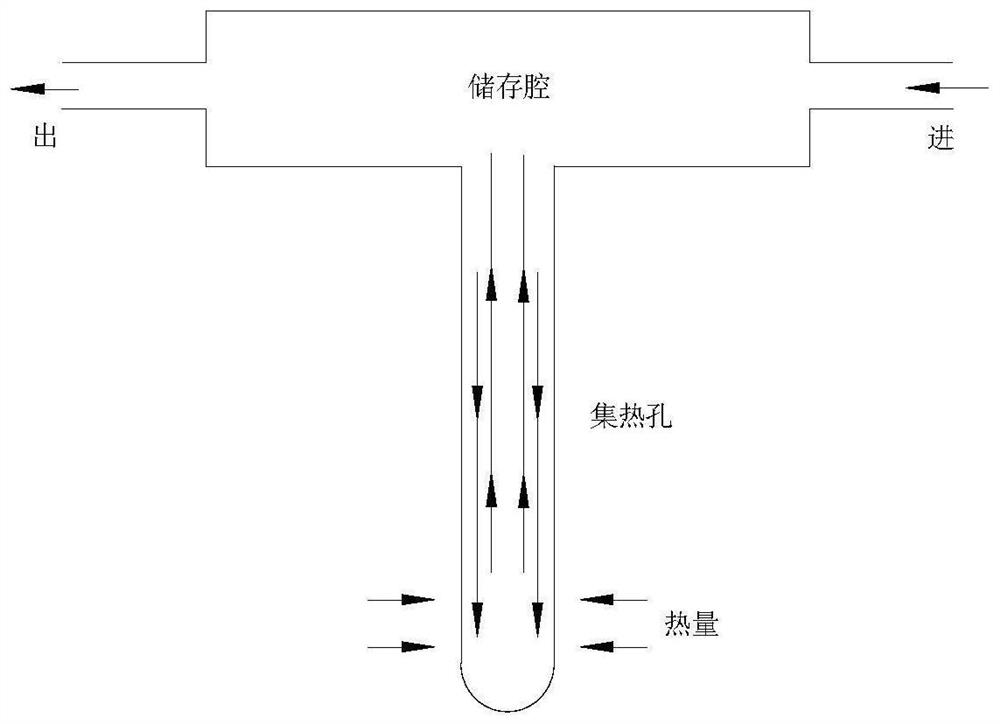

Method for purifying natural capsaicin

ActiveCN106431961AEvenly brokenEasy to pick upCarboxylic acid amide separation/purificationChemistryCellulase

The invention relates to the field of pepper processing and specifically discloses a method for purifying natural capsaicin. The method comprises the following steps: decomposing the pepper into three parts, including embryo tissues, peels and pepper seeds; respectively smashing the three parts; adding a corresponding amount of cellulase into the smashed tissues; stirring and mixing at different rotating speeds and for different stirring durations; accelerating the damage to cells; accelerating the separation of capsaicin; extracting the capsaicin from the pepper tissues; dissolving the capsaicin in a solution; and then separating capsaicin crystals from the solution, thereby completing the whole capsaicin extracting and purifying processes. According to the scheme, the pepper is divided into three parts and the three parts in different capsaicin contents are respectively processed, so that the separation of the capsaicin as much as possible can be guaranteed.

Owner:贵州遵义新佳裕食品有限公司

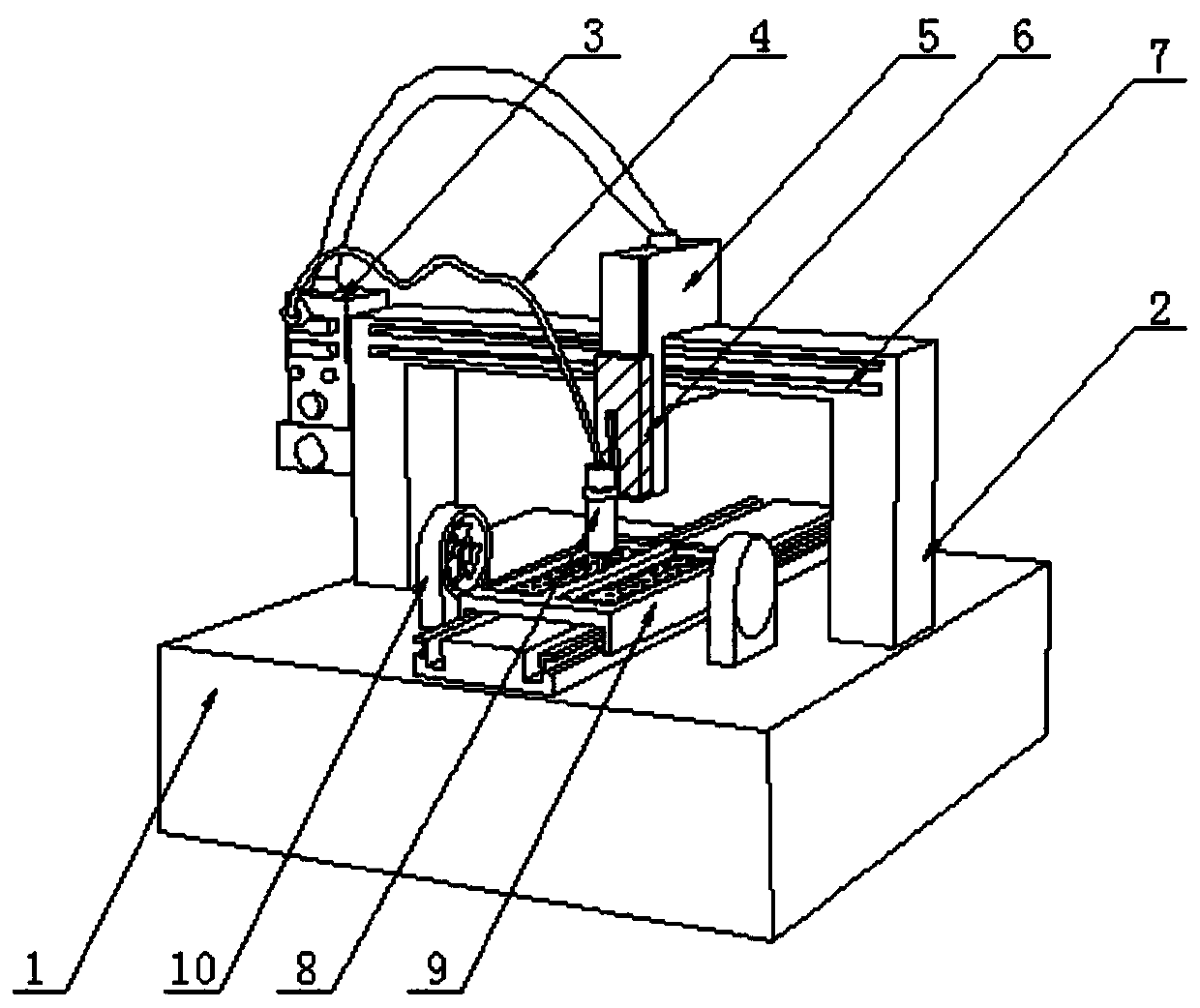

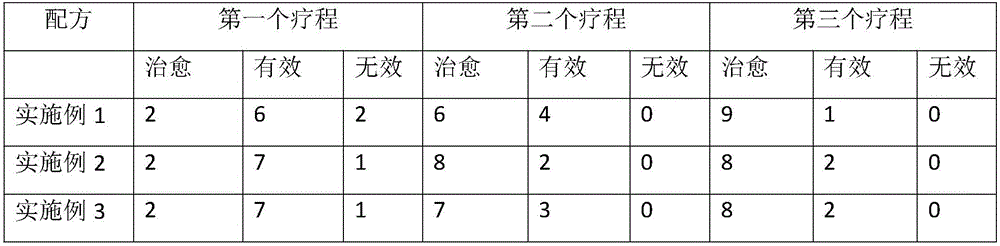

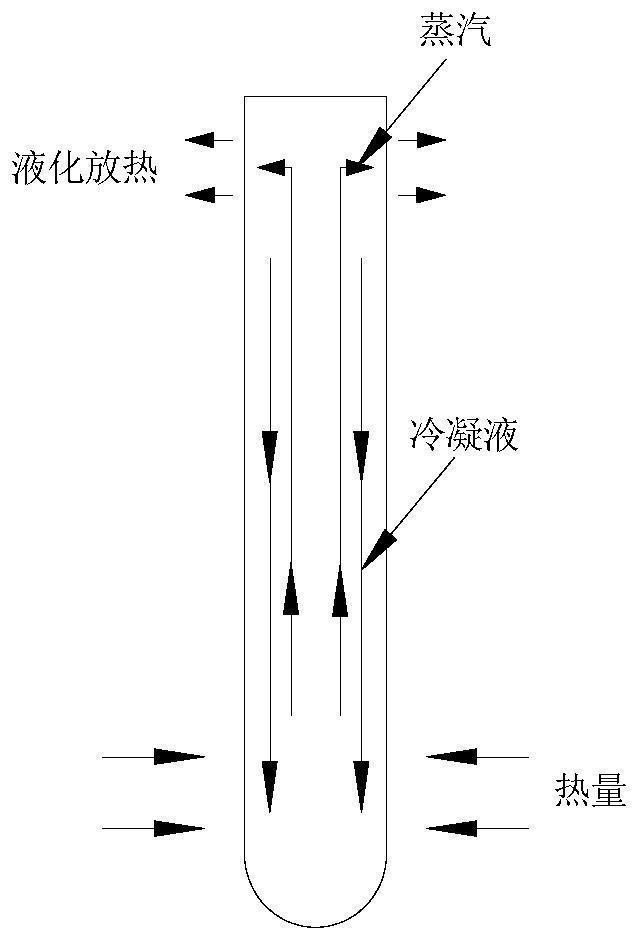

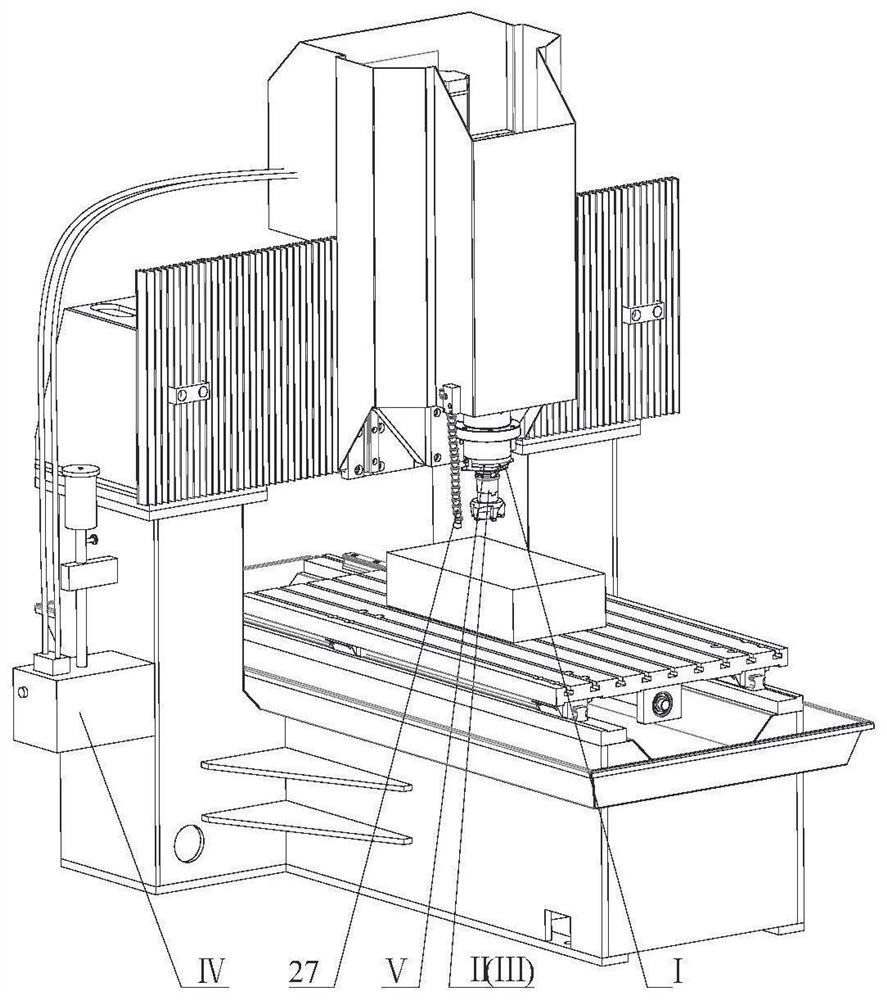

Medium circulation heat dissipation milling system based on intelligent switching of internal cooling and external cooling

ActiveCN113319337AGuaranteed cooling effectReduce processing and transformation costsMilling cuttersMilling equipment detailsEngineeringMachining system

The invention relates to a medium circulation heat dissipation milling system based on intelligent switching of internal cooling and external cooling. The system comprises a workbench, a main shaft connected with a power system, a fixing ring which sleeves the periphery of the main shaft, can rotate relative to the main shaft and is provided with a medium inlet and a medium outlet, and a cutter assembly connected with the main shaft. A storage cavity is formed in the cutter assembly, the storage cavity is communicated with one end of a first flow channel and one end of a second flow channel, the other end of the first flow channel and the other end of the second flow channel are communicated with a through hole formed in the main shaft, a heat collection hole communicated with the storage cavity is further formed, is a blind hole and extends to a blade of the cutter assembly, the first flow channel and the second flow channel are configured in the mode that under relative rotation of the fixing ring and the main shaft, the first flow channel is communicated with the medium inlet, the second flow channel is communicated with the medium outlet simultaneously, the second flow channel is communicated with the medium inlet simultaneously, the first flow channel is communicated with the medium outlet, the transformation cost of the milling system is low, and intelligent switching of cooling modes can be achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

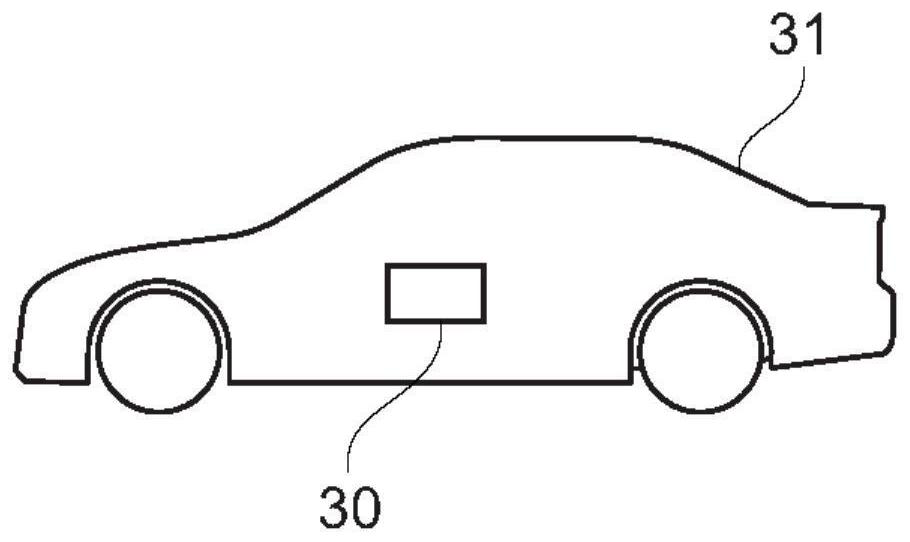

Aqueous pesticide filling device

ActiveCN107662719AAchieve outflowIt is convenient to control the discharge timeLiquid materialLiquid bottlingToxicologyPesticide

The invention relates to the field of pesticide processing and particularly discloses an aqueous pesticide filling device. When the filling device performs aqueous pesticide filling, the impact forceof an aqueous pesticide itself can be utilized to open a discharging port of a box body, and aqueous pesticide filling is achieved. In addition, the aqueous pesticide impacts a membrane, the flowing speed of the aqueous pesticide can be effectively reduced, thus the situation that the aqueous pesticide is splashed in the filling process can be avoided, aqueous pesticide waste can be reduced, and the amount of pesticidemolecules in a processing environment can be decreased. By adopting the scheme, the flowing speed during aqueous pesticide filling can be reduced, and aqueous pesticidesplashingcan be prevented.

Owner:重庆康养研究院有限责任公司

A black tea withering device

ActiveCN108812976BAccelerated churnAccelerate the loss of evaporation purposePre-extraction tea treatmentWater flowMechanical engineering

The invention discloses a black tea withering device, which comprises a water loss cylinder, a swing frame and a reciprocating propulsion device; the water loss cylinder is placed vertically; the swing frame is placed directly above the water loss cylinder; the swing frame The body includes a circular plate in the middle and a sloping plate extending obliquely upward from the edge of the circular plate; and the end of the sloping plate is also provided with a mounting wall extending downward, so that the vertical section of the swinging frame is M shape structure; and the outer side of the installation wall is also provided with a circle of ring-shaped baffles. The device can realize the purpose that the black tea is shaken and the water flows out and falls into the water loss cylinder to evaporate and lose water, realize the continuous work of the black tea and improve the water loss and evaporation effect of the black tea, and achieve the purpose of improving production efficiency and quality.

Owner:句容市茅山茶场有限公司

Spraying arm and cleaning device

ActiveCN109395902AIncrease jet areaReduce technical effectSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention provides a spraying arm and a cleaning device. The spraying arm and the cleaning device are used for cleaning a device body, wherein the spraying arm comprises a first body, a second body, a flow guide part and a nozzle, and the second body and the first body define a hollow cavity; the guide part is located on the outer wall of the first body, and one side surface of the flow guidepart is a flow guide surface; the nozzle is arranged on the outer wall of the first body, a flow channel is formed in the nozzle, and the flow channel communicates with the hollow cavity; and the flowchannel extends along the outer wall of the first body, a cleaning liquid is enabled to hit on the flow guide surface after flowing out along the outer wall of the first body. Due to the fact that the cleaning liquid becomes a jet area increasing the cleaning liquid when the bearing frame body is guided by a flow guiding surface, the cleaning range of the spraying arm is further enlarged accordingly, and the situation that a cleaning dead angle is caused due to incomplete coverage of the cleaning range of the spraying arm is avoided; and meanwhile, due to the fact that the cleaning range of the spraying arm is enlarged, the time for cleaning by the spraying arm is shortened, so that the technical effect of saving the cleaning fluid is achieved, and the use cost of a product is reduced.

Owner:MIDEA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com