Improved aerating rotating brush device and method capable of improving aeration capacity and saving energy

A technology of aeration brush and oxygenation capacity, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve the problems of high energy consumption, insufficient utilization of aeration brush oxygenation capacity, etc., to achieve optimal water power conditions, increased oxygen transfer rate, enhanced mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

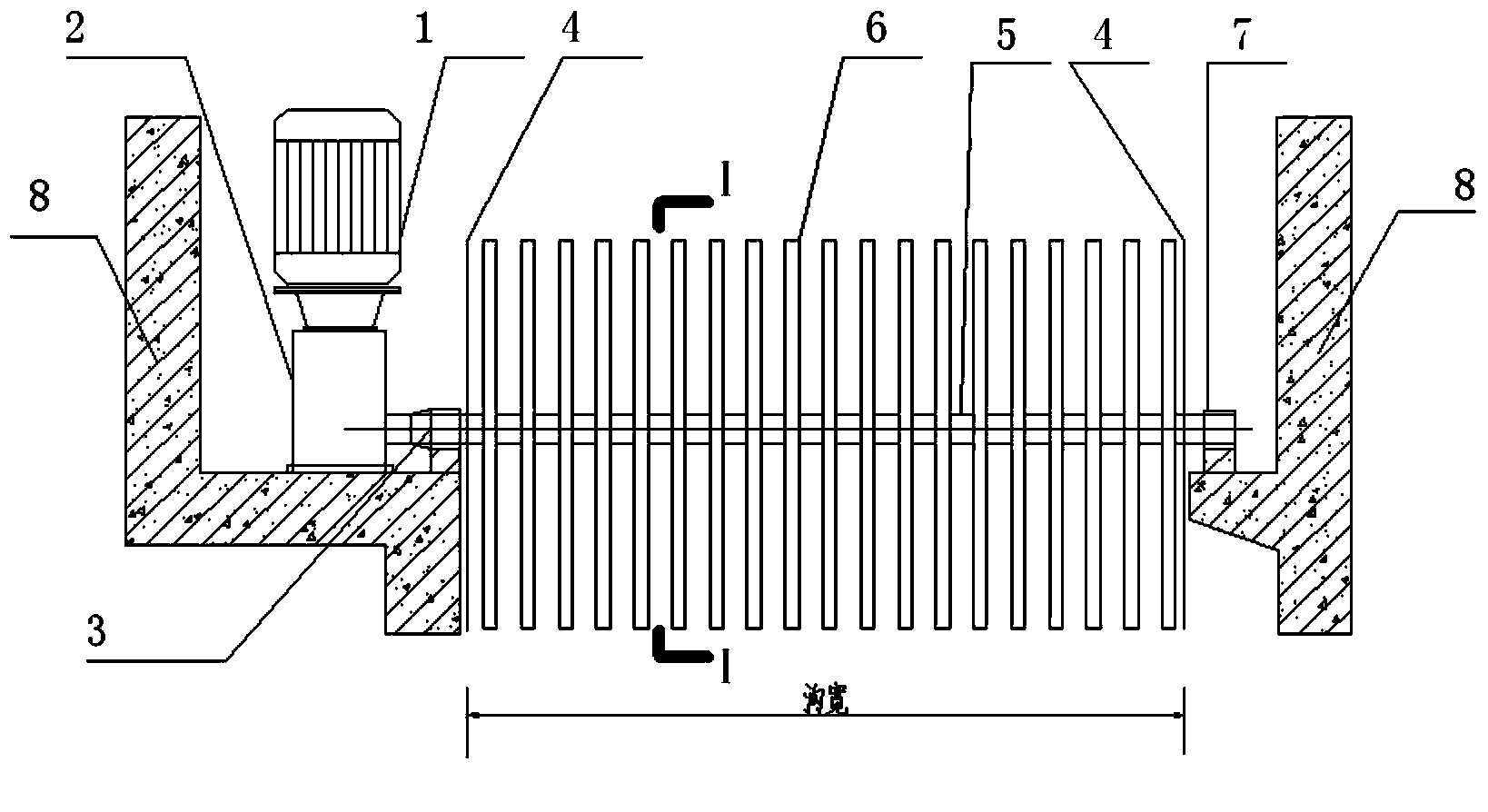

[0024] Specific embodiment 1: The improved aeration brush device of this embodiment includes a motor 1, a transmission device 2, a coupling 3, a water retaining plate 4, a main shaft 5, a plurality of rotating brush blades 6, a bearing seat 7 and a supporting structure 8;

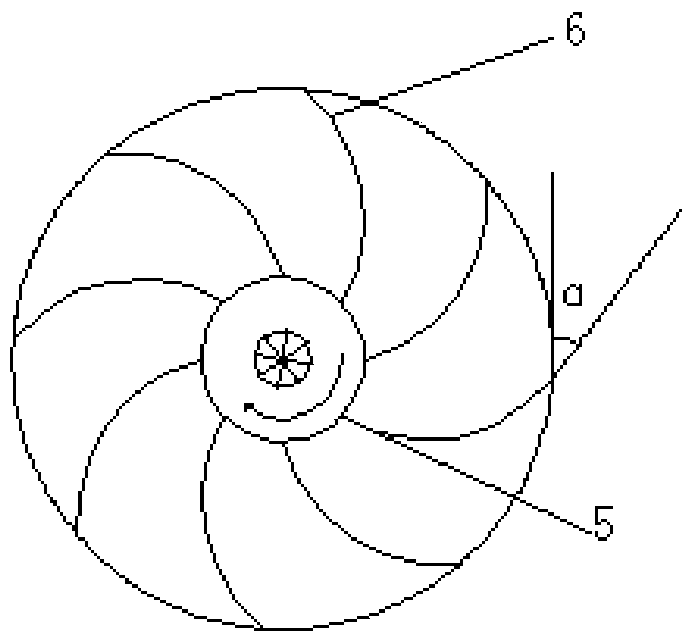

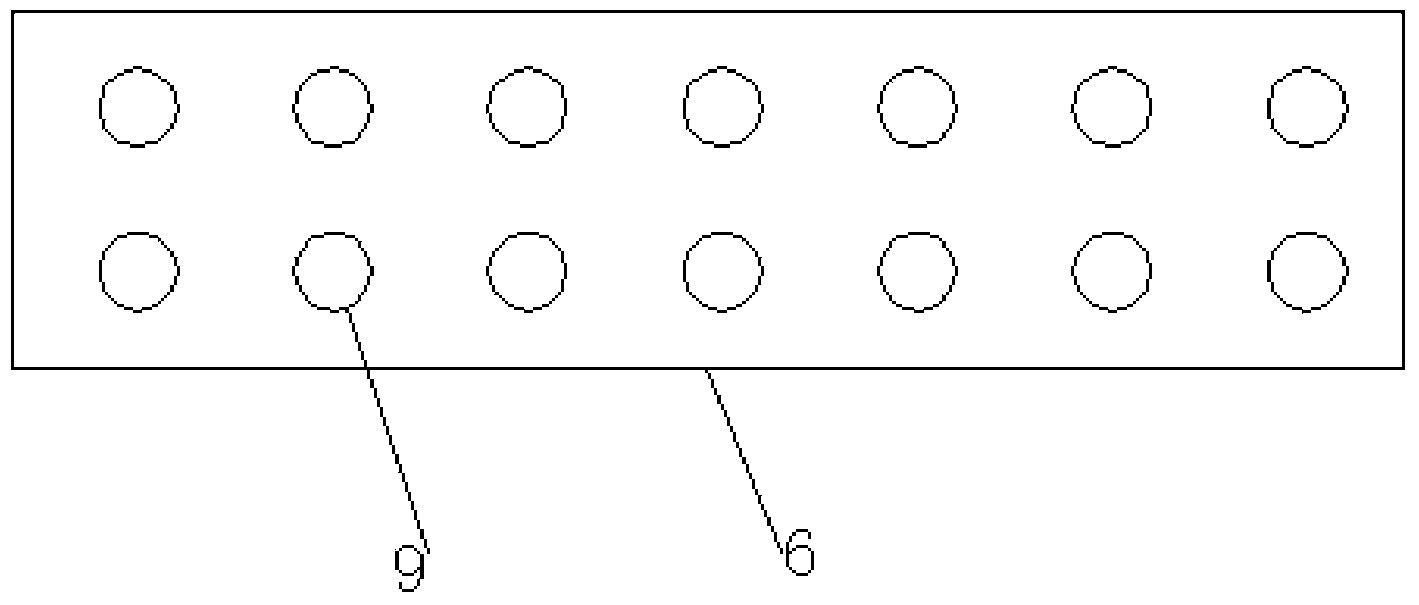

[0025] The main shaft 5 is fixed by supporting structures 8 arranged on both sides, the main shaft 5 is connected with the bearing seat 7 through a coupling 3, the rotating brush blade 6 is installed on the main shaft 5, and the rotating brush blade 6 and the support structure 8 are provided with a water retaining plate 4, and a transmission device 2 is provided on one side of the support structure 8, and a motor 1 is connected to the transmission device 2, and the feature is that the rotating brush blade 6 adopts an arc-shaped structure , the rotating brush blade is provided with the rotating brush perforation 9.

[0026] In this embodiment, the rotating brush blade 6 is a combined hoop type, which is con...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that: the electric motor 1 is controlled by an electric control system. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the connection between the rotating brush blades 6 and the main shaft 5 adopts a combined hoop type, and the rotating brush blades 6 are arranged in a spiral along the axial direction of the main shaft 5 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curved arc | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com