Aqueous pesticide filling device

A filling device and pesticide technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as air pollution, water-based pesticide waste, harsh working environment, etc., and achieve smooth flow path, avoid splashing, and avoid splashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below by specific embodiments:

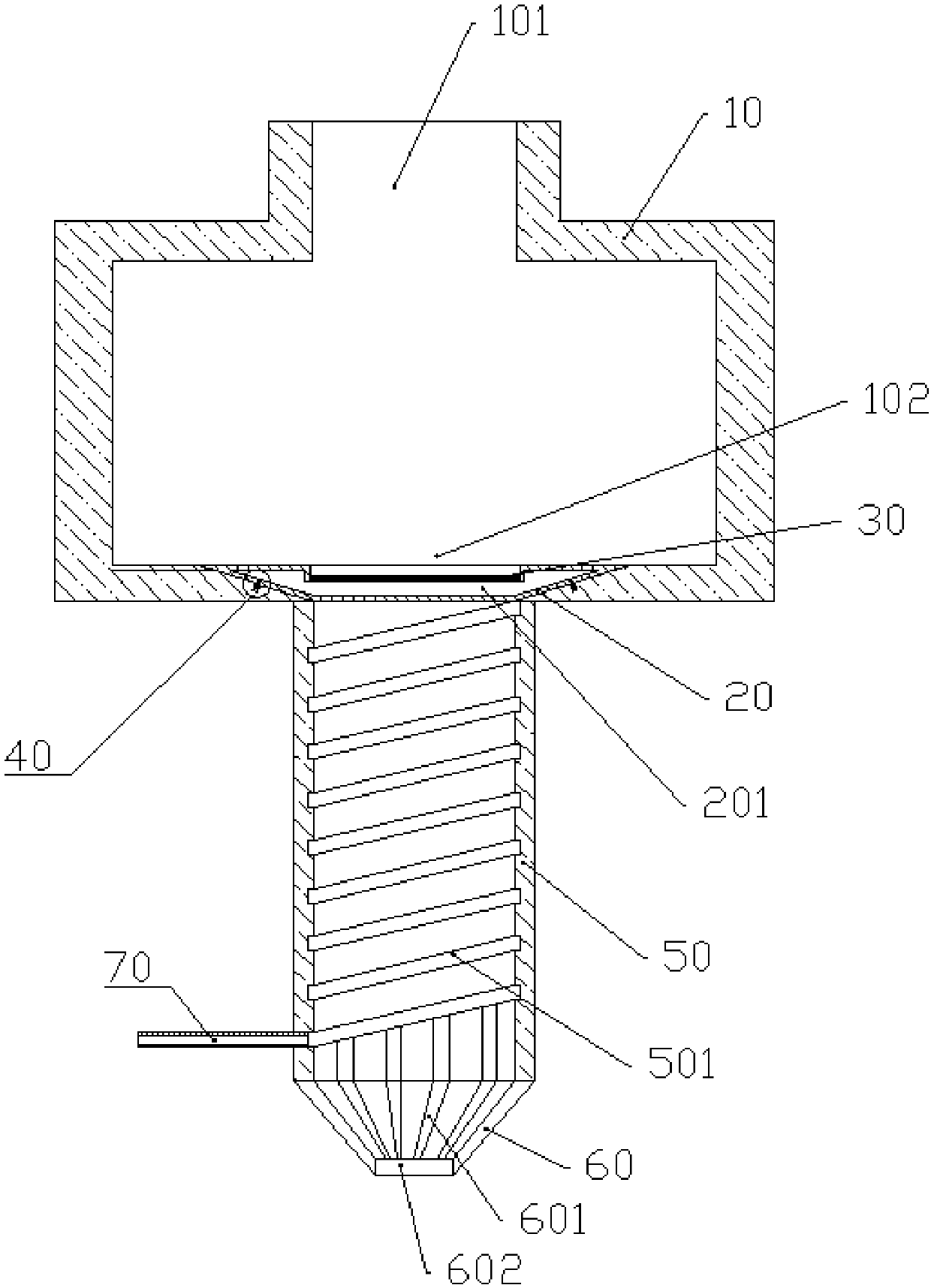

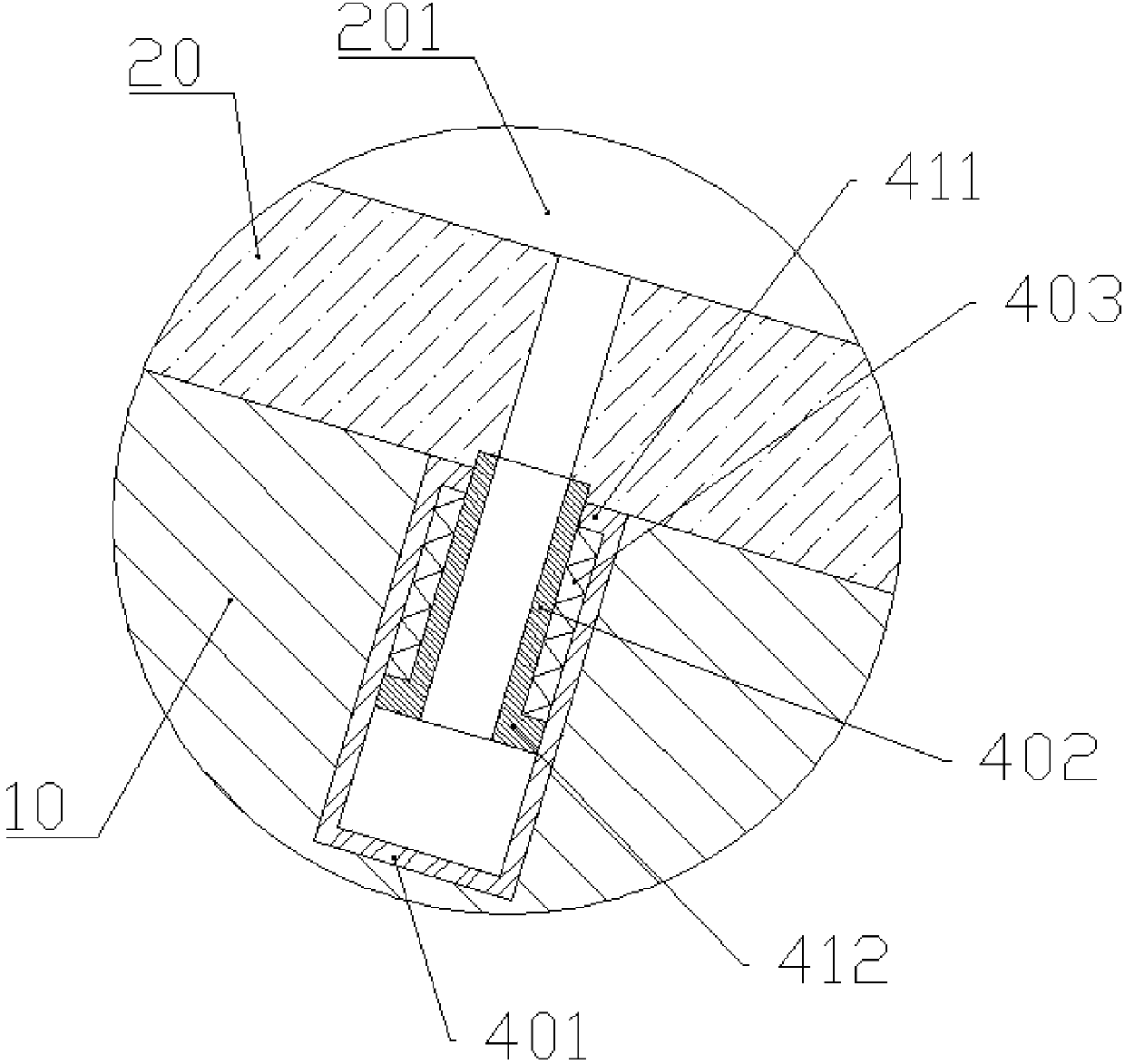

[0017] The reference signs in the drawings of the description include: box body 10, material inlet 101, material outlet 102, blocking block 20, accommodation chamber 201, diaphragm 30, hydraulic rod 40, sleeve 401, first boss 411 , the connecting pipe 402 , the second boss 412 , the pressure spring 403 , the nozzle 50 , the first flow channel 501 , the nozzle 60 , the second flow channel 601 , the liquid outlet 602 , and the capillary 70 .

[0018] The example is basically as attached figure 1 And attached figure 2 Shown: a water-based pesticide filling device, including a loading mechanism and a filling mechanism.

[0019] The bearing mechanism includes a box body 10, a blocking block 20, an elastically deformable diaphragm 30 and a plurality of hydraulic rods 40. The upper end of the box body 10 is provided with a feed port 101, and the lower end of the box body 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com