Open impeller structure for high-speed pump

A technology for open impellers and high-speed pumps, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of unsuitable balance holes for blades, large turbulence, and increased losses, and achieve balanced axial force , weaken the hump curve, weaken the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments shown in the accompanying drawings.

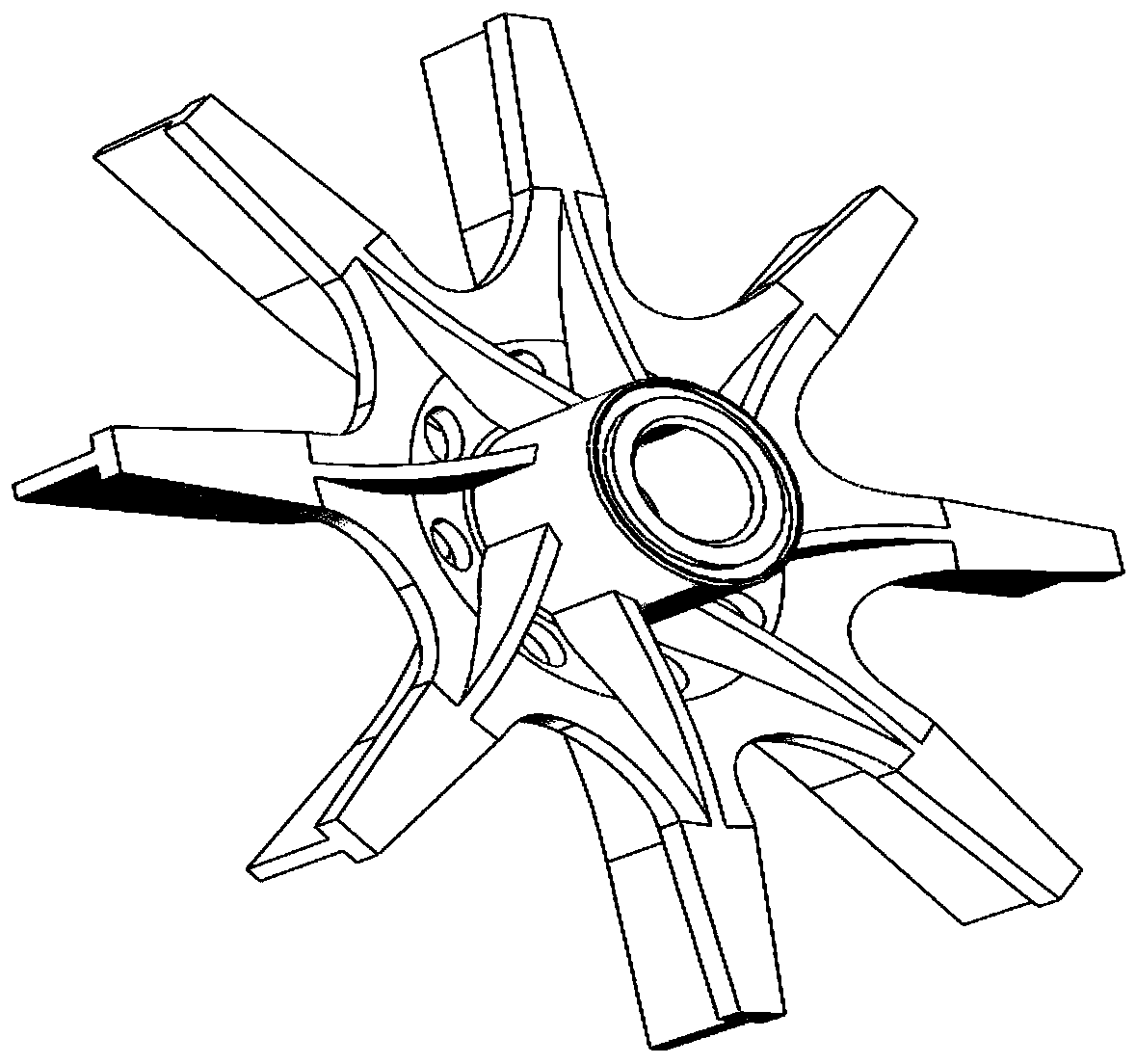

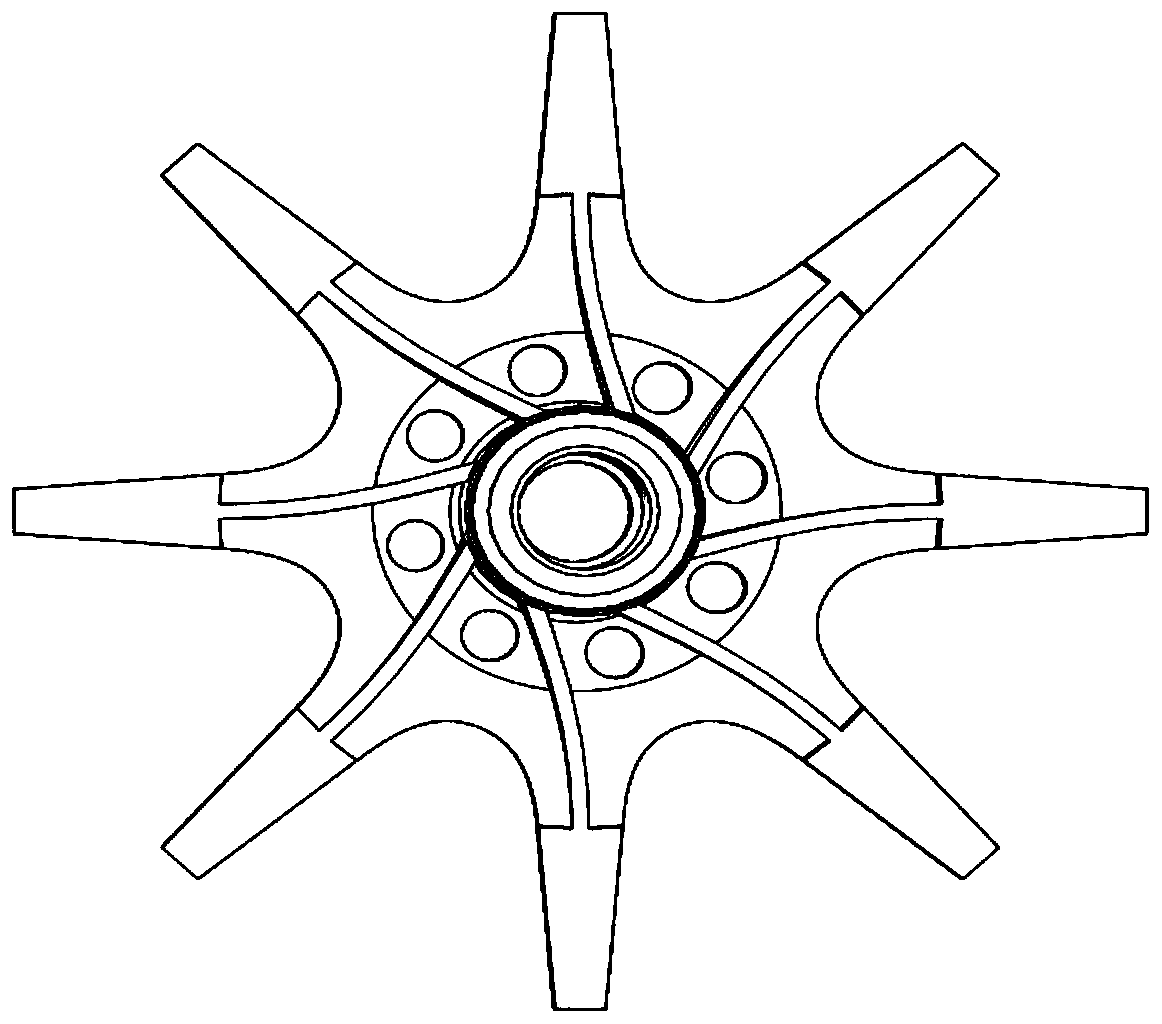

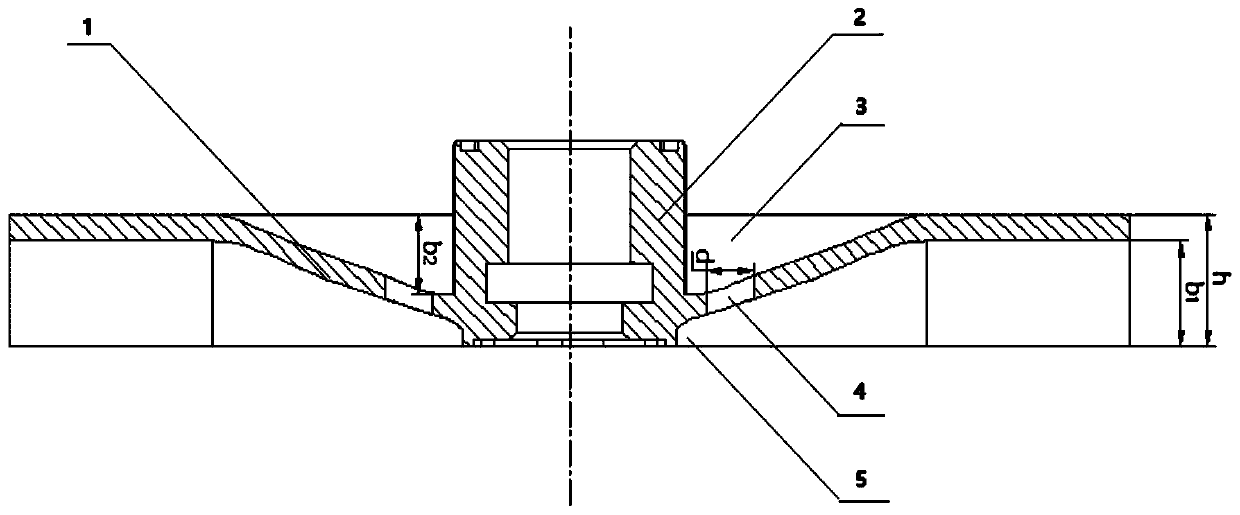

[0036] 1. Specific embodiments of the open impeller for high-speed pumps according to the present invention are as follows: figure 1 with figure 2 As shown, the blades of the high-speed impeller are no longer completely straight blades, but are twisted at the inlet section, and a certain inlet angle is set

[0037] can be derived from the following formula:

[0038]

[0039] In the formula: Q--flow rate (determined by design requirements)

[0040] f 1 --Axial flow channel cross-sectional area (determined by design requirements)

[0041] n v --The volumetric efficiency of the pump (determined by the design requirements)

[0042] D. 1 --Impeller inlet diameter

[0043] δ 1 --thickness of blade

[0044] lambda 1 --The included angle between the axial surface section line and the axial surface streamline, here is taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com