Combined gas piston compressor

A compressor and piston type technology, which is applied in the field of raw gas and cycle gas combined gas piston compressor, can solve the problems of low utilization rate of motion mechanism, poor economy of compressor, redundant pipeline system, etc., and achieve simple structure, High mechanical efficiency, avoiding the effect of many total stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0011] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

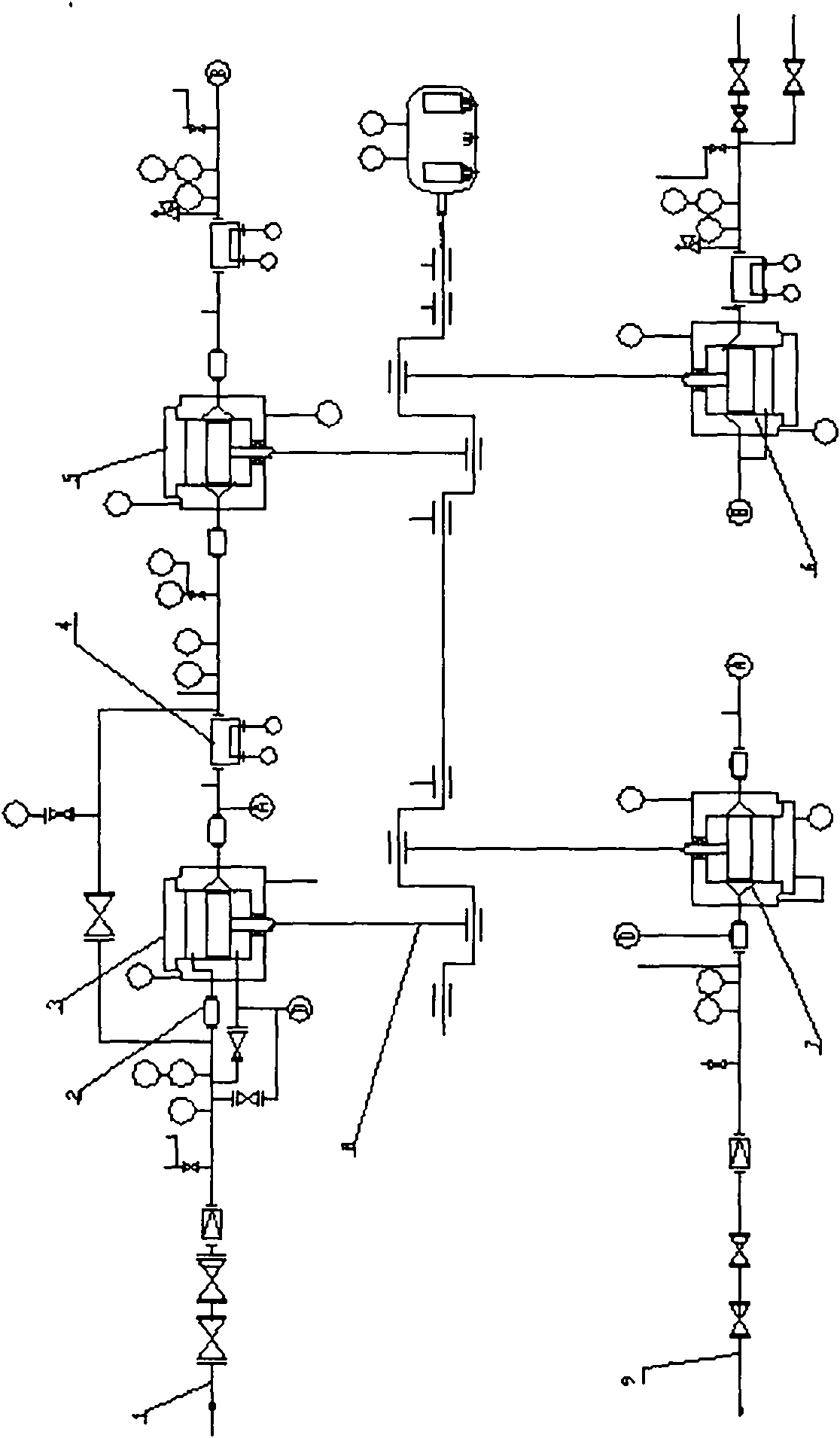

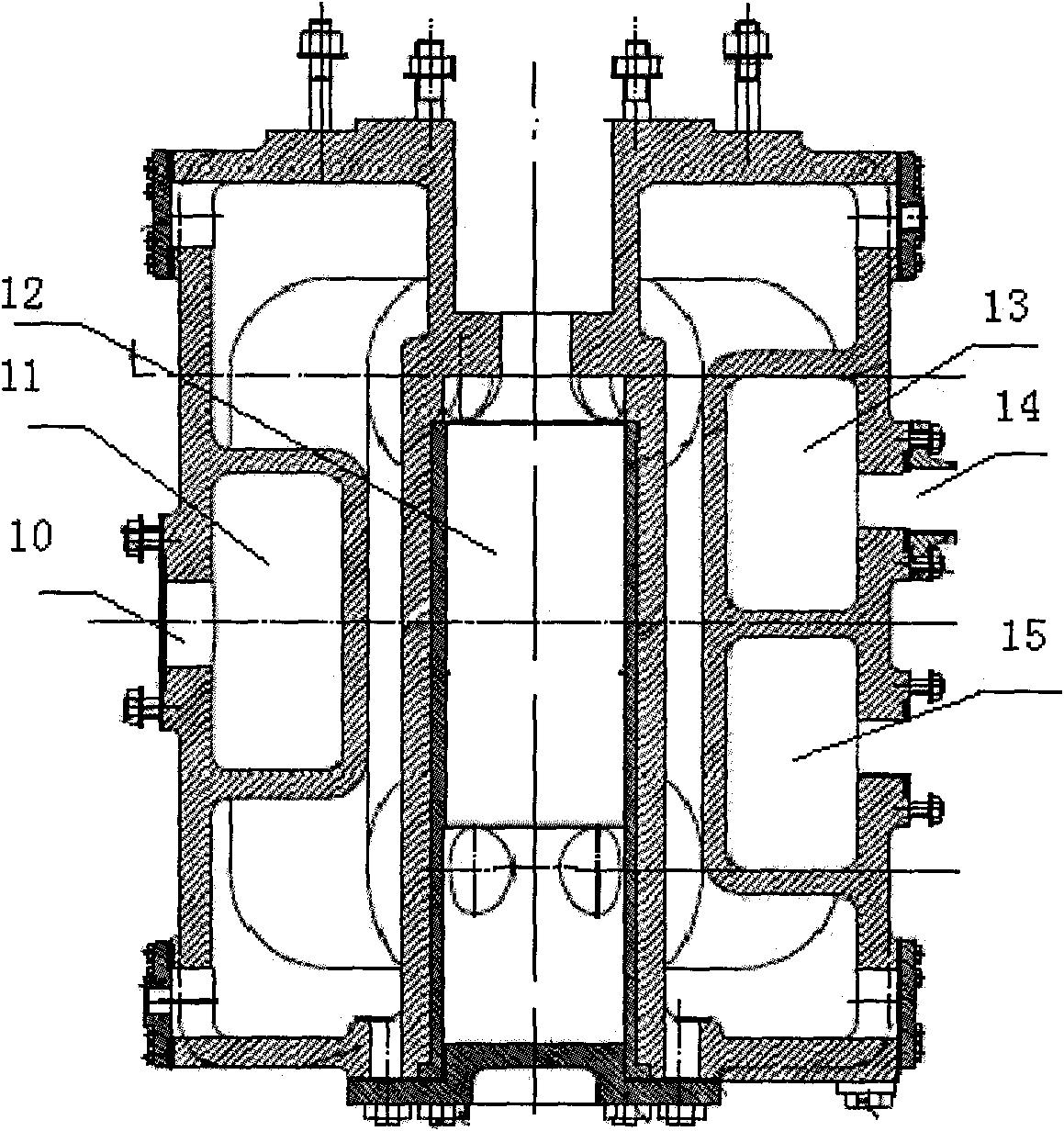

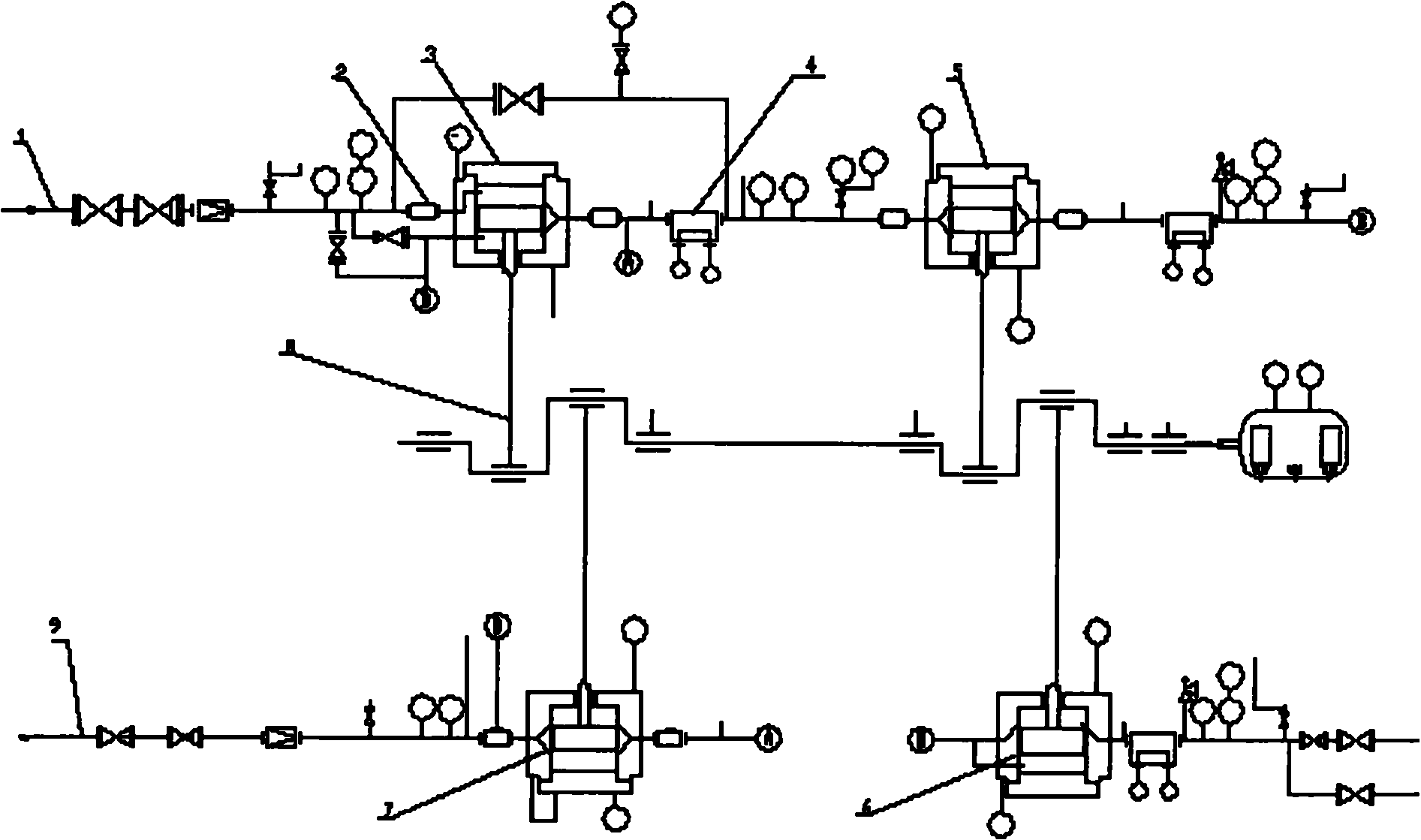

[0012] like figure 1 , 2 The M-type shown adopts a combined gas compressor with four rows of symmetrical layout, including the first and second two first-stage cylinders (3, 7), one second-stage cylinder 5, and one third-stage cylinder 6; Including intake chamber, compression chamber and exhaust chamber; the specially designed first-stage cylinder 3 is a double-acting compression cylinder, and the intake chamber of the double-sided compression cylinder is divided into two independent intake cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com