Electric shock-proof joint for pipeline system

A pipeline system, anti-electric shock technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of water flow impact, large space occupied by insulating joints, etc., to achieve the effect of reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

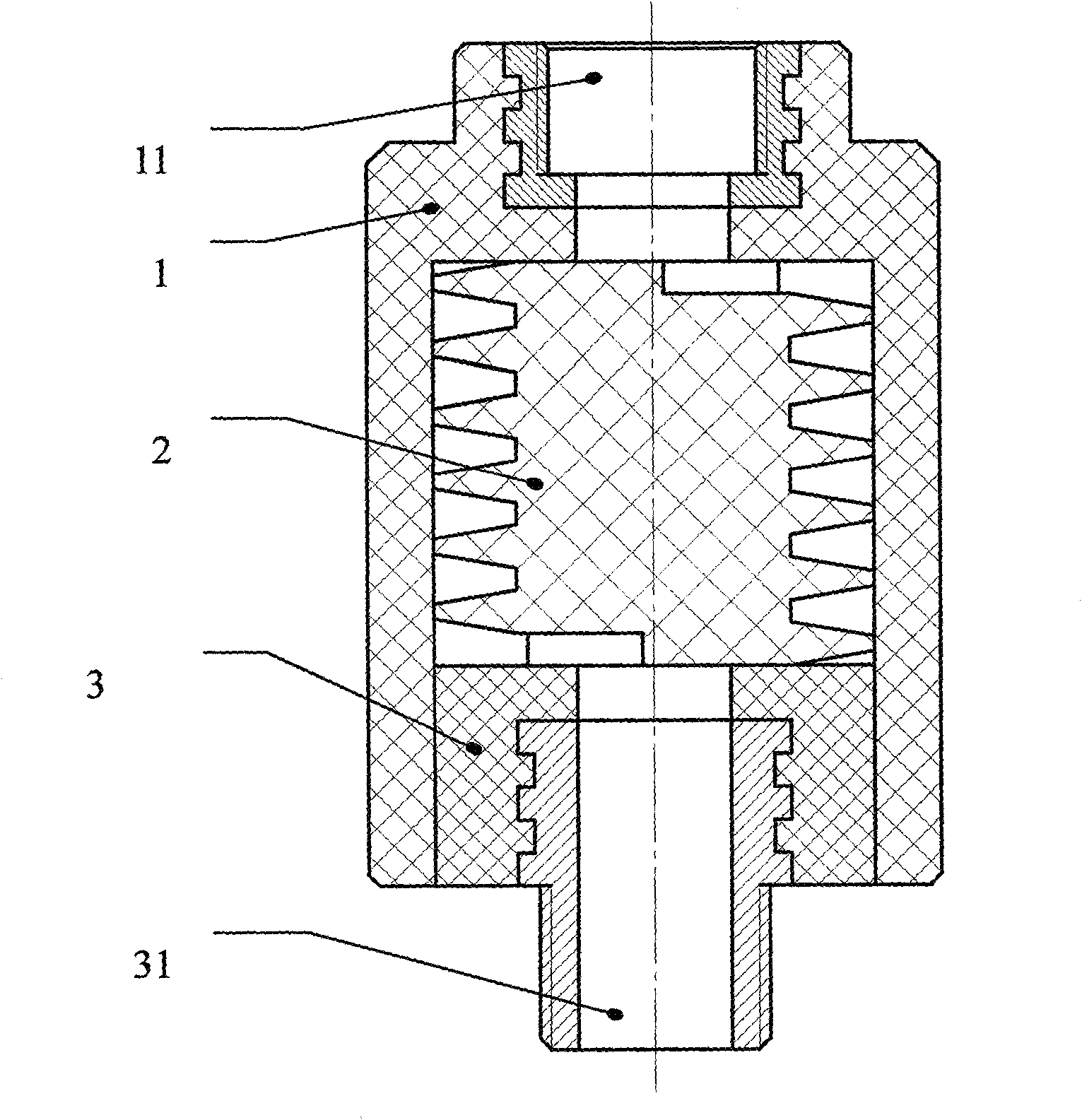

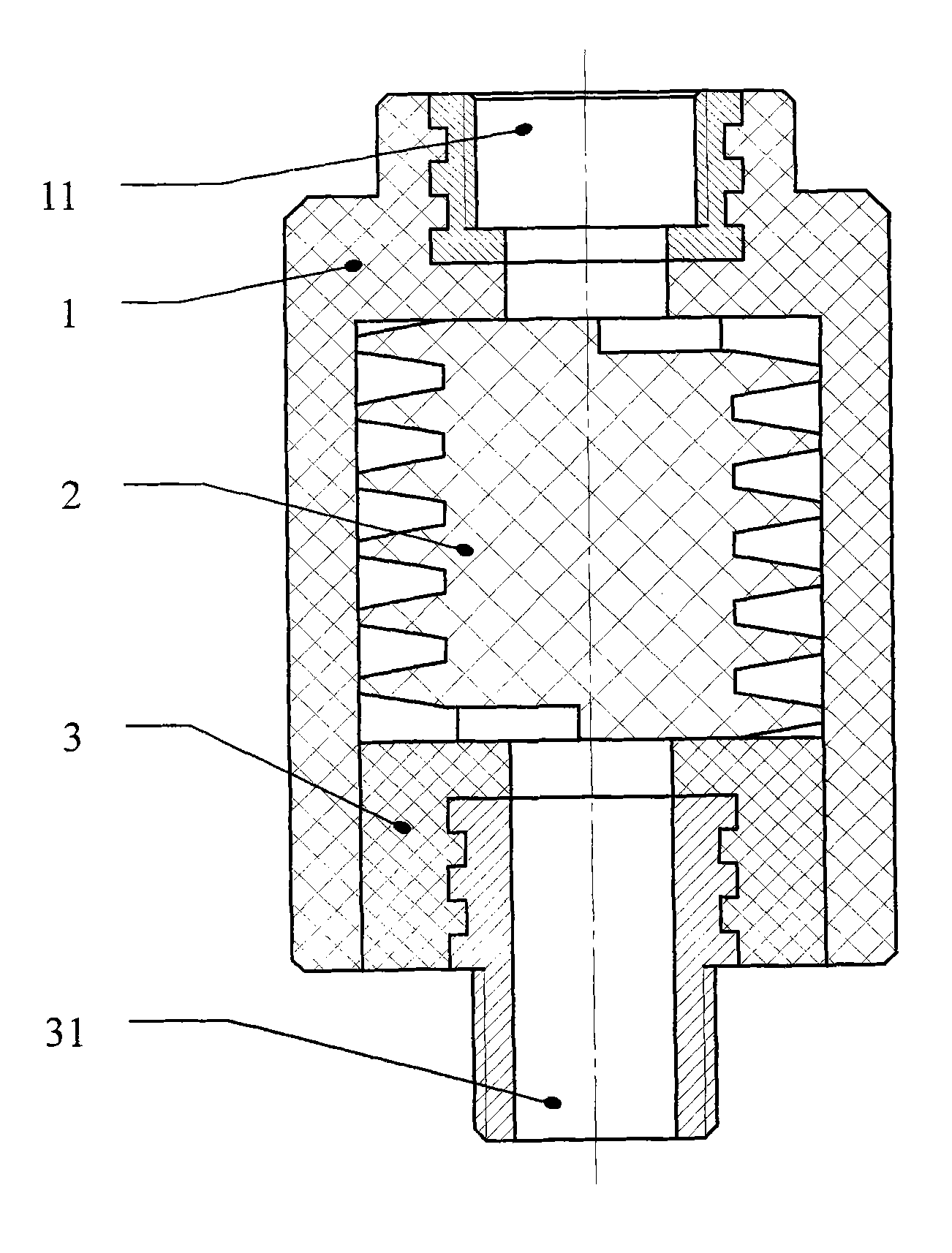

[0011] like figure 1 As shown, a kind of anti-shock joint used in the pipeline system of the present invention is composed of a first insulating joint 1 and a second insulating joint 3, and the first insulating joint 1 is composed of a first plastic pipe body and a A metal insert 11 embedded in the first plastic pipe body is formed, and the second insulating joint 3 is composed of a second plastic pipe body and an end embedded in the second plastic pipe body The metal insert 31 in the middle, wherein, the other end of the first plastic pipe body extends downwards and fits with the built-in insulator 2 and then is sealed and connected with the second plastic pipe body, the first A built-in insulator 2 is arranged between the plastic pipe body, the upper end of the second plastic pipe body and the bottom of the metal insert 11, and a spiral groove is arranged on the outside of the built-in insulator 2, and the teeth of the spiral groove The size of the top is equal to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com