Medium circulation heat dissipation milling system based on intelligent switching of internal cooling and external cooling

A technology of intelligent switching and medium circulation, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as misjudgment, waste of human resources, and ineffective heat dissipation in the cutting area, so as to reduce processing and transformation costs and save money. Human resources, the effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

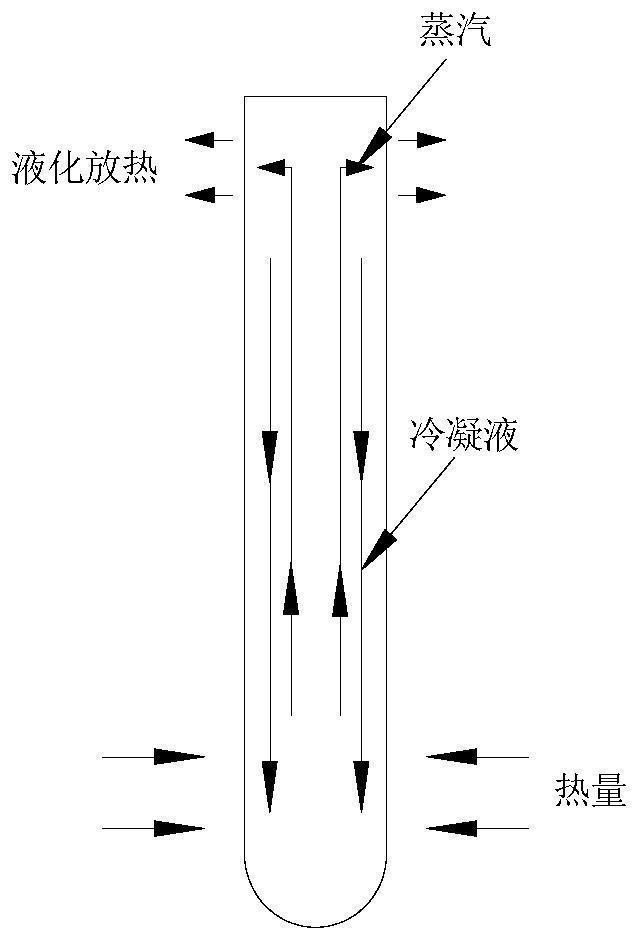

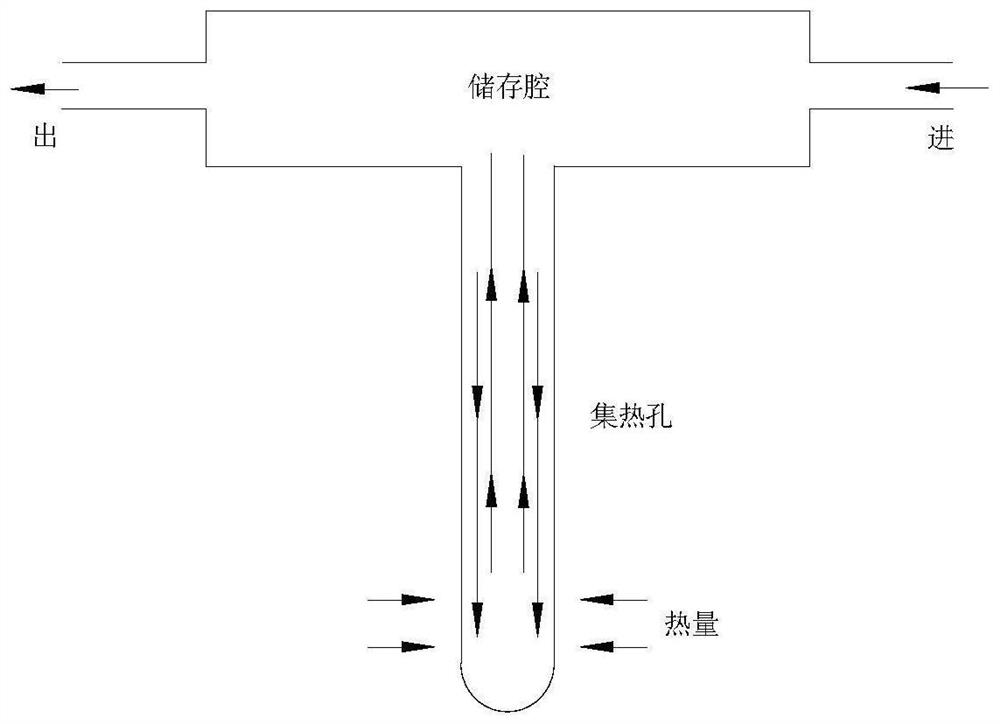

[0071] The heat absorption and heat release of objects are relative. Whenever there is a temperature difference, the phenomenon of heat transfer from high temperature to low temperature will inevitably occur. From the perspective of three ways of heat transfer (radiation, convection, conduction), convection conduction is the fastest. The heat pipe uses the phase change process in which the medium evaporates at the hot end and condenses at the cold end (that is, uses the latent heat of evaporation and latent heat of condensation of the liquid) to conduct heat quickly. A general heat pipe consists of a shell, a liquid-absorbing core and an end cap. The inside of the heat pipe is pumped into a negative pressure state and filled with a suitable liquid, which has a low boiling point and is easy to volatilize. Such as figure 1 As shown, one end of the heat pipe is the evaporation end, and the other end is the condensation end. When one end of the heat pipe is heated, the liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com