Pressurization and non-pressurization combined type dual piezoelectric fuel gas injection device

A non-pressurized combined type, injection device technology, applied in the direction of oil supply device, charging system, combustion engine, etc., can solve the problems of size limitation, limited matching engine power, long transmission pipeline, etc., to achieve high power output, Achieve low power output and reduce installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with legend:

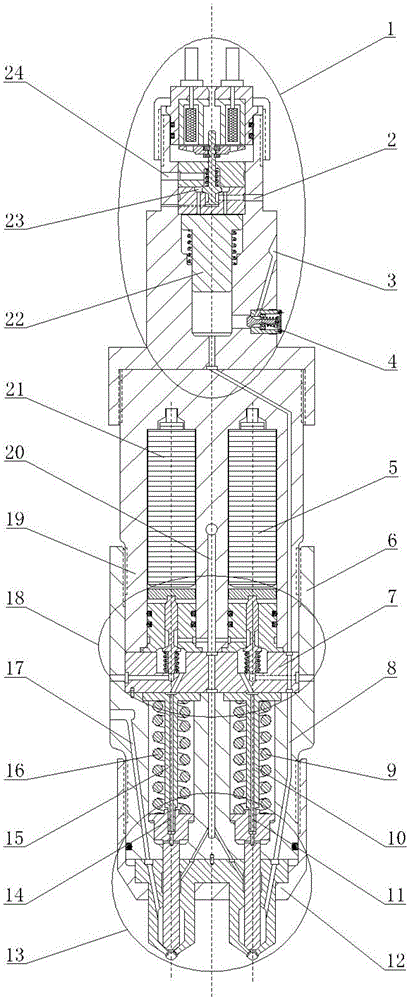

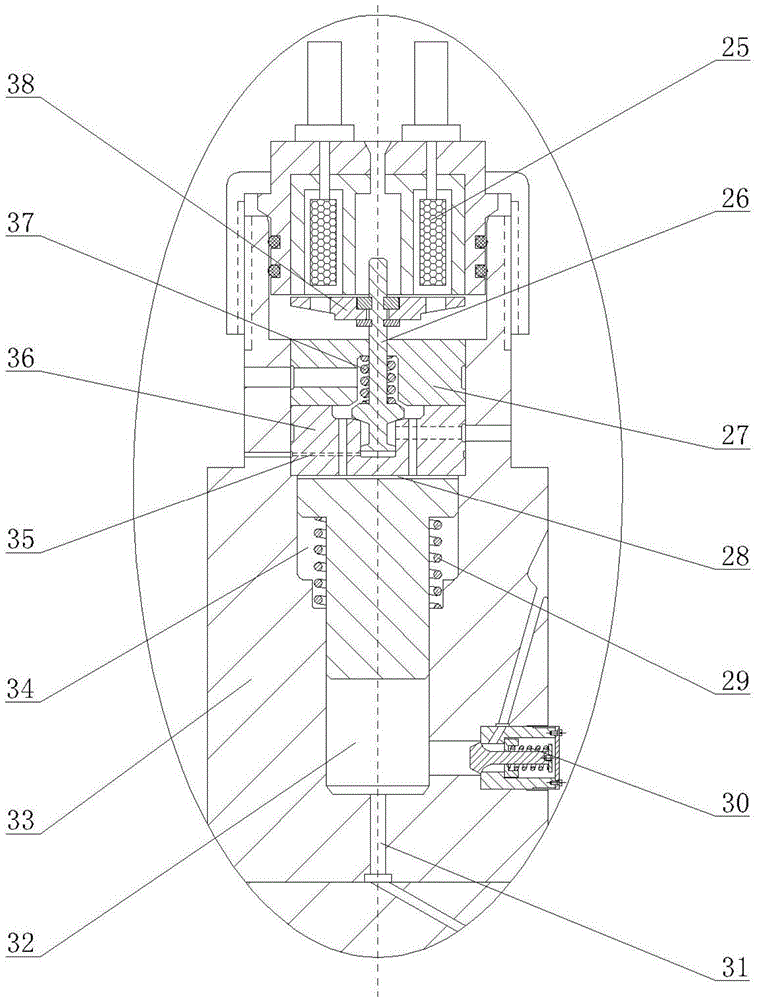

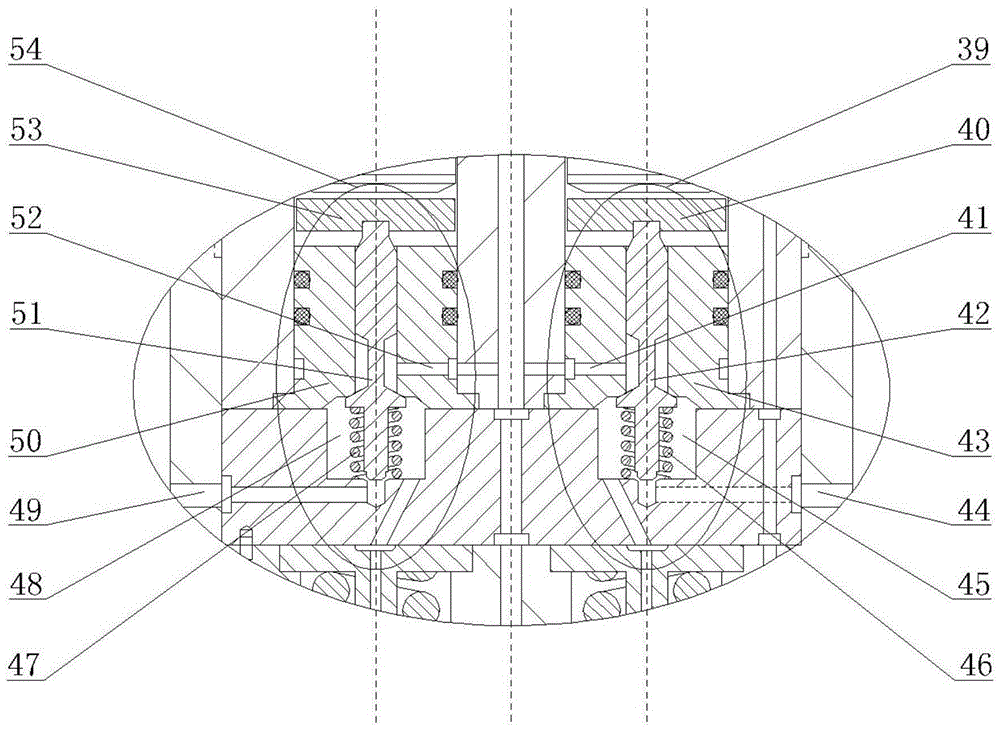

[0021] combine Figure 1-4 , the combined pressurized-non-supercharged dual-piezo electric gas injection device of the present invention mainly includes a gas pressurized part 1, a dual-piezoelectric control part 18, a double gas nozzle part 13, a pressurized device housing 33, a control device housing 19, Injection device housing 6, air intake passage I8, air intake passage II17, pressurized oil inlet oil passage 2, pressurized oil discharge oil passage 24, oil inlet oil passage 20.

[0022]Gas booster part 1 is composed of booster piston 22, booster piston upper cavity 28, booster piston lower cavity 32, booster piston return spring 37, booster piston return spring chamber 34, booster solenoid valve coil 25, booster armature 38. Boost control valve stem 26, boost control valve return spring 29, air inlet 3, boost gas outlet 31, boost control valve oil chamber 23, boost control valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com