Mold for molding light guide plate

A light guide plate and mold technology, applied in the field of molds, can solve the problems of large flow channel pressure loss, unreasonable flow channel design, slow molding speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

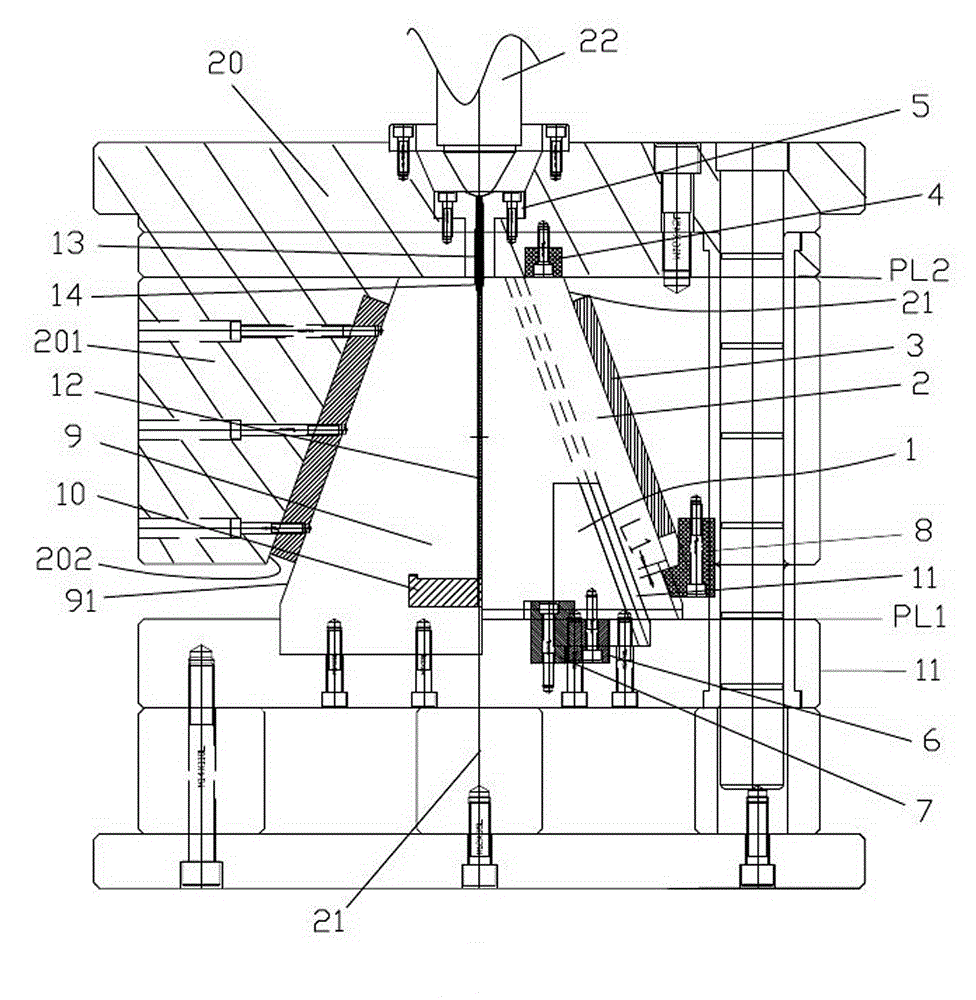

[0032] Embodiment 1, the mold of this embodiment is suitable for a horizontal injection molding machine.

[0033] Such as figure 1 As shown, a mold for forming a light guide plate includes a main flow channel 13 that feeds glue straightly. 14 connected.

[0034] Also include the front formwork 20 and the back formwork 11 that are arranged oppositely, the geometric center of the front formwork 20 plate surface and the geometric center of the back formwork 11 plate surface are called the center line 21 of this mould;

[0035] The left side of the geometric center on the front template 20 protrudes a front mold slope block 201 toward the rear template 11, and the front module slope 201 has a slope 202, and the slope 202 is located on the side close to the geometric center of the front template 20, And the angle between the slope 202 and the front template 20 is greater than 90 degrees on the side close to the centerline 21;

[0036] On the left side of the center line 21 on th...

Embodiment 2

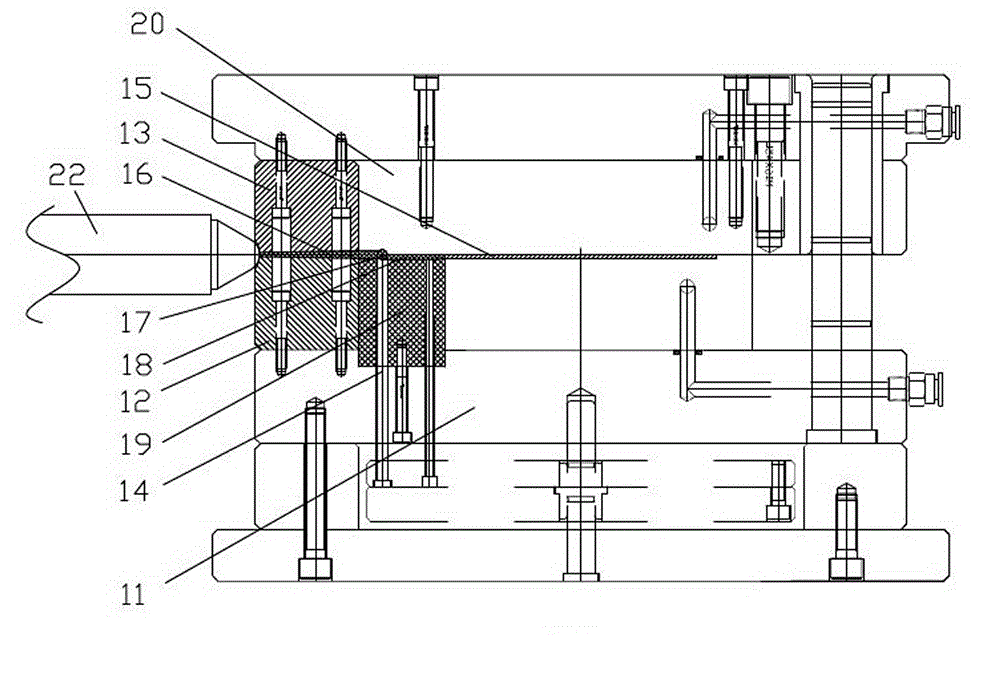

[0054] Embodiment 2, the mold of this embodiment is suitable for an angle injection molding machine.

[0055] Such as figure 2 As shown, a mold for forming a light guide plate includes a main flow channel 13 that feeds glue straightly. 14 connected.

[0056] Also include the front formwork 20 and the back formwork 11 that are arranged oppositely, the geometric center of the front formwork 20 plate surface and the geometric center of the back formwork 11 plate surface are called the center line 21 of this mould;

[0057] Install the first nozzle insert 15 on the front template 20, the first nozzle insert 15 is the front mold side forming the sprue 13, and fix the second nozzle at the position facing the first nozzle insert 15 on the back template 11 The insert 17 and the second nozzle insert 17 form the rear mold side of the sprue 13 , and the front mold side of the sprue 13 and the rear mold side of the sprue are closed to form the sprue 13 .

[0058] On the rear template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com