Patents

Literature

49results about How to "Smooth runner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

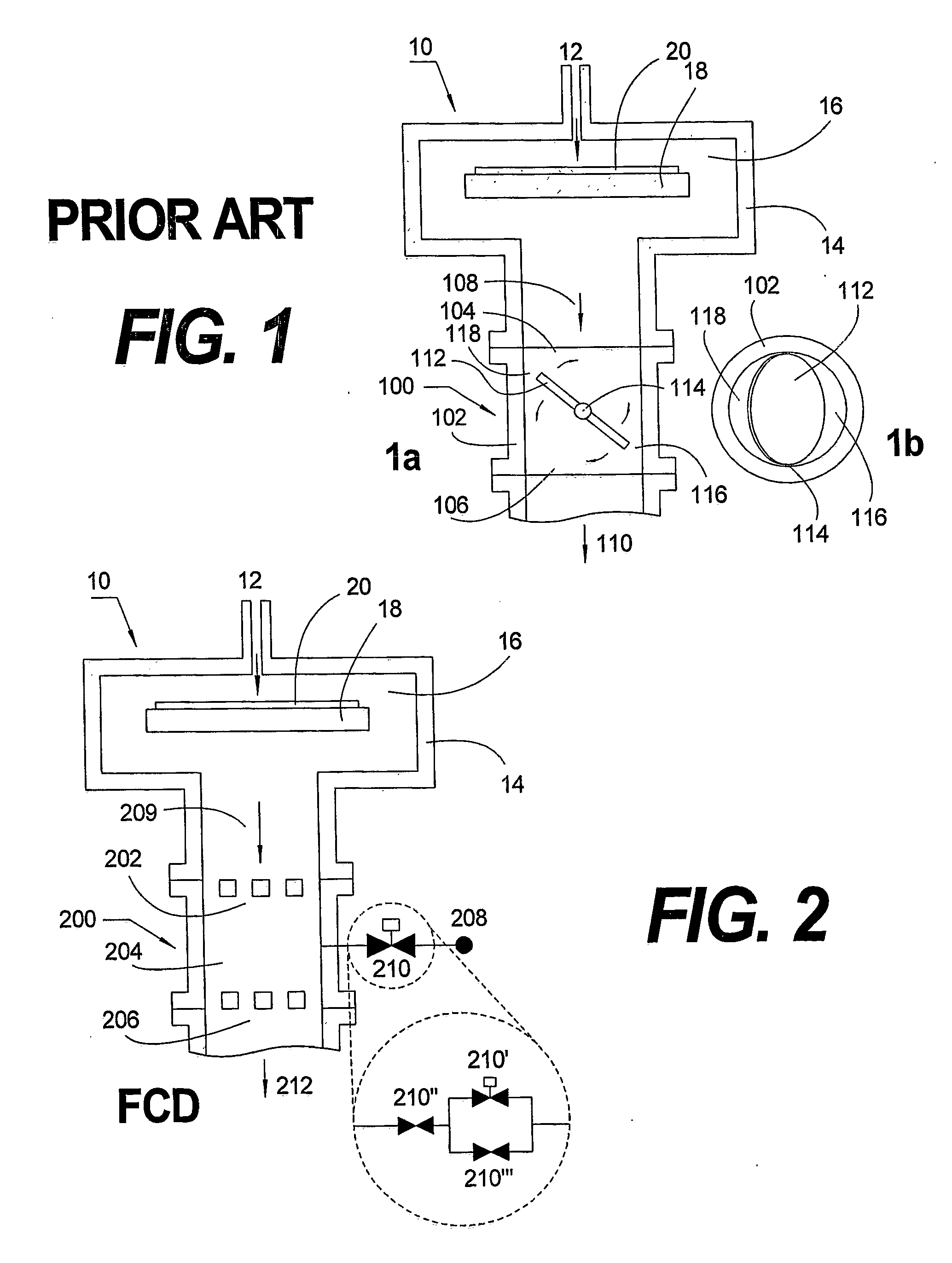

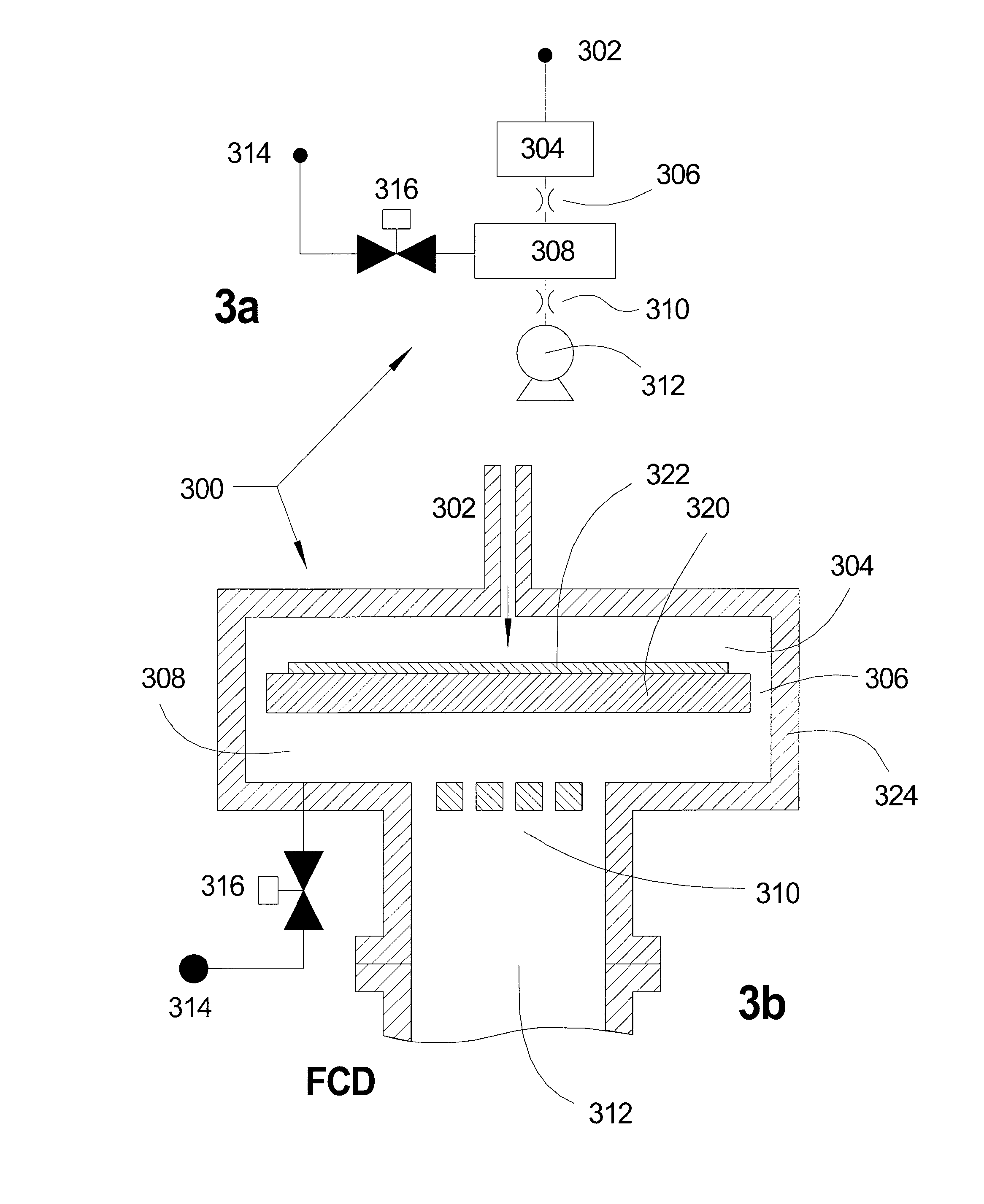

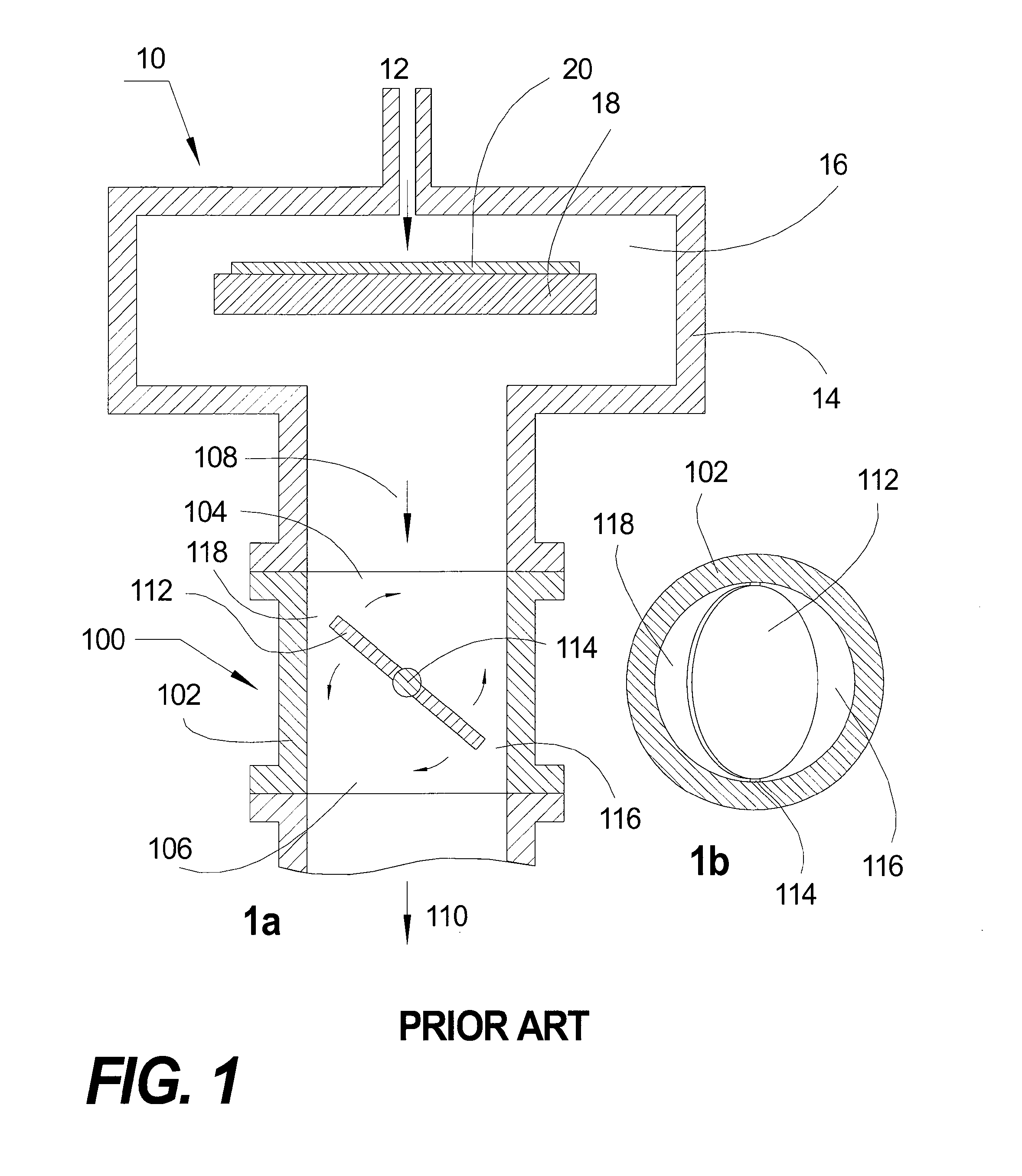

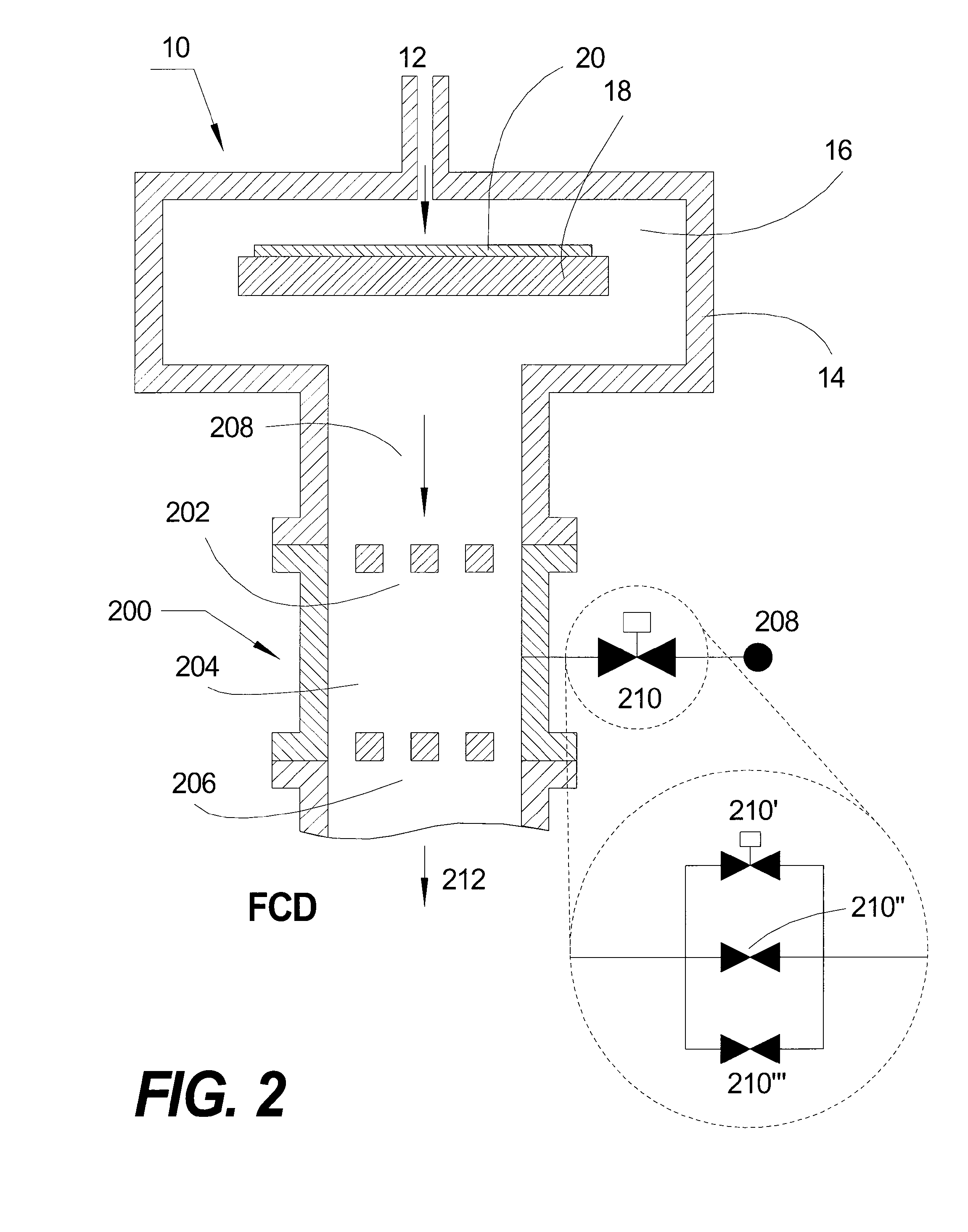

Apparatus and method for downstream pressure control and sub-atmospheric reactive gas abatement

InactiveUS20070012402A1Rapid responseOptimized and smooth flow passageSemiconductor/solid-state device manufacturingPipeline systemsReactive gasStream flow

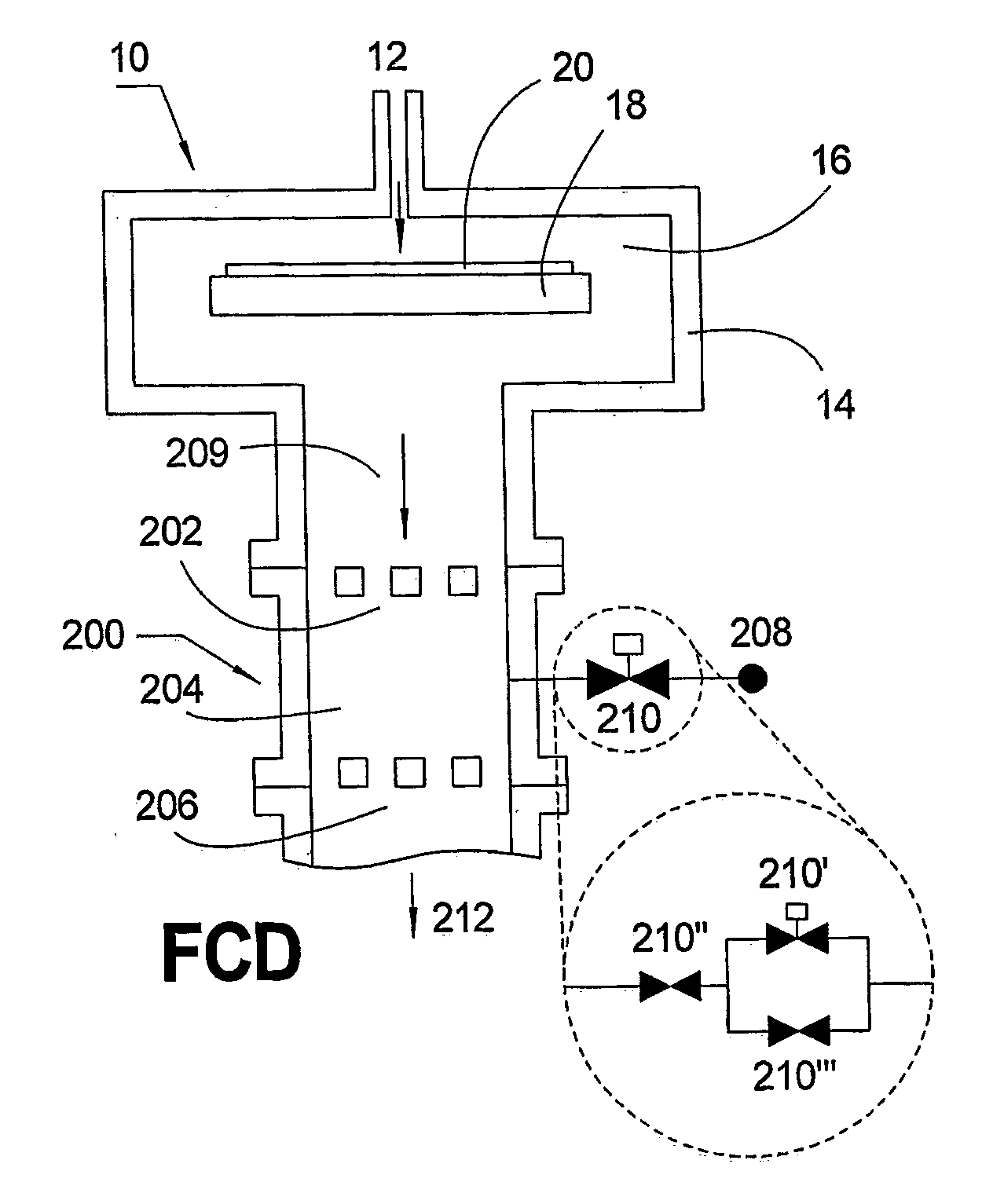

A sub-atmospheric downstream pressure control apparatus (200) includes a first flow restricting element (FRE) (202); a pressure control chamber (PCC) (204) located in serial fluidic communication downstream from the first FRE; a second FRE (206) located in serial fluidic communication downstream from the PCC; a gas source (208); and a flow controlling device (210) in serial fluidic communication downstream from the gas source and upstream from the PCC.

Owner:SUNDEW TECH

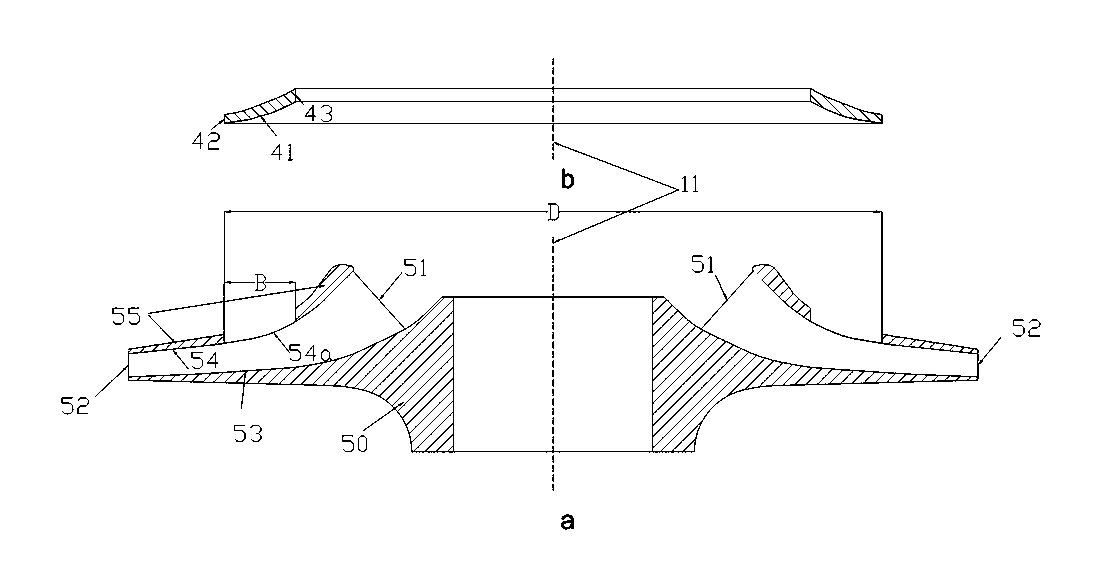

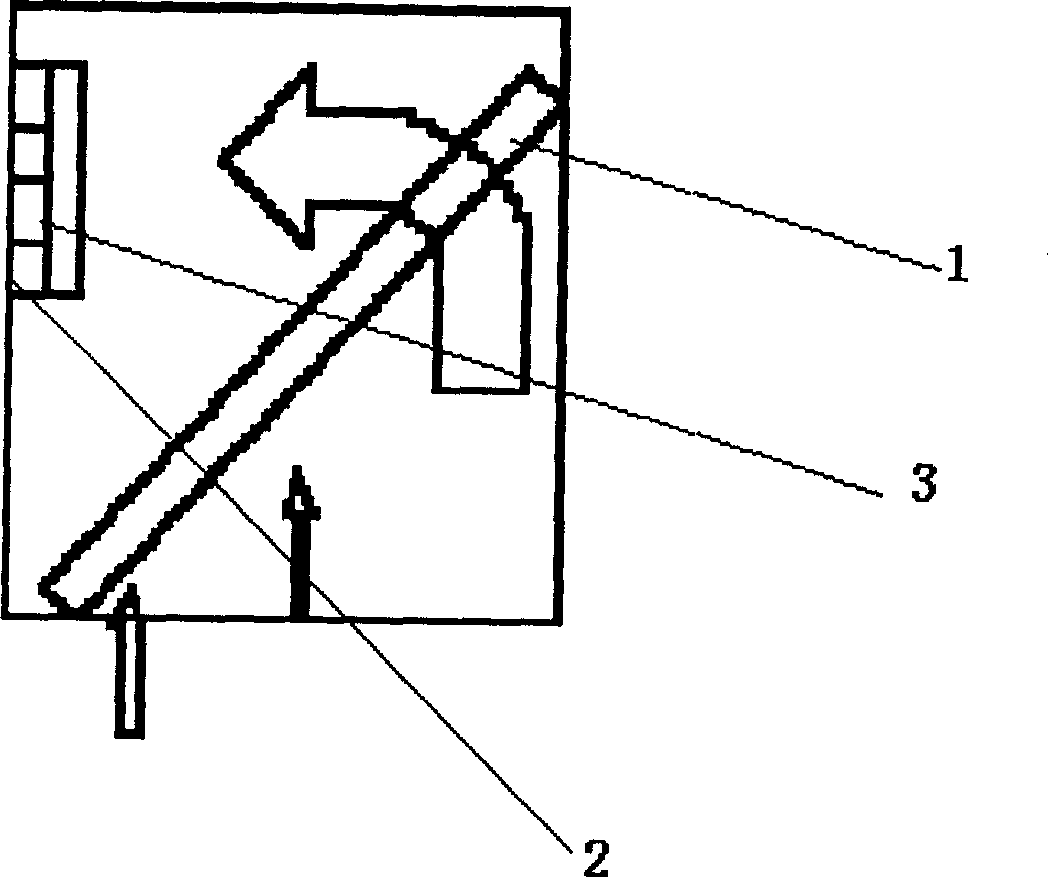

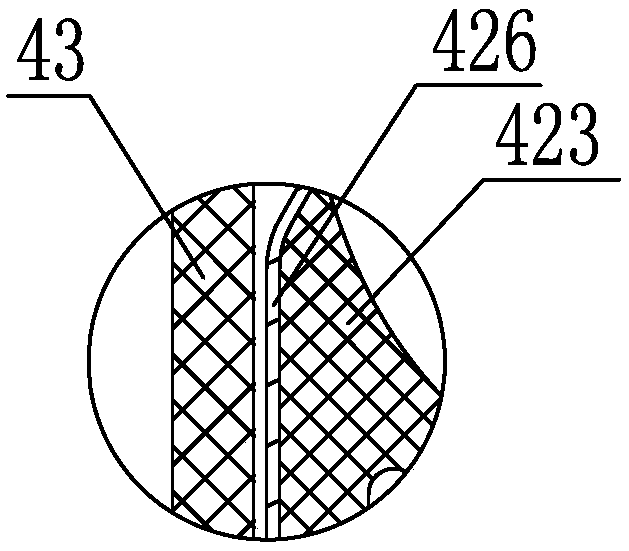

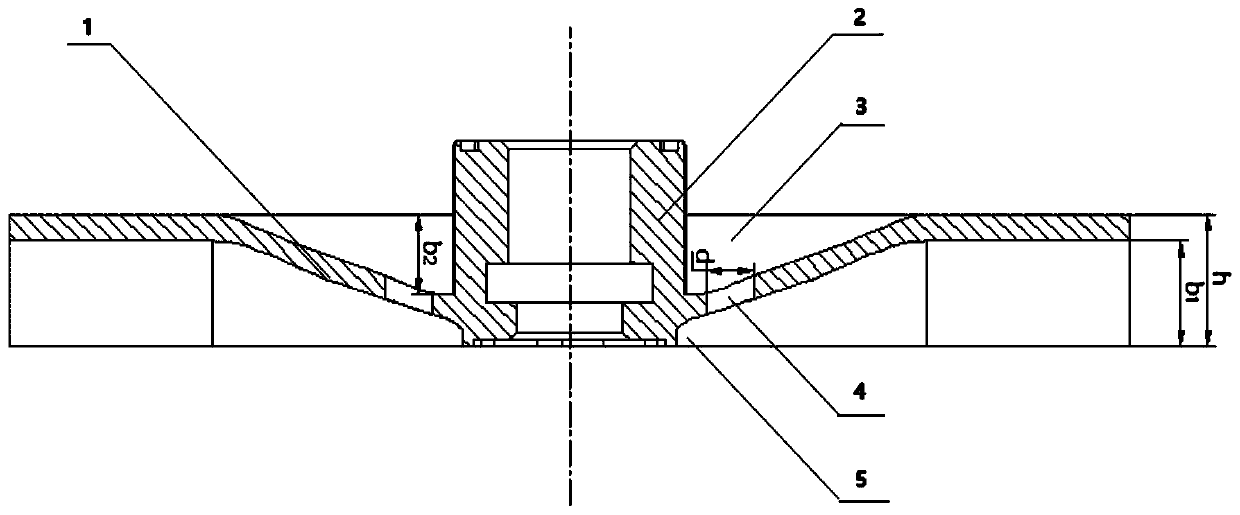

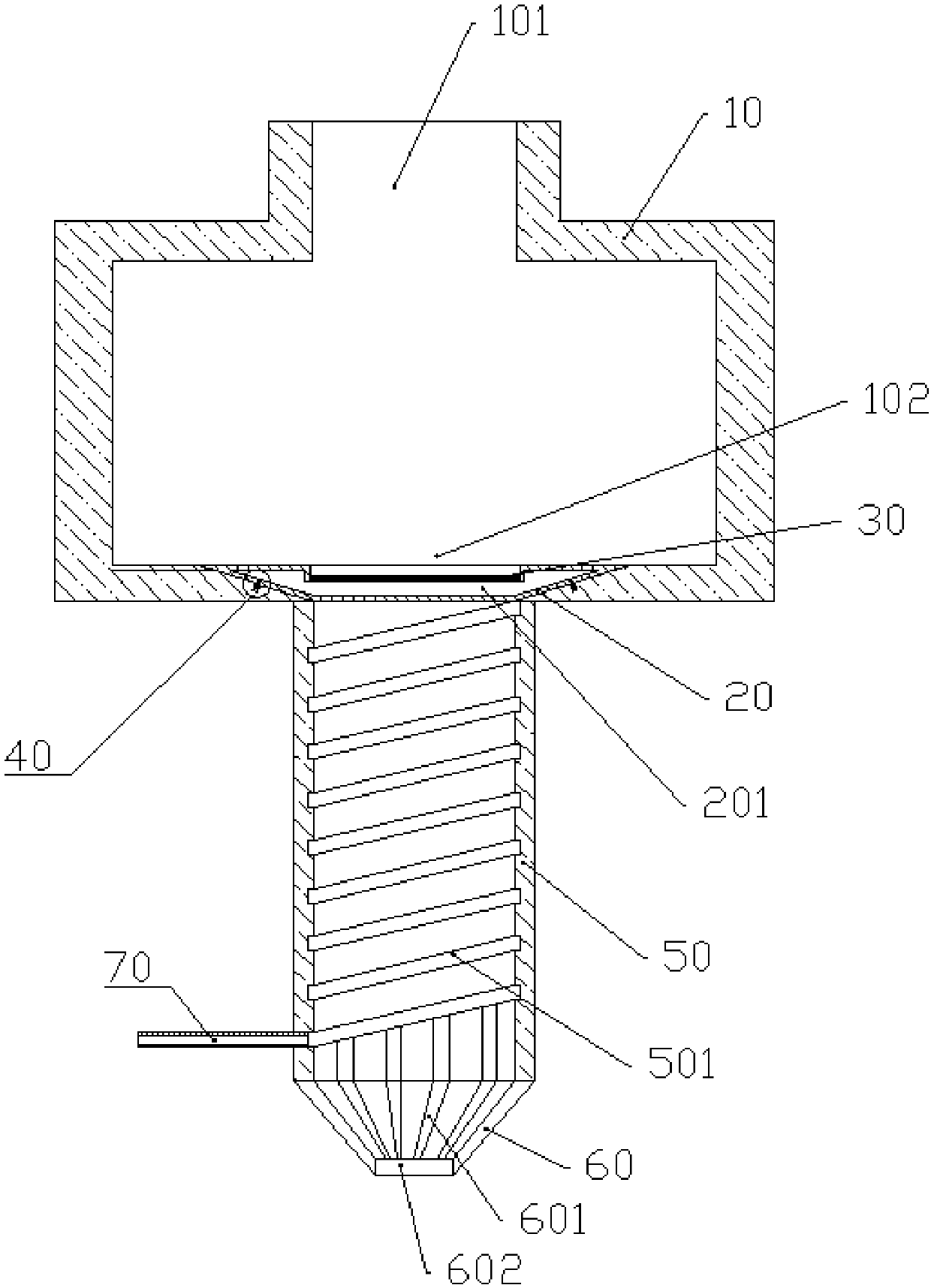

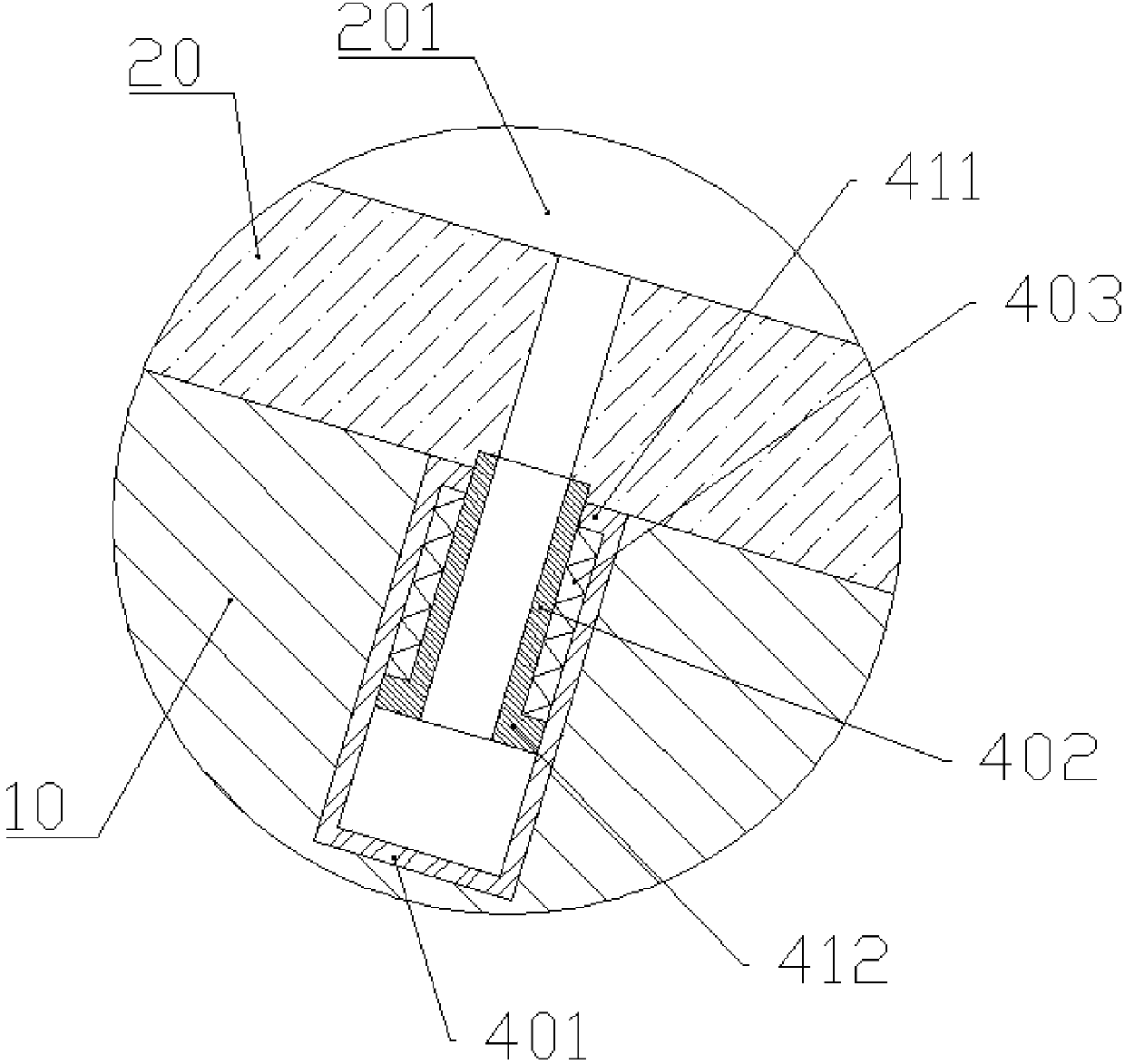

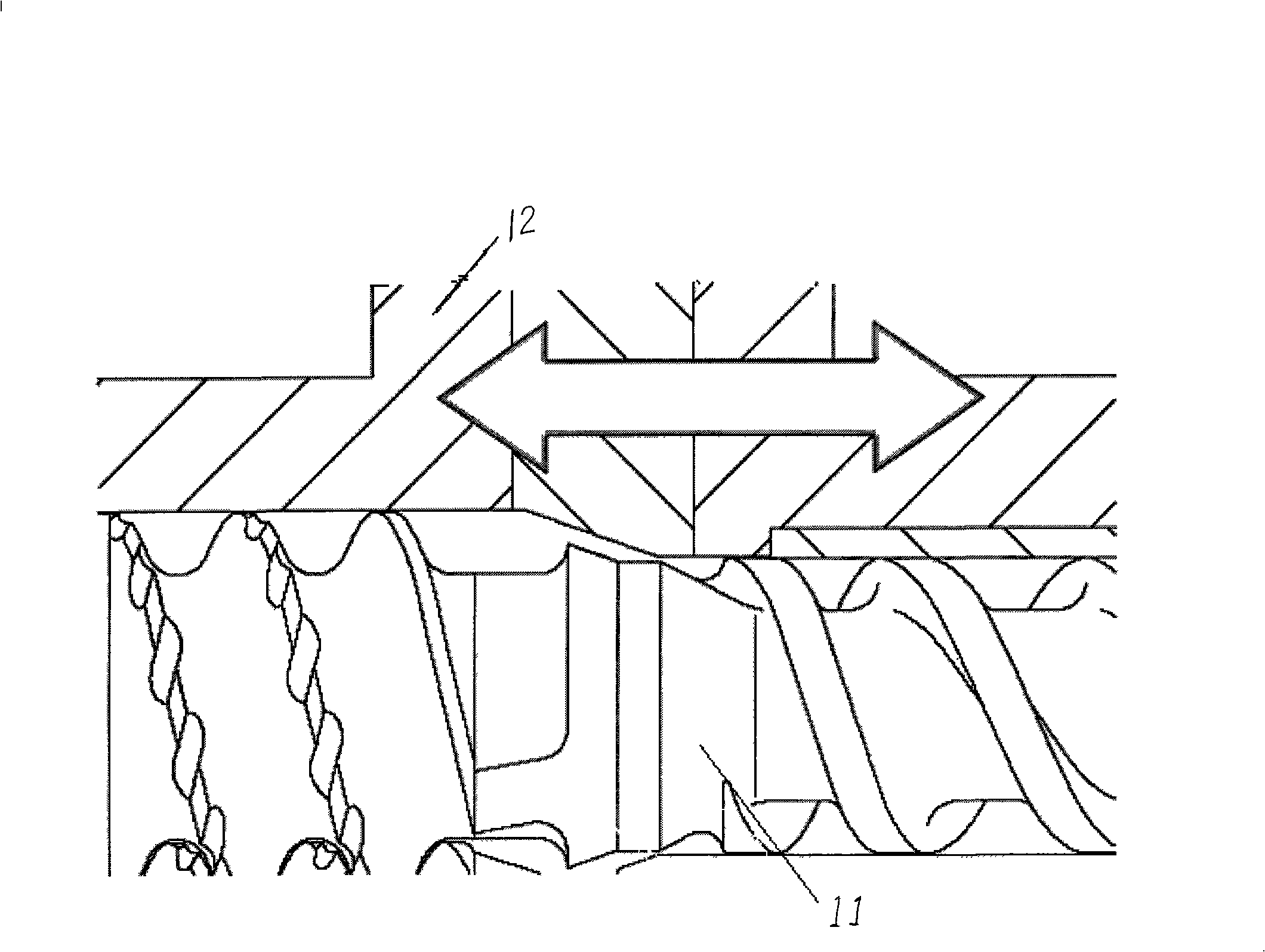

Method for extruding and forming short fiber reinforced-rubber composite material in radial direction

The invention relates to a short fiber reinforced rubber composite material radial orientation extrusion molding method and the procedures are as follows: at first, rubber molten mass containing short fiber is carried out with the extrusion processing in an extruder; at the end of the screw rod in the extruder tube, the rubber is extruded into an axial orientation channel, the flow direction of the rubber mass is adopted for orientation, and the axial orientation of the short fiber is realized in the axial orientation channel of a machine head; the rubber mass which goes through the axial orientation passes through a resistance dam formed by contracting the thickness of the channel under the function of extrusion pressure; the rubber is characterized by extrusion swelling, so the short fiber is inclined owing to rolling over after the rubber mass passes through the resistance dam; the expanded rubber mass keeps flowing along the channel, the inclined degree of the part in middle and at edge is increased owing to velocity gradient, the radial orientation of the short fiber is increased and then the radial orientation is realized. The method of the invention has the advantages of simple and easily-controlled technique procedures, wide application range, good radial orientation quality of products, and low cost.

Owner:QINGDAO UNIV OF SCI & TECH

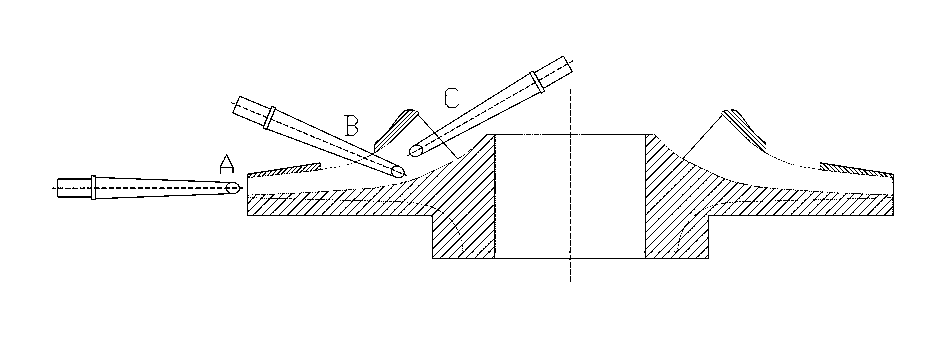

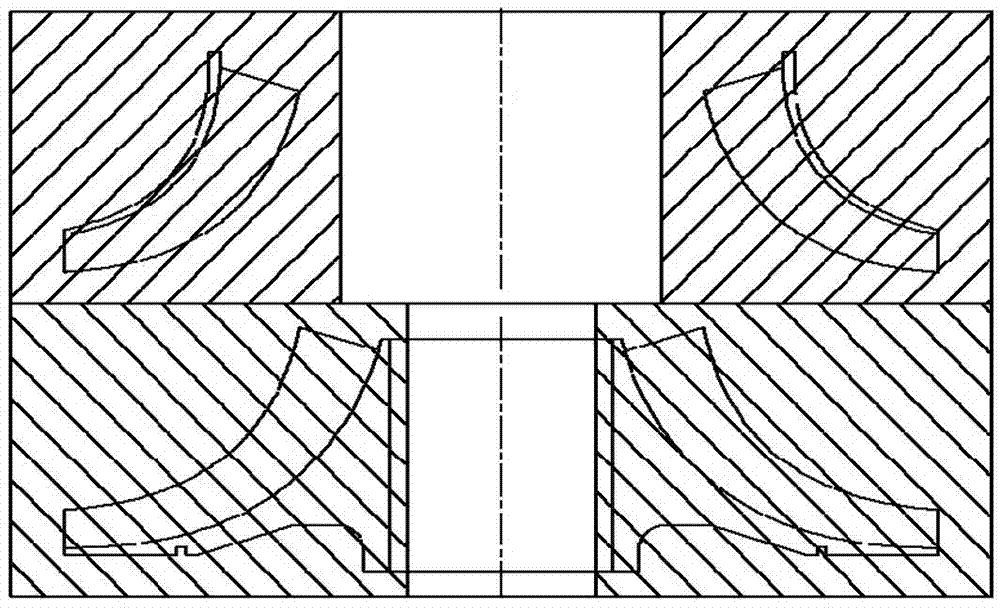

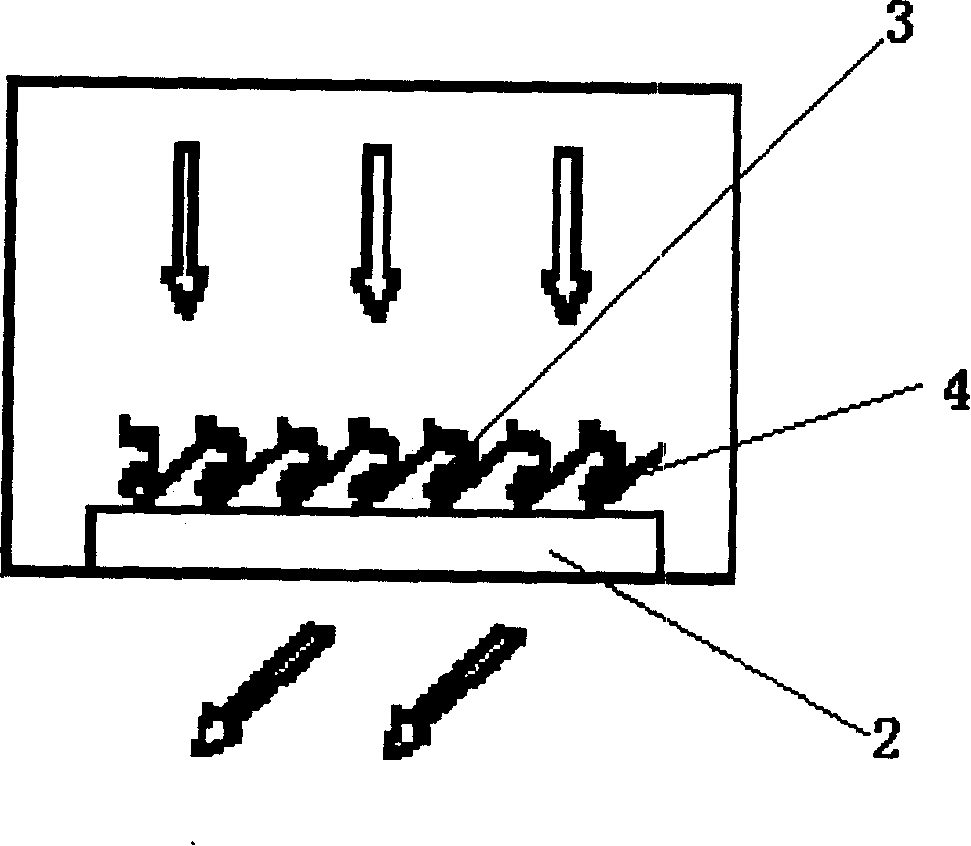

Machining method of closed three-elemental impeller with small flow

The invention relates to a machining method of a closed three-elemental impeller with a small flow. The machining method comprises the following steps of: 1. mounting an impeller forging on a lathe machining center of a numerically-controlled machine tool, thereby carrying out semi-finishing treatment on the impeller forging; 2. machining a circular groove in an impeller cover and completing the machining of the whole flow channel of an impeller; and 3. welding a circular impeller cover shielding plate on the impeller cover and completing the contour finishing of the impeller cover and an impeller hub, wherein the semi-finishing treatment is performed by clamping the impeller forging on the lathe machining center of the numerically-controlled machine tool and carrying out the lathe machining on the impeller forging; the lathe machining in an axial feeding manner is performed until reaching an air inlet of an impeller blade; the outer contour of the impeller cover is formed by performing the lathe machining in a radial feeding manner; and the allowance of 4 to 6mm is left between the impeller cover and the impeller hub. The method has the characteristics of weldless flow channel forming surface, smooth flow channel, effective reduction in aerodynamic resistance, good aerodynamic performance and aerodynamic efficiency, good machining quality, high impeller strength, good corrosion resistance and the like.

Owner:杭州杭氧透平机械有限公司

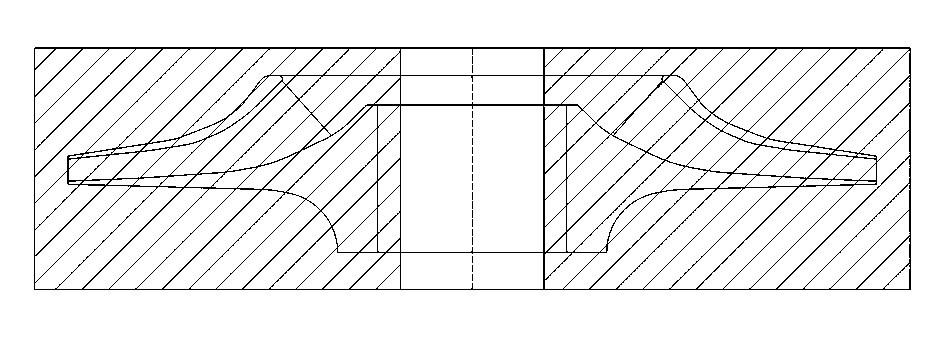

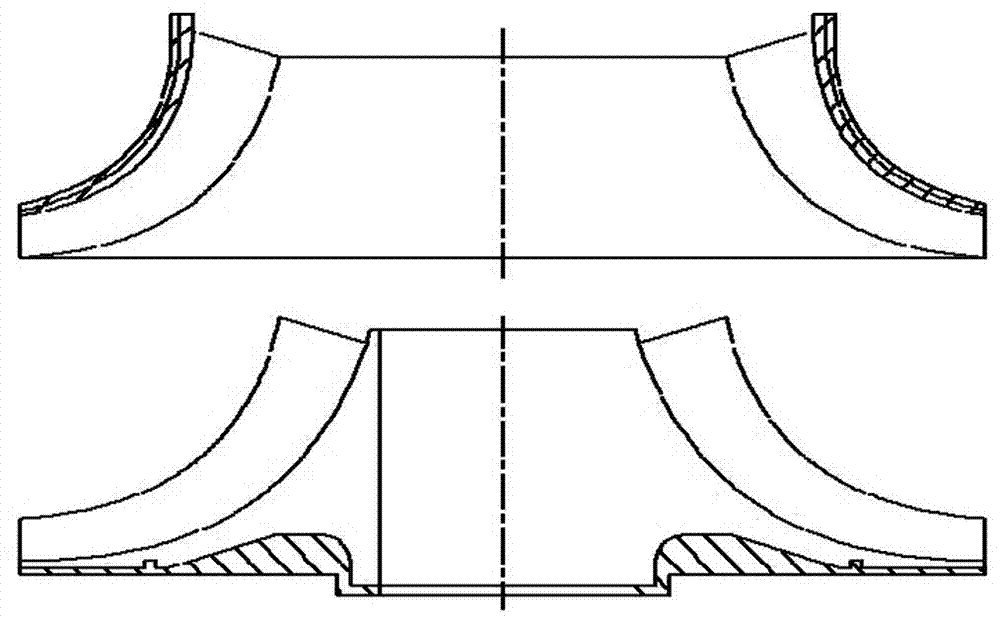

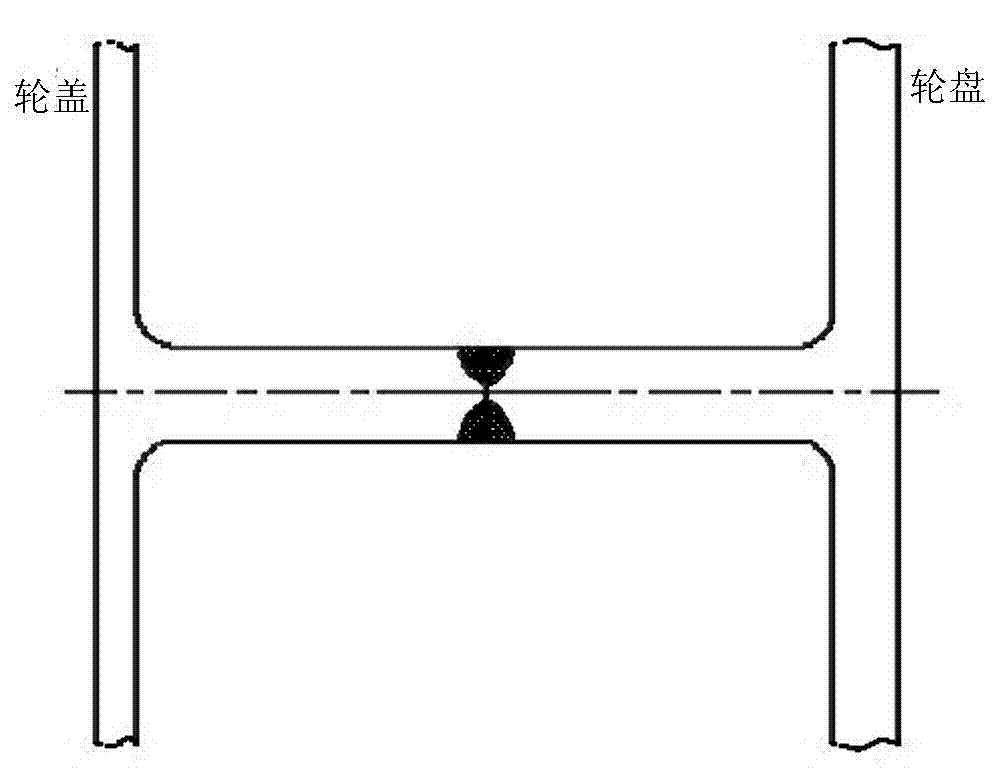

High-flow-rate ultra-large-diameter semi-milling and semi-welding closed ternary impeller and manufacturing method

The invention provides a high-flow-rate ultra-large-diameter semi-milling and semi-welding closed ternary impeller and a manufacturing method. The closed ternary impeller mainly comprises a wheel cover, a wheel disc and a blade, wherein the blade is uniformly divided into two halves, one half of blade is integrally milled and formed with the wheel cover, the other half of blade is integrally milled and formed with the wheel disc, in addition, the two halves of blades are welded at a butt joint part for forming an integral blade, a groove is formed in the butt joint part of the two halves of blades, and in addition, a welding seam is formed in the middle of the whole blade after the welding. The manufacturing method comprises the following steps that the blade of the ternary impeller is uniformly divided into two parts, one half of blade is integrally milled into the wheel disc, one half of blade is integrally milled into the wheel cover, the groove is formed in the butt joint part of the two halves of the blades, in addition, the whole blade is welded after the fixation by a tooling, and the welding seam is formed in the middle of the whole blade; after the welding of the wheel cover and the wheel disc of the impeller is completed, the stress is eliminated, and the outer contour of the impeller is finely turned in the turning processing center of a numerical control machine tool after the re-installing and re-clamping; finally, the welding part of the blade is manually ground to be smooth. The ternary impeller and the manufacturing method have the characteristics that better pneumatic performance and pneumatic efficiency are realized, the processing quality is good, the impeller intensity is high, and the like.

Owner:杭州杭氧透平机械有限公司

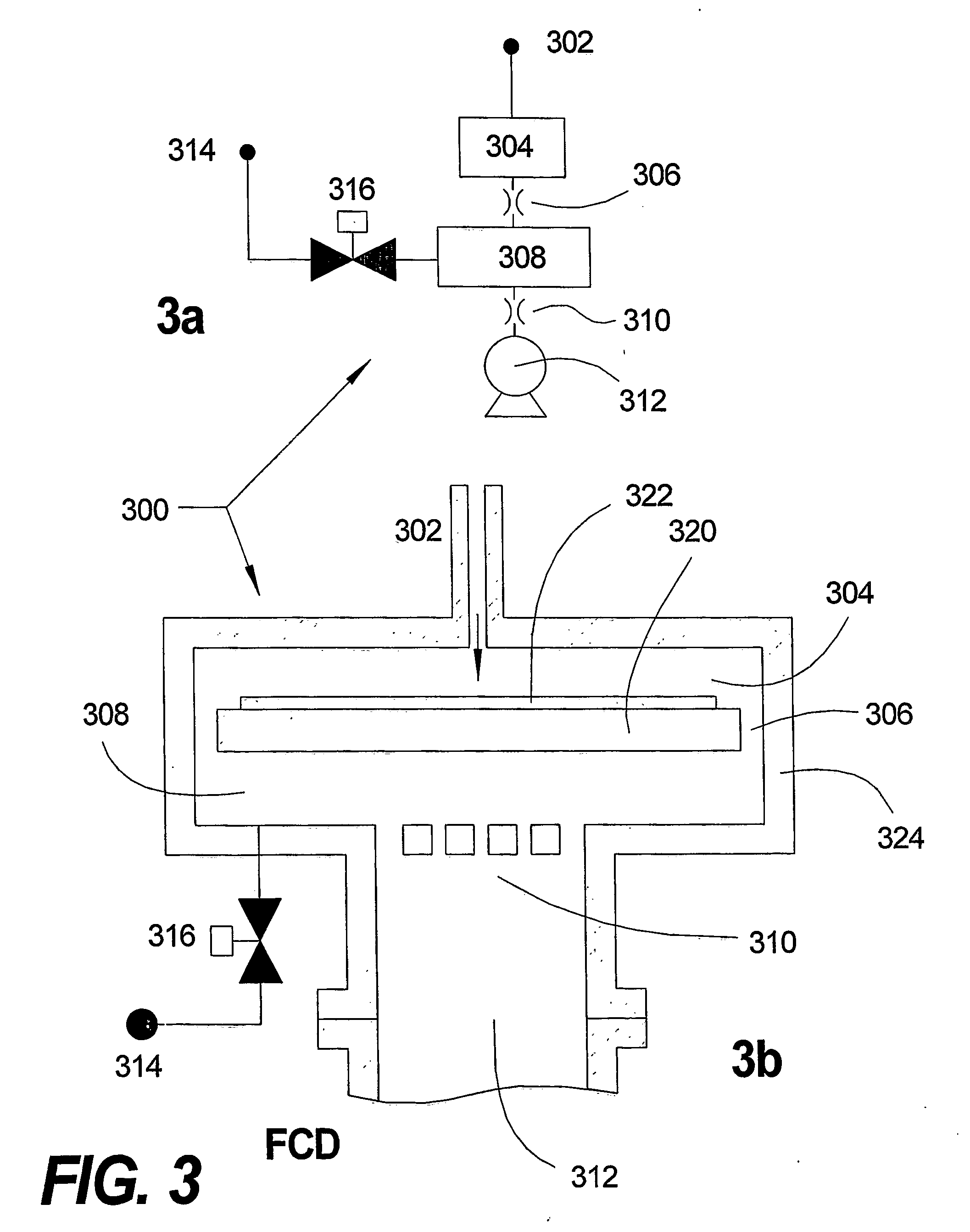

Apparatus and method for downstream pressure control and sub-atmospheric reactive gas abatement

InactiveUS20100301011A1Rapid responseSmooth runnerDecorative surface effectsSemiconductor/solid-state device manufacturingReactive gasEngineering

A sub-atmospheric downstream pressure control apparatus includes a first flow restricting element (FRE); a pressure control chamber (PCC) located in serial fluidic communication downstream from the first FRE; a second FRE located in serial fluidic communication downstream from the PCC; a gas source; and a flow controlling device in serial fluidic communication downstream from the gas source and upstream from the PCC.

Owner:SUNDEW TECH

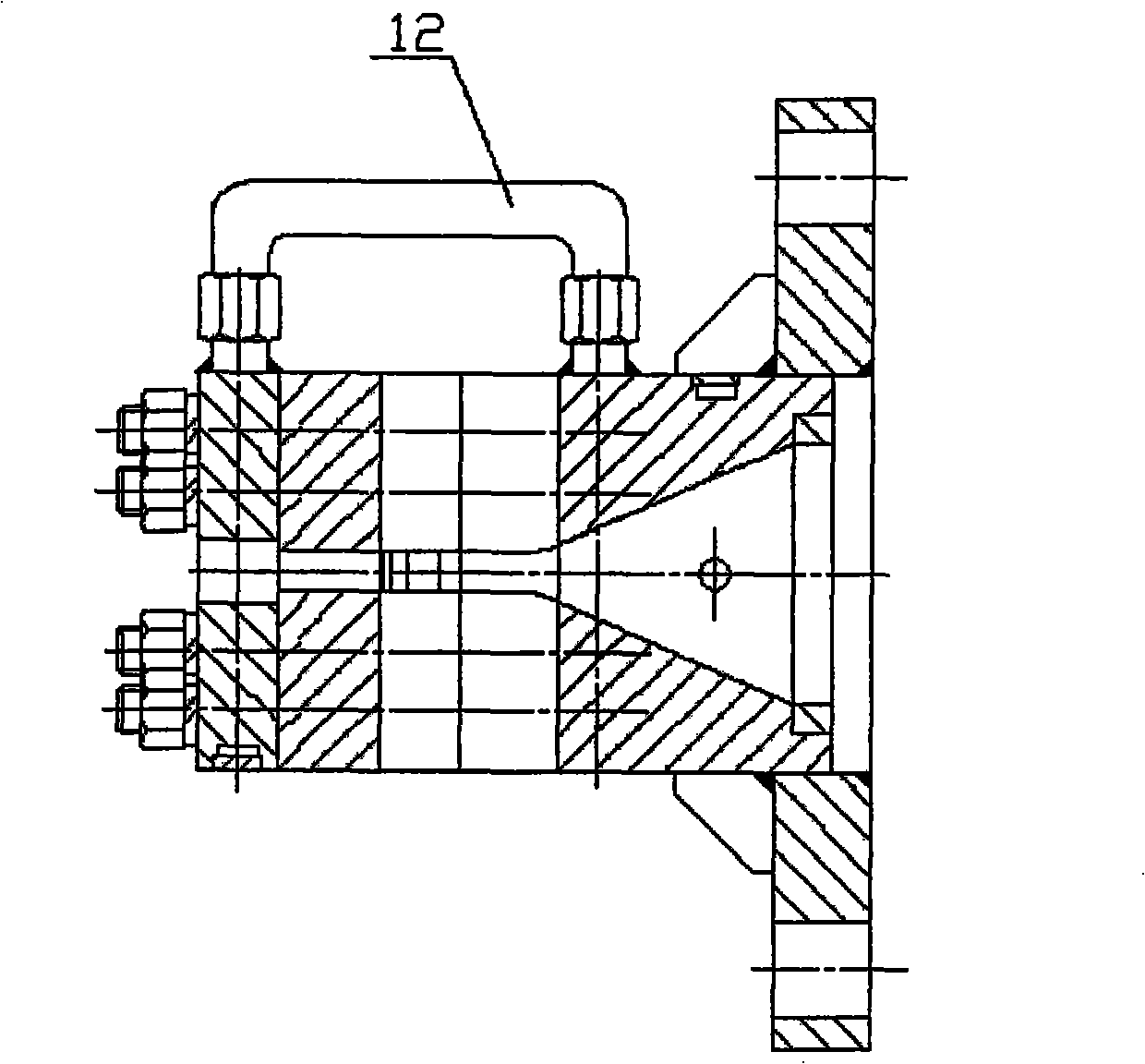

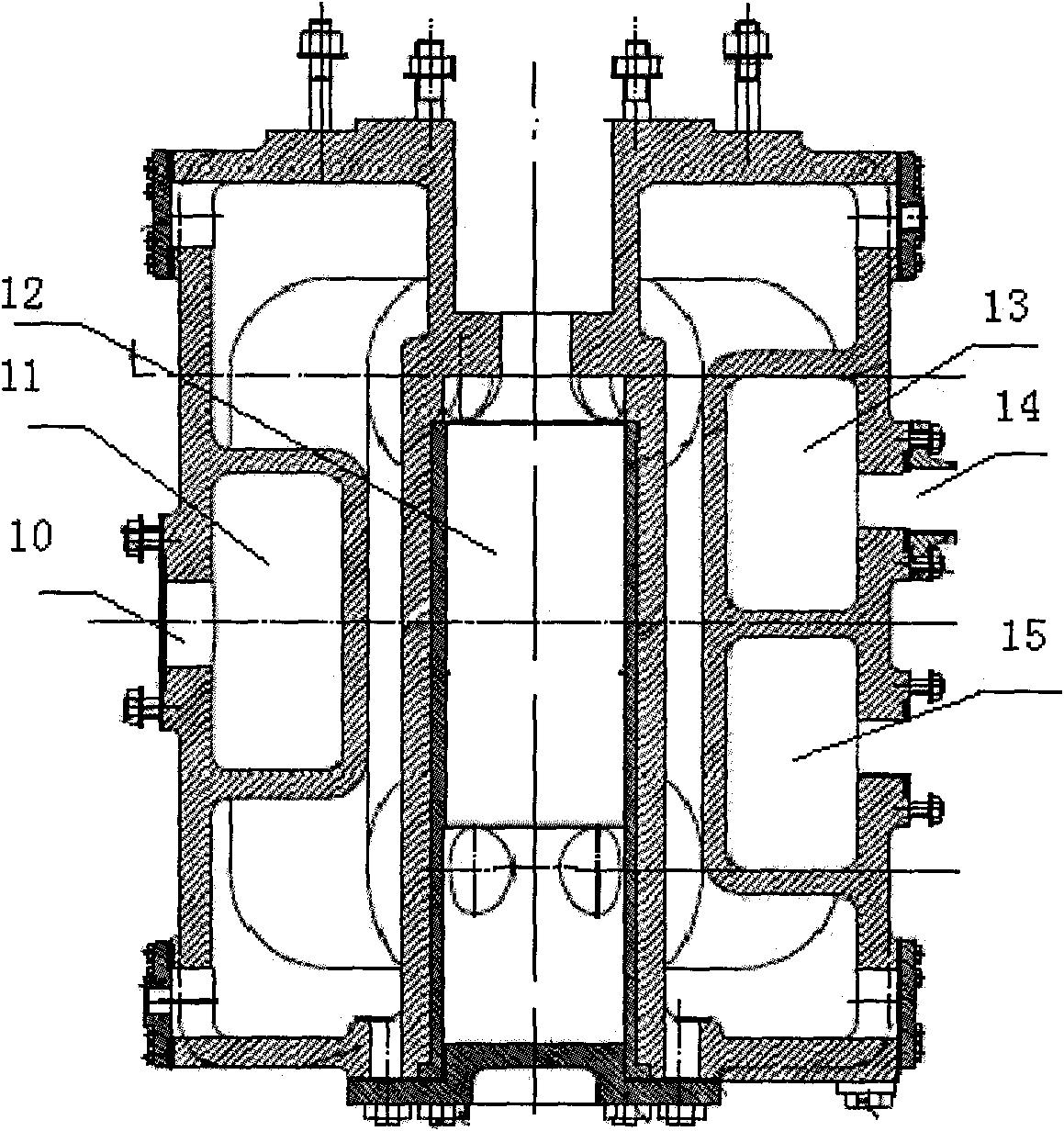

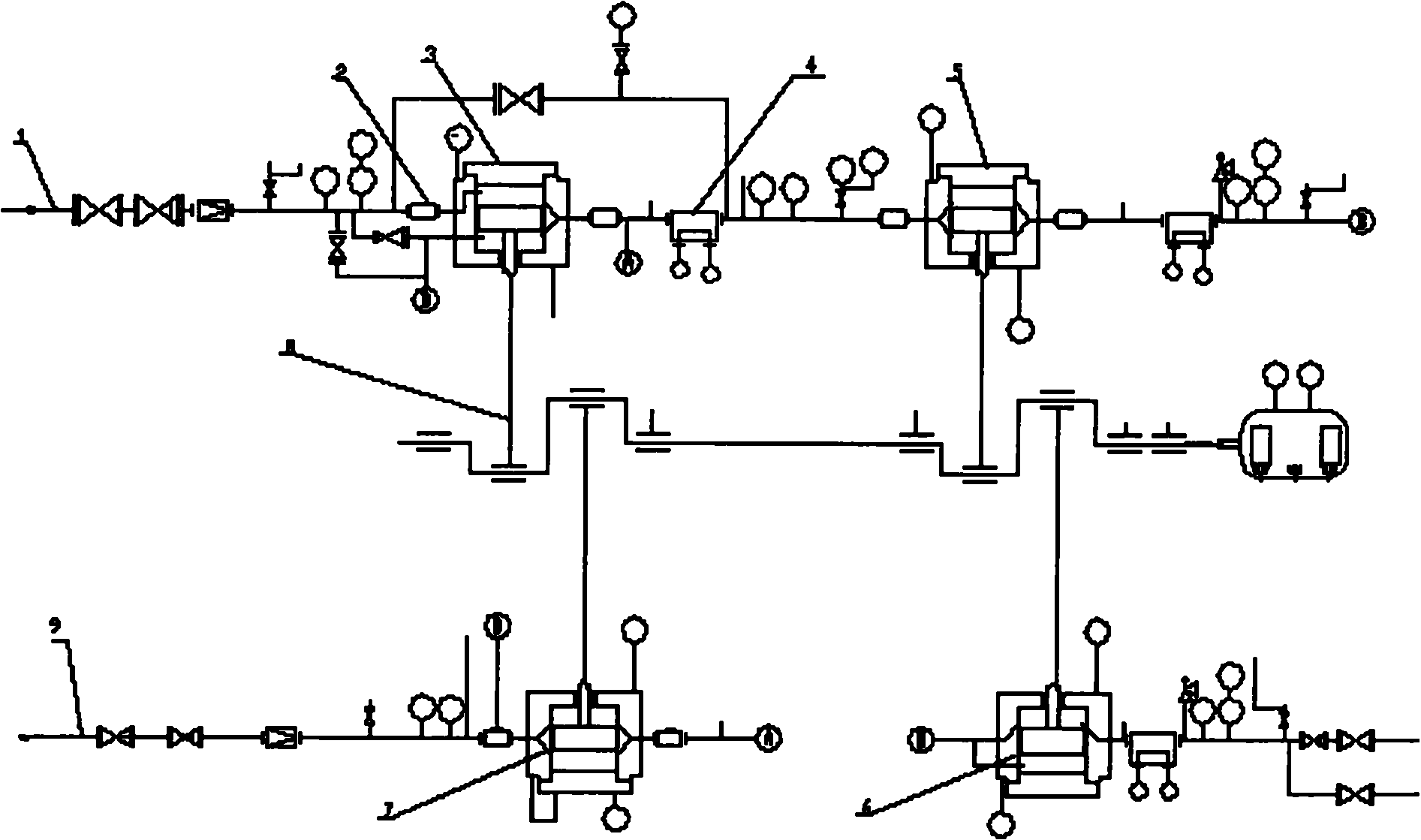

Combined gas piston compressor

InactiveCN101858324ASmooth runnerGuaranteed structural strengthPositive displacement pump componentsMulti-stage pumpsGas compressorProcess engineering

The invention discloses a combined gas piston compressor, comprising an M-type compressor which consists of a first first-stage cylinder, a second first-stage cylinder, a second-stage cylinder and a third-stage cylinder; the first first-stage cylinder consists of two independent gas inlet chambers and a mixed gas exhausting chamber which are communicated with a compression chamber; the two gas inlet chambers are respectively communicated with a feed gas channel and a branch channel of recycle gas; the gas inlet chamber of the second first-stage cylinder is communicated with the other branch channel of the recycle gas; the mixed gas exhausting chamber is communicated with the gas exhausting chamber of the second first-stage cylinder and the gas inlet chamber of the second-stage cylinder; the gas exhausting chamber of the second-stage cylinder is communicated with the gas inlet chamber of the third-stage cylinder; and the gas exhausting chamber of the third-stage cylinder is communicated with a lead-out pipeline. Preceding stage pressurization, mixing and compression are carried out on feed gas and the recycle gas with different initial pressures by the specially designed first first-stage cylinder to meet the requirements. The combined gas piston compressor has the advantages of simple structure, high integration, high mechanical efficiency, small occupied area, easy maintenance and the like.

Owner:四川空分设备(集团)有限责任公司

Cabinet air-conditioner air outlet oscillating blade system

A blade swinging system arranged on cabinet air conditioner air outlet comprises a plurality of air guide plates which are connected into a whole by a connecting device and arranged according to a certain intervals. The air guide plates can be driven to rotate by a stepping motor arranged beside an air outlet through a linkage mechanism, and the air guide plates are made of flexible rubber. Two long sides of each air guide plate are respectively provided with a mounting shaft, wherein, one mounting shaft is arranged on the linkage mechanism which should be positioned on the outer edge of the air outlet, and the other mounting shaft is fixed in the air outlet; a short side of each air guide plate is provided with a groove. When the air guide plates are driven by a connecting rod to swing left and right, the air guide plates made of rubber materials can be bent to form a natural curved surface, so as to lead the flow passage of airflow flowing through the air outlet to be smoother, which greatly reduces the vortex flow of airflow, increases outlet air amount and decreases noise.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

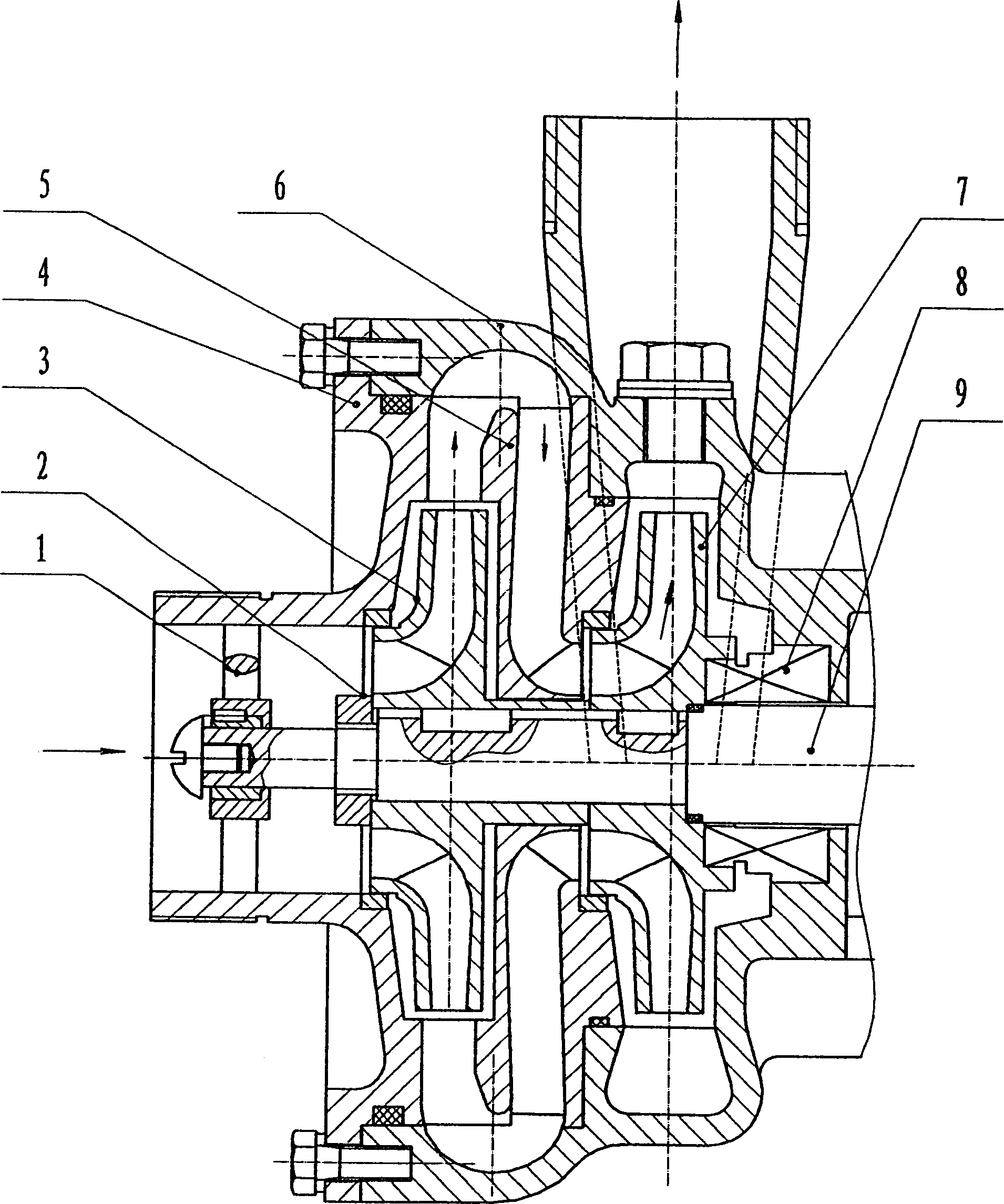

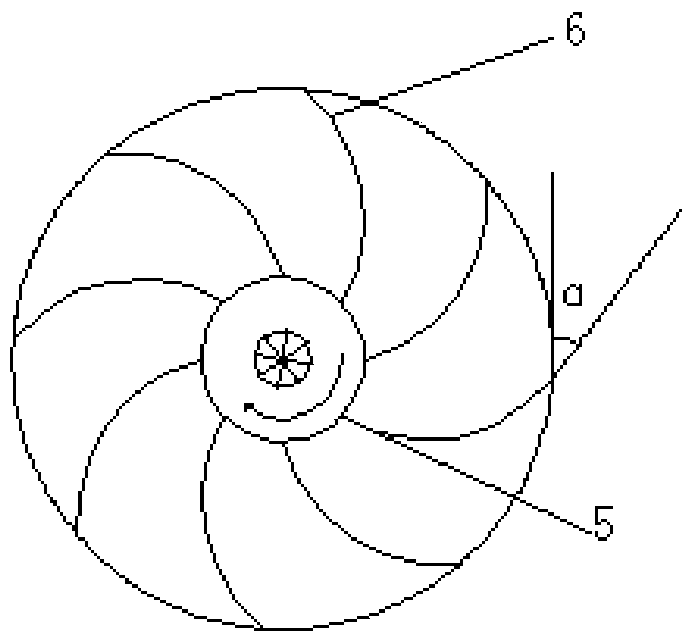

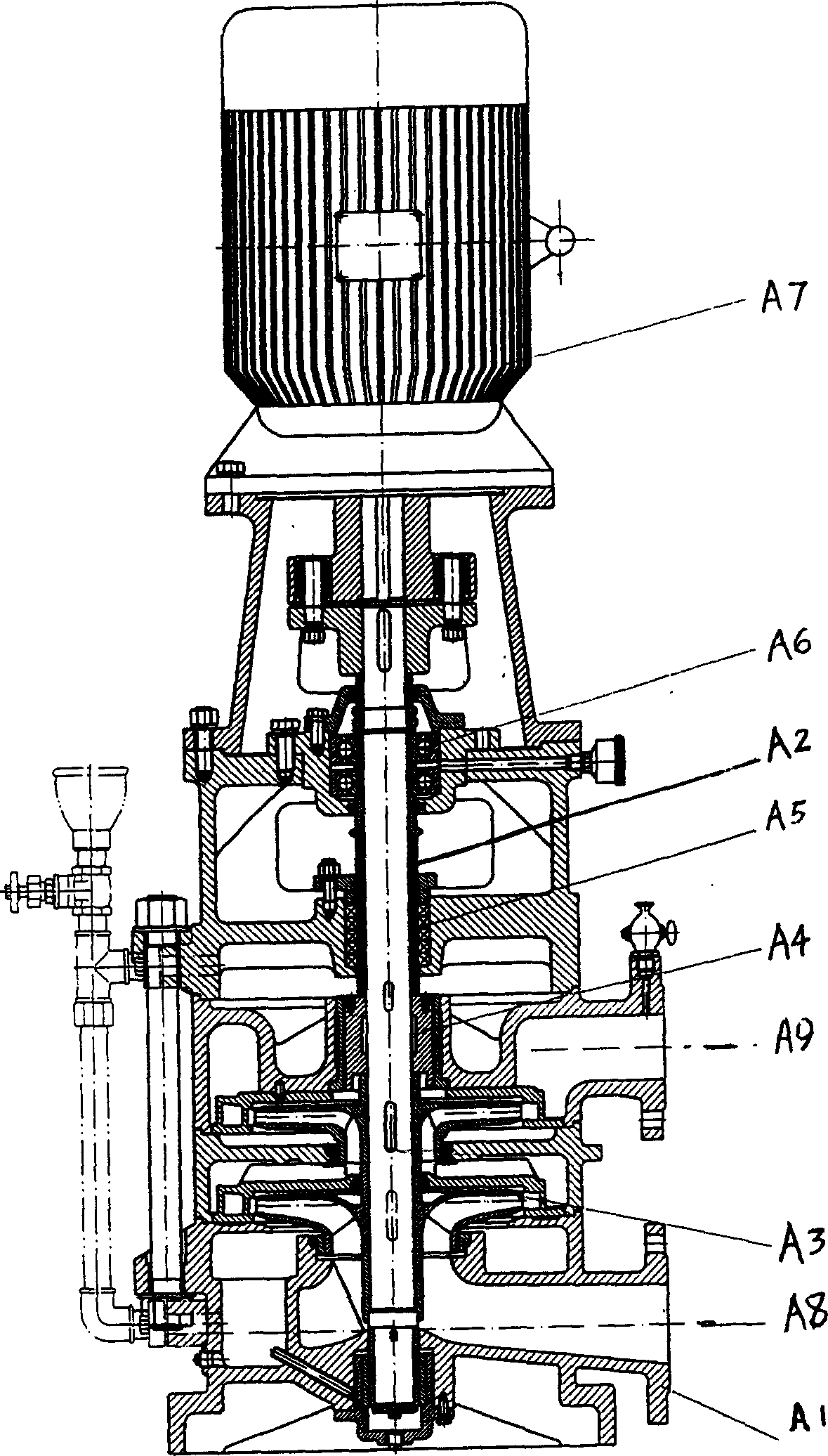

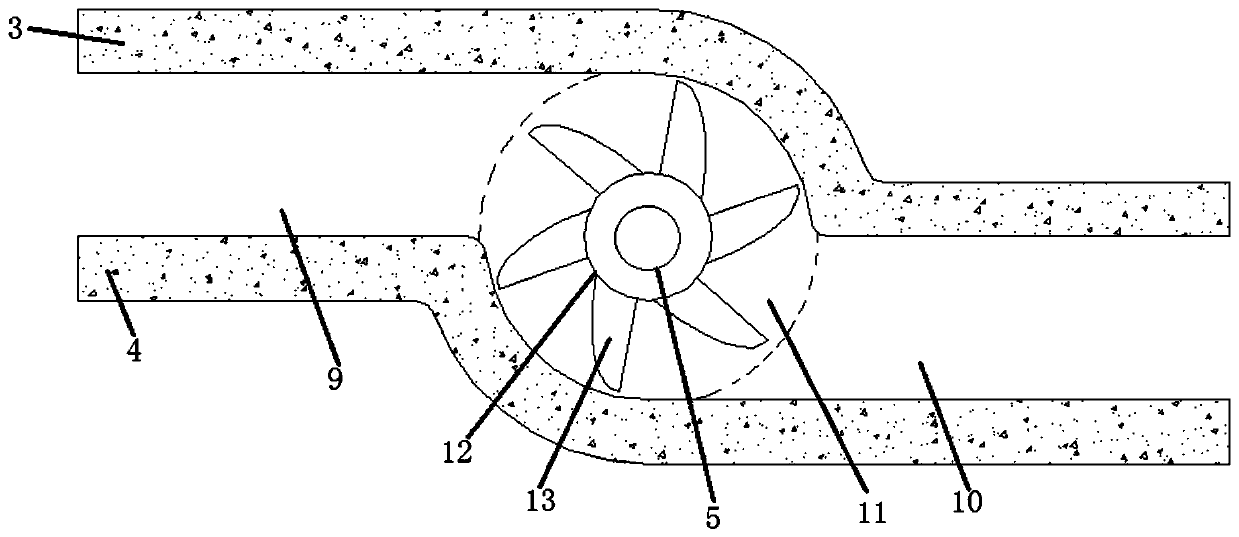

Two stage pump in type of combining guide vane with spiral case

InactiveCN1696516AImprove efficiencyReduce weightPump componentsRadial flow pumpsImpellerEngineering

A two stage pump in type of combining guide vane with spiral case has structure of combination mode of entrance bucket and scroll casing, symmetrical radial entrance buckets are added at impeller outlet of the scroll casing which facilitated casting and processing, and support point of the pump axle is added at sucking inlet of the pump body, the pump operates reposefully. The operation principle is that when the pump operating, combination mode of entrance bucket and scroll casing is adopted which can ensure that the liquid in the impeller has stable relative movement, a majority of kinetic energy of the high speed liquid flowed from the impeller channel is converted into pressure energy, the speed circulation of the liquid is eliminated, radial force is reduced and efficiency of the pump is improved.

Owner:JIANGSU UNIV

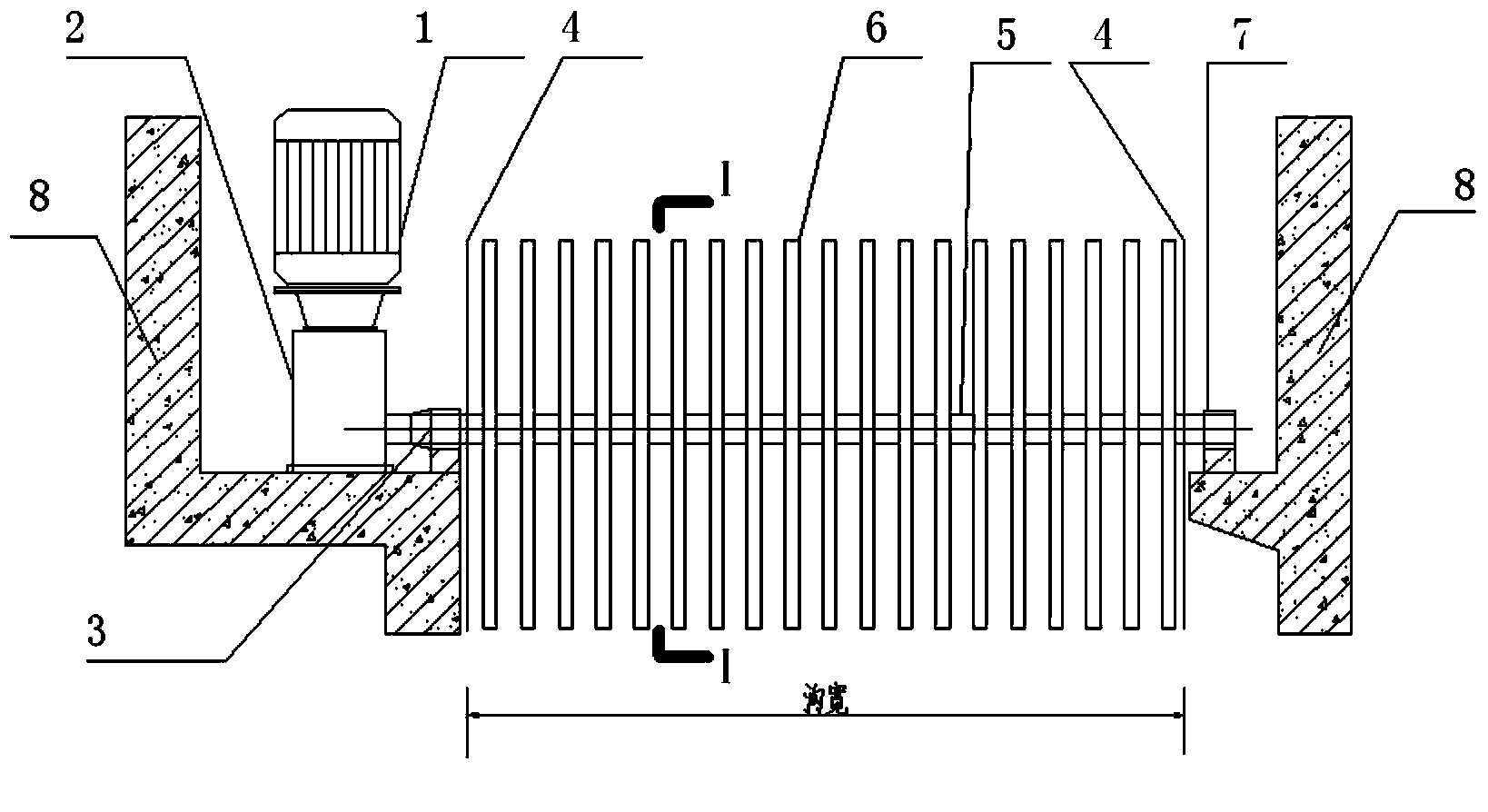

Improved aerating rotating brush device and method capable of improving aeration capacity and saving energy

InactiveCN103466788APrevent precipitationWell mixed contactTreatment using aerobic processesSustainable biological treatmentCouplingEngineering

The invention belongs to the field of sewage treatment, and relates to an improved aerating rotating brush device and method capable of improving aeration capacity and saving energy, in particular to an improved aerating device capable of treating sewage by carrying out aeration in a mechanical rotating mode and a method capable of improving aeration capacity and saving energy. The improved aerating device and method mainly solve the problem that the aeration capacity of an existing aerating rotating brush is not fully utilized and energy consumption is high. The improved aerating rotating brush device comprises a motor, a transmission device, couplings, a water baffle, a main shaft, rotating brush blades, bearing pedestals and a supporting structure. The method includes the steps of first, setting the rotation rate of the main shaft to be 40-70r / min and the immersion depth to be 15mm, and second, starting the motor. The improved aerating device and method are applied to the field of sewage treatment.

Owner:FOSHAN WATER GRP +1

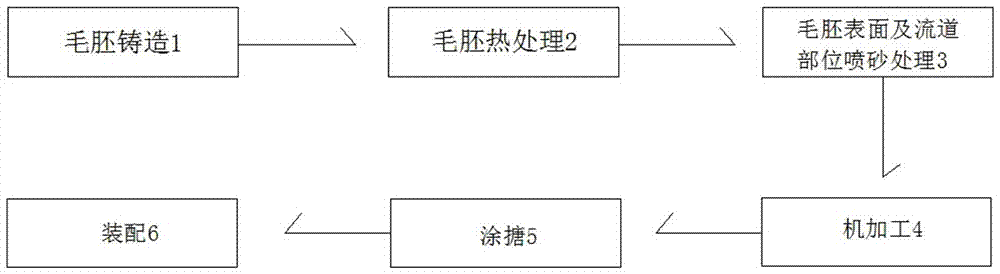

Pump body manufacturing technology

InactiveCN107971698ASmooth runnerExtended service lifePump componentsPumpsManufacturing technologySand blasting

The invention provides a pump body manufacturing technology and relates to the field of pump body manufacture. The pump body manufacturing technology includes the following processing steps of blank casting, blank thermal treatment, sand blasting of blank surface and flow channel position, machining, enameling and assembling, coating with corrosion resistance and wear resistance are used for sandblasting of the blank surface and the flow channel position, and the coating with corrosion resistance and wear resistance is a ceramic particle coating. The strength and the toughness of flow passagecomponents of the produced pump body adopting the new processing steps are greatly improved, the corrosion resistance and the wear resistance of flow passage components of the pump body are greatly improved, the service life of the pump body is prolonged at the same time, the production cost is saved, and the production efficiency is improved.

Owner:湖南长一泵业有限公司

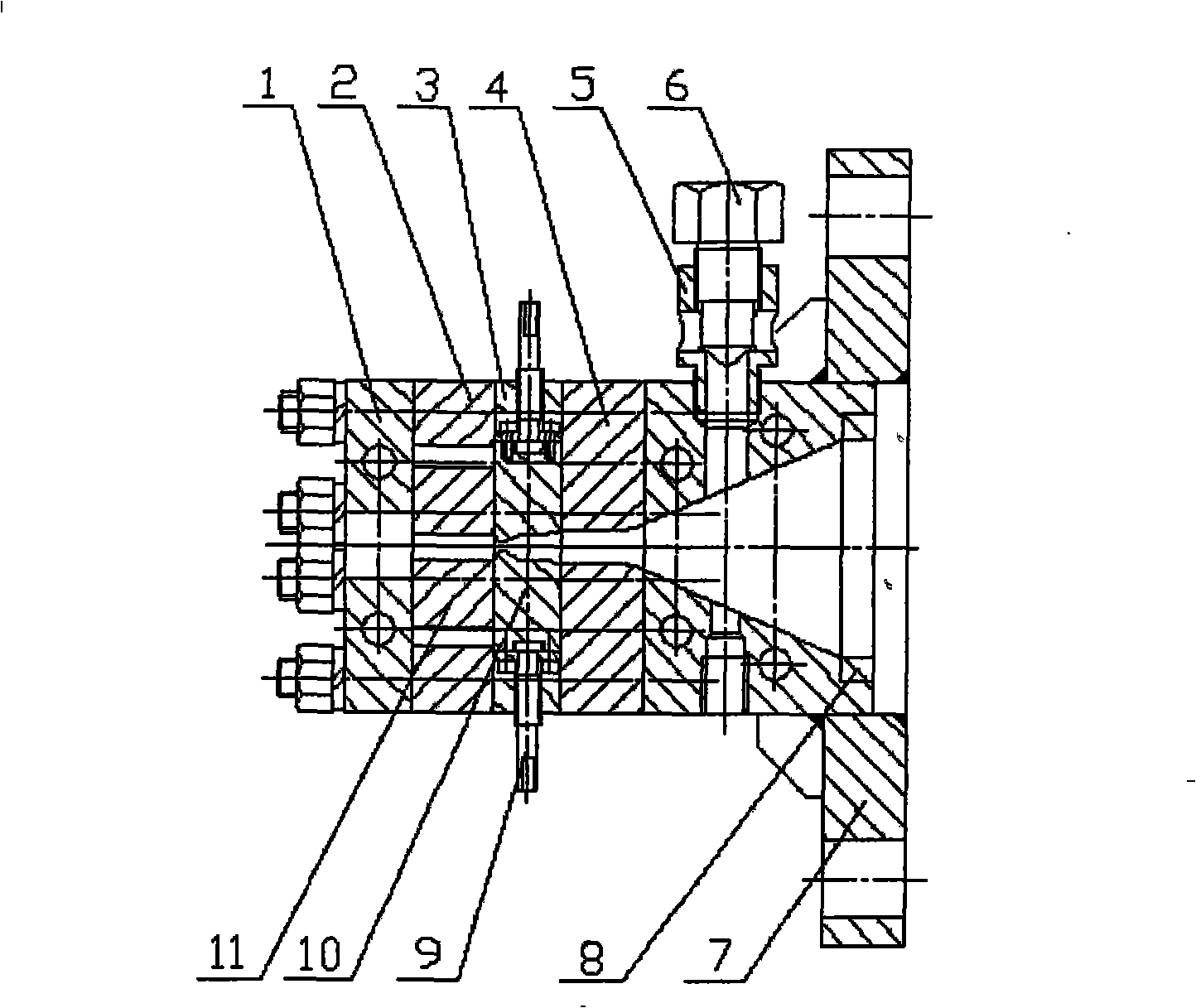

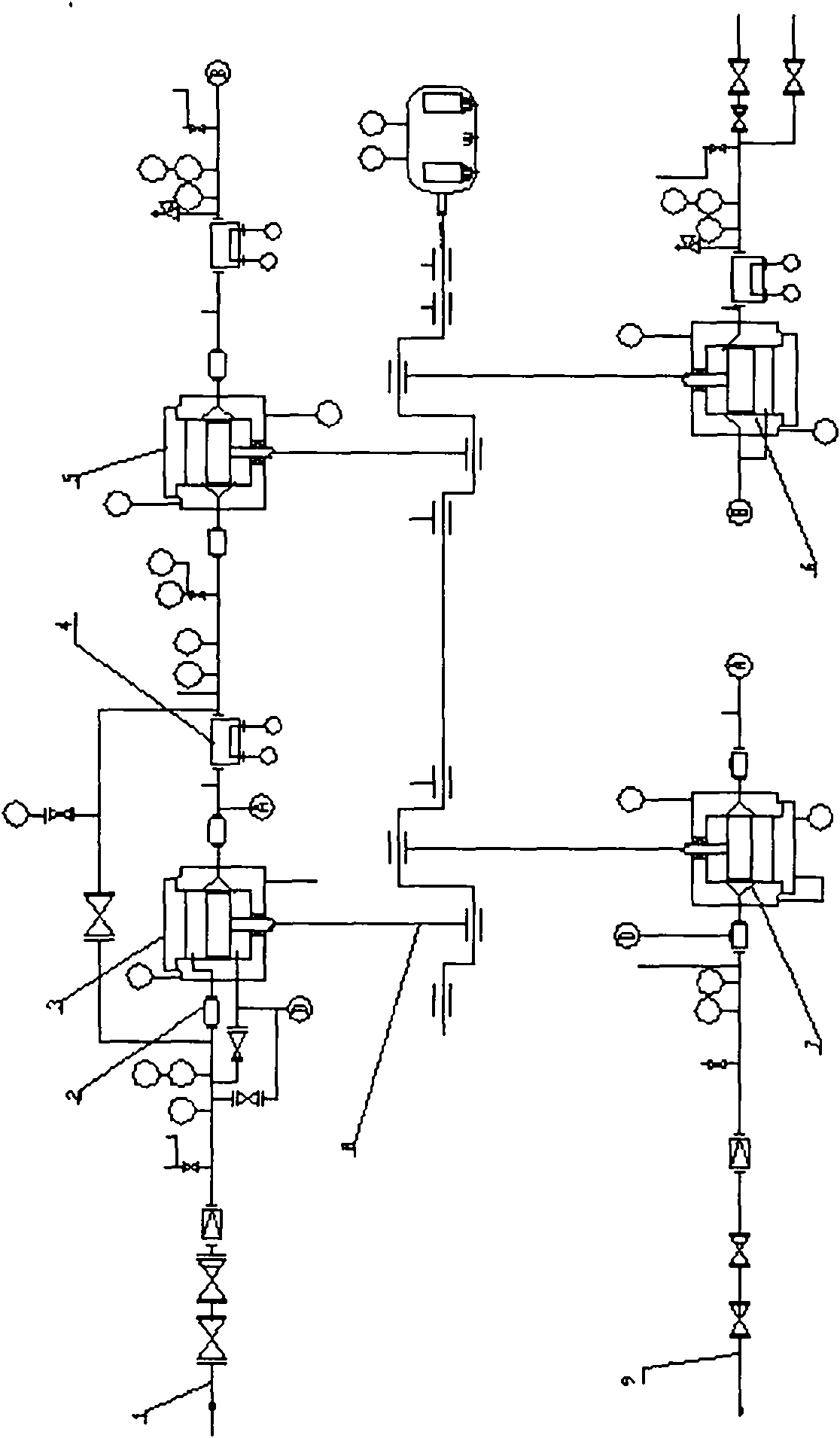

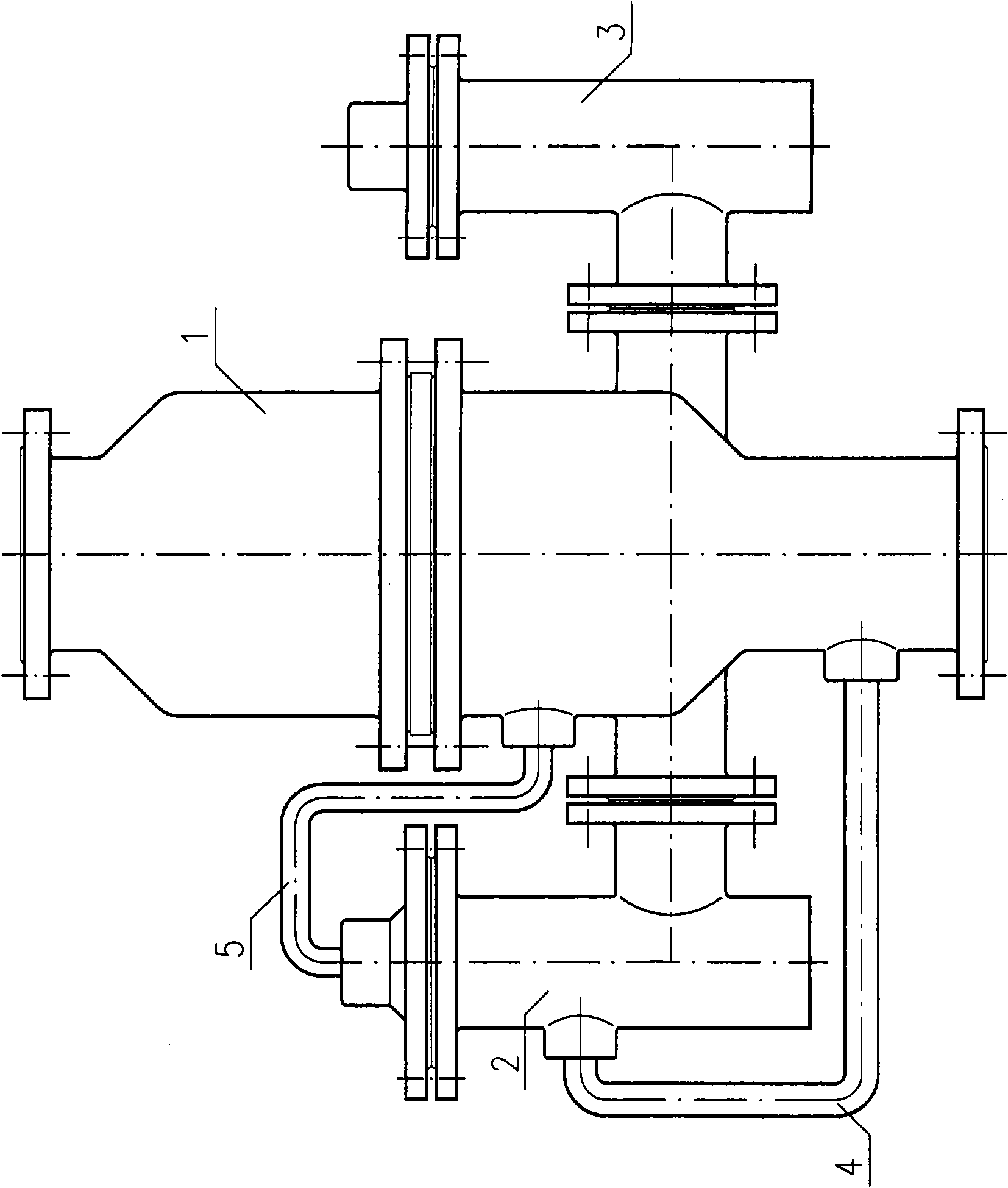

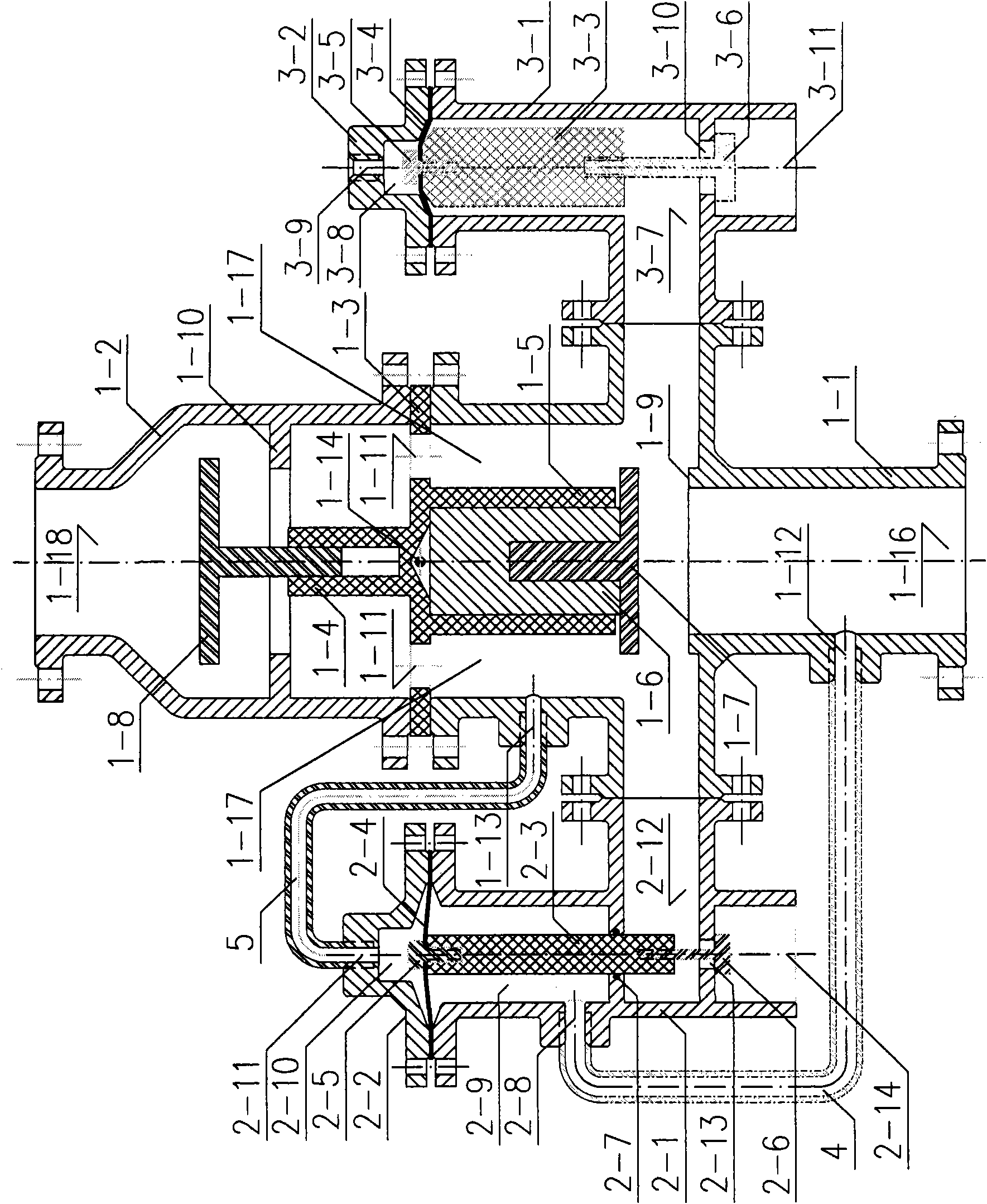

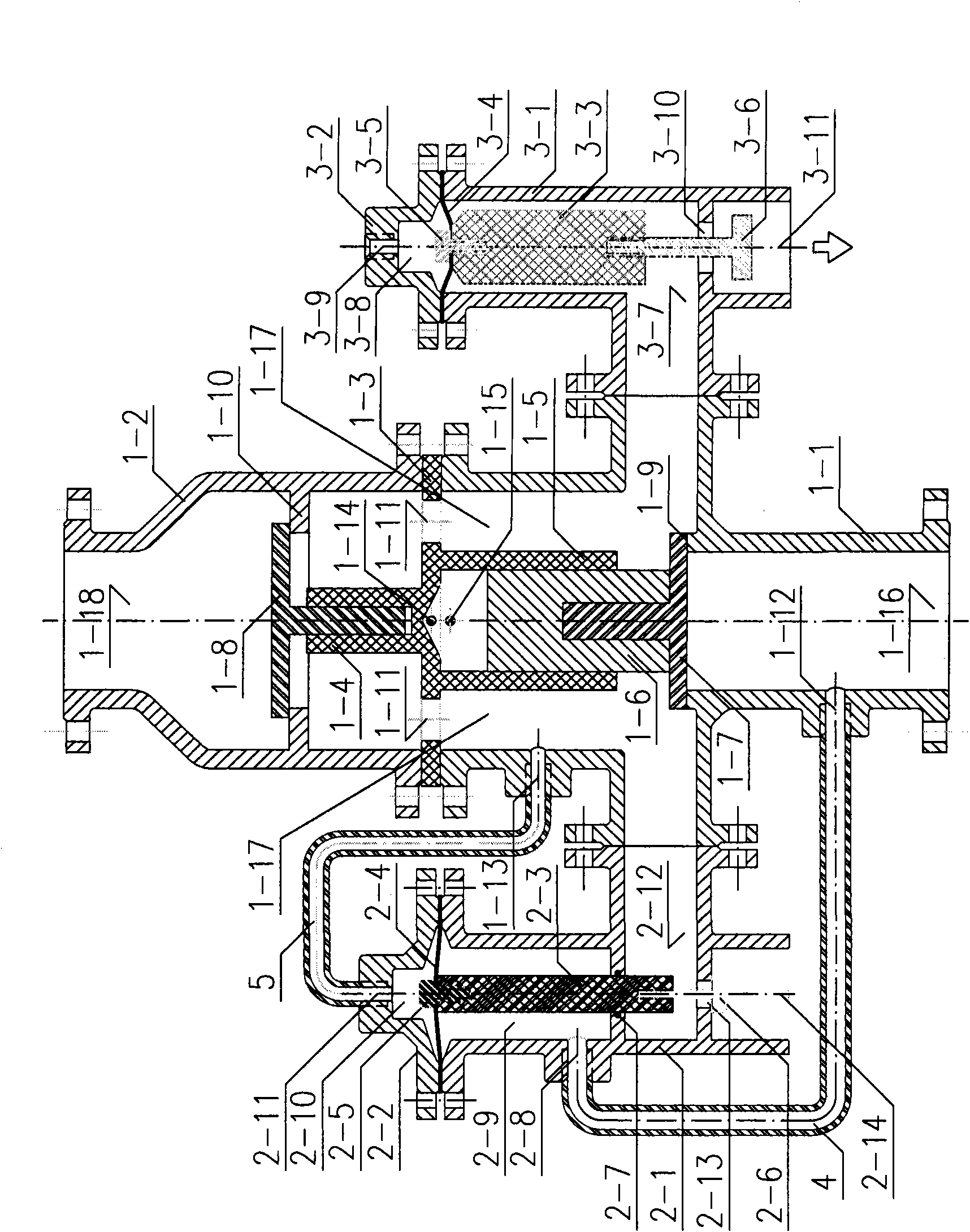

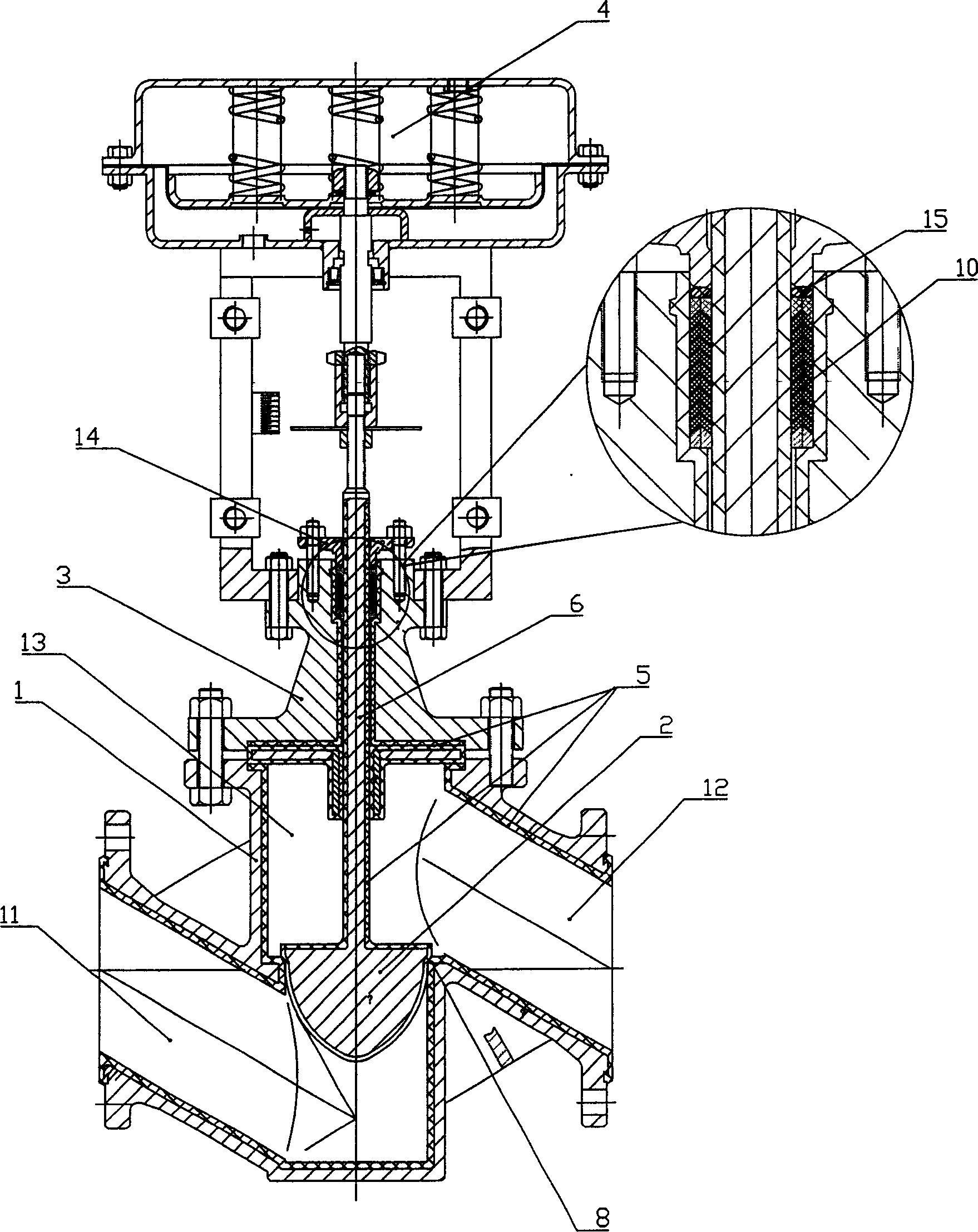

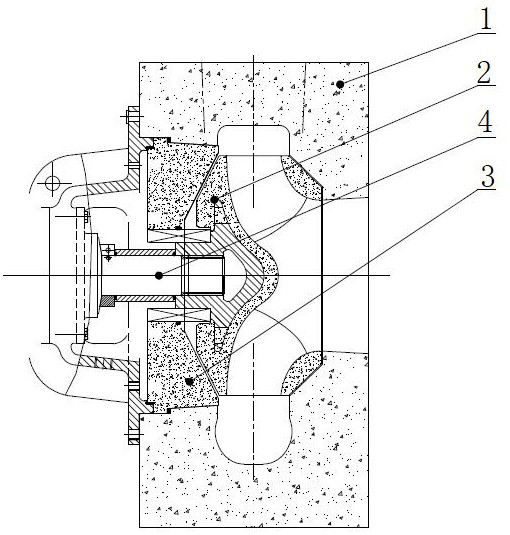

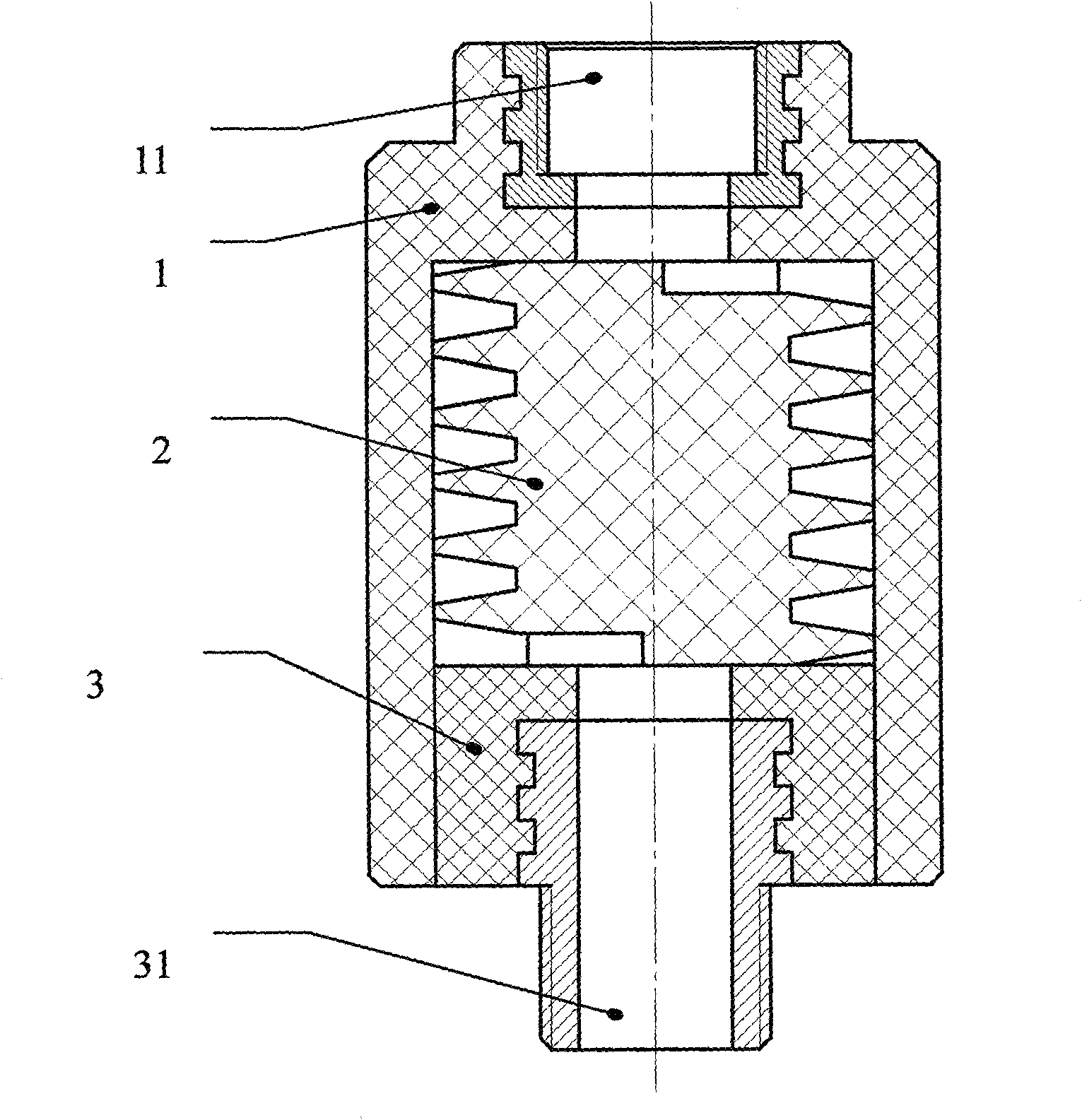

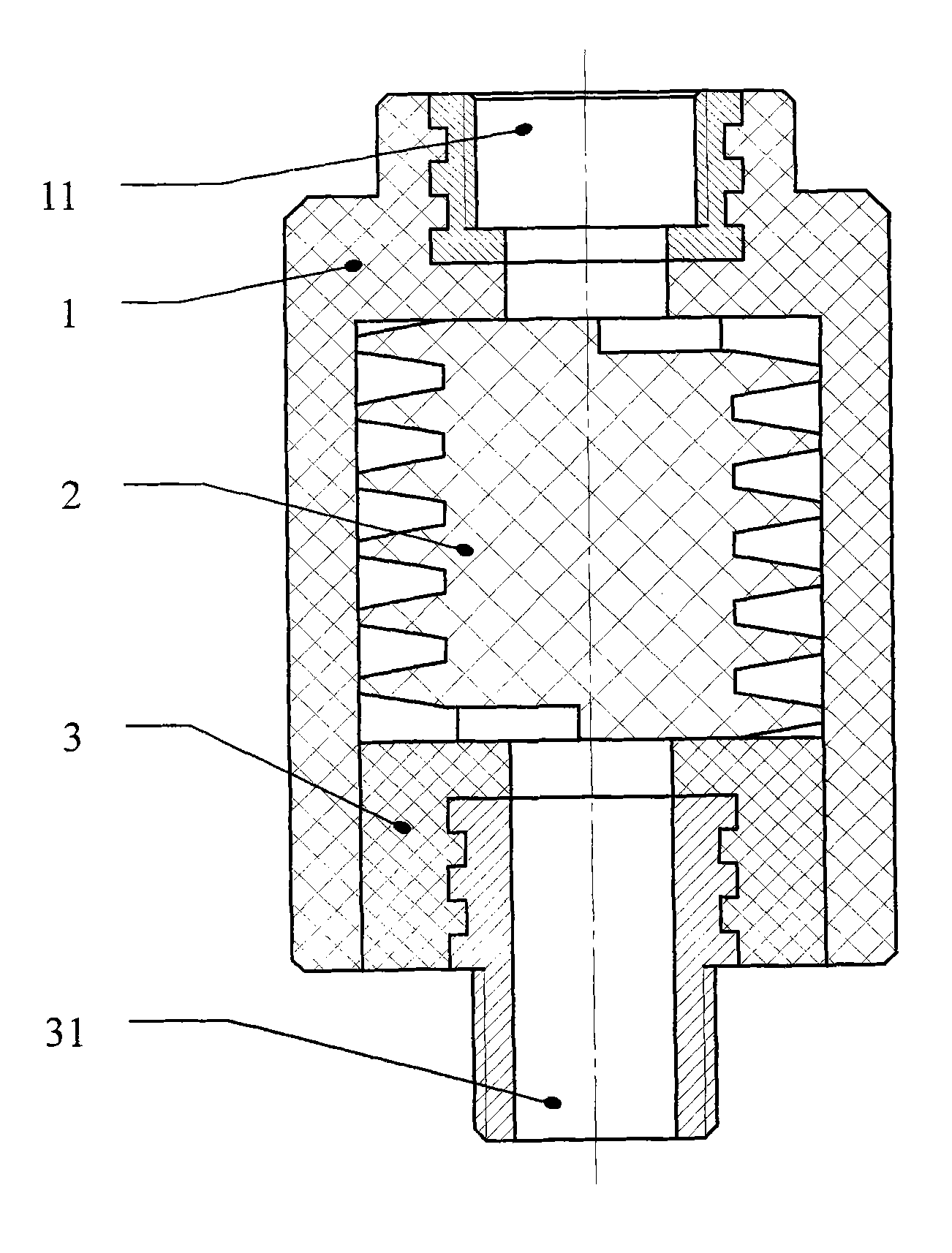

Gravity type backflow preventer

ActiveCN101839358AReduce lossesEliminate the disadvantages of high resistanceCheck valvesMultiple way valvesWater flowEngineering

The invention discloses a gravity type backflow preventer, which is applied to a place where pressure water in a pipeline is strictly limited to flow in one way. The gravity type backflow preventer mainly comprises a main valve (1), a pressure difference water escape valve (2) and a gravity water escape valve (3), wherein the main valve (1) mainly comprises valve bodies (1-1 and 1-2), a positioning board (1-3), a sliding sleeve (1-6) and lifting type check valve plates (1-7 and 1-8); the pressure difference water escape valve (2) mainly comprises a valve body (2-1), a valve cover (2-2), a weight (2-3), a flexible membrane (2-4) and a lifting type valve plate (2-6); and the gravity water escape valve (3) mainly comprises a valve body (3-1), a valve cover (3-2), a weight (3-3), a flexible membrane (3-4) and a lifting type valve plate (3-6). Compared with the prior art, the gravity type backflow preventer has the outstanding advantages that: water flow resistance is extremely low; and the total loss of head is reduced from over 0.05MPa to below 0.005MPa.

Owner:广西南亚科技有限公司

High efficiency smart fluorine-lined control valve

ActiveCN1834511AGood anti-corrosion performanceSimple structureSpindle sealingsLift valveEngineeringControl valves

The present invention discloses a high-effective intelligent fluorine-lined control valve. It includes valve body, valve cavity, inlet tube, outlet tube, valve cover and valve core. In the interior of valve cavity, between the inlet tube and outlet tube a valve seat is set, in the interior of valve cavity, inlet tube and outlet tube on the surface which can be contacted with the fluid an integrally-formed fluorine plastic layer is made, on the external surface of integral valve core and valve rod a fluorine plastic layer is integrally-formed, and on the valve cover an integrally-formed fluorine plastic layer is made in the position which can be contacted with fluid, and the described valve seat is a fluorine plastic layer integrally-formed ring-shaped fluorine plastic valve seat in the valve cavity.

Owner:朱孝有

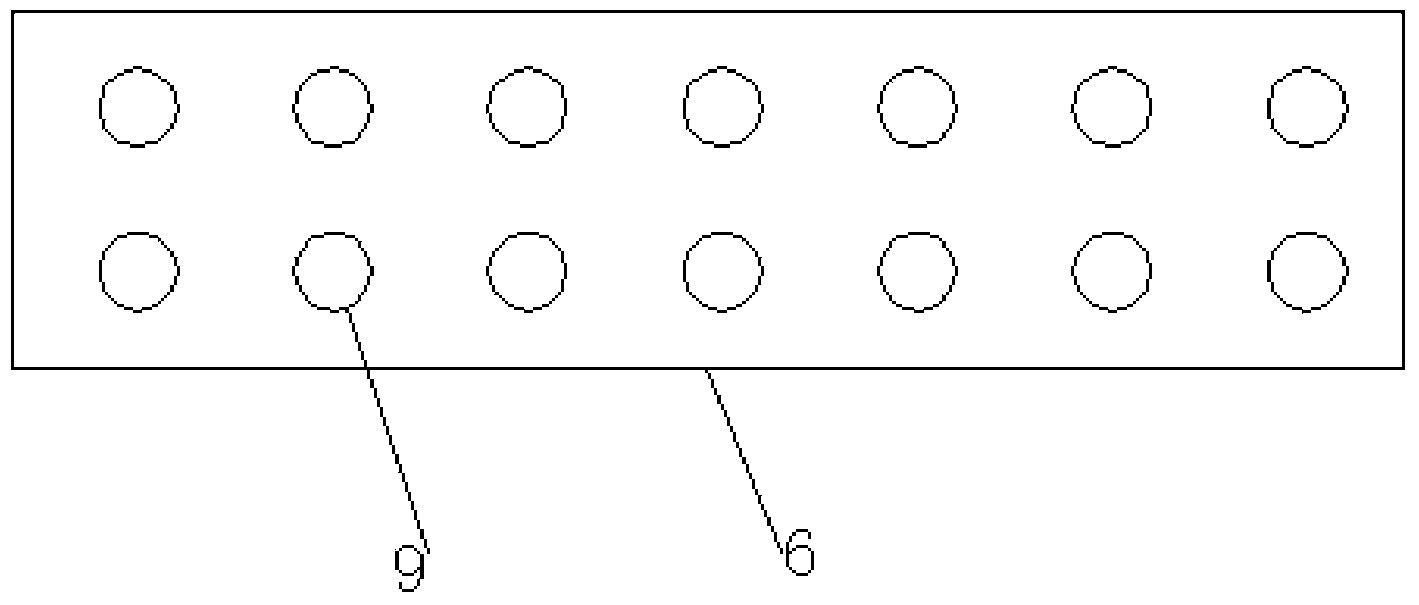

Gas-liquid distributor

The invention relates to the technical field of reactor internals, in particular to a gas-liquid distributor. The gas-liquid distributor comprises a bubble cap, a center pipe and a bubble cap ring; the upper end of the center pipe is arranged in the bubble cap, and is connected with the top wall of the bubble cap, and an annular space is formed between the bubble cap and the center pipe; the lower end of the bubble cap is provided with the bubble cap ring, the bubble cap ring is provided with multiple through holes, and the bubble cap ring is used for filling a gap between the bubble cap and the center pipe. The gas-liquid distributor can enable bubbles to be smaller, improves the capability of purging a catalyst of a material flow, and improves a bed gas volume fraction and material flow impact force, the catalyst near the bubble cap can be rushed up during restarting after shut down, and the possibility that the catalyst enters the annular space of the bubble cap when countercurrent occurs can be reduced to the greatest extent.

Owner:SINOPEC ENG GRP CO LTD

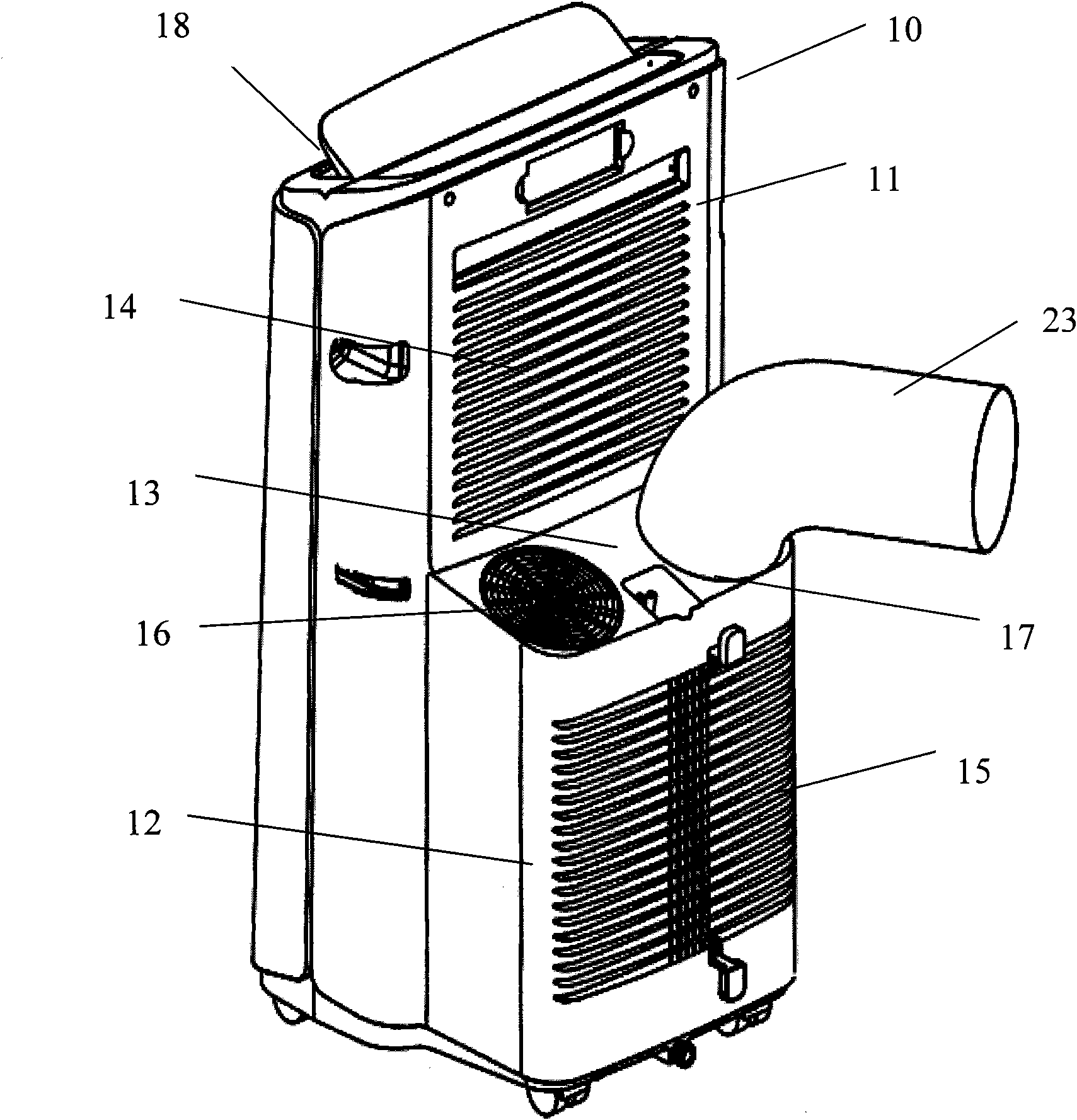

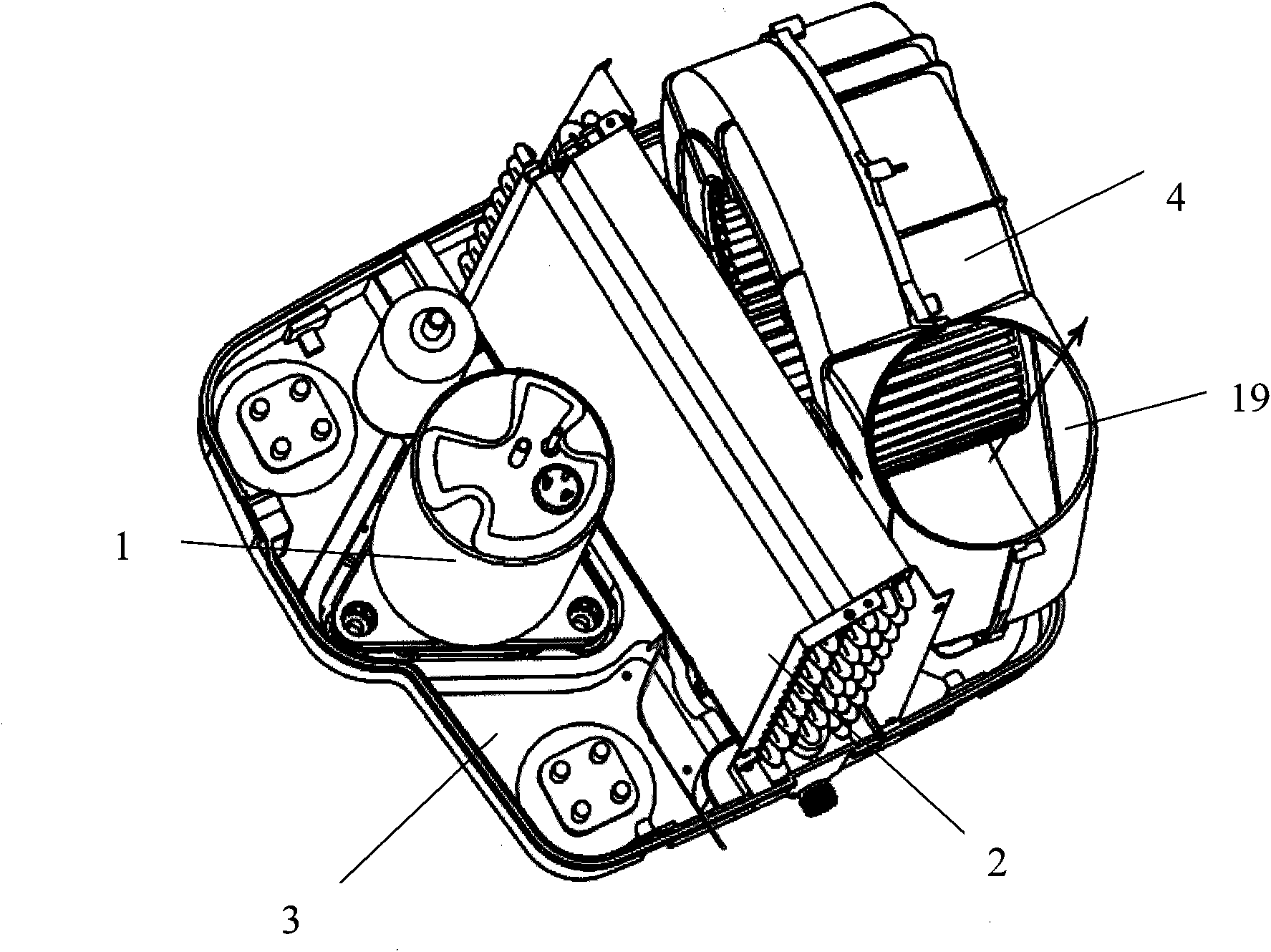

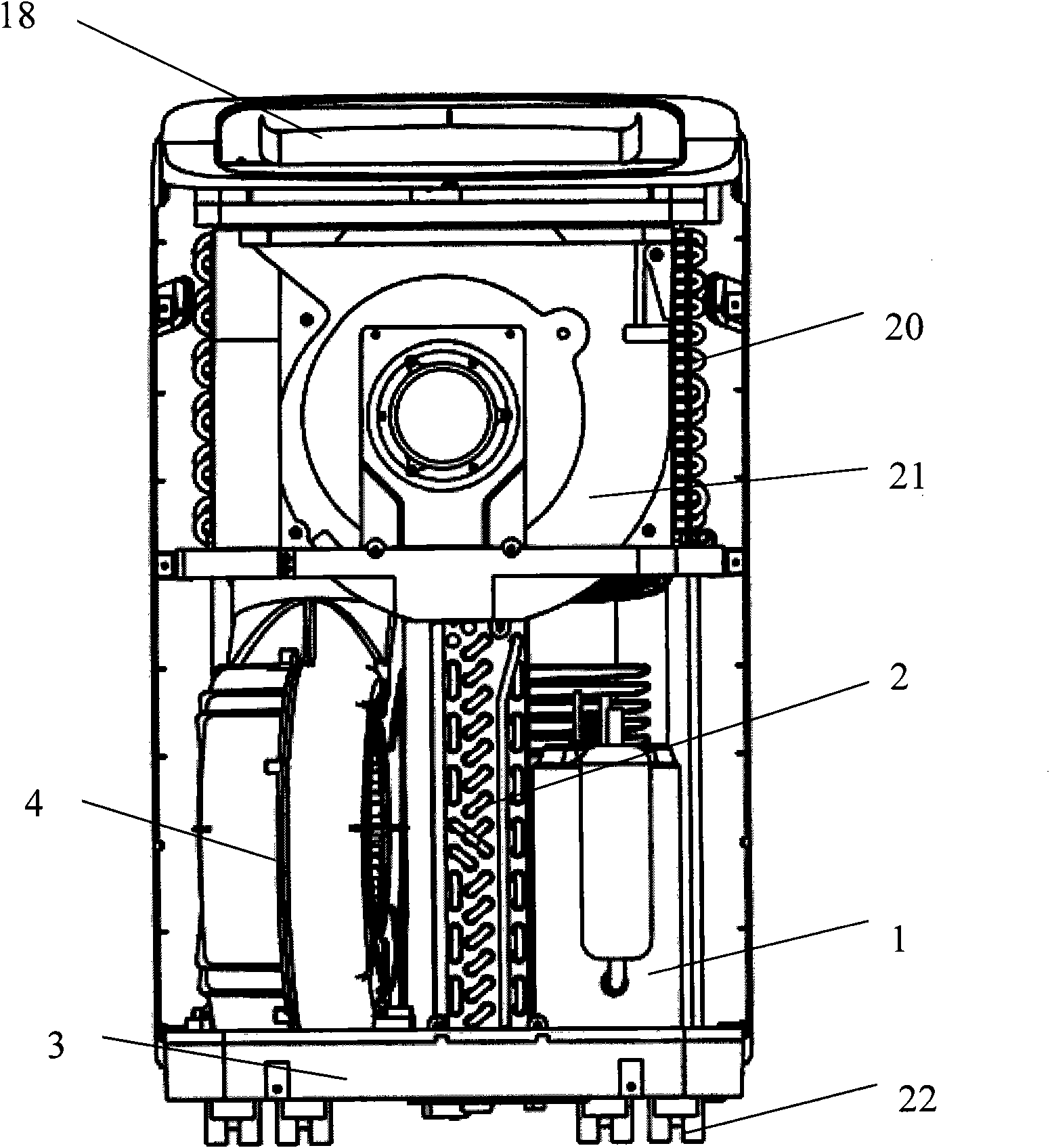

Mobile air conditioner

InactiveCN101788170ASmall diameterReduce noiseLighting and heating apparatusAir conditioning systemsLow noiseEngineering

The invention discloses a mobile air conditioner. The mobile air conditioner comprises a compressor, an outdoor heat exchanger, an outdoor heat exchanger blower, an indoor heat exchanger and an indoor heat exchanger blower which are installed in a cabinet-type box body; the outdoor heat exchanger is arranged on a chassis along the width direction of the mobile air conditioner; a space of the chassis is divided into a front part and a rear part, the compressor is arranged in the rear part adjacent to a rear panel at the lower part, the outdoor heat exchanger blower provided with a cross flow fan is arranged in the front part adjacent to a front panel, and an air outlet of the outdoor heat exchanger blower is communicated by a connection pipe with a wind pipe inserted on an air outlet of the outdoor heat exchanger on a connection plate so as to discharge air heat-exchanged by the outdoor heat exchanger to the outside. In the invention, air flow enters the outdoor heat exchanger blower along the straight line direction through the outdoor heat exchanger without any corner; therefore, the mobile air conditioner has the characteristics of smooth flow path, less losses, low noise and compact structure.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

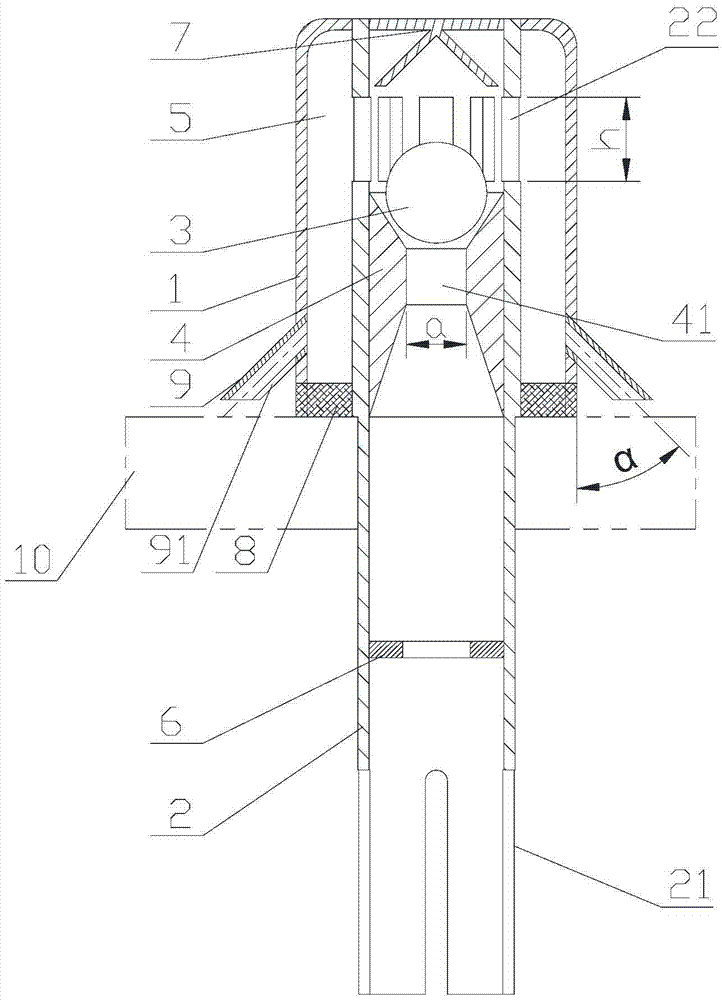

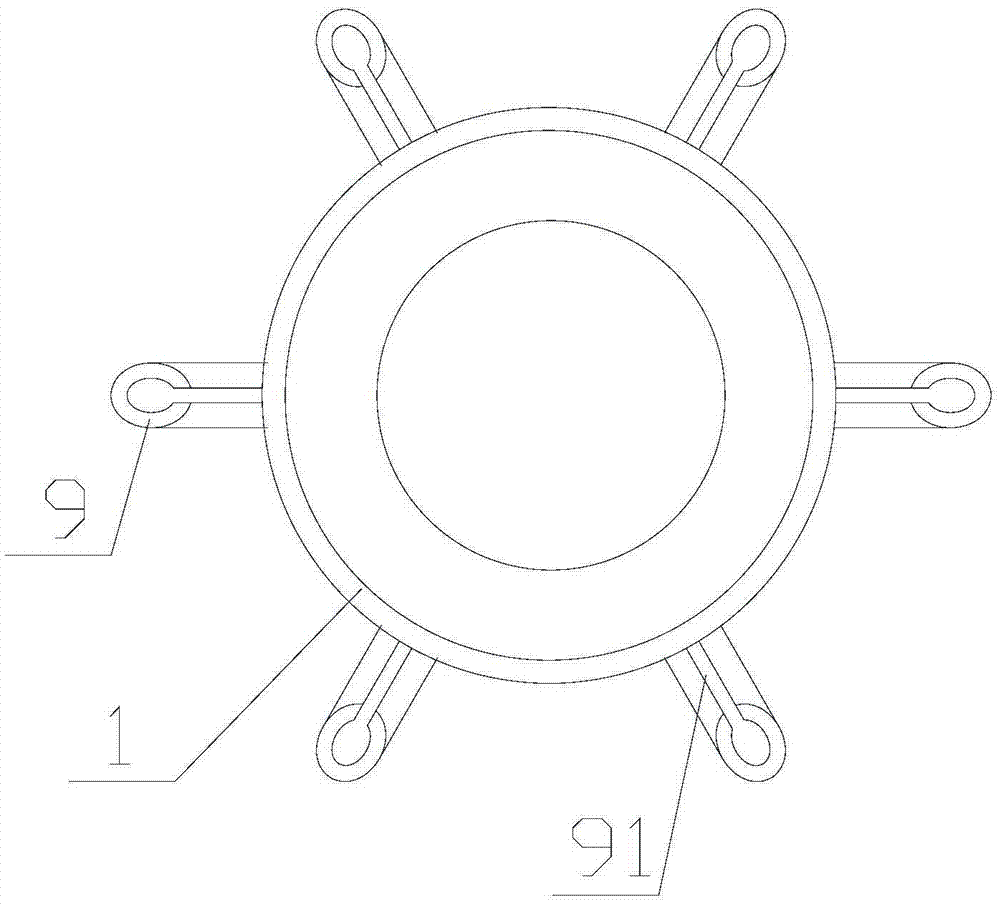

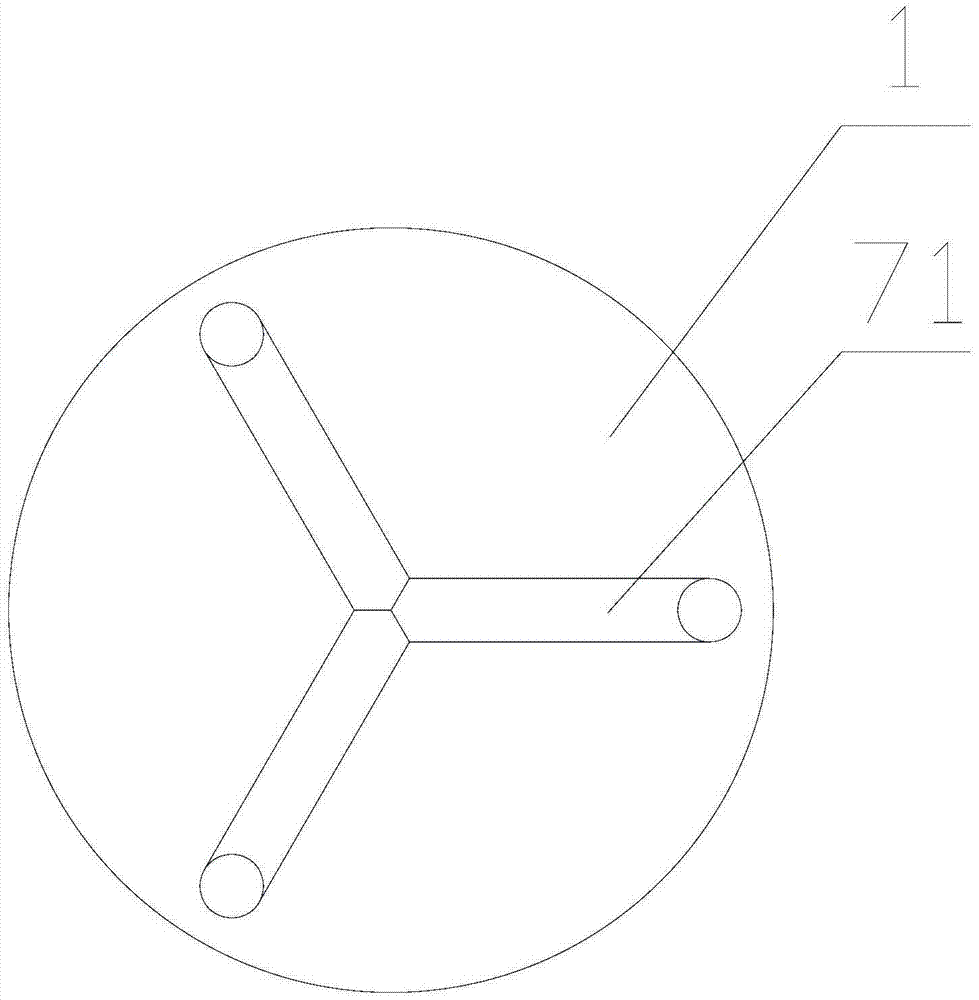

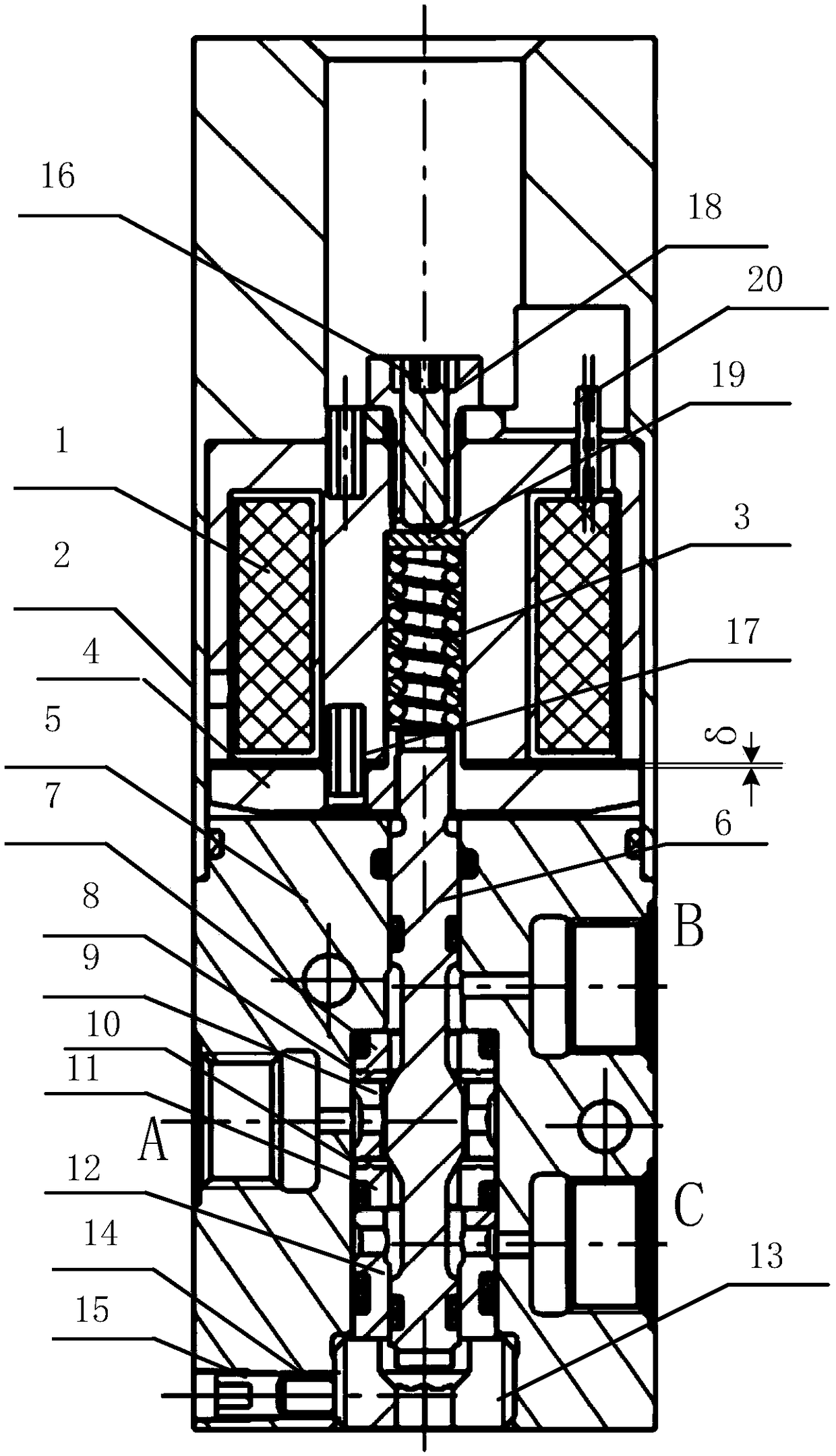

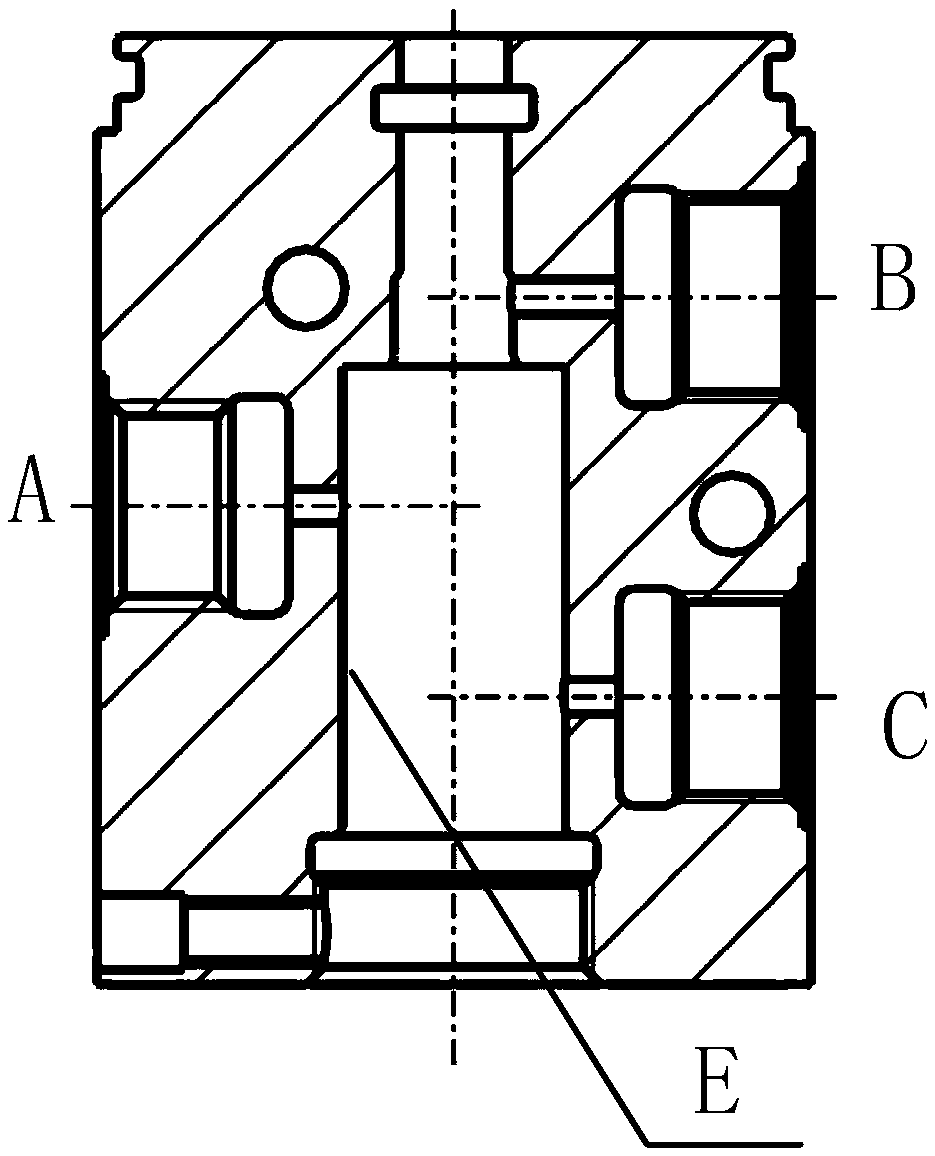

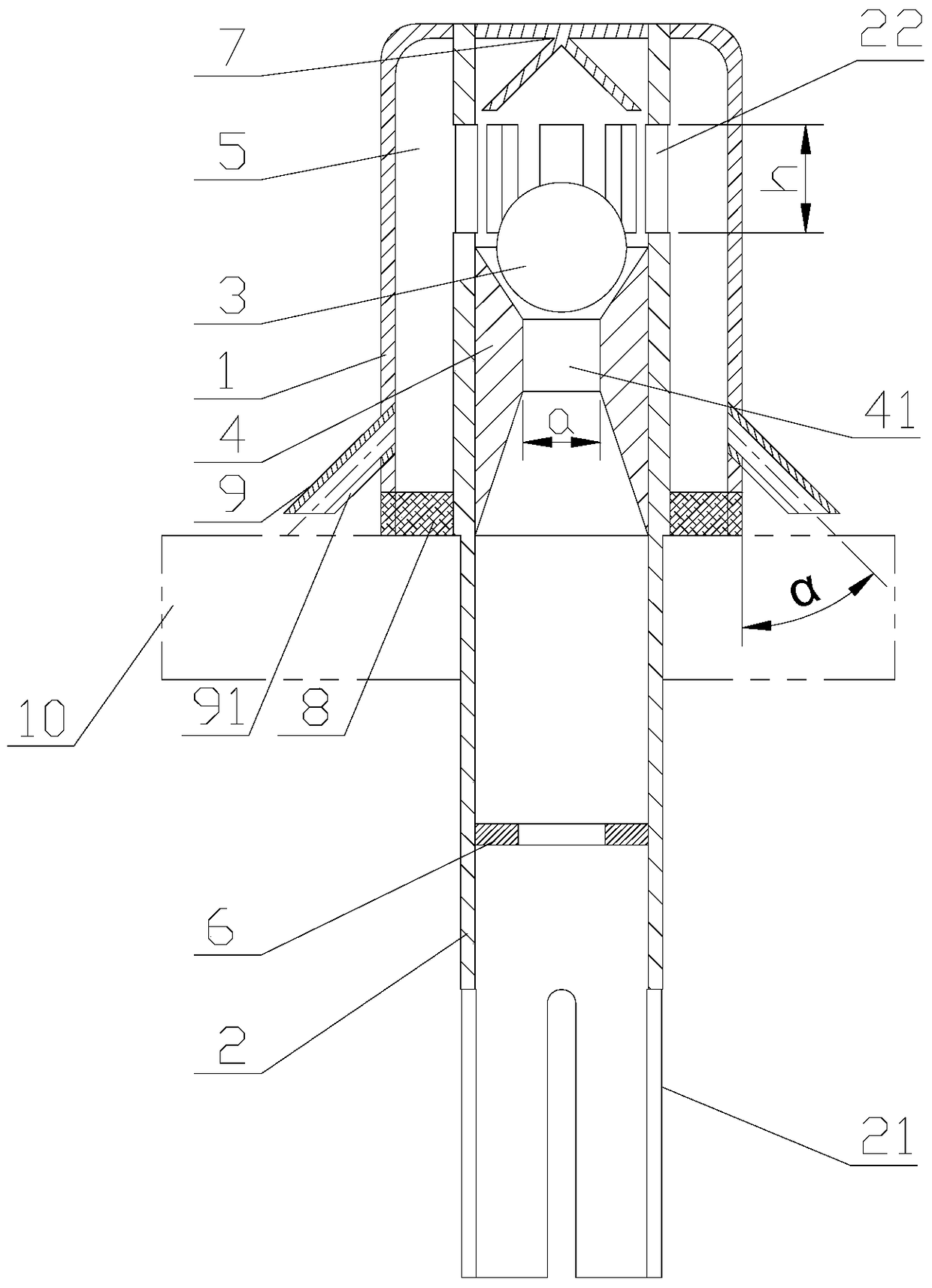

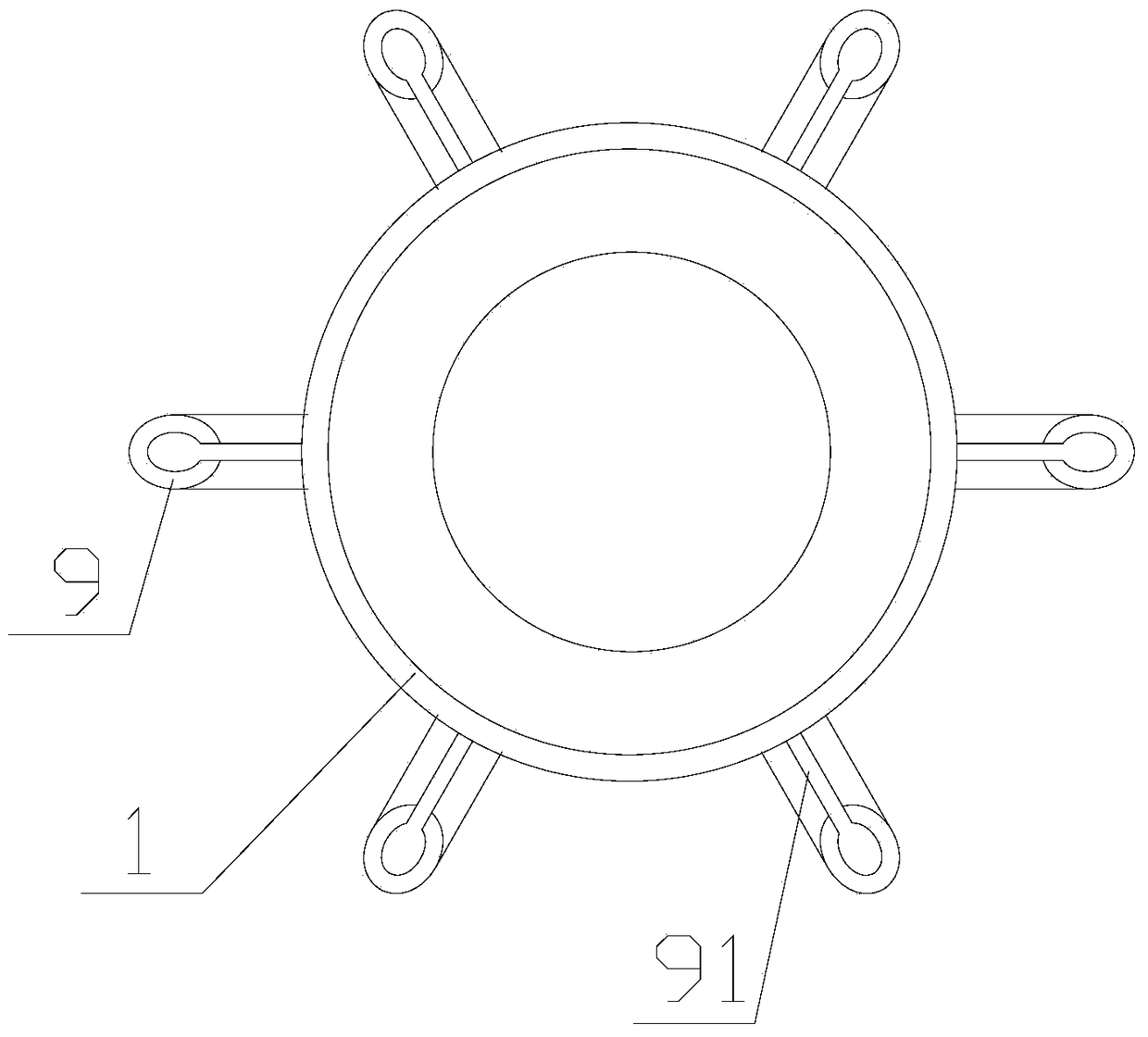

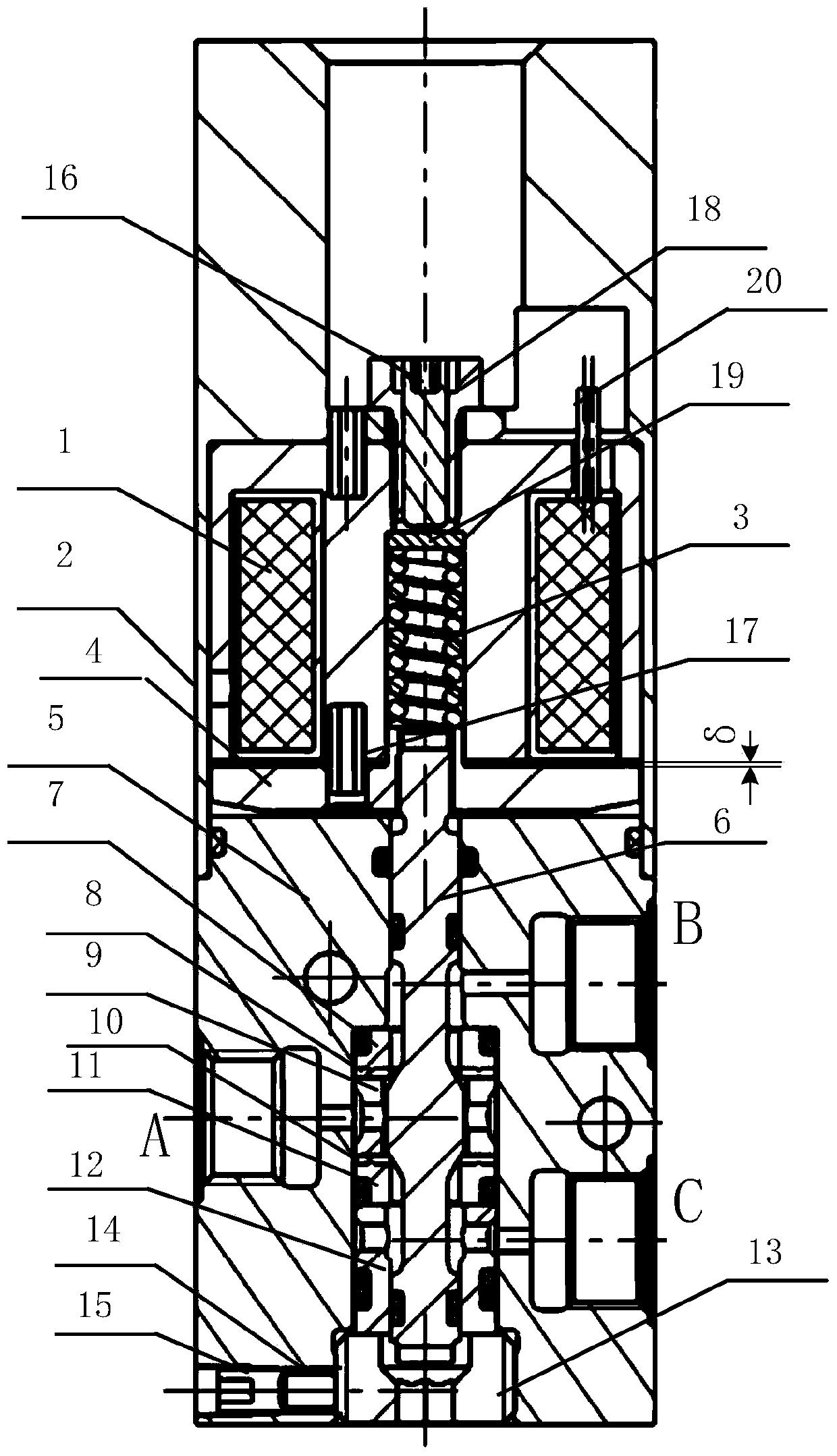

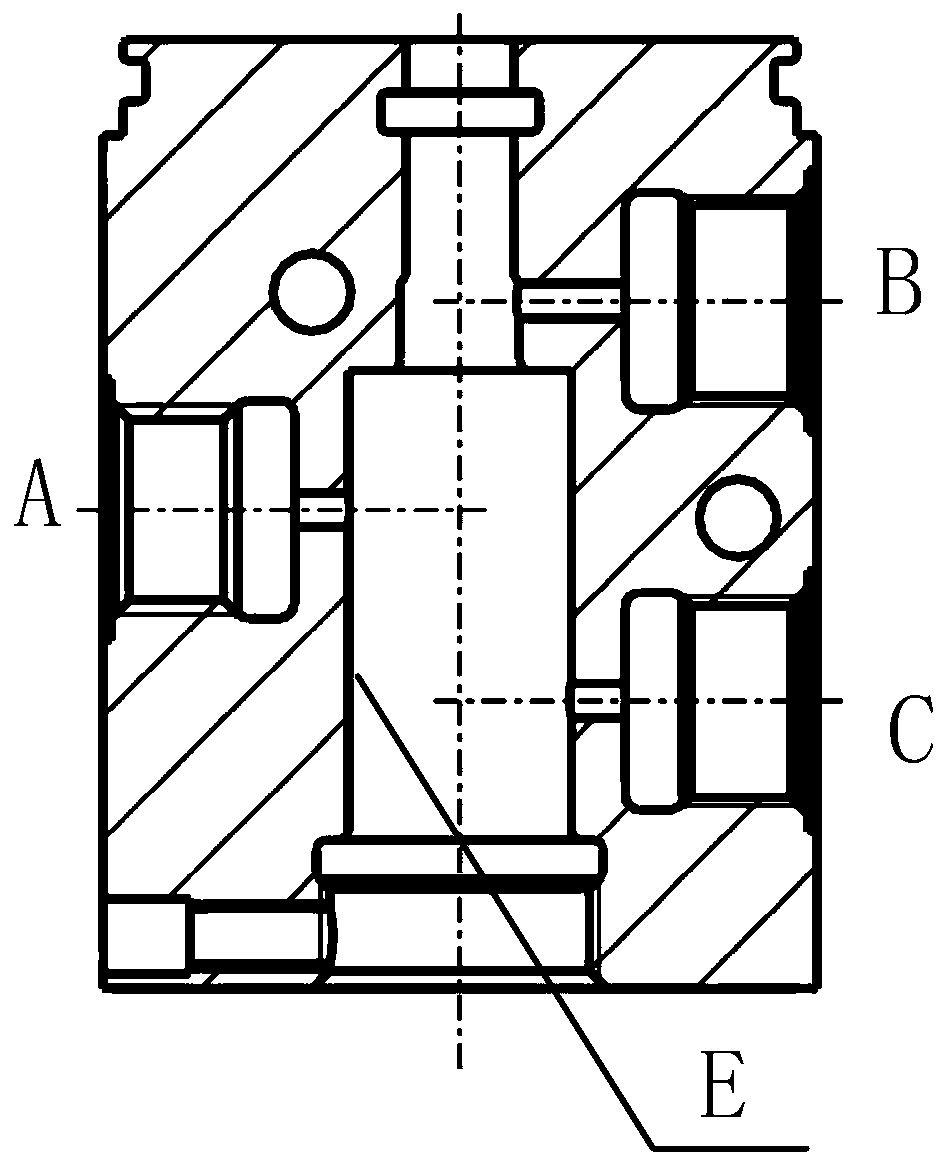

High-voltage multifunctional two-position three-way solenoid valve

ActiveCN108916419ARealize high pressure and even ultra high pressureSame cross-sectional areaOperating means/releasing devices for valvesMultiple way valvesSolenoid valveEngineering

A high-voltage multifunctional two-position three-way solenoid valve comprises an electromagnet (1), an electromagnet housing (2), a return spring (3), an armature (4), a valve body (5), a valve stem(6), an upper valve seat (7) and a lower valve seat (11). Three vent holes formed in the valve body (5) can be used as fluid inlet holes or fluid outlet holes. The valve stem (6) is mounted in an inner cavity E of the valve body (5) through the upper valve seat (7), an upper valve seat sealing gasket (8), a middle valve sleeve (9), a lower valve port sealing gasket (10), the lower valve seat (11)and a bottom valve sleeve (12). The diameter of the sealing portion of the valve stem (6) and the valve body (5), the diameter of the contact portion of the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) and the diameter of the sealing portion of the valve stem (6) and the bottom valve sleeve (12) are identical. One hole A is communicated with a circumferential hole formed in the middle valve sleeve (9). When the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) is sealed, the vent holeA is communicated with the other vent holes.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

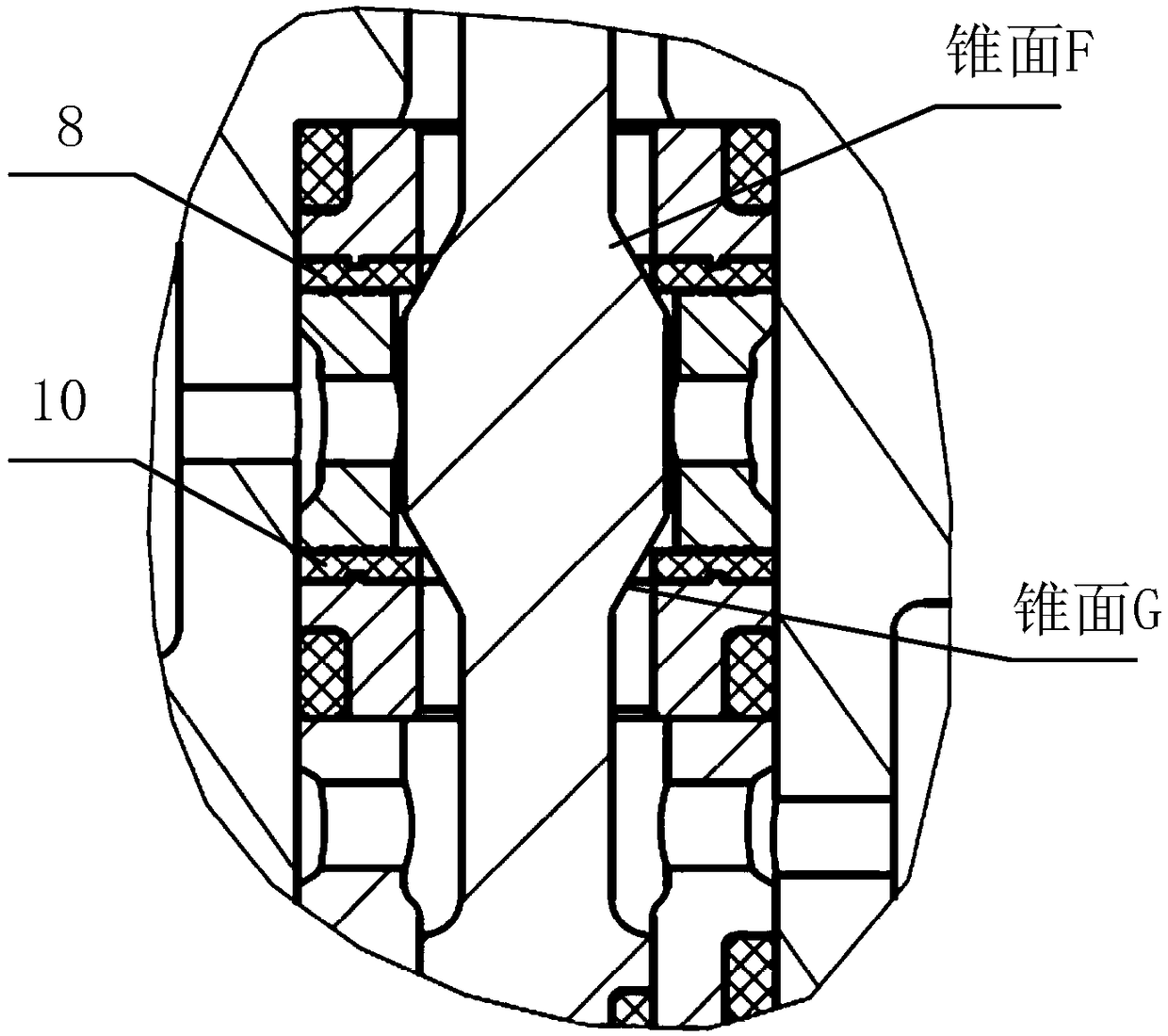

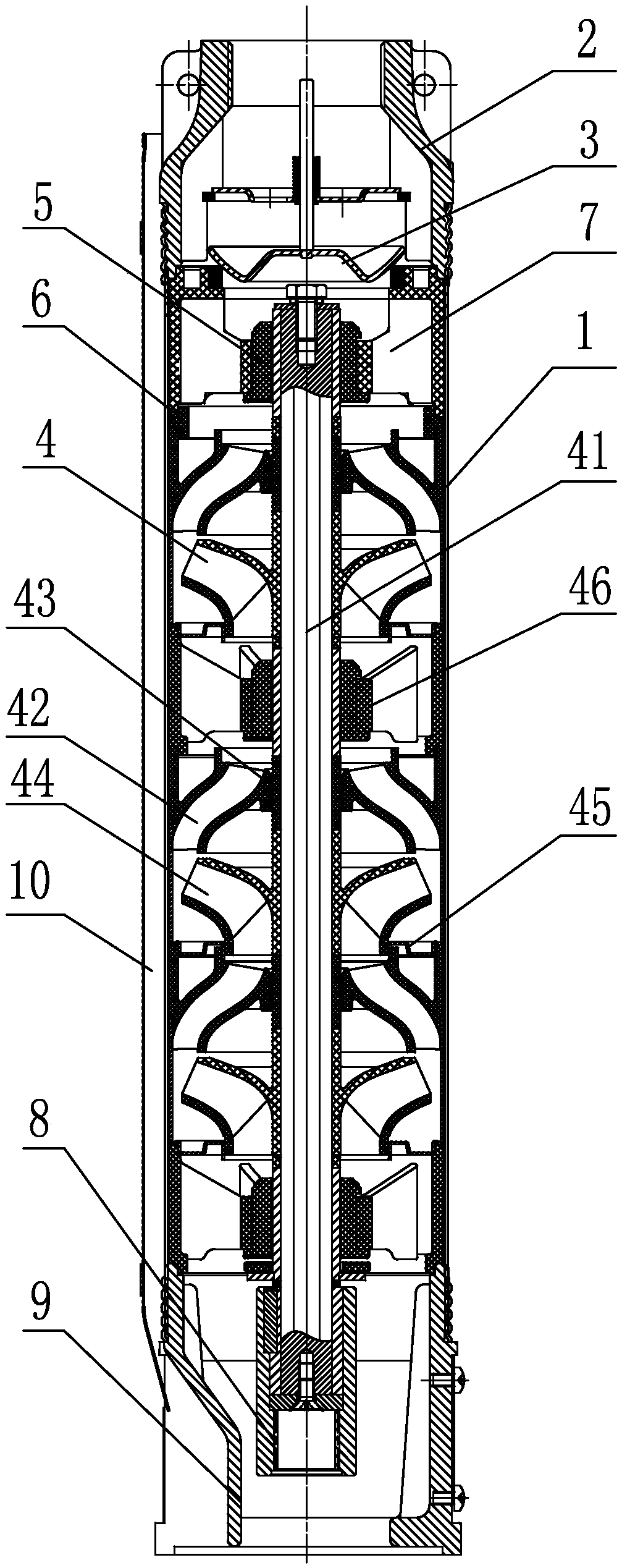

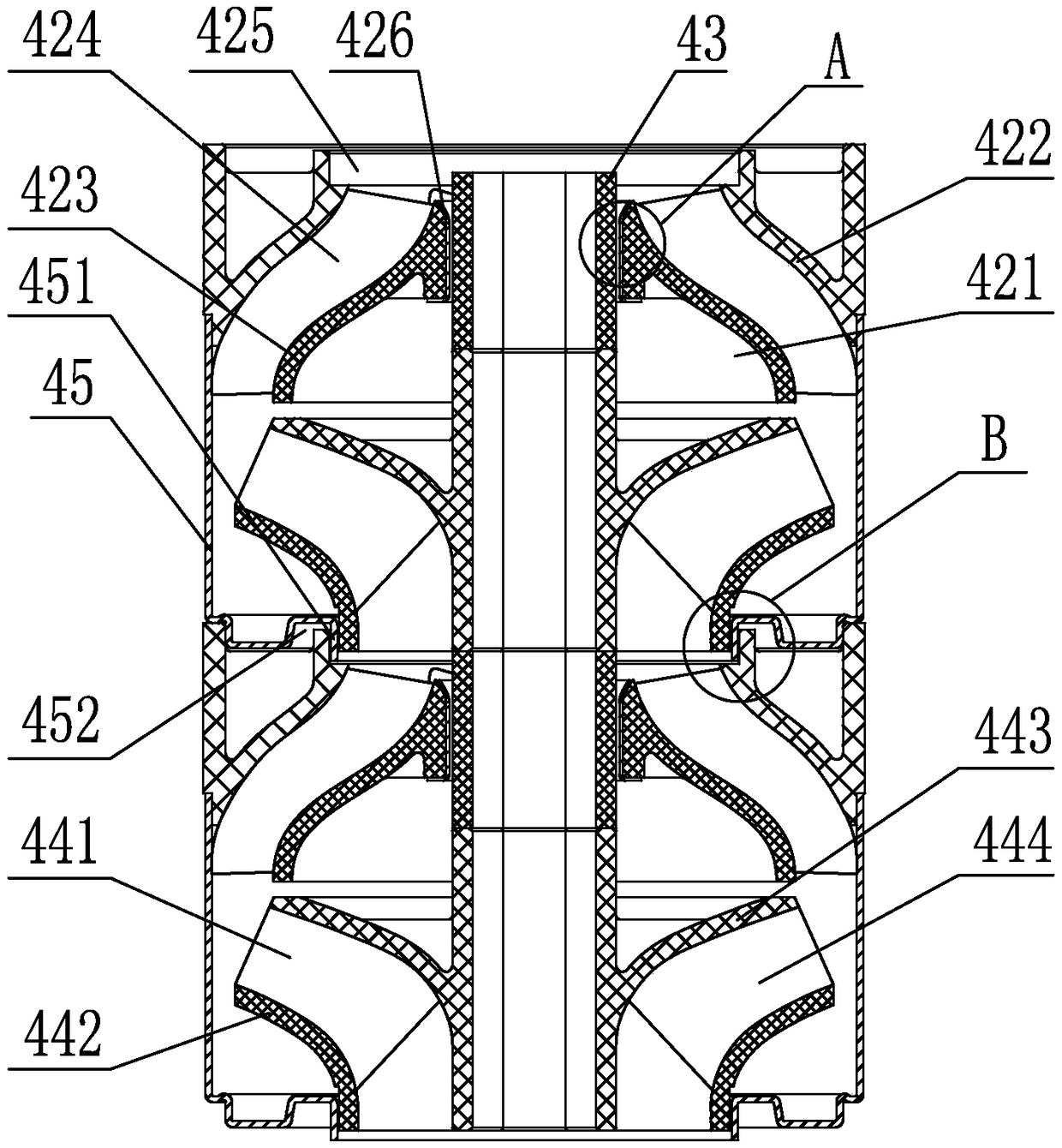

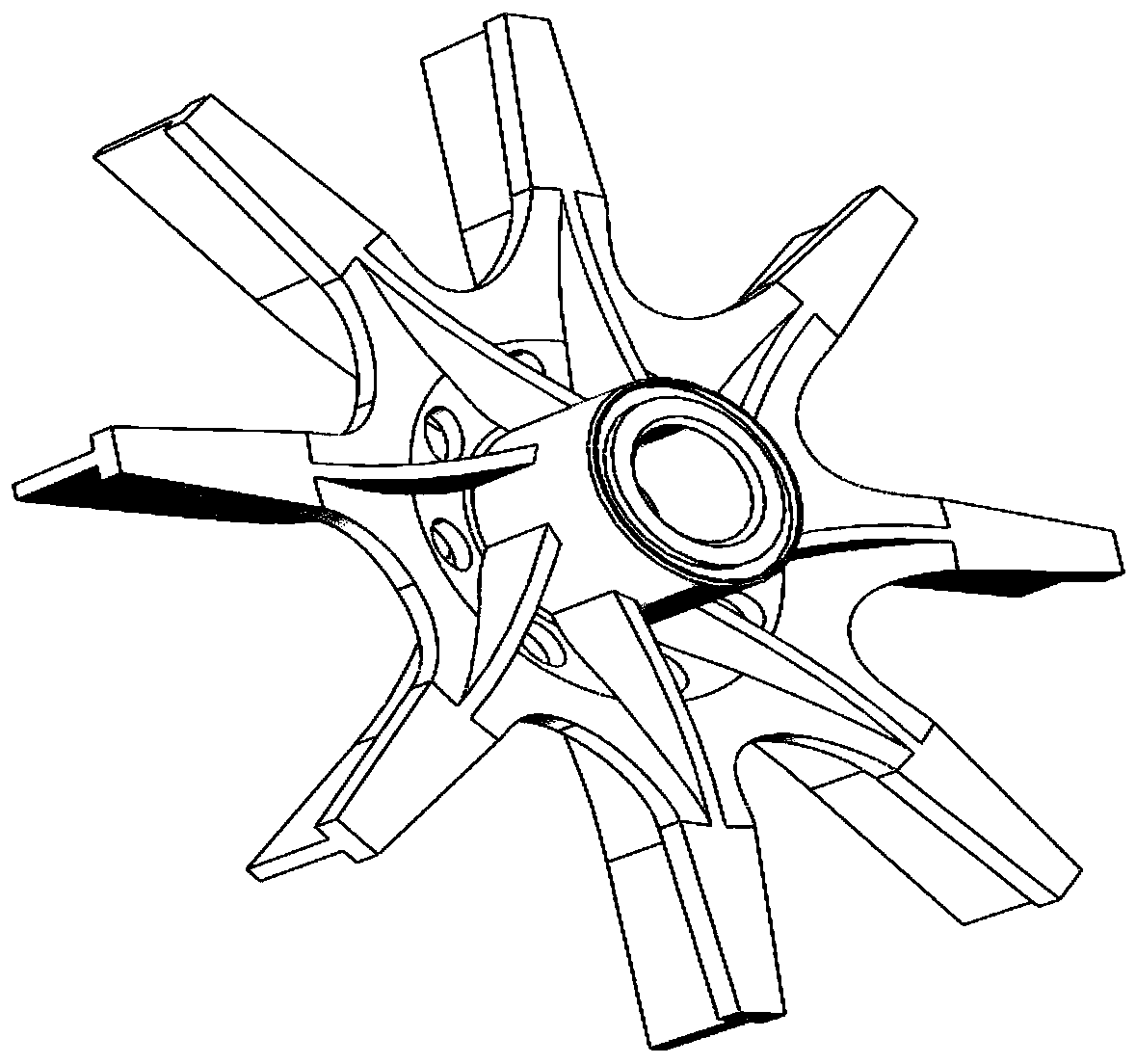

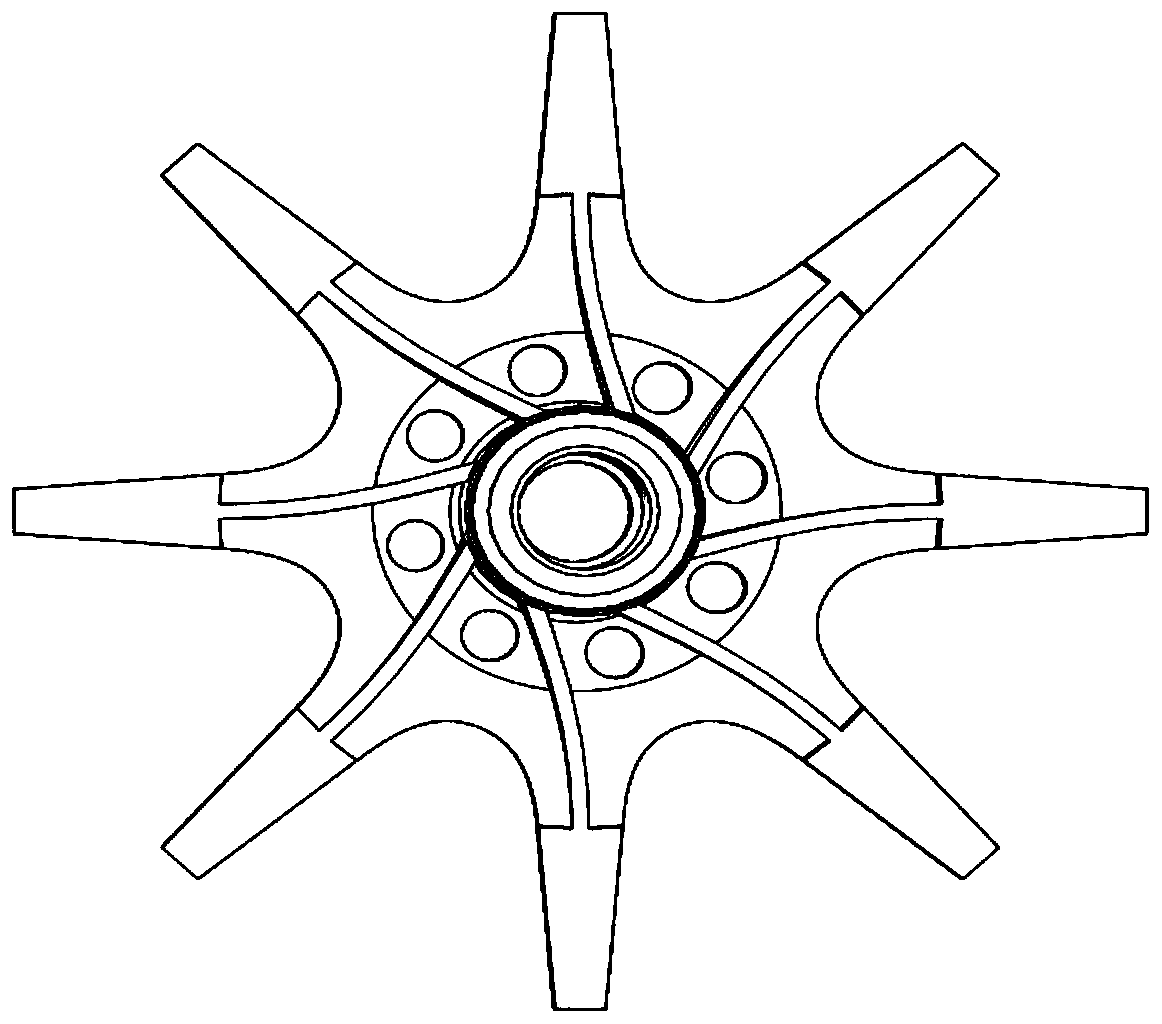

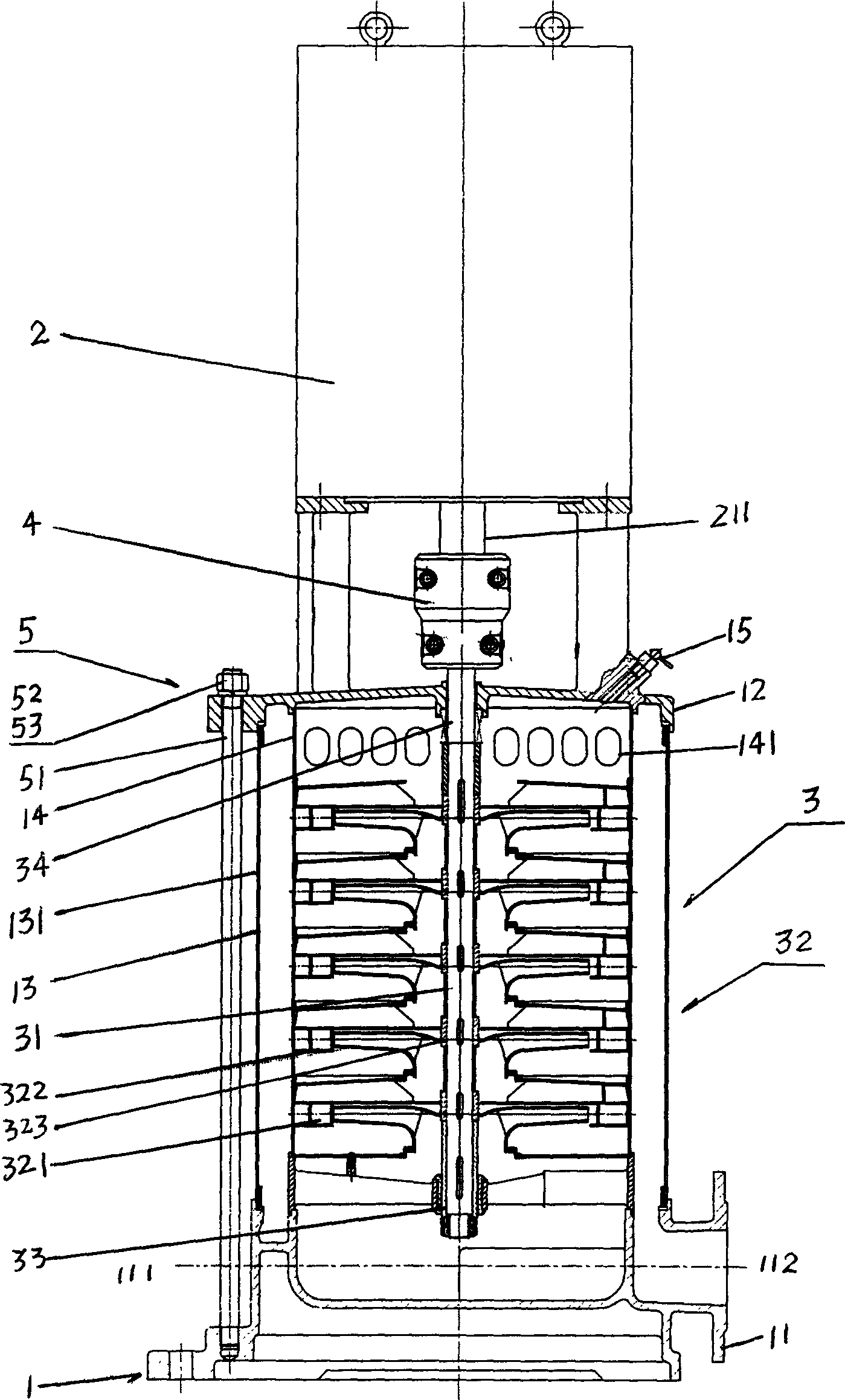

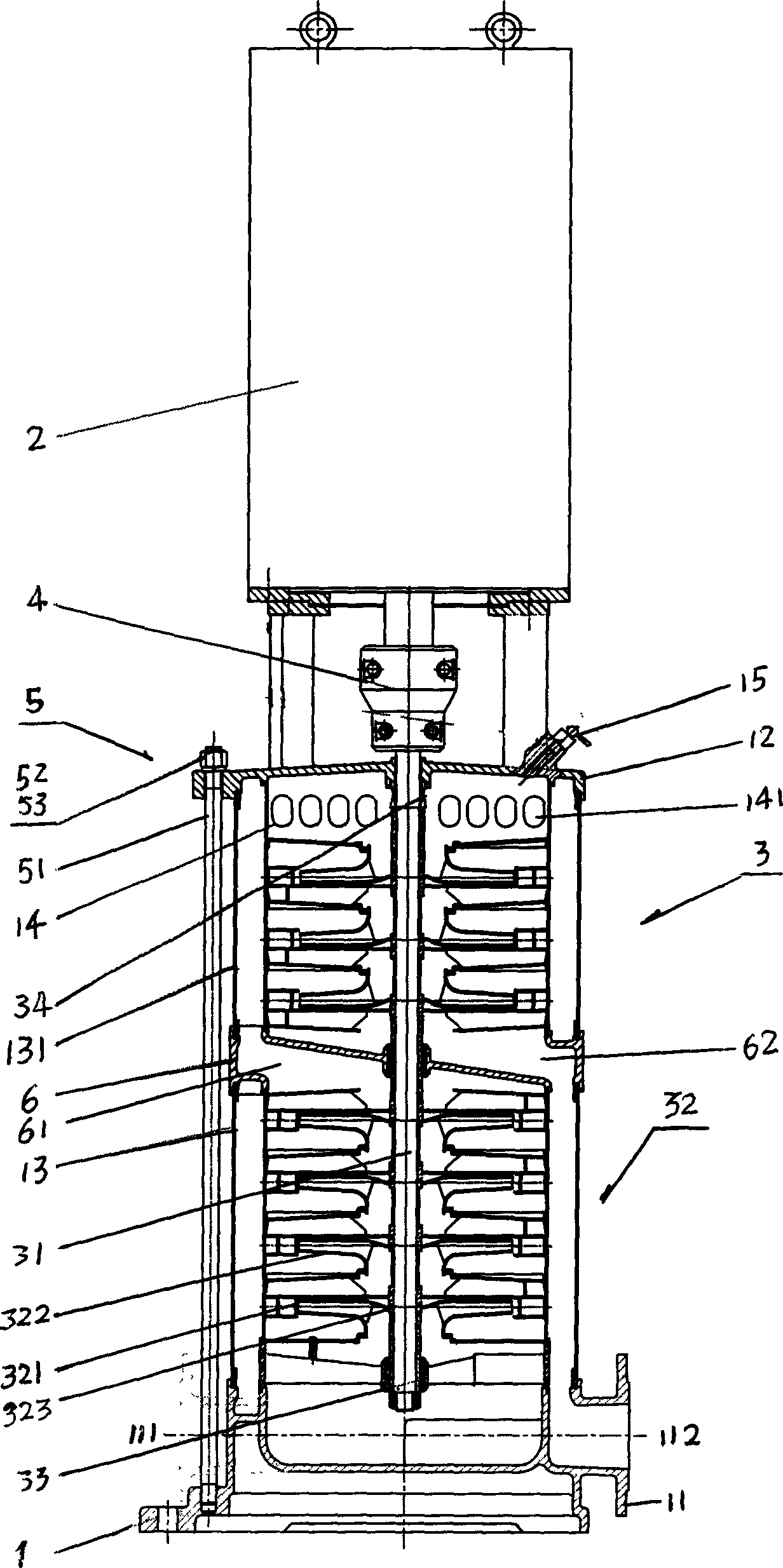

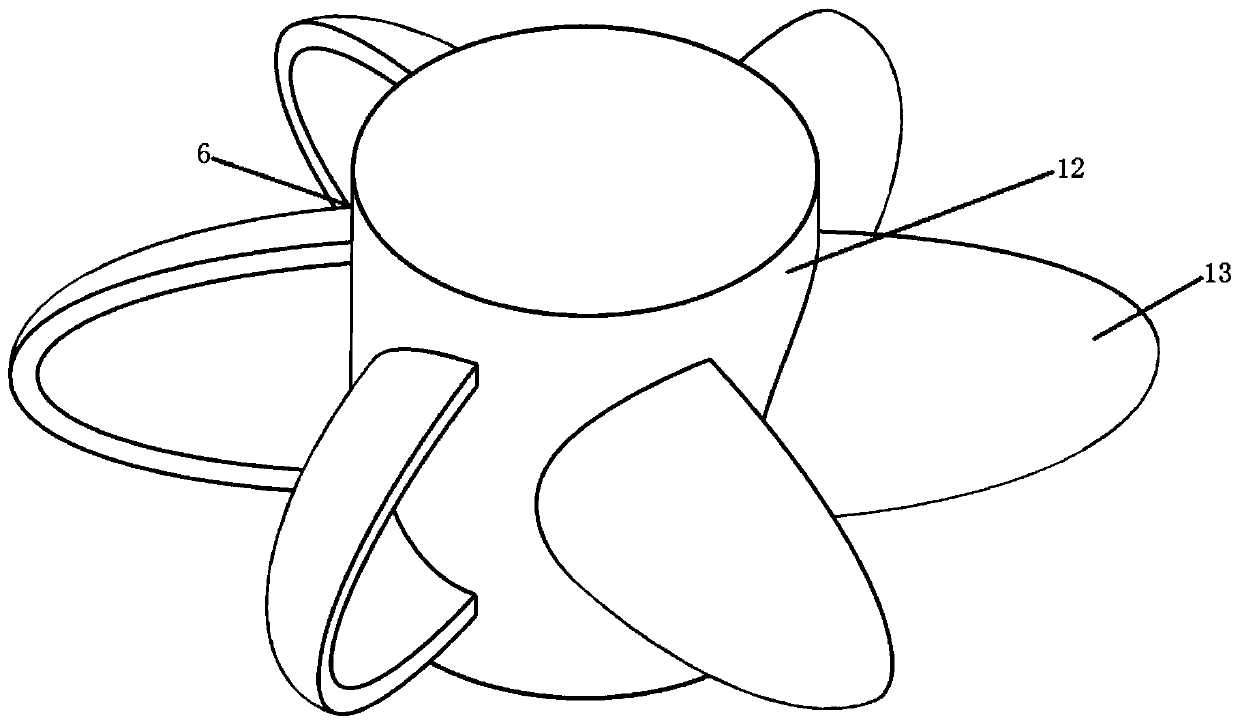

Space twisting plastic impeller type well submersible pump

PendingCN109441841ASmall pressure lossIncrease the sealing areaPump componentsPump installationsImpellerCoupling

The invention discloses a space twisting plastic impeller type well submersible pump comprising a shell, a water outlet pump head, a check valve, a bearing seat, a sliding bearing, an adjusting ring,a multi-stage impeller assembly including a hexagonal pump shaft, a guiding impeller, a shaft sleeve, an impeller, a blower inlet casing and a pump shaft bearing frame, a coupling, a water inlet baseand a wire trough; and the guiding impeller is formed by welding a guide vane seat and a fairing which are obtained through injection molding, the impeller is formed by welding a main impeller and animpeller front cover plate which are obtained through injection molding, the guide vane seat includes a conical bottom cover designed according to the Bezier curve and seven spiral guide vanes, the main impeller includes a conical back cover plate designed according to the Bezier curve and six spiral blades, the spiral direction of the blades is opposite to the spiral direction of the guide vanes,the protruding water inlet of the blower inlet casing is in clearance fit with a water inlet of the impeller front cover plate, and an annular groove surrounding the protruding water inlet is in transition fit with the end of a water outlet of the fairing for positioning. The space twisting plastic impeller type well submersible pump has the beneficial effects of being large in flow rate and highin lift, being capable of reducing the pressure loss, improving the water pump efficiency and being low in cost.

Owner:GUANGDONG RUIRONG PUMP IND

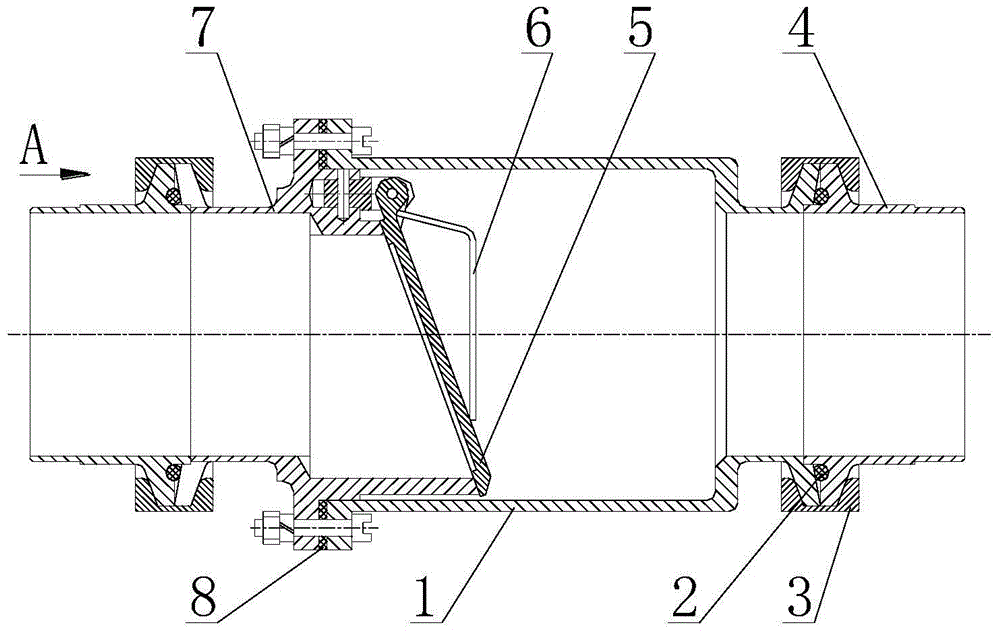

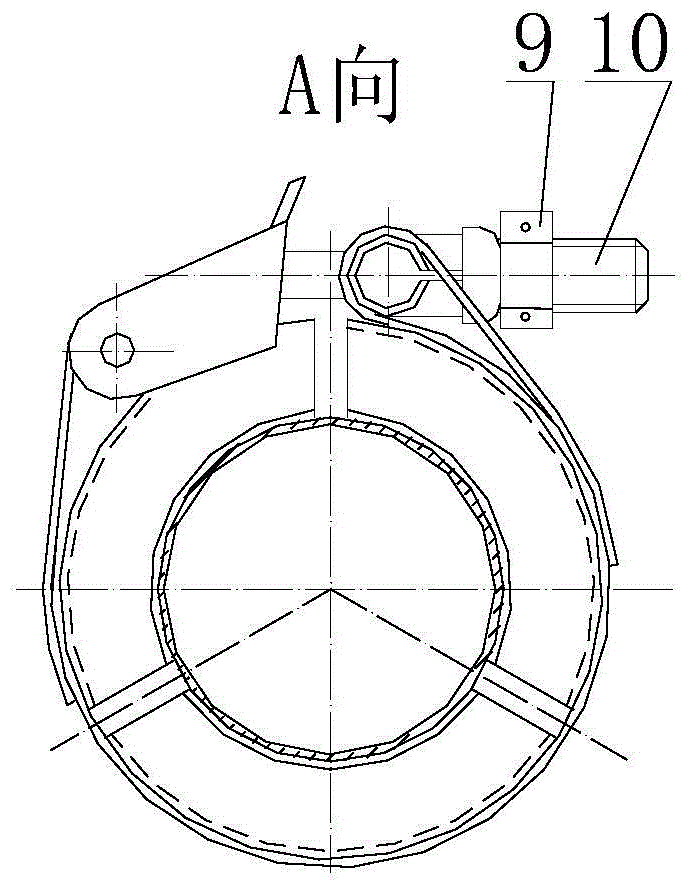

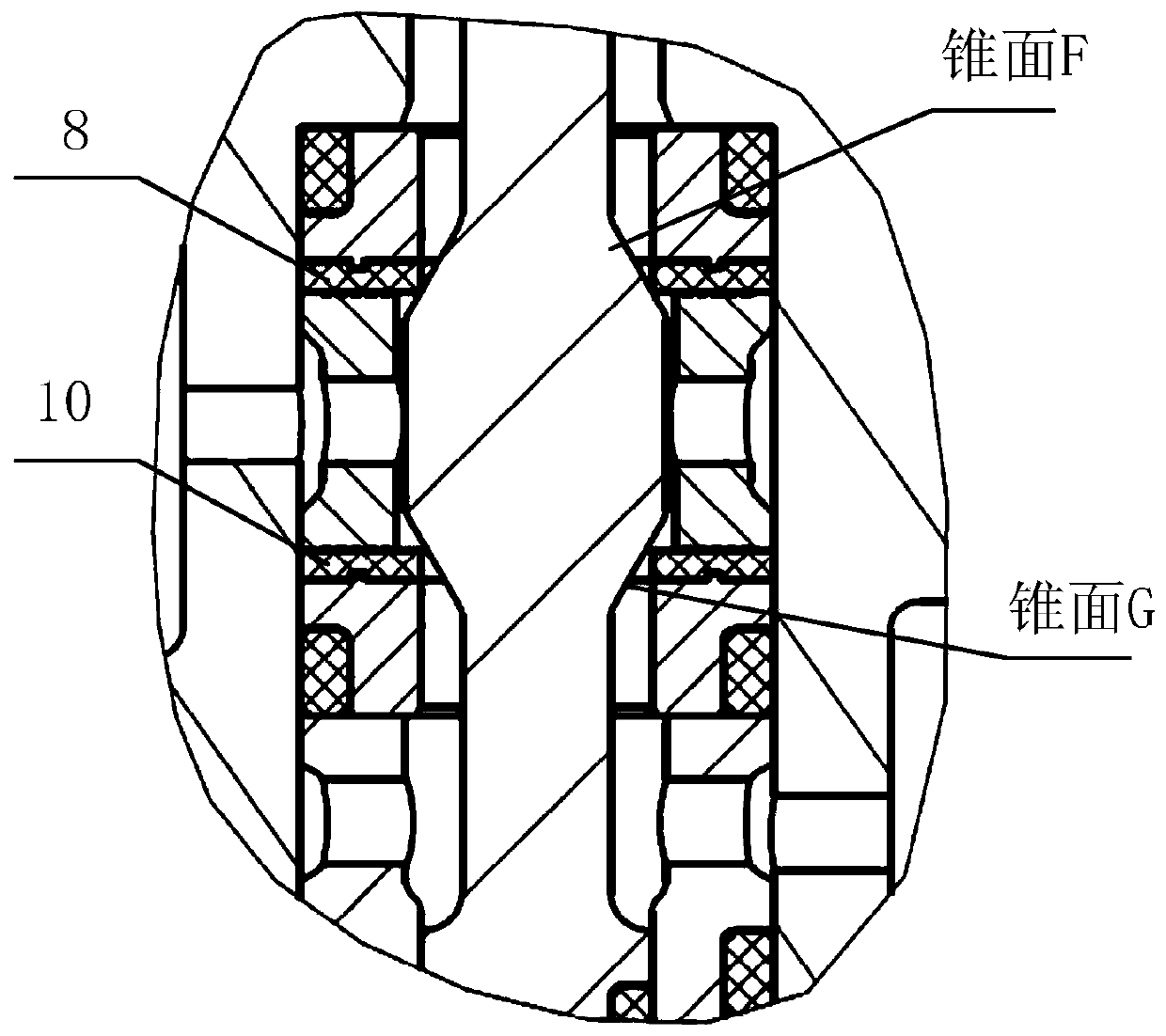

Metal seal quickly-detaching one-way valve for airplane

The invention belongs to the technical field of airplane fuel systems and relates to a metal seal quickly-detaching one-way valve for an airplane. According to the metal seal quickly-detaching one-way valve for the airplane, one end of a valve assembly shell (1) is connected with a valve assembly connector (7) through a flange. The joint is sealed through a rubber mat (8). The other end of the valve assembly shell is in butt joint with one end of a convex connector (4) through a quickly-detaching hoop (3). The butt joint position is sealed through an O-shaped sealing ring (2), and the other end of the convex connector (4) is welded to a pipeline. A valve (5) is installed on the valve assembly connector (7) through a screw and a torsional spring (6), the valve (5) is sealed in a normally-closed mode, and initial sealing pretightening force is provided by the torsional spring (6). The defects in the prior art are overcome, the workload of maintenance staff for detaching and installing the one-way valve can be greatly relieved, the product service life is prolonged, the use maintainability of the system is effectively improved, and use cost is reduced.

Owner:SHAANXI AIRCRAFT CORPORATION

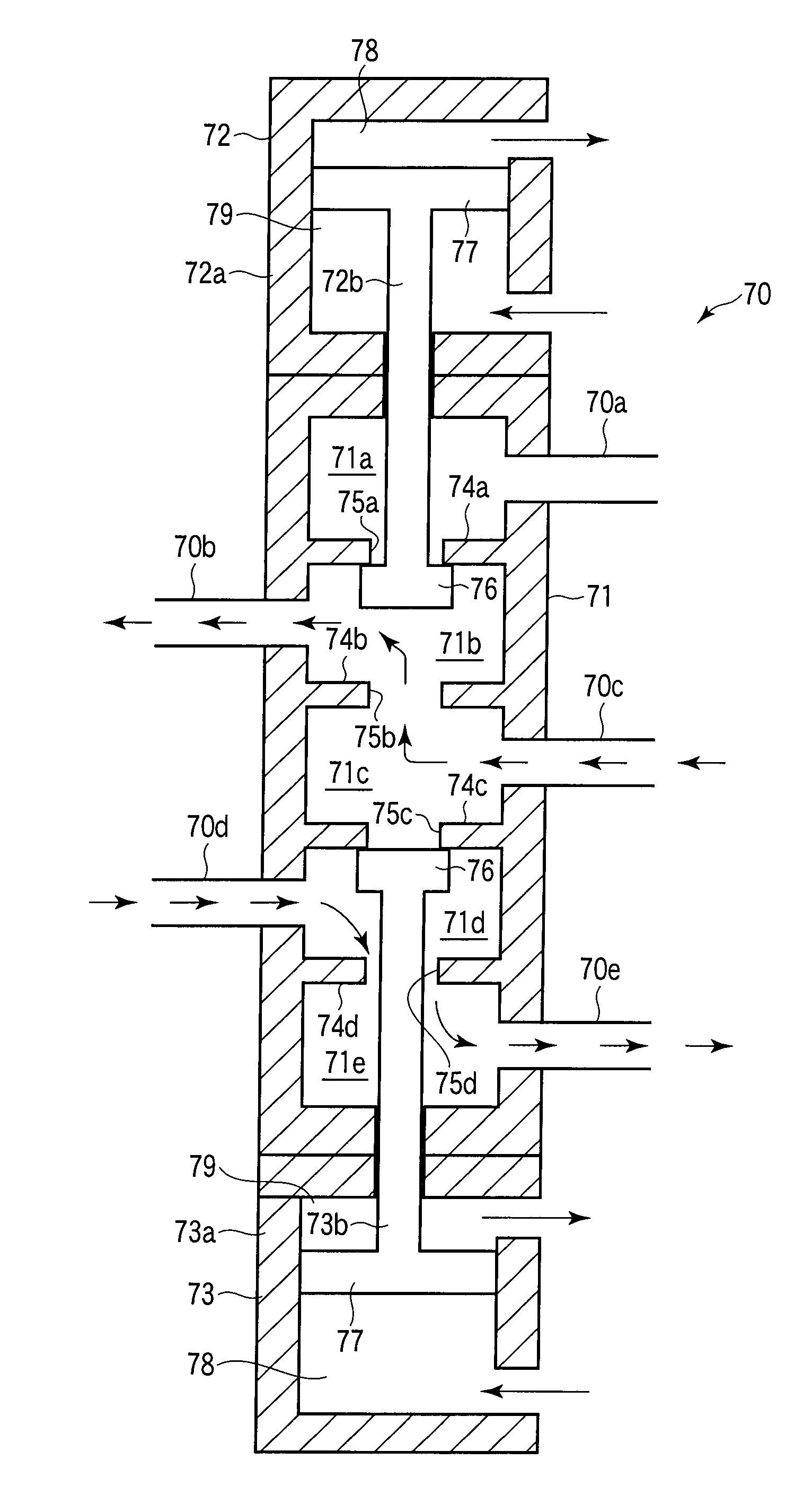

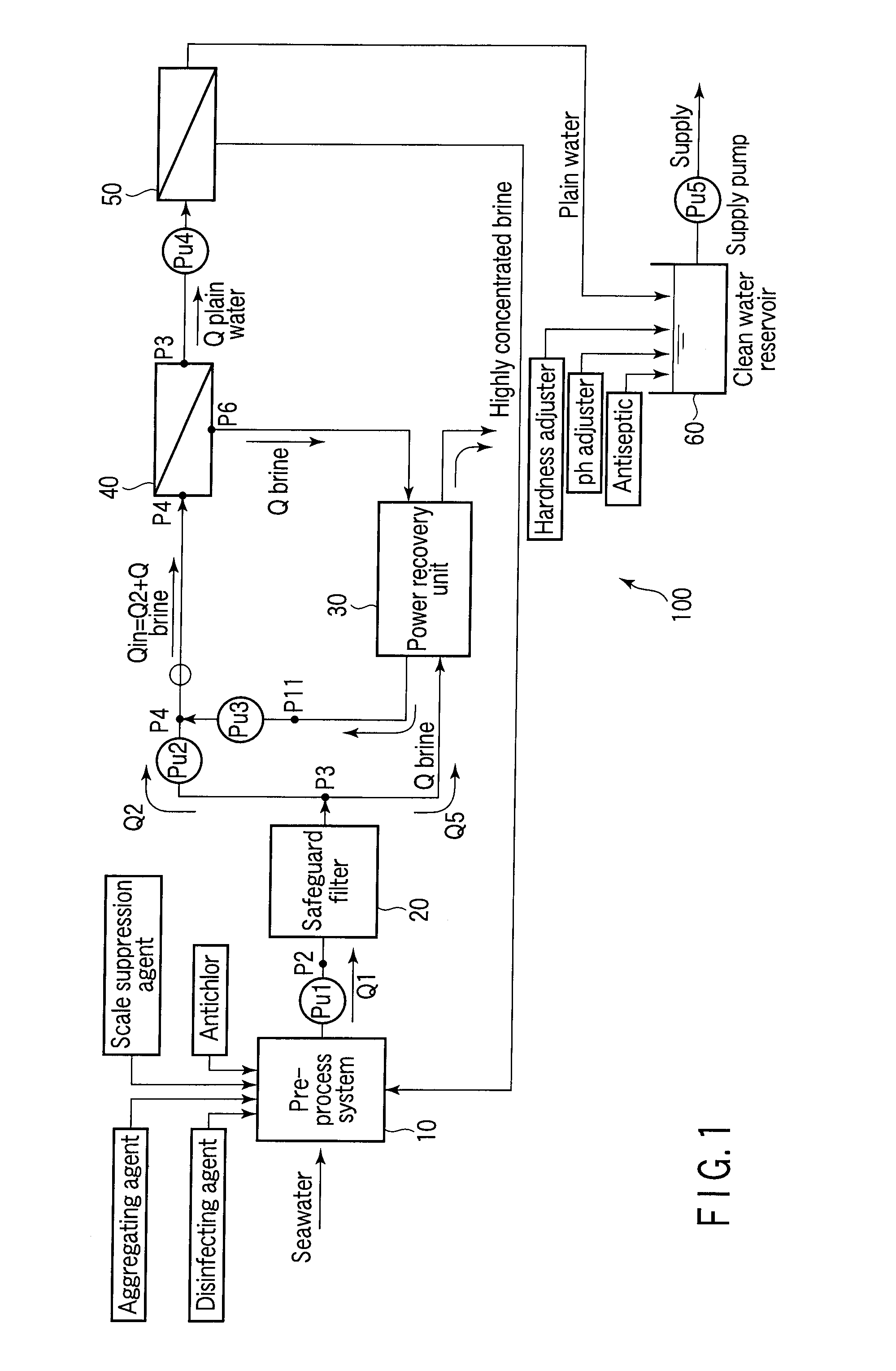

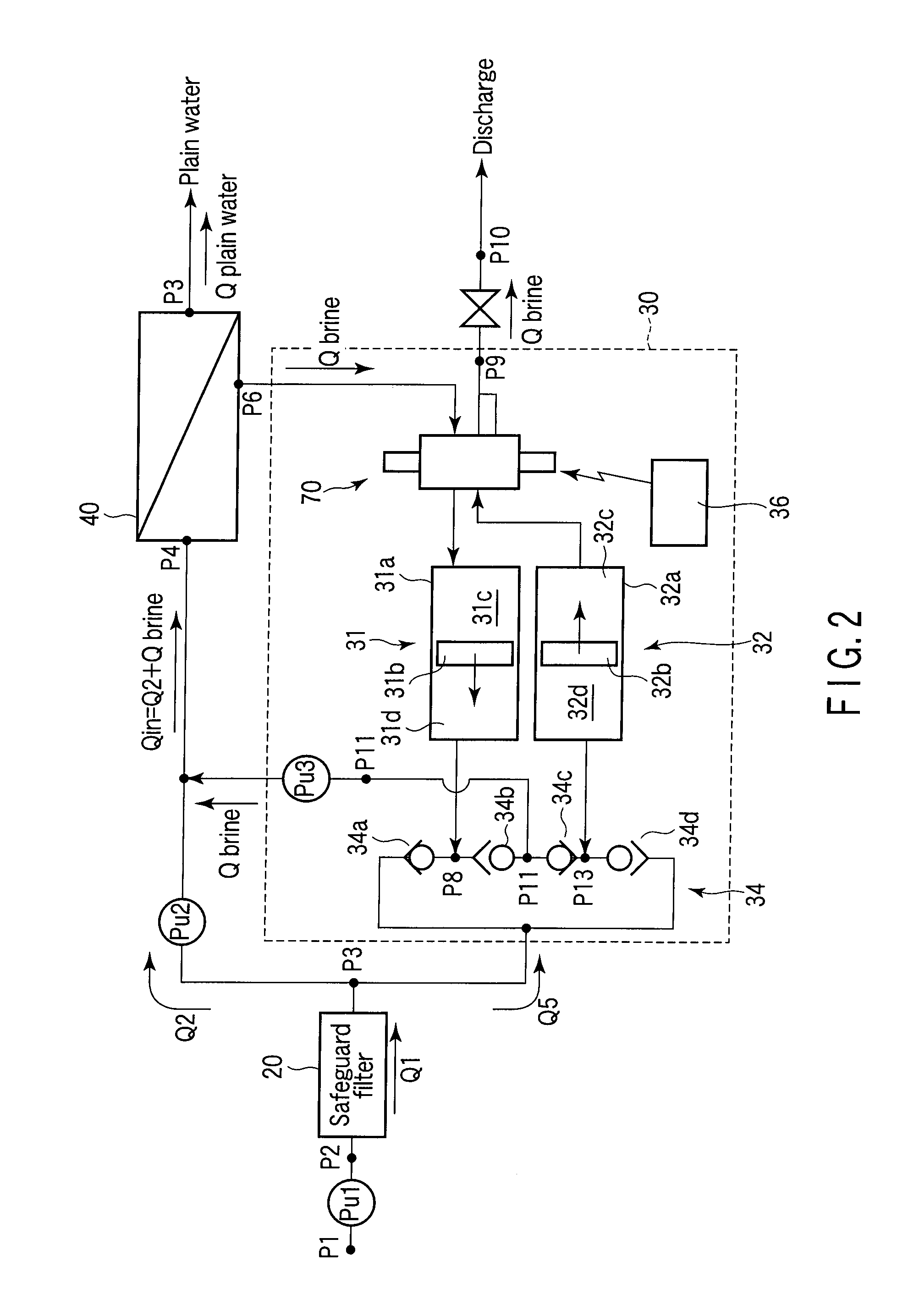

Flow channel switching device

InactiveUS20110073203A1Smooth runnerAvoid pressure lossSeawater treatmentUltrafiltrationActuatorEngineering

A five-port switch valve includes a cylinder having five chambers defined by four partitions, and two actuators. The valve body of one actuator alternately opens and closes a hole formed in the partition and a hole formed in the partition. The valve body of the other actuator alternately opens and closes a hole formed in the partition and a hole formed in the partition. By virtue of this structure, brine fed into the central chamber through a port is alternately fed into two pressure converters through ports.

Owner:KK TOSHIBA

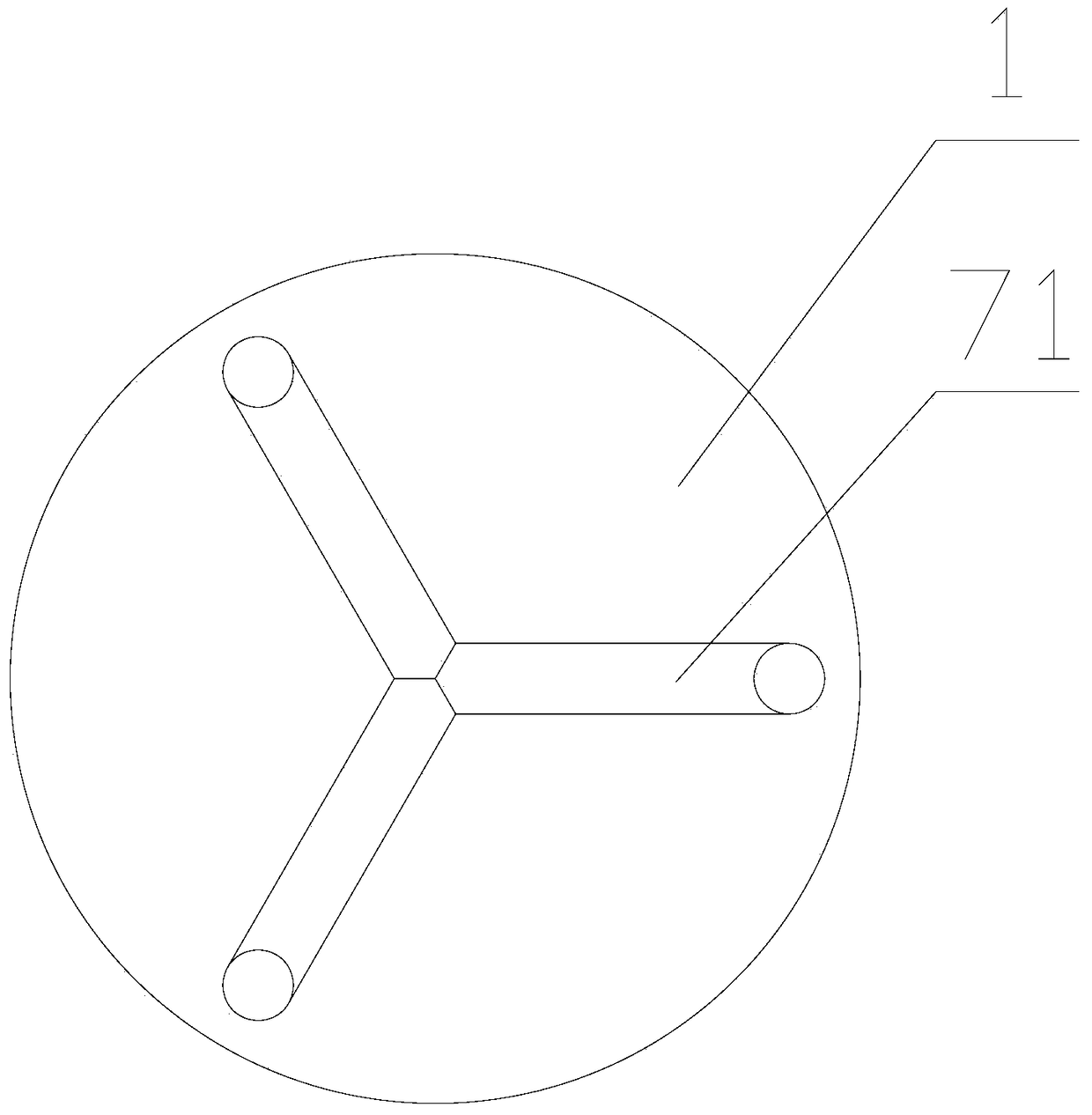

Open impeller structure for high-speed pump

The invention relates to the engineering machinery, and aims to provide an improvement of an open impeller structure. An impeller should have the characteristics of weakening or eliminating a hump curve, balancing the axial force, reducing an extrusion phenomenon, reducing an inlet flow rate and reducing the hydraulic loss of a pump. According to the technical scheme, the open impeller structure for the high-speed pump comprises a hub, a plurality of blade bearing plates which are connected with the hub into a whole and are arranged in a radial mode with the axis of the hub as the center and aplurality of blades which are arranged on the blade bearing plates in a one-to-one correspondence manner, and is characterized in that each blade bearing plate is composed of an inclined section which is close to the hub and is inclined to the axis of the hub and a straight line section perpendicular to the axis of the hub; one part of each blade penetrates through and is embedded in a preset through groove at the inclined section of the blade bearing plate, part of each blade is exposed out of the back face of the impeller to form an auxiliary blade, and the other part of each blade serves as a front blade to be fixed to the front face of the straight-line section of the blade bearing plate and is perpendicular to the plane of the straight-line section.

Owner:ZHEJIANG SCI-TECH UNIV +1

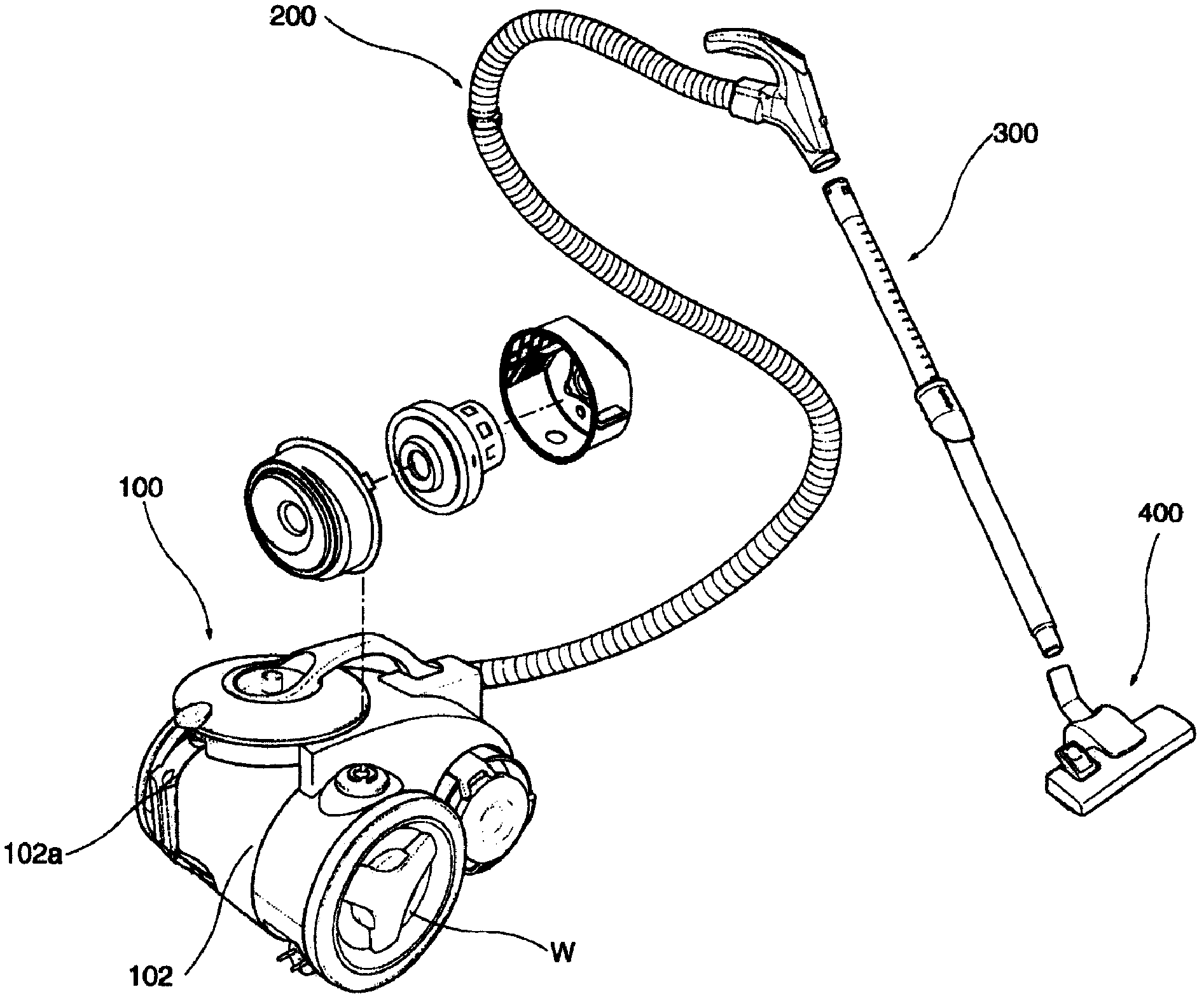

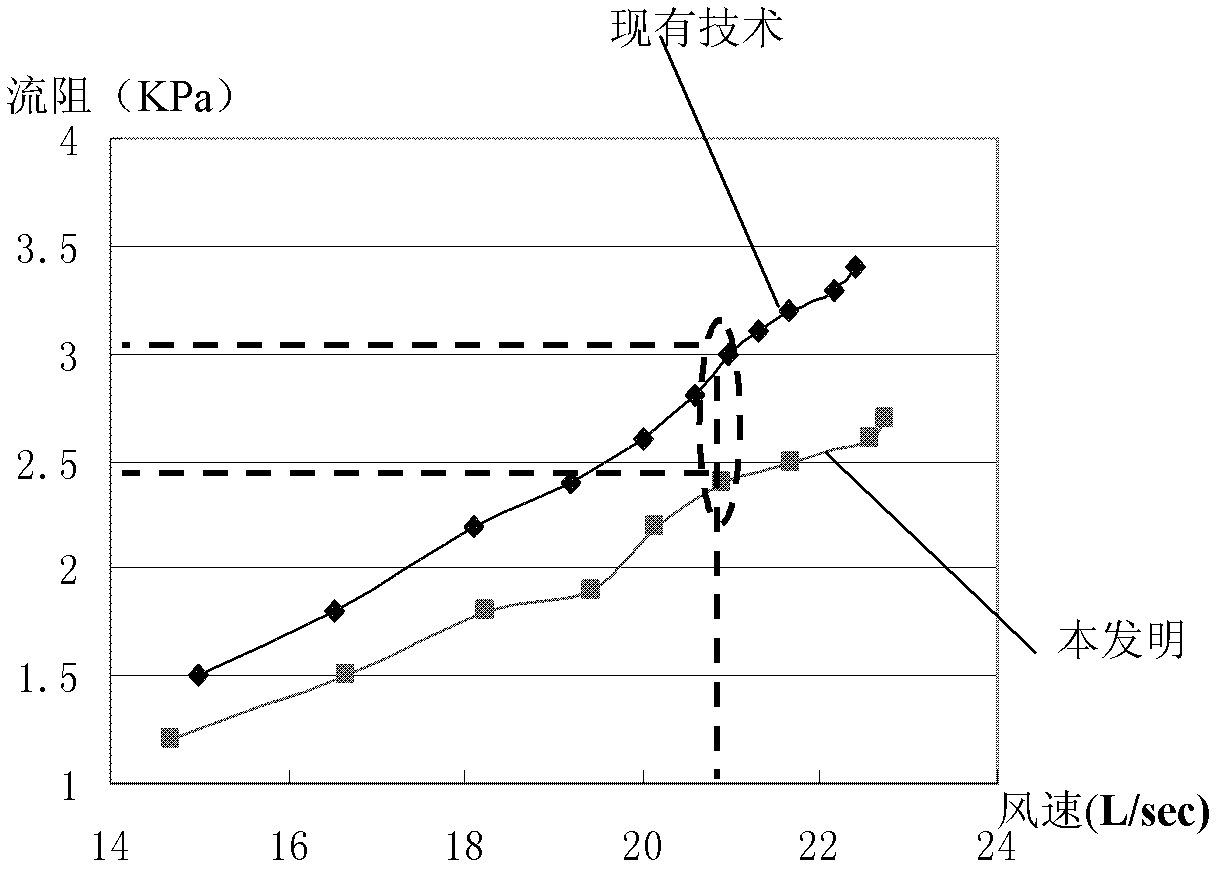

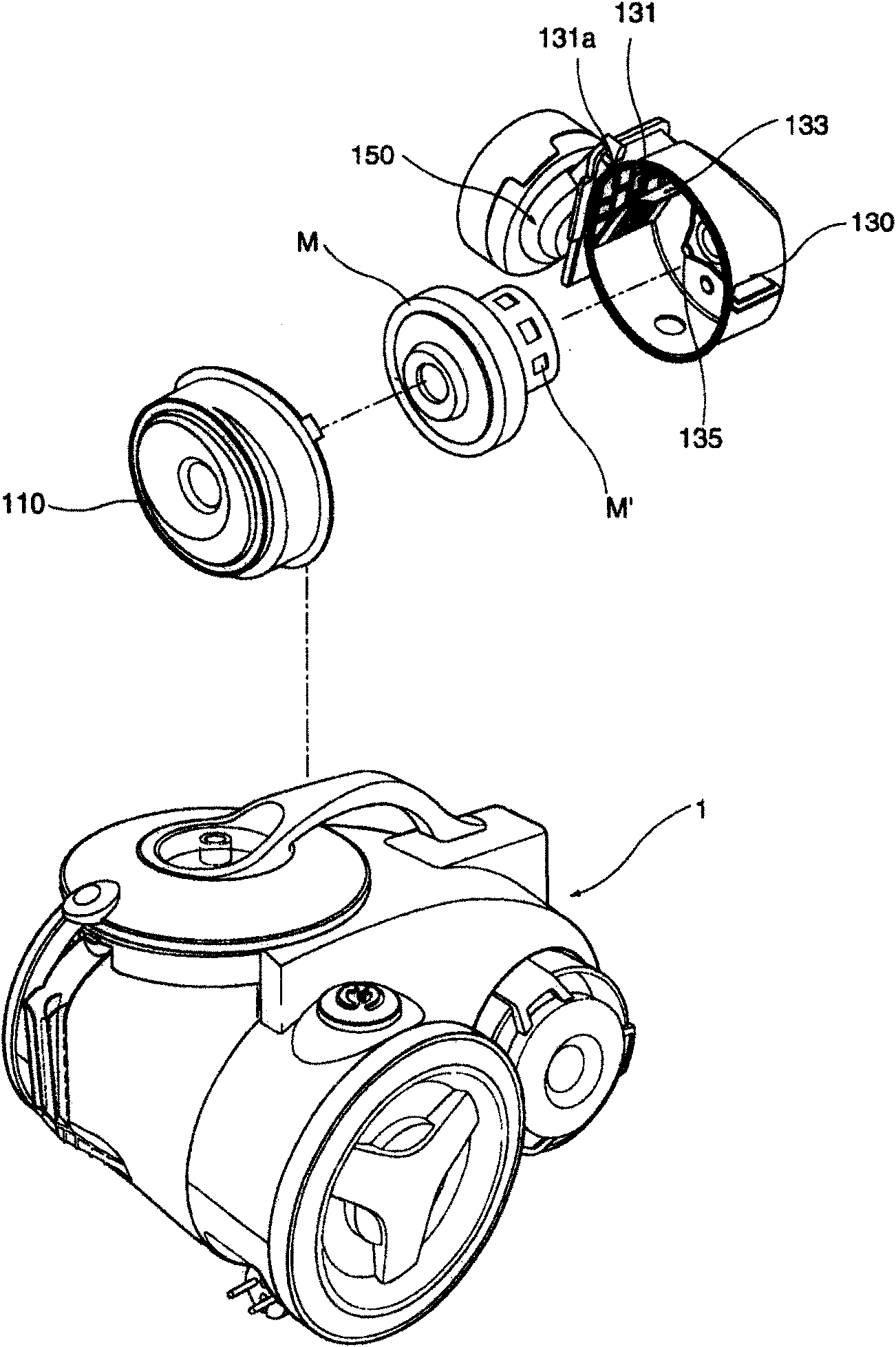

Motor casing with spiral airflow chamber

InactiveCN102599852AReduce noiseImproved low-frequency aerodynamic noiseSuction cleanersSupports/enclosures/casingsExpansion chamberSpiral flow

The invention discloses a motor casing with a spiral airflow chamber, which comprises a chamber body, an air inlet and an air outlet. The air inlet is located at the bottom of the chamber body, and the air outlet is located on the lateral surface of the chamber body. The chamber body is provided with a baffle plate which is formed by a panel and a curved plate connected alternately. An expansion chamber and a contraction chamber which are communicated and arranged alternately are arranged between the baffle plate and the outer wall of the chamber body. A grid-shaped air hole is arranged at a position opposite to the air outlet. A flow channel of spiral air-out passing through the air inlet, the alternated expansion chamber and contraction chamber and the air outlet sequentially. The motor casing is provided with a longer spiral flow channel. The flow resistance of the spiral flow channel is smaller, so that the motor casing provided is further beneficial for improving the overall efficiency of the dust collector and reducing the noise. And the alternate expansion chamber and contraction chamber are arranged in the spiral flow channel so as to increase the loss of sound energy.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Aqueous pesticide filling device

ActiveCN107662719AAchieve outflowIt is convenient to control the discharge timeLiquid materialLiquid bottlingToxicologyPesticide

The invention relates to the field of pesticide processing and particularly discloses an aqueous pesticide filling device. When the filling device performs aqueous pesticide filling, the impact forceof an aqueous pesticide itself can be utilized to open a discharging port of a box body, and aqueous pesticide filling is achieved. In addition, the aqueous pesticide impacts a membrane, the flowing speed of the aqueous pesticide can be effectively reduced, thus the situation that the aqueous pesticide is splashed in the filling process can be avoided, aqueous pesticide waste can be reduced, and the amount of pesticidemolecules in a processing environment can be decreased. By adopting the scheme, the flowing speed during aqueous pesticide filling can be reduced, and aqueous pesticidesplashingcan be prevented.

Owner:重庆康养研究院有限责任公司

Gas-liquid distributor

The invention relates to the technical field of reactor internals, in particular to a gas-liquid distributor. The gas-liquid distributor comprises a bubble cap, a center pipe and a bubble cap ring; the upper end of the center pipe is arranged in the bubble cap, and is connected with the top wall of the bubble cap, and an annular space is formed between the bubble cap and the center pipe; the lower end of the bubble cap is provided with the bubble cap ring, the bubble cap ring is provided with multiple through holes, and the bubble cap ring is used for filling a gap between the bubble cap and the center pipe. The gas-liquid distributor can enable bubbles to be smaller, improves the capability of purging a catalyst of a material flow, and improves a bed gas volume fraction and material flow impact force, the catalyst near the bubble cap can be rushed up during restarting after shut down, and the possibility that the catalyst enters the annular space of the bubble cap when countercurrent occurs can be reduced to the greatest extent.

Owner:SINOPEC ENG GRP CO LTD

Low-noise tourmaline ecological water purifying pump

InactiveCN1840918AImprove cell activityEnhance metabolic functionWater/sewage treatmentPump installationsClutchImpeller

The invention discloses a low-noise TimeLine economical water-purifying pump, which comprises the following parts: pump chassis, motor rack and cylinder between chassis and rack, wherein the motor and water-cooling device constitutes water-cooling motor, which is sealed by machine on the pump shaft, several adjacent blade components on the pump shaft and rotary component under the pump shaft; a layer of TimeLine is coated on the inner face of cylinder; the water-cooling motor connects the motor rack; two ends of clutch connect the motor shaft and pump shaft separately; the rod-crossing component integrates the motor with pump chassis.

Owner:上海山川泵业制造有限公司

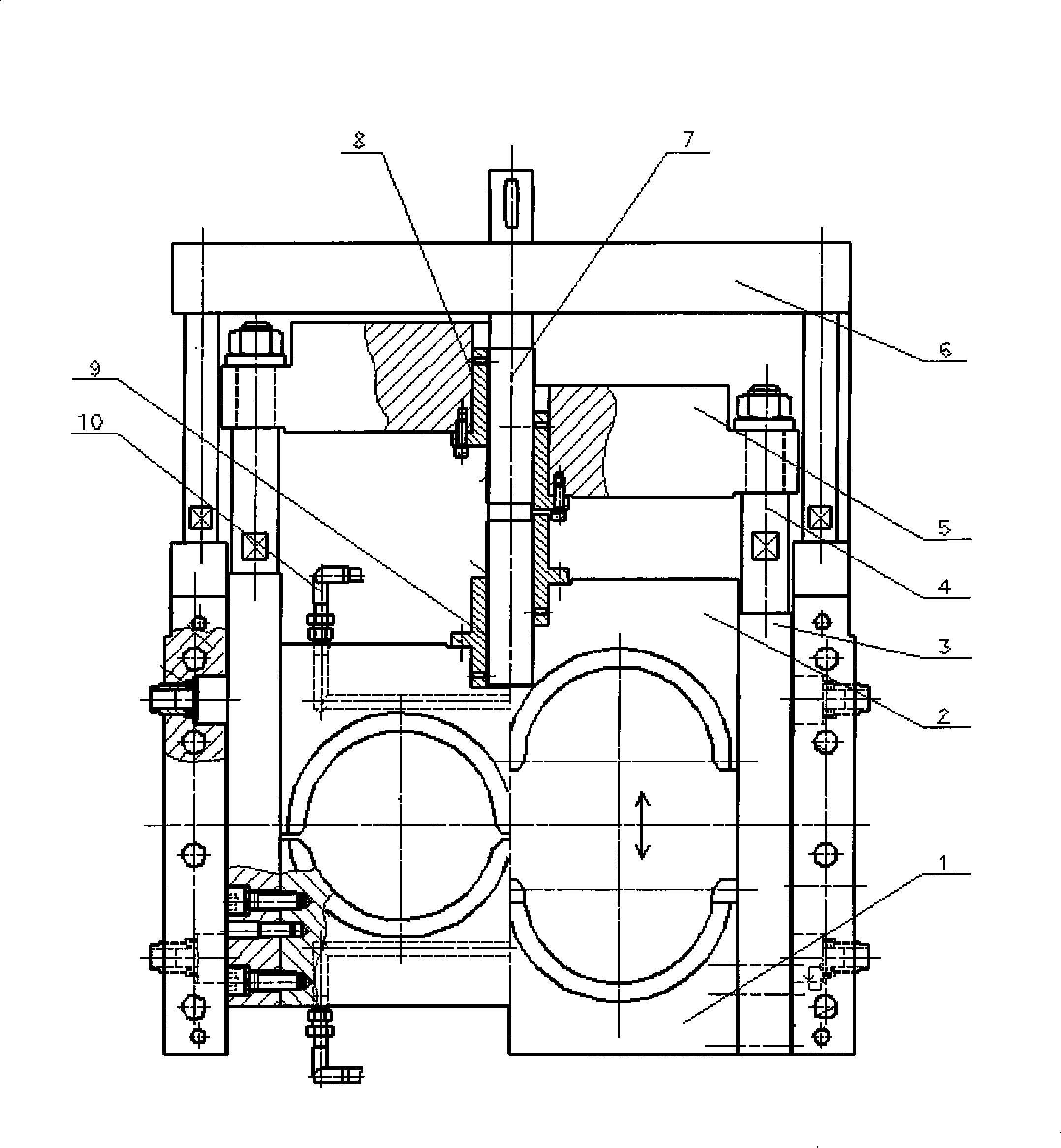

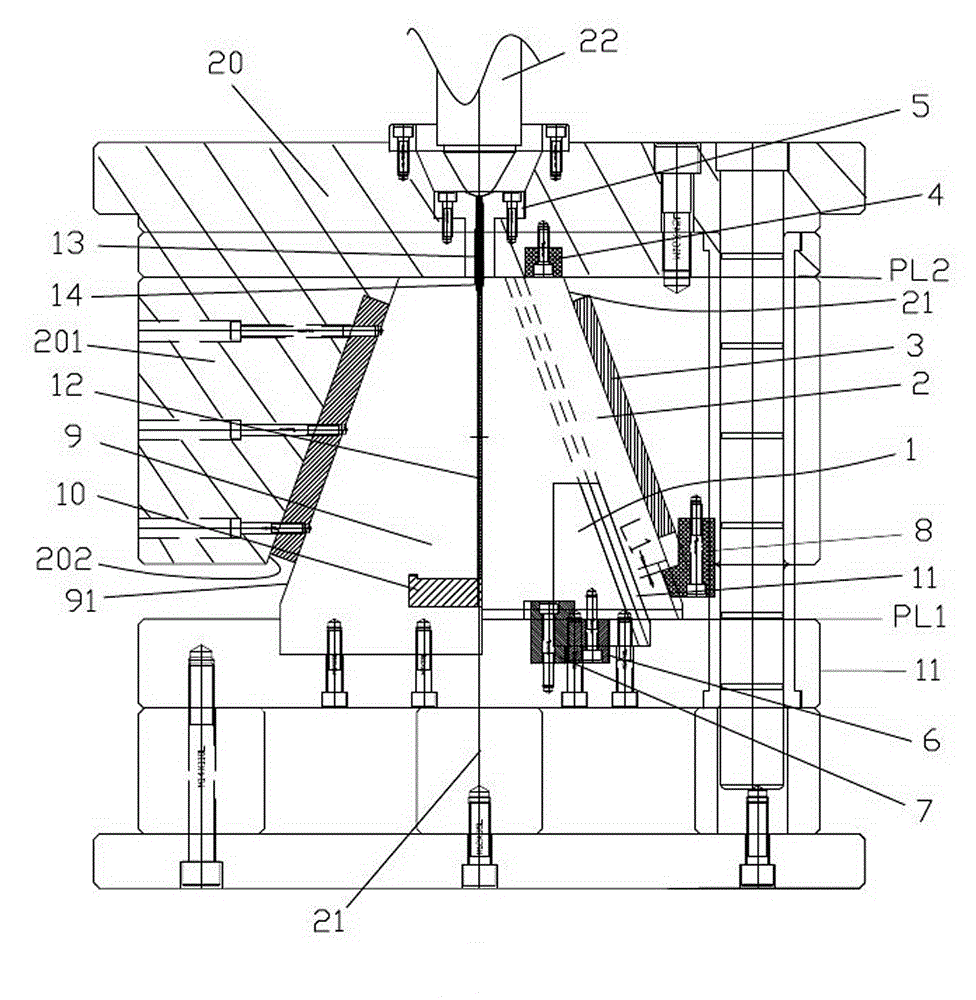

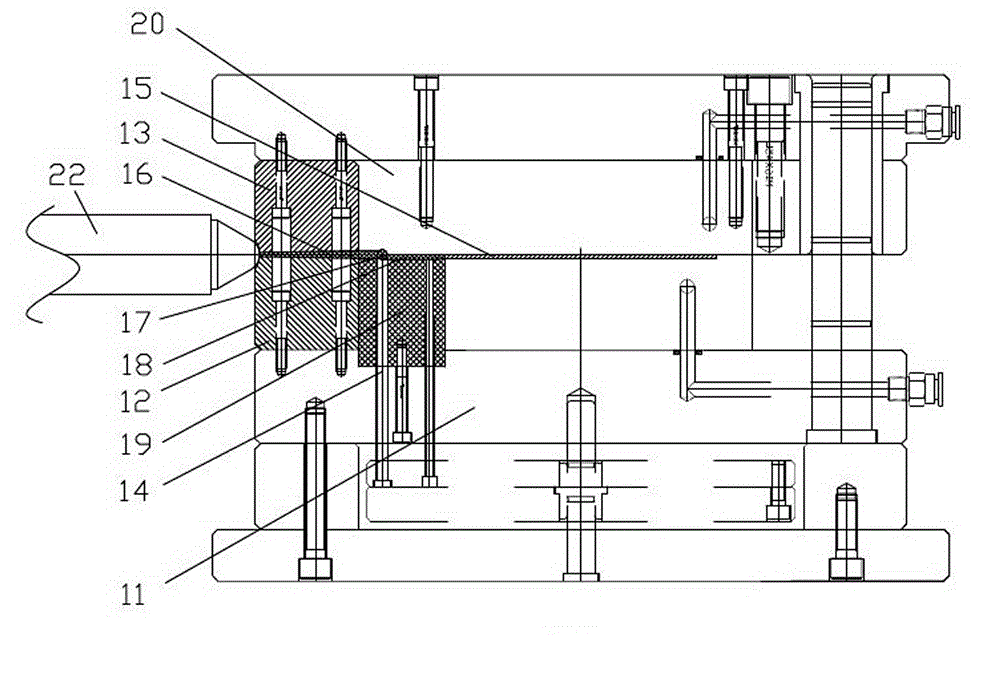

Door melt mass adjusting device of pugging and extruding pelletizer

ActiveCN101288987AChange the degree of mixingSimple mechanical structurePelletizingMechanical construction

The invention relates to a novel adjusting device for fused mass mixing degree, in particular to a door type fused mass adjusting device of a continuous mixing extruding granulating set. The adjusting device mainly consists of a lower door body and an upper door body; the upper door body and the lower door body are respectively connected with an opening-closing drive device; the drive device drives the upper door body and the lower door body to simultaneously move to the same direction or move oppositely. The device of the invention is matched to be used with the continuous mixing extruding granulating set and can be mounted between two sections of machine cylinders vertically or in a certain angle. The control on the opening and closing as well as the opening and closing degrees of the door bodies is obtained by utilizing the principle that the upper and the lower bodies which are symmetrically arranged are simultaneously moved to the same direction or oppositely to change the passing-through area of the materials; thereby changing the mixing degree of a mixing system. The device of the invention has the advantages that the mechanical structure is simple and compact, the processing and manufacture costs are low, the installation and the maintenance are convenient as well as adjustment and detection are convenient; cooled water is accessed into the door bodies to carry out cooling on the fused mass, thus realizing self seal of the fused mass; the seal is reliable and impurities are reduced.

Owner:大连橡胶塑料机械有限公司

Box type composite silicon carbide ceramic pump and manufacturing method thereof

PendingCN113357155ANo emissionsUniform materialSpecific fluid pumpsPump componentsEpoxyCarbide silicon

The invention discloses a box type composite silicon carbide ceramic pump which comprises a pump body and a rear protection plate located on the axial bearing side of an impeller. The impeller is installed on a transmission shaft; the pump body and the rear protection plate are formed by one-time casting of a silicon carbide ceramic composite material in a mold; the impeller is made of the silicon carbide ceramic composite material lined with a metal framework; and the silicon carbide ceramic composite material comprises the following components in parts by mass: 300 to 500 parts of silicon carbide particles, 80 to 120 parts of epoxy resin and 10 to 30 parts of a curing agent. According to the box type composite silicon carbide ceramic pump and the manufacturing method thereof provided by the invention, the silicon carbide ceramic composite material is poured after being vacuumized, and is free of bubbles, uniform in material, few in defect and high in strength; inorganic materials such as silicon carbide are filled with resin, so that the thermal expansion coefficient is low; and the pump body, the protection plate and the impeller are formed through one-time casting, so that the size precision is high, and reprocessing is not needed. Low-temperature pouring is adopted, the cost is low, and no pollutant is discharged in the production process.

Owner:CHANGZHOU KAIRUN MASCH CO LTD

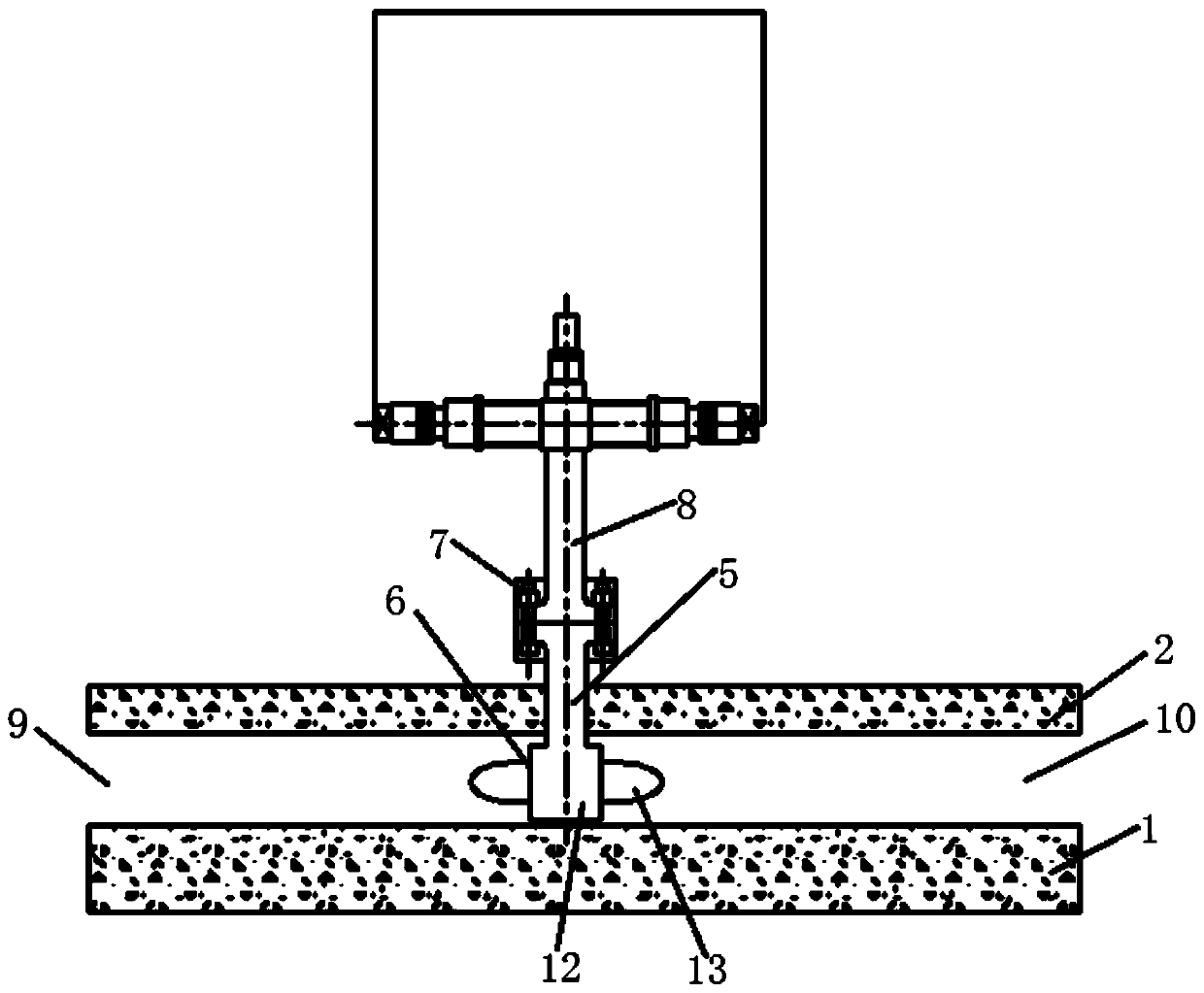

A tidal power generation device with catenary blades

ActiveCN106762379BReduce excavationSmooth runnerHydro energy generationReaction enginesImpellerCoupling

The invention discloses a tidal power generation apparatus with catenary suspension type blades. The tidal power generation apparatus include a water flow channel formed by connecting a horizontal wall a, a horizontal wall b, a vertical wall c, and a vertical wall d; a vertical impeller main shaft is arranged in the water flow channel; the impeller main shaft is sleeved with an impeller; and one end of the impeller main shaft is connected to the wall a, the other end of the impeller main shaft passes through the wall b and is connected to an engine main shaft through a coupling member. According to the invention, a power generator main shaft is arranged outside of the water flow channel, a seal and damp-proof problem of the power generator can be avoided; the Z-shaped water flow channel is flat and smooth, and loss is less in a flowing process; the water flow channel does not have to be designed into a diffusion channel, the earth and stone excavation amount of a power generation station is reduced, and operation and maintenance is facilitated; the catenary suspension type blades are adopted, the machining and design cost is low; the rotation directions are consistent in a forward working condition and a backward working condition; the problem that the conventional tidal power generation stations are huge in investment cost and are complex in unit structure can be overcome; and the tidal power generation apparatus has high use value.

Owner:XIAN UNIV OF TECH

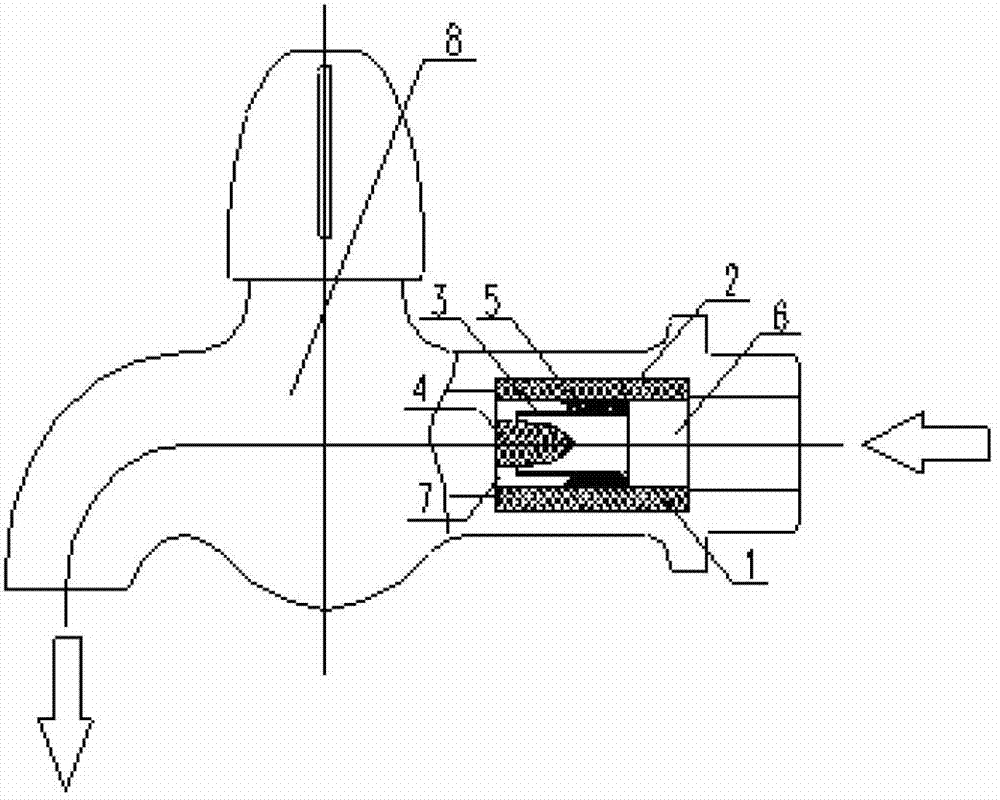

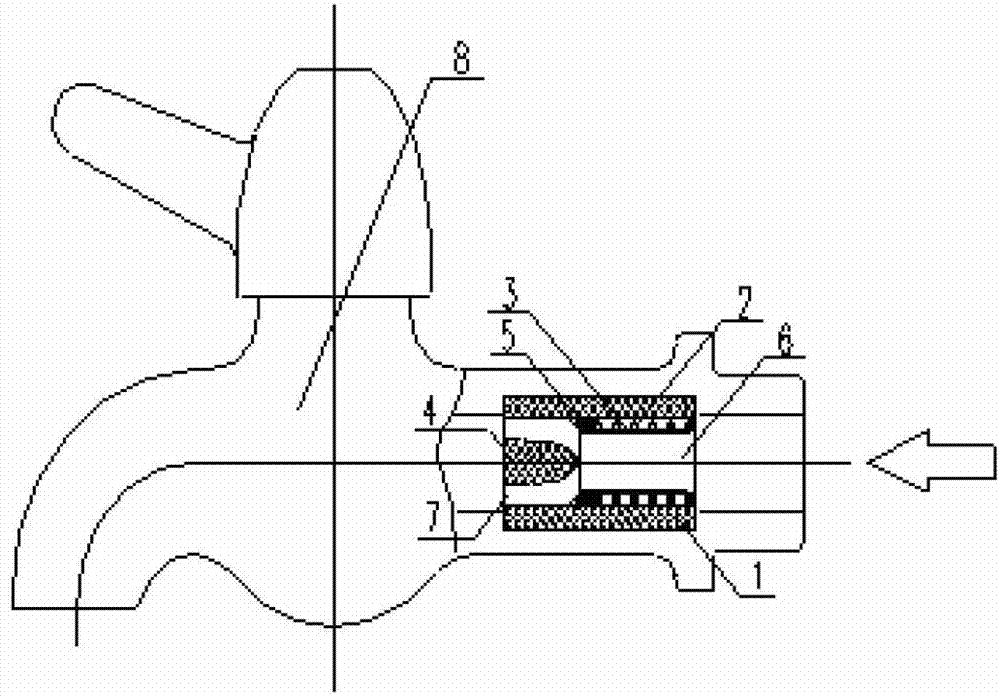

Self-adaptive throttling faucet

The invention discloses a self-adaptive throttling faucet which is used for opening or closing water tail end flow of a water supply network. The self-adaptive throttling faucet mainly comprises a fixed sleeve (1), a spring (2), a sliding sleeve (3), a resistance cone (4) and a faucet (8). The self-adaptive throttling faucet has the main advantages that under the action of water pressure within a preset range, the faucet automatically maintains a stable outflow, so that throttling and water conservation are achieved.

Owner:何际跃

Electric shock-proof joint for pipeline system

InactiveCN102116399AReduce the overall heightReduce shockPipe connection arrangementsEngineeringElectric shock

The invention relates to an electric shock-proof joint for a pipeline system. The electric shock-proof joint is composed of a first insulating joint, a second insulating joint and a built-in insulating piece, wherein the first insulating joint can be a plastic piece or a plastic metal composite piece, one end of the first insulating joint is provided with an interface which is connected with other pipeline fittings, and the other end of the first insulating piece extends downward and is connected with the second insulating joint in a sealing mode after the other end of the first insulating joint is sleeved with the built-in insulating piece; the second insulating joint can be a plastic piece or a plastic metal composite piece, one end of the second insulating joint is provided with an interface which is connected with other pipeline fittings, and the other end of the second insulating piece is connected with the first insulating joint in a sealing mode and presses the built-in insulating piece tightly. The outer side surface of the built-in insulating piece is provided with a spiral groove, a spiral type flow channel is formed between the spiral groove and the inner wall of the first insulating joint, and on the premise of ensuring the length of the flow channel, the whole width of the flow channel is shortened, and further the whole height of the electric shock-proof joint is shortened.

Owner:上海龙胜实业有限公司

A high-pressure multifunctional two-position three-way solenoid valve

ActiveCN108916419BRealize high pressure and even ultra high pressureSame cross-sectional areaOperating means/releasing devices for valvesMultiple way valvesSolenoid valveEngineering

A high-voltage multifunctional two-position three-way solenoid valve comprises an electromagnet (1), an electromagnet housing (2), a return spring (3), an armature (4), a valve body (5), a valve stem(6), an upper valve seat (7) and a lower valve seat (11). Three vent holes formed in the valve body (5) can be used as fluid inlet holes or fluid outlet holes. The valve stem (6) is mounted in an inner cavity E of the valve body (5) through the upper valve seat (7), an upper valve seat sealing gasket (8), a middle valve sleeve (9), a lower valve port sealing gasket (10), the lower valve seat (11)and a bottom valve sleeve (12). The diameter of the sealing portion of the valve stem (6) and the valve body (5), the diameter of the contact portion of the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) and the diameter of the sealing portion of the valve stem (6) and the bottom valve sleeve (12) are identical. One hole A is communicated with a circumferential hole formed in the middle valve sleeve (9). When the valve stem (6) and the upper valve seat sealing gasket (8) or the lower valve port sealing gasket (10) is sealed, the vent holeA is communicated with the other vent holes.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Mold for molding light guide plate

InactiveCN104476730ASmall pressure lossReduce manufacturing costLight guideInjection molding machine

The invention discloses a mold for molding a light guide plate, and relates to a mold technique. The mold comprises a main runner for charging glue straightly, a front mold plate and a rear mold plate; a glue charge end of the main runner is communicated with an injection nozzle of an injection molding machine; a glue discharge end of the main runner is communicated with a sprue of a mold cavity; the front mold plate and the rear mold plate are arranged oppositely. The main runner for charging glue straightly is adopted so as to form main runner straight ejection and branch runner straight ejection; the runner and the glue charge are smooth, the pressure loss in the runner is very low, and the glue charge speed is high, so that the molding speed is high, the yield is high, and the manufacture cost is reduced; meanwhile, because the pressure loss in the runner is very low, a high-power injection molding machine is not required to be adopted; on one hand, the energy consumption is reduced, the equipment investment can be reduced, and the production cost of a product is reduced further; according to calculation, the manufacture cost of the light guide plate can be reduced by about 5%, and the market competitiveness is improved.

Owner:东莞市现代精工实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com