Low-noise tourmaline ecological water purifying pump

An ecological water purification and tourmaline technology, applied in the direction of pumps, pump devices, non-variable-capacity pumps, etc., can solve the problems of reducing the service life of bearings, external environmental pollution, and short time, and meet the requirements of ensuring the axial size, The effect of promoting metabolic function and enhancing cell activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

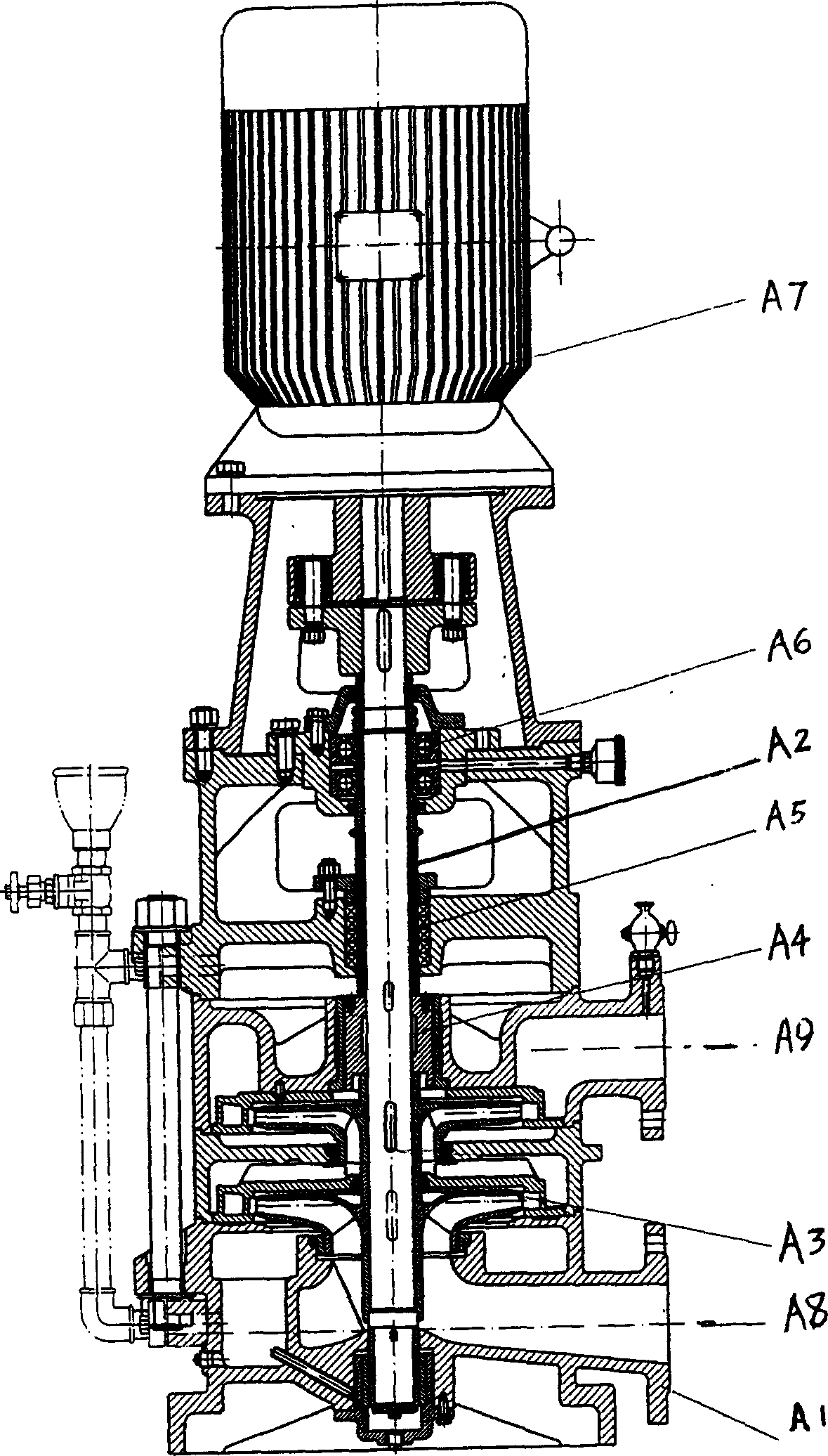

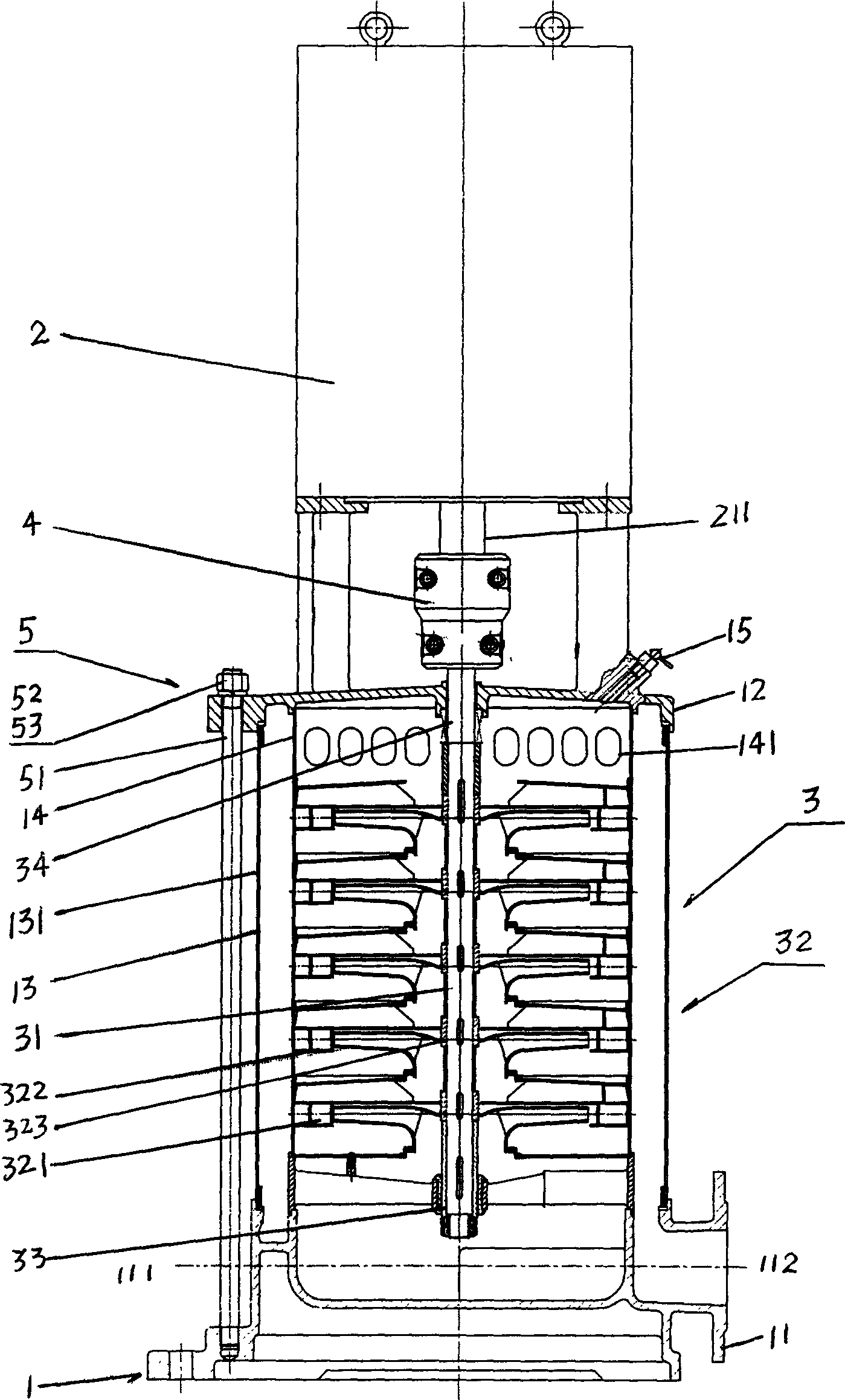

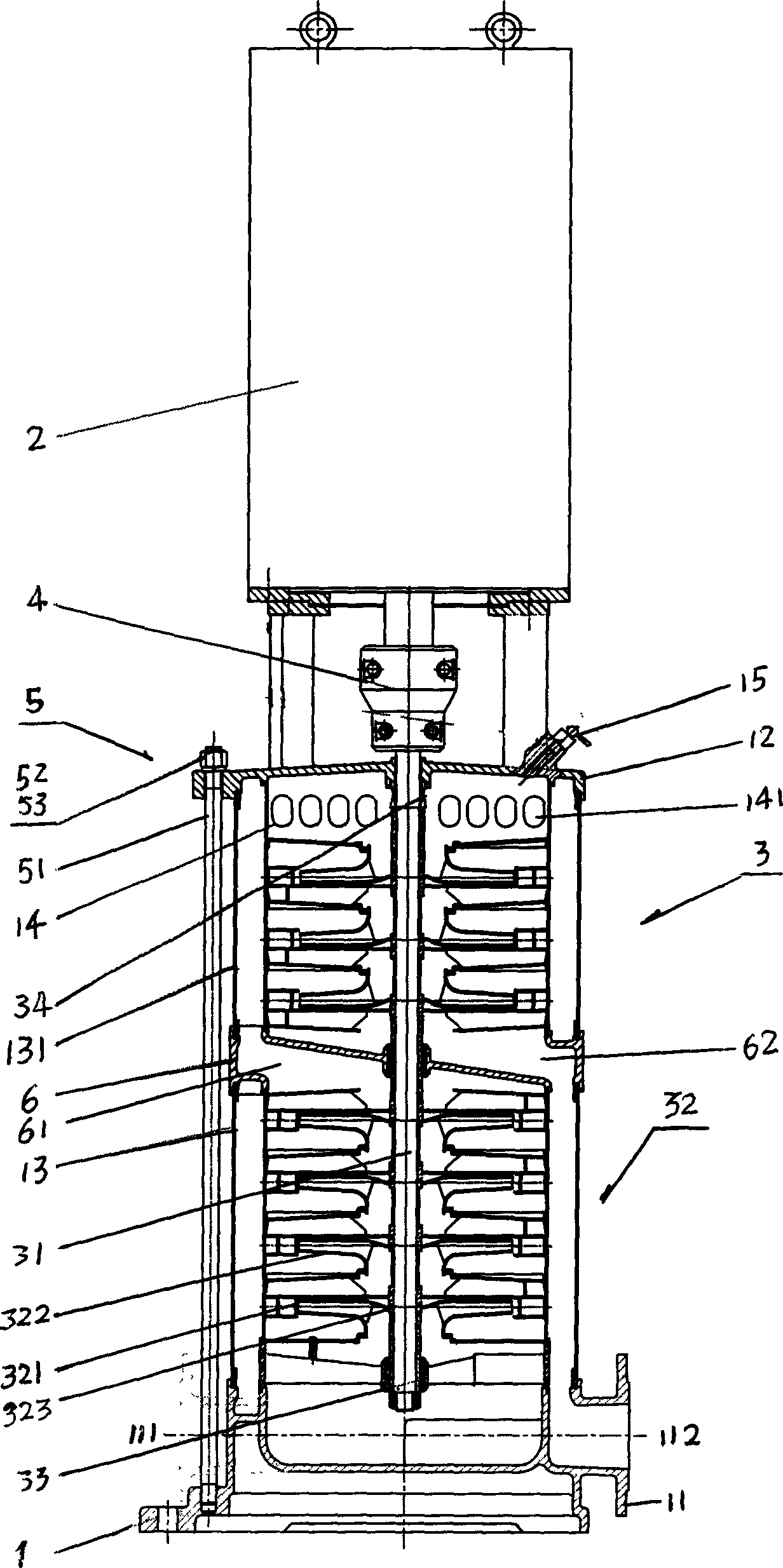

[0047] See figure 2Shown is a schematic structural view of a low-noise tourmaline ecological water purification pump according to an embodiment of the present invention. The low-noise tourmaline ecological water purification pump of this embodiment is used for low-lift water intake and drainage.

[0048] The low-noise tourmaline ecological water purification pump includes a pump body 1, a water-cooled motor 2, rotating parts 3, a coupling 4, and a rod assembly 5.

[0049] The pump body 1 is composed of a pump body base 11, a motor bracket 12 and an outer sleeve 13 embedded between the pump body base 11 and the motor bracket 12; the lower parts of both sides of the pump body base 11 are respectively provided with a water inlet 111 and a water outlet 112 ; On one side of the motor bracket 12 is provided with a deflation valve 15 .

[0050] Please refer to Figure 4 The inner wall of the outer sleeve 13 is coated with a layer of tourmaline 131; the outer sleeve 13 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com