Machining method of closed three-elemental impeller with small flow

A processing method and technology of ternary impeller, applied in the processing field of small flow closed ternary impeller, can solve the problems of inability to process, low impeller strength, narrow air outlet width, etc., to achieve good aerodynamic performance and aerodynamic efficiency, good durability. Corrosive, aerodynamic drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

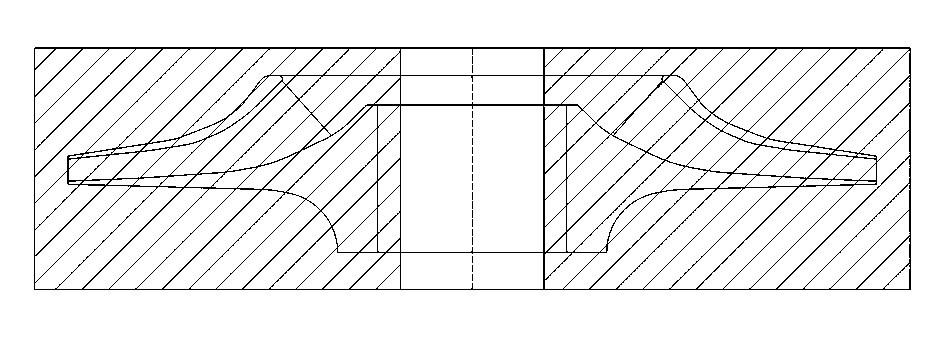

[0026] image 3 — Figure 6 It is a flow chart of processing small flow closed ternary impeller according to the present invention, wherein:

[0027] Such as image 3 As shown, the overall forging is clamped on the CNC machining center, and the forging is turned. The axial feed is turned to the air inlet 51 of the impeller blade, and the radial feed is used to turn the outer contour of the wheel cover. Pay attention to ensure that the machining allowance is 4~ 6mm;

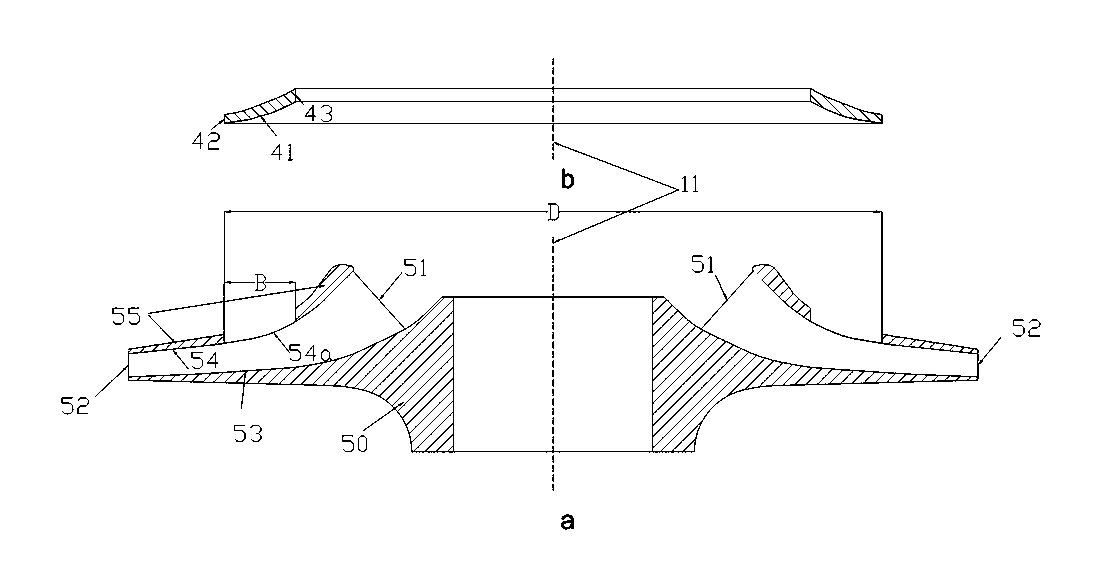

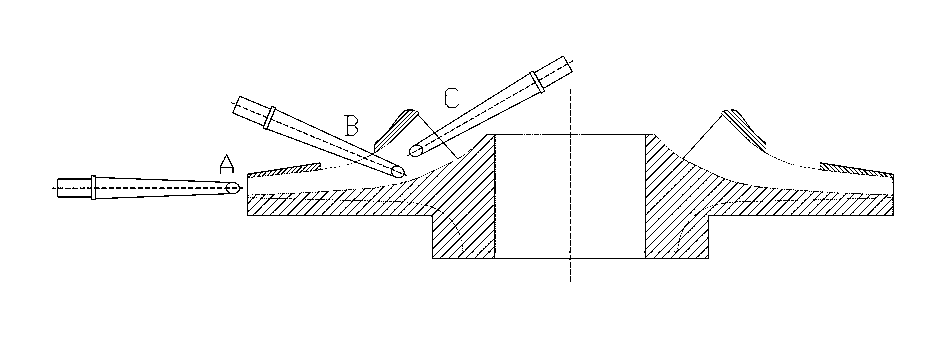

[0028] According to the radial width B of the cover plate and the radial position dimension D, the part of the wheel cover cover plate is dug out on the semi-finishing forging, such as Figure 4 shown; in accordance with figure 2 In the method shown, the rough machining, semi-finishing and finishing machining of the entire impeller channel are completed from the three positions and orientations of A, B, and C. After completing this process step, the size of the impeller channel has fully met the requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com