Door melt mass adjusting device of pugging and extruding pelletizer

A technology of extrusion granulation and adjustment device is applied in the field of melt mixing degree adjustment device, which can solve the problems of high design and manufacturing cost, inconvenient adjustment and detection, and large structure.

Active Publication Date: 2008-10-22

大连橡胶塑料机械有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because the moving part is the entire machine barrel, this structure has problems such as huge mechanism, high design and manufacturing costs, and the most serious disadvantage is that adjustment and detection are inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

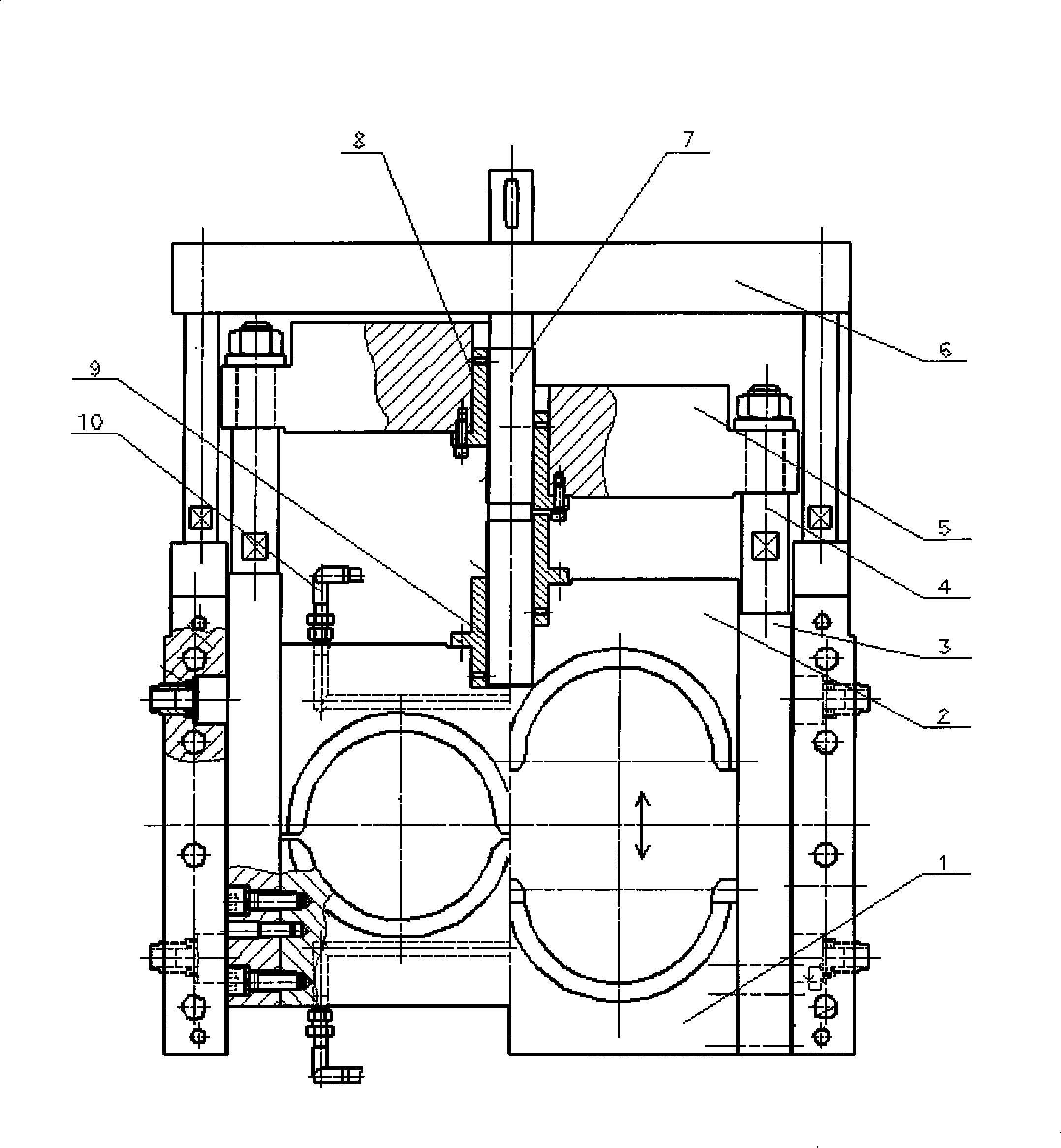

The invention relates to a novel adjusting device for fused mass mixing degree, in particular to a door type fused mass adjusting device of a continuous mixing extruding granulating set. The adjusting device mainly consists of a lower door body and an upper door body; the upper door body and the lower door body are respectively connected with an opening-closing drive device; the drive device drives the upper door body and the lower door body to simultaneously move to the same direction or move oppositely. The device of the invention is matched to be used with the continuous mixing extruding granulating set and can be mounted between two sections of machine cylinders vertically or in a certain angle. The control on the opening and closing as well as the opening and closing degrees of the door bodies is obtained by utilizing the principle that the upper and the lower bodies which are symmetrically arranged are simultaneously moved to the same direction or oppositely to change the passing-through area of the materials; thereby changing the mixing degree of a mixing system. The device of the invention has the advantages that the mechanical structure is simple and compact, the processing and manufacture costs are low, the installation and the maintenance are convenient as well as adjustment and detection are convenient; cooled water is accessed into the door bodies to carry out cooling on the fused mass, thus realizing self seal of the fused mass; the seal is reliable and impurities are reduced.

Description

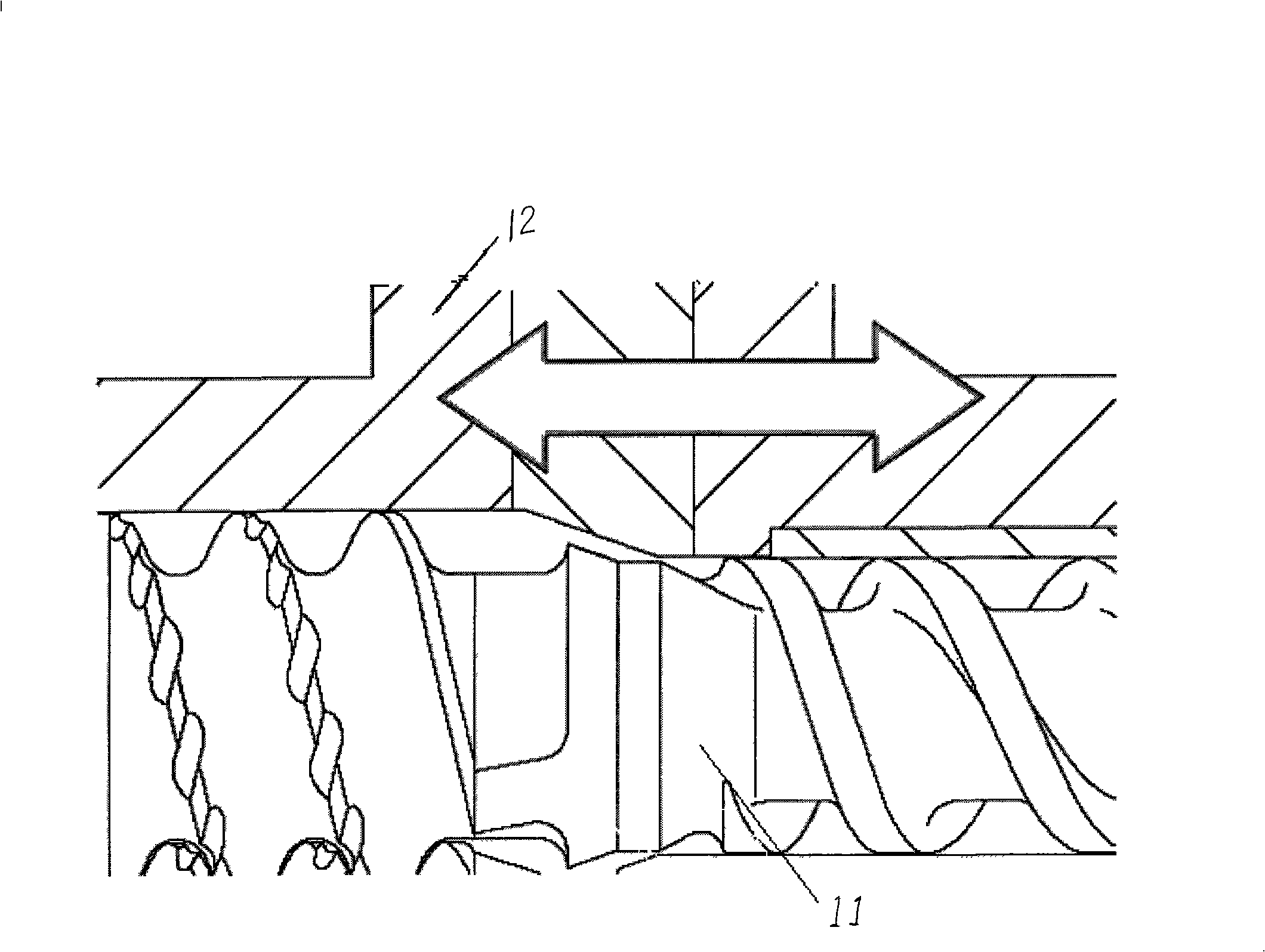

Door-type melt adjustment device for mixing extrusion granulation unit 1. Technical field The invention relates to a novel melt kneading degree adjusting device. 2. Background technology The continuous mixing extrusion granulation unit is one of the most important equipment for ethylene engineering in the petrochemical industry. This type of extruder not only has the forced conveying and plasticizing ability of the traditional screw extruder, but also has the strong mixing ability of the rubber and plastic internal mixer. The melt mixing degree adjustment device is one of the indispensable key components of the mixing extrusion granulation unit. Its main function is to control the mixing degree and material temperature according to different grades of materials and output. In the past, the unit has a structure as shown in Figure 1: a snap ring is set on the screw, and the gap between the screw 11 and the barrel 12 is changed by moving the barrel back and forth, so as to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29B9/10B29C48/92

CPCB29C47/92B29C48/04

Inventor 何桂红王艳群刘鑫传郑广超

Owner 大连橡胶塑料机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com