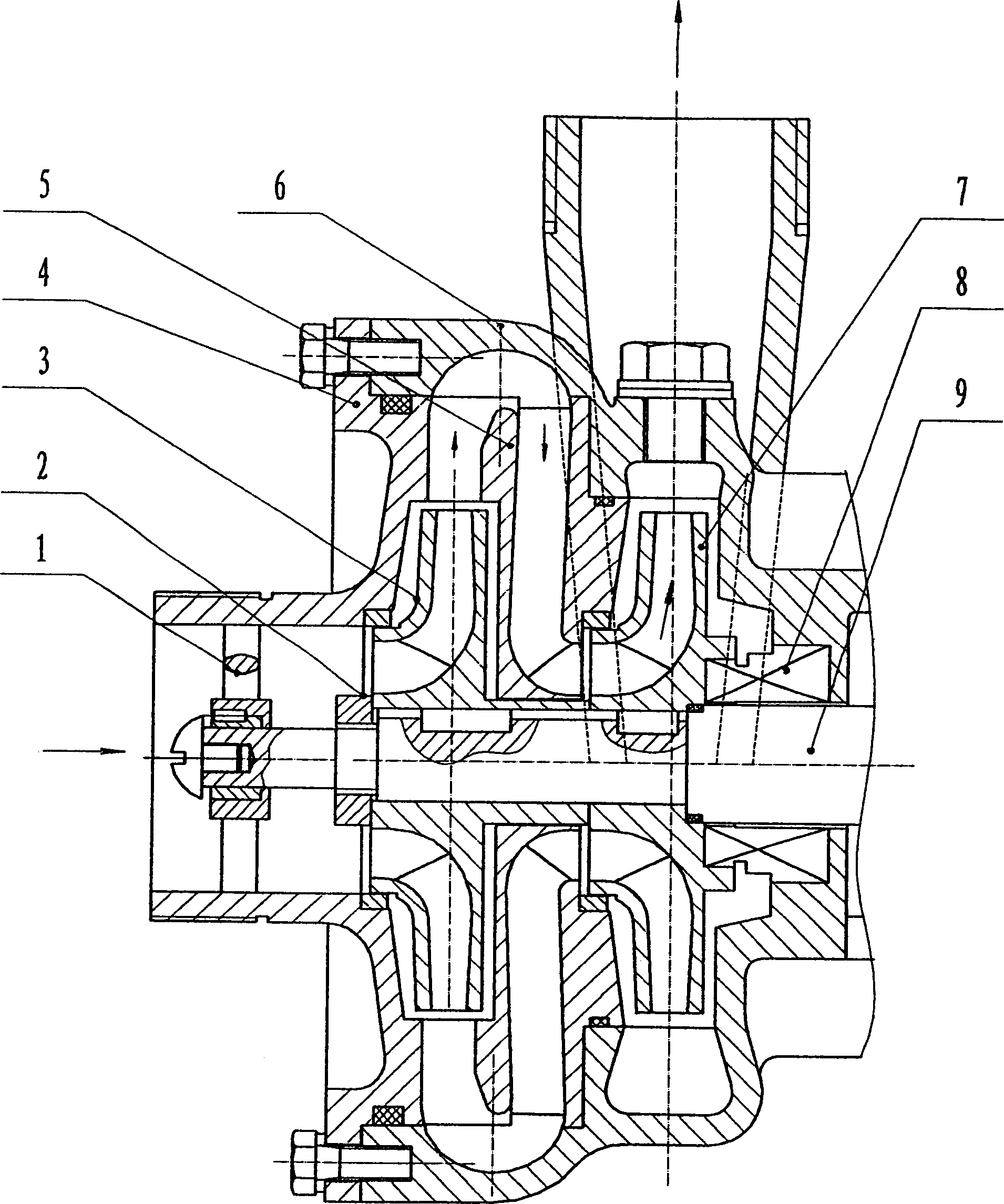

Two stage pump in type of combining guide vane with spiral case

A combined, two-stage pump technology, applied in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of large guide vane structure, difficult manufacturing process, complex structure, etc., and achieve low manufacturing cost, The effect of easy casting and processing, and thin wall of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] exist figure 1 , when the guide vane volute combined double-stage pump shaft [10] rotates, the impeller is driven to work, the liquid enters the pump cover [4] and the inlet of the derotator [1], and the liquid encounters the derotator to play a derotation effect. At the same time, the liquid enters the first-stage impeller [3], and the high-speed liquid flowing out of the impeller channel enters the pump casing [6] and guide vane [5]. Since the area of the guide vane channel is larger than the area of the impeller channel, the velocity energy is converted into pressure at this time. It can eliminate the velocity circulation of the liquid, reduce the radial force, and then the liquid enters the final stage impeller [7], and then exits from the volute, and the pump works normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com